Self-sealing type low-rank coal and coal slime negative pressure drying device

A technology of negative pressure drying and low-rank coal, which is applied in the directions of heating devices, drying solid materials, and dry cargo handling, etc., which can solve the problems that the closed negative pressure environment is difficult to obtain, and achieve the effect of ingenious structural design and self-sealing state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

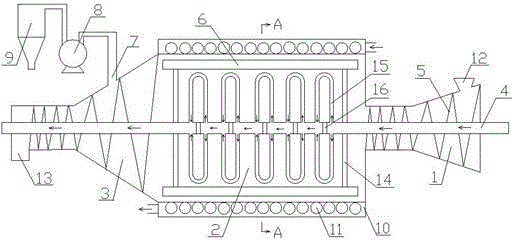

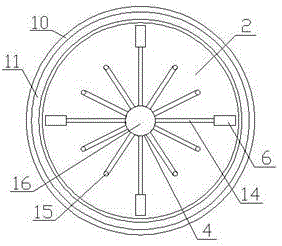

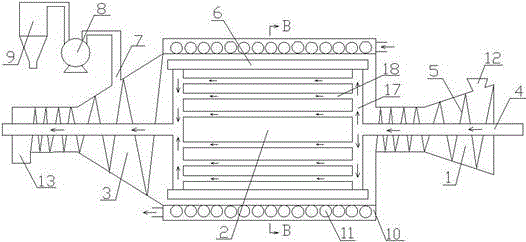

[0042] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0043] figure 1 and figure 2 Shown is a specific implementation of the first technical solution in the present invention, including a screw feeder 1, a drying cylinder 2 and a screw discharger 3 connected in sequence, and a screw feeder 1 and a screw discharger 3 Both include a cylindrical part and a truncated conical part, wherein the cylindrical part of the screw feeder 1 is connected to the drying cylinder 2, and the truncated conical part of the screw discharger 3 is connected to the drying cylinder 2;

[0044] The truncated conical part of the screw feeder 1 is provided with a material inlet 12, and the end of the cylindrical part of the screw feeder 3 is provided with a discharge port 13;

[0045] The spiral feeder 1 and the spiral discharger 3 are internally provided with spiral blades 5, and the pitch betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com