Break-free machine injection and plastic type multipurpose shaft gland

A non-stop and shaft sealing technology, applied in the direction of engine sealing, mechanical equipment, engine components, etc., can solve the problems of poor sealing effect of seals, large economic losses, large leakage, etc., to achieve convenient disassembly and replacement and low manufacturing cost Low, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

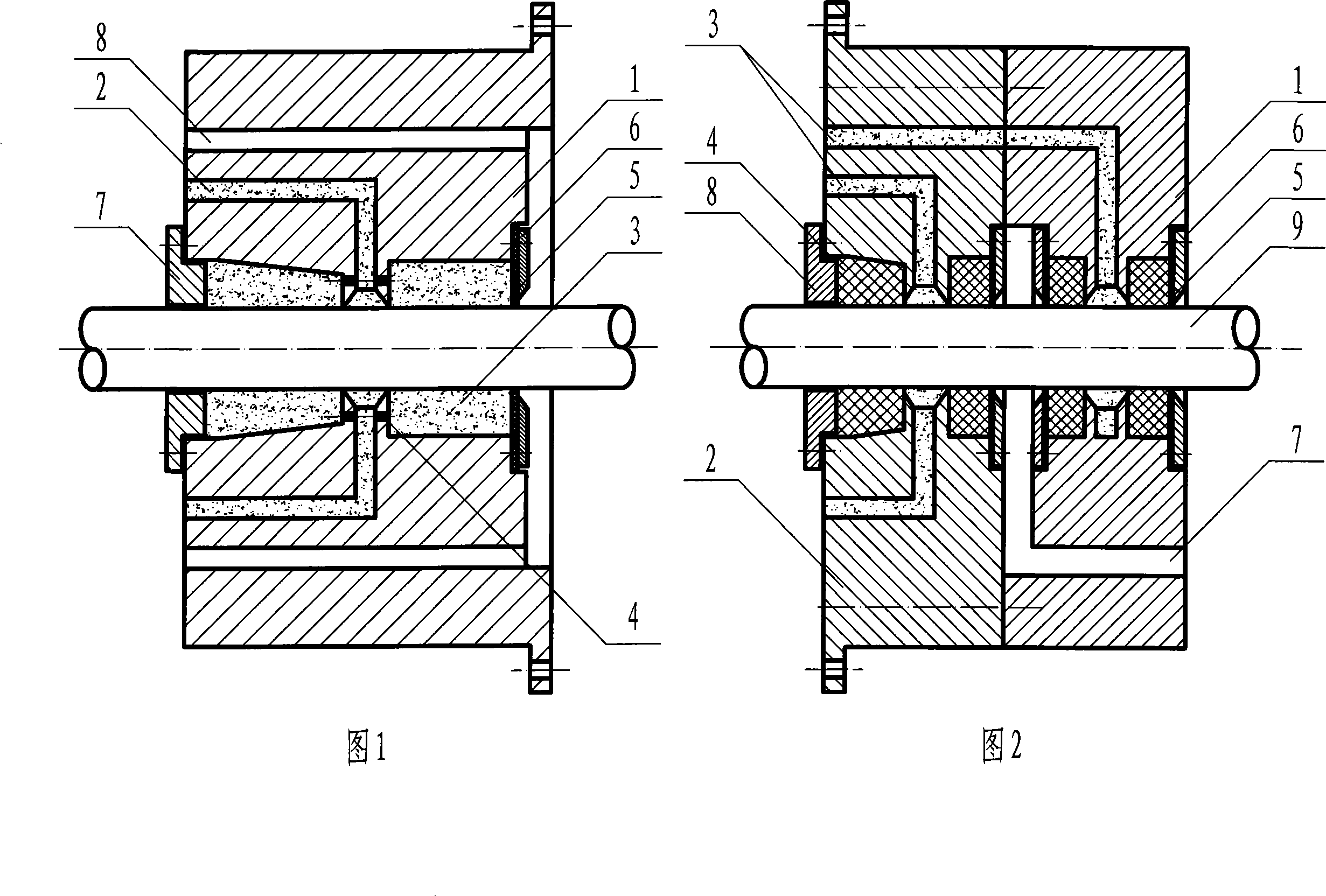

Embodiment 1

[0033] As shown in Figure 1, the non-stop injection and plastic multi-purpose shaft seal of the present invention has a structure including a single-stage sealing body 1, and an injection hole 2 is opened in the single-stage sealing body 1, and the end of the injection hole 2 is connected to a single-stage seal An annular sealed chamber surrounded by the body 1 and the rotating shaft. Filling chambers 3 are arranged on both sides of the annular sealed chamber. The injection hole 2 and the stuffing chamber 3 are connected through the distribution hole 4. A material blocking pad 5 and a material baffle plate 6 are arranged sequentially from the inside to the outside, and a gland 7 is arranged on the outside of the packing chamber 3 on the left side of the sealing body 1, and a pressure relief hole 8 penetrating left and right is opened on the single-stage sealing body 1 .

[0034] This sealing structure is used in conjunction with traditional seals such as labyrinth seals, that ...

Embodiment 2

[0036] As shown in Figure 2, the non-stop injection and plastic multi-purpose shaft seal of the present invention has a structure including a primary sealing body 1 and a secondary sealing body 2, and the primary sealing body 1 and the secondary sealing body 2 are respectively opened with The injection hole 3, the end of the injection hole 3 is connected to the annular sealing room surrounded by the first-level sealing body 1, the second-level sealing body 2 and the rotating shaft, the two sides of the annular sealing room are provided with a packing room, and the plastic sealing material 4 is arranged in the packing room. The outer side of the plastic sealing material 4 is provided with a material blocking pad 5 and a material blocking plate 6 sequentially from the inside to the outside, an oil return hole 7 is left between the above-mentioned two-stage sealing bodies, and a gland 8 is arranged on the outside of the secondary sealing body 2 . After the high-pressure oil leaks ...

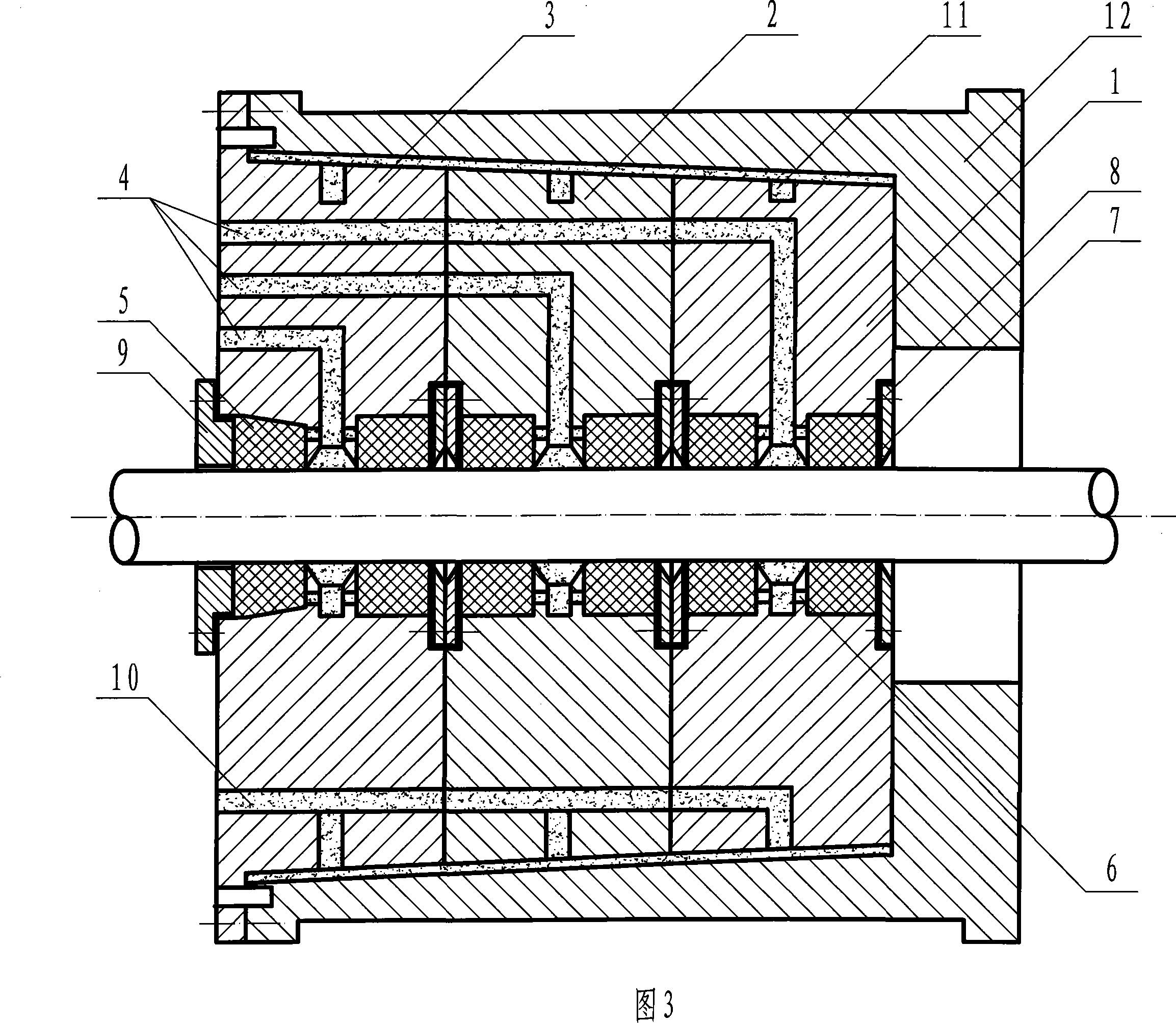

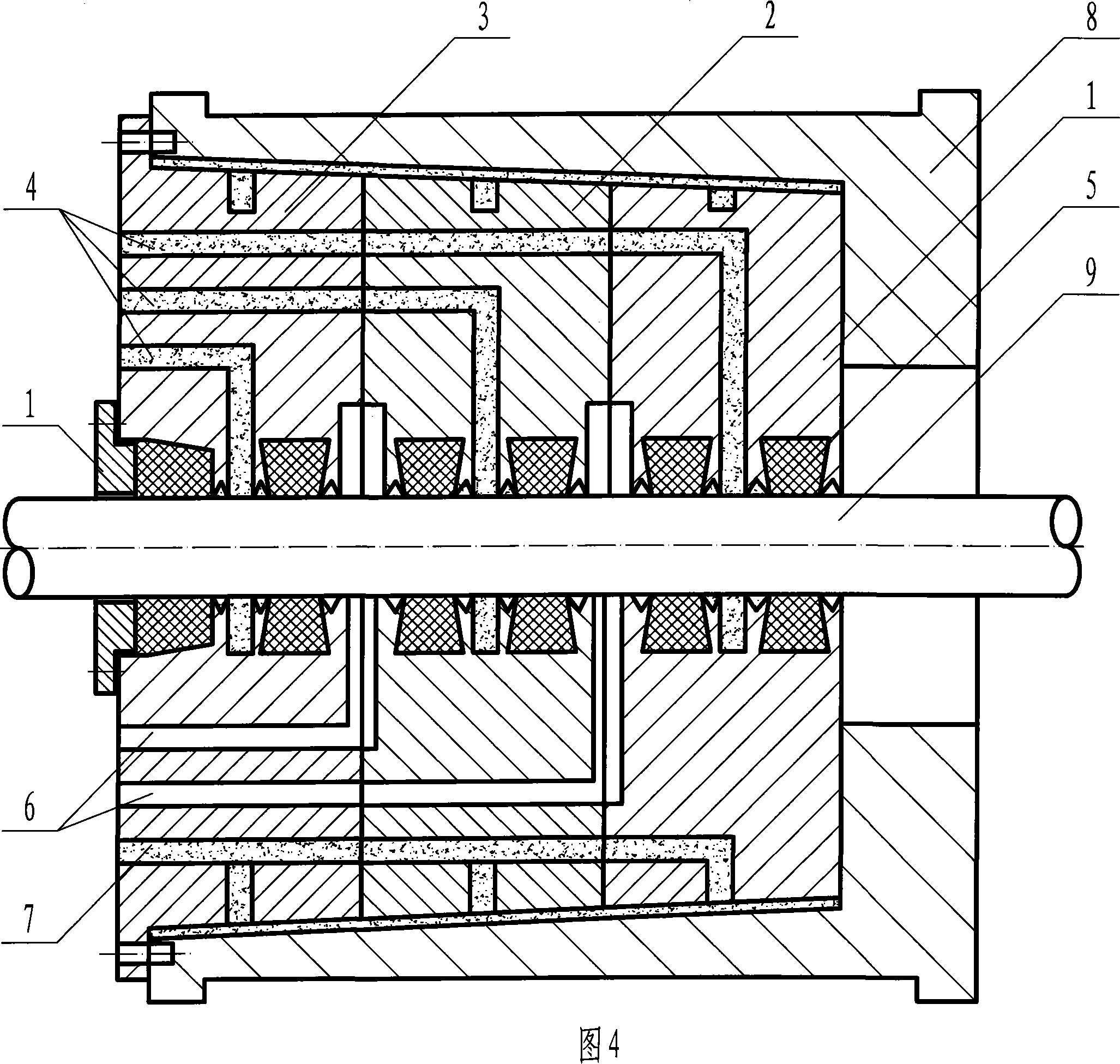

Embodiment 3

[0038] As shown in Figure 3, the non-stop injection and plastic multi-purpose shaft seal of the present invention has a structure comprising a first-level sealing body 1, a second-level sealing body 2 and a third-level sealing body 3 in a conical structure, and the first-level sealing body 1. There are injection holes 4 in the secondary sealing body 2 and the tertiary sealing body 3 respectively, and the ends of the injection holes 4 are connected to the ring formed by the primary sealing body 1, the secondary sealing body 2, the tertiary sealing body 3 and the rotating shaft Sealing chamber, the two sides of the annular sealing chamber are provided with packing chambers, and the plastic sealing material 5 is arranged in the packing chamber, the injection hole 4 and the packing chamber are connected through the material distribution hole 6, and the outside of the plastic sealing material 5 is arranged in sequence from the inside to the outside There is a material blocking pad 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com