Duliang compound chinese medicine soft capsules and preparation process thereof

A technology of soft capsules and technology, applied in the field of Duliang soft capsules and its preparation technology, can solve the problems of unsatisfactory drug stability of dripping pills, insufficient dosage of medicinal ingredients, poor production quality stability, etc., and achieve no toxic side effects, fast Absorption, high precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 prepares 1000 Duliang compound soft capsules

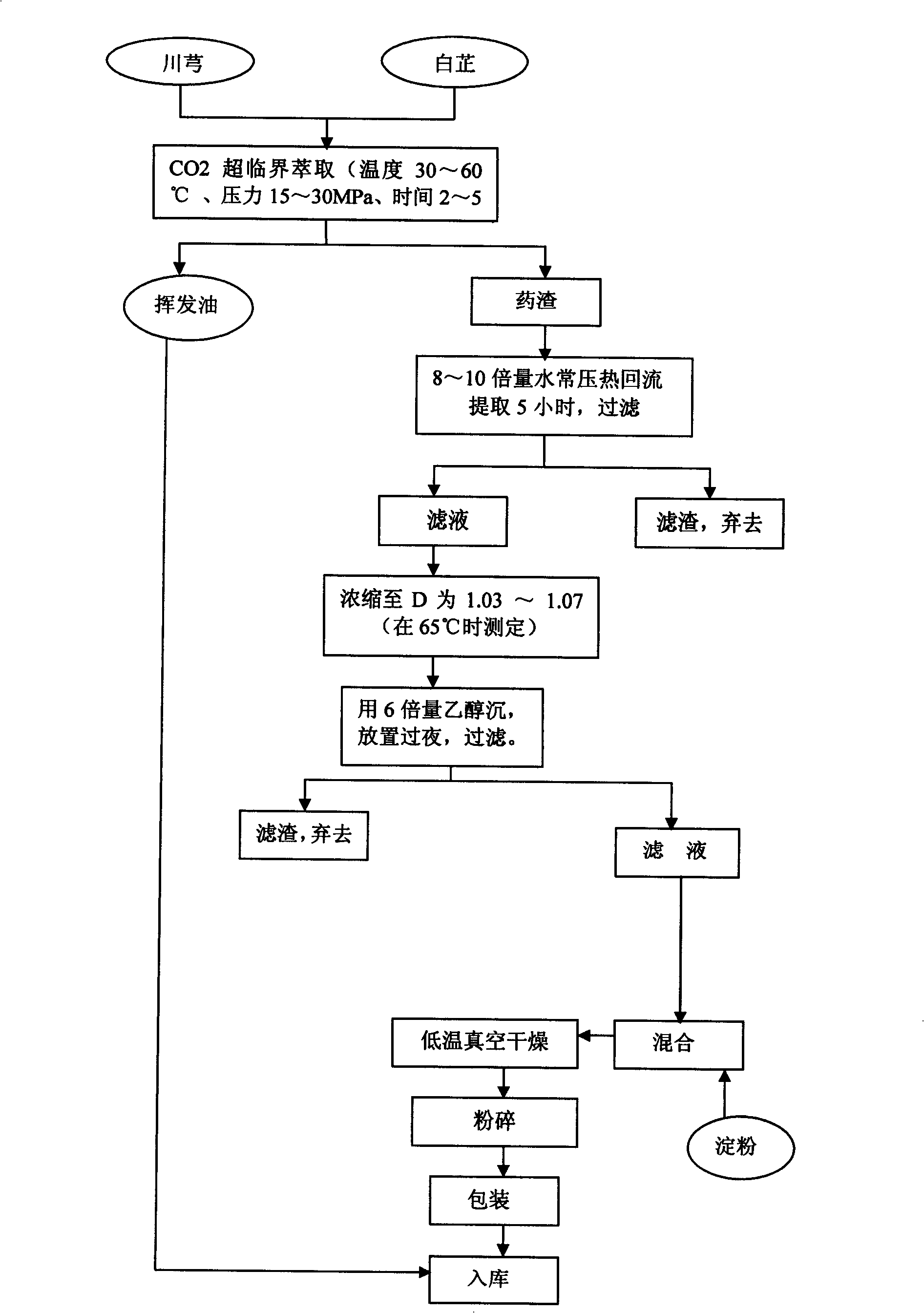

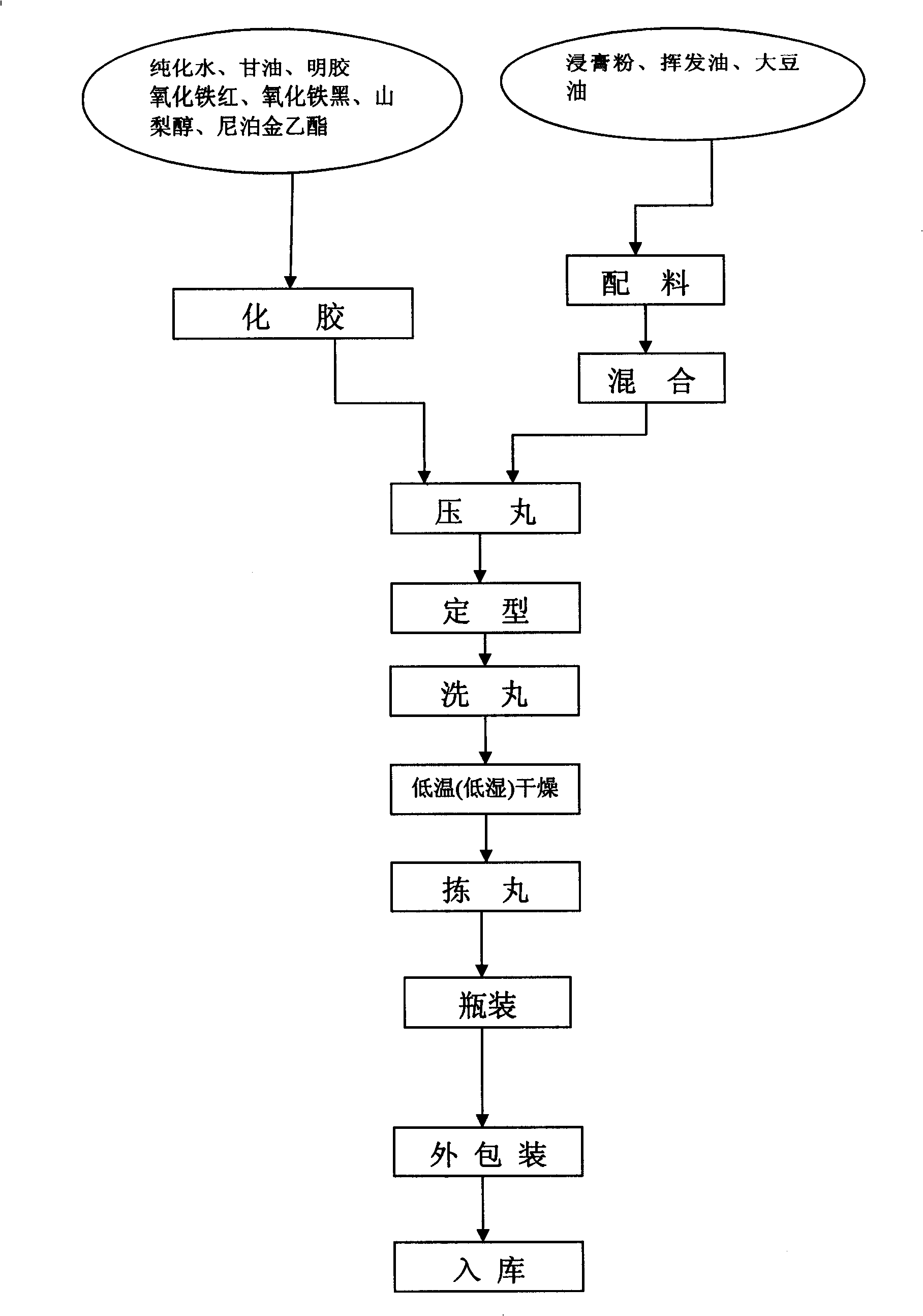

[0026] Such as figure 1 , 2 Shown technical process, prepare according to the following steps:

[0027] a. CO of active ingredients 2 supercritical extraction

[0028] According to the recipe, after mixing 1128g of Angelica dahurica and 282g of Rhizoma Chuanxiong, the mixture is subjected to supercritical extraction of carbon dioxide under low temperature conditions. The process conditions are: extraction temperature: 30°C, extraction pressure: 15Mpa, extraction time: 2 hours, CO 2 The flow rate is 300L / h, and the volatile oil and medicinal residues of the mixture are obtained, which are collected for use;

[0029] b. Decoction and extraction of medicinal dregs

[0030] Add 8 times the amount of water to the dregs of step a, heat and boil under normal pressure for 5 hours, then filter, concentrate the filtrate containing active ingredients, measure at 60°C to a thick paste with a specific gravity of 1.03g / ...

Embodiment 2

[0040] Such as figure 1 , 2 Shown technical process, prepare according to the following steps:

[0041] a.CO 2 supercritical extraction

[0042] According to the formula, after mixing 1128g of Angelica dahurica and 282g of Rhizoma Chuanxiong, the mixture is subjected to supercritical extraction of carbon dioxide under low temperature conditions. The process conditions are: extraction temperature: 45°C, extraction pressure: 20Mpa, extraction time: 4 hours; CO 2 The flow rate is 320L / h, and the mixed volatile oil, medicinal liquid, and medicinal residues are obtained, and the volatile oil is to be collected for use;

[0043] b. Decoction and extraction of medicinal dregs

[0044] Add 9 times the amount of water to the dregs of step a, heat and boil under normal pressure for 5 hours, then filter, concentrate the filtrate containing active ingredients, measure at 60°C, and collect a thick paste with a specific gravity of 1.05g / ml for later use ;

[0045] c. Alcohol precipita...

Embodiment 3

[0054] Such as figure 1 , 2 Shown technical process, prepare according to the following steps:

[0055] a.CO 2 supercritical extraction

[0056] According to the recipe, after mixing 1128g of Angelica dahurica and 282g of Rhizoma Chuanxiong, the mixture is subjected to supercritical extraction of carbon dioxide under low temperature conditions. The process conditions are: extraction temperature: 60°C, extraction pressure: 30Mpa, extraction time: 5 hours, CO 2 Flow rate: 350L / h, get the mixture volatile oil, medicinal liquid, medicinal residue, volatile oil to be collected for use;

[0057] b. Decoction and extraction of medicinal dregs

[0058] Add 10 times the amount of water to the dregs of step a, heat and decoct under normal pressure for 5 hours, then filter, concentrate the filtrate containing active ingredients, measure at 60°C, and find a thick paste with a specific gravity of 1.07g / ml, collect it for use ;

[0059] c. Alcohol precipitation

[0060] Stir the thic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com