Method for combustion synthesis of silicon nitride powder by using polytetrafluoroethylene as additive

A polytetrafluoroethylene, combustion synthesis technology, applied in the direction of chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve the problems of unsuitable industrial production, low net yield, increased cost, etc., to avoid the process of process, The effect of low production cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

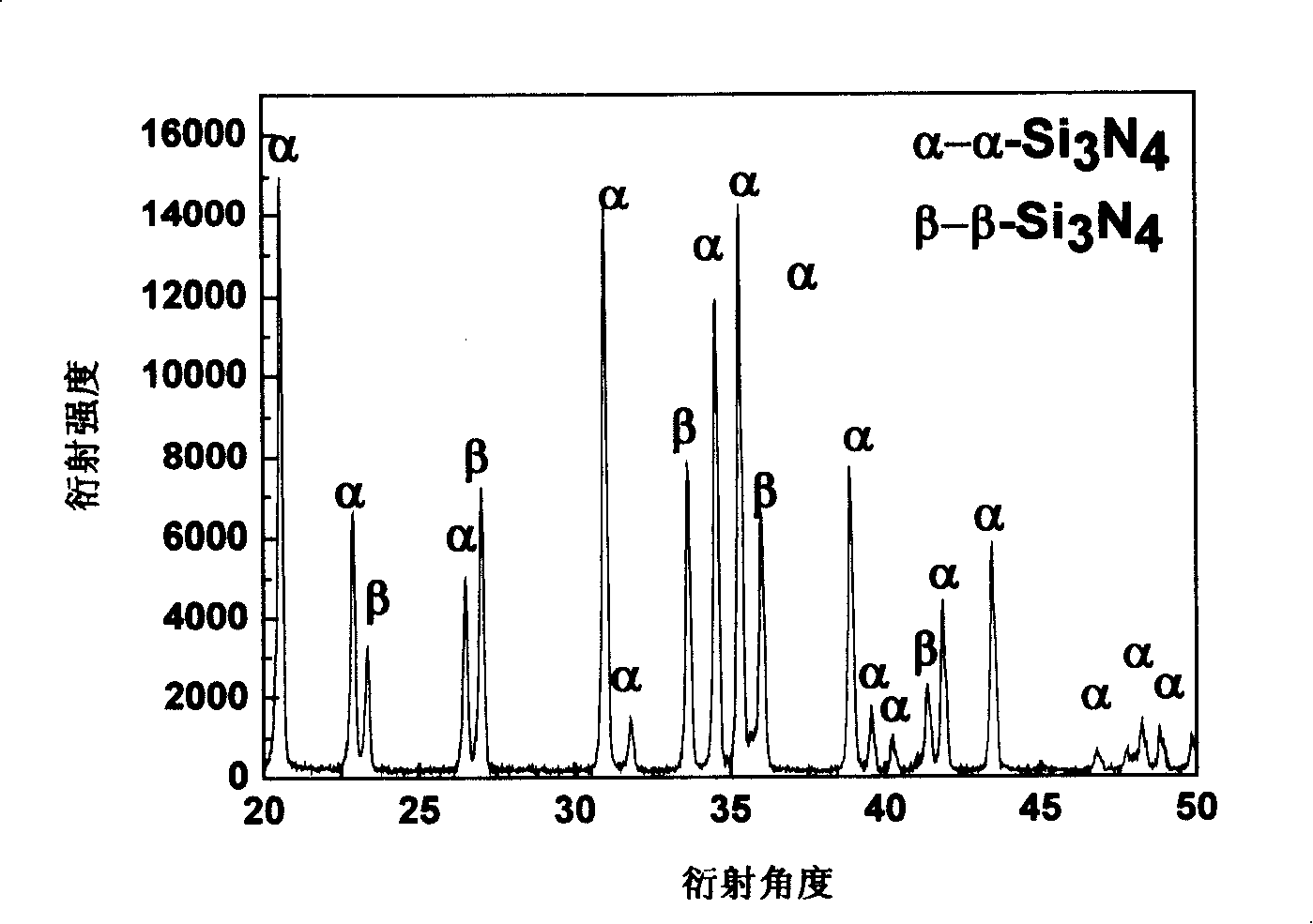

Embodiment 1

[0031] Weigh the raw materials according to the weight ratio of silicon powder (purity > 99%, particle size range 0.1-10 μm): ammonium chloride: PTFE 90:9:1, put the prepared raw materials on a vibrating grinder, mix and grind for 1 hour , After grinding, the powder is sieved, and then put into a porous graphite crucible, the bulk density is 0.8~2.0g / cm 3 . Put the powdered porous graphite crucible into a 40L combustion synthesis reaction device, and place a spiral tungsten wire and titanium powder at one end of the powder blank as an ignition source. After vacuuming, fill the combustion synthesis reaction device with nitrogen until the pressure reaches 1.5 MPa. The tungsten wire is energized and heated to ignite the titanium powder, inducing the combustion synthesis reaction of the powder system. Combustion synthesized products with furnace cooling. The obtained product is subjected to post-treatment processes such as pulverization and fine grinding to obtain a homogeneous...

Embodiment 2

[0034] Take the raw material according to the weight ratio of silicon powder (purity > 99%, particle size range is 0.1 ~ 10 μ m): ammonium salt: PTFE is 73: 22: 5, wherein the ammonium salt is the mixture of ammonium chloride and ammonium fluoride, The ratio of parts by weight is 1:1. Put the prepared raw materials on a vibrating grinder and mix and grind for 1 hour. After grinding, the powder is sieved and then put into a porous graphite crucible. The bulk density is 0.8-2.0g / cm 3 . Put the powdered porous graphite crucible into a 40L combustion synthesis reaction device, and place a spiral tungsten wire and titanium powder at one end of the powder blank as an ignition source. After vacuuming, a mixture of nitrogen and argon is charged into the combustion synthesis reaction device, wherein the proportion of argon is 20 vol%, until the pressure reaches 3 MPa. The tungsten wire is energized and heated to ignite the titanium powder, and (by local heating) induces the combustio...

Embodiment 3

[0036] According to silicon powder (purity > 99%, particle diameter range is 0.1~10 μ m): (ammonium salt+nitrogen-containing compound): PTFE is the weight ratio of 81: 10: 9 and takes raw material, wherein ammonium salt is ammonium chloride and Ammonium carbonate, the nitrogen-containing compound is urea, and its weight ratio is 1:1:1. Put the prepared raw materials on a vibrating grinder and mix and grind for 1 hour. After grinding, the powder is sieved and then put into a porous graphite crucible. The bulk density is 0.8-2.0g / cm 3 . Put the powdered porous graphite crucible into a 40L combustion synthesis reaction device, and place a spiral tungsten wire and titanium powder at one end of the powder blank as an ignition source. After vacuuming, a mixture of nitrogen and hydrogen is charged into the combustion synthesis reaction device, wherein the proportion of hydrogen is 25 vol%, until the pressure reaches 4.5 MPa. The tungsten wire is energized and heated to ignite the t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com