Multicenter electric spraying ion source for micro liquid phase separation system and mass spectrum

An electrospray ion source and separation system technology, applied in the field of ion sources, can solve the problems of different ionization efficiency, inability to realize the combination of multiple sets of liquid phase separation systems, increase ionization efficiency, etc., and achieve strong versatility and practicability , simple structure, and the effect of increasing ionization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

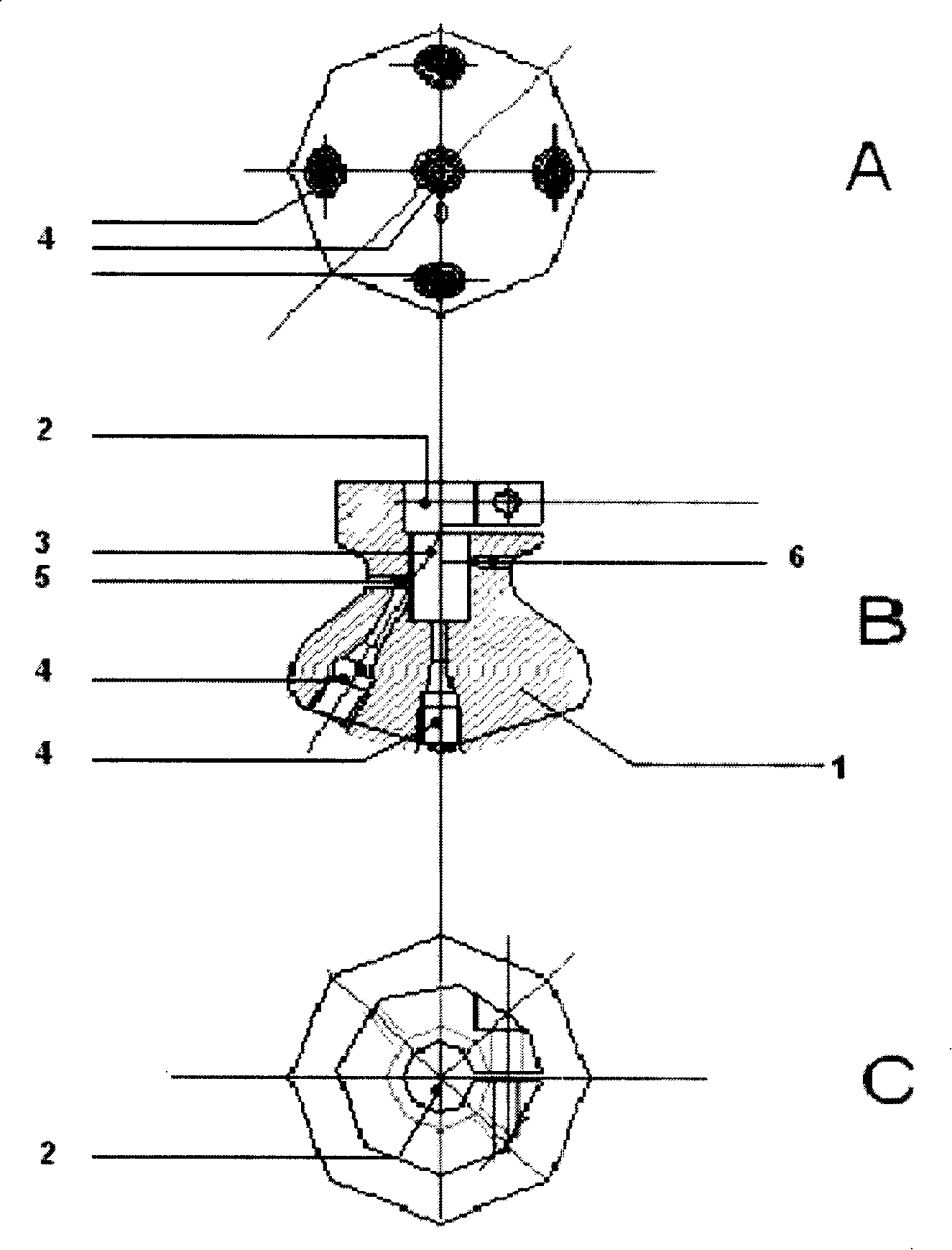

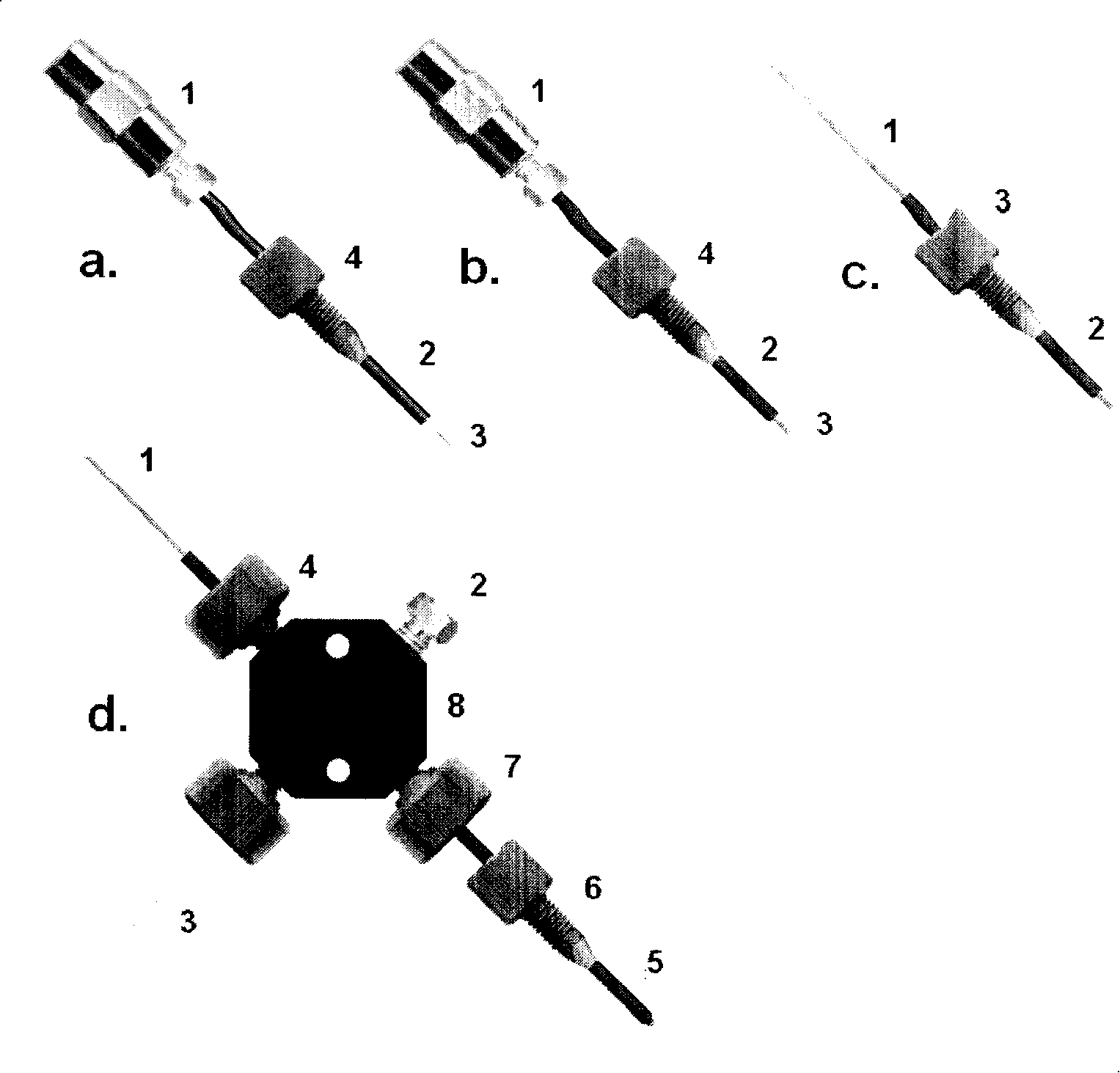

[0029] Such as figure 1 Shown is a multi-channel electrospray ionization source coupled with a micro-liquid phase separation system and a mass spectrometer. A five-channel design is adopted, that is, the ion source 1 is composed of a heating capillary sleeve 2, a spray chamber 3, and five sockets 4 for installing a single-channel electrospray nozzle / nozzle distributed in a fan-shaped space. In addition, 5 is a nitrogen inlet, and 6 is a nitrogen outlet. Needles / nozzles suitable for different modes of separation systems coupled with mass spectrometers can be easily installed in 4, and the best spray effect can be achieved by adjusting the distance between the needles / nozzles and the inlet of the vacuum region of the mass spectrometer (heated capillary orifice). In this embodiment, ensure that the central axis of each single-channel electrospray nozzle / nozzle end intersects at the position of 0.8 cm from the front end of the vacuum zone inlet, so that the central axes of the fo...

Embodiment 2

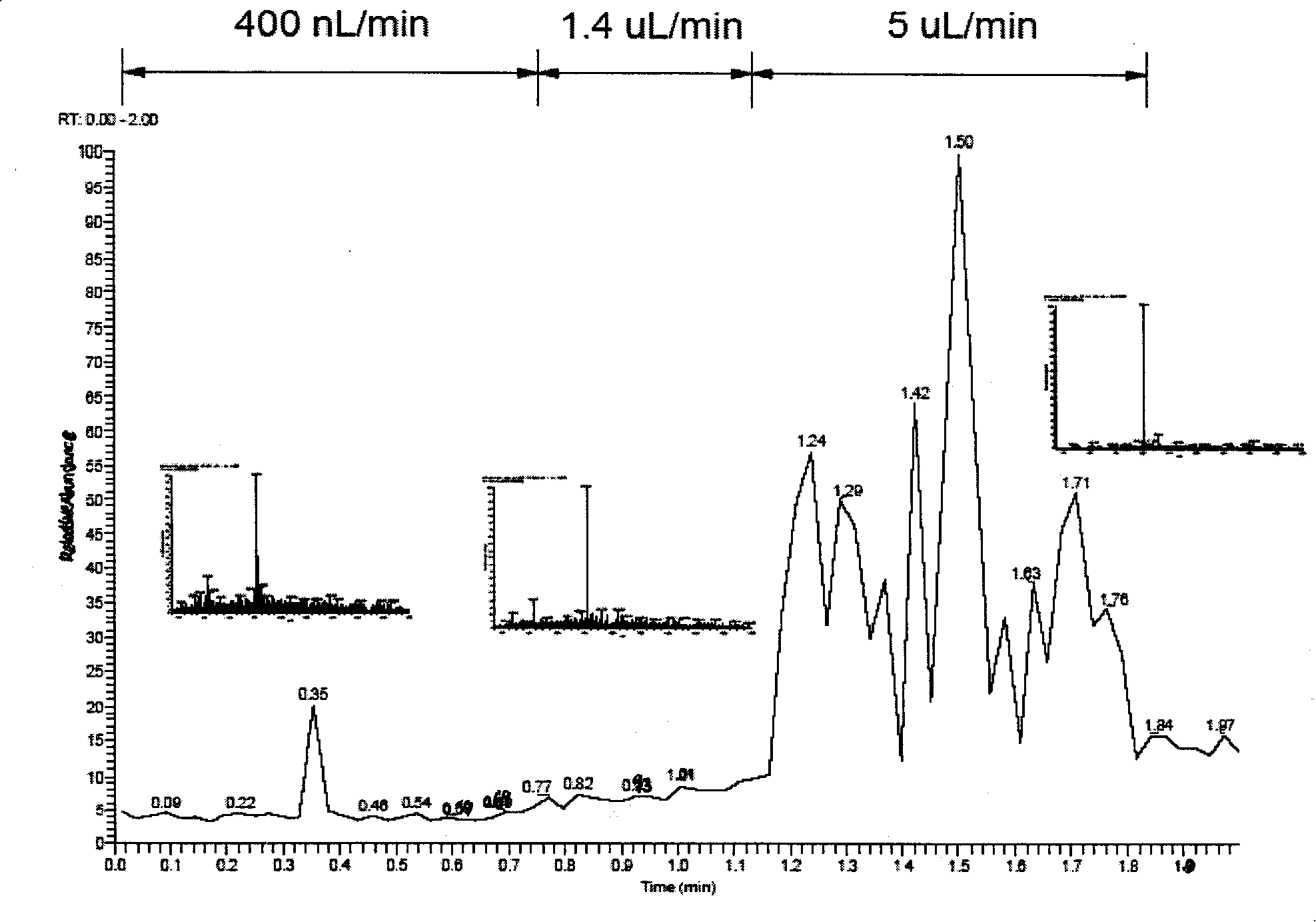

[0035] Experimental conditions: capillary (Hebei Yongnian Ruifeng Chromatography Device Co., Ltd., inner diameter: 50 μm, outer diameter: 375 μm), syringe pump (Harvard, USA), LCQ duo Ion trap mass spectrometry (U.S. Finnigan company), the ion source used is the five-channel micro-liquid phase separation system described in embodiment 1 and the electrospray ion source coupled with mass spectrometry, the central axis of each single-channel electrospray nozzle / nozzle end Intersect at the position 0.6cm from the front end of the inlet of the vacuum area, so that the central axis of the end of the four single-channel electrospray nozzles / nozzles is at an angle of 45 degrees to the axis of the vacuum inlet, and the spray voltage is 2.2kV.

[0036] Sample: a polypeptide (m / z=815) (0.1% formic acid aqueous solution)

[0037] see image 3 , which is obtained by using a micro-liquid phase separation system provided in Example 1 of the present invention coupled with a mass spectrometer...

Embodiment 3

[0039] Experimental conditions: Michrom multidimensional liquid chromatography, LCQ duo Ion trap mass spectrometry (Finnigan, USA). The ion source used is the five-channel micro-liquid phase separation system described in Example 1 and the electrospray ion source coupled with mass spectrometry. The central axis of each single-channel electrospray nozzle / jet end intersects at the position of 1 cm from the front end of the vacuum zone inlet At the position, the central axes of the four single-channel electrospray needle / nozzle ends are at an angle of 45 degrees to the vacuum inlet axis, and the spray voltage is 3kV.

[0040] Liquid conditions: Chromatographic column: 250μm×50mm, 5μ C18

[0041] Mobile phase: A: 2% ACN (containing 0.1% formic acid, 0.05% HFBA) B: 98% ACN (containing 0.1% formic acid, 0.05% HFBA); 60min gradient: 0min: 10%A; 50min: 40%; 55min: 60%A; 60min: 60%A; injection volume 2μL; flow rate 5μL / min.

[0042] Sample: 50μg / mL β-Casein hydrolyzate

[0043] see...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com