Yttrium niobate solid-phase reaction synthetic sintering method capable of being used for microwave dielectric ceramic

A technology of microwave dielectric ceramics and solid phase reaction, which is applied in the field of functional ceramic materials, can solve the problems of preparation methods and dielectric properties that have not been reported in special research reports, and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

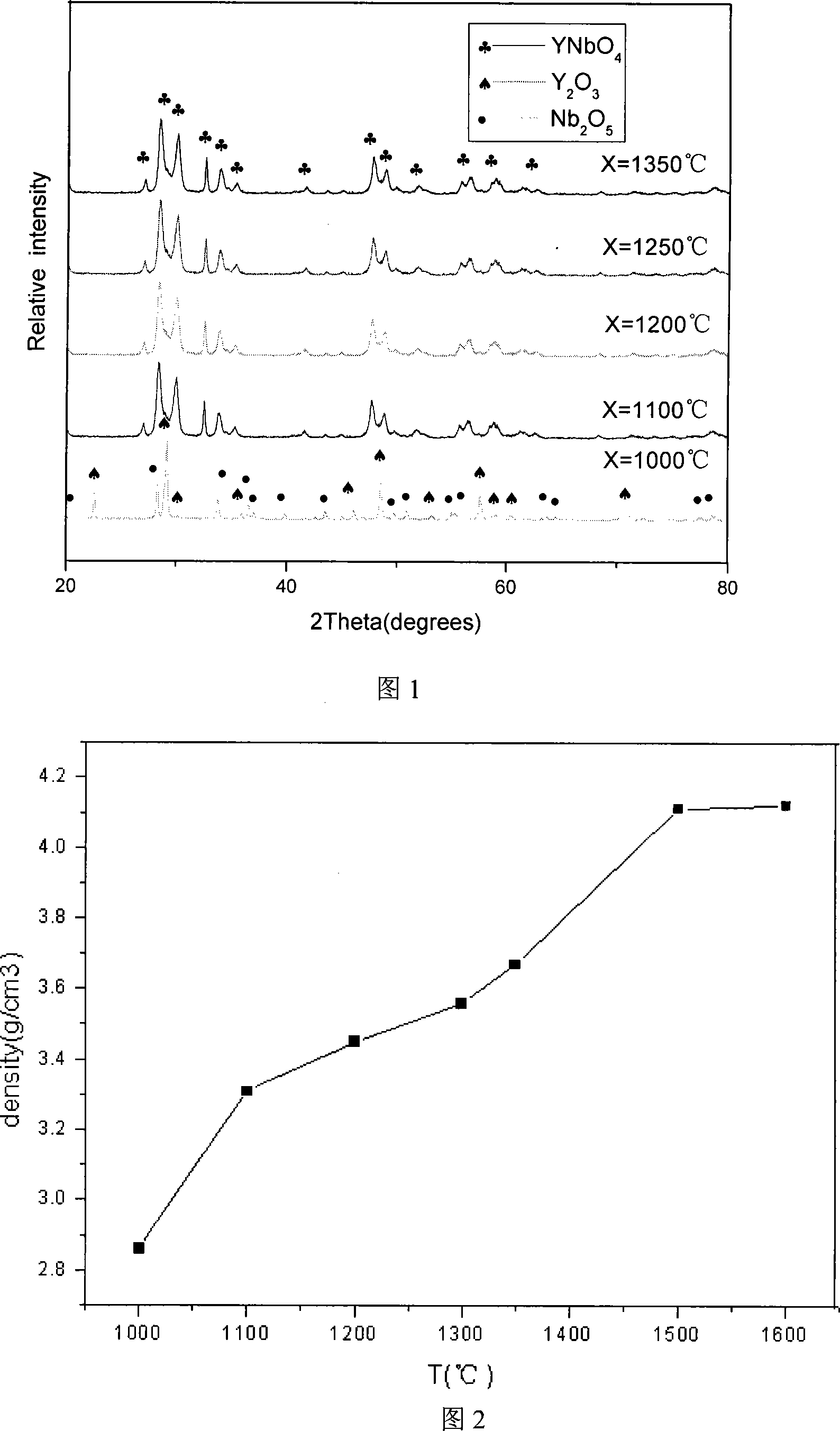

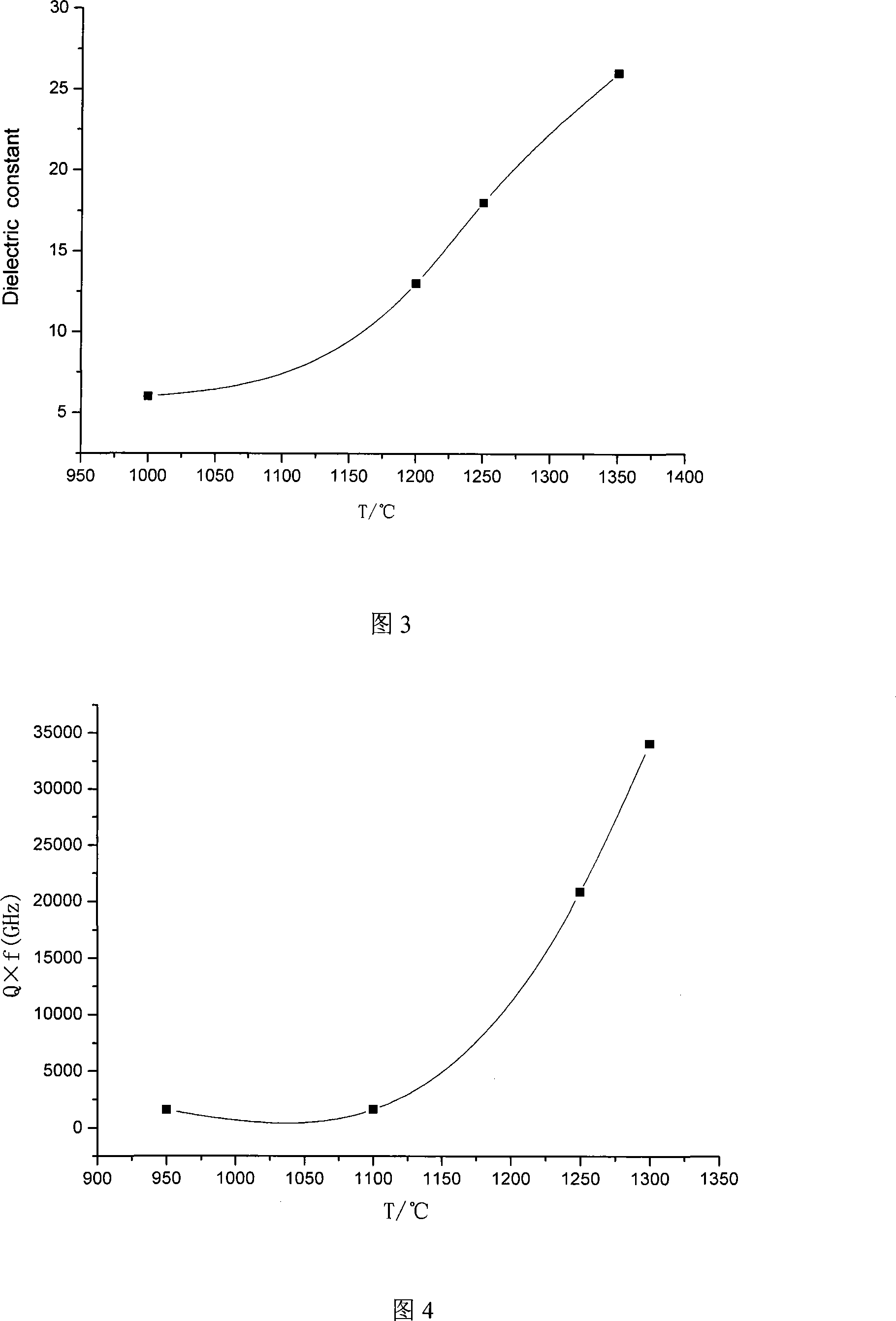

[0023] A solid phase reaction synthesis and sintering method of yttrium niobate that can be used for microwave dielectric ceramics, the specific steps of the method:

[0024] Step 1, weigh 1:1 equimolar Y 2 o 3 , Nb 2 o 5 Powder, Nb 2 o 5 The purity is 99.9%, d 50 = 8.3 µm and Y 2 o 3 The purity is 99.8%, d 50 =7.9 microns, placed in an alumina ball mill jar.

[0025] Step 2: Weigh agate balls with a diameter of 12mm in an alumina ball milling jar according to the volume ratio of the ball to material at 2:1; weigh anhydrous ethanol into the alumina ball milling jar at a volume ratio of 0.7:1 for the liquid material.

[0026] Step 3, ball milling, fixing the ball mill jar on the planetary ball mill, and ball milling at 180r / min for 8 hours.

[0027] Step 4, drying and sieving, separate the mixed slurry and dry it in a drying oven at 60°C; first sieve with 200 mesh, then 100 mesh, repeat the operation twice to obtain evenly mixed raw materials ;

[0028] Step 5, comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com