Charge roller and method of producing the same

A charging roller and conductive surface technology, applied in the field of charging roller and its preparation, can solve the problems of charging roller surface roughness reduction, oozing pollution, insufficient conductivity, etc., and achieve reduced roughness, proper elasticity, and good wear resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

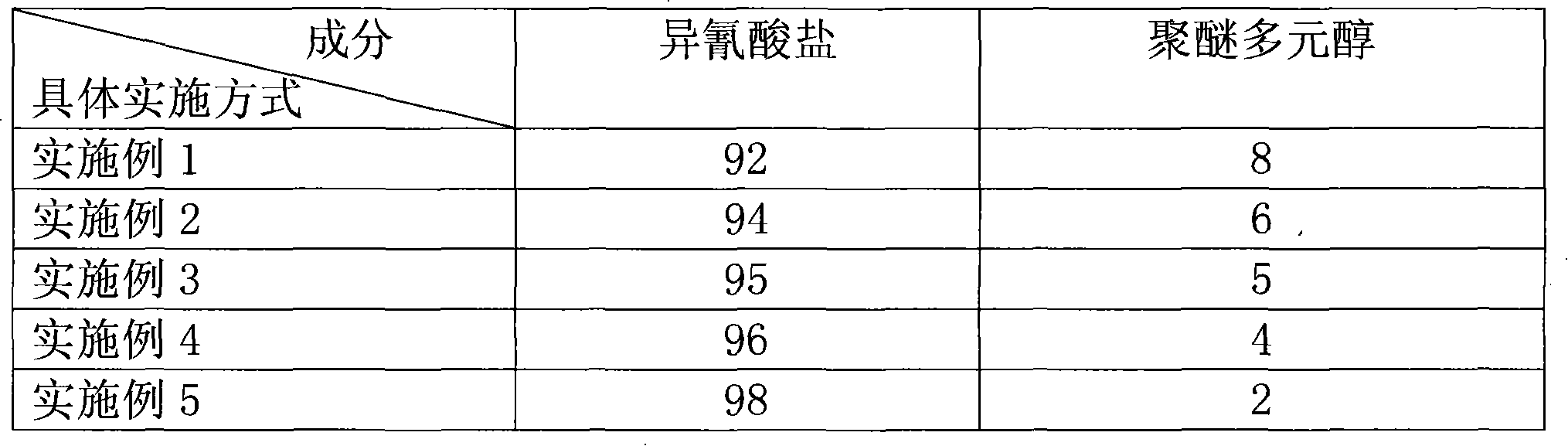

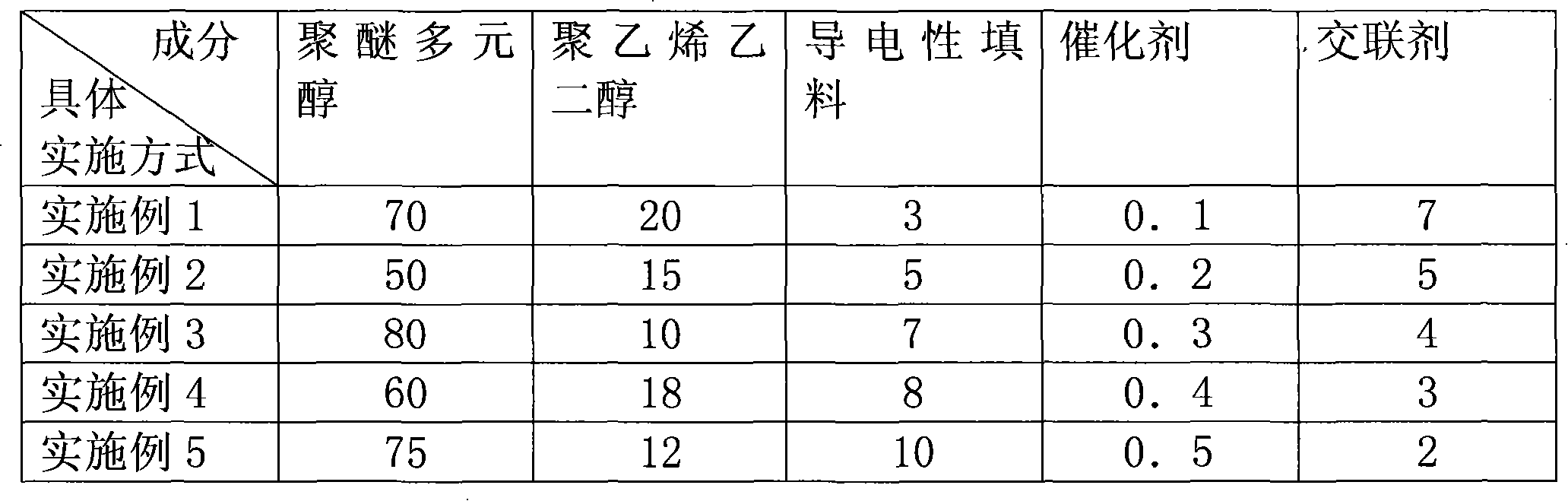

Method used

Image

Examples

Embodiment 2

[0050] The dispersant described in Example 2 is made of acrylic copolymer: 35% by weight; propylene glycol methyl ether acetate: 40%; ethylene glycol butyl ether: 25%; the mixed resin is made of Acrylic resin in weight percentage: 65%; isobutyl alcohol: 8%; methyl isobutyl ketone: 7%; the rest is made of xylene; the defoamer is polymerized by silicone resin in weight percentage Substance: 15%; ethyl hydroxyacetate: 8%; ethylene glycol butyl ether: 1.5%; the rest is made of solvent gasoline; the organic solvent is acetone;

Embodiment 3

[0051] The dispersant described in Example 3 is made by weight percentage of acrylic copolymer: 40%; propylene glycol methyl ether acetate: 25%; ethylene glycol butyl ether: 35%; the mixed resin is made of Acrylic resin in weight percentage: 70%; isobutyl alcohol: 7%; methyl isobutyl ketone: 8%; the rest is made of heavy aromatic hydrocarbons; the defoamer is polymerized by silicone resin in weight percentage Substance: 20%; ethyl hydroxyacetate: 7%; ethylene glycol butyl ether: 1%; the rest is made of solvent gasoline; the organic solvent is methyl ethyl ketone;

Embodiment 4

[0052] The dispersant described in Example 4 is made of acrylic copolymer: 45% by weight; propylene glycol methyl ether acetate: 30%; ethylene glycol butyl ether: 25%; the mixed resin is made of Acrylic resin in weight percentage: 75%; isobutyl alcohol: 10%; methyl isobutyl ketone: 5%; the rest is made of a mixture of toluene and xylene; the defoamer is made by weight percentage It is silicone resin polymer: 25%; ethyl hydroxyacetate: 6%; ethylene glycol butyl ether: 1%; the rest is made of solvent gasoline; the organic solvent is acetone;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface roughness | aaaaa | aaaaa |

| Surface roughness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com