Method for preparing MgB2 superconducting material

A technology of superconducting materials and organic acids, applied in the field of preparation of MgB2 superconducting materials, can solve the problems of increased preparation cost, easy to be peeled off, increased specific surface area, etc. The effect of flux pinning force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0012] (1) Weigh Mg powder and B powder according to molar ratio Mg: B=1: 2, Mg powder purity is 95%, 70 microns, and B powder purity is 90%, 1-2 microns, weighs simultaneously the quality is Mg powder Dissolve benzoic acid with a total mass of 5% of B powder in 5 mL of ethanol, mix the benzoic acid ethanol solution with Mg powder and B powder, and ball mill for 1 hour; then heat-preserve and dry at 80°C for 1 hour in a vacuum drying oven;

[0013] (2) Tablet the gained powder to obtain MgB 2 superconducting bulk;

[0014] (3) Put the obtained block in a vacuum furnace, under vacuum, heat treatment temperature is 650 ℃, keep warm for 0.5 hours, and finally obtain MgB 2 superconducting material.

example 2

[0016] Weigh the Mg powder and the B powder according to the molar ratio Mg: B=1: 2, the Mg powder purity is 99.99%, 0.5 micron, the B powder purity is 99.9999%, 1-2 micron, and the weighing quality is the Mg powder and the B powder The 30% magnesium stearate of total mass is dissolved in 50mL acetone, after the magnesium stearate acetone solution is mixed with Mg powder and B powder, ball milling 10 hours, then in a vacuum oven at 50 ℃ of temperature insulation drying 5 hours; put the obtained powder into the iron-copper composite tube, and after sealing, carry out swaging and drawing successively with a deformation rate of 5%, to obtain MgB 2 Superconducting wire; place the obtained wire in a vacuum furnace, under the protection of argon, heat treatment at a temperature of 950°C, and keep it warm for 2 hours to finally obtain MgB 2 superconducting material.

example 3

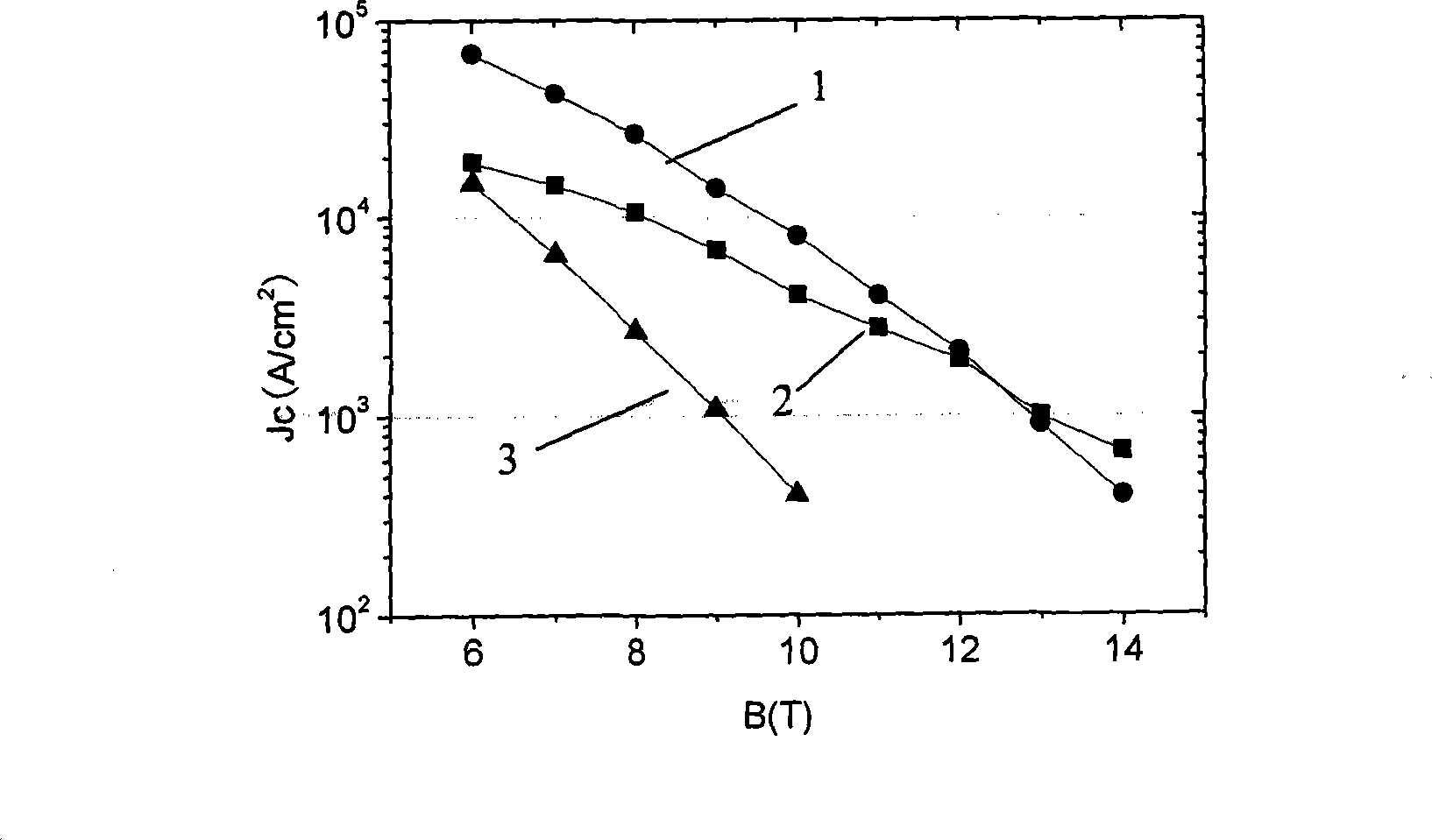

[0018] Weigh Mg powder and B powder according to the molar ratio Mg: B=1: 2, Mg powder purity is 99.8%, 44 microns, B powder purity is 92%, 1-2 microns, and weighing quality is Mg powder and B powder simultaneously 5% of the total mass of stearic acid was dissolved in 10mL of acetone, the stearic acid acetone solution was mixed with Mg powder and B powder, ball milled for 2 hours, and then dried in a vacuum oven at a temperature of 70°C for 2 hours; Put the obtained powder into a pure iron pipe, and after sealing, carry out swaging, drawing and rolling with a deformation rate of 5% in sequence to obtain MgB 2 Superconducting tape; put the obtained tape in a vacuum furnace, under the protection of argon, heat treatment temperature is 950 ℃, keep it warm for 1 hour, and finally get MgB 2 superconducting material. The critical current density of the obtained strip was 4.02×10 3 A / cm 2 (4.2K, 10T).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Critical current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com