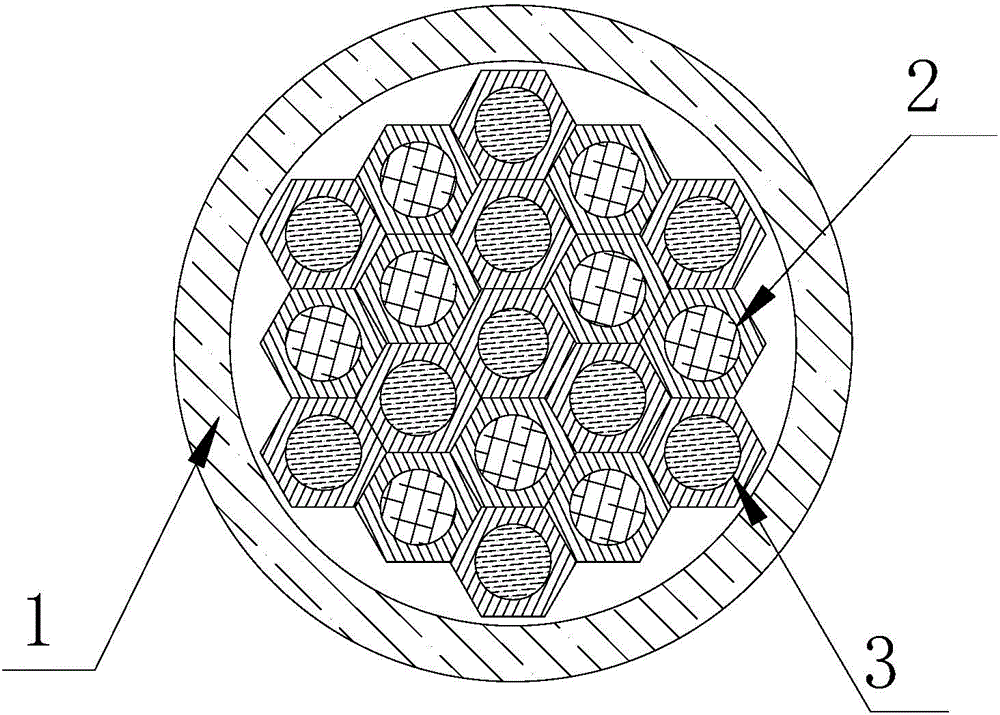

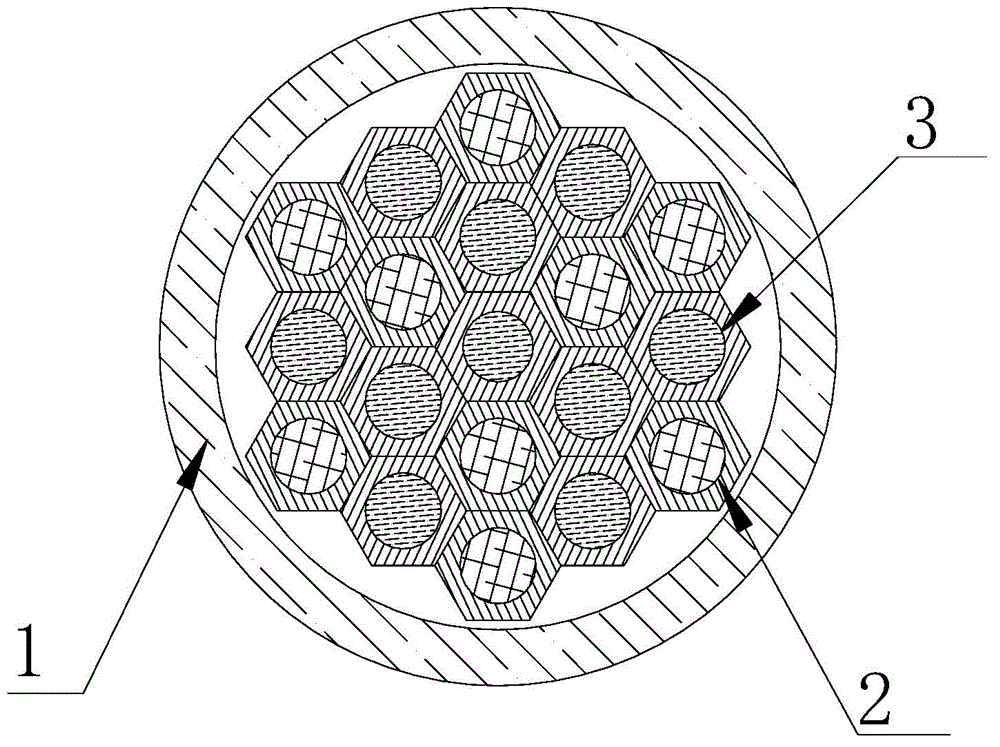

Preparation method of MgB2-NbTi composite superconducting wire

A technology of superconducting wires and wires, which is applied in the usage of superconducting elements, superconducting devices, superconducting/high-conducting conductors, etc., and can solve critical current density greatly affected by magnetic field, critical current attenuation, lack of pinning centers, etc. problem, achieve the effect of increasing critical current density, improving fluidity, and wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] MgB with a specification of Ф1.2mm 2 - Preparation of NbTi composite superconducting wire:

[0040] Step 1. Preparation of MgB 2 Single-core wire 2, the specific process is:

[0041] Step 101. Weigh Mg powder, B powder and TiC powder according to the atomic ratio of Mg:B:(Ti+C)=1.05:3.92:0.08, mix them evenly, and press to form to obtain a powder compact;

[0042] Step 102: Under the protection of a hydrogen-argon mixed atmosphere, the powder compact in step 101 is kept at a temperature of 900°C for 3 hours for high-temperature heat treatment, and then naturally cooled to a room temperature of 25°C; in the hydrogen-argon mixed atmosphere The volume ratio of hydrogen to argon is 5:95;

[0043] In step 103, the powder compact after the high temperature heat treatment in step 102 is crushed, ground and screened in sequence, and then Mg powder is added to the powder compact after the screening process, and the atomic ratio Mg:B: is obtained after mixing evenly. (Ti+C)=2...

Embodiment 2

[0052] MgB with a specification of Ф1.5mm 2 - Preparation of NbTi composite superconducting wire:

[0053] Step 1. Preparation of MgB 2 Single-core wire 2, the specific process is:

[0054] Step 101. Weigh Mg powder, B powder and TiC powder according to the atomic ratio of Mg:B:(Ti+C)=1.05:3.84:0.16, mix them evenly, and press to form to obtain a powder compact;

[0055] Step 102: Under the protection of a hydrogen-argon mixed atmosphere, the powder compact in step 101 is kept at a temperature of 1000°C for 2 hours for high-temperature heat treatment, and then naturally cooled to a room temperature of 25°C; in the hydrogen-argon mixed atmosphere The volume ratio of hydrogen to argon is 4:96;

[0056] In step 103, the powder compact after the high temperature heat treatment in step 102 is crushed, ground and screened in sequence, and then Mg powder is added to the powder compact after the screening process, and the atomic ratio Mg:B: is obtained after mixing evenly. (Ti+C)=...

Embodiment 3

[0065] MgB with a specification of Ф1.3mm 2 - Preparation of NbTi composite superconducting wire:

[0066] Step 1. Preparation of MgB 2 Single-core wire 2, the specific process is:

[0067] Step 101. Weigh Mg powder, B powder and TiC powder according to the atomic ratio of Mg:B:(Ti+C)=1.05:3.88:0.12, mix them evenly, and press to form to obtain a powder compact;

[0068] Step 102: Under the protection of a hydrogen-argon mixed atmosphere, the powder compact in step 101 is kept at a temperature of 950°C for 2.5 hours for high-temperature heat treatment, and then naturally cooled to a room temperature of 25°C; the hydrogen-argon mixed atmosphere The volume ratio of hydrogen to argon is 8:92;

[0069] In step 103, the powder compact after the high temperature heat treatment in step 102 is crushed, ground and screened in sequence, and then Mg powder is added to the powder compact after the screening process, and the atomic ratio Mg:B: is obtained after mixing evenly. (Ti+C)=2....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com