Nanostructures superconducting composite film and preparation method thereof

A composite thin film and nanostructure technology, applied in the field of nanostructured superconducting composite thin films and their preparation, can solve the problems of high cost, difficulty in changing the volume fraction of superconducting thin films, and inability to prepare real-time adjustable superconducting thin films with doping concentration, etc. To achieve the effect of improving the ability to carry current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

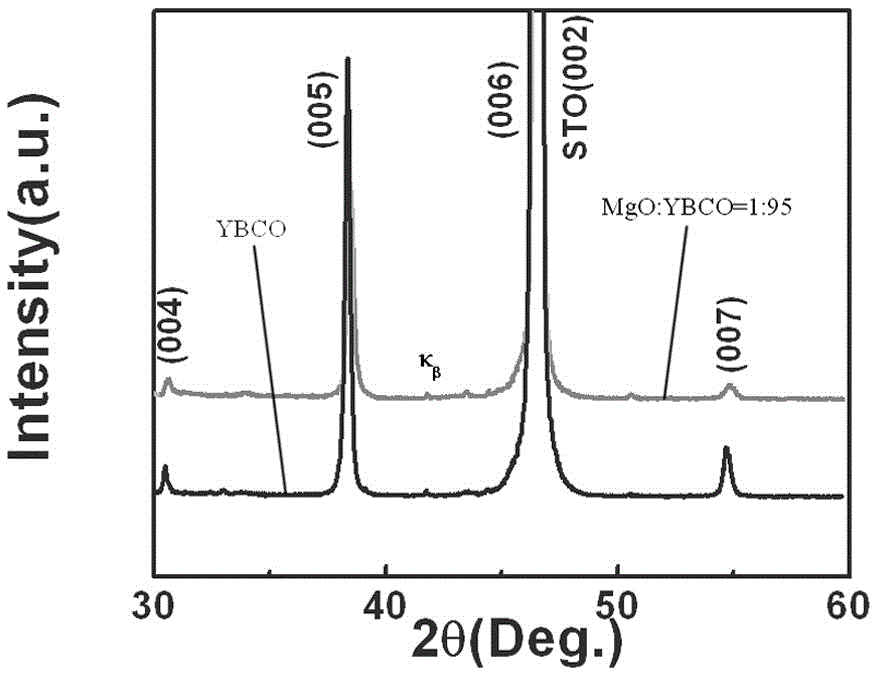

[0028] Example 1, preparation of STO-based MgO:YBCO=1:95 superconducting composite film.

[0029] 1. Target preparation and STO substrate cleaning: In the magnetron and pulse laser co-deposition device, the magnetron target is made of high-purity MgO (purity>99.95%, Beijing Antaike Technology Co., Ltd.) ceramic target, and the laser target Choose high-purity YBa 2 Cu 3 o 7-x (purity>99.95%, Beijing Antaike Technology Co., Ltd.) target material. Clean the 0.5mm thick STO (001) single crystal substrate in acetone and absolute ethanol sequentially for 10 minutes with ultrasonic waves, and blow dry it with high-purity nitrogen to ensure that the substrate is clean. Stick the substrate on the sample holder with silver glue, and then put the sample holder into the magnetron and pulse laser co-deposition device.

[0030] 2. Preparation of nanostructured MgO-doped YBCO composite film: the vacuum degree of the back and bottom of the vacuum chamber is 2×10 -4 Pa, the magnetron targ...

Embodiment 2

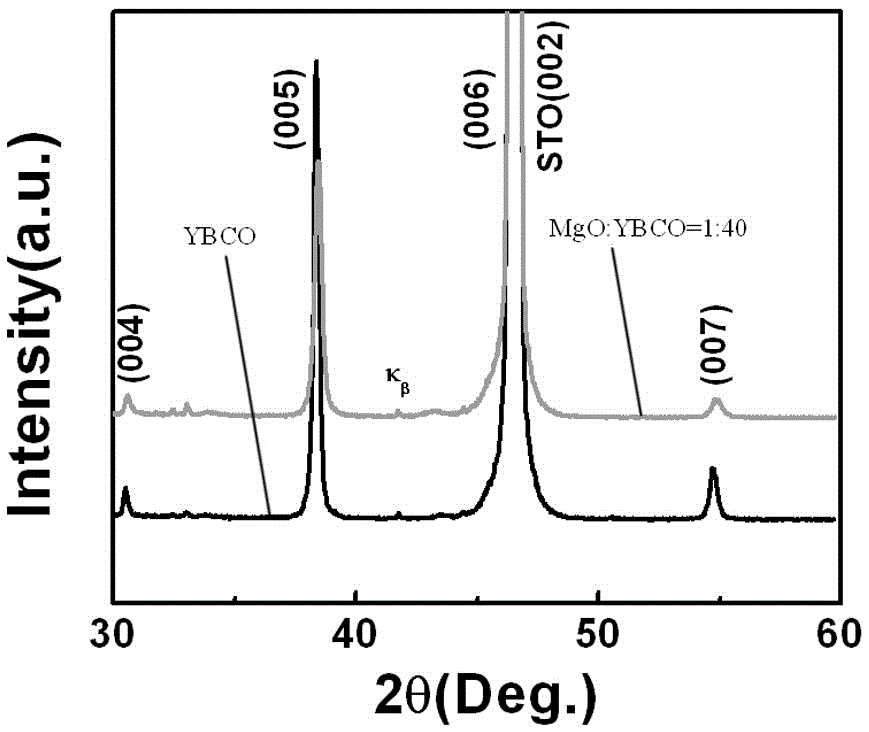

[0035] Example 2, preparation of STO-based MgO:YBCO=1:40 superconducting composite film.

[0036] 1. Target preparation and STO substrate cleaning: In the magnetron and pulse laser co-deposition device, the magnetron target is made of high-purity MgO (purity>99.95%, Beijing Antaike Technology Co., Ltd.) ceramic target, and the laser target Choose high-purity YBa 2 Cu 3 o 7-x (purity>99.95%, Beijing Antaike Technology Co., Ltd.) target material. Clean the 0.5mm thick STO (001) single crystal substrate in acetone and absolute ethanol sequentially for 10 minutes with ultrasonic waves, and blow dry it with high-purity nitrogen to ensure that the substrate is clean. Stick the substrate on the sample holder with silver glue, and then put the sample holder into the magnetron and pulse laser co-deposition device.

[0037] 2. Preparation of nanostructured MgO-doped YBCO composite film: the vacuum degree of the back and bottom of the vacuum chamber is 2×10 -4 Pa, the magnetron targ...

Embodiment 3

[0041] Example 3, preparation of MgO:YBCO=1:95 superconducting composite film on flexible metal substrate.

[0042] 1. Target preparation and metal substrate cleaning: In the magnetron and pulse laser co-deposition device, the magnetron target is made of high-purity MgO (purity>99.95%, Beijing Antaike Technology Co., Ltd.) ceramic target, and the laser target is selected High purity YBa 2 Cu 3 o 7-x (purity>99.95%, Beijing Antaike Technology Co., Ltd.) target material. Clean the 0.1mm thick metal base tape with a buffer layer in acetone and absolute ethanol for 10 minutes in sequence, and blow it dry with high-purity nitrogen to ensure that the base tape is clean. Use silver glue to stick the base tape on the sample holder, and then put the sample holder into the magnetron and pulse laser co-deposition device.

[0043] 2. Preparation of nanostructured MgO-doped YBCO composite film: the vacuum degree of the back and bottom of the vacuum chamber is 2×10 -4 Pa, the magnetron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com