Method for manufacturing yttrium barium copper oxide target

A technology of yttrium barium copper oxide and target materials, which is applied in the field of manufacturing high-temperature superconducting thin films, can solve the problems of complex process and poor density of targets, and achieve superconducting performance, small grain size and high density Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

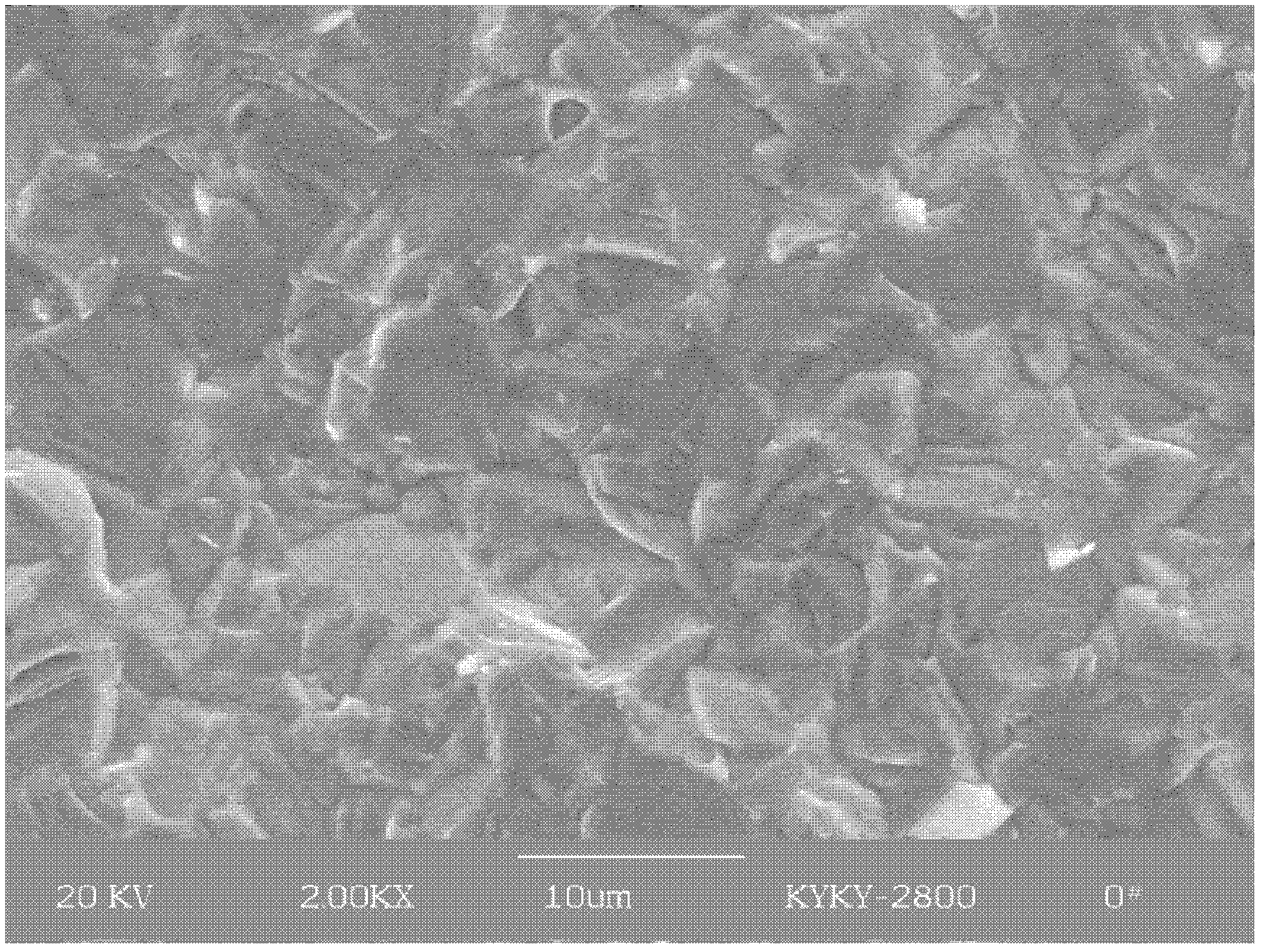

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with specific embodiments, but the present invention is not limited to the following embodiments.

[0026] A preparation method of yttrium-barium-copper-oxygen target material includes the following steps in sequence:

[0027] (1) Put Y 2 O 3 , BaO, CuO are mixed uniformly according to the atomic ratio Y:Ba:Cu=1:2:3 to obtain a mixed powder, Y 2 O 3 , The primary particle size of BaO and CuO is 100~200nm, and the purity is greater than 99.9wt%;

[0028] (2) The mixed powder is formed by cold pressing with a four-column hydraulic press, and the cold pressing pressure is 250MPa;

[0029] (3) Put the cold-pressed mixture into an oxygen atmospheric sintering furnace and sinter at 900°C. The sintering time is 12 hours. After the sintering is completed, it is cooled to room temperature and taken out and crushed into -300 meshes to obtain barium yttrium. Copper oxygen superconducting phase po...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com