A method for making GaMnN sparse magnetic semiconductor nano wire

A dilute magnetic semiconductor and nanowire technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as material difficulties, magnetic impurity phase precipitation, and low sample yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

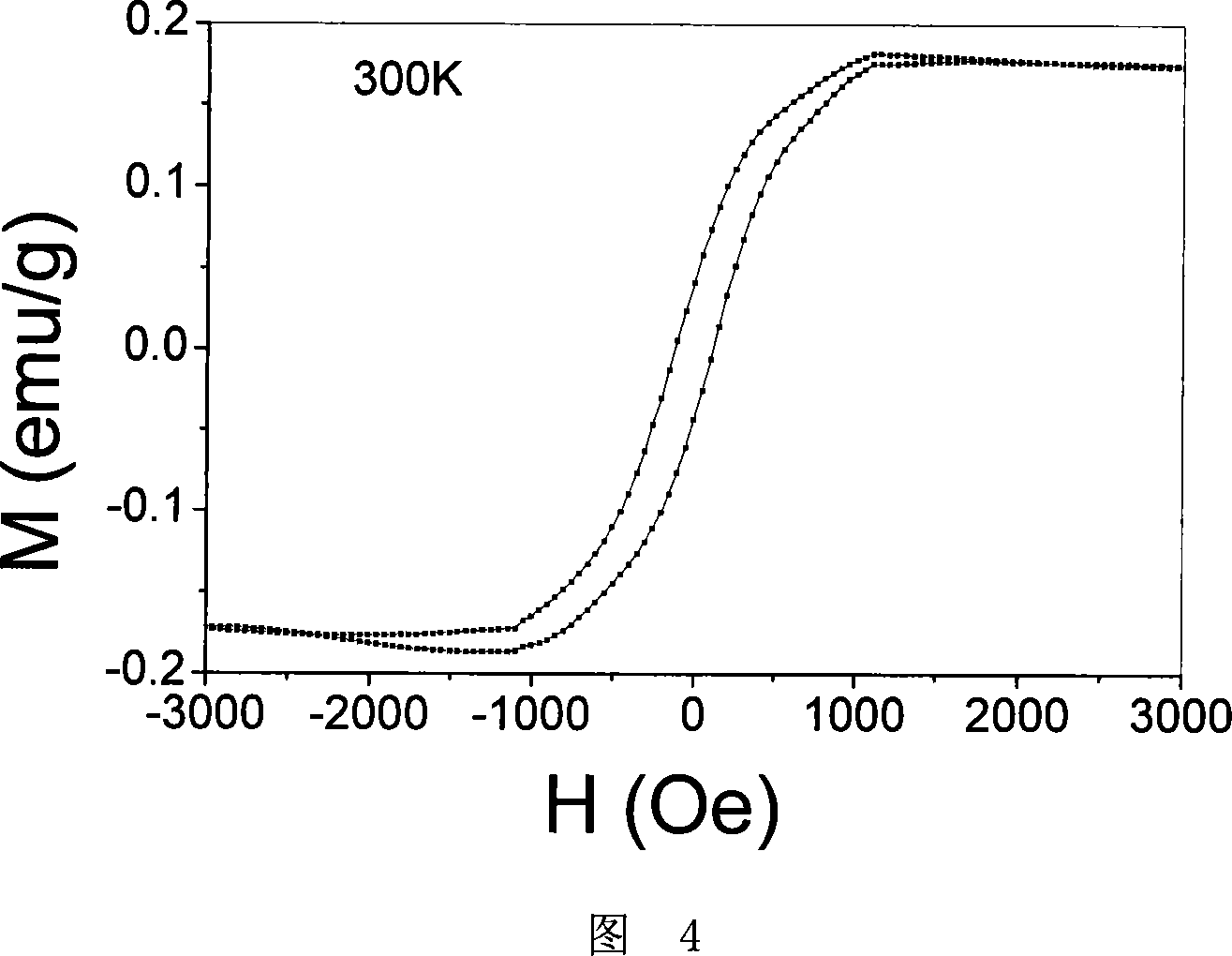

[0019] 1. GaMnN dilute magnetic semiconductor nanowires were prepared in large quantities by oxide ammoniation method.

[0020] A Si sheet coated with a 5nm gold film was used as the collection substrate of the product, and the MnCl 2 4H 2 A small ceramic cup of O powder, a gallium source substrate (a Si sheet with 100 mg of gallium metal placed on it) and three collection substrates were put into a quartz boat with one end open in turn, and the small ceramic cup was about 10 cm away from the gallium source substrate. Then place the quartz boat in the center of the tube furnace with the open end facing the direction of the airflow. After closing the system, turn on the mechanical pump to evacuate to a vacuum, pass in argon gas for cleaning, and raise the system pressure to normal pressure, and repeat this three times. After the experiment started, the required pressure (0.6-0.9 standard atmospheric pressure) was maintained by manually controlling the needle valve, and the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com