Method for synthesizing electron-ion mixed conductor material

A technology of mixed conductors and synthesis methods, applied in the direction of cobalt oxide/cobalt hydroxide, etc., can solve the problems of material synthesis difficulties, research and application difficulties, etc., and achieve the effect of easy control of the synthesis process, simple and easy synthesis process, and fine particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of precursor solution: press La 2 NiO 4+δ The stoichiometric ratio weighs a certain amount of lanthanum hydroxide La(OH) 3 and basic nickel carbonate NiCO 3 2Ni(OH) 2 4H 2 O, add diethylenetriaminepentaacetic acid according to the molar ratio of diethylenetriaminepentaacetic acid to the total amount of various metal ions of 1.7:3, put the mixture in a beaker and add an appropriate amount of deionized water, and put it at 90 ° C Heated and stirred for 4 hours to obtain a clear and transparent precursor solution;

[0020] (2) Preparation of solid precursor: put the above precursor solution into a constant temperature drying oven, heat and dry the precursor solution at 120° C. for 12 hours to obtain a transparent glassy aminopolycarboxylic acid complex precursor;

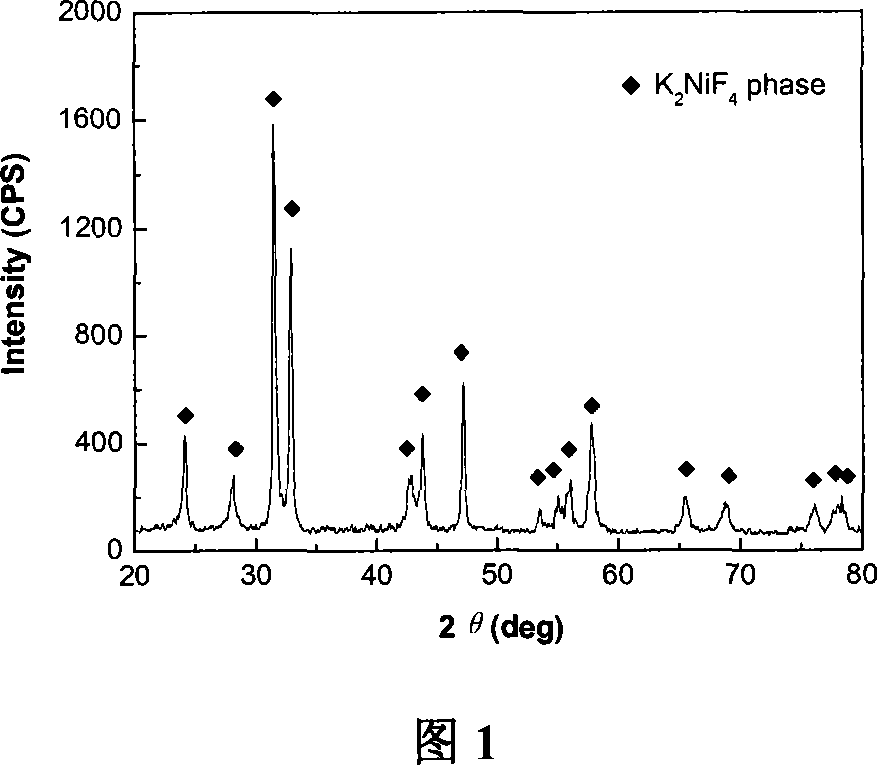

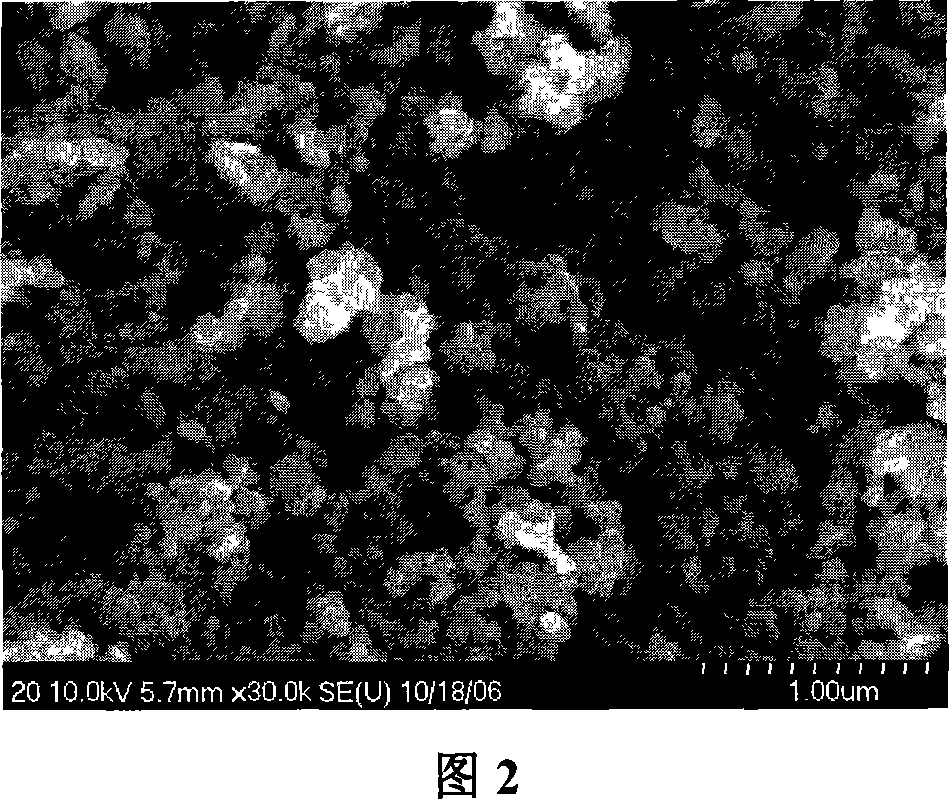

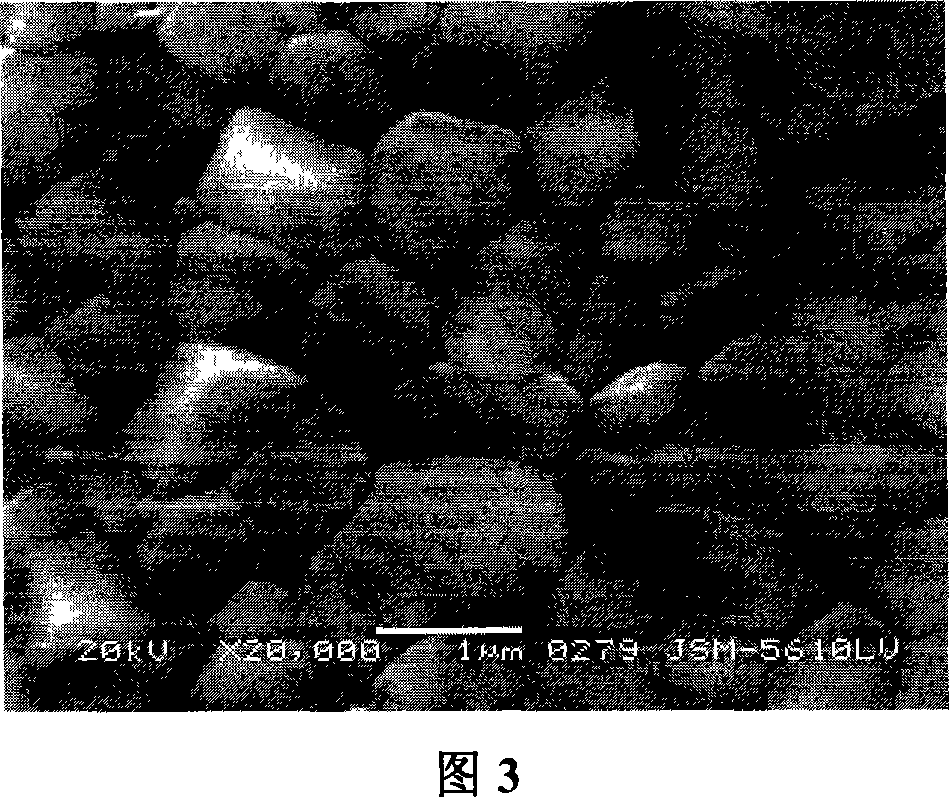

[0021] (3) Preparation of synthetic powder: the obtained solid precursor was placed on a corundum plate and sent into a muffle furnace, heated to 900° C. in an air atmosphere and kept for 2 ...

Embodiment 2

[0023] (1) Preparation of precursor solution: press La 1.8 Sr 0.4 NiO 4+δ The stoichiometric ratio weighs a certain amount of lanthanum hydroxide La(OH) 3 , strontium carbonate SrCO 3 and basic nickel carbonate NiCO 3 2Ni(OH) 2 4H 2 O, add diethylenetriaminepentaacetic acid according to the molar ratio of diethylenetriaminepentaacetic acid to the total amount of various metal ions of 1.6:3, put the mixture in a beaker and add an appropriate amount of deionized water, and put it at 100 ° C Heated and stirred for 6 hours to obtain a clear and transparent precursor solution;

[0024] (2) Preparation of solid precursor: put the above precursor solution into a constant temperature drying oven, heat and dry the precursor solution at 140° C. for 8 hours to obtain a transparent glassy aminopolycarboxylic acid complex precursor;

[0025](3) Preparation of synthetic powder: the obtained solid precursor was placed on a corundum plate and sent into a muffle furnace, heated to 800° ...

Embodiment 3

[0027] (1) Preparation of precursor solution: press La 2 Ni 0.8 co 0.2 o 4+δ The stoichiometric ratio weighs a certain amount of lanthanum hydroxide La(OH) 3 , Basic nickel carbonate NiCO 3 2Ni(OH) 2 4H 2 O and cobalt carbonate CoCO 3 , add diethylenetriaminepentaacetic acid according to the molar ratio of diethylenetriaminepentaacetic acid to the total amount of various metal ions of 1.9:3, put the mixed solution in a beaker and add an appropriate amount of deionized water, at 80 ° C Heated and stirred for 8 hours to obtain a clear and transparent precursor solution;

[0028] (2) Preparation of solid precursor: put the above precursor solution into a constant temperature drying oven, heat and dry the precursor solution at 110° C. for 18 hours to obtain a transparent glassy aminopolycarboxylic acid complex precursor;

[0029] (3) Preparation of synthetic powder: the obtained solid precursor was placed on a corundum plate and sent into a muffle furnace, heated to 950° C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com