Cellulated wiremesh carrier with alumina coat, and preparation method

A honeycomb metal, alumina coating technology, applied in catalyst carriers, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of expensive equipment, affecting the dispersion of catalytic active components, and complex preparation processes, and achieves a reduction in The effect of manufacturing cost, improving thermal shock resistance and mechanical vibration resistance, and simple molding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] According to the method of the present invention, an aluminum oxide coating with a thickness of 20 μm can be prepared on the surface of the wire mesh, and the formed honeycomb wire mesh carrier has a small volume, which can meet the needs of laboratory catalytic reactions.

[0045] Implementation preparation

[0046] Cut the wire mesh with 40 mesh to 1.5×1.5cm 2 The wire mesh is the flat wire mesh that forms the carrier of the honeycomb wire mesh, while the corrugated wire mesh is first cut into a flat wire mesh with a width of 1.5cm and a length of 2.5cm, and then this The wire mesh is placed in the abrasive tool and punched into a corrugated wire mesh with a tooth height of 2.0mm and a tooth spacing of 4.5mm;

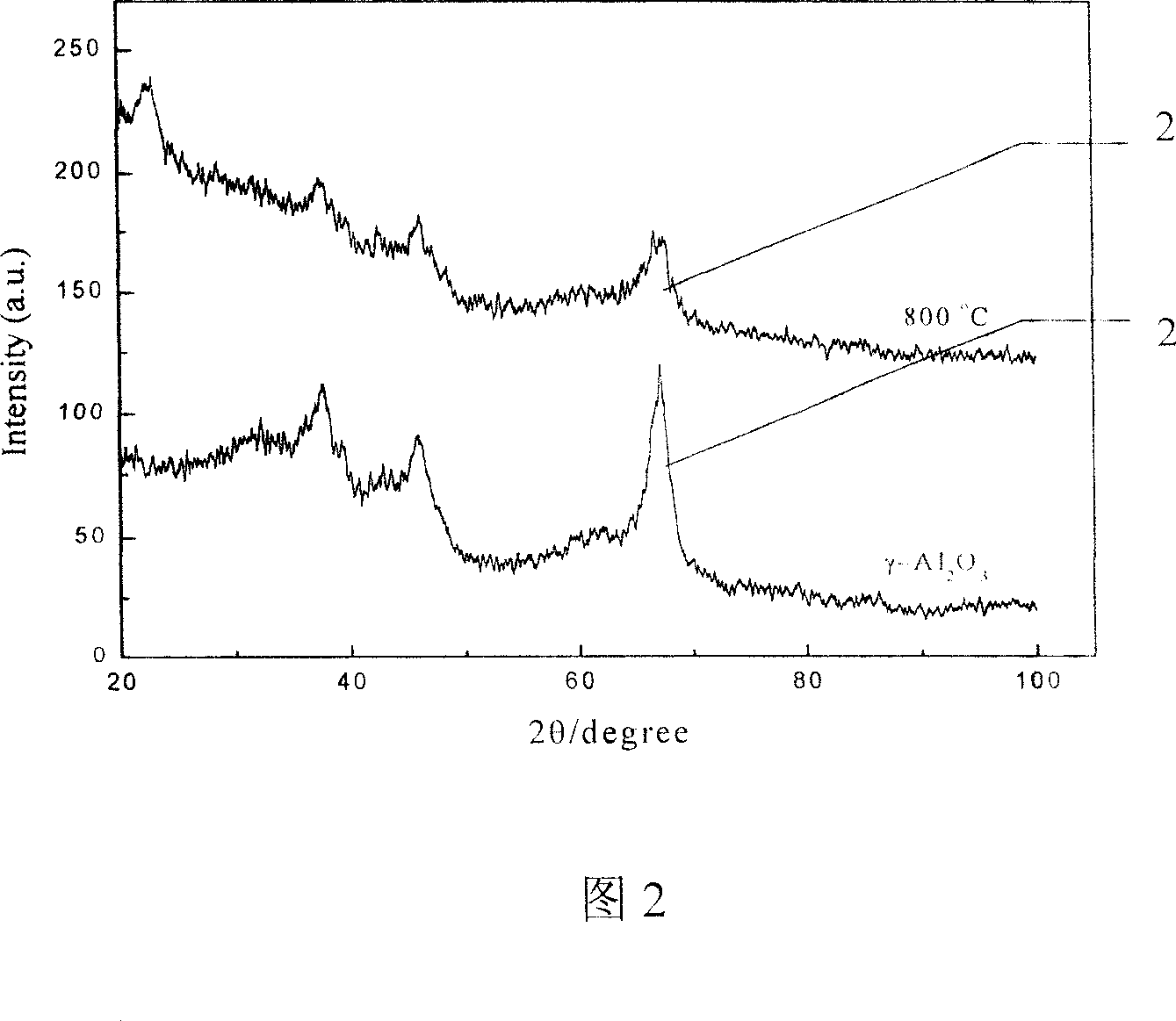

[0047] Preparation of alumina coating

[0048] The first step, pretreatment of stainless steel wire mesh

[0049] Immerse 5 pieces of flat and 6 pieces of corrugated wire mesh required for molding in 50ml of 0.1mol / L hydrochloric acid solution for 30min, tak...

Embodiment 2

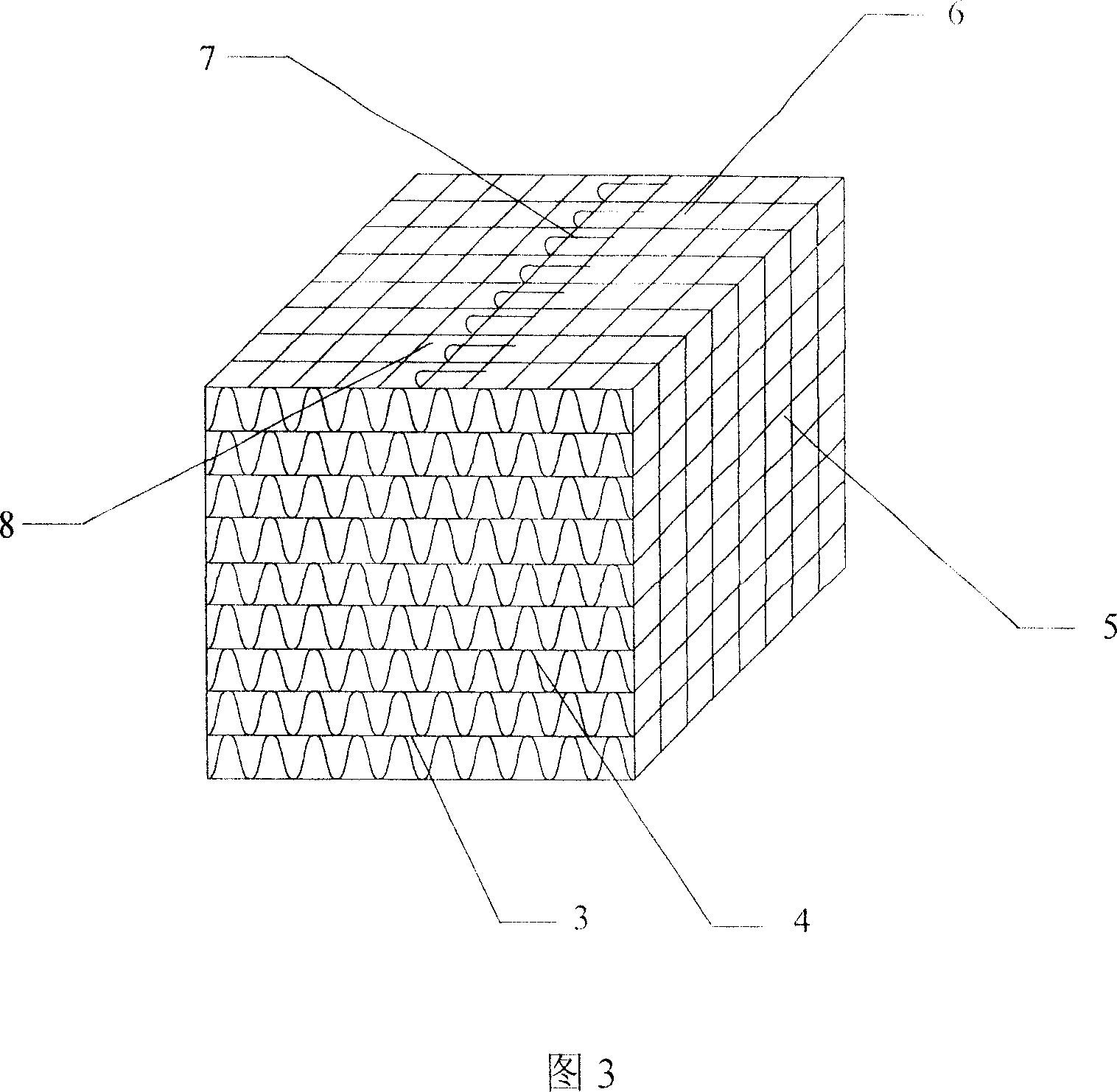

[0058] According to this method, an alumina coating with a thickness of 50 μm can be prepared on the surface of the wire mesh, and the volume of the formed honeycomb wire mesh carrier can meet the requirements of the metal carrier required by the automotive exhaust converter and small-scale reactions in the industry;

[0059] Implementation preparation

[0060] Cut the wire mesh with a mesh number of 20 to 2.5×3.5cm 2 The wire mesh is the flat wire mesh that forms the honeycomb wire mesh carrier, while the corrugated wire mesh is first cut into a flat wire mesh with a width of 2.5cm and a length of 4.5cm, and then this The wire mesh is placed in a self-made abrasive tool, and punched into a corrugated wire mesh with a tooth height of 3.0 mm and a tooth spacing of 5.0 mm.

[0061] The first step, pretreatment of stainless steel wire mesh

[0062] Immerse 11 pieces of flat and 12 pieces of corrugated wire mesh required for molding in 100ml of 0.1mol / L hydrochloric acid solutio...

Embodiment 3

[0070] According to this method, an alumina coating with a thickness of 80 μm can be prepared on the surface of the wire mesh, and the formed honeycomb wire mesh carrier has a large volume, which can meet the requirements of large-volume metal carriers required in industrial production.

[0071] Implementation preparation

[0072] Cut the wire mesh with a mesh number of 5 to 25.0×45.0cm 2 The wire mesh is the flat wire mesh that forms the carrier of the honeycomb wire mesh, while the corrugated wire mesh is first cut into a flat wire mesh with a width of 25.0cm and a length of 40.0cm, and then this The wire mesh is placed in a self-made abrasive tool, and punched into a corrugated wire mesh with a tooth height of 4.0mm and a tooth spacing of 4.5mm;

[0073] The first step, pretreatment of stainless steel wire mesh

[0074] Immerse 100 pieces of flat and 101 pieces of corrugated wire mesh required for molding into 5L 0.1mol / L hydrochloric acid solution for 30 minutes, take it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tooth spacing | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com