Electrooxidation treatment technique for wastewater of chlorobenzene-containing compound

A treatment process and compound technology, applied in water/sewage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problems of easy loss of granular particle electrodes, lack of catalytic effect of electrodes, lack of catalytic effect, etc. , to achieve significant market development prospects, low operating costs, and small equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Preparation of titanium-based composite metal lead oxide electrode modified by fluororesin

[0030] The fluororesin-modified titanium-based composite metal lead oxide electrode can be coated with Sn and Sb metal oxide films in the middle layer by thermal decomposition, with a content of 10 -5 mol / cm 3 order of magnitude; lead oxide active layer prepared by electrodeposition, α-PbO by alkali plating 2 , acid-plated β-PbO 2 , add fluorine resin emulsion when acid plating. Alkaline plating α-PbO 2 and acid plating β-PbO 2 For the process, refer to the literature ("Plating and Performance Research of Tubular Ceramic Lead Dioxide Anode", Ma Chun'an, etc., Fine Chemical Industry (Supplement), 1996; "Plating and Enhanced Life of Hydrophobic Lead Dioxide Electrode", Gan Yongping , Chemical World, 2002), the addition amount of fluororesin emulsion is 3.0mol / L.

Embodiment 2

[0031] Example 2: Mn-Sn-Sb / γ-Al 2 o 3 Preparation of Honeycomb Ceramic Active Catalytic Electrode

[0032] The Mn, Sn, and Sb active components of the regular active particle electrode can be prepared by impregnation, using soluble chloride or nitrate containing metal ions to impregnate γ-Al2 o 3 The carrier is left to stand for 3-4 hours, dried at 90° C. for 2-3 hours, and then calcined at 550° C. for 3-4 hours to obtain a finished electrode with regular active particles.

[0033] The γ-Al 2 o 3 The carrier is γ-Al 2 o 3 Honeycomb ceramic carrier, dimensions 47×47×47mm, number of holes 200-400 holes / inch 2 , wall thickness 0.15 ~ 0.3mm, opening area ratio ≥ 70%, specific surface area 60 ~ 100m 2 / g, the diameter of noble metal particles is 2-10nm, and the coating thickness is ≤3μm.

Embodiment 3

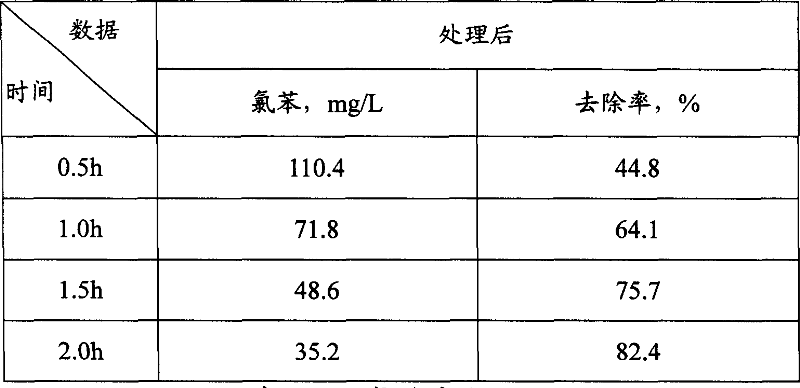

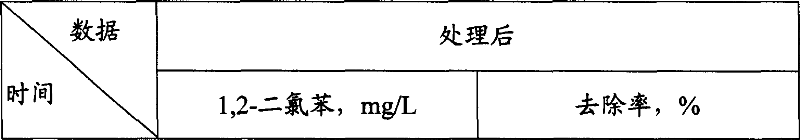

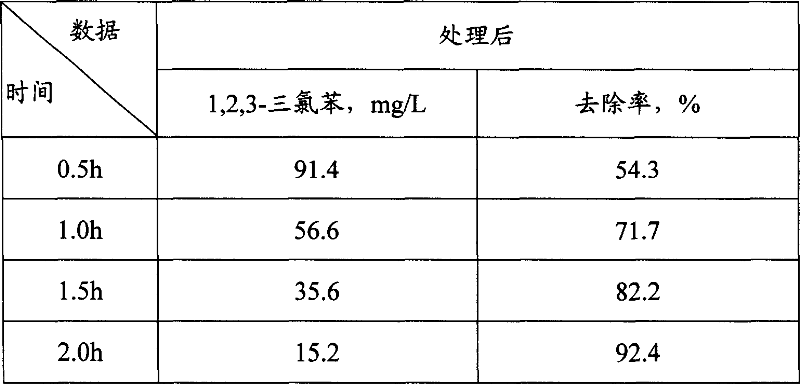

[0034] Embodiment 3: Wastewater treatment test containing chlorobenzene compounds

[0035] Wastewater containing chlorobenzene compounds:

[0036] (1) Wastewater containing chlorobenzene 200mg / L, pH neutral;

[0037] (2) Wastewater containing 200 mg / L of 1,2-dichlorobenzene, pH neutral;

[0038] (3) Wastewater containing 1,3-dichlorobenzene 200mg / L, pH neutral;

[0039] (4) Wastewater containing 1,4-dichlorobenzene 200mg / L, pH neutral;

[0040] (5) Wastewater containing 200 mg / L of 1,2,3-trichlorobenzene, with neutral pH.

[0041] Chlorobenzene compounds were determined by gas chromatography with an electron capture detector, the pH value was determined by a pH meter, and chloride ions were determined by a PXD-2 universal ion meter.

[0042] In an electrocatalytic reaction tank made of plexiglass, the composite catalytic electrode is set in the way of cathode and anode interlaced, the cathode has one anode, and the active honeycomb ceramic particle electrode is filled betw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wall thickness | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com