Single-phase ultrahigh heat flow micro-column heat exchanger

A heat exchanger and micro-column technology, which is applied in the field of single-phase ultra-high heat flow micro-column group heat exchangers, can solve the problems of limited heat dissipation capacity of CPU liquid-cooled heat exchangers, and achieve a reduction in decent ratio, small size and large size. Effect of heat transfer coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

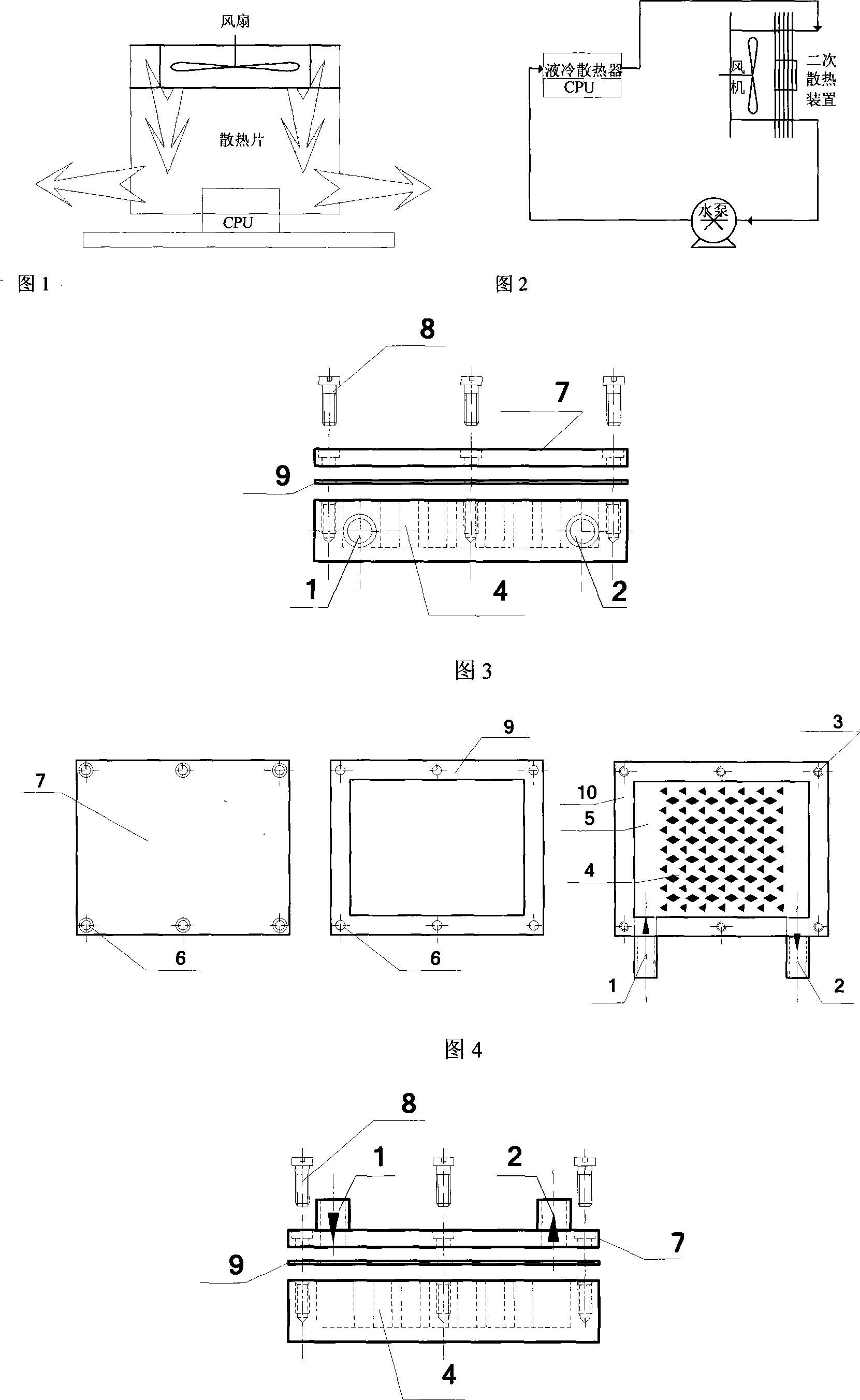

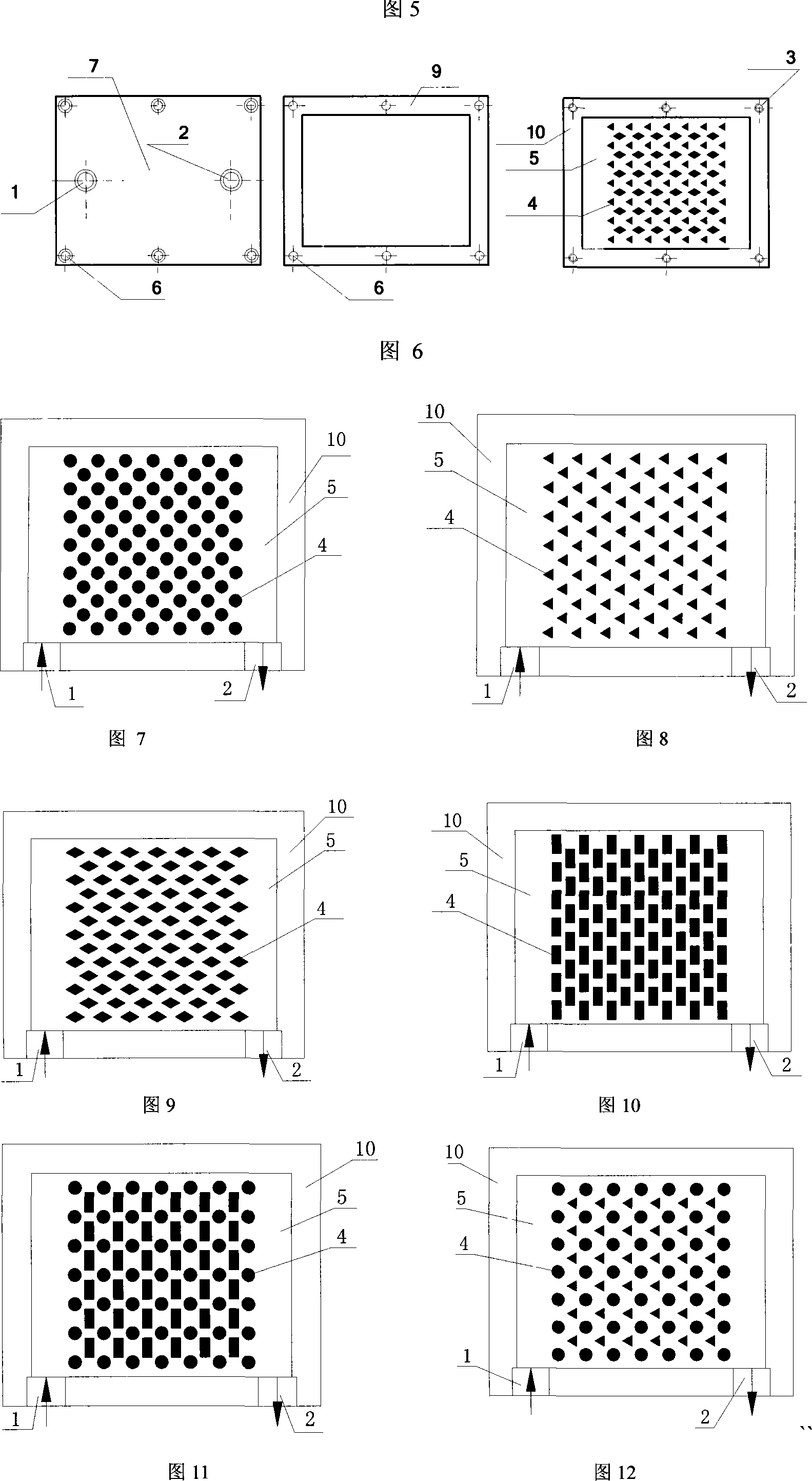

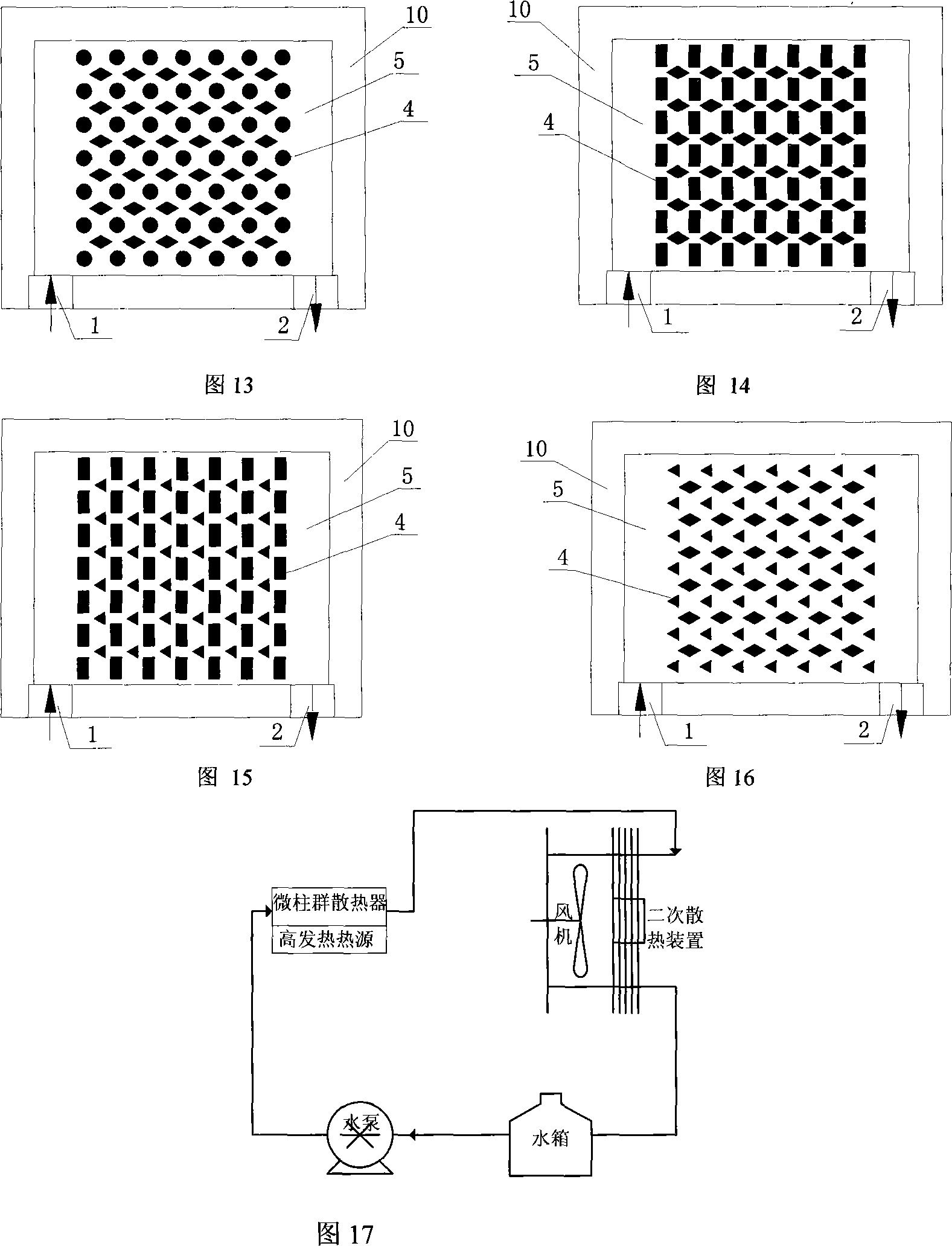

[0029] As shown in Figure 1, this mode is a common way for the existing general computer CPU to dissipate heat. Its main working principle is to install cooling fins on the heating end of the CPU, and the heat in the CPU is taken out through the fins, and then the heat is taken out by the fan. The incoming wind takes away the heat in the fins. This scheme has a simple structure and is relatively easy to realize. However, we know that when the calorific value of the heating element reaches 20W / cm 2 , air cooling is more difficult to solve. In the scheme in Figure 1, the effective heat dissipation of the CPU is realized by increasing the heat exchange area (fin processing). In Intel's Pentium 4 processor (3.06GHz), its maximum calorific value is close to 50W / cm 2 , the result of the above scheme is that the heat dissipation structure is huge and heavy. However, the rapid increase in the heat generation of heat-generating chips is inevitable for development, although chip manufac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com