Method of preparing biological diesel oil catalyzed by solid base

A solid alkali catalyst and biodiesel technology, which is applied in the preparation of biological raw materials, biofuels, liquid hydrocarbon mixtures, etc., can solve the problems of easy loss, serious pollution, and unfavorable recycling, so as to reduce water consumption and production costs , The effect of production cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

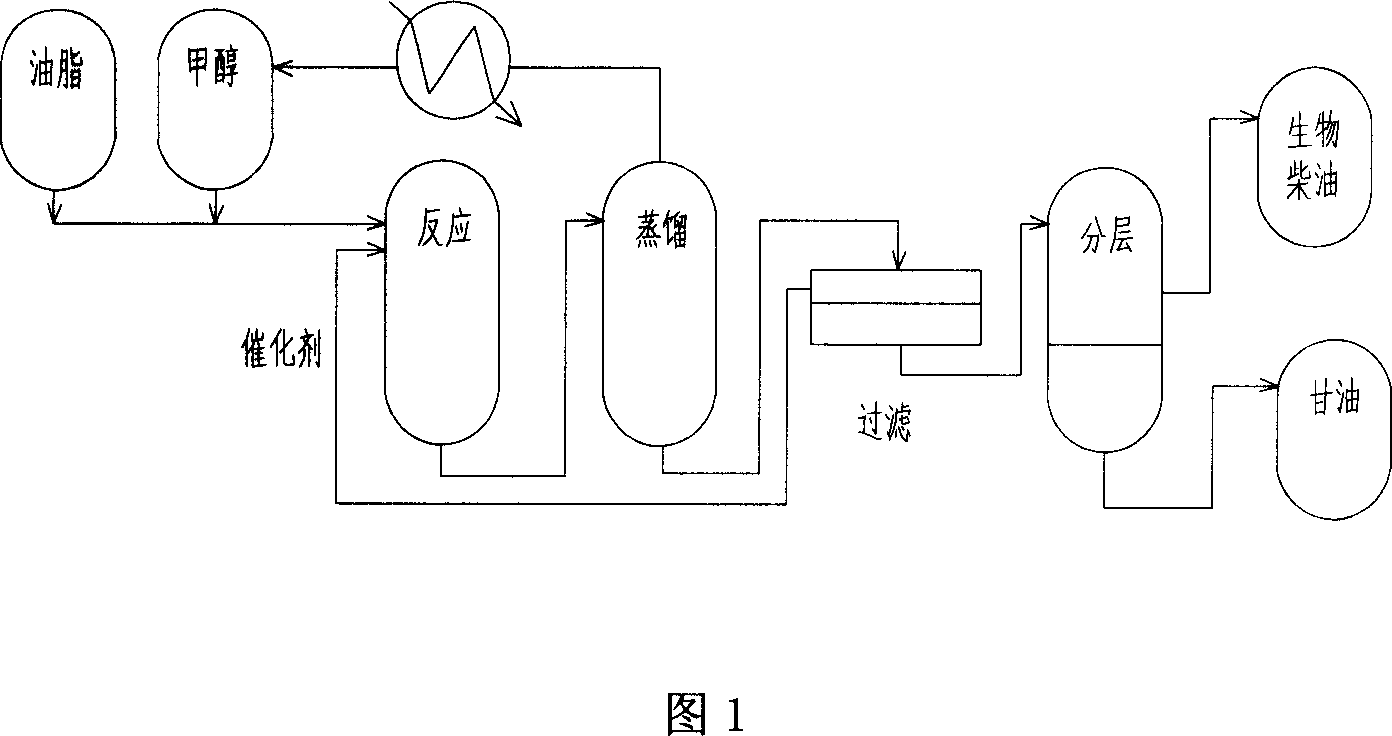

Image

Examples

Embodiment 1

[0035] Embodiment 1: use Sr(OCH 3 ) 2 Preparation of biodiesel with solid base catalyst

[0036] 1) join 24.2ml methanol in the slurry bed reactor of jacket, start to stir;

[0037] 2) Slowly add 1 gram of Sr(OCH 3 ) 2 solid base catalyst;

[0038] 3) add 50ml soybean oil in the reactor;

[0039] 4) Heating the reaction system to 40°C, the operating pressure is 0.1MPa;

[0040] 5) After reacting for 2 hours, the product is filtered through a filter to recover the catalyst;

[0041] 6) the product is passed into a vacuum distillation unit to reclaim unreacted methanol;

[0042] 7) The product after removing the methanol is passed into the clarification device to stand for stratification, and the glycerol in the lower layer is removed to obtain the biodiesel product, and the biodiesel yield is 95% through chromatographic analysis.

Embodiment 2

[0043] Embodiment 2: with Ca (OCH 3 ) 2 Preparation of biodiesel with solid base catalyst

[0044] 1) join 24.2ml methanol in the slurry bed reactor of jacket, start to stir;

[0045] 2) Slowly add 1 gram of Ca(OCH 3 ) 2 solid base catalyst;

[0046] 3) add 50ml soybean oil in the reactor;

[0047] 4) Heating the reaction system to 300°C, and the operating pressure is 30MPa;

[0048] 5) After reacting for 30 minutes, stop the reaction, and lower the temperature and release the pressure;

[0049] 6) The product is filtered through a filter to recover the catalyst;

[0050] 7) the product is passed into a vacuum distillation unit to reclaim unreacted methanol;

[0051] 8) The product after removing the methanol is passed into the clarification device to stand for stratification, and the glycerol in the lower layer is removed to obtain the biodiesel product, and the yield of the biodiesel is 95% through chromatographic analysis.

Embodiment 3

[0052] Embodiment 3: use Sr(OCH 3 ) 2 Preparation of biodiesel with solid base catalyst

[0053] 1) Methanol, soybean oil and Sr(OCH 3 ) 2 The catalyst is preheated to 250°C through the preheater;

[0054] 2) Pass the preheated reaction material into a tubular continuous reactor and react for 30 minutes;

[0055] 3) The reaction product is discharged through a pressure reducing valve;

[0056] 4) The product is filtered through a filter to recover the catalyst;

[0057] 5) the product is passed into a vacuum distillation unit to reclaim unreacted methanol;

[0058] 6) The product after removing the methanol is passed into the clarification device to stand for stratification, and the glycerol in the lower layer is removed to obtain the biodiesel product, and the biodiesel yield is 95% through chromatographic analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com