Anode-electrolyte-cathode assembly of middly temp SOFC and preparation method thereof

A cathode component and electrolyte technology, applied in the direction of solid electrolyte fuel cells, electrical components, fuel cell parts, etc., can solve the problems of co-firing structure warping and deformation, difficult casting technology, and high requirements for powder raw materials, and achieve Effects of cost savings, avoidance of warpage and stress cracking, and high output performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

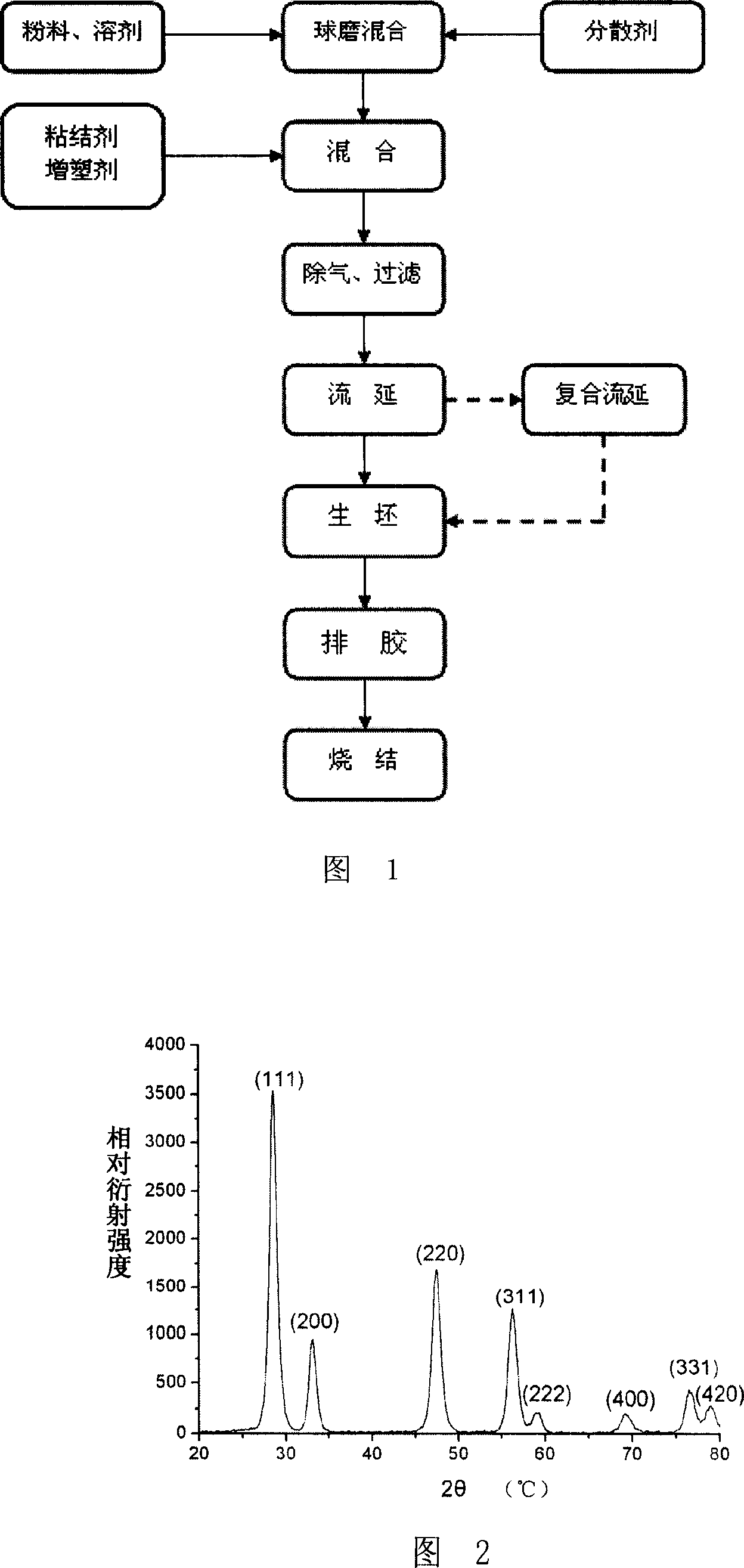

Method used

Image

Examples

Embodiment 1

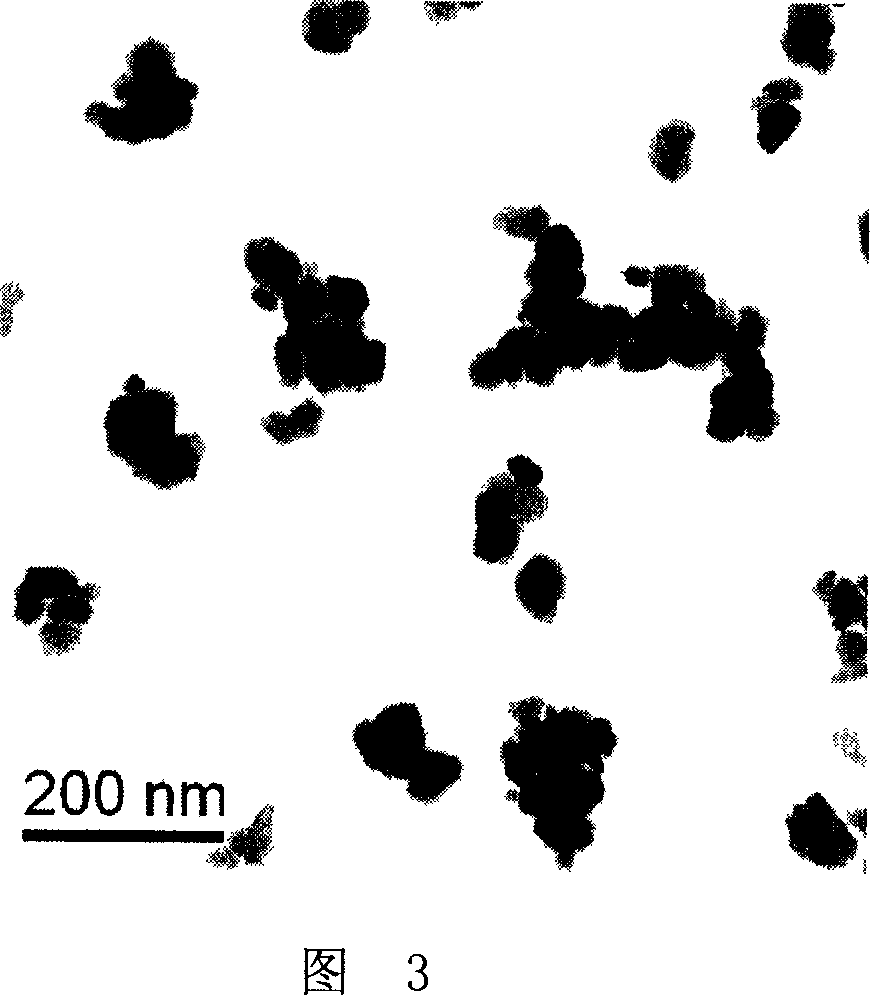

[0031] The preparation of embodiment 1, GYDC

[0032] 1. Preparation conforms to Ce 0.8 Gd 0.05 Y 0.15 o 1.9 Stoichiometric ratio of gadolinium, yttrium composite doped ceria electrolyte

[0033] According to the stoichiometric ratio of cerium, gadolinium and yttrium ions in the molar ratio of 0.8:0.05:0.15, weigh cerium nitrate, gadolinium nitrate and yttrium nitrate, dissolve them in deionized water, stir continuously to dissolve them fully, form a clear solution and add Glycine, so that the molar ratio of glycine and nitrate ions is 0.2:1, adjust the pH value of the solution to 7.5 with ammonia water, then heat and evaporate at 80°C to remove water until a tan viscous gel is formed, and the water in the gel is evaporated to dryness Finally, move it to a constant temperature electric furnace at 200°C. The dry gel begins to expand, boil, and smoke in about 3 minutes, and then generates a flame and discharges a large amount of gas. After the reaction is completed, a light ...

Embodiment 2

[0046] Example 2, Preparation of an anode-electrolyte-cathode assembly of a medium temperature solid oxide fuel cell

[0047] 1. Preparation of GYDC-based anode-electrolyte bilayer structure

[0048] (1) Preparation of electrolyte thin film green body

[0049] First prepare the GYDC slurry. Be the Ce prepared in Example 1 with a grain size of 40-60nm 0.8 Gd 0.05 Y 0.15 o 1.9 Powder is used as raw material, ethanol and methyl ethyl ketone are added as organic solvent, dibutyl phthalate is added as plasticizer, castor oil is added as dispersant, polyvinyl butyral is added as binder, and ball milling is carried out Mix to obtain a homogeneous slurry. Among them, the amount of ethanol added is Ce 0.8 Gd 0.05 Y 0.15 o 1.9 70% of the powder mass, the amount of methyl ethyl ketone added is Ce 0.8 Gd 0.05 Y 0.15 o 1.9 47% of the powder mass, the amount of plasticizer added is Ce 0.8 Gd 0.05 Y 0.15 o 1.9 1% of powder mass, the amount of dispersant added is Ce 0.8 Gd ...

Embodiment 3

[0057] Example 3, Preparation of an anode-electrolyte-cathode assembly of a medium temperature solid oxide fuel cell

[0058] 1. Preparation of GYDC-based anode-electrolyte bilayer structure

[0059] (1) Preparation of electrolyte thin film green body

[0060] First prepare the GYDC slurry. Be the Ce prepared in Example 1 with a particle diameter of 30-50nm 0.8 Gd 0.1 Y 0.1 o 1.9 Powder is used as raw material, ethanol and methyl ethyl ketone are added as organic solvent, polyethylene glycol is added as plasticizer, fish oil is added as dispersant, polyvinyl butyral is added as binder, and ball milling is performed to obtain a uniform slurry . Among them, the amount of ethanol added is Ce 0.8 Gd 0.1 Y 0.1 o 1.9 70% of the powder mass, the amount of butanone added is Ce 0.8 Gd 0.1 Y 0.1 o 1.9 82% of the powder mass, the amount of plasticizer added is Ce 0.8 Gd 0.1 Y 0.1 o 1.9 5% of powder mass, the amount of dispersant added is Ce 0.8 Gd 0.1 Y 0.1 o 1.9 1%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com