Composite lithium titanate electrode material and preparation method thereof

A technology of composite lithium titanate and electrode materials, which is applied in the direction of electrode manufacturing, battery electrodes, chemical instruments and methods, etc., can solve the problems of difficulty in realizing large-scale industrial production, low utilization rate of reaction furnace, and rising cost, etc., so as to increase effective Reaction area, improvement of high-rate performance, and improvement of processability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the composite lithium titanate electrode material of the present invention comprises the following steps: 1. 27.5-24.75wt% inorganic lithium salt, 72.5-65.25wt% industrial grade titanium dioxide, 1-10wt% nano-carbon coating material Or more than 0-10wt% doping modifier, using high-speed stirring, solid-phase high-energy ball milling or liquid-phase high-energy ball milling for 2 to 40 hours to prepare a composite lithium titanate precursor mixture; 2. Disperse the above mixture in In the organic solvent ethanol or acetone, the dispersed powder is obtained by a transient drying method; 3. The dispersed powder is heat-treated in the temperature range of 500 to 950 ° C for 4 to 40 hours, and the protective gas is filled during the heat treatment. The protective gas is nitrogen, argon, helium, neon, CO or CO 2 Gas; 4. Natural cooling to below 150°C for crushing and sieving.

[0034] The solid-phase high-energy ball milling method or the liquid-pha...

Embodiment 1

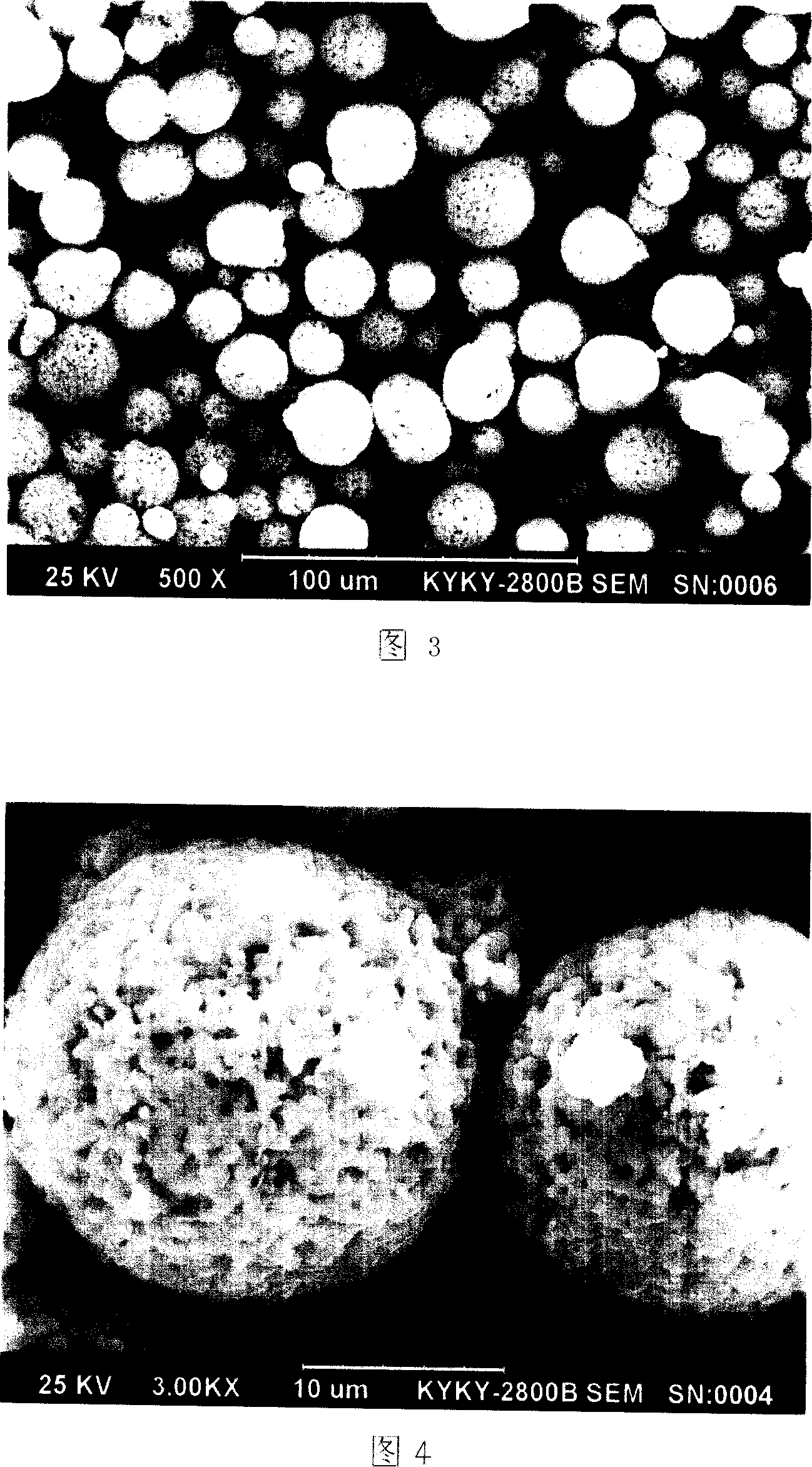

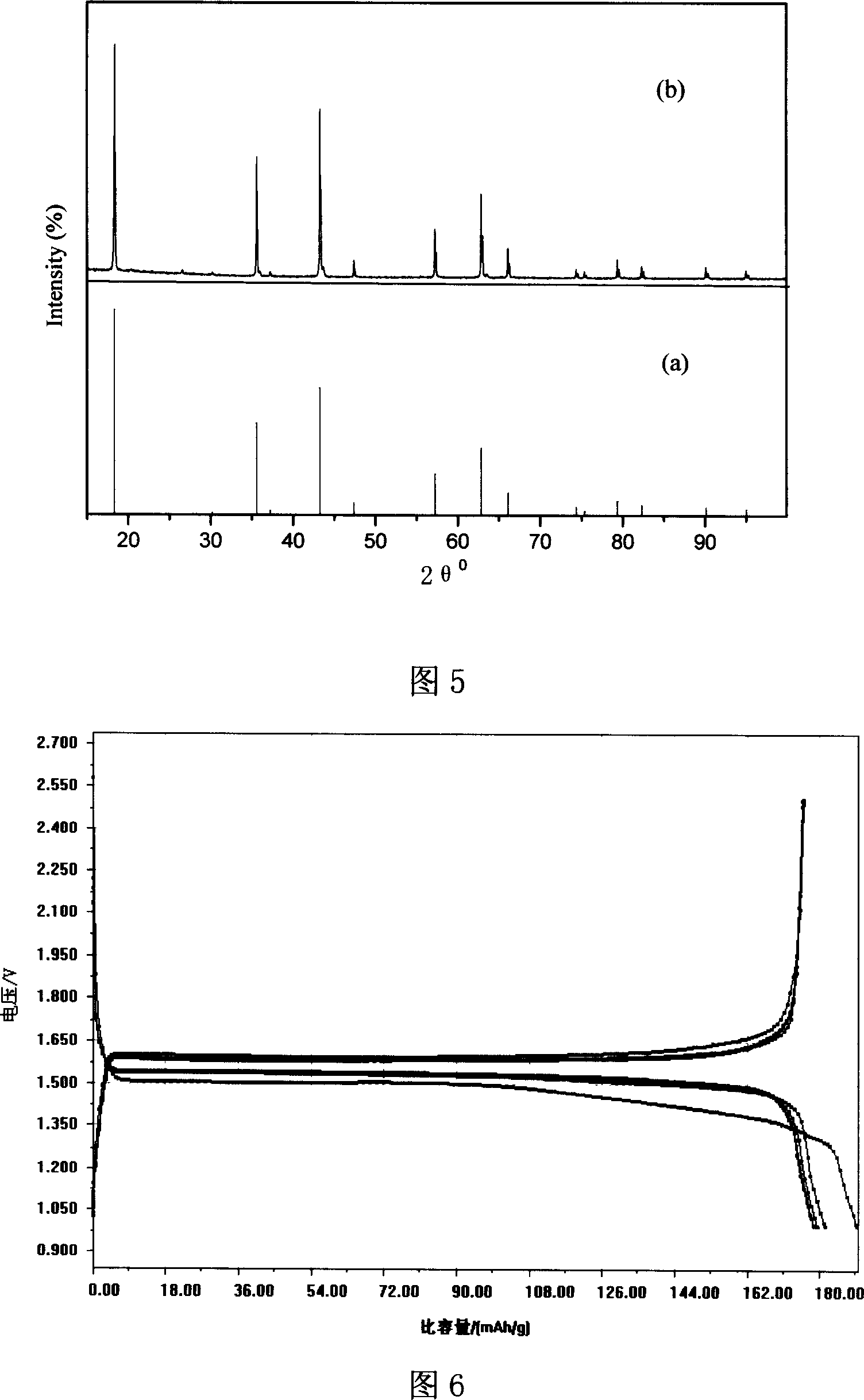

[0037] Embodiment 1: Take by weighing 500g of industrially produced titanium dioxide and 189.6g of lithium carbonate in a ball mill jar, add 36.3g of nano-graphite powder, and obtain a precursor mixture after 10 hours of ball milling at a speed of 350 rpm on a planetary ball mill, and the precursor particles As shown in Figure 1, the mixture is dispersed in ethanol, and the dispersed powder is obtained by a transient drying method. The dispersed powder is shown in Figure 2. The resulting dispersed powder is placed in a crucible and placed in a nitrogen atmosphere to protect the high temperature furnace , heat up to 600°C, keep warm for 15 hours, cool naturally to below 150°C, take it out, crush and sieve to obtain the composite lithium titanate material, as shown in Figure 3 and Figure 4, the prepared composite lithium titanate The particles are secondary particles composed of nano-lithium titanate and nano-carbon materials. The composite lithium titanate particles have spheric...

Embodiment 2

[0038] Embodiment 2: Weigh 500g of industrially produced titanium dioxide and 189.6g of lithium carbonate in a ball mill jar, add 76.6g of glucose as a carbon coating material, and obtain a precursor mixture after ball milling at a speed of 350rpm on a planetary ball mill for 40 hours. Disperse the mixture in an ethanol solvent, and use a transient drying method to obtain a dispersed powder. The obtained dispersed powder is placed in a crucible, placed in a high-temperature furnace protected by a nitrogen atmosphere, and heated to 950 ° C. After 4 hours of heat preservation, it is naturally cooled to Below 150°C, take it out, crush and sieve to get the composite lithium titanate material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com