Method for producing alloy phase change material nano-dot matrix

A kind of alloy phase and nanotechnology, applied in the direction of metal material coating technology, nanotechnology, nanotechnology, etc., can solve the problems of high production cost and complicated preparation process, achieve high uniformity, simple process, reduce voltage and power consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

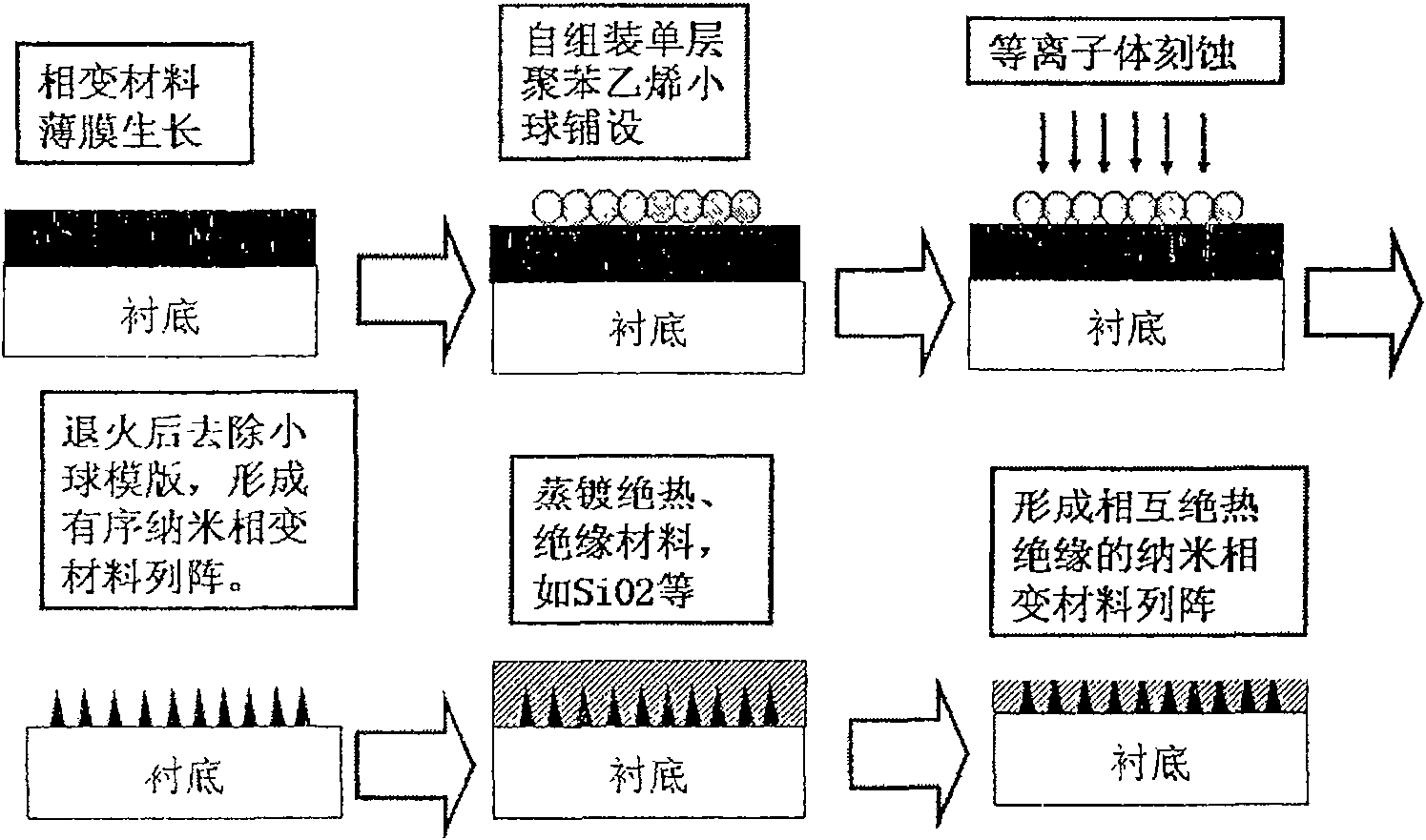

[0022] A method for preparing an alloy phase change material nano-lattice in this embodiment is shown in FIG. 1, and the preparation process includes the following steps:

[0023] The first step is to lay a single layer of nano-polystyrene beads PS beads on the water surface: use the surface tension of the water to lay a single layer of PS colloid (50nm-500nm) beads on the water surface to form a high density on the water surface , Large area, orderly arranged single-layer PS colloidal sphere membrane, let the PS colloid sphere membrane stand on the water surface for about 10 minutes.

[0024] The second step is to fish the single-layer film of the PS ball: use the substrate sheet covered with the silicon antimony tellurium film to pick up the PS ball film, and evaporate and dry naturally in the air; in order to make the PS colloidal ball film better adhere to the substrate Together, the dried products are annealed at 60±5°C for 1±0.1 hours.

[0025] The third step, reactive ion e...

Embodiment 2

[0030] The basic steps of the method for preparing the alloy phase change material nano-lattice in this embodiment are the same as those in the first embodiment, but the difference lies in:

[0031] 1. In the second step, a substrate sheet covered with germanium, antimony, tellurium film is used to pick up the PS ball film, and then it is naturally volatilized and dried in the air and annealed.

[0032] 2. In the third step, a single-layer polystyrene ball attached to the germanium, antimony, tellurium film is used as a mask, and carbon tetrafluoride gas is used to perform reactive ion etching on the sample (ME3A type multifunctional reactive ion Etching machine) to form a germanium-antimony-tellurium nano-array.

[0033] 3. In the fourth step, put the products of the previous step into acetone ultrasonic solution to soak, and completely remove the polystyrene beads.

[0034] 4. In the fifth step, the zirconium dioxide thermal insulation and insulating material is evaporated on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com