Method for producing a semiconductor layer with a textured surface, method for producing a solar cell

A solar cell and textured surface technology, which is applied in semiconductor/solid-state device manufacturing, semiconductor devices, circuits, etc., can solve problems such as inability to produce in large quantities, poor flatness of thin chips, and inability to provide thin chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] First provide a patterned sapphire substrate, image 3 A scanning electron microscope image showing regular patterns on a sapphire substrate.

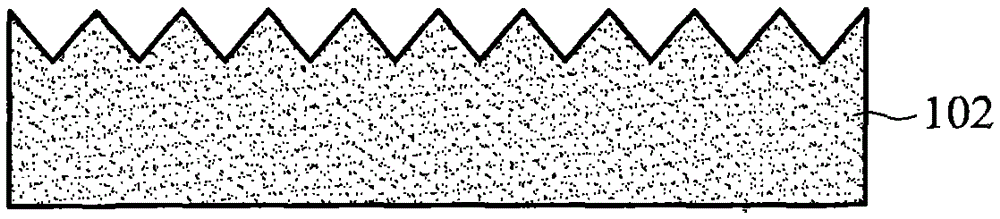

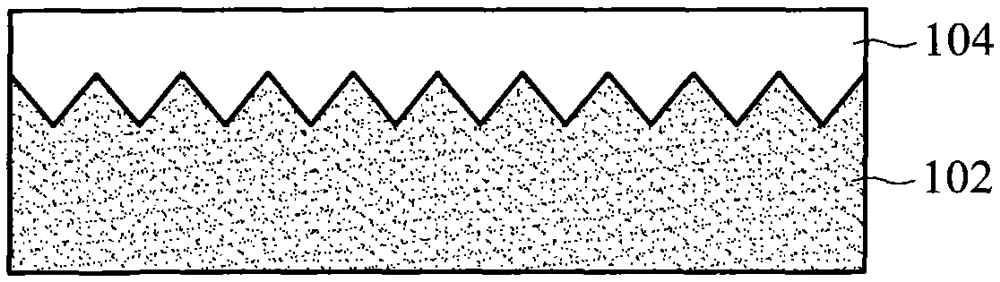

[0068] Afterwards, using plasma-assisted chemical vapor deposition (Plasma enhanced chemical vapor deposition, PECVD), pass into silane (SiH 4 ) as a reaction gas, under the conditions of a coating temperature of about 200° C., a coating pressure of about 0.5 torr, and a coating power of about 200 W, microcrystalline silicon with a thickness of about 3 μm is formed on the patterned sapphire substrate.

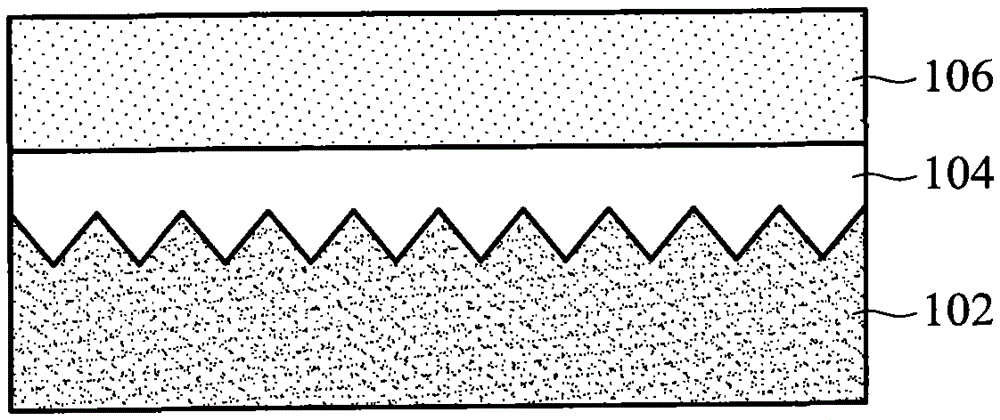

[0069] Next, a conductive silver paste (DuPont PV-159) was coated on the surface of the microcrystalline silicon. Afterwards, the patterned sapphire substrate is placed in an oven at 600°C for 30 minutes of heat treatment, and the microcrystalline silicon layer can be transferred to the conductive silver glue to obtain a thin silicon layer with a regular pattern on the conductive silver glue. Figure 4 A scanning electron micro...

Embodiment 2

[0071] The preparation method of embodiment 2 is similar to embodiment 1, and the only difference is that conductive silver glue (DuPont PV-412) is coated on the microcrystalline silicon surface. Afterwards, the patterned sapphire substrate was placed in an oven at 250°C for 10 minutes of heat treatment, and then the microcrystalline silicon layer was transferred onto the conductive silver paste to obtain a thin silicon layer with a regular pattern on the conductive silver paste.

Embodiment 3

[0072] Embodiment 3 is made into a solar cell

[0073] Taking the thin silicon layer of Example 1, a silicon nitride anti-reflection layer was formed on the thin silicon layer by coating method. Afterwards, a silver metal layer is formed by electroplating to complete a thin solar cell, wherein the conductive silver paste can be used as a back contact, and the silver metal layer can be used as a front contact.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com