Process for preparing vertical structure phase-change memory

A technology of phase change memory and vertical structure, applied in static memory, digital memory information, information storage, etc., can solve the problems of complex process and high power consumption, and achieve the effect of simple process, reduced power consumption, and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

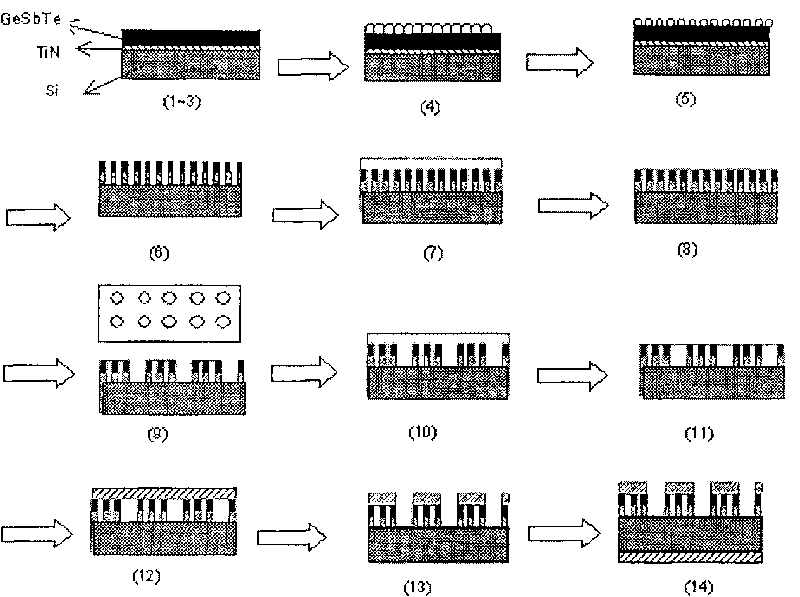

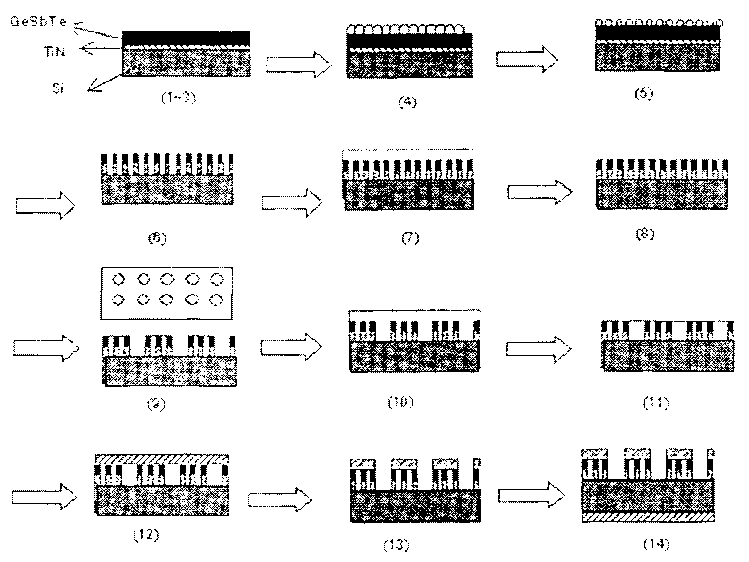

[0027] In this example, the method for preparing a sub-30 nanometer-scale chalcogenide compound nano-lattice vertical structure phase-change memory is as follows: figure 1 shown, including the following steps

[0028] 1. Prepare the substrate - select n+ or p+ type single-sided polished silicon wafer as the substrate, firstly clean it by boiling sulfuric acid + hydrogen peroxide, then rinse it with deionized water and dry it.

[0029] 2. Plating a heat-insulating layer—use a magnetron sputtering method (sputtering conditions: pressure: 0.2 Pa, substrate temperature: 550° C.) to vapor-deposit a 50-100 nanometer TiN layer as a heat-insulating layer.

[0030] 3. Coating film layer - use magnetron sputtering method (conditions: vacuum degree: 2 × 10 -4 Pa; sputtering pressure: 0.15Pa) evaporation thickness of 100-150 nanometer germanium antimony tellurium or silicon antimony tellurium thin film material.

[0031] 4. Laying templates—laying single-layer polystyrene pellets (50 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com