Ultrasound wave auxiliary laser braze (fuse) welding method

An auxiliary laser and ultrasonic welding technology, applied in laser welding equipment, welding/welding/cutting items, welding equipment, etc., can solve the problems of poor wetting and spreading, insufficient filling amount, insufficient solder penetration, etc., to improve welding The effect of seam forming, reducing laser power, and increasing weld fill

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

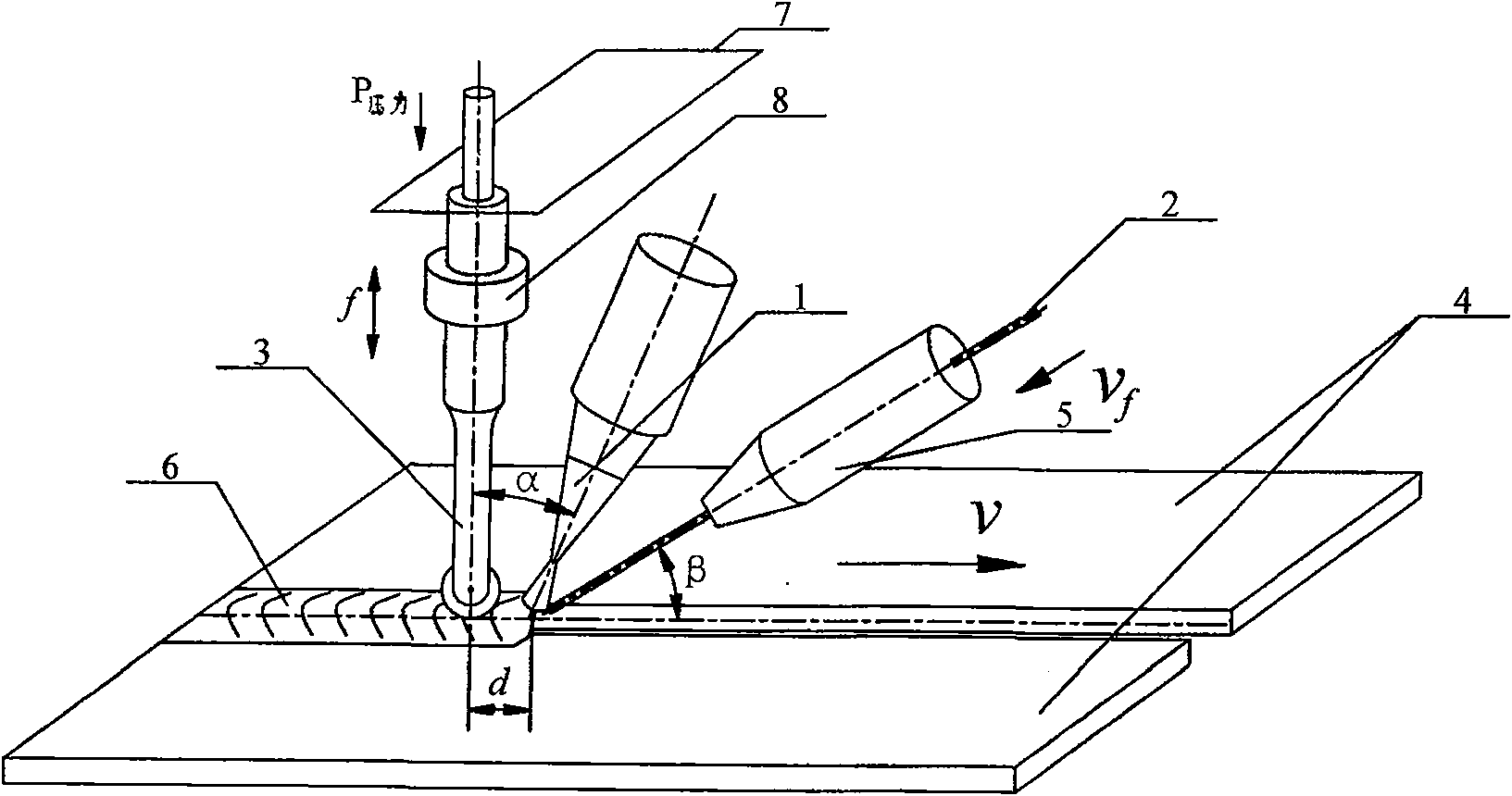

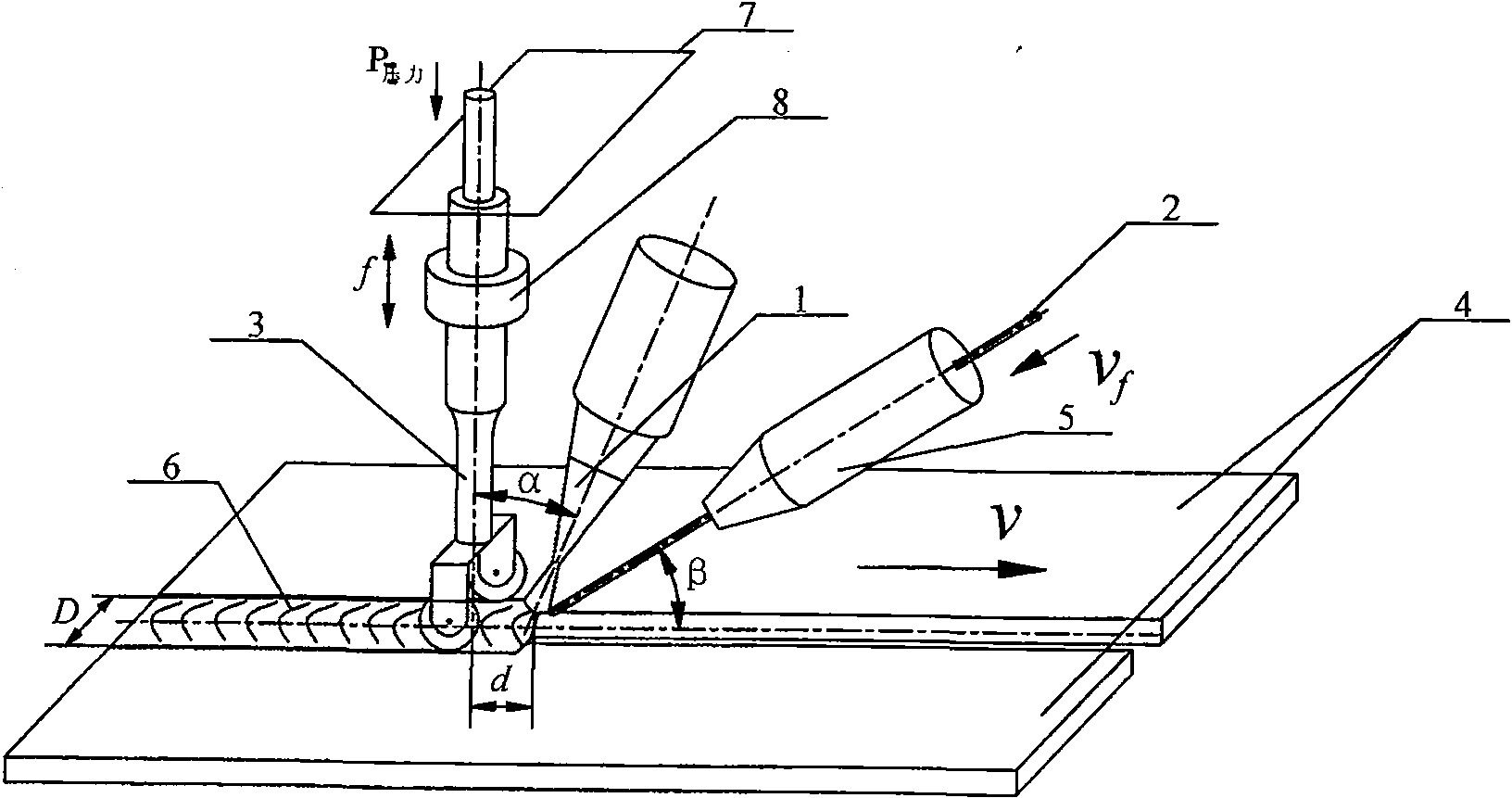

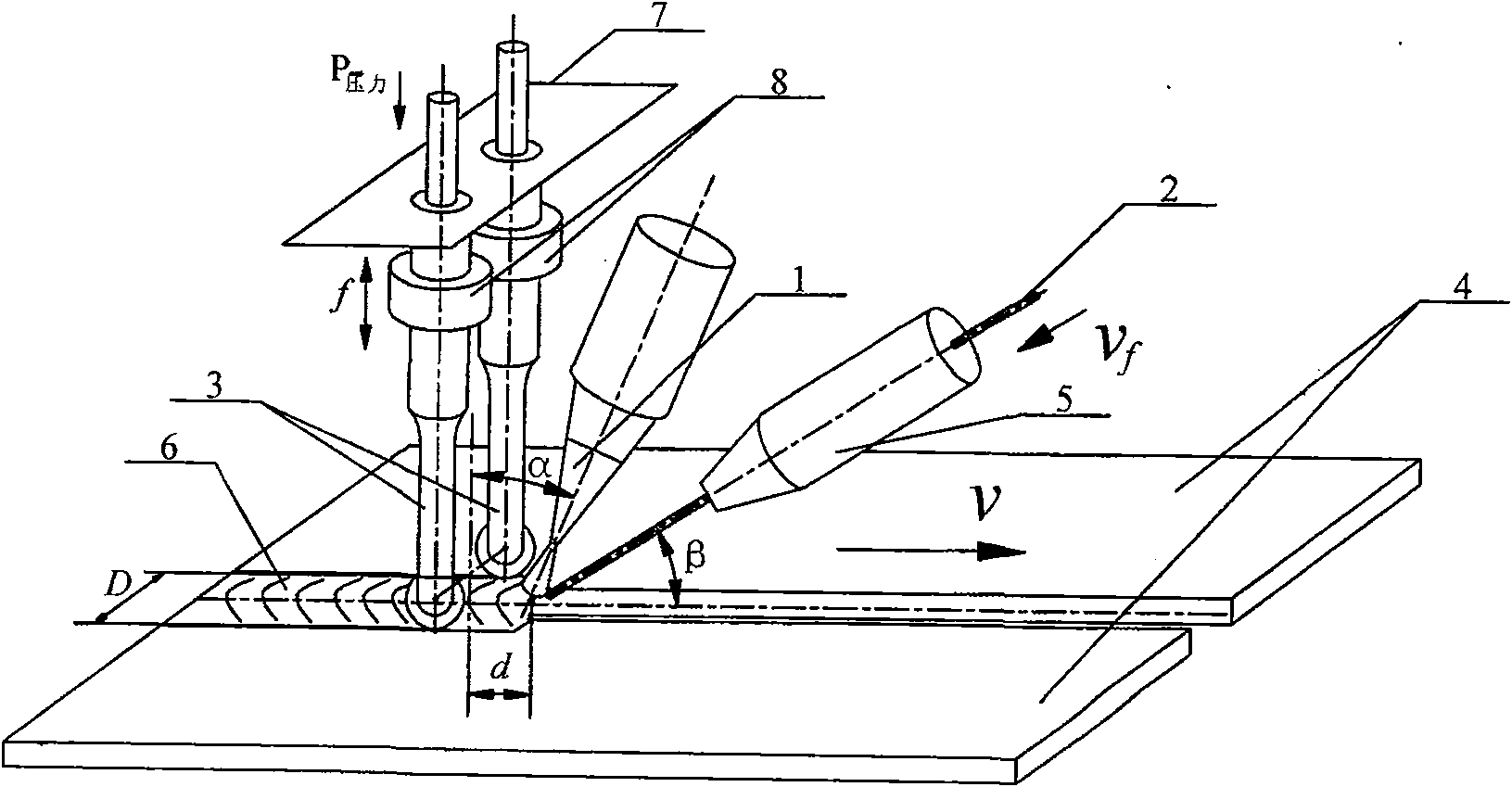

[0012] Specific implementation mode one: (see figure 1 , figure 2 and image 3 ) The ultrasonic-assisted laser brazing (melting) welding method in this embodiment is to use ultrasonic and laser brazing (melting) welding techniques to weld low-melting point coating metals or dissimilar metal materials, that is, to use laser brazing low-melting point coating metals or laser brazing In the process of welding dissimilar metals, high-frequency vibration ultrasonic waves are applied in the weld area that is about to solidify at the same time. The ultrasonic waves are generated by ultrasonic welding devices. 压力 0.1~0.5MPa and working frequency 20~100kHz, the laser is directly irradiated on the workpiece and the welding wire in the form of defocusing, the energy ratio acting on the welding wire and the workpiece is 1.2~1.3:1, and the laser spot diameter is 2 The angle a between the laser and the ultrasonic welding device is between 5° and 30°, and the angle β between the welding wi...

specific Embodiment approach 2

[0014] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the laser is made of CO 2 Gas laser, YAG solid-state laser or semiconductor laser output. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Specific implementation mode three: (see figure 1 ) This embodiment differs from Embodiment 1 in that the horn of the ultrasonic welding device acts in the middle of the weld seam in a straight line with the laser and the welding wire, and the distance d between the ultrasonic horn and the incident position of the laser is 3-6 mm. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com