Low-temperature lead-free alloy flux and preparation method thereof

A lead-free alloy, low-temperature technology, applied in welding equipment, metal processing equipment, welding/cutting media/materials, etc., can solve the problem of high energy consumption, high-temperature oxidation slag rate and high volatile organic compounds, which cannot be applied to low-temperature lead-free welding process Requirements, high production costs, etc., to achieve the effect of protecting the production environment, bright and full solder joints, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

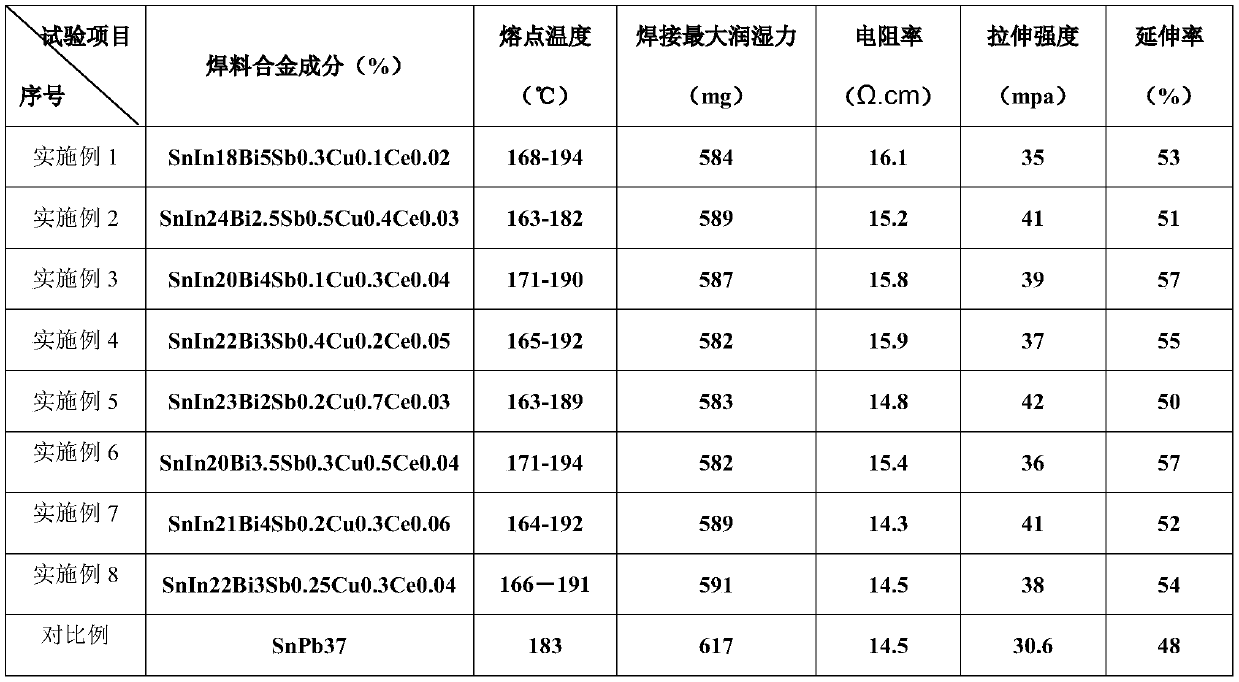

Embodiment 1

[0032] A low-temperature lead-free alloy solder, the raw material ratio is as follows: In 18kg; Bi 5kg; Sb 0.3kg; Cu 0.1kg; Ce0.02kg; Sn 76.58kg.

[0033] Preparation:

[0034] (1) Put 76.58kg of tin ingot into the stainless steel melting pot, heat up to melt the tin ingot and when the temperature rises to 480°C±2°C, then gently add 0.1kg of copper material into the tin liquid, keep the copper material at 480°C It is continuously melted by the tin liquid, and after 30 minutes, slowly stir the tin liquid until the copper material is completely melted evenly, which is a liquid SnCu alloy.

[0035] (2) Gently put 0.3 kg of antimony material into the SnCu alloy liquid prepared in step (1). The temperature of the alloy liquid is still kept at 480°C±2°C. After 30 minutes, slowly stir the alloy liquid until all the antimony material is melted evenly. It is a liquid SnSbCu alloy.

[0036] (3) When the SnSbCu liquid alloy prepared in step (2) is cooled to 420°C±2°C, then gently put 5...

Embodiment 2

[0042] A low-temperature lead-free alloy solder, the raw material ratio is as follows: In 24kg; Bi 2.5kg; Sb 0.5kg; Cu 0.4kg; Ce 0.03kg; Sn 72.57kg.

[0043] Preparation:

[0044] (1) Put 72.57kg of tin ingot into the stainless steel melting pot, heat up to melt the tin ingot and when the temperature rises to 500°C±2°C, then gently add 0.4kg of copper material into the tin liquid, keep the copper material at 500°C It is continuously melted by the tin liquid, and after 30 minutes, slowly stir the tin liquid until the copper material is completely melted evenly, which is a liquid SnCu alloy.

[0045] (2) Gently put 0.5 kg of antimony material into the SnCu alloy liquid prepared in step (1), the temperature of the alloy liquid is still maintained at 500°C±2°C, and after 30 minutes, slowly stir the alloy liquid until all the antimony material is melted evenly, this is Liquid SnSbCu alloy.

[0046] (3) When the SnSbCu liquid alloy prepared in step (2) is cooled to 450°C±2°C, then...

Embodiment 3

[0052] A low-temperature lead-free alloy solder, the raw material ratio is as follows: In 20kg; Bi 4kg; Sb 0.1kg; Cu 0.31kg; Ce 0.04kg; Sn 75.56kg.

[0053] Preparation method: same as Example 1, wherein the temperature of step (1) and step (2) is 480±2°C, the temperature of step (3) and (4) is 400±2°C, and the temperature of step (7) is 280°C ±2°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com