ZnO based LED and its preparing process

A technology of light-emitting diodes and substrates, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of p-type ZnO thin film performance needs to be improved, growth conditions are not easy to control, and equipment maintenance is difficult, so as to improve repeatability, growth The effect of low cost and improved device performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

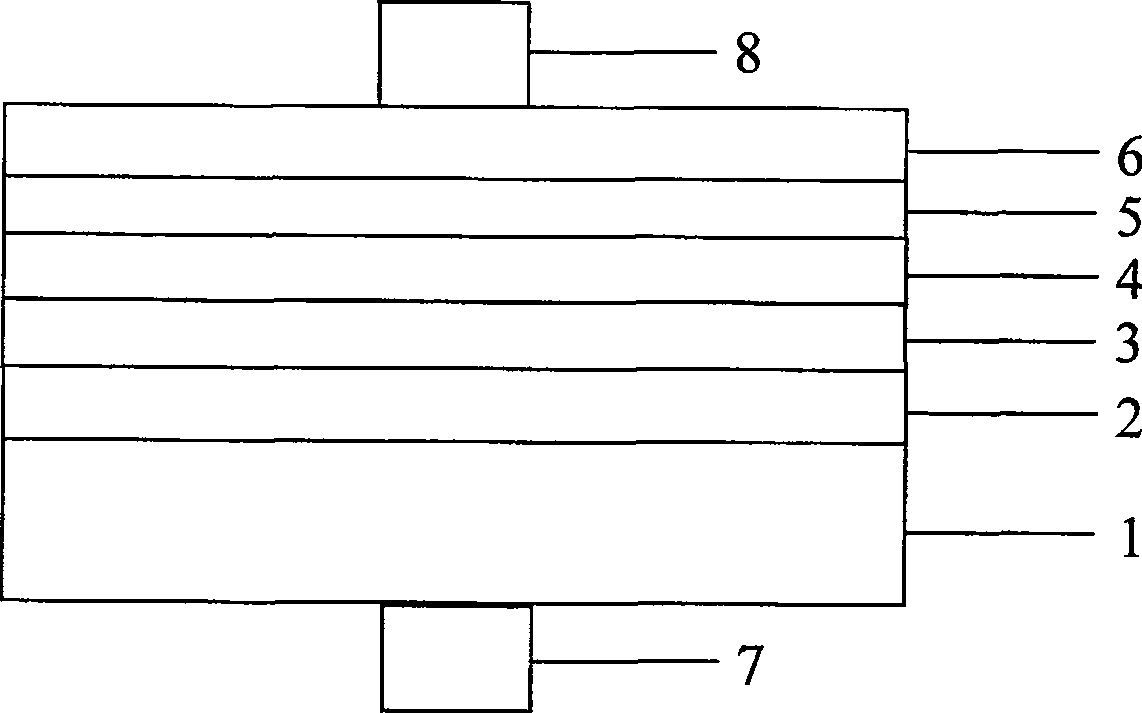

Image

Examples

Embodiment 1

[0017] Clean the surface of the silicon substrate and put it into the growth chamber of the metal-organic chemical vapor deposition system, and the growth chamber is evacuated to 10 -4 Pa, heat the substrate to 500°C, feed the organic zinc source and oxygen, and deposit n-ZnO thin film on one side of the substrate with Ga as the dopant source, the growth pressure is 50 Torr, and the thickness of the film is 2 μm; then feed the organic zinc Source, organic magnesium source, oxygen, the growth pressure is 50Torr, deposit n-Zn on the n-ZnO film layer 0.8 Mg 0.2 O film layer, the thickness of the film layer is 50nm; then alternately feed organic zinc source, oxygen and organic zinc source, organic magnesium source, oxygen, the growth pressure is 50Torr, deposit ZnO layer and Zn 0.9 Mg 0.1 O layer, forming 5 cycles of ZnO / Zn 0.9 Mg 0.1 O quantum well layer, ZnO and Zn 0.9 Mg 0.1 The O widths are 5nm and 6nm respectively; then lower the temperature to 400°C and feed organic zi...

Embodiment 2

[0019] Clean the surface of the zinc oxide substrate and put it into the growth chamber of the metal organic chemical vapor deposition system, and the growth chamber is evacuated to 10 -4 Pa, heat the substrate to 550°C, feed organic zinc source and oxygen, and deposit n-ZnO film layer on one side of the substrate with Ga as the dopant source, the growth pressure is 50 Torr, and the film thickness is 1.5 μm; Zinc source, organic magnesium source, oxygen, growth pressure of 50Torr, deposit n-Zn on the n-ZnO film layer 0.75 Mg 0.25 O film layer, the thickness of the film layer is 50nm; then alternately feed organic zinc source, oxygen and organic zinc source, organic magnesium source, oxygen, the growth pressure is 50Torr, deposit ZnO layer and Zn 0.8 Mg 0.2 O layer, forming 7 periods of ZnO / Zn 0.8 Mg 0.2 O quantum well layer, ZnO and Zn 0.8 Mg 0.2 The O widths are 5nm and 5nm respectively; then lower the temperature to 400°C and feed organic zinc source, organic magnesium...

Embodiment 3

[0021] Clean the gallium nitride substrate surface and put it into the growth chamber of the metal-organic chemical vapor deposition system, and the growth chamber is evacuated to 10 -4 Pa, heat the substrate to 600°C, feed organic zinc source and oxygen, and deposit n-ZnO film layer on one side of the substrate with Al as the doping source, the growth pressure is 50Torr, and the film thickness is 2μm; then feed organic zinc Source, organic magnesium source, oxygen, the growth pressure is 50Torr, deposit n-Zn on the n-ZnO film layer 0.5 Mg 0.5 O thin film layer, the thickness of the film layer is 30nm; then alternately feed organic zinc source, oxygen, organic zinc source, organic magnesium source, oxygen, the growth pressure is 50Torr, deposit ZnO layer and Zn 0.6 Mg 0.4 O layer, forming 10 cycles of ZnO / Zn 0.6 Mg 0.4 O quantum well layer, ZnO and Zn 0.6 Mg 0.4 The O widths are 4nm and 4nm respectively; then lower the temperature to 400°C and feed organic zinc source, o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com