Solid phase reduction preparation method for platinum, carbon catalyst of fuel cell

A fuel cell and catalyst technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem that manual grinding is not suitable for large-scale production, the probability of collision is low, and the process is not easy to control, etc. problem, to achieve the effect of improving catalytic activity and anti-toxic performance, reducing waste generation, and making the preparation process simple and convenient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

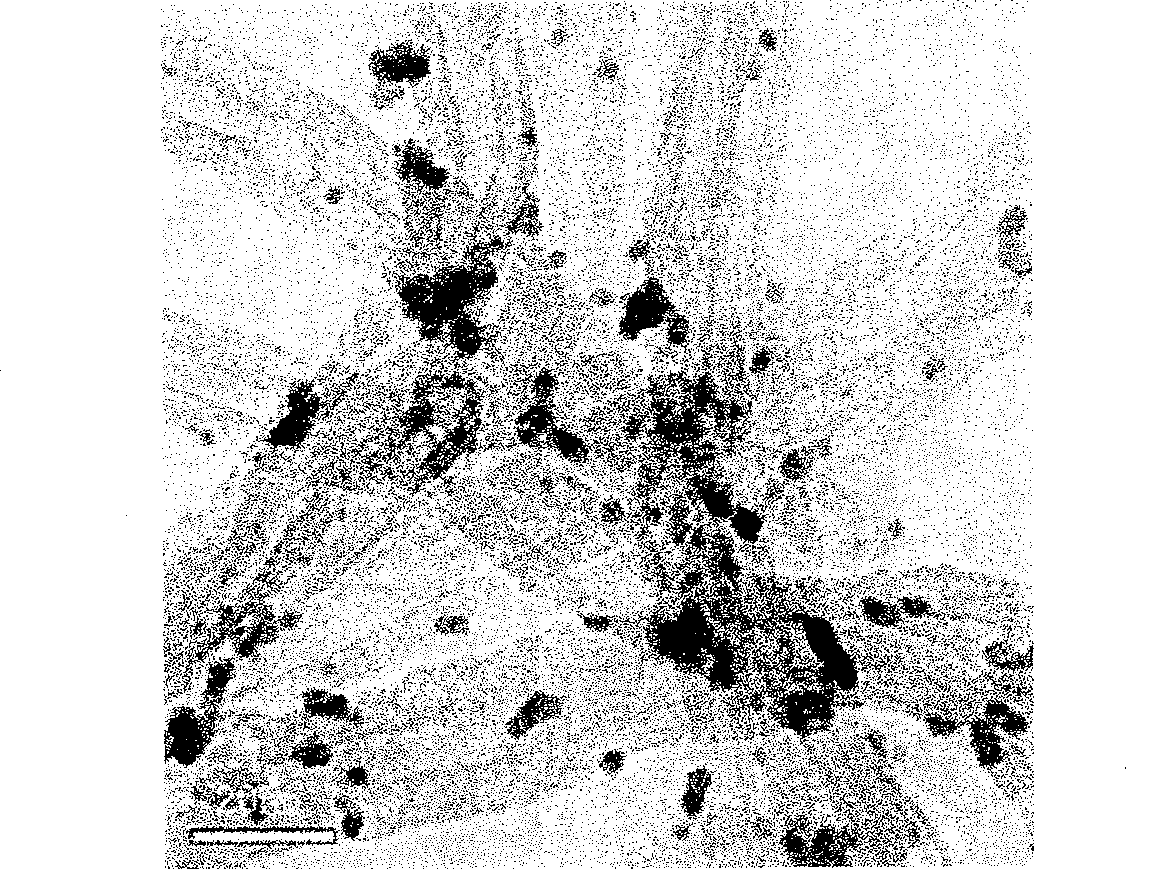

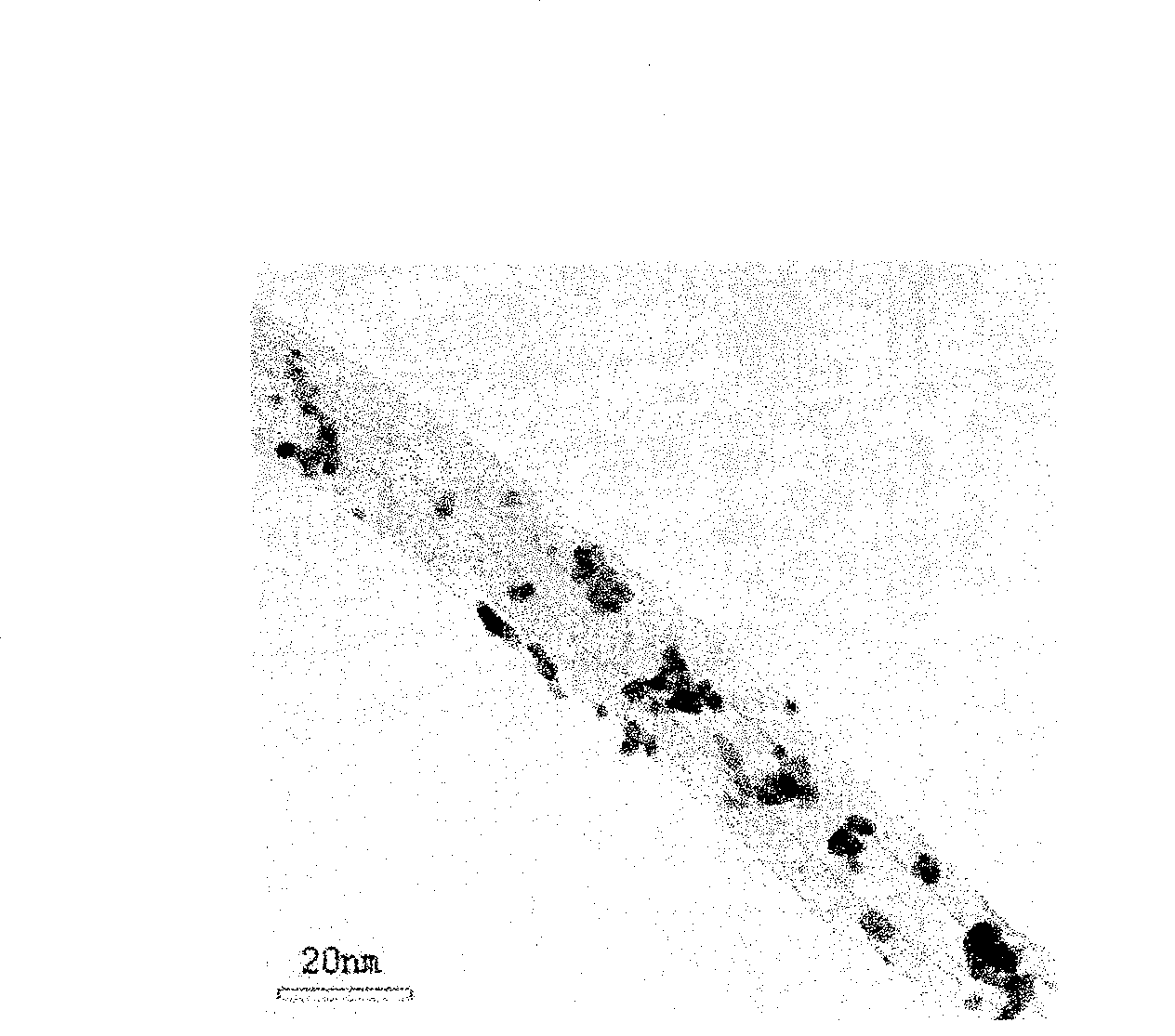

Image

Examples

Embodiment 1

[0036] (1) The metal salt precursor H 2 PtCl 6 ·6H 2 Add O and complexing agent sodium citrate into water, and ultrasonically dissolve it completely; H in aqueous solution 2 PtCl 6 ·6H 2 O mass volume concentration is 50g / L, H 2 PtCl 6 ·6H 2 The mass ratio of O to sodium citrate is 2:1.

[0037] (2) Add 2mol / L NaOH aqueous solution to the solution obtained in step (1), adjust the pH value to 8, add XC-72R carbon black, the amount of substance ratio Pt:C=0.015:1, ultrasonic 0.5h; 90 ℃ vacuum drying.

[0038] (3) After taking out the material gained in the step (2) and grinding it, add it into an aqueous solution of sodium formate (mass volume concentration is 70g / L) and uniformly impregnate it, vacuum-dry it at 90°C for 3h, and 2 PtCl 6 ·6H 2 The mass ratio of O to sodium formate is 1:1.

[0039] (4) After taking out the material obtained in step (3) and grinding it, put it into a ceramic boat, put it into a tubular electric furnace, treat it at 140°C for 2 hours un...

Embodiment 2

[0042] (1) The metal salt precursor H 2 PtCl 6 ·6H 2 O, RuCl 3 Add the sodium tartrate complexing agent into the mixed solution of water and acetone (volume ratio 3:1), and ultrasonically dissolve it completely; the H in the mixed solution 2 PtCl 6 ·6H 2 O and RuCl 3 The mass volume concentration is 150g / L, H 2 PtCl 6 ·6H 2 O, RuCl 3 The molar ratio of substances is Pt:Ru=1:1; metal salt precursor H 2 PtCl 6 ·6H 2 O, RuCl 3 , and the substance ratio of sodium tartrate is 1:5.

[0043] (2) Add 2mol / L NaOH aqueous solution to the mixed solution obtained in step (1), adjust the pH value to 11, add XC-72R carbon black, the ratio of substances is Pt:C=0.075:1, ultrasonic 1h, 90 ℃ vacuum drying.

[0044] (3) After taking out the material obtained in step (2) and grinding it, it is added to an aqueous solution of glucose (mass volume concentration is 200g / L) for uniform impregnation, and then vacuum-dried at 90° C. for 5 hours; the metal salt precursor H 2 PtCl 6 ·6H...

Embodiment 3

[0048] (1) The metal salt precursor H 2 PtCl 6 ·6H 2 Add O and disodium edetate complexing agent into water and isopropanol solvent (volume ratio 3:1), and ultrasonically dissolve it completely; then add solid accelerator silicomomolybdic acid, and continue ultrasonication for 10 minutes; mix H in solution 2 PtCl 6 ·6H 2 The mass volume concentration of O is 100g / L, and the H 2 PtCl 6 ·6H 2 The mass ratio of O to disodium edetate is 1:2, and the mass ratio of O to silicomomolybdic acid is 1:1.

[0049] (2) Add 2 mol / L NaOH aqueous solution to the mixed solution obtained in step (1), adjust the pH value to 10, add XC-72R carbon black, the amount of substance ratio Pt:C=0.025:1, ultrasonic 0.75h; Vacuum dried at 90°C.

[0050] (3) After taking out the material obtained in step (2) and grinding it, it is added to an aqueous solution of sodium sulfite (mass volume concentration is 100g / L) for uniform impregnation, and then vacuum-dried at 90° C. for 4 hours; the metal sal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com