Capillary pump cooler with micro-groove wing structure and its manufacturing method

A technology of cooling device and micro-groove, which is applied in the direction of cooling/ventilation/heating transformation, lighting and heating equipment, indirect heat exchanger, etc. Minimization and other issues, to achieve the effect of thin heat sink, no mechanical moving parts, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in further detail below in conjunction with the embodiments and accompanying drawings, but the protection scope of the present invention is not limited to the range indicated by the embodiments.

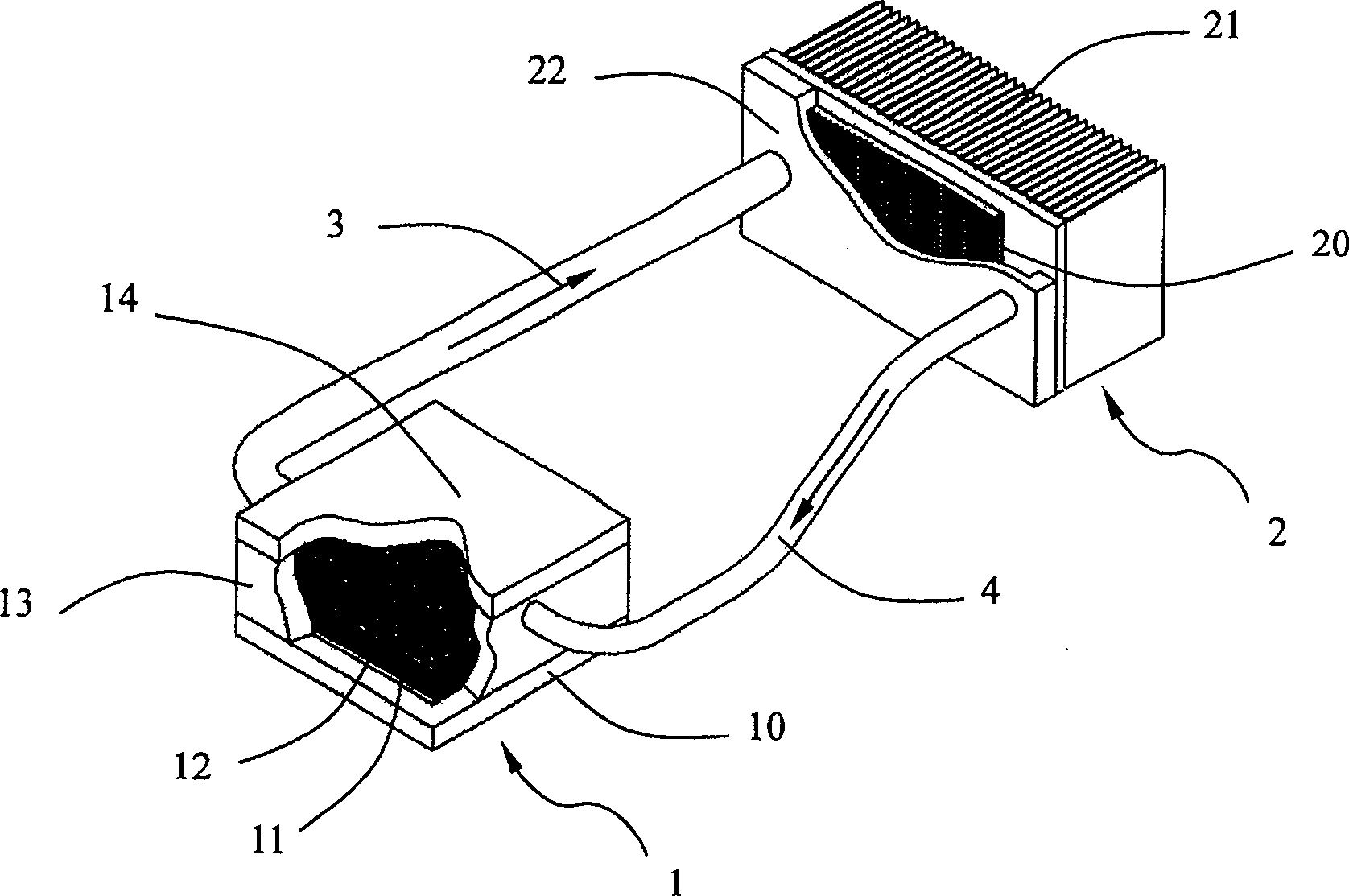

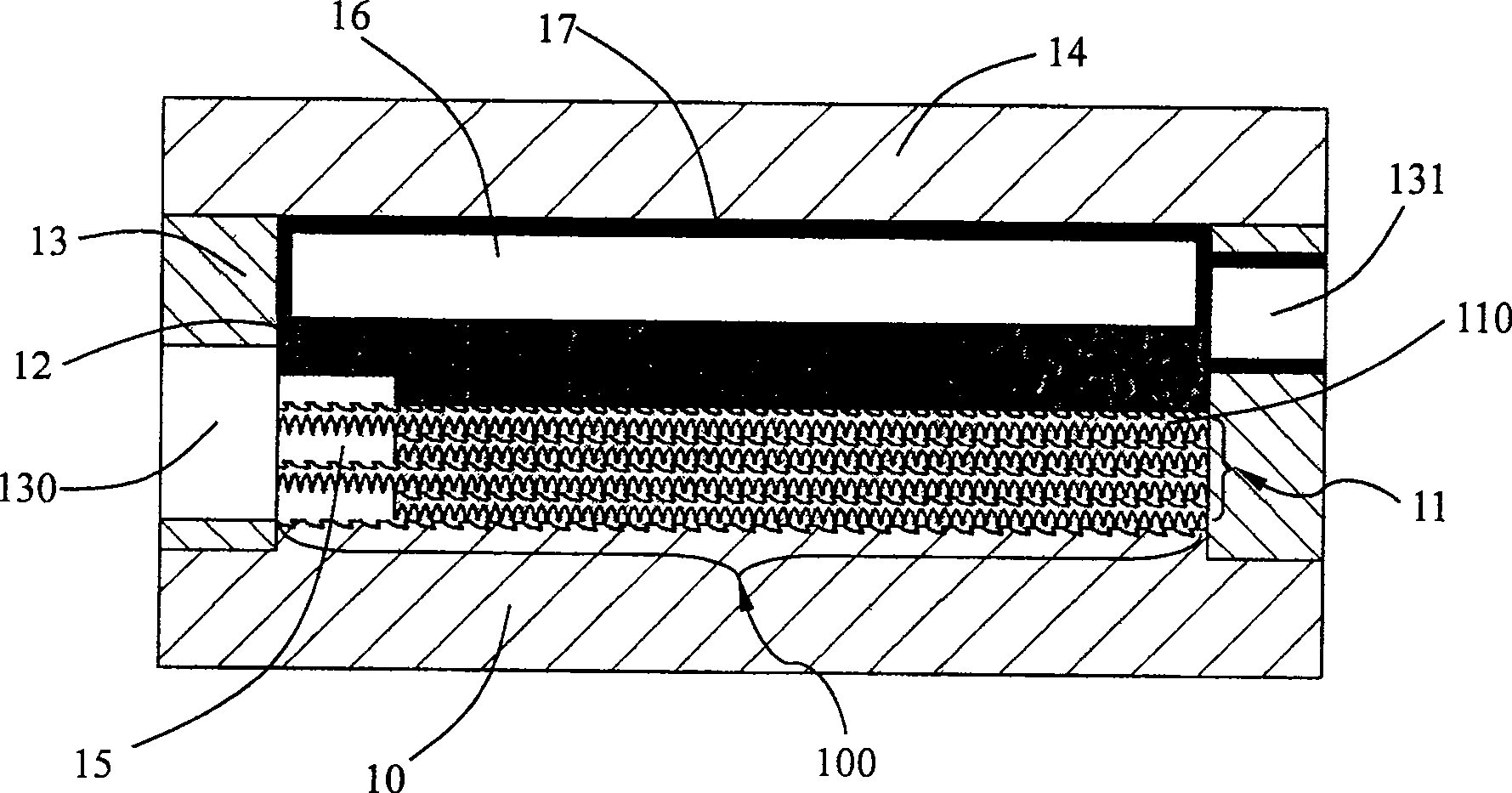

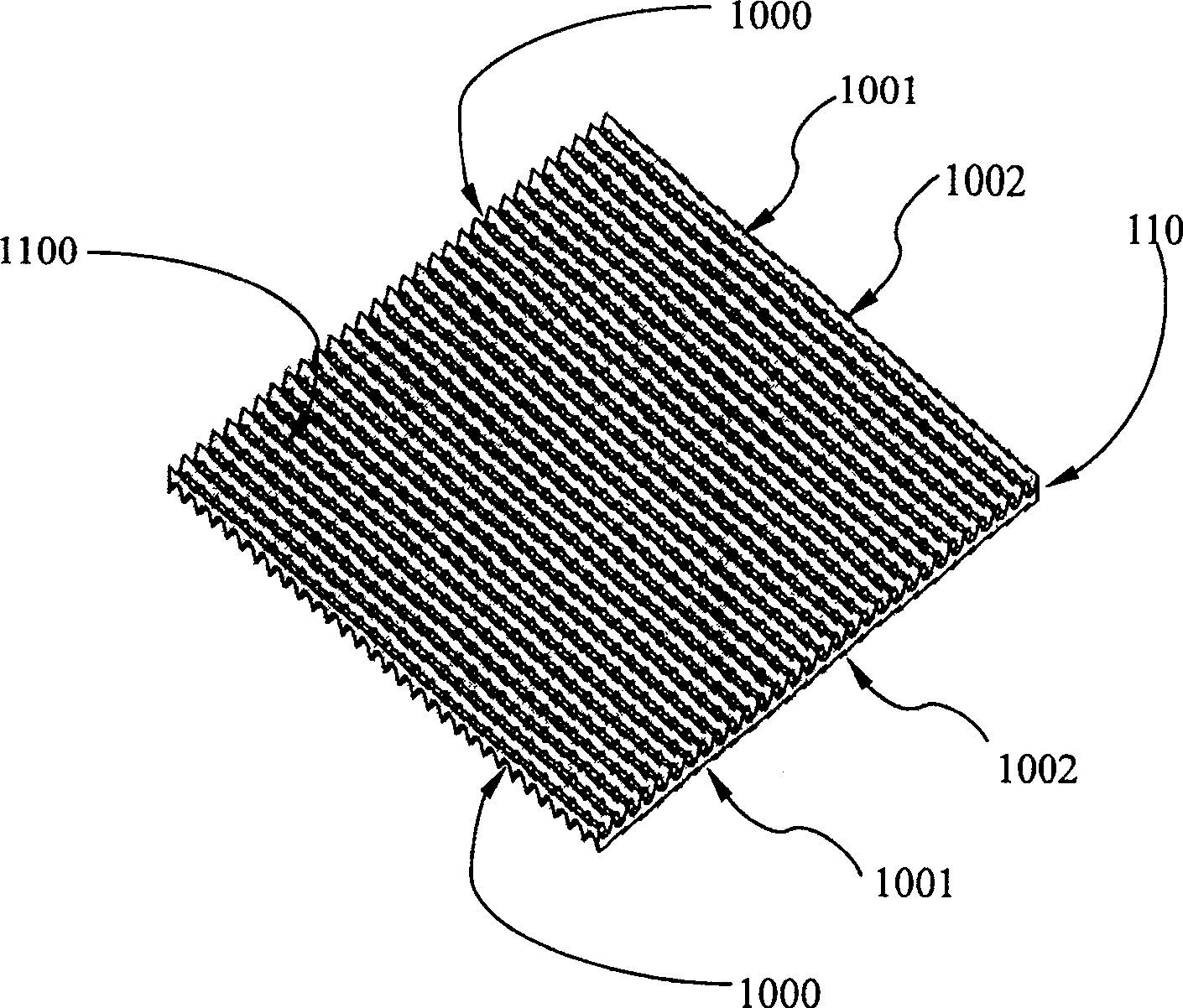

[0037] Such as figure 1 As shown, the capillary pump cooling device with a micro-groove fin structure includes an evaporator 1, a condenser 2, a steam manifold 3 and a liquid manifold 4, and the interior is filled with a certain amount of liquid working fluid whose boiling point is lower than the temperature to be radiated , In this embodiment, the working fluid is methanol, with a boiling point of 64.7°C. According to heat dissipation requirements, the liquid working fluid can also use ethanol, ethylene, acetone, ammonia water, isobutane, FC-72, PF-5060, HCFC 141b and other different working fluids. The evaporator 1 and the condenser 2 are connected by a steam connecting pipe 3 and a liquid connecting pipe 4 to form a loop system, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com