Frequently pole-reversing electroosmosis method for extracting and concentrating sodium lactate from garbage fermentation liquid

A technology of frequent electrode reversal and electrodialysis, which is applied in electrodialysis, separation/purification of carboxylic acid compounds, organic chemistry, etc., can solve membrane pollution and other problems, and achieve the effect of simple process, pollution reduction and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

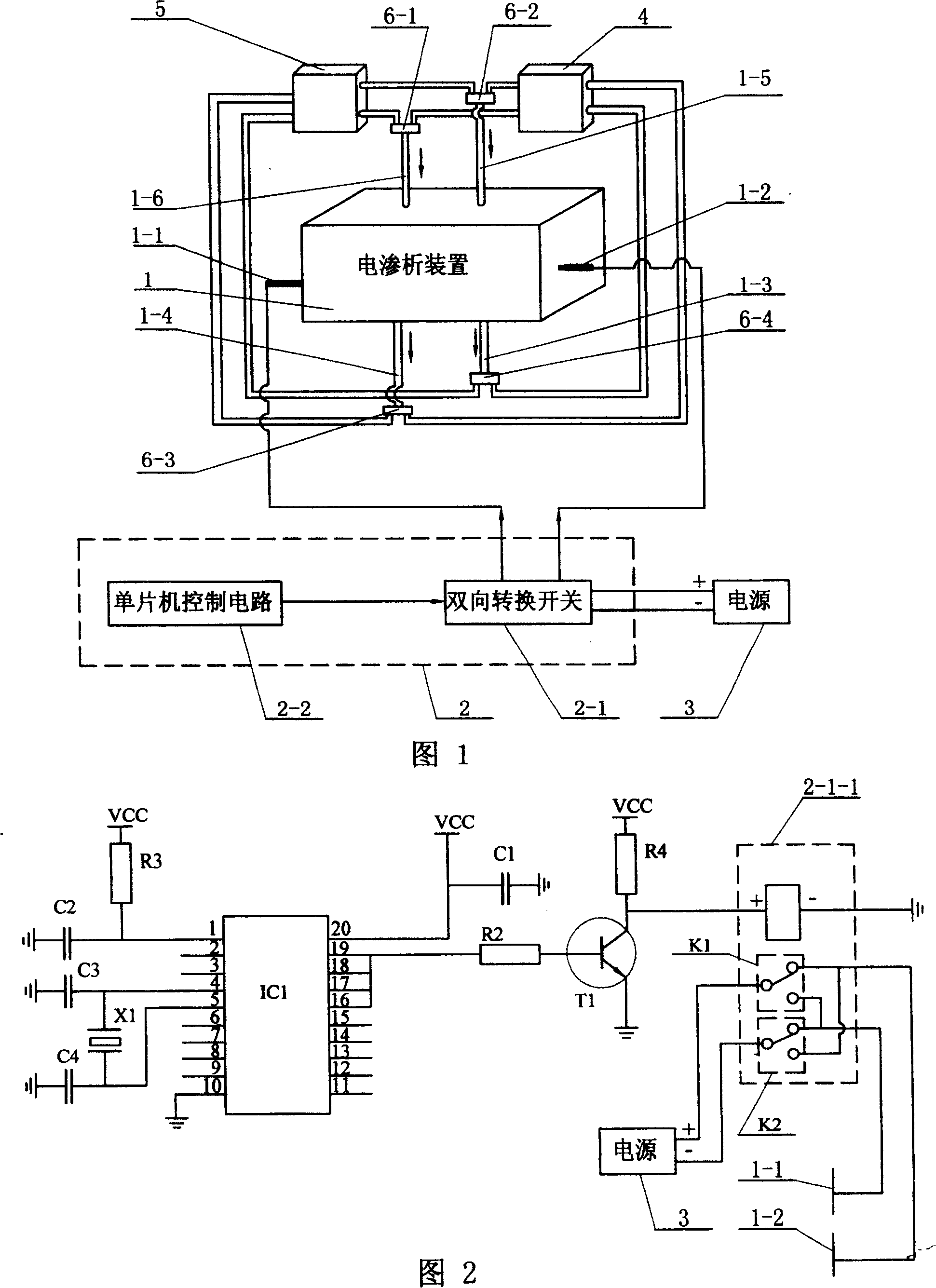

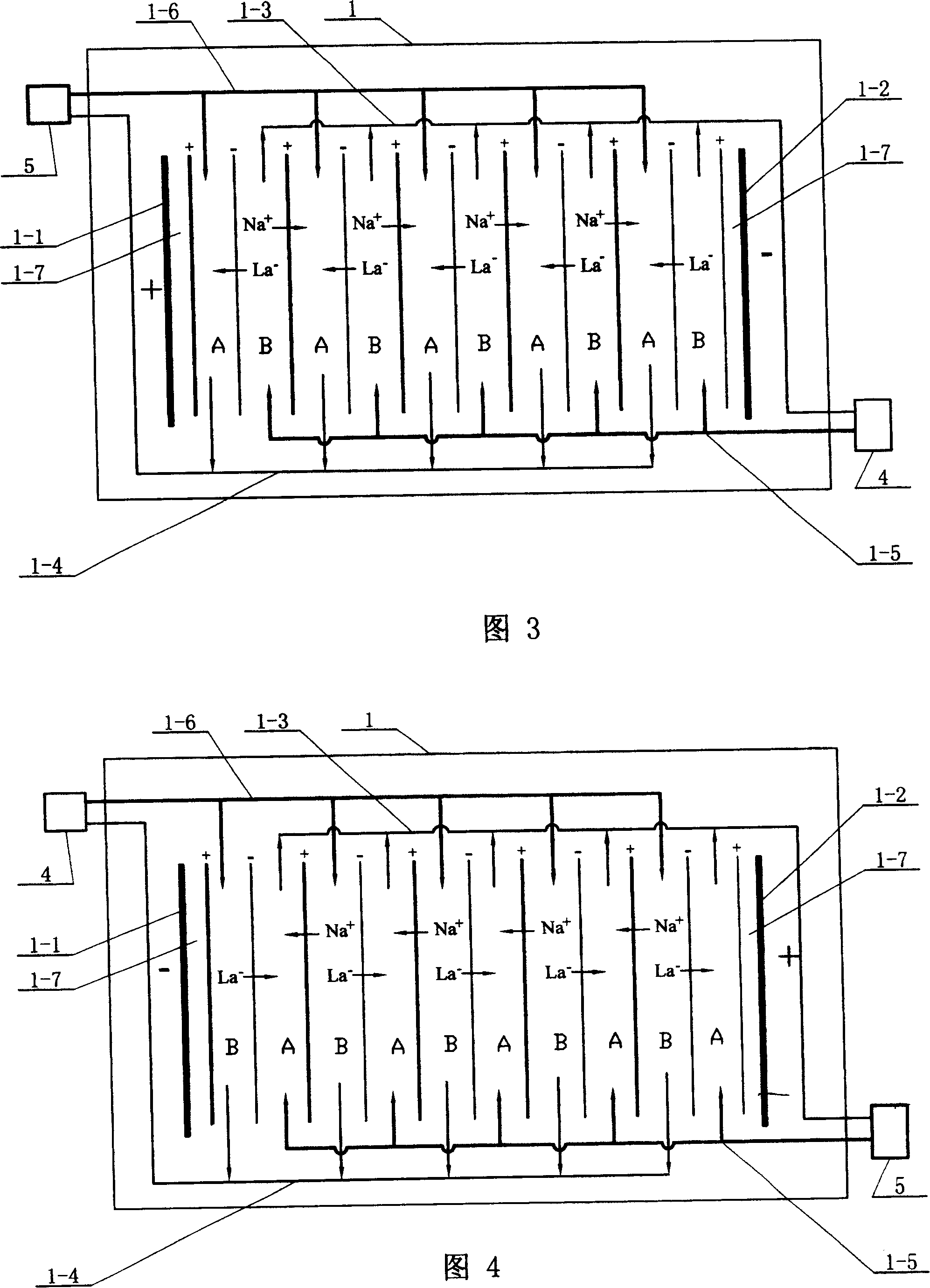

[0012] Specific embodiment one: referring to Fig. 1 and Fig. 3, the method of this specific embodiment is carried out according to the following steps: one, add the required solution of extracting sodium lactate: the garbage fermented liquid that obtains after packing into after lactic acid fermentation in the electrodialysis desalination tank 4 , the dilute lactate solution of packing into in the electrodialysis concentrating tank 5, the electrode liquid of packing into in the electrode chamber 1-7 in the electrodialysis device 1; The first electrode 1-1 of the dialysis device 1, the second electrode 1-2 of the electrodialysis device 1 is connected to another control output end of the frequent reverse pole circuit 2; The first liquid inlet pipe 1-6 of the dialysis device 1 communicates with the desalination tank 4 and the concentration tank 5 respectively, and the second liquid inlet pipe 1-6 of the electrodialysis device 1 is connected to the second two-position three-way dir...

specific Embodiment approach 2

[0014] Specific embodiment two: referring to Fig. 1, fermented liquid is 1000 milliliters in the first step of this specific embodiment, and lactate solution is 200 milliliters, and electrode solution adopts dilute sulfuric acid; The 3rd step is in the process of electrodialysis, every The polarities of the first electrode 1-1 and the second electrode 1-2 of the electrodialysis device 1 are exchanged once in 15 minutes by using the frequent pole reversal circuit 2, and after 12 hours, the required concentrated sodium lactate solution can be obtained in the concentration tank. The steps and devices of other methods are the same as those in the first embodiment.

specific Embodiment approach 3

[0015]Specific embodiment three: Referring to Fig. 2, the difference between this specific embodiment and specific embodiment two is: in the frequent pole reversal circuit 2, the changeover switch 2-1 adopts an electromagnetic relay 2-1- 1. The single-chip microcomputer control circuit 2-2 is composed of a single-chip microcomputer IC1, a first capacitor C1, a second capacitor C2, a third capacitor C3, a fourth capacitor C4, a crystal oscillator X1, a transistor T1, a second resistor R2, a third resistor R3, The fourth resistor R4 is composed of the DC power supply VCC. The single-chip microcomputer IC1 adopts the model AT89C2051. Pins 16, 17, 18, and 19 of the single-chip microcomputer IC1 are connected together. Pin 16 of the single-chip microcomputer IC1 is connected to the base of the transistor T1 through the second resistor R2. connection, the emitter of the triode T1 is grounded, the collector of the triode T1 is connected to one end of the fourth resistor R4 and the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com