Thin-film solar battery barrier with flexible substrate and production method thereof

A technology for thin-film solar cells and flexible substrates, applied in coatings, circuits, photovoltaic power generation, etc., can solve problems affecting battery output characteristics and uniformity, cracks in thin-film solar cells, and unsatisfactory stress matching, so as to avoid air Oxidation and impurity contamination, guaranteed battery performance, and effects of improving output characteristics and uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

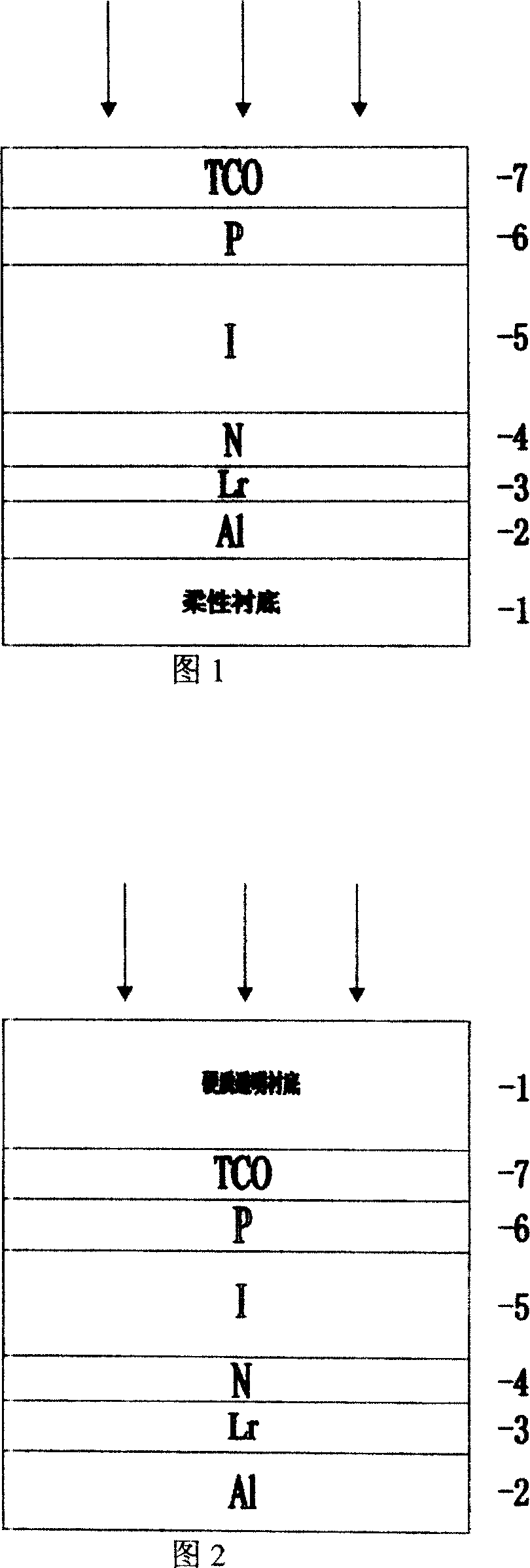

[0033] The structure of the flexible substrate thin film solar cell is shown in Figure 1. The main steps of the cell body are as follows:

[0034] The prepared polyimide flexible substrate with metal aluminum electrode, metal nickel (the thickness of nickel layer is about 40nm) or metal titanium barrier layer is put into the plasma enhanced chemical vapor deposition system, and the substrate is heated to 160 -180 ℃, and constant temperature for 2 hours; N, I, P three-layer silicon-based thin films were deposited in three different reaction chambers respectively. The reaction gases in the N chamber are silane, phosphine and hydrogen, the reaction power is 28W, and the film thickness is about 30nm; the reaction gases in the I chamber are silane, germane and hydrogen, the reaction power is 8W, and the film thickness is about 500nm; the P chamber reaction gas is Silane, borane, methane and hydrogen, the reaction power is 30W, and the film thickness is about 20nm. After the three-...

Embodiment 2

[0039] The structure of the transparent hard substrate thin film solar cell is shown in Figure 2. The main steps of the cell body are as follows:

[0040] The hard transparent substrate with the transparent conductive film was put into the plasma enhanced chemical vapor deposition system, and three layers of silicon-based films of P, I, and N were respectively deposited, and the experimental conditions were the same as those in Example 1. After cooling to room temperature, the solar cell was taken out from the plasma-enhanced chemical vapor deposition system, put into a coating machine to deposit a metal nickel or metal titanium barrier layer, and then metal aluminum was deposited. The experimental conditions were the same as in Example 1, except that the first deposition A metallic nickel or titanium barrier layer redeposits metallic aluminum. Take it out after cooling down, and the thickness of the barrier layer is about 45nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com