Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

56results about How to "To achieve the purpose of thickening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing instant flavour solid soup material

The instant flavor solid soup material is prepared with vegetable, meat, edible mushroom and other material, and through sorting, washing, cutting, color keeping, cooking, thickening, tray loading, freezing, vacuum freezing to dry, and packing. The instant flavor solid soup material has water re-combining speed, good dispersivity, high viscosity after being mixed with boiling water and other features. It may be in different local flavors.

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

Vertical type single-component polyurethane waterproof coating and preparation method thereof

InactiveCN101818022AReduce labor costsTo achieve the purpose of thickeningPolyurea/polyurethane coatingsBenzeneAlcohol

The invention provides a vertical type single-component polyurethane waterproof coating. The coating is prepared from the following components in parts by weight: 15-25 parts of polyether trihydric alcohol, 3-5 parts of toluene di-isocyanate, and 0.3-1.0 part of amine curing agent. The invention also provides a method for preparing the waterproof coating. The waterproof coating has the advantages of high strength, high extension, high adhesion property, no benzene or coal tar, safety, environment protection and the like, can be coated on the vertical surface with the thickness of 0.5-1.0mm each time, has no flowing and dropping, and only needs to coat 2-3 times for the vertical surface to reach the thickness of 2mm.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

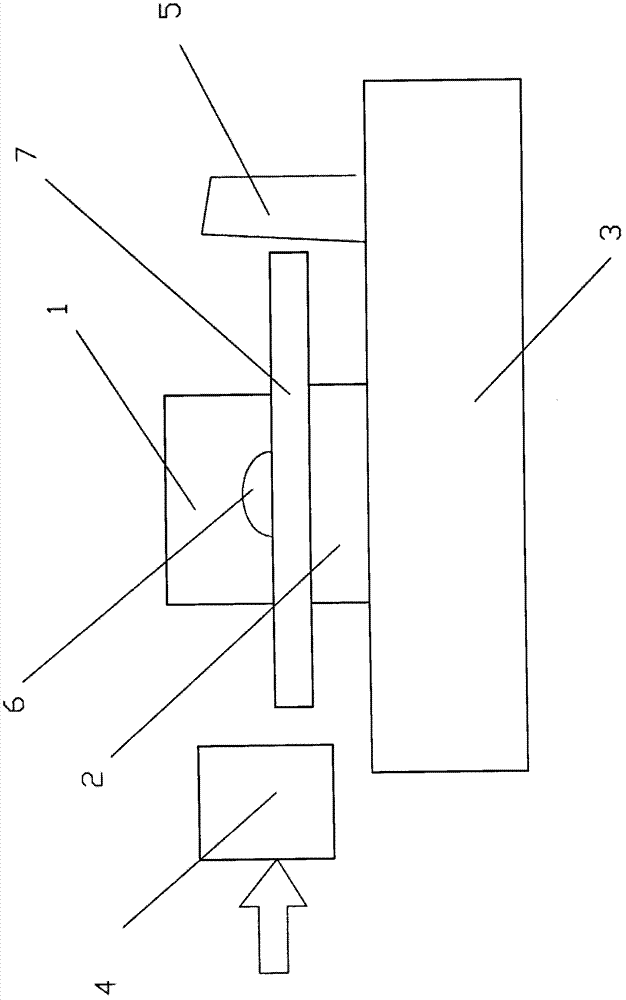

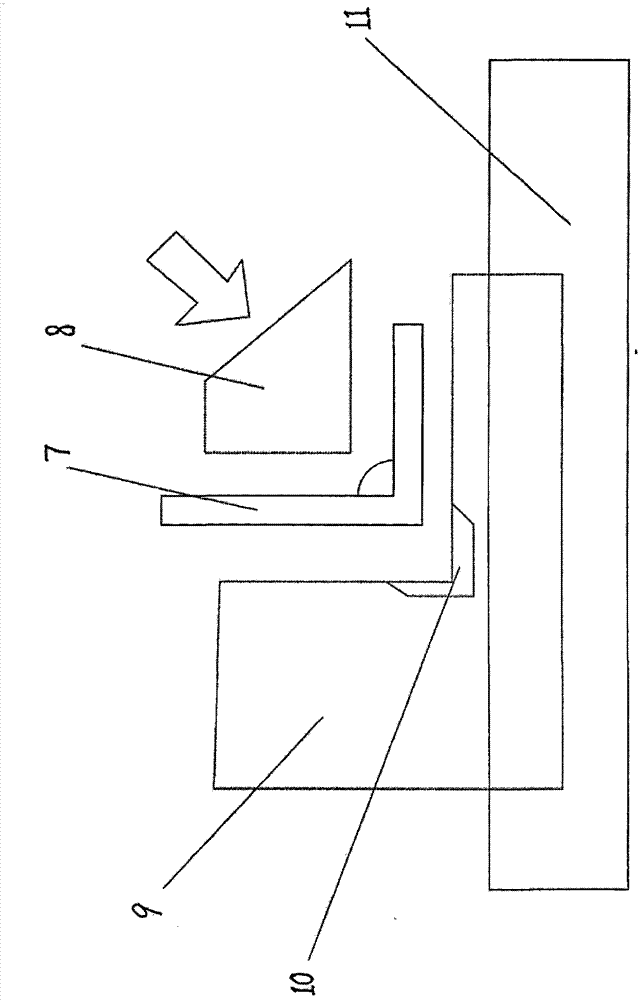

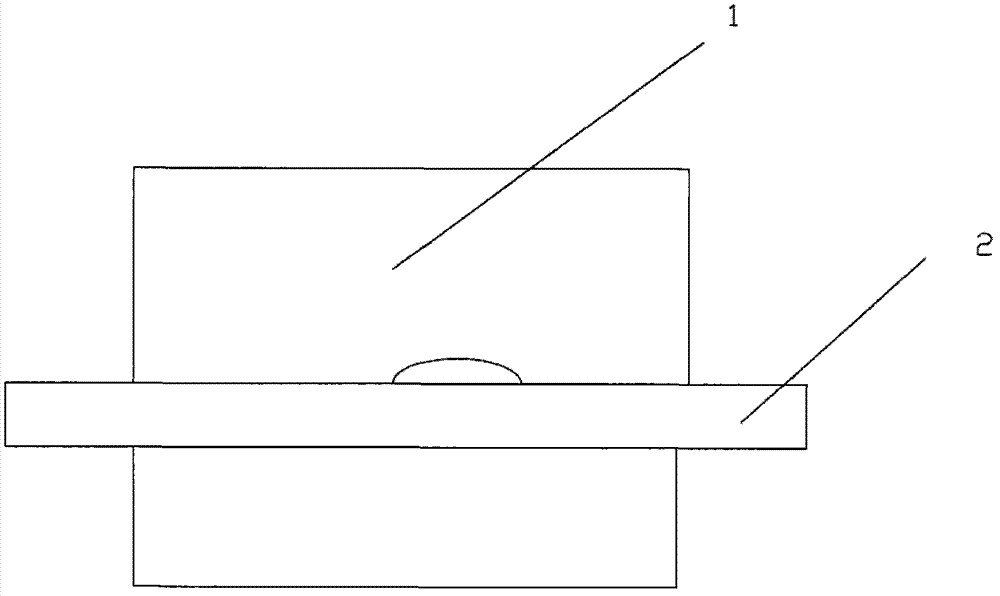

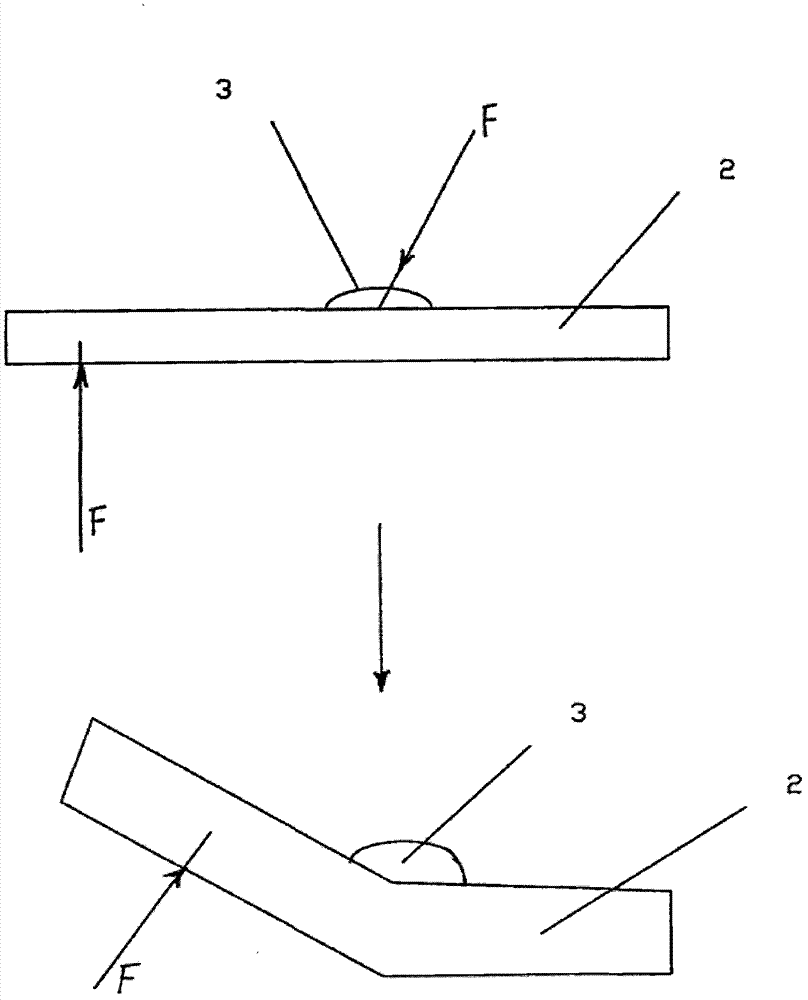

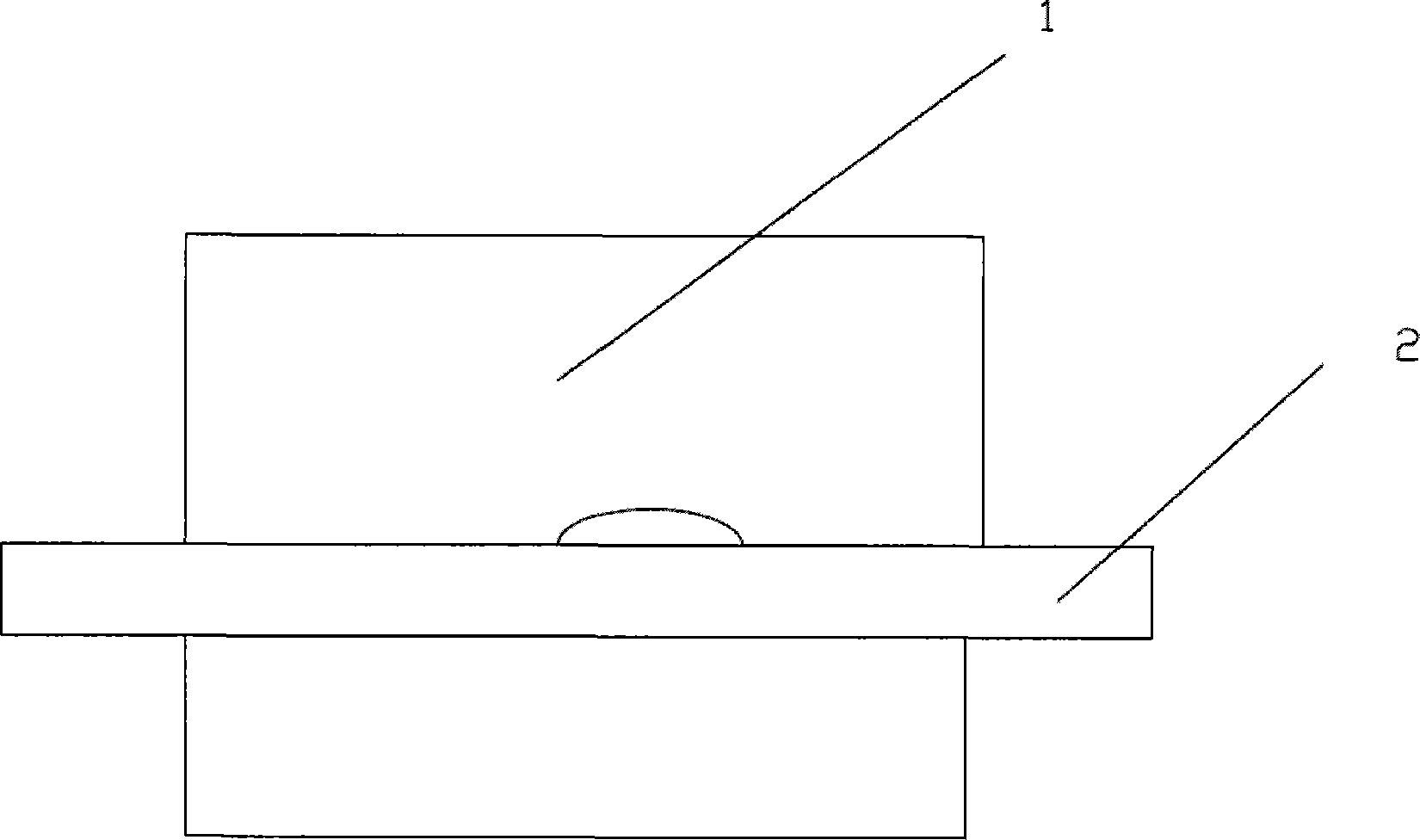

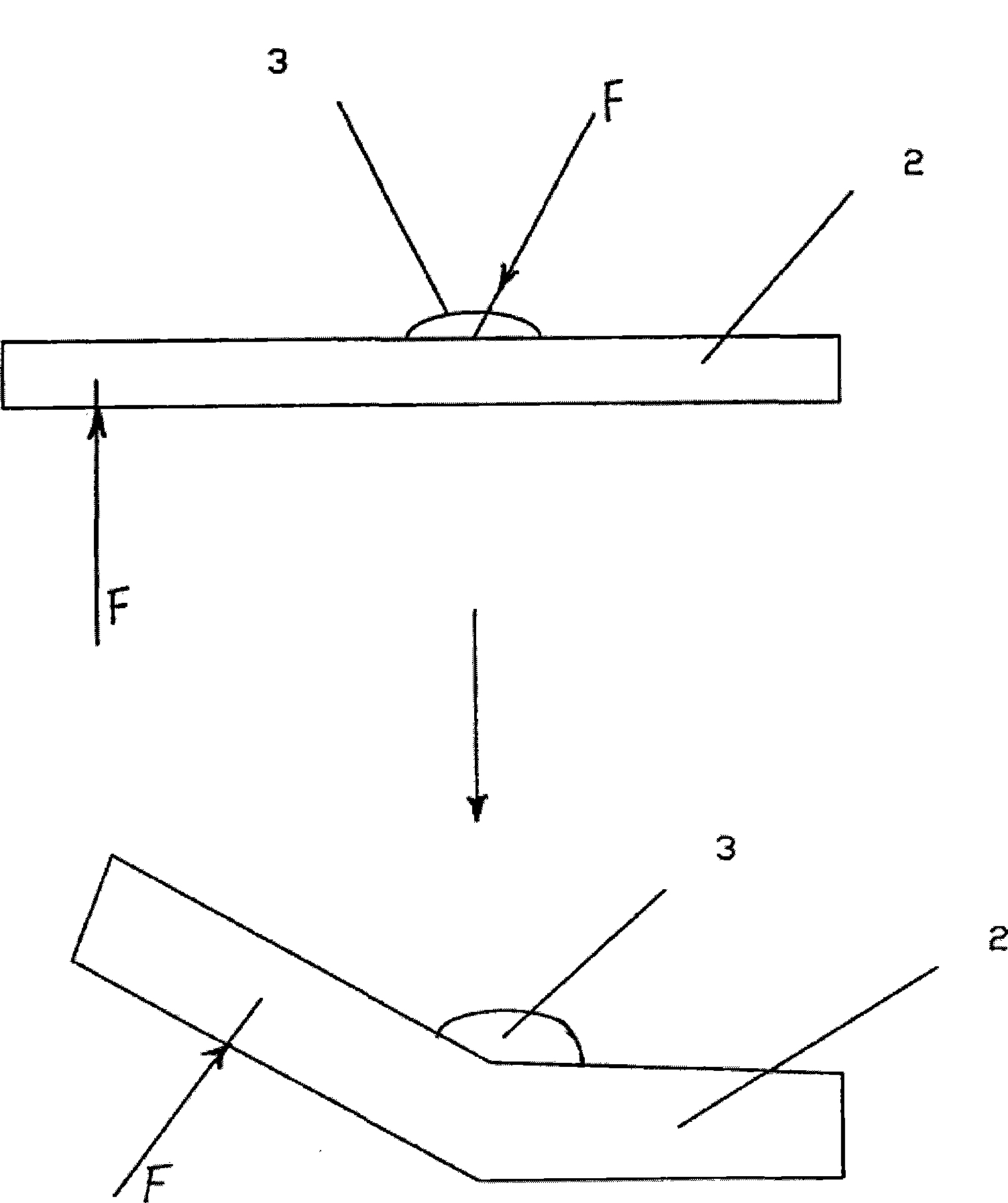

Manufacture method and die for producing pallet fork with thickened bottom

ActiveCN102814448ALow densityTo achieve the purpose of thickeningShaping toolsForging/hammering/pressing machinesMechanical engineeringPallet fork

The invention relates to a die for producing a pallet fork with a thickened bottom. The die comprises an upsetting die for upsetting a pallet fork blank and a stamping die for finalizing a shape of the pallet fork. The upsetting die comprises an upper die plate, a lower die plate, a working bench and a pressure device. The stamping die comprises a fixed die plate and a moving die plate, wherein the fixed die plate and the moving die plate are respectively L-shaped. A small L-shaped groove with the same width to the width of the pallet fork blank is arranged at the L-shaped bottom-corner position of the fixed die plate.

Owner:NINGBO RENBA FORK

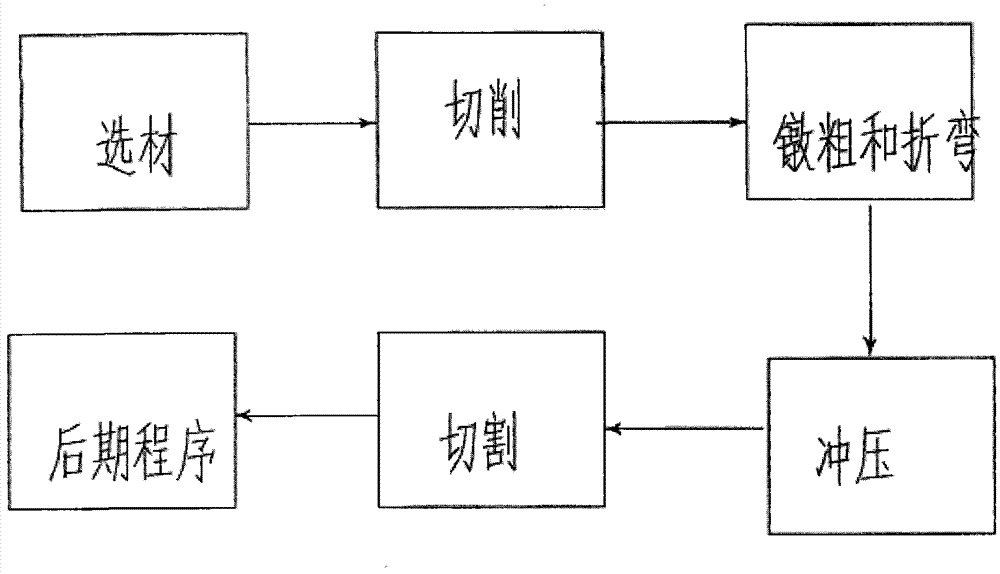

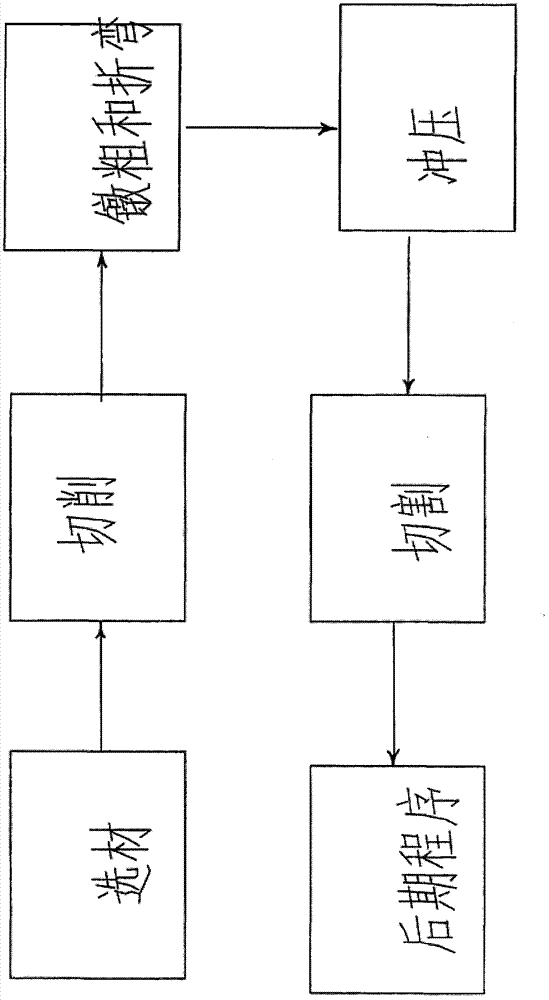

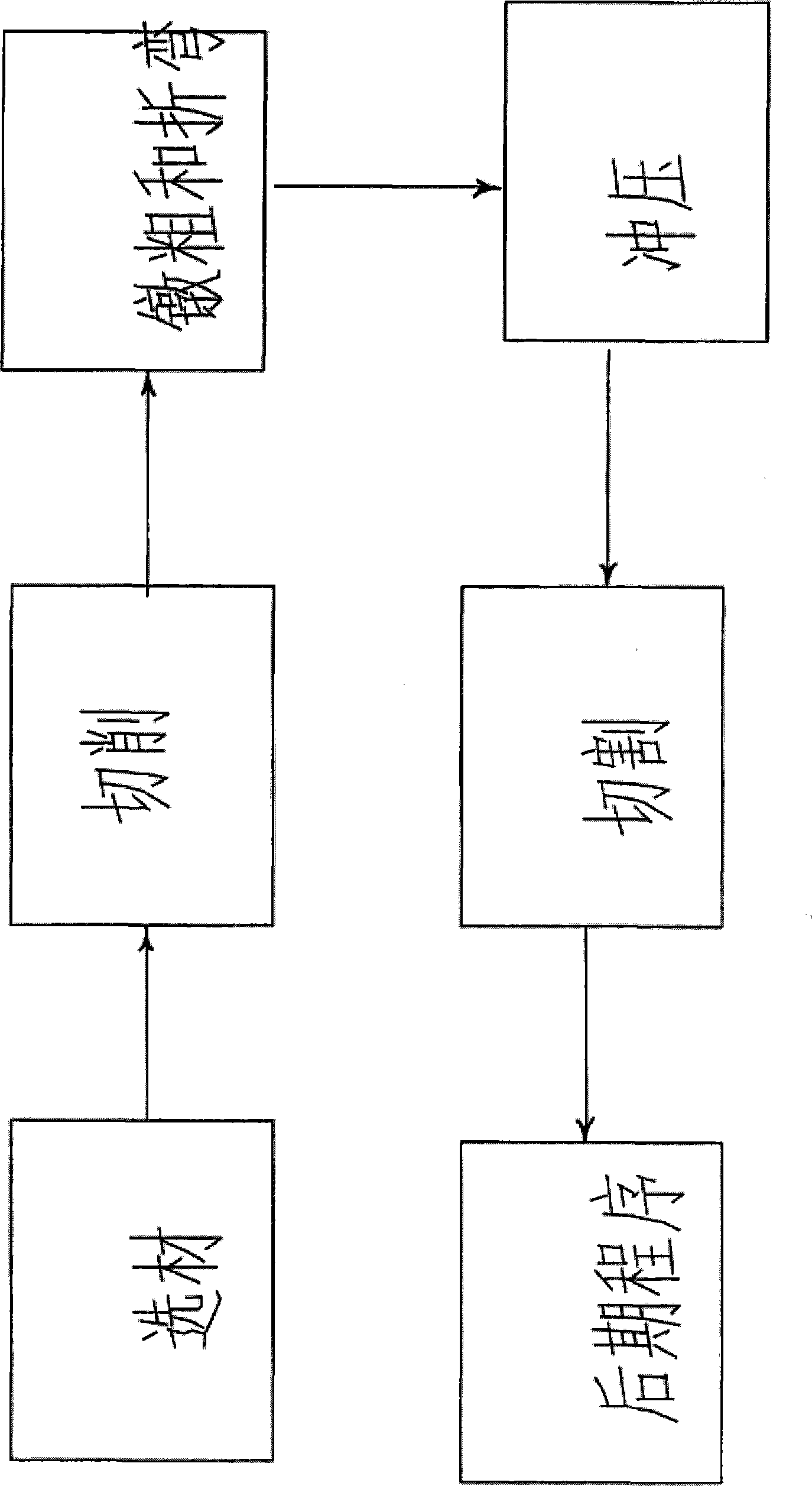

Manufacture method for fork of forklift

The invention relates to a manufacture method for a fork of a forklift. The manufacture method comprises the following steps of: selecting a rectangular or quadrate long strip-shaped steel with the same cross section as that of the fork to be processed; cutting the long strip-shaped steel in length according to a technical requirement, and cutting to obtain various inclined faces as required; partially heating the cut proximate matters at bending parts; partially upsetting and forming in dies, and bending a convex face at an upsetting part as an internal surface to form a fork shape by utilizing afterheat; extruding a protuberance inside a bending angle of the fork to the outside of the bending angle through a punching die so as to form a thickened external surface of a fork bottom; cutting two ends of the fork as required; and then carrying out processing programs.

Owner:NINGBO RENBA FORK

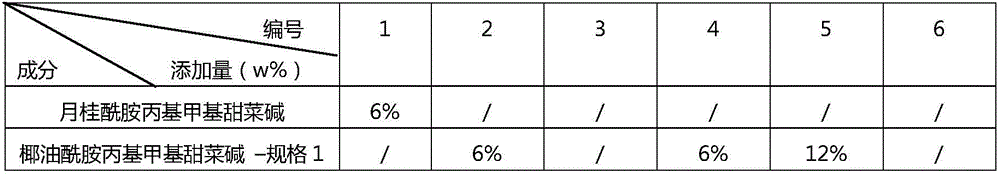

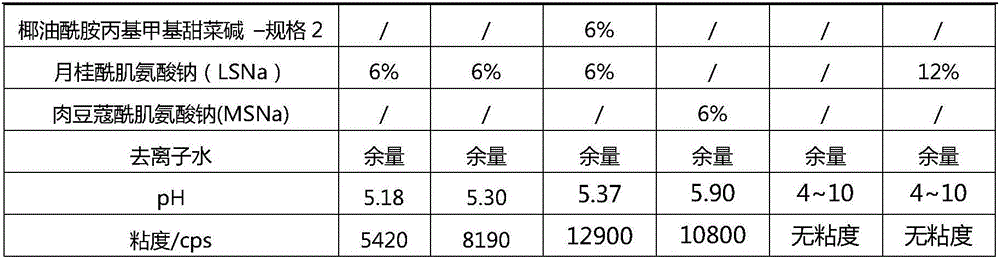

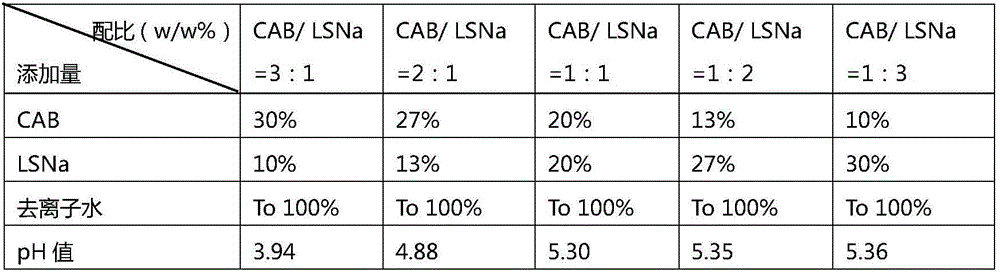

Cleaning and thickening system composition containing fatty acyl sarcosinate

InactiveCN106726660ATo achieve the purpose of thickeningCosmetic preparationsToilet preparationsGlycineBetaine

The invention discloses a cleaning and thickening system composition containing fatty acyl sarcosinate. The composition is prepared from fatty acyl sarcosinate, fatty acid amide alkyl glycine betaine, a pH value conditioning agent and water; the weight ratio of the fatty acyl sarcosinate to the fatty acid amide alkyl glycine betaine is 3:1 to 1:3; and the pH value of the composition is 4.8 to 6.0. According to the cleaning and thickening system composition containing the fatty acyl sarcosinate, which is disclosed by the invention, multiple surface active agent combining modes are adopted to change the micelle state of surface active agents in a water solution to achieve the thickening purpose. By combination, two surface active agents can give play to advantages respectively, and make up for disadvantages of each other.

Owner:JIUJIANG TINCI ADVANCED MATERIALS CO LTD

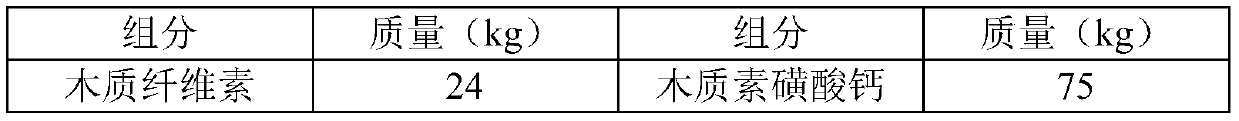

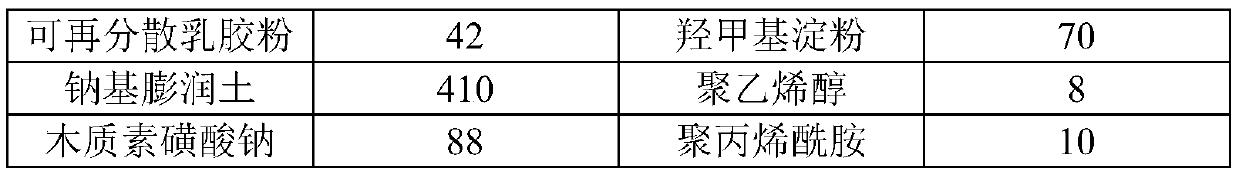

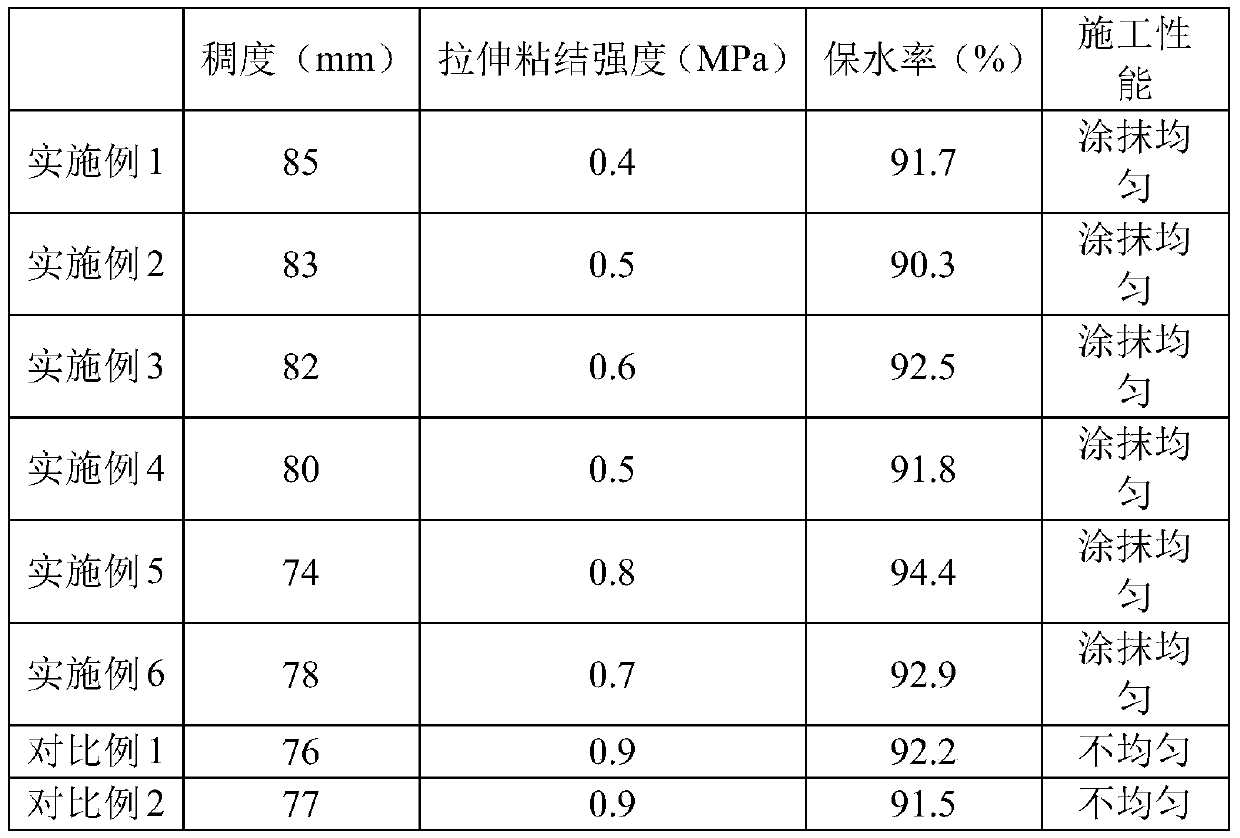

Thickening powder for dry-mixed mortar and preparation method of thickening powder

The invention relates to thickening powder for dry-mixed mortar and a preparation method of the thickening powder. The invention relates to the technical field of dry-mixed mortar. The thickening powder particularly includes the following components: 20-30 kg / t of cellulose, 30-45 kg / t of redispersible latex powder, 380-430 kg / t of bentonite, 80-100 kg / t of sodium lignosulphonate and 60-80 kg / t ofcalcium lignosulphonate. The thickening powder also comprises 50 to 70 kg / t of hydroxymethyl starch, 5 to 10 kg / t of polyvinyl alcohol, and 10 to 15 kg / t of polyacrylamide. The thickening powder prepared by the invention is added into the dry-mixed mortar, so that the consistency of the mortar can be ensured, and the binding power between the mortar and a wall body can be improved.

Owner:宁波新广亿建材有限公司

Dye type gel ink and preparation thereof

The invention provides a dye type neutral ink. The dye type neural ink comprises five colors of red, yellow, blue back, orange and green; the dye type neutral ink comprises the compositions of water-solubility dye, condensing agent, copolymerization liquid, glycerin, lubricant, hygroscopic agent and distilled water. The preparation method comprises the following steps that: concentrated sulphuric acid, formaldehyde and water are adopted and mixed to prepare the condensing agent; salicylsulfonic acid is adopted and added with the distilled water for dissolution, then the formaldehyde and acetic acid are added and condensed to prepare a copolymerization liquid; the water-solubility dye, the formaldehyde in the condensing agent and the copolymerization liquid have condensation reaction under the acid action to form a macromolecule dye, and the other compositions are added to prepare the dye type neutral ink. The method has simple preparation process and low cost; the prepared dye type neutral ink is smooth in writing, does not block a pen and has stable performance, good light fastness and water resisting property.

Owner:SHANXI UNIV

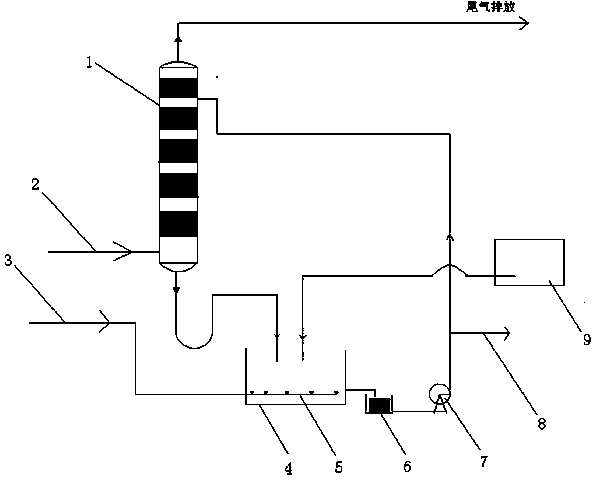

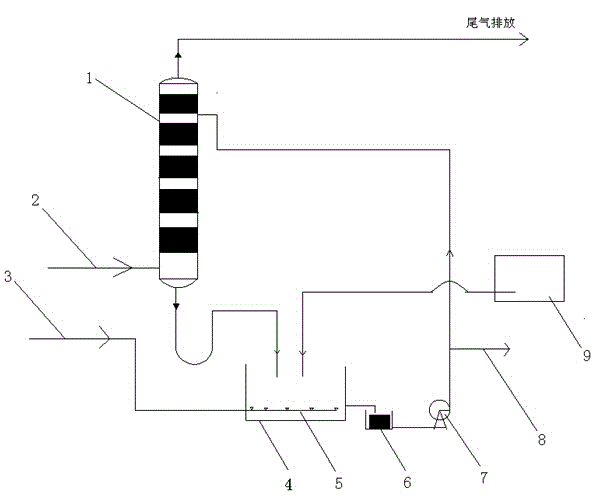

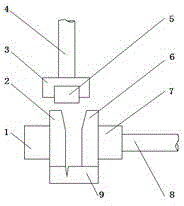

Method for preparing magnesium nitrate solution by using nitric acid tail gas and apparatus thereof

ActiveCN104108734AHigh utilization of NOThorough responseDispersed particle separationMagnesium nitratesExhaust gasMagnesium nitrate

The invention provides a method for preparing a magnesium nitrate solution by using nitric acid tail gas, which comprises the following steps: respectively injecting nitric acid tail gas after being washed by a washing tower and water on magnesium oxide surface to form a solution; uniformly introducing compressed air and then stirring to generate the magnesium nitrate solution; filtering the magnesium nitrate solution and then introducing in the washing tower and repeatedly generating the magnesium nitrate solution to increase its concentration; deposing for 8-10 hours, and filtering to obtain the finished product magnesium nitrate solution. The invention also provides an apparatus. According to the invention, a non-pressure process and a pressurization method are used for producing dilute nitric acid, tail gas generated by dilute nitric acid contains a lot of nitrogen oxides such as NO and NO2, the nitrogen oxides are washed by the washing tower to remove the impurities, and then added in magnesium oxide with water and compressed air, so that nitrogen oxides, water, and alkalescence suspending liquid prepared by oxygen and magnesium oxide are reacted to directly generate the magnesium nitrate solution. According to the invention, reaction is mild, acid mist and nitrogen oxides are not generated, so that personal safety is ensured and environment can not be polluted, and magnesium nitrate concentration can be gradually increased to 40%.

Owner:宁夏润夏能源化工有限公司

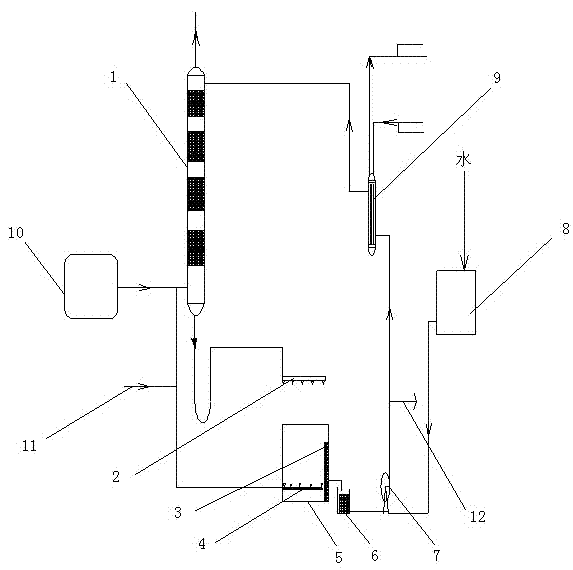

Preparation method and device for producing calcium nitrate liquor by nitrification gas

InactiveCN103803624AHigh utilization of NOEnergy saving and environmental protection production costCalcium/strontium/barium nitratesProduct gasOxygen enrichment

The invention provides a preparation method and a device for producing calcium nitrate liquor by a nitrification gas. The preparation method comprises the following steps: carrying a reaction on the nitrification gas and cooling water to generate dilute nitric acid; carrying out a reaction on dilute nitric acid and quick lime to generate calcium nitrate liquor; after filtering and cooling the calcium nitrate liquor, repeating the previous two steps to improve the concentration of the calcium nitrate liquor till the nitrification gas reacts completely; stirring the calcium nitrate liquor and adjusting pH value of the calcium nitrate liquor; and settling and filtering to obtain the product calcium nitrate liquor. According to the invention, by fully utilizing the characteristic that the nitrification gas of a constant pressure pressurizing dilute nitric acid production device contains NOX gases, NOX gases and water are reacted to generate dilute nitric acid under a condition of oxygen enrichment, and the dilute nitric acid and quick lime (CaO) are in acid-base reaction to generate the calcium nitrate liquor. The reaction is mild without acid mist and acid mist which are harmful to personal safety and pollute the environment.

Owner:ANHUI WANBEI COAL REFCO GRP LTD HANSHAN HENGTAI NONMETALLIC MATERIALS BRANCH

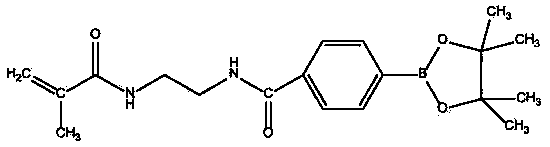

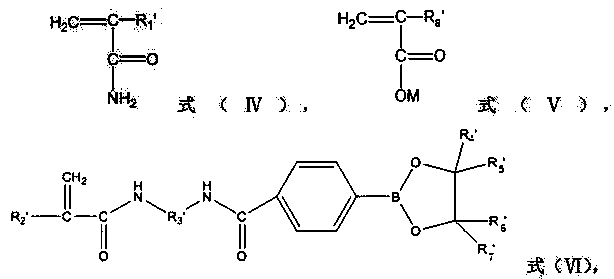

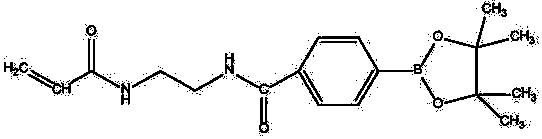

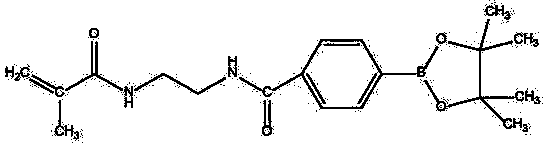

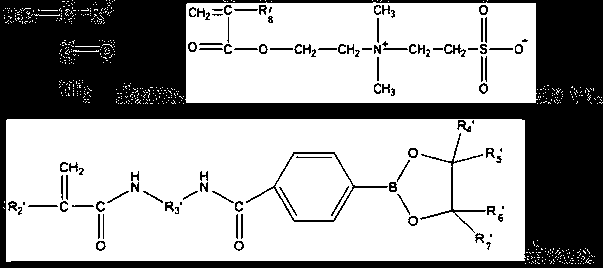

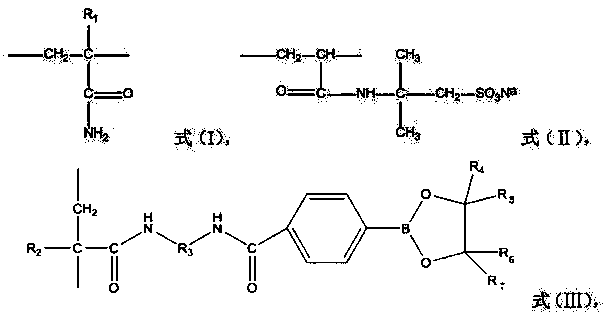

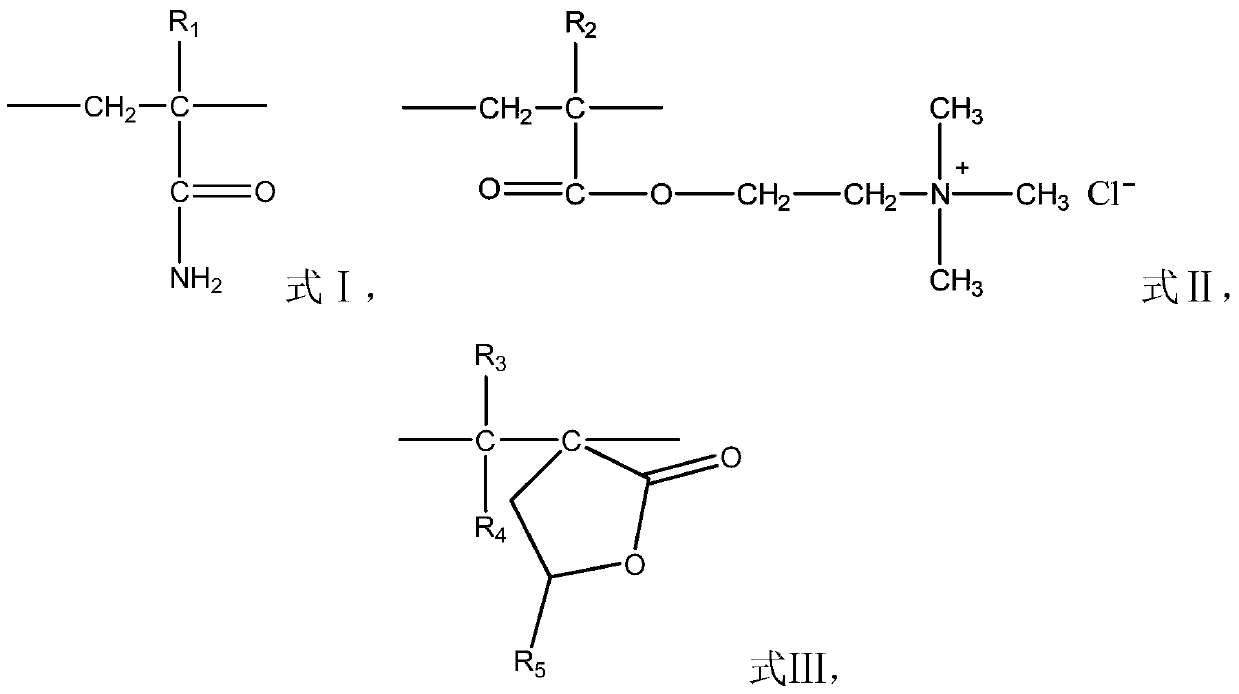

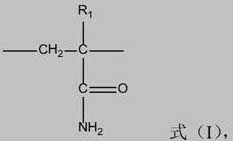

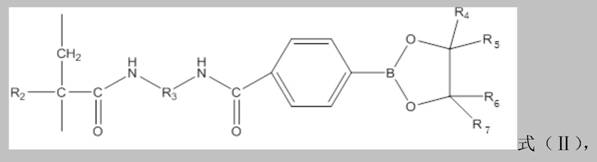

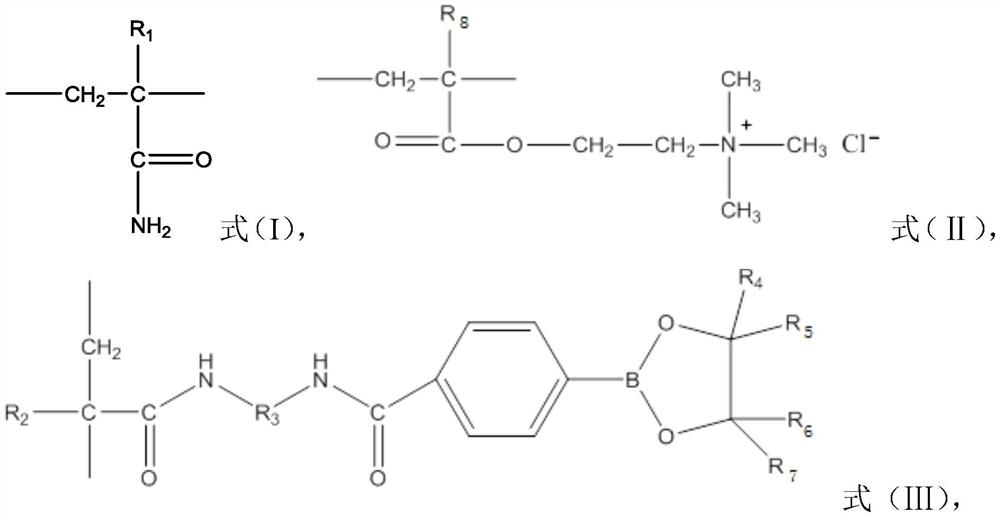

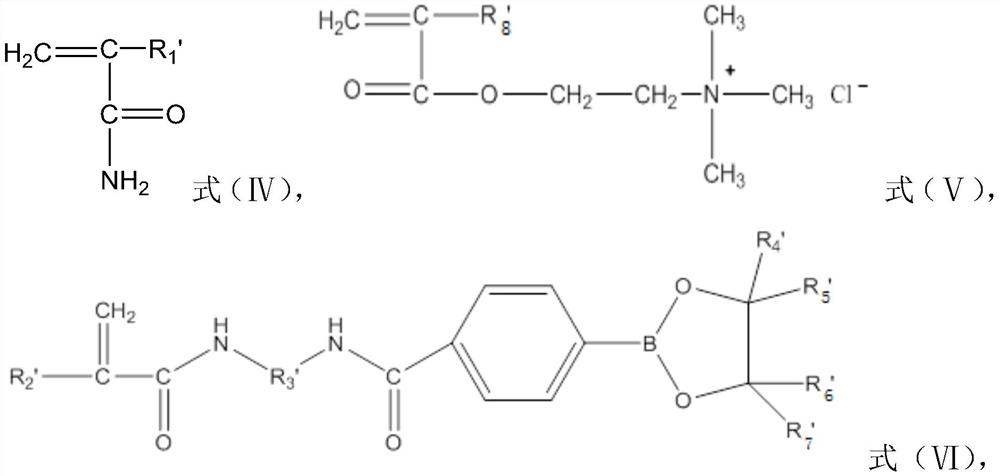

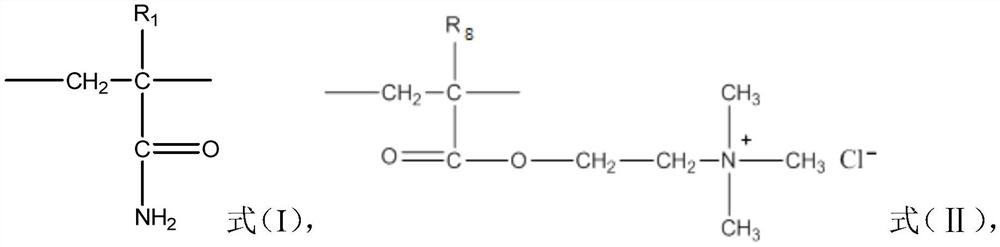

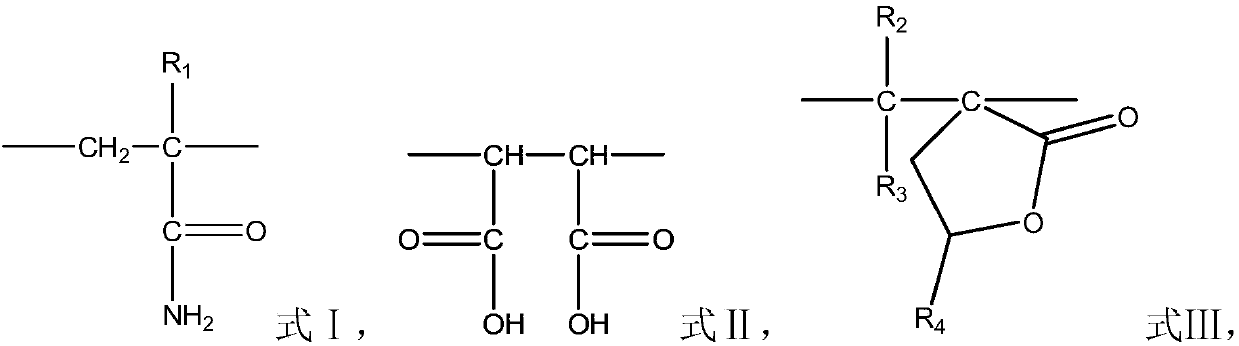

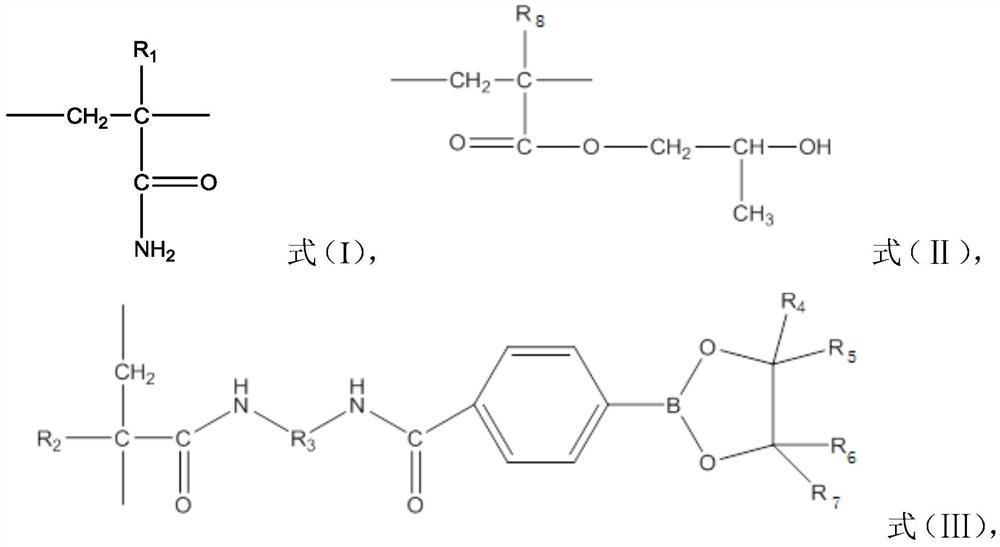

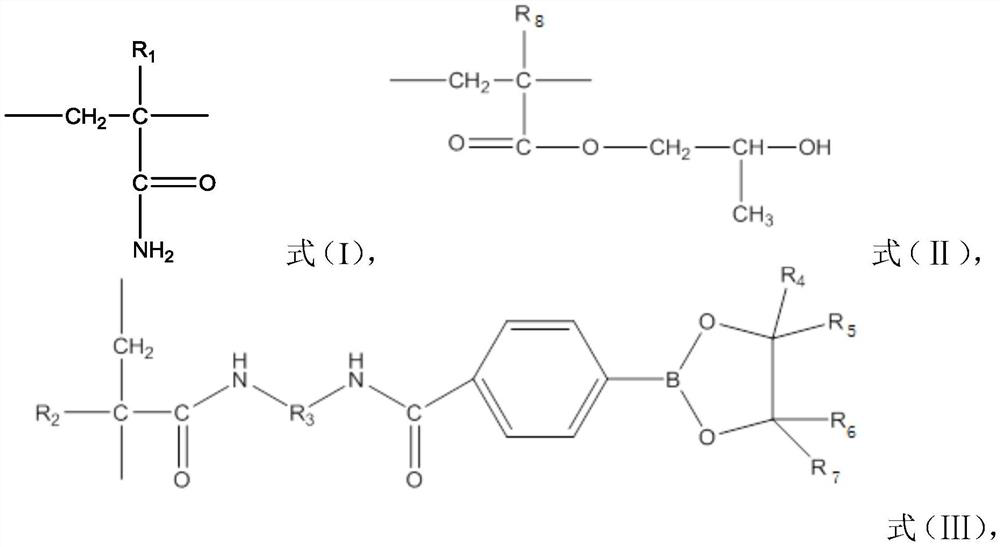

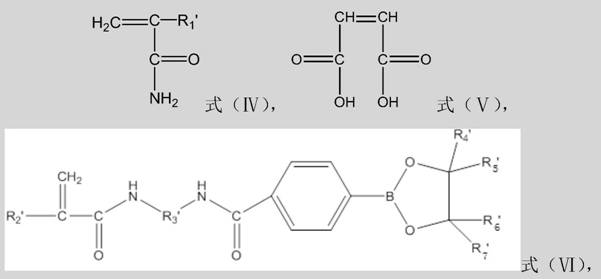

Acrylamide copolymer as well as preparation method and application thereof

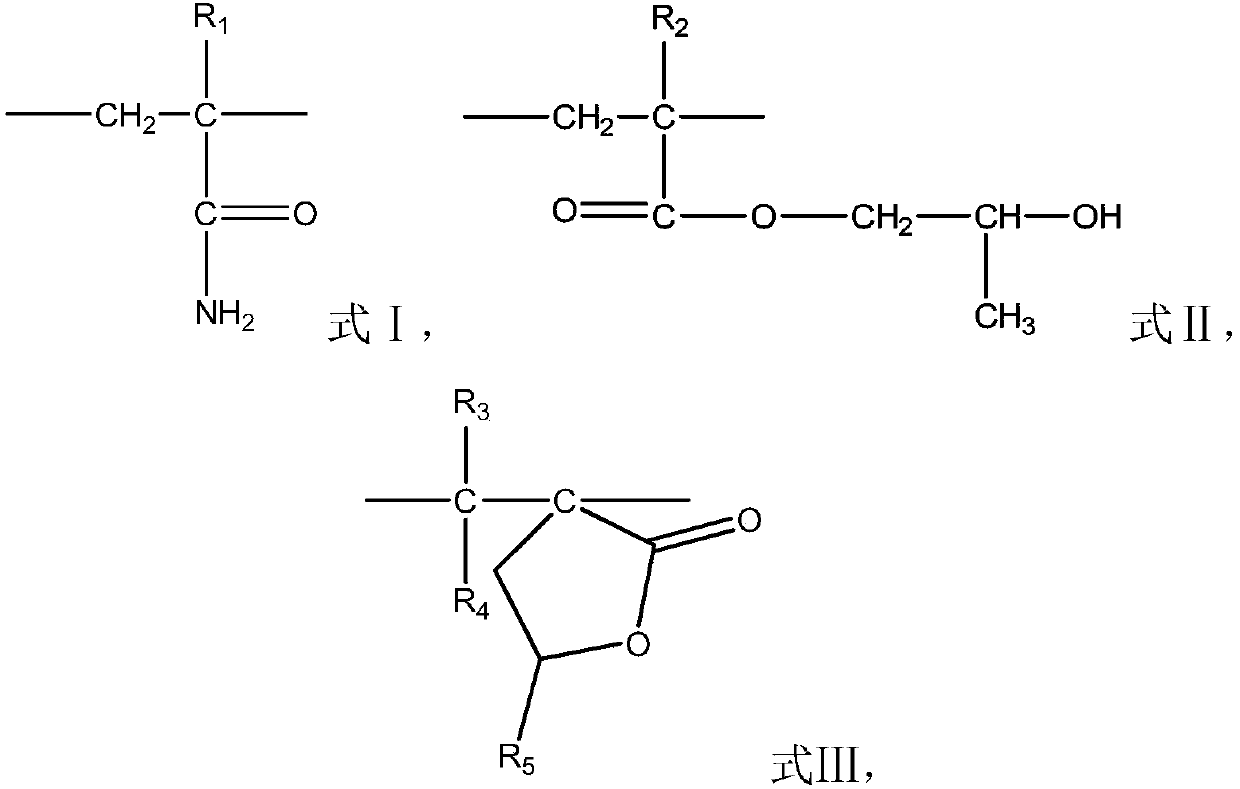

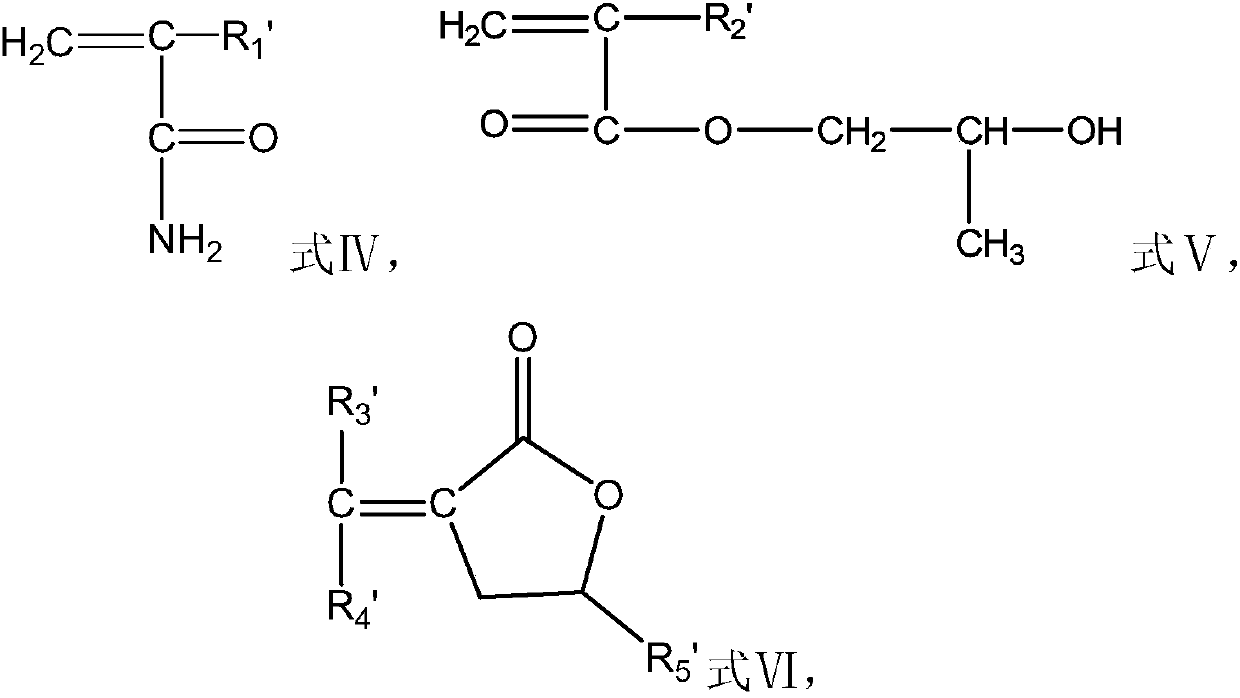

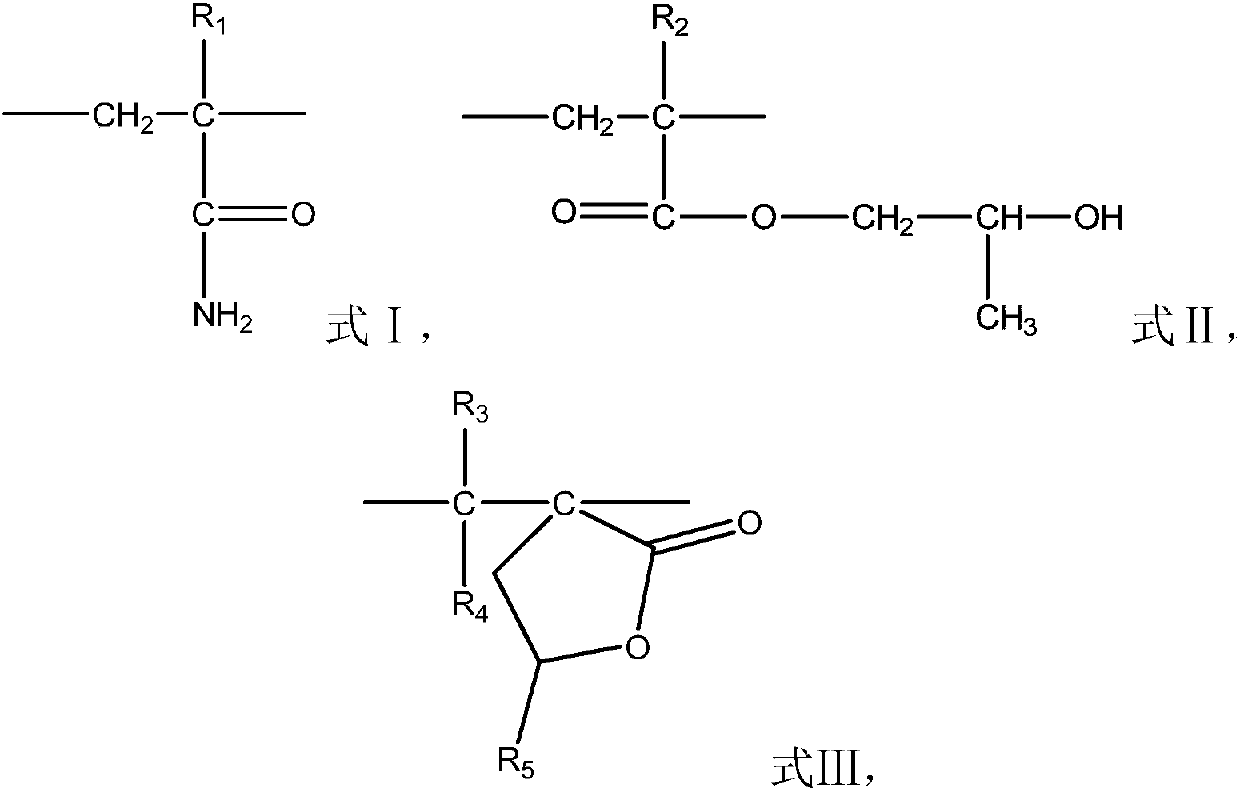

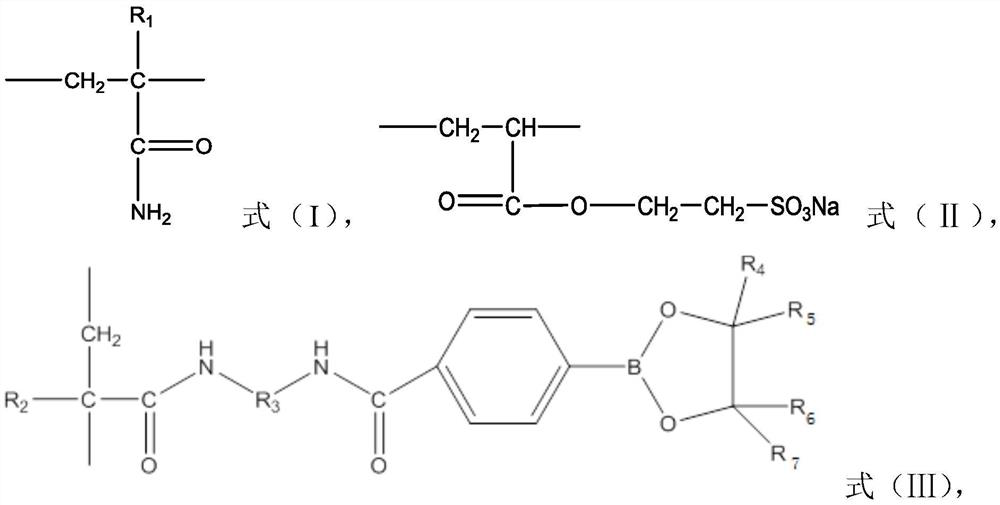

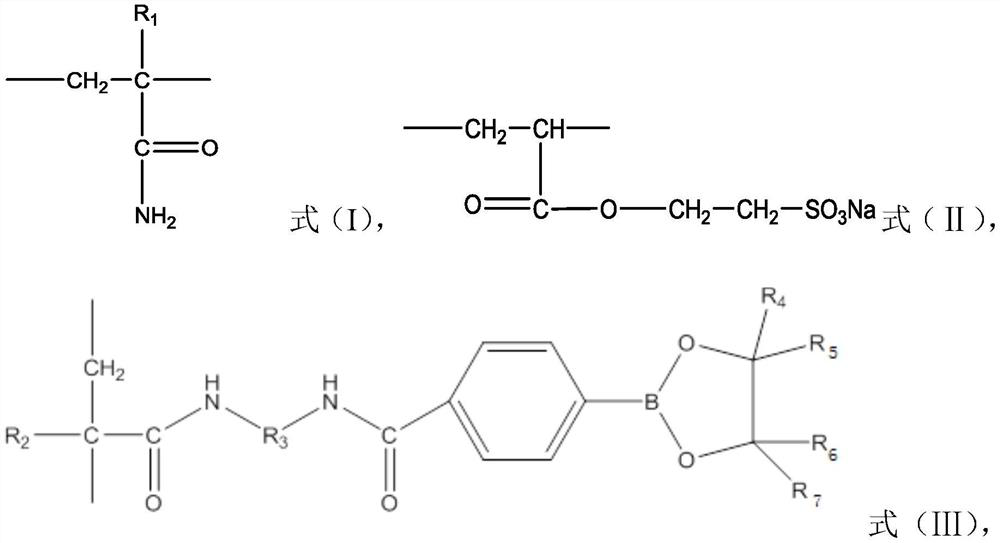

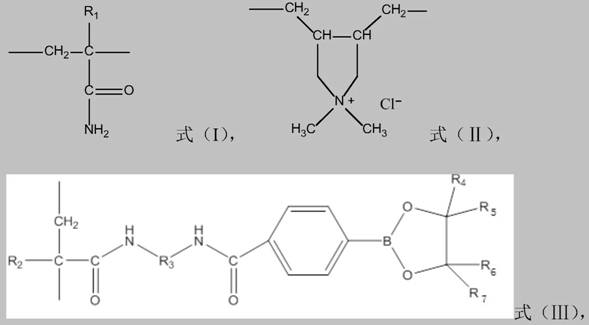

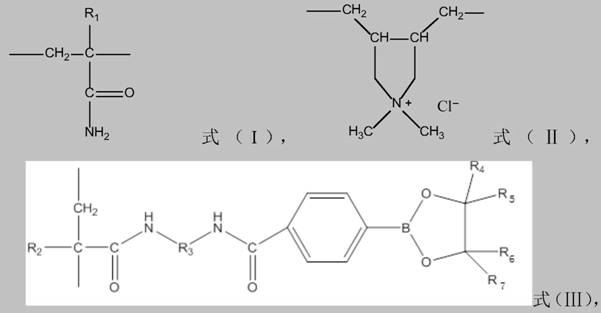

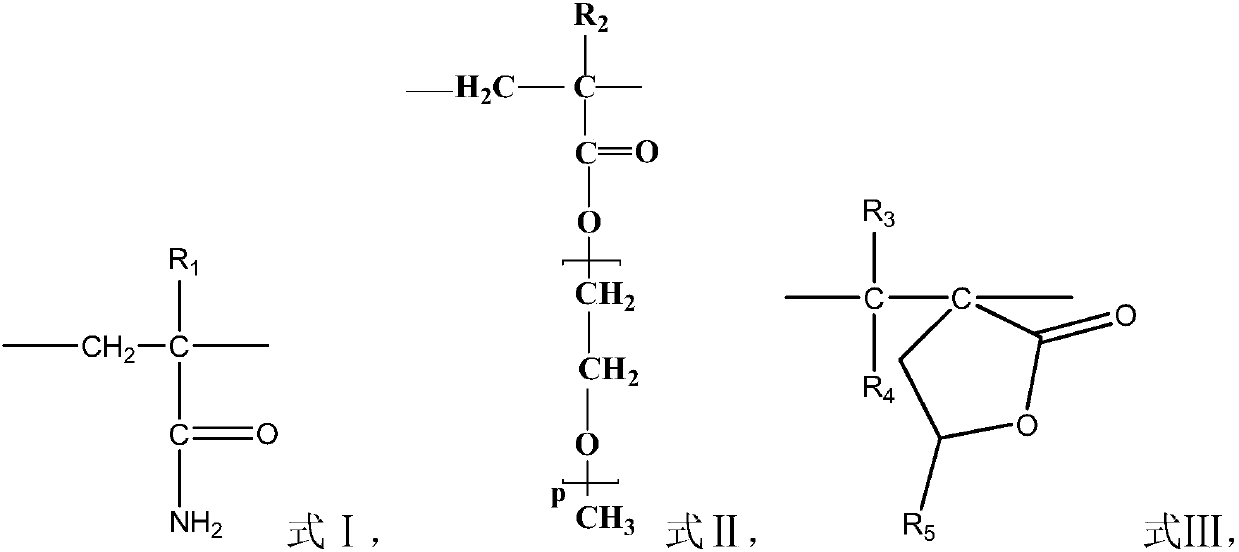

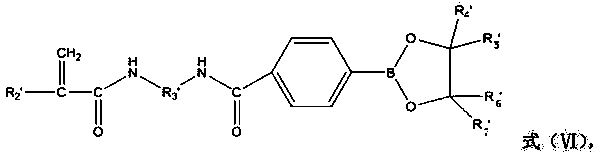

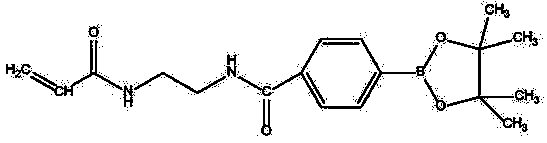

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a constitutional unit A shown as formula (I) in the description, a constitutional unit B shown as formula (II) in the description and a constitutional unit C shown as formula (III) in the description; by takingthe total weight of the acrylamide copolymer as the baseline, the constitutional unit A accounts for 70wt%-90wt%, the constitutional unit B accounts for 8wt%-28wt% and the constitutional unit C accounts for 0.1wt%-5wt%. The acrylamide copolymer can be used as a hot thickener for tertiary oil recovery of high-temperature and high-salinity reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylamide copolymer as well as preparation method and application thereof

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a constitutional unit A shown as formula (I) in the description, a constitutional unit B shown as formula (II) in the description and a constitutional unit C shown as formula (III) in the description; by takingthe total weight of the acrylamide copolymer as the baseline, the constitutional unit A accounts for 70wt%-90wt%, the constitutional unit B accounts for 8wt%-28wt% and the constitutional unit C accounts for 0.1wt%-5wt%. The acrylamide copolymer can be used as a hot thickener for tertiary oil recovery of high-temperature and high-salinity reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Processing method of locally electroplated thick gold product

PendingCN110933860ATo achieve the purpose of thickeningConductive material chemical/electrolytical removalConductive pattern reinforcementSurface coatingGold plating

The invention discloses a processing method of a locally electroplated thick gold product, which is combined with an existing process wire thick gold electroplating process, a local gold electroplating area imaging process is added after a microwave printed board is electroplated with gold for the first time, secondary gold electroplating is carried out on a local area on the basis, finally, a surface coating is removed, and a process wire is removed by etching. Compared with the prior art, the high-frequency microwave printed board processing technology method for locally electroplating thickgold can be suitable for processing high-frequency microwave printed board products with inconsistent gold plating layer thicknesses in patterns, an electroplating area is limited mainly through a special means, and secondary gold plating is carried out in combination with a wire electroplating mode, so that the purpose of thickening a local gold plating layer is achieved.

Owner:CHENGDU AEROSPACE COMM EQUIP CO LTD

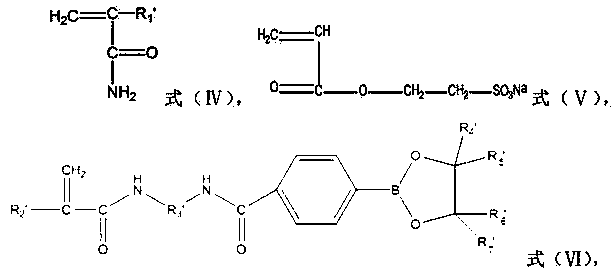

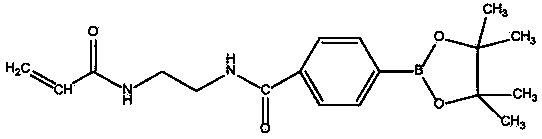

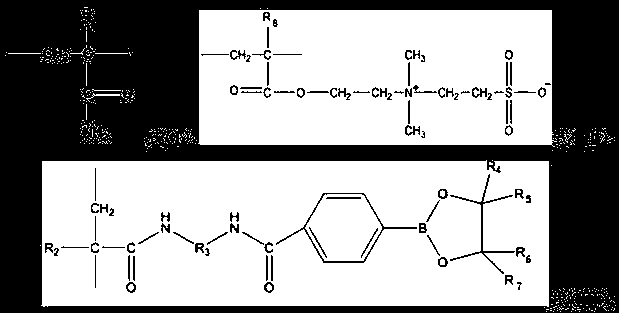

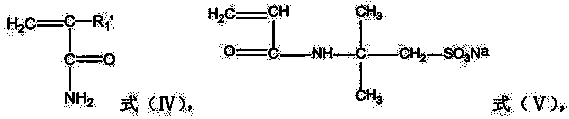

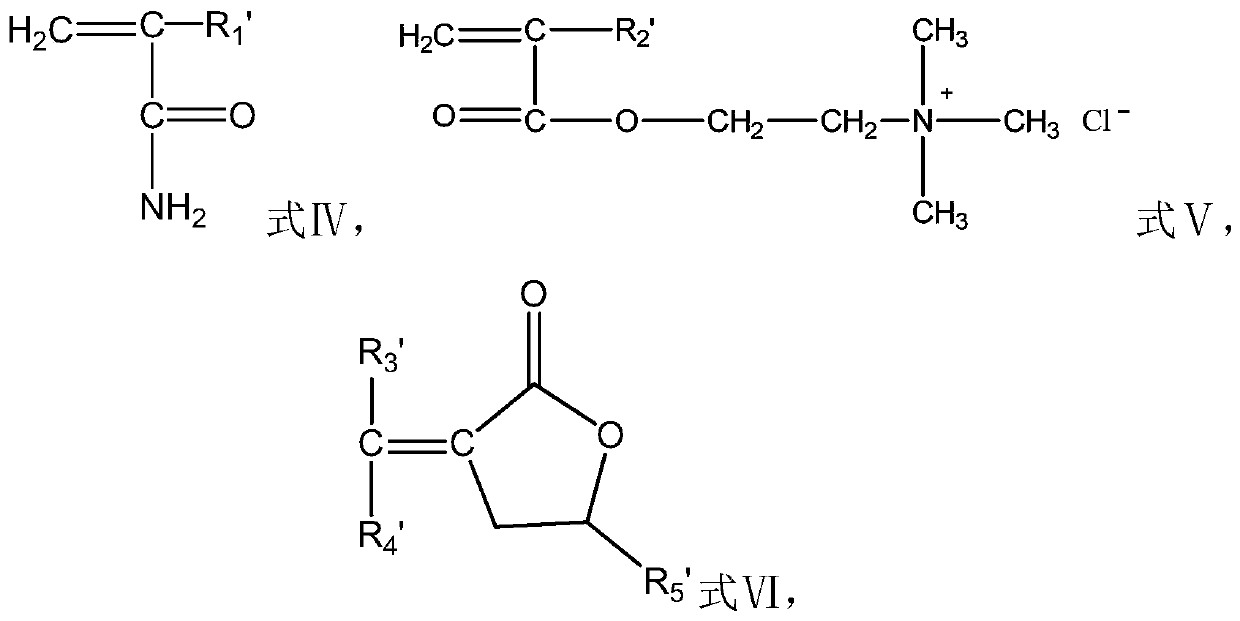

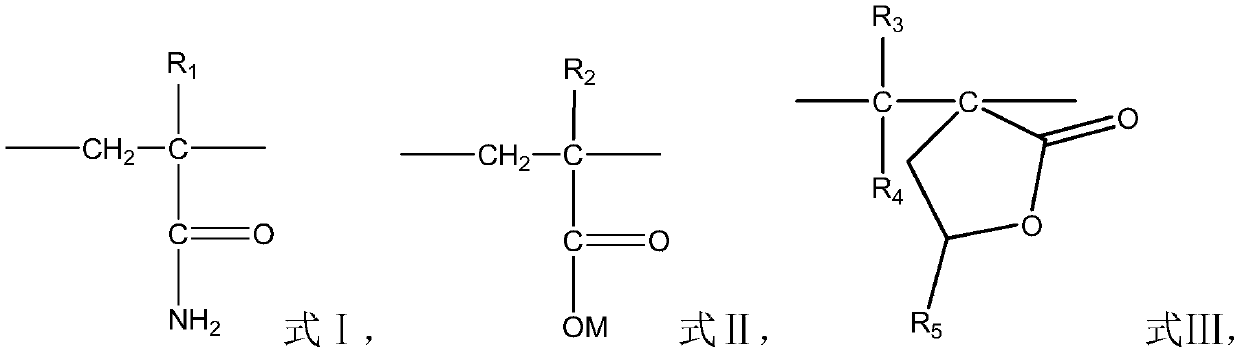

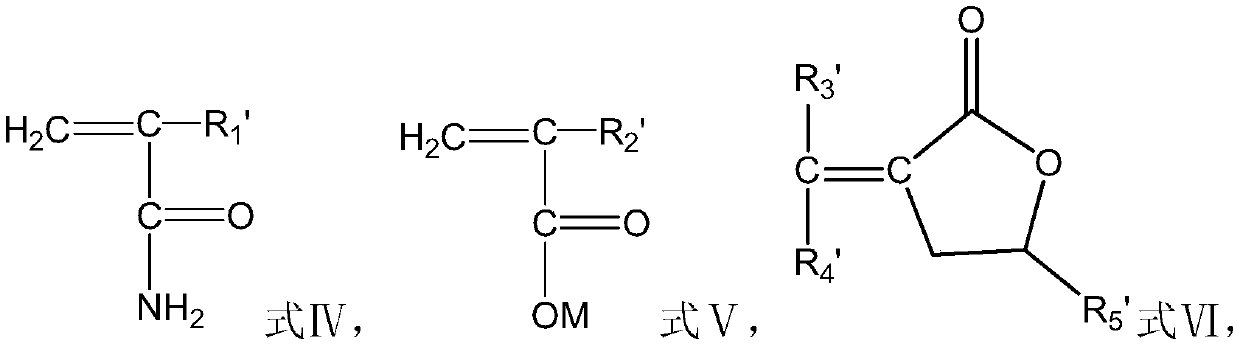

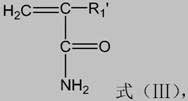

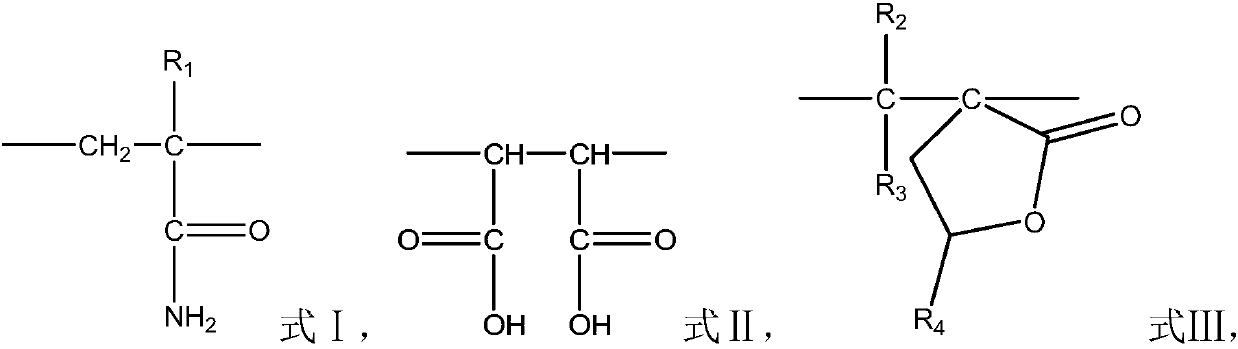

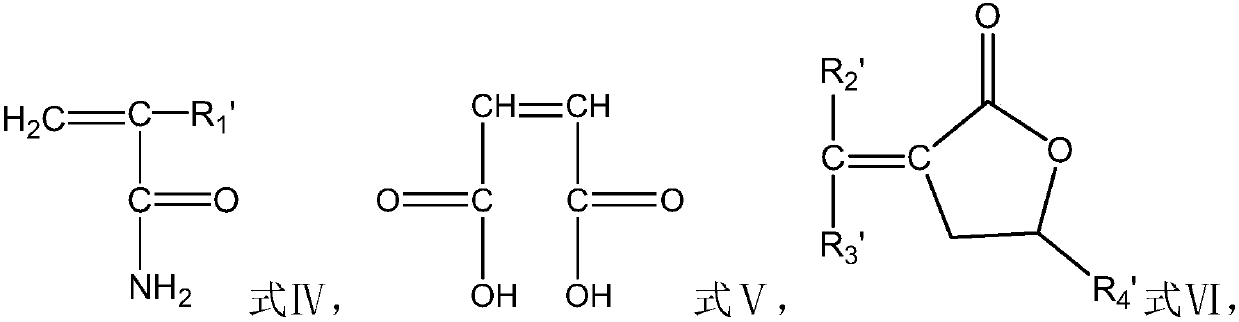

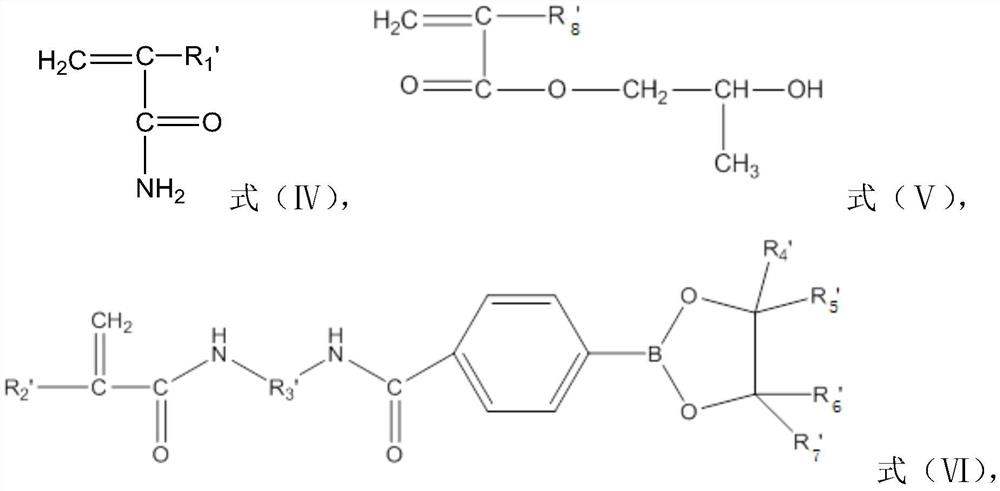

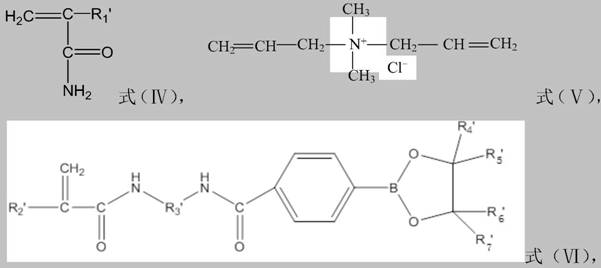

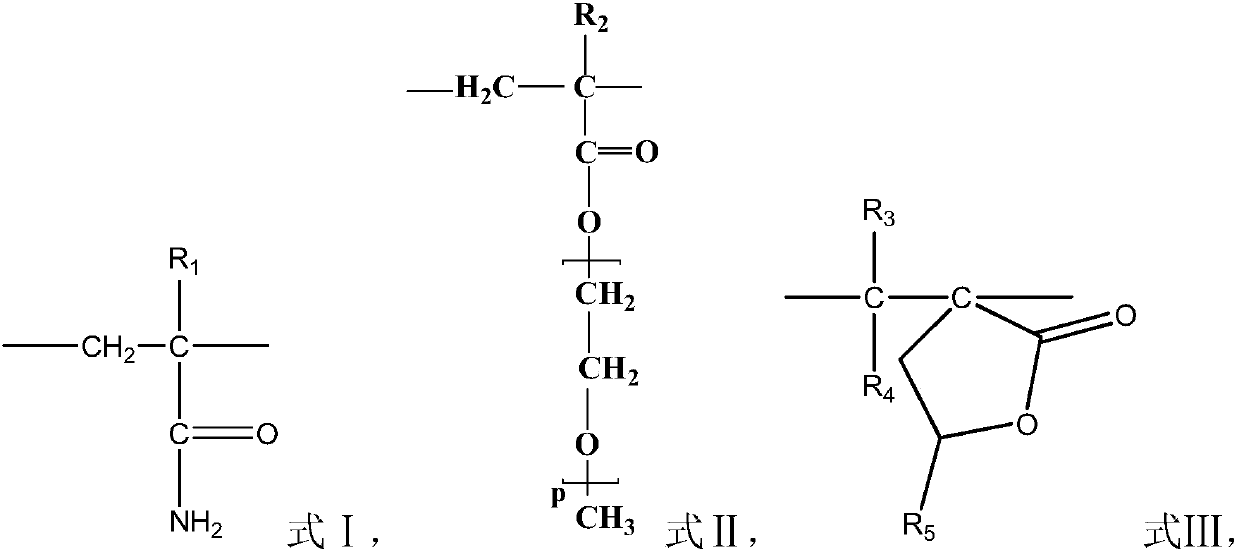

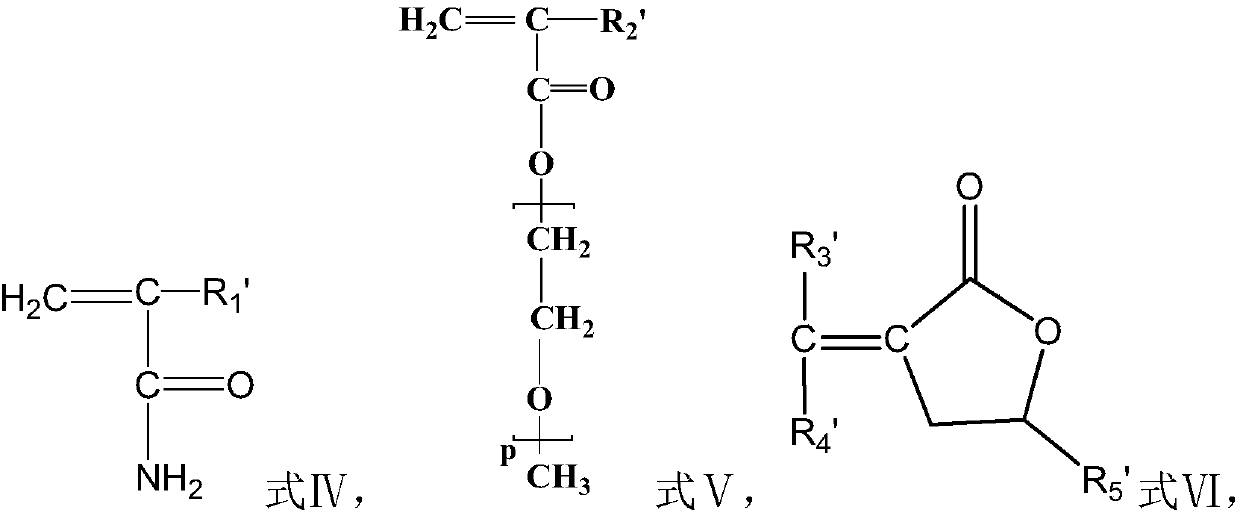

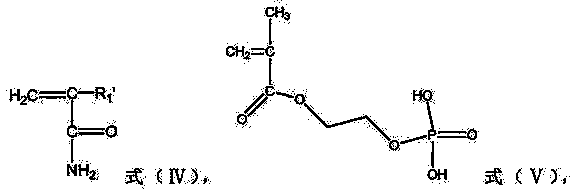

Acrylamide copolymer as well as preparation method and application thereof

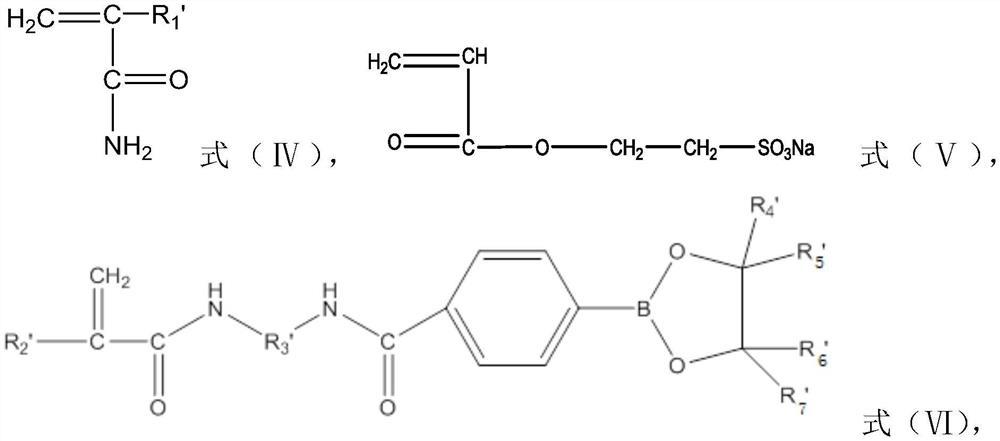

ActiveCN107868171AGood water solubilityGood low temperature stabilityDrilling compositionSolubilityWater soluble

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a structure unit A shown in the formula I, a structure unit B shown in the formula II and a structure unit C shown in the formula III; on the basis of the total weight of the acrylamide copolymer, the content of the structure unit A is 43.5wt%-98wt%, the content of the structure unit B is 0.6wt%-39wt%, and the content of the structure unit C is 0.6wt%-39wt%. The acrylamide copolymer has good water solubility and a thermothickening function and is applicable to three-time oil recovery of a high-temperature and high-salinity reservoir as a thermothickening agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

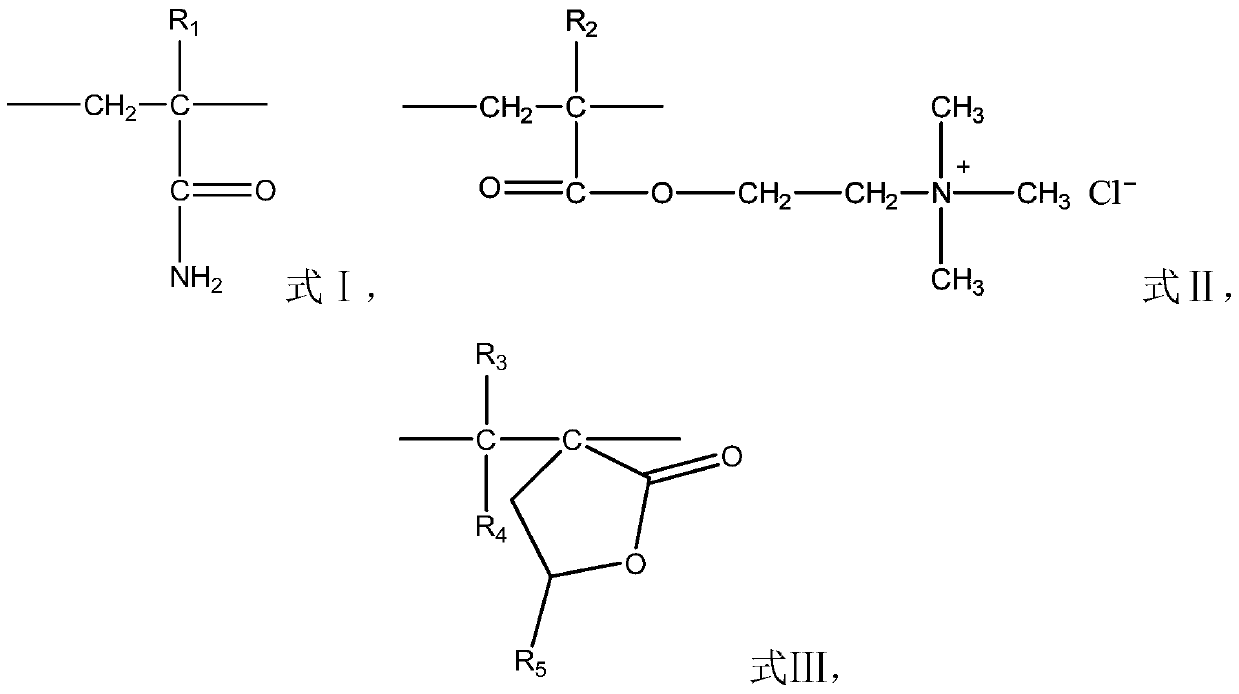

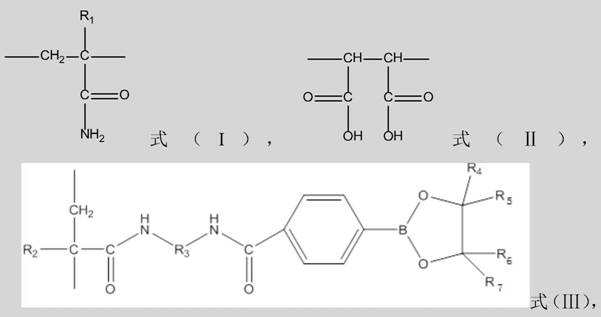

Acrylamide copolymer and its preparation method and application

ActiveCN109232810BHigh viscosityGood water solubilityDrilling compositionPolymer scienceOrganic chemistry

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a constitutional unit A shown as formula (I) in the description, a constitutional unit B shown as formula (II) in the description and a constitutional unit C shown as formula (III) in the description; by takingthe total weight of the acrylamide copolymer as the baseline, the constitutional unit A accounts for 70wt%-90wt%, the constitutional unit B accounts for 8wt%-28wt% and the constitutional unit C accounts for 0.1wt%-5wt%. The acrylamide copolymer can be used as a hot thickener for tertiary oil recovery of high-temperature and high-salinity reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing instant flavour solid soup material

Owner:NINGBO HAITONG FOOD SCI & TECH CO LTD +1

A method and device for preparing magnesium nitrate solution using nitric acid tail gas

ActiveCN104108734BIncrease concentrationMild responseDispersed particle separationMagnesium nitratesNitrogen oxideOxygen

The invention provides a method for preparing a magnesium nitrate solution by using nitric acid tail gas, which comprises the following steps: respectively injecting nitric acid tail gas after being washed by a washing tower and water on magnesium oxide surface to form a solution; uniformly introducing compressed air and then stirring to generate the magnesium nitrate solution; filtering the magnesium nitrate solution and then introducing in the washing tower and repeatedly generating the magnesium nitrate solution to increase its concentration; deposing for 8-10 hours, and filtering to obtain the finished product magnesium nitrate solution. The invention also provides an apparatus. According to the invention, a non-pressure process and a pressurization method are used for producing dilute nitric acid, tail gas generated by dilute nitric acid contains a lot of nitrogen oxides such as NO and NO2, the nitrogen oxides are washed by the washing tower to remove the impurities, and then added in magnesium oxide with water and compressed air, so that nitrogen oxides, water, and alkalescence suspending liquid prepared by oxygen and magnesium oxide are reacted to directly generate the magnesium nitrate solution. According to the invention, reaction is mild, acid mist and nitrogen oxides are not generated, so that personal safety is ensured and environment can not be polluted, and magnesium nitrate concentration can be gradually increased to 40%.

Owner:宁夏润夏能源化工有限公司

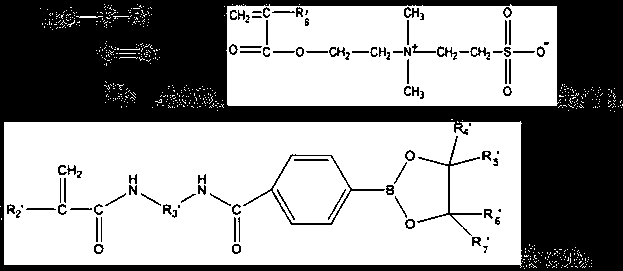

Acrylamide copolymer as well as preparation method and application thereof

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a constitutional unit A shown as formula (I) in the description, a constitutional unit B shown as formula (II) in the description and a constitutional unit C shown as formula (III) in the description; by takingthe total weight of the acrylamide copolymer as the baseline, the constitutional unit A accounts for 70wt%-90wt%, the constitutional unit B accounts for 8wt%-28wt% and the constitutional unit C accounts for 0.1wt%-5wt%. The acrylamide copolymer can be used as a hot thickener for tertiary oil recovery of high-temperature and high-salinity reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylamide copolymer as well as preparation method and application thereof

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a constitutional unit A shown as formula (I) in the description, a constitutional unit B shown as formula (II) in the description and a constitutional unit C shown as formula (III) in the description; by takingthe total weight of the acrylamide copolymer as the baseline, the constitutional unit A accounts for 70wt%-90wt%, the constitutional unit B accounts for 8wt%-28wt% and the constitutional unit C accounts for 0.1wt%-5wt%. The acrylamide copolymer can be used as a hot thickener for tertiary oil recovery of high-temperature and high-salinity reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of acrylamide copolymer and its preparation method and application

ActiveCN107868177BGood water solubilityGood low temperature stabilityDrilling compositionPolymer scienceAqueous solubility

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a structure unit A shown in the formula I, a structure unit B shown in the formula II and a structure unit C shown in the formula III; on the basis of the total weight of the acrylamide copolymer, the content of the structure unit A is 43.5wt%-98wt%, the content of the structure unit B is 0.6wt%-39wt%, and the content of the structure unit C is 0.6wt%-39wt%. The acrylamide copolymer has good water solubility and a thermothickening function and is applicable to three-time oil recovery of a high-temperature and high-salinity reservoir as a thermothickening agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of acrylamide copolymer and its preparation method and application

ActiveCN107868178BGood water solubilityGood low temperature stabilityDrilling compositionPolymer scienceAqueous solubility

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a structure unit A shown in the formula I, a structure unit B shown in the formula II and a structure unit C shown in the formula III; on the basis of the total weight of the acrylamide copolymer, the content of the structure unit A is 43.5wt%-98wt%, the content of the structure unit B is 0.6wt%-39wt%, and the content of the structure unit C is 0.6wt%-39wt%. The acrylamide copolymer has good water solubility and a thermothickening function and is applicable to three-time oil recovery of a high-temperature and high-salinity reservoir as a thermothickening agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

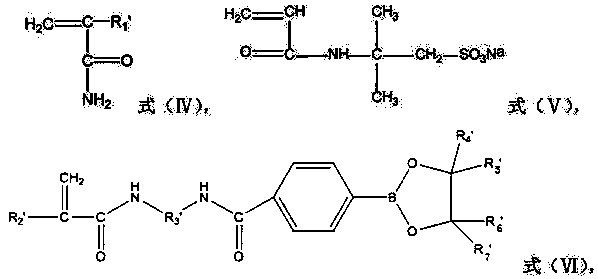

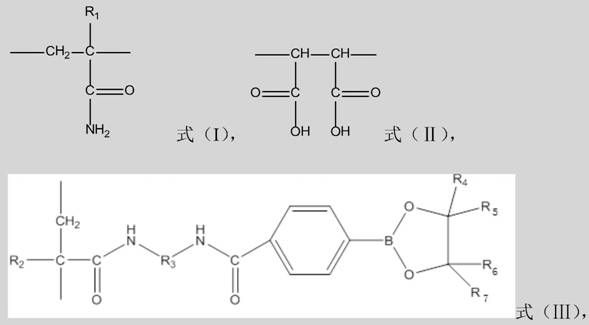

Acrylamide copolymer and its preparation method and application

ActiveCN109232802BHigh viscosityIncreased hydration radiusDrilling compositionPolymer scienceOrganic chemistry

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a constitutional unit A shown as formula (I) in the description and a constitutional unit B shown as formula (II) in the description; by taking the total weight of the acrylamide copolymer as the baseline, theconstitutional unit A accounts for 95wt%-99.9wt%, and the constitutional unit B accounts for 0.1wt%-5wt%. The acrylamide copolymer can be used as a hot thickener for tertiary oil recovery of high-temperature and high-salinity reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylamide copolymer and its preparation method and application

ActiveCN109232807BHigh viscosityGood water solubilityDrilling compositionPolymer scienceOrganic chemistry

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylamide copolymer as well as preparation method and application thereof

ActiveCN107868172AGood water solubilityGood low temperature stabilityDrilling compositionSolubilityWater soluble

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a structure unit A shown in the formula I, a structure unit B shown in the formula II and a structure unit C shown in the formula III; on the basis of the total weight of the acrylamide copolymer, the content of the structure unit A is 43.5wt%-98wt%, the content of the structure unit B is 0.6wt%-39wt%, and the content of the structure unit C is 0.6wt%-39wt%. The acrylamide copolymer has good water solubility and a thermothickening function and is applicable to three-time oil recovery of a high-temperature and high-salinity reservoir as a thermothickening agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Knife back forming machine

InactiveCN102744344BTo achieve the purpose of thickeningForming regular and beautifulForging/hammering/pressing machinesForging press detailsUltimate tensile strengthCoal

The invention discloses a knife back forming machine, which comprises an upper die, a lower die, a fixed side die, a movable side die, a main hydraulic device and an auxiliary hydraulic device, wherein the main hydraulic device and the auxiliary hydraulic device are fixed on a base; the upper die is fixed on a plunger end of the main hydraulic device; the bottom shape of the upper die is adaptive to the shape required by the top of the knife back; the lower die is fixed on the base; a knife edge slot used for fixing a knife is arranged above the lower die; the fixed side die is fixed on the base; the movable side die is fixed on a plunger end of the auxiliary hydraulic device; and the combined shape of the opposite surfaces of the fixed side die and the movable side die is adaptive to the required shaped by the cross section of the knife. According to the knife back forming machine disclosed by the invention, a purpose of thickening the knife back can be realized, and the knife back forming machine is regular and beautiful in forming. When the knife back forming machine disclosed by the invention is adopted, the knife back of the knife can be processed within 10 seconds, no coal needs to be fired, the energy is saved, the environment is protected, the production efficiency is improved, the labor intensity is lowered, and the production cost is lowered.

Owner:嘉禾县刀王刀具有限公司

Manufacture method for fork of forklift

The invention relates to a manufacture method for a fork of a forklift. The manufacture method comprises the following steps of: selecting a rectangular or quadrate long strip-shaped steel with the same cross section as that of the fork to be processed; cutting the long strip-shaped steel in length according to a technical requirement, and cutting to obtain various inclined faces as required; partially heating the cut proximate matters at bending parts; partially upsetting and forming in dies, and bending a convex face at an upsetting part as an internal surface to form a fork shape by utilizing afterheat; extruding a protuberance inside a bending angle of the fork to the outside of the bending angle through a punching die so as to form a thickened external surface of a fork bottom; cutting two ends of the fork as required; and then carrying out processing programs.

Owner:NINGBO RENBA FORK

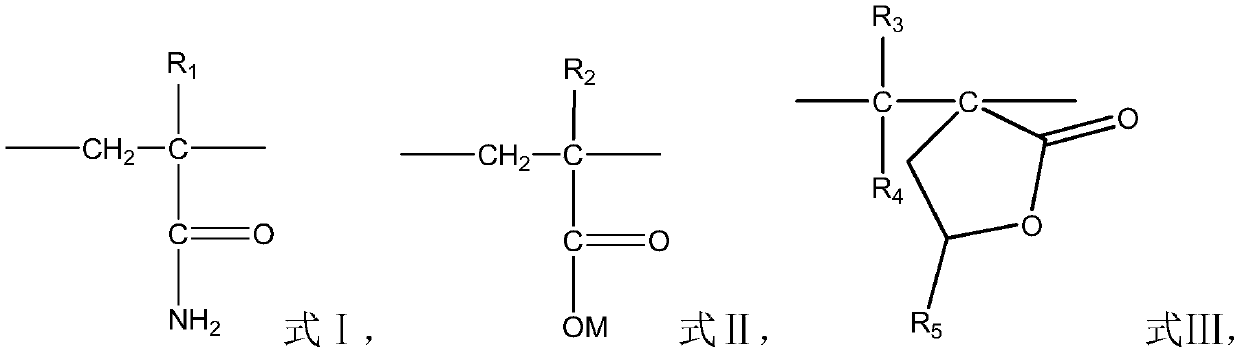

Acrylamide copolymer and its preparation method and application

ActiveCN109232806BHigh viscosityGood water solubilityDrilling compositionPolymer scienceOrganic chemistry

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a constitutional unit A shown as formula (I) in the description, a constitutional unit B shown as formula (II) in the description and a constitutional unit C shown as formula (III) in the description; by takingthe total weight of the acrylamide copolymer as the baseline, the constitutional unit A accounts for 70wt%-90wt%, the constitutional unit B accounts for 8wt%-28wt% and the constitutional unit C accounts for 0.1wt%-5wt%. The acrylamide copolymer can be used as a hot thickener for tertiary oil recovery of high-temperature and high-salinity reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylamide copolymer and its preparation method and application

ActiveCN109232798BHigh viscosityGood water solubilityDrilling compositionPolymer scienceOrganic chemistry

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a constitutional unit A shown as formula (I) in the description, a constitutional unit B shown as formula (II) in the description and a constitutional unit C shown as formula (III) in the description; by takingthe total weight of the acrylamide copolymer as the baseline, the constitutional unit A accounts for 70wt%-90wt%, the constitutional unit B accounts for 8wt%-28wt% and the constitutional unit C accounts for 0.1wt%-5wt%. The acrylamide copolymer can be used as a hot thickener for tertiary oil recovery of high-temperature and high-salinity reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylamide copolymer and its preparation method and application

ActiveCN109232808BHigh viscosityGood water solubilityDrilling compositionPolymer scienceOrganic chemistry

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a constitutional unit A shown as formula (I) in the description, a constitutional unit B shown as formula (II) in the description and a constitutional unit C shown as formula (III) in the description; by takingthe total weight of the acrylamide copolymer as the baseline, the constitutional unit A accounts for 70wt%-90wt%, the constitutional unit B accounts for 8wt%-28wt% and the constitutional unit C accounts for 0.1wt%-5wt%. The acrylamide copolymer can be used as a hot thickener for tertiary oil recovery of high-temperature and high-salinity reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylamide copolymer as well as preparation method and application thereof

ActiveCN107868189AGood water solubilityGood low temperature stabilityDrilling compositionSolubilityWater soluble

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a structure unit A shown in the formula I, a structure unit B shown in the formula II and a structure unit C shown in the formula III; on the basis of the total weight of the acrylamide copolymer, the content of the structure unit A is 43.5wt%-98wt%, the content of the structure unit B is 0.6wt%-39wt%, and the content of the structure unit C is 0.6wt%-39wt%. The acrylamide copolymer has good water solubility and a thermothickening function and is applicable to three-time oil recovery of a high-temperature and high-salinity reservoir as a thermothickening agent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Acrylamide copolymer as well as preparation method and application thereof

The invention relates to the field of oil field chemicals and discloses an acrylamide copolymer as well as a preparation method and an application thereof. The acrylamide copolymer contains a constitutional unit A shown as formula (I) in the description, a constitutional unit B shown as formula (II) in the description and a constitutional unit C shown as formula (III) in the description; by takingthe total weight of the acrylamide copolymer as the baseline, the constitutional unit A accounts for 70wt%-90wt%, the constitutional unit B accounts for 8wt%-28wt% and the constitutional unit C accounts for 0.1wt%-5wt%. The acrylamide copolymer can be used as a hot thickener for tertiary oil recovery of high-temperature and high-salinity reservoirs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com