Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Quick positioning operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

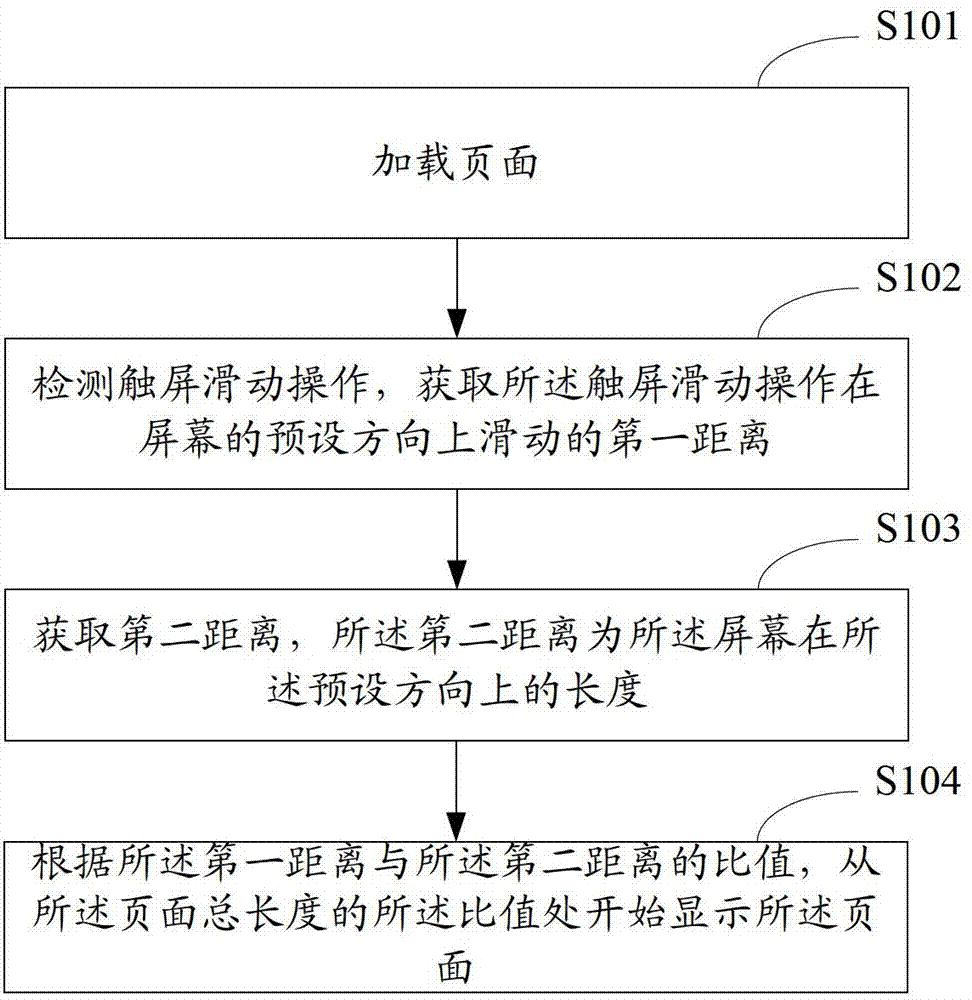

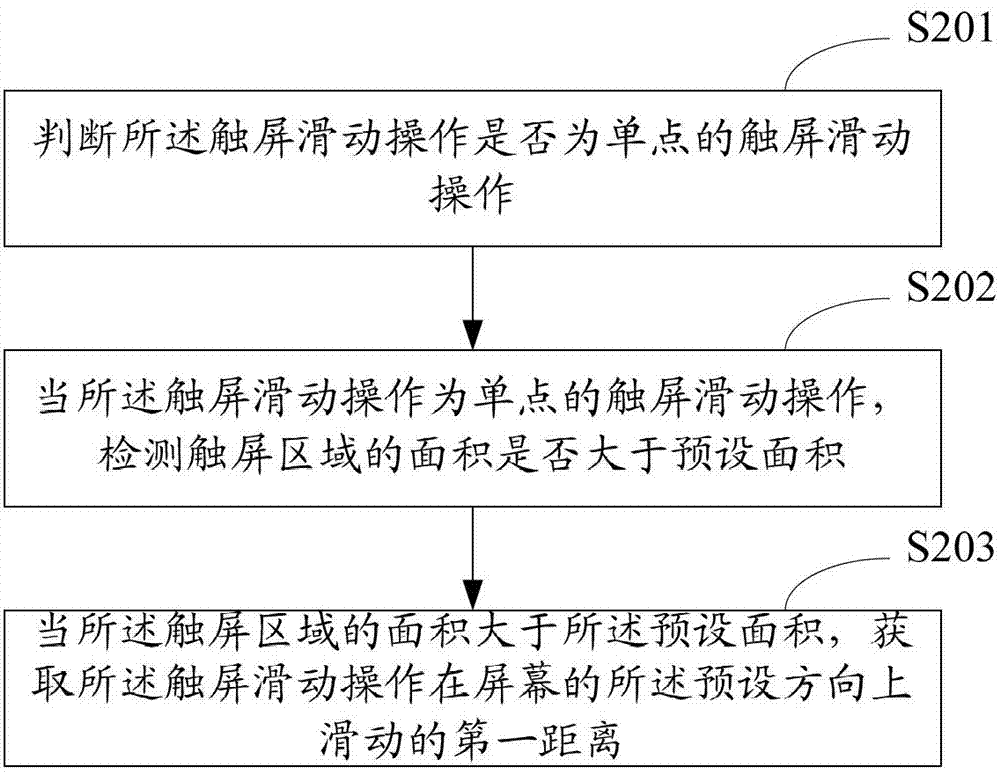

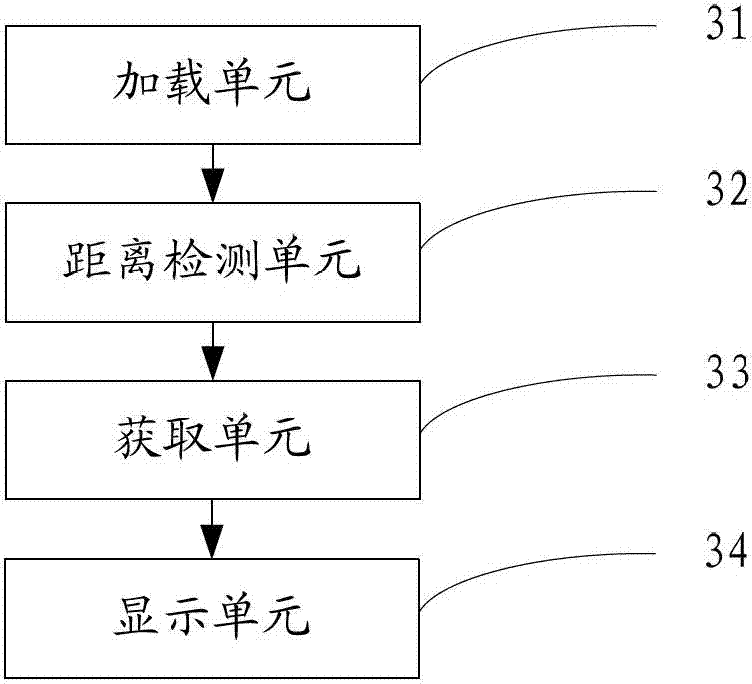

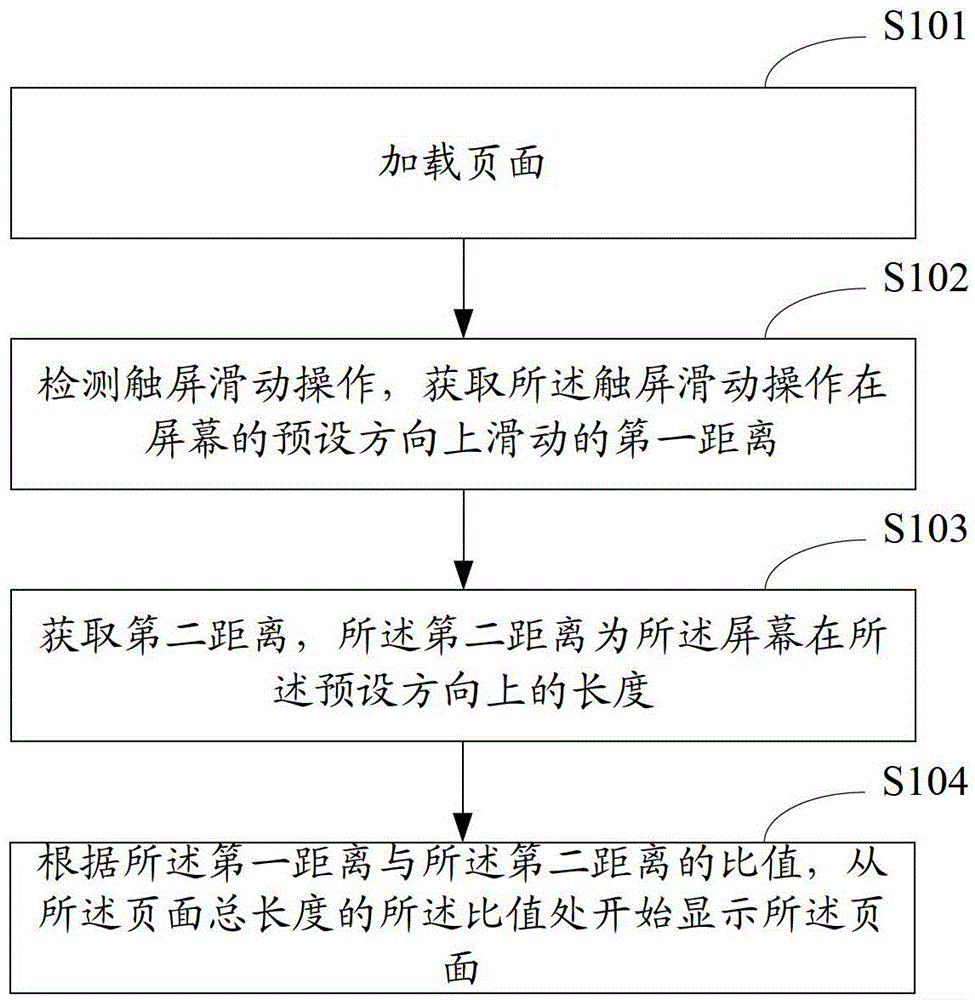

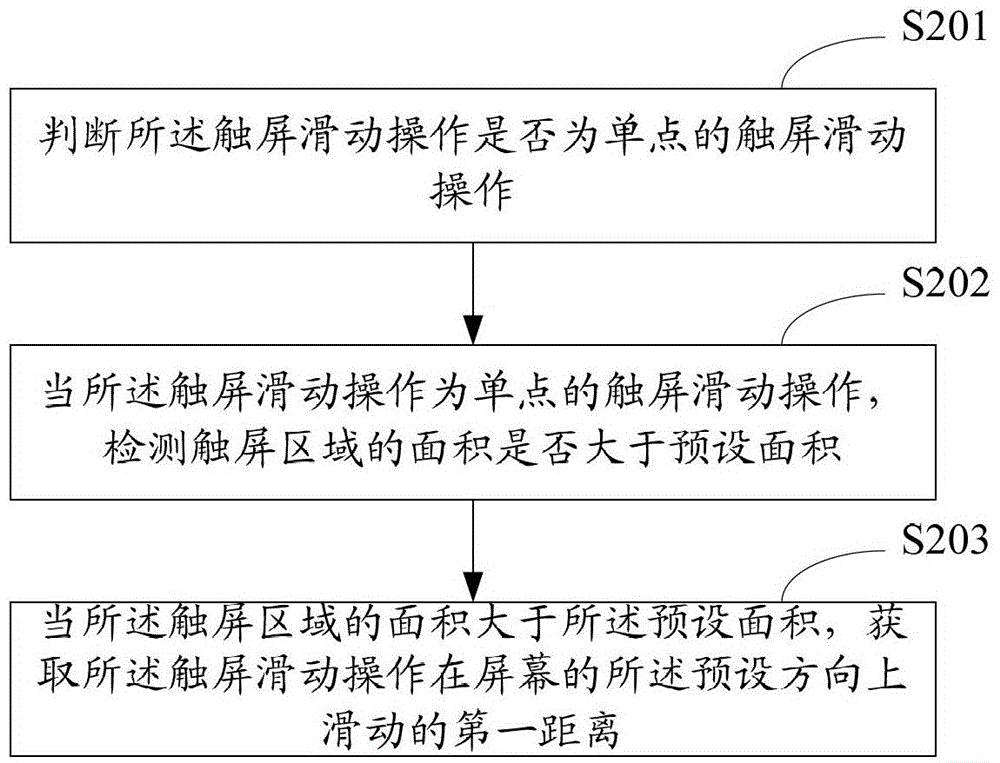

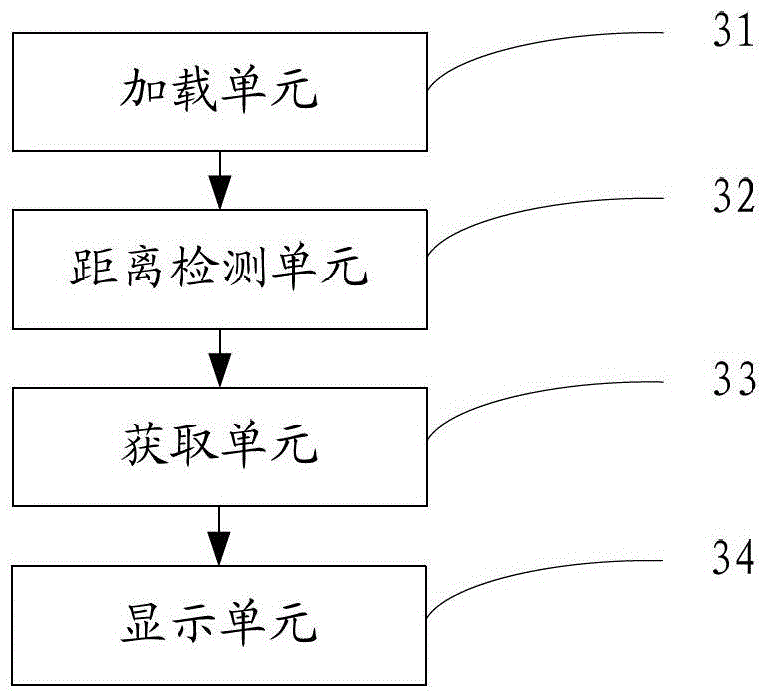

Page location method and page location system for mobile terminals

ActiveCN103034451AQuick positioning operationImprove reading efficiencyInput/output processes for data processingComputer scienceLocation systems

The invention is applicable to the technical field of mobile terminals, and provides a page location method and a page location system for mobile terminals. The page location method includes the following steps: a page is loaded; touch screen-sliding operation is detected, and a first distance of touch screen-sliding operation along a preset direction on a screen is acquired; a second distance, which is the length of the screen along the preset distance, is acquired; and according to the ratio of the first distance to the second distance, the page is displayed from the ratio of the total length of the page. In the invention, touch screen-sliding operation is detected in a mobile terminal, location is carried out in the page according to the touch screen-sliding distance, so that the page is scrolled to a located position, the page starts to be displayed from the located position, consequently, rapid location operation on the long page is realized, the operating efficiency is increased, and thereby the efficiency of reading the long page is increased as well.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

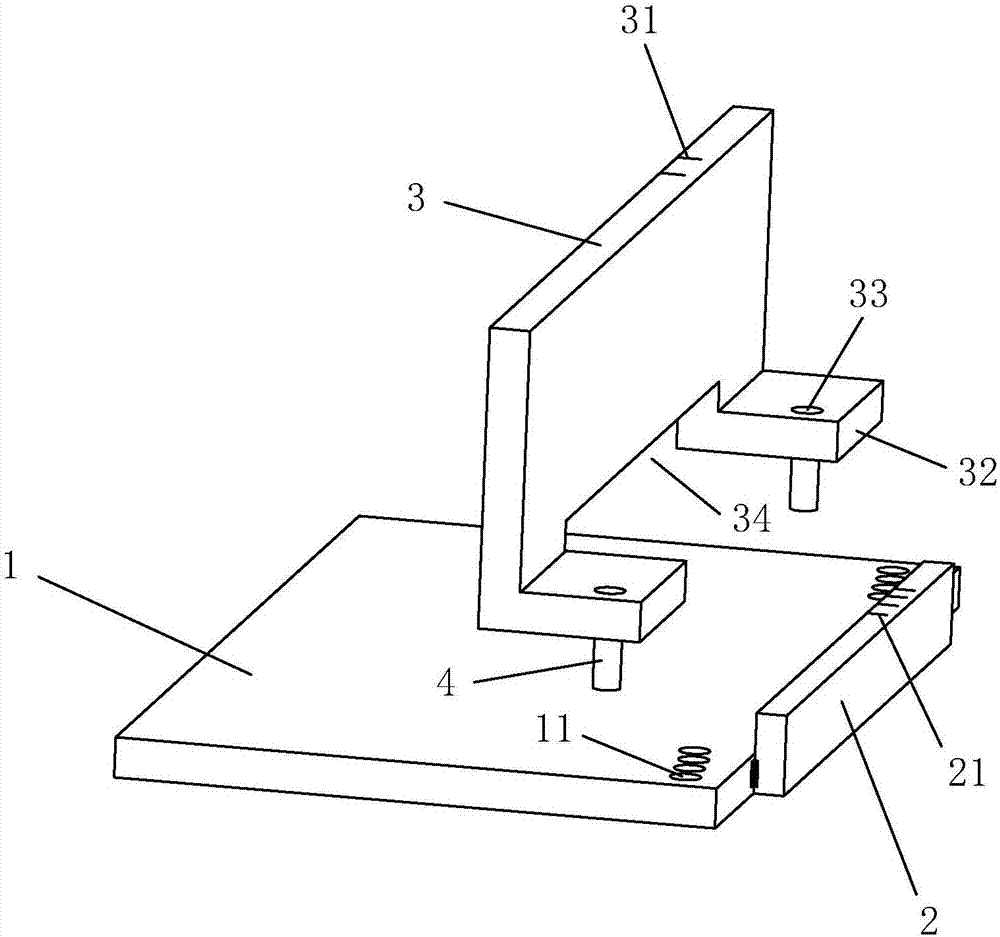

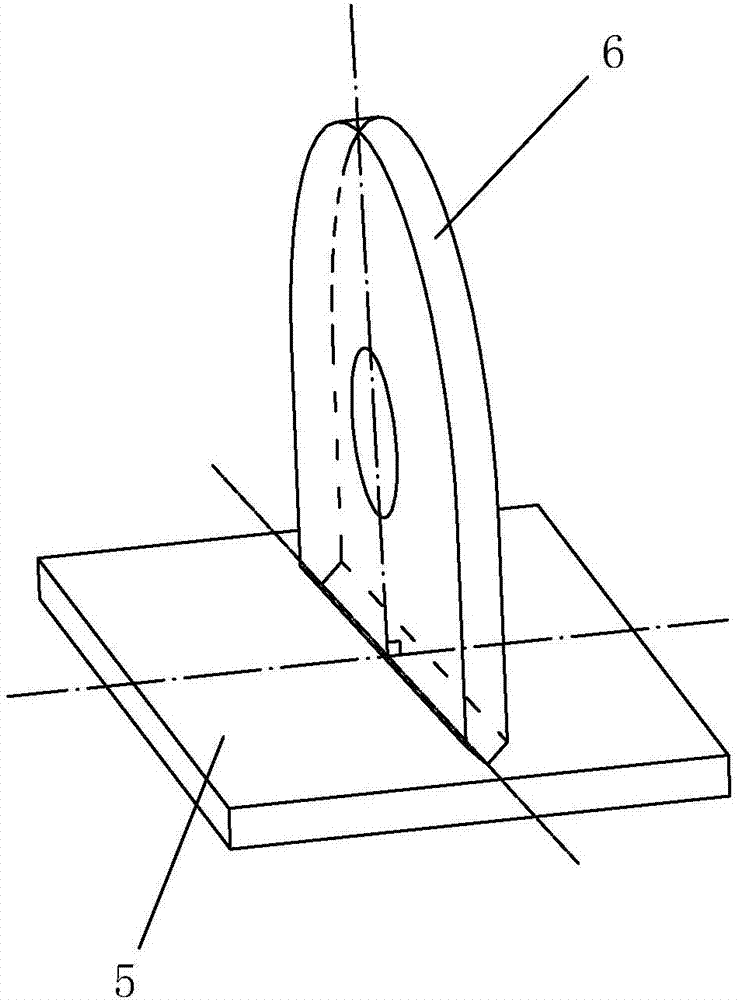

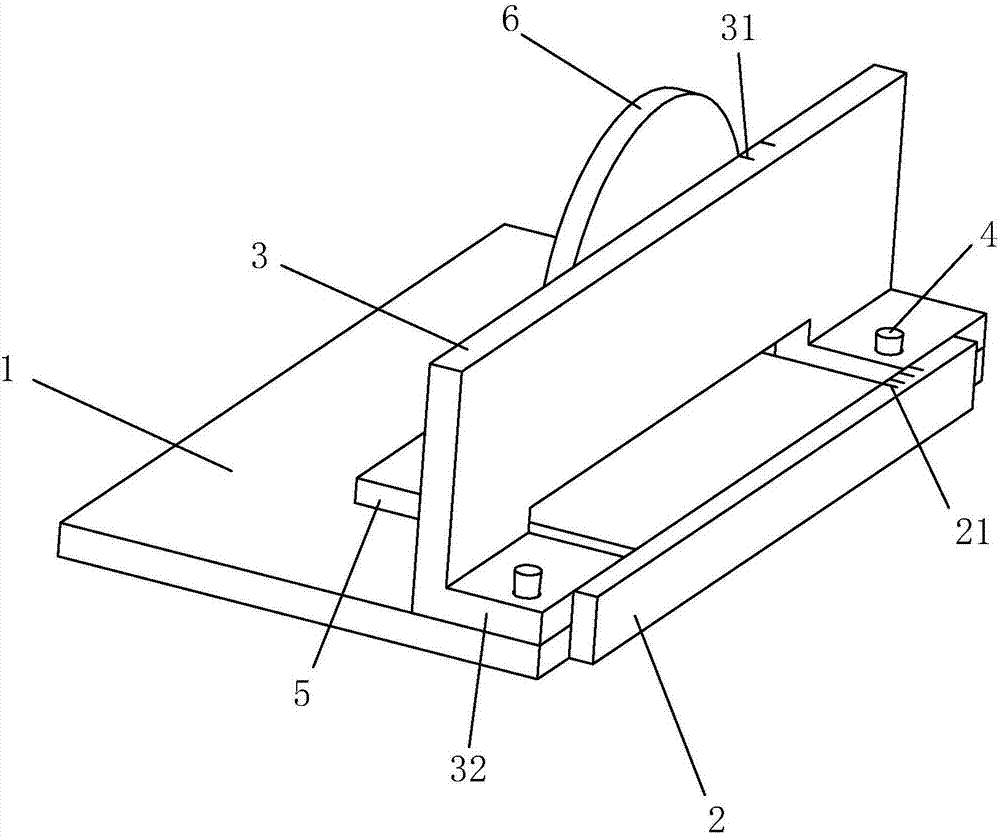

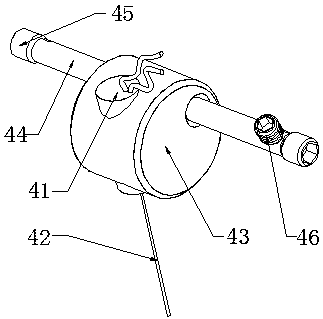

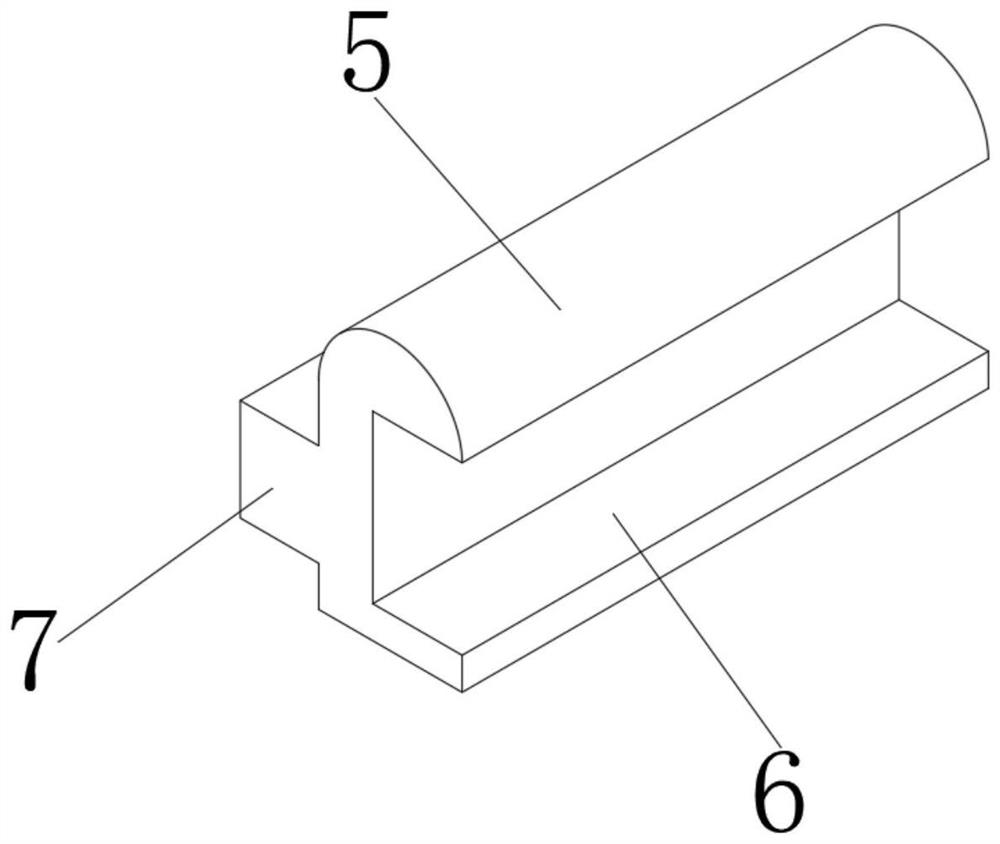

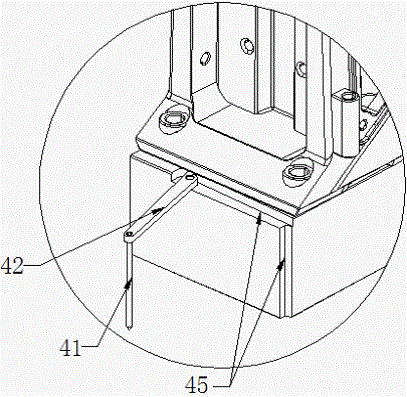

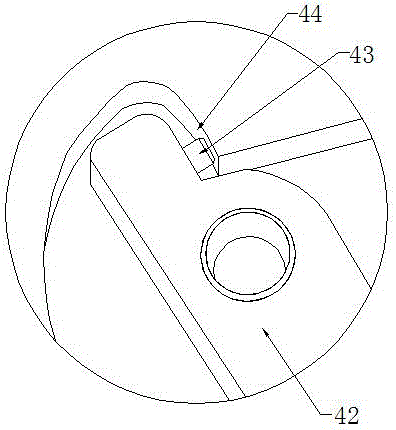

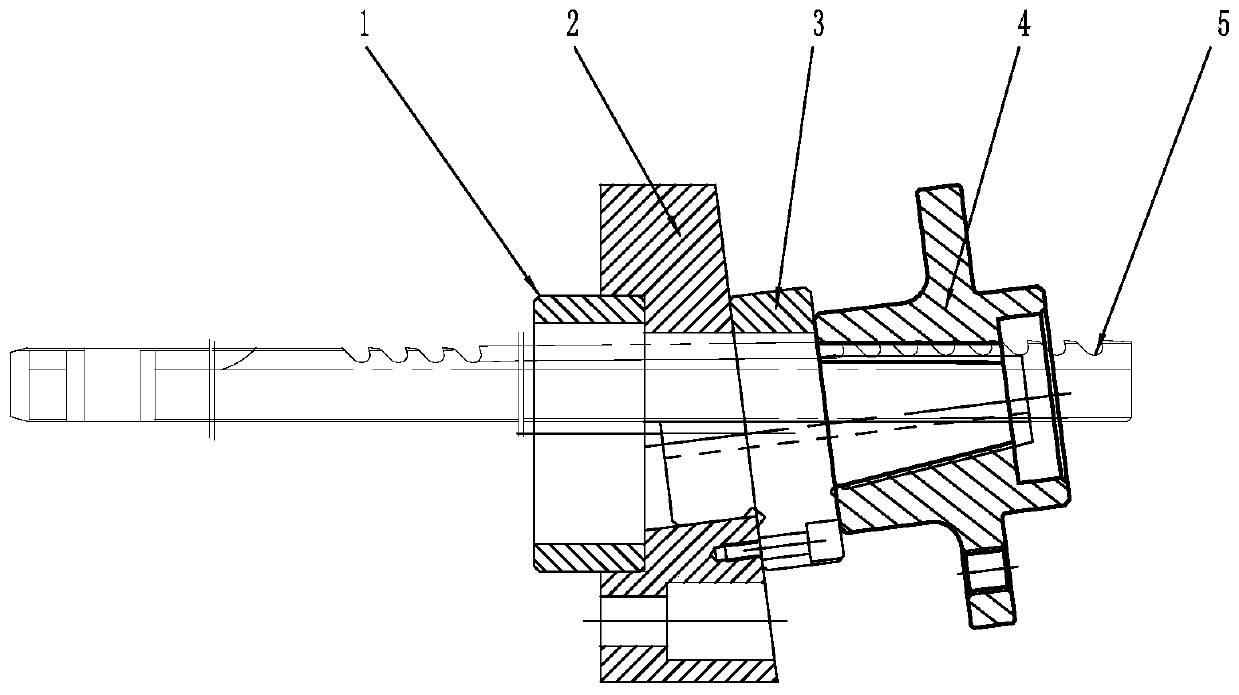

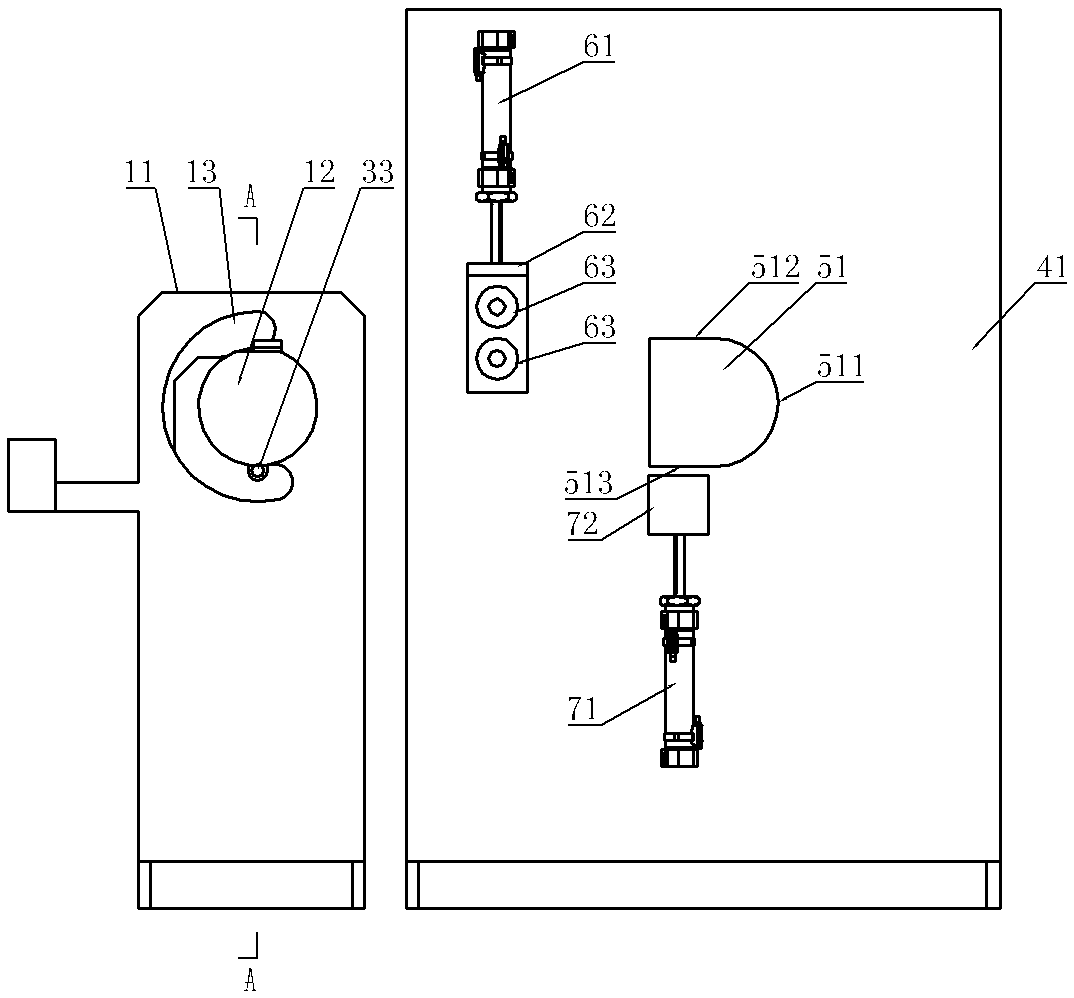

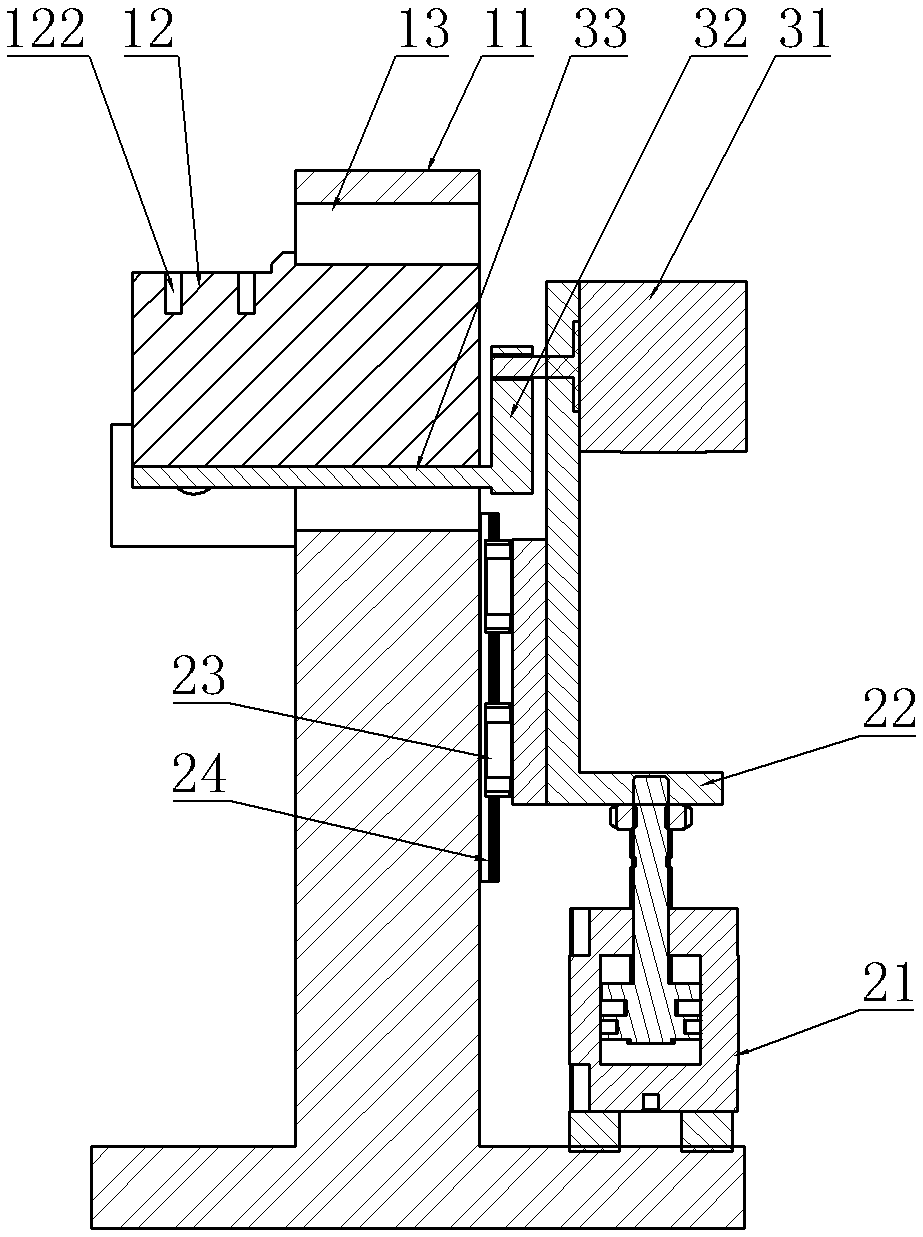

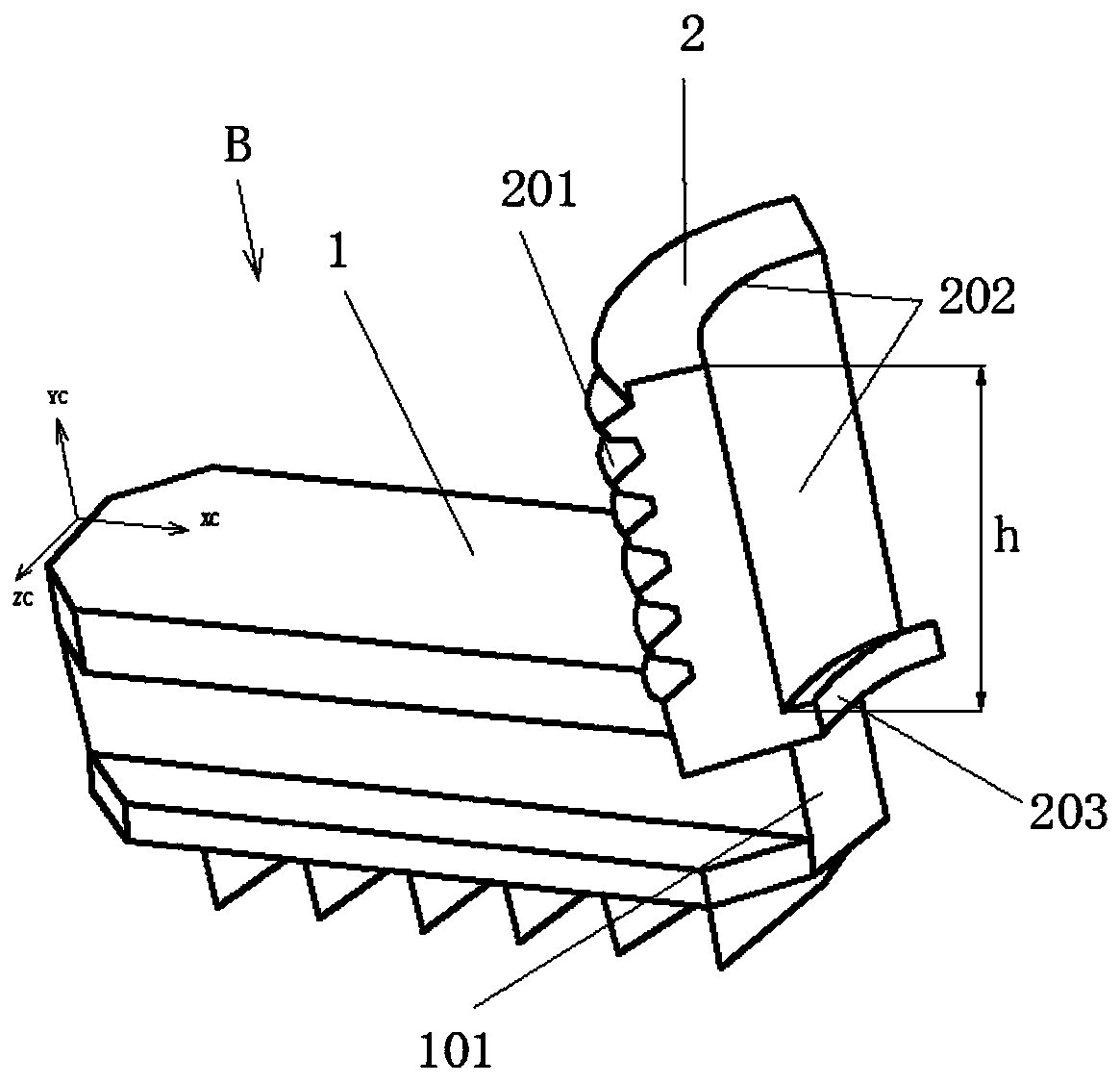

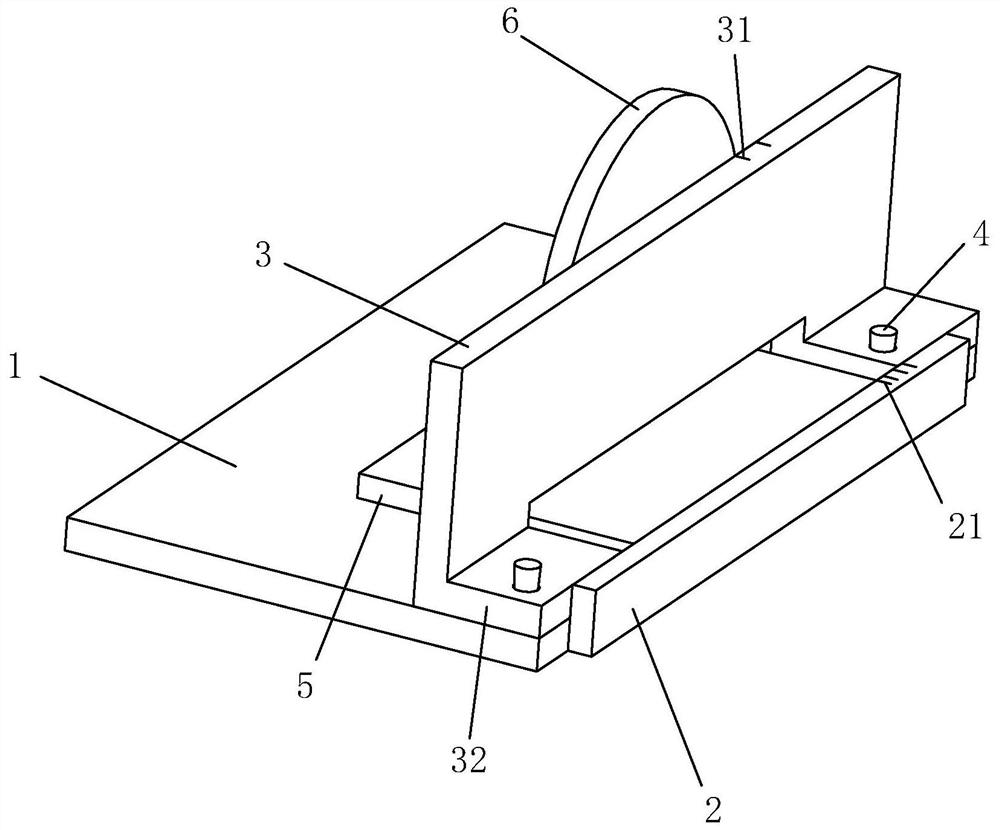

B-type hanging ring assembling and positioning tooling

ActiveCN107877430ASimple structureQuick positioning operationWork holdersMetal-working hand toolsEngineering

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

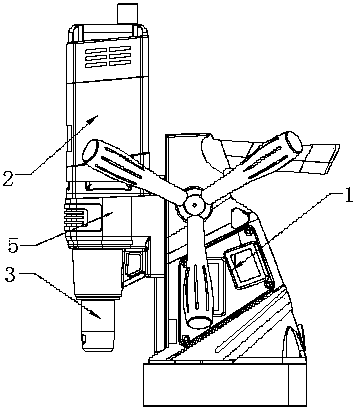

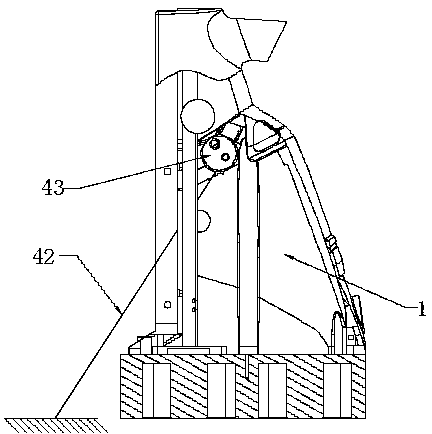

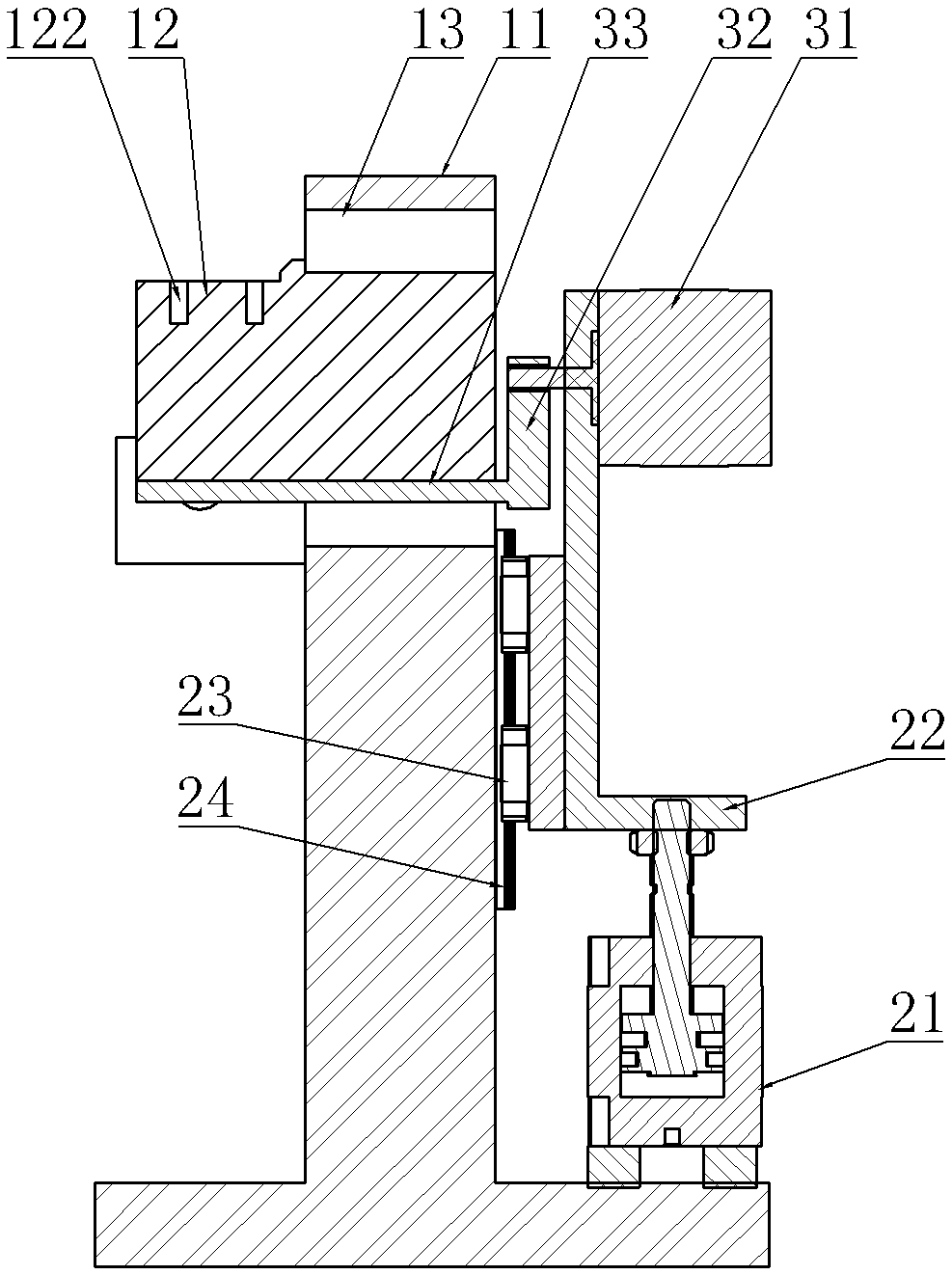

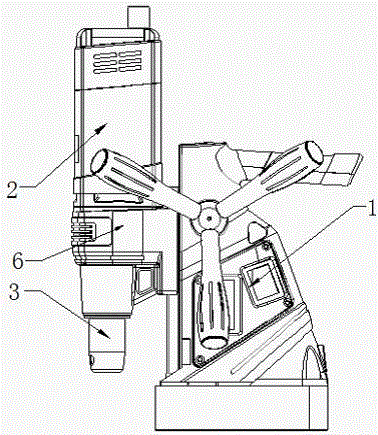

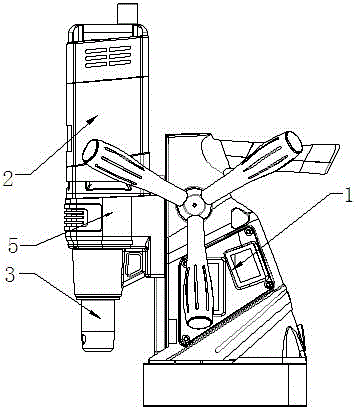

Drilling machine with optical positioning device

ActiveCN104209549AEasy to fixZero degrees of freedomAutomatic control devicesLarge fixed membersLight beamEngineering

The invention discloses a drilling machine with an optical positioning device. The drilling machine comprises a fixed machine body and a machine head, the machine head moves back and forth by being perpendicular to the bottom of the machine body, and the machine head is provided with a spindle where a tool is installed. The drilling machine further comprises the optical positioning device. The optical positioning device comprises an optical positioning lamp, and the intersection point between light beams emitted by the optical positioning lamp in a power-on state and the bottom plane of the machine body is located on the axis of the spindle. The drilling machine can finish drilling positioning operation conveniently and rapidly.

Owner:ZHEJIANG XINXING TOOLS CO LTD

Milling planing rotor base locating device used by pavement milling planer

InactiveCN102433830AImprove connection rigidityEasy positioningRoads maintainenceArchitectural engineeringRoad surface

The invention discloses a milling planing rotor base locating device used by a pavement milling planer, and relates to engineering machinery. The milling planing rotor base locating device comprises a barrel body, a base, a cutter sleeve and a cutter head, wherein a locating groove is manufactured on the bottom surface of the base; a locating block is fixed on an external cylindrical surface of the barrel body; and when the base is replaced by a new base, the locating groove of the base is inserted and then welded in the locating block, so that the base can be accurately located. When the base is replaced by the new base, the operation is convenient and fast, the location is accurate, and the working efficiency is high. The base is closely matched and connected with the locating block by the locating groove, so that the connection rigidity can be improved. The locating block is welded on the barrel body or connected on the barrel body in other ways.

Owner:徐州昂拓机械科技有限公司

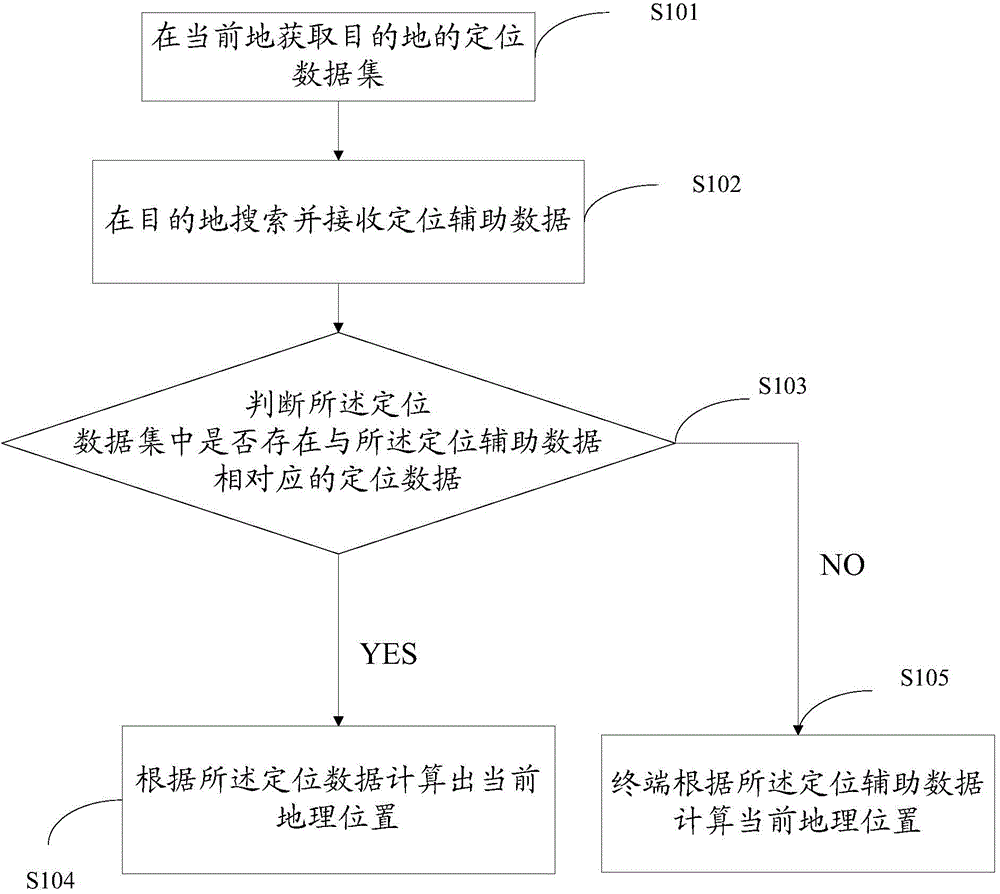

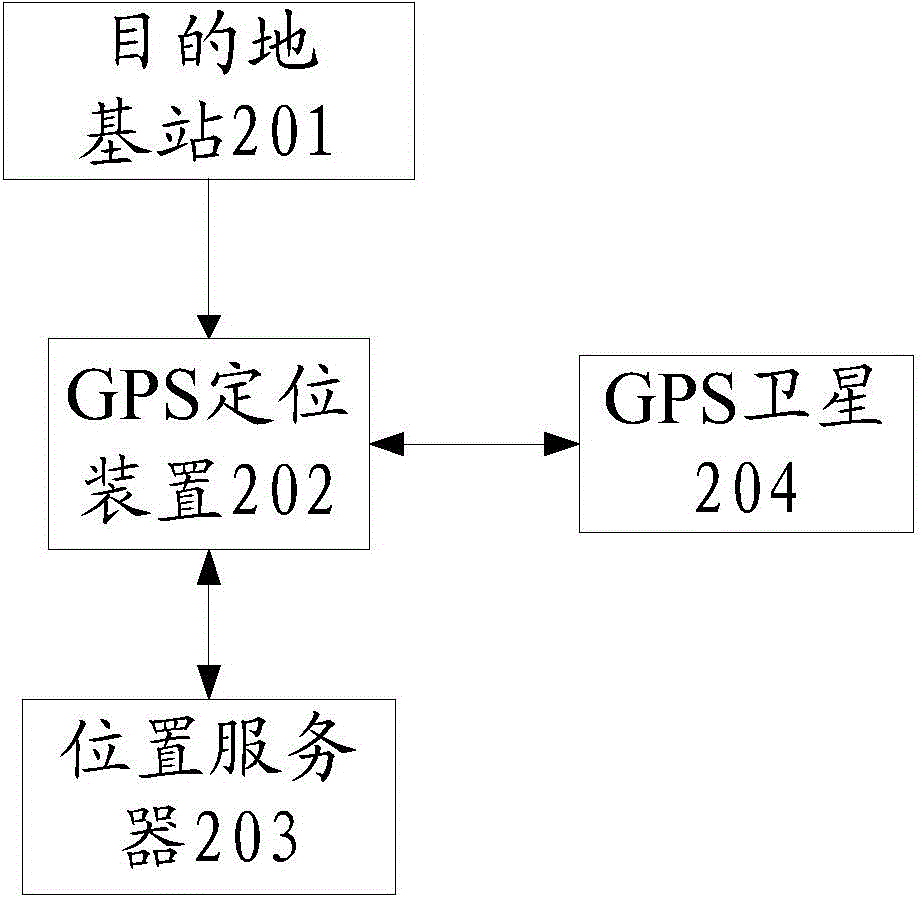

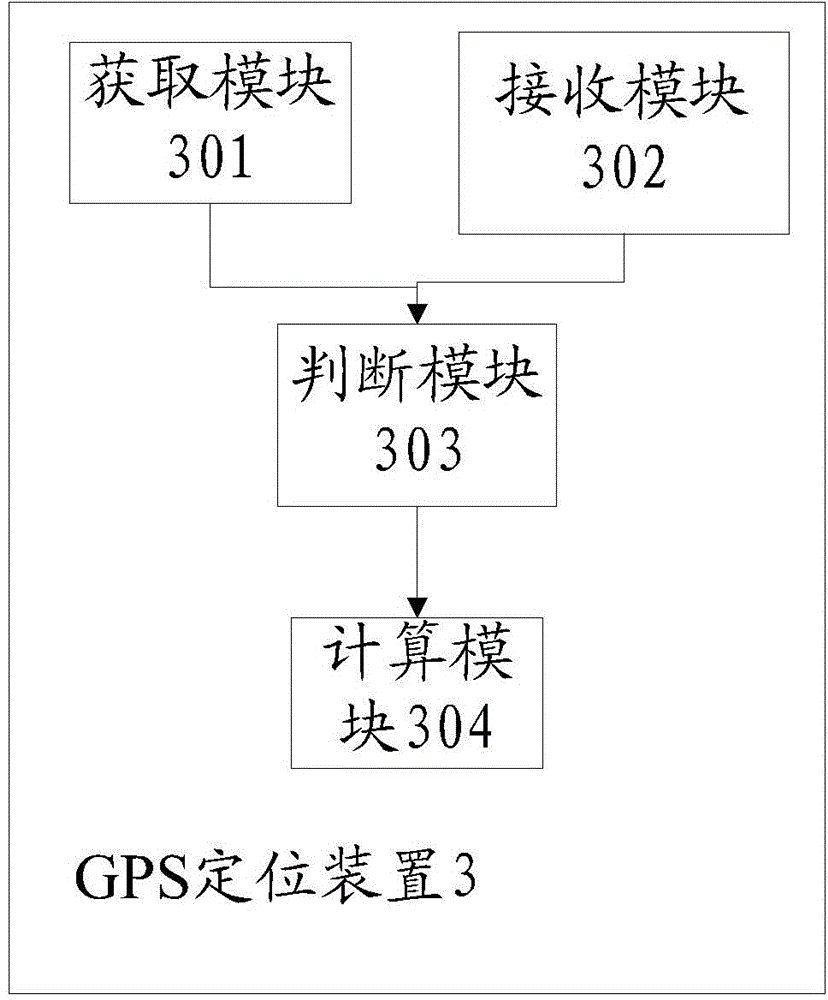

Method and device for locating

ActiveCN103558621AImprove experienceEasy to complete the positioning operationSatellite radio beaconingGeographic siteData set

The invention provides a method and device for locating. The method includes the steps of obtaining a location data set of a destination at the current place which is different from the destination, searching for a GPS satellite at the destination, receiving location auxiliary data collected by the searched GPS satellite, judging whether location data corresponding to the location auxiliary data exist in the location data set or not, and calculating the current geographic position according to the location data when the location data corresponding to the location auxiliary data exist in the location data set. According to the method and device, the problems that a user can download the location data set only after reaching the destination to further conduct location operation, the location data set cannot be downloaded at the current place, if the network condition is poor or no network exists, the location time is excessively long, and therefore the user experience is influenced are solved.

Owner:YULONG COMPUTER TELECOMM SCI (SHENZHEN) CO LTD

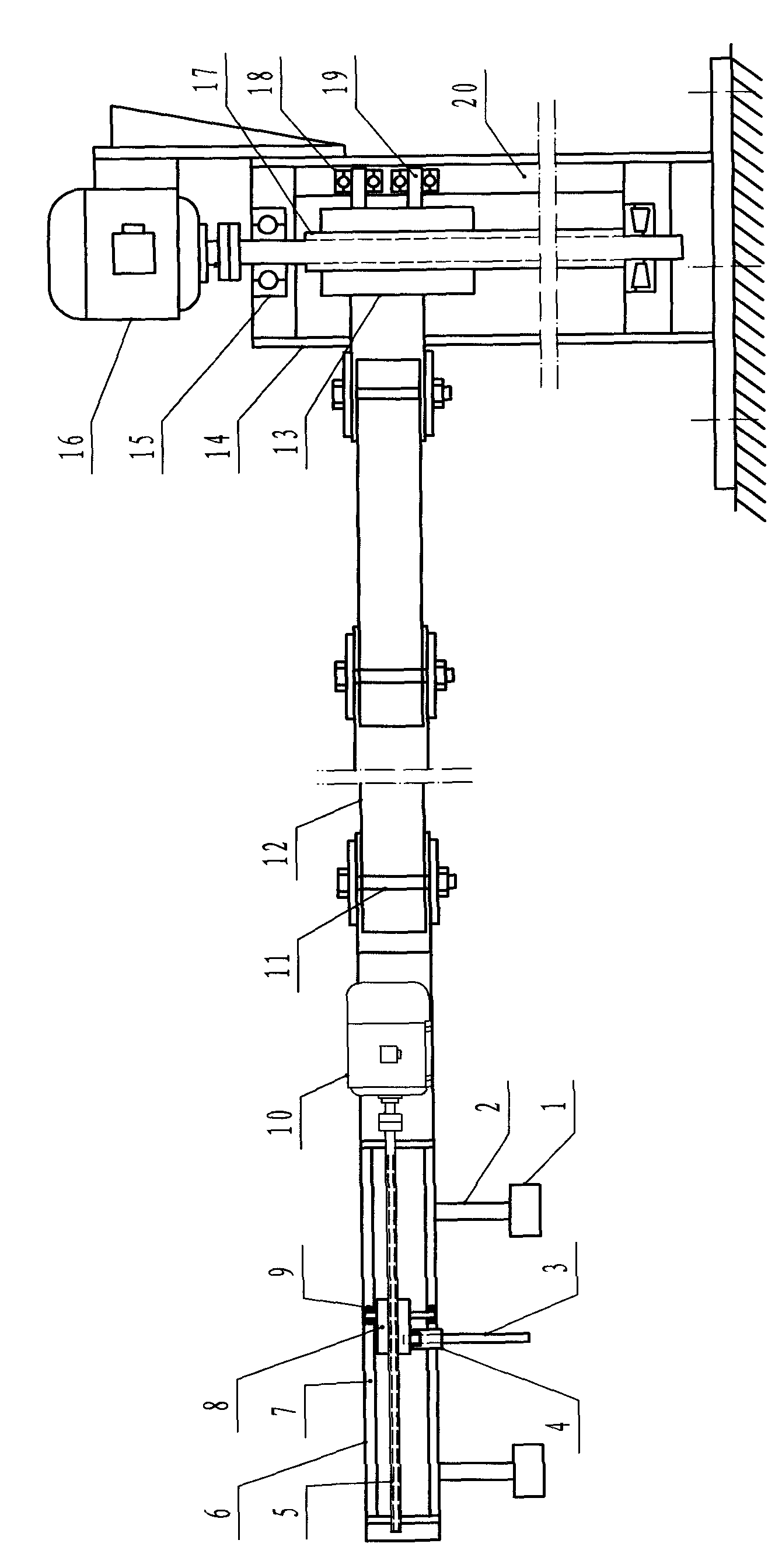

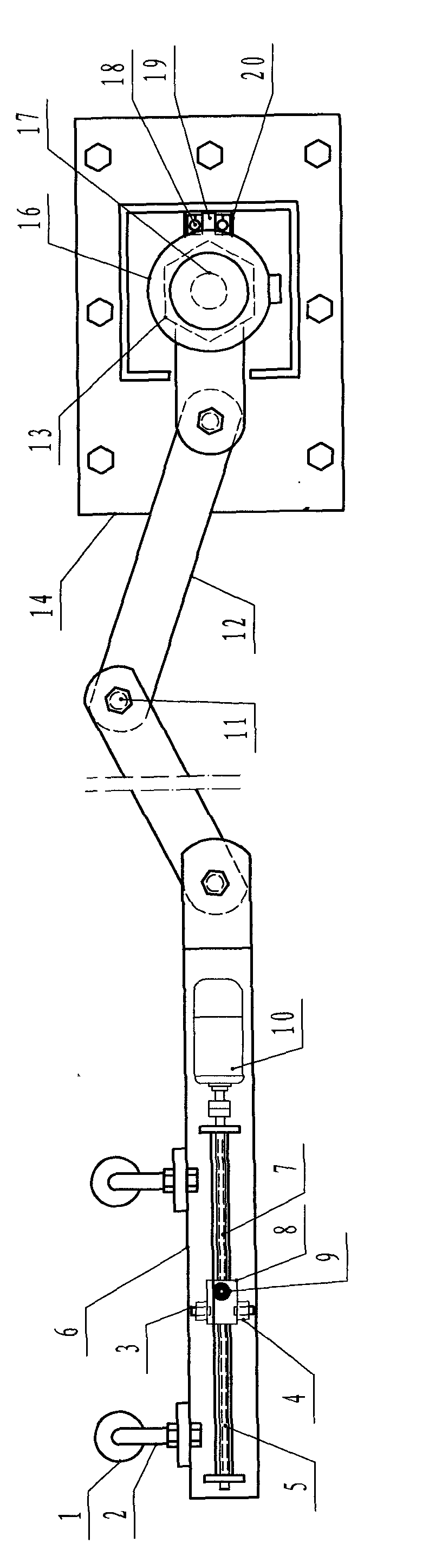

Large-size workpiece weld holder

InactiveCN102152039AQuick positioning operationPrecise positioningWelding/cutting auxillary devicesAuxillary welding devicesDrive motorLarge size

The invention relates to a large-size workpiece weld holder, comprising a supporting arm consisting of a welding arm and a hinge arm, wherein the hinge arm is of multiple sections which are connected by rotating shafts, the welding arm is fixedly arranged on the front end of the hinge arm, the welding arm is provided with a welding-gun mobile motor, a welding-gun mobile screw rod and a welding gun frame, two sides of the welding gun frame are respectively provided with a welding gun, the rear end of the hinge arm is fixedly provided with a rack screw-rod nut, the middle part of a rack is provided with a rack screw rod, the rack screw-rod nut is sleeved on the rack screw rod, the upper end and the lower end of the rack screw rod are fixed by bearings, the upper end of the rack screw rod is connected with a driving motor, a positioning frame is arranged on the side face of the welding arm, and an electromagnetic sucker is arranged below the positioning frame; and the rack is an independent stand column, the lower end of the rack is fixed on the ground, and only one supporting arm is arranged on the rack. When the large-size workpiece welding holder is used for welding, the advantages of easiness for positioning and high working efficiency are achieved.

Owner:云南通变冷作铆焊有限公司

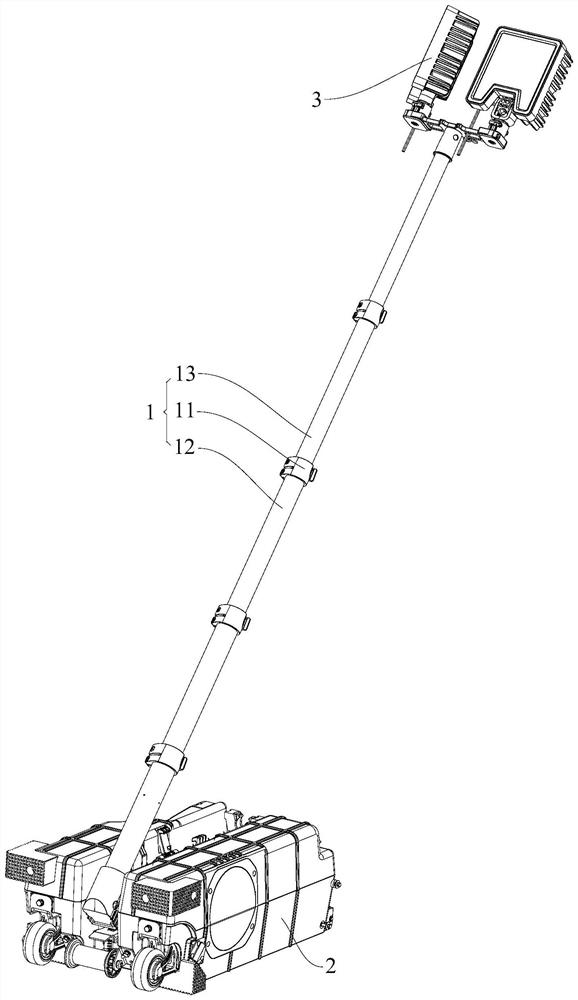

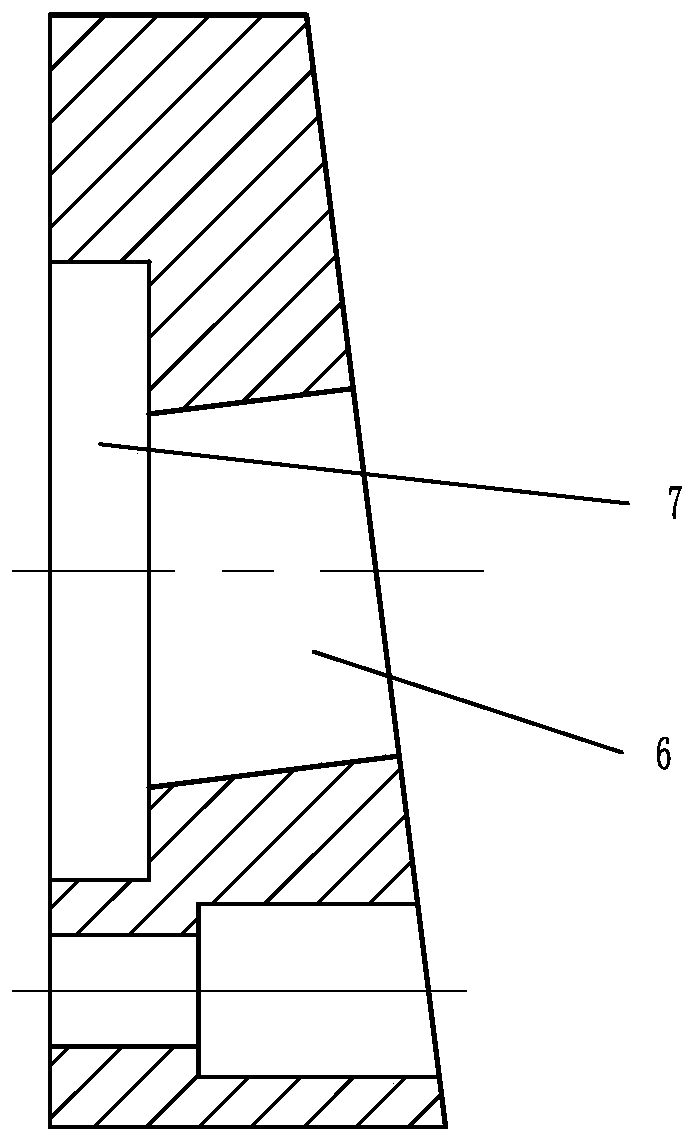

Lifting type lighting device

InactiveCN112361268AMeet high requirementsSimplify the lifting processLighting support devicesFixed installationStructural engineeringLight head

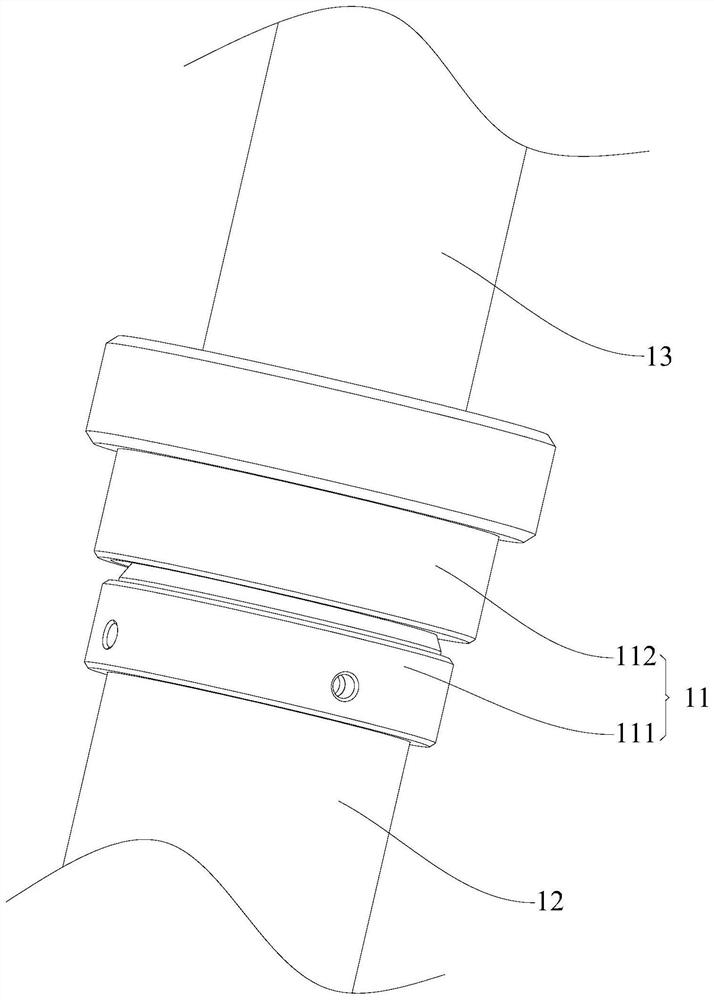

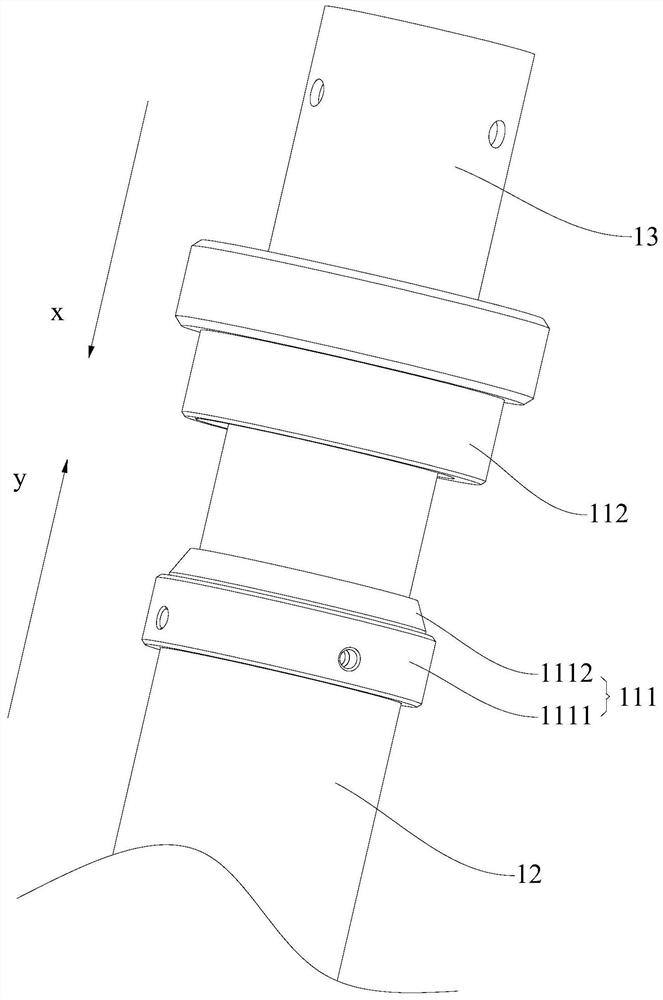

The invention is suitable for the technical field of mechanical self-locking, and provides a lifting type lighting device which comprises a lamp holder, a lifting rod connected to the lamp holder anda lamp cap arranged on the lifting rod. The lifting rod comprises a self-locking assembly and at least two rod bodies which are sequentially and movably connected in a sleeved mode in the axial direction, and every two adjacent rod bodies are the first rod body and the second rod body respectively. The self-locking assembly comprises a first locking sleeve and a second locking sleeve, the first rod body is sleeved with the first locking sleeve, and the second rod body is movably sleeved with the second locking sleeve; the section, close to the first locking sleeve, of the second locking sleeveis eccentric, and the second locking sleeve is connected to the first locking sleeve in a sleeving mode and inclines relative to the second rod body so that self-locking limiting of the first rod body and the second rod body in the axial direction can be formed. In the embodiment of the invention, the second locking sleeve sleeves the first locking sleeve and inclines relative to the second rod body so as to clamp the second rod body, so that self-locking limiting of the first rod body and the second rod body in the axial direction is realized, and the lifting and locking operations of the lifting rod are very simple and rapid.

Owner:SHENZHEN OCEANS KING LIGHTING ENG CO LTD +2

Drama background device

InactiveCN107989415AImprove replacement efficiencyChanging the background is quick and easyStage arrangementsTheatresEngineeringMechanical engineering

A drama background device comprises a drama background bearing plate, a drama background moving base, moving locking positioning assemblies, a first background reinforcing side plate and a second background reinforcing side plate, one end of the drama background bearing plate is mounted on the drama background moving base, and the first background reinforcing side plate and the second background reinforcing side plate are mounted on the two sides of the drama background bearing plate in a mutual symmetry mode. According to the drama background device, by arranging the drama background bearingplate, the drama background moving base, the moving locking positioning assemblies, the first background reinforcing side plate and the second background reinforcing side plate, the drama background moving base can be moved rapidly through a first moving rotating shaft, a second moving rotating shaft and a third moving rotating shaft, and rapid locking positioning operation is conducted through the moving locking positioning assembly; and manual carrying replacement of a background wall is not needed, and background replacement is rapid and convenient, so that the drama performance presentation effect is better.

Owner:惠州市威帝食品科技有限公司

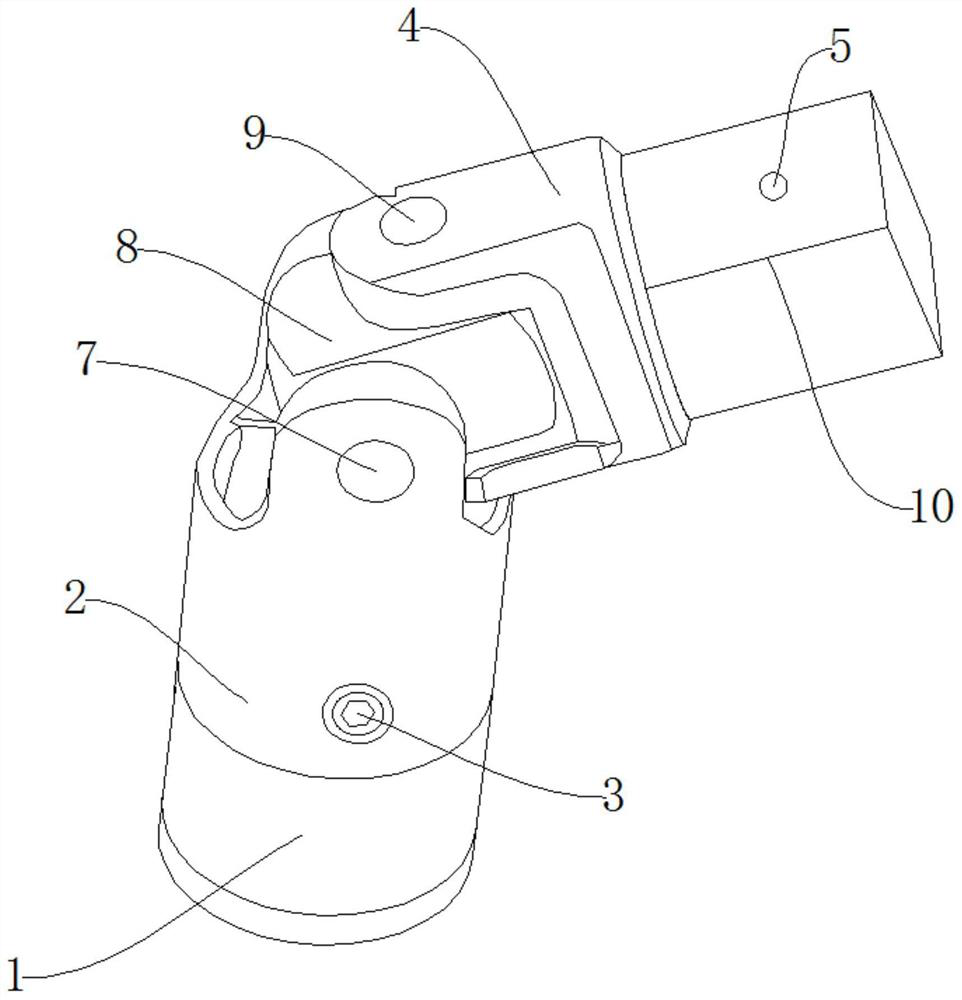

Universal sleeve conversion tool

InactiveCN112775877AAchieve constant torque outputAffect flexibilitySpannersWrenchesEngineeringSteel ball

The invention discloses a universal sleeve conversion tool. The universal sleeve conversion tool comprises a sleeve connecting piece, a first universal support, a second universal support and a wrench fixing piece, wherein a sleeve fixing groove is arranged in the sleeve connecting piece; the first universal support is arranged above the sleeve connecting piece; and a torque adjusting threaded hole is formed in the side wall of the first universal support. The universal sleeve conversion tool has the beneficial effects that by arranging a torque adjusting supporting pressure spring, a torque adjusting supporting block and a torque adjusting screw, the acting force between a supporting steel ball and a supporting groove can be adjusted, then the torque transmitted between the first universal support and the sleeve connecting piece is adjusted, constant torque output can be achieved, and the universal sleeve conversion tool is convenient and practical; and by arranging a flexible protection cover, the influence on the flexibility of angle adjustment of the universal sleeve conversion tool due to the entry of external dust can be prevented, and the performance of the universal sleeve conversion tool is improved.

Owner:刘可夫

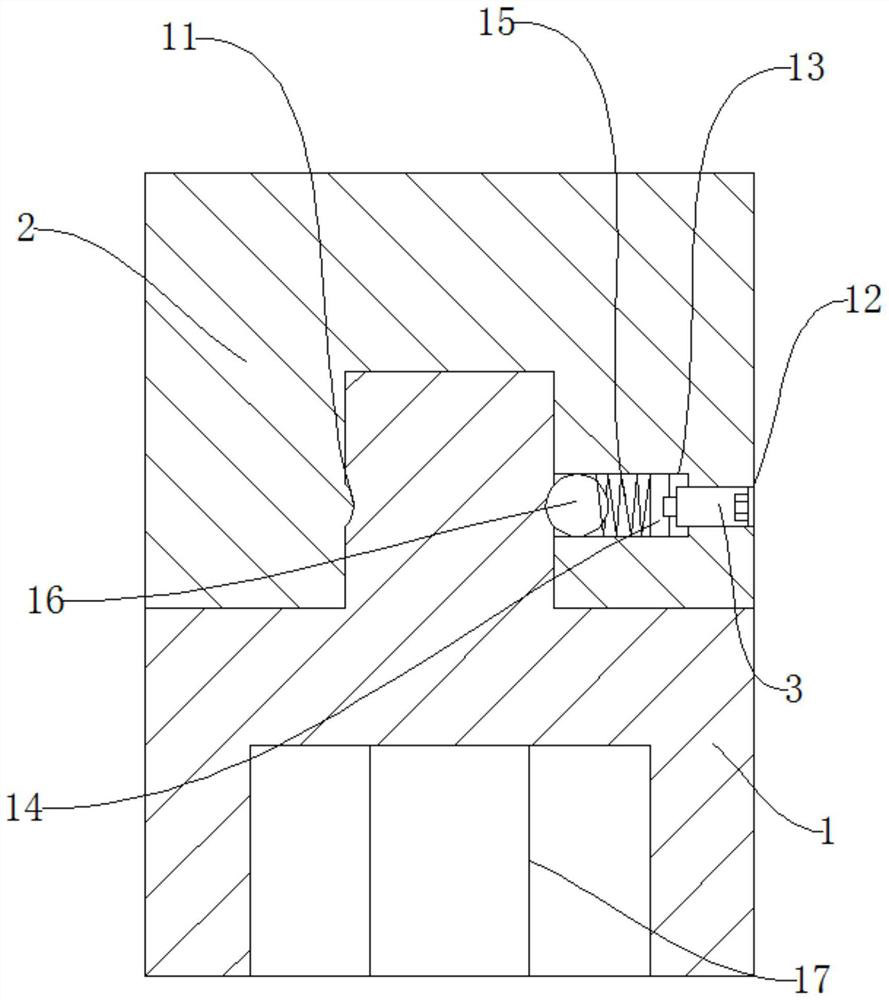

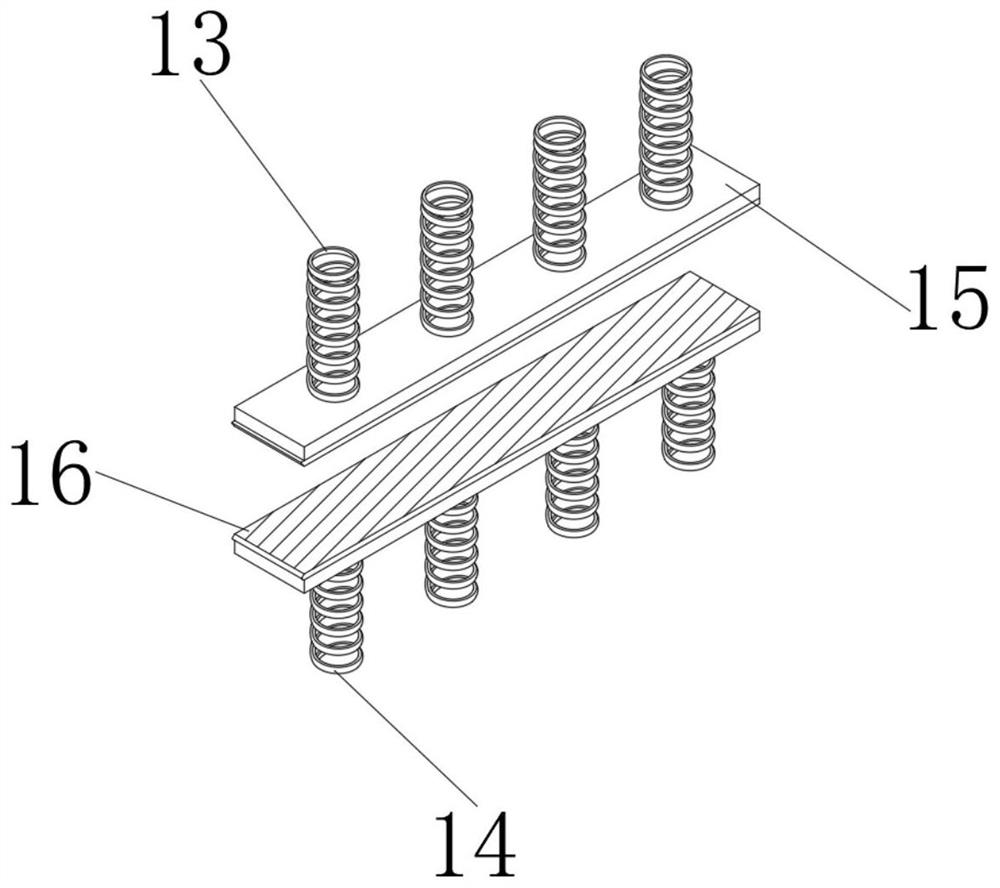

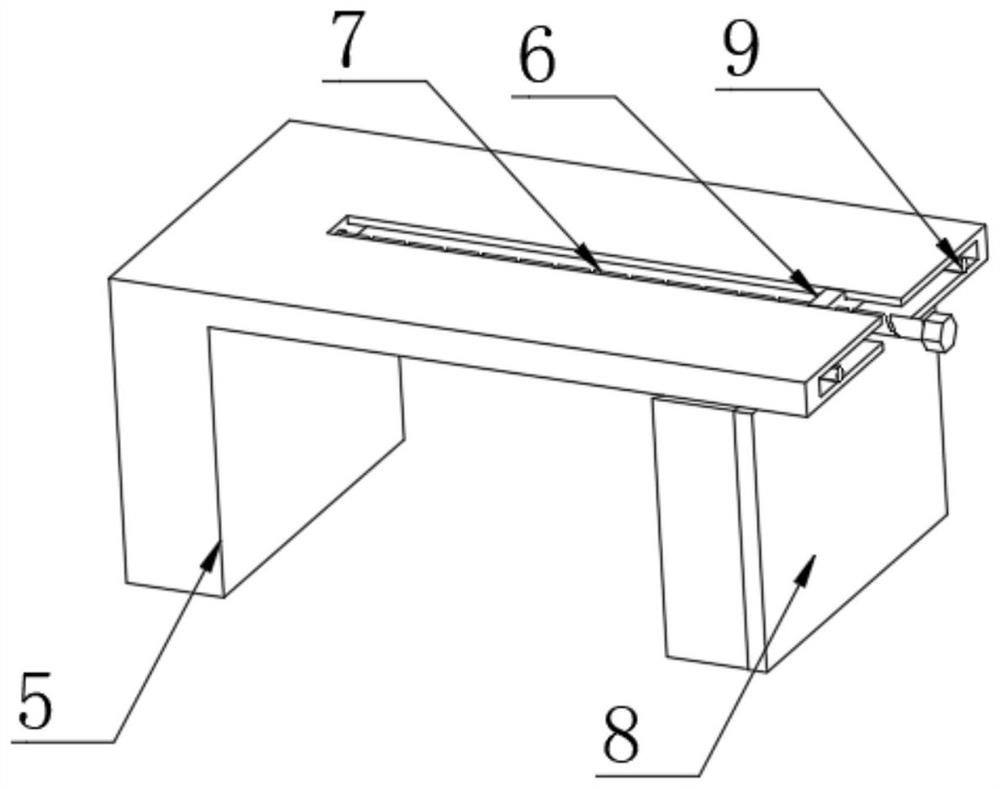

Plate shearing machine with positioning mechanism

PendingCN112809079ARapid positioningQuick positioning operationShearing machinesShearing machine accessoriesClassical mechanicsEngineering

The invention relates to the technical field of plate shearing machine equipment, in particular to a plate shearing machine with a positioning mechanism. The plate shearing machine comprises a worktable, a plate shearing machine body, a first sliding rail, a second sliding rail and a first positioning frame, a first positioning groove is formed in one side of the first positioning frame, a first connecting block is fixedly connected to the other side of the first positioning frame, a first supporting plate and a second supporting plate are sequentially and fixedly connected to the upper surface of the workbench from left to right. A steel plate can be quickly positioned and fixed through the first positioning frame and the second positioning frame, in the actual use process, a worker firstly places the two ends of the steel plate needing to be subjected to plate shearing operation into the first positioning frame and the second positioning frame correspondingly, a first spring assembly and a second spring assembly can respectively push a first clamping plate and a second clamping plate to firmly jack and fix the steel plate in a positioning groove of a positioning frame, so that the steel plate can be stably fixed through the design.

Owner:NANTONG MTR MACHINE TOOL CO LTD

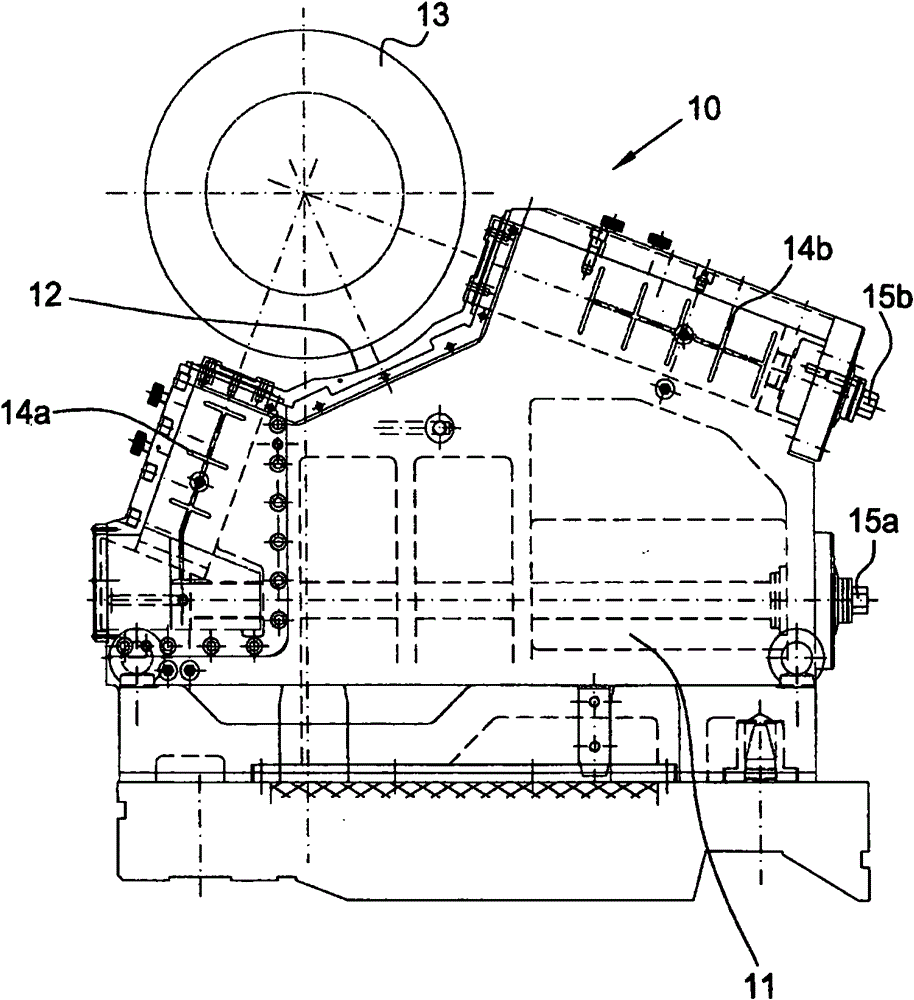

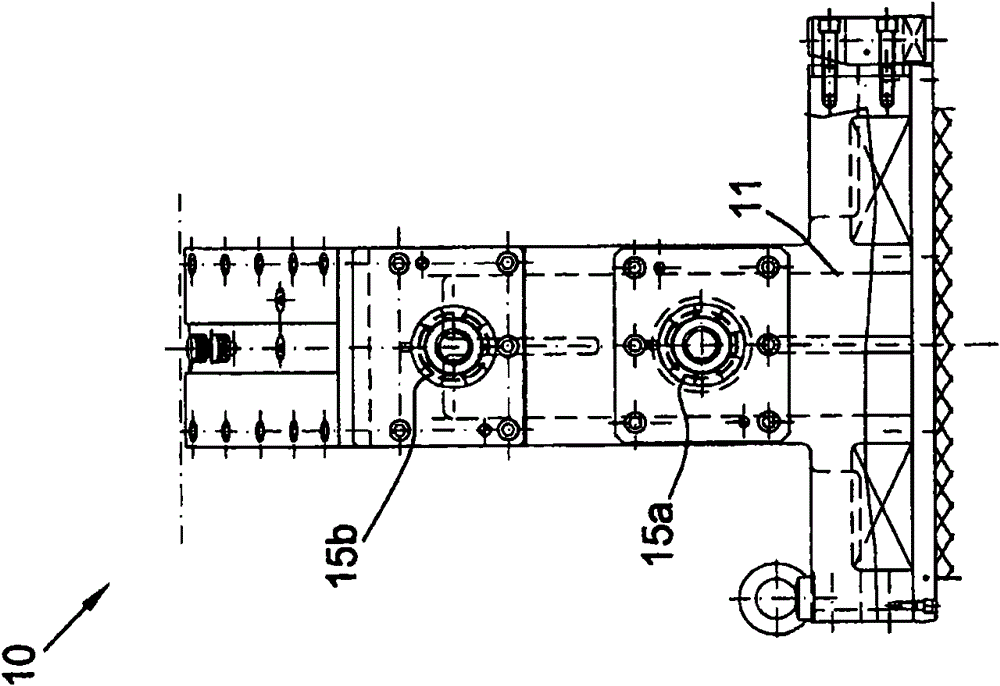

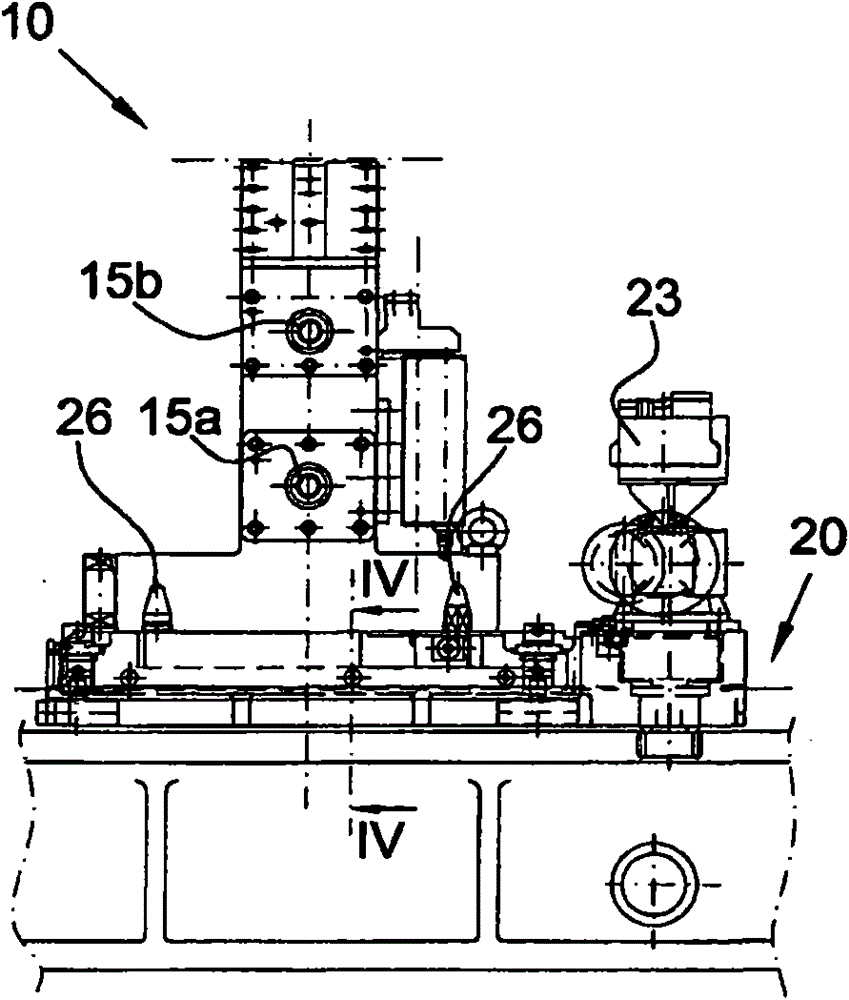

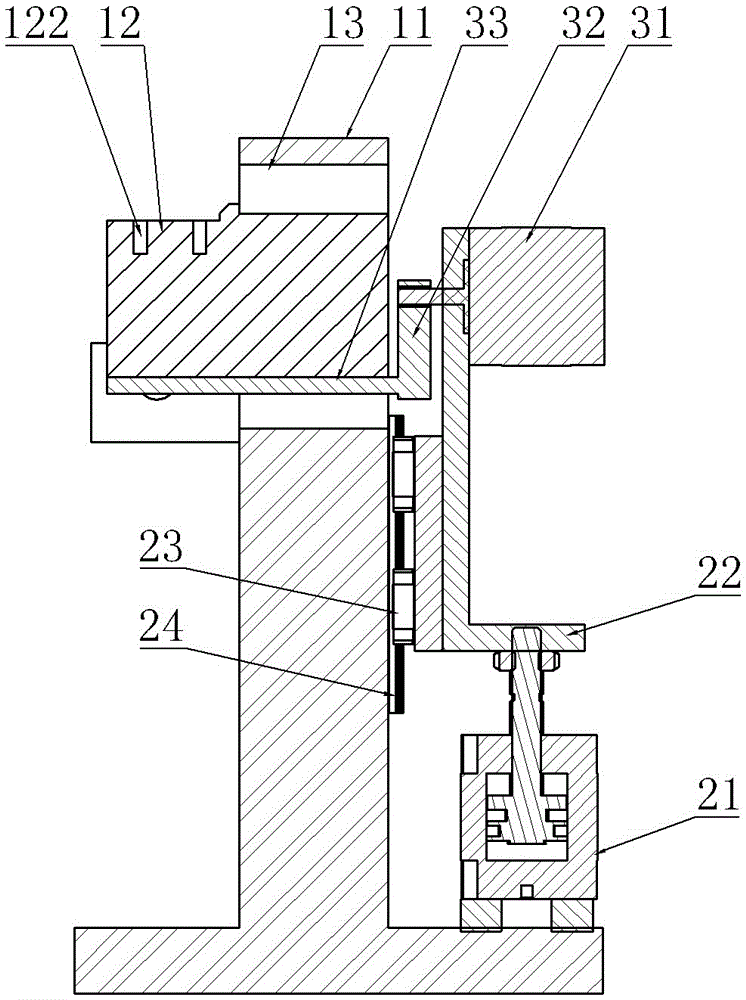

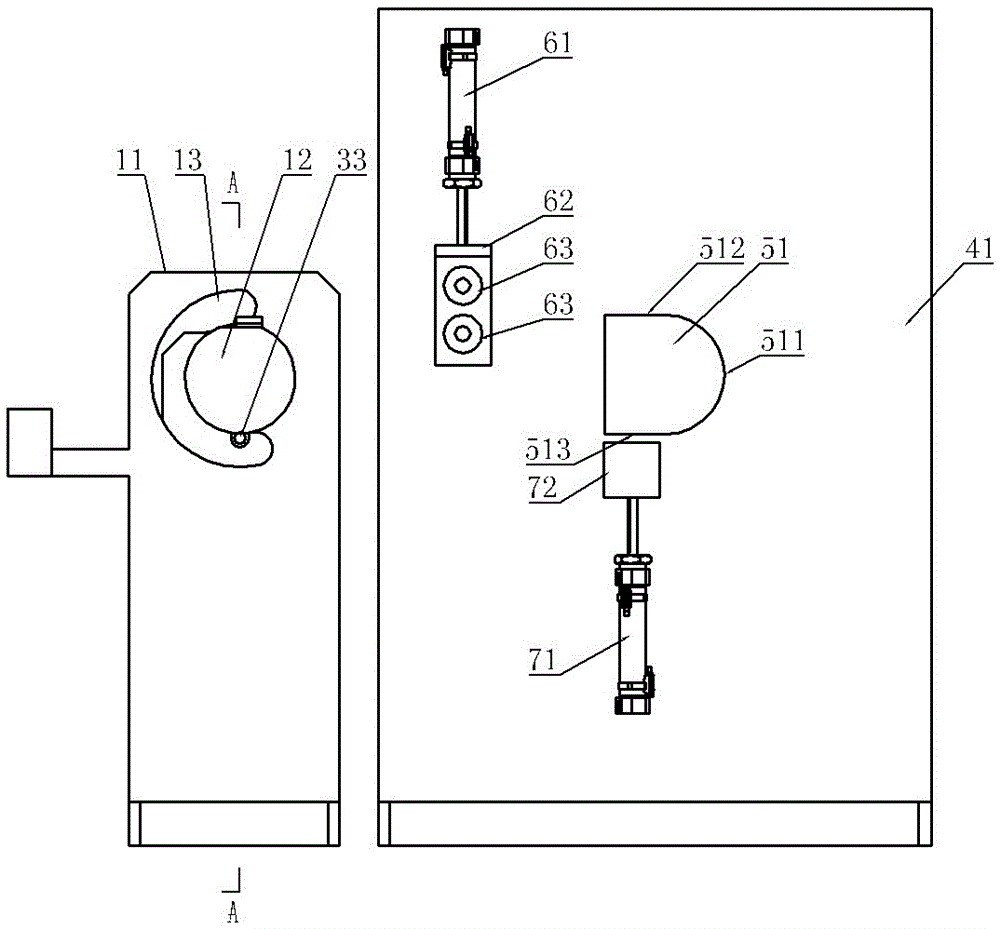

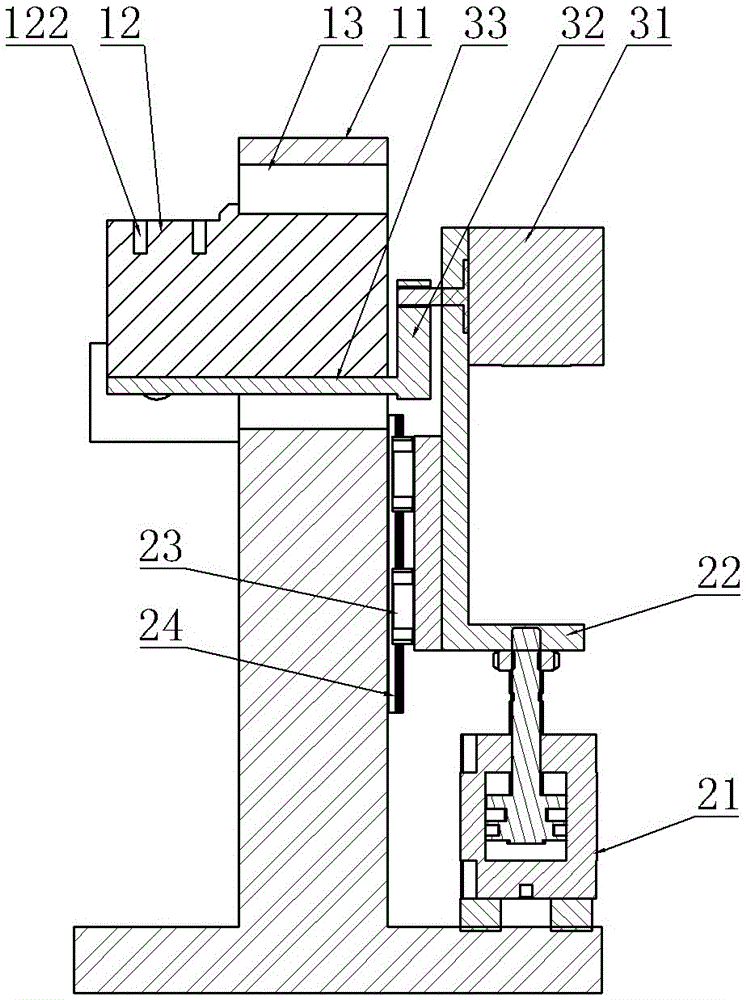

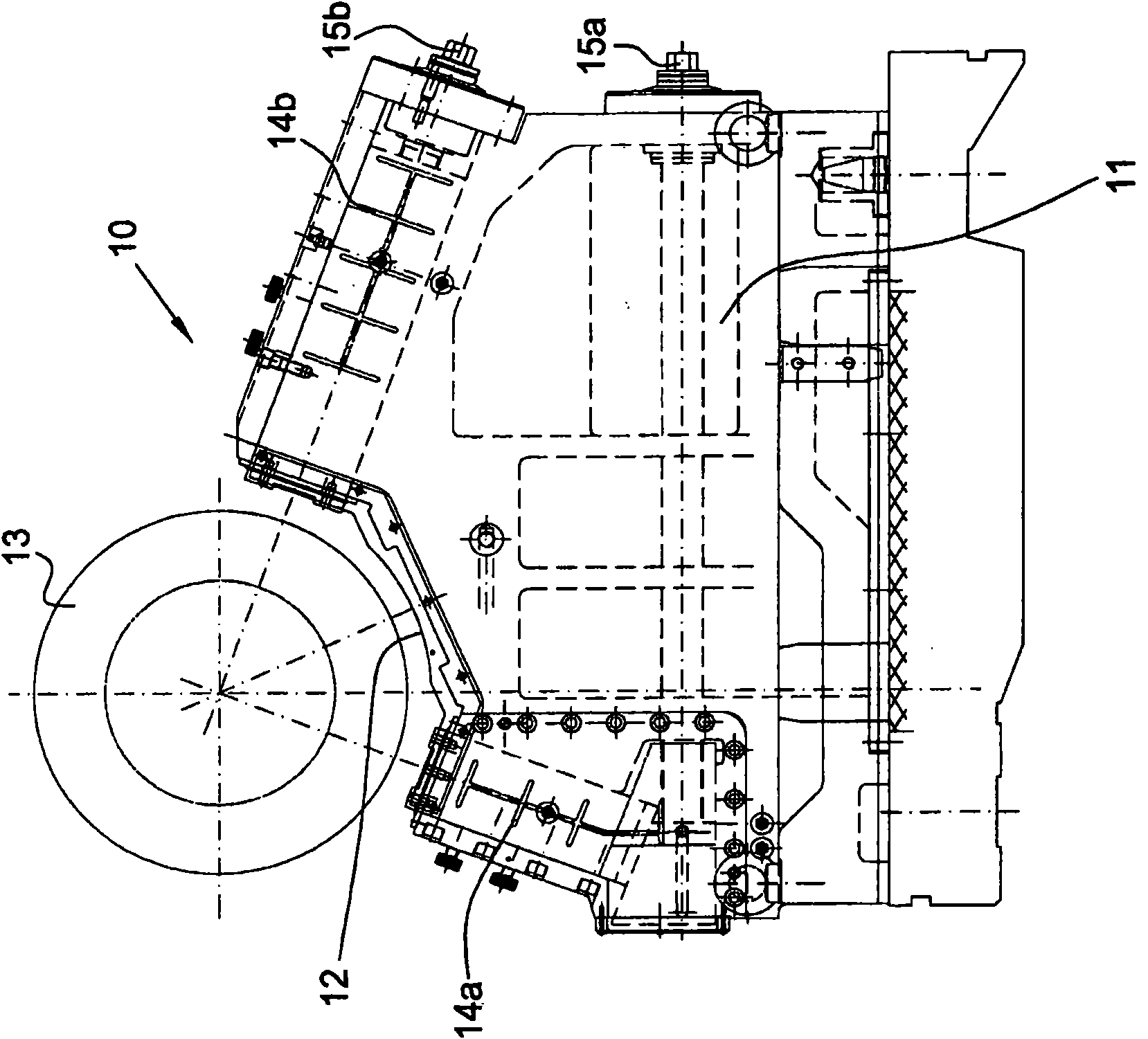

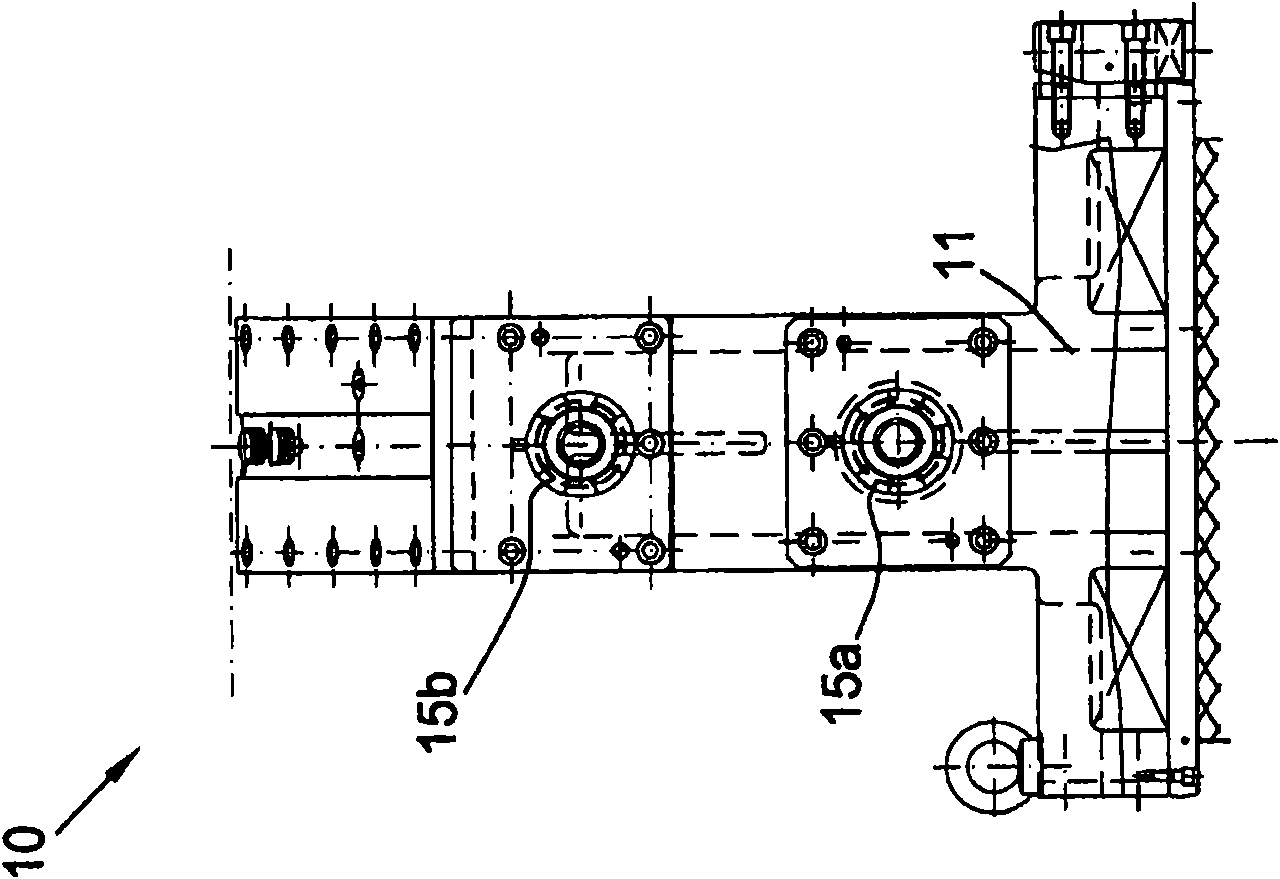

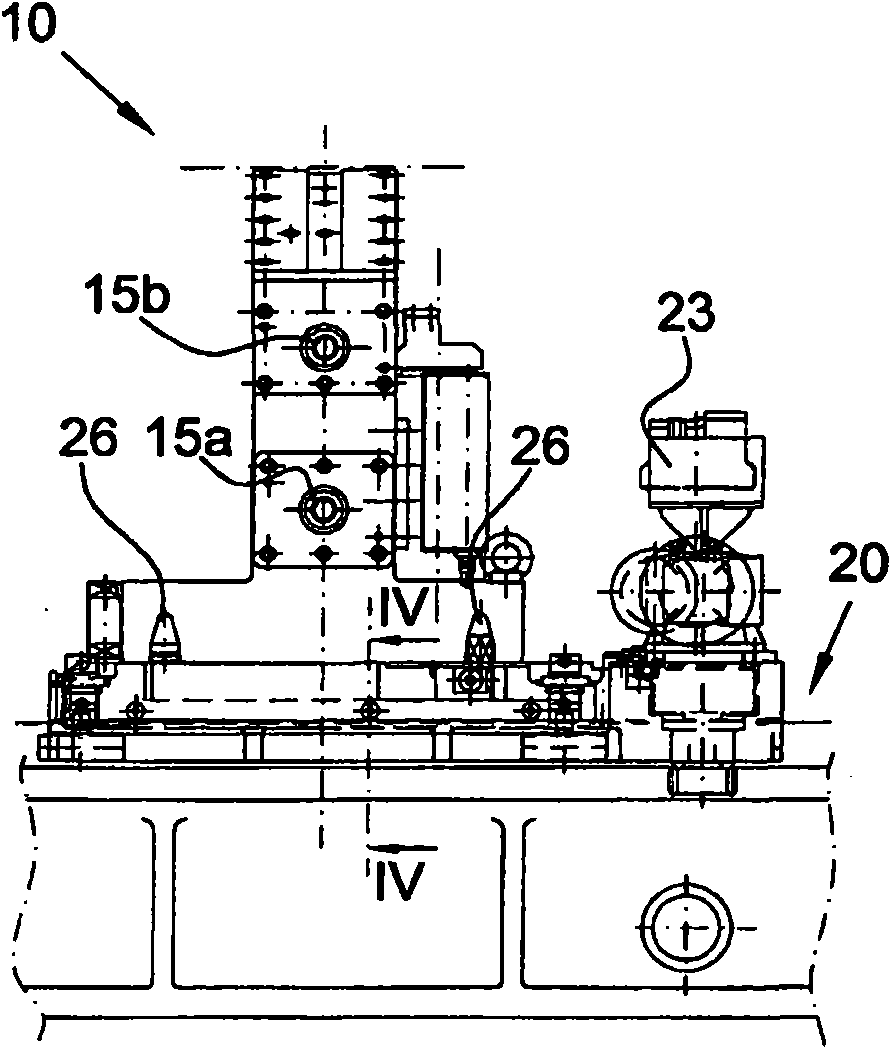

Device and method for positioning and blocking steady rests for rolling milly cylinders in grinding machines and grinding machines employing the same

ActiveCN101605632BEasy positioningQuick positioning operationPermanent magnetsLarge fixed membersEngineeringGrinding mill

Positioning and blocking device (20) for steady rests (10) comprising a substantially flat carriage (21) provided with translation means (23) and blocking means (22) characterised in that said blocking means are magnetic.

Owner:TENOVA

Intraocular lens positioner

The invention relates to the technical field of medical instruments, and discloses an intraocular lens positioner for intraocular lens suture fixation, which comprises a transparent cornea part, a venthole formed in the center of the cornea part, puncture hole positioning loops arranged at the edge of the cornea part, an intraocular lens optical part positioning line arranged close to the center of the cornea part, and a limbus positioning line arranged close to the edge of the cornea part, the number of the puncture hole positioning loops is two or three, the puncture hole positioning loops are suitable for being implanted into two-loop or three-loop type intraocular lenses respectively, and the puncture hole positioning loops are provided with a plurality of puncture holes which are evenly distributed so as to adapt to the intraocular lenses of different models. During use, the limbus corneae positioning line coincides with the limbus corneae edge of a patient to achieve self-positioning, then a needle can be inserted from the puncture hole in the puncture hole positioning loop, and when the intraocular lens is adjusted to coincide with the intraocular lens optical portion positioning line, the intraocular lens is centered, positioning is convenient and fast, and the situation that visual positioning only depends on doctor experience is avoided. Operation quality is improved.

Owner:叶飞飞

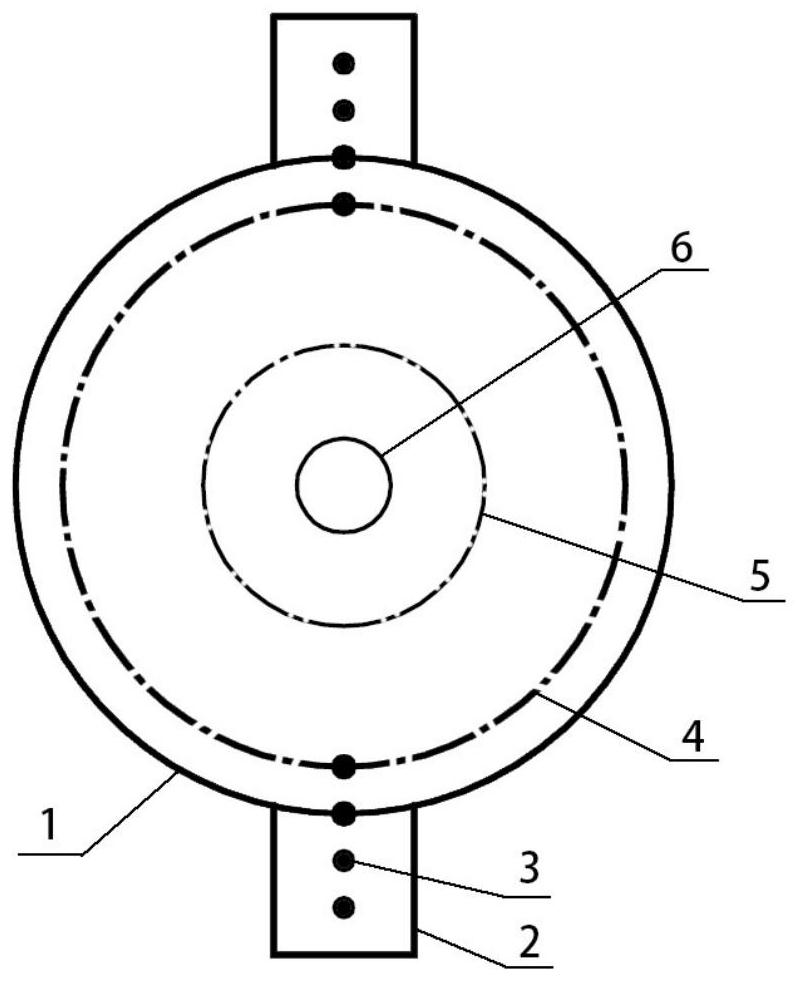

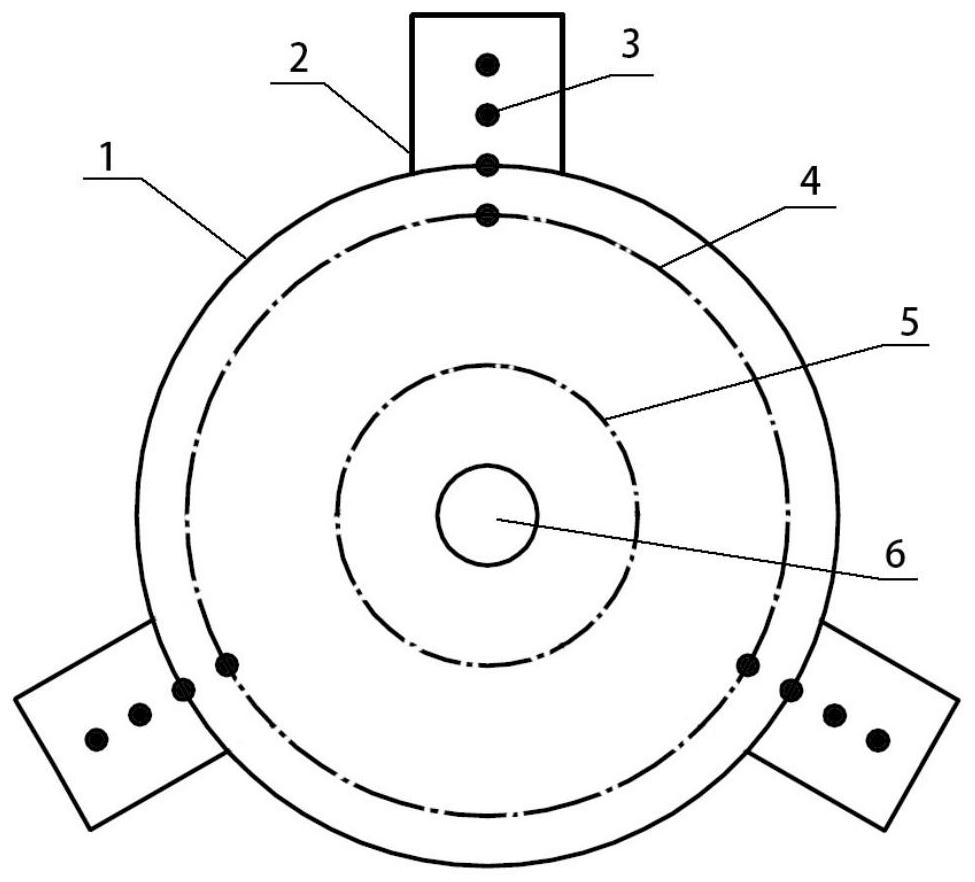

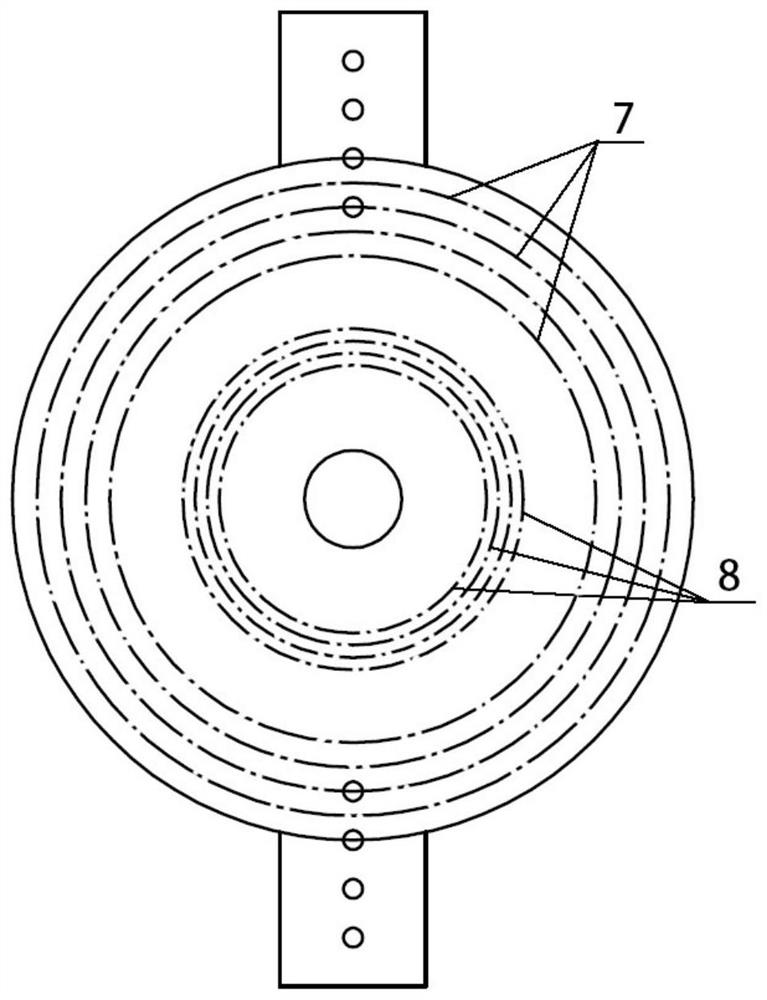

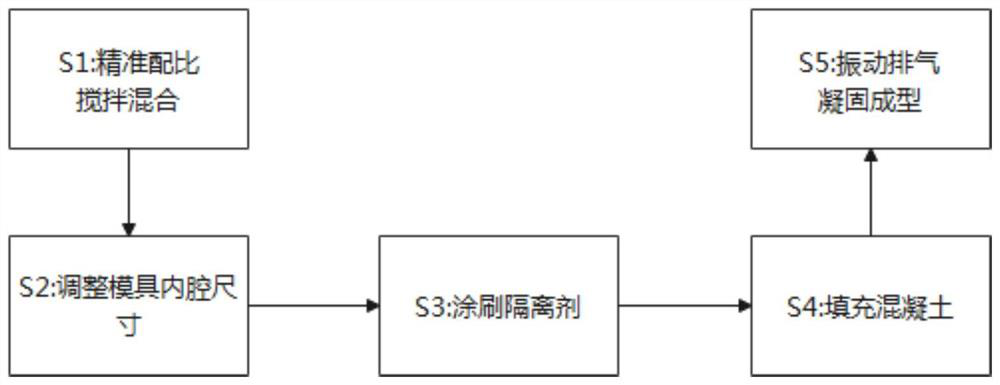

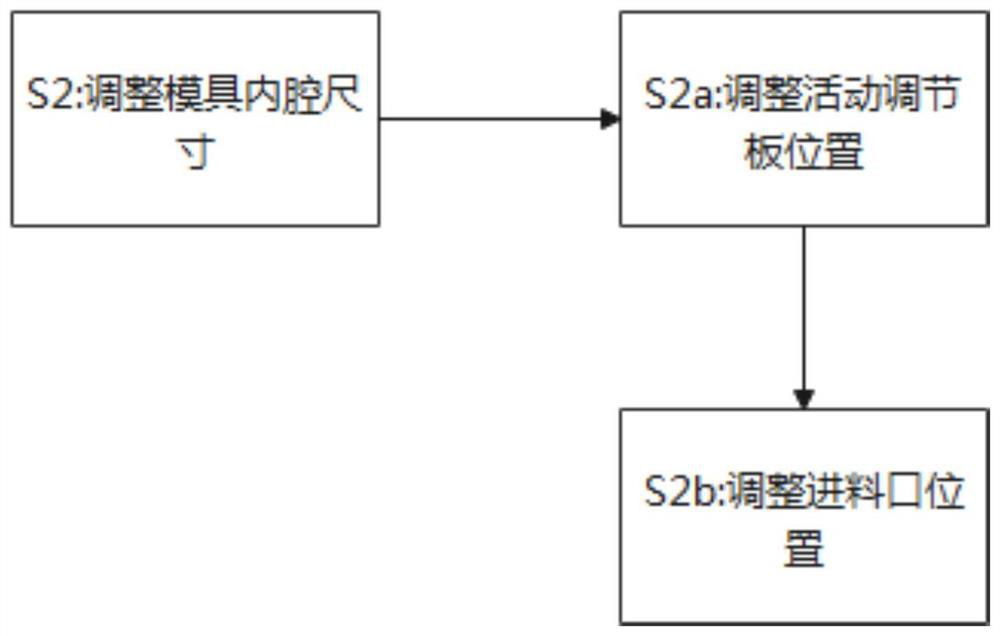

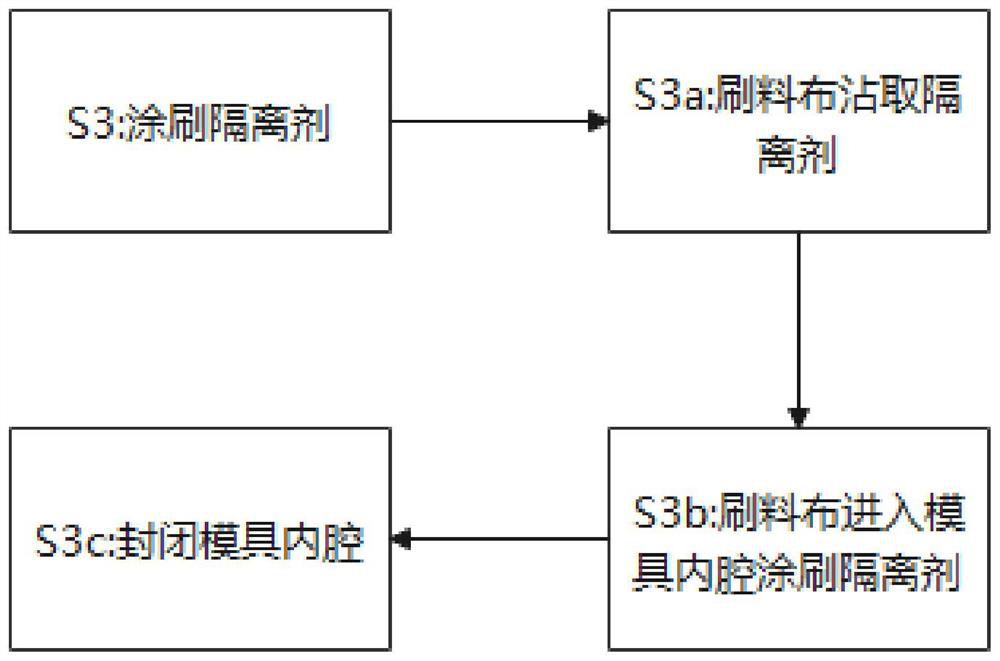

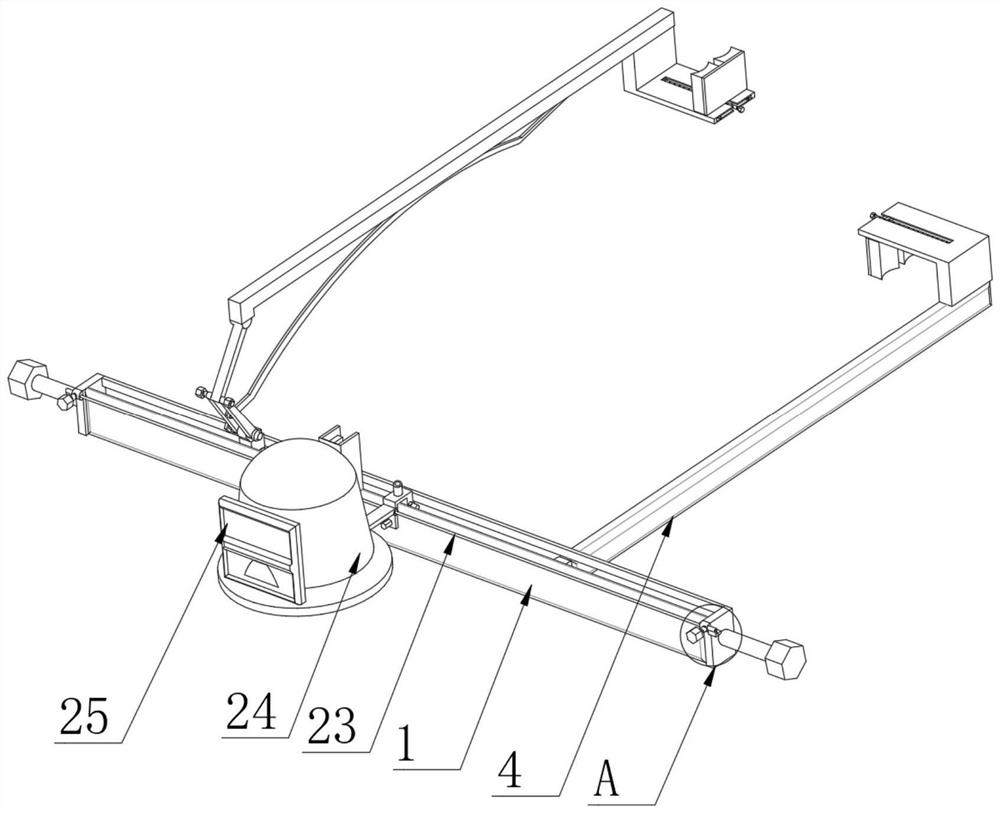

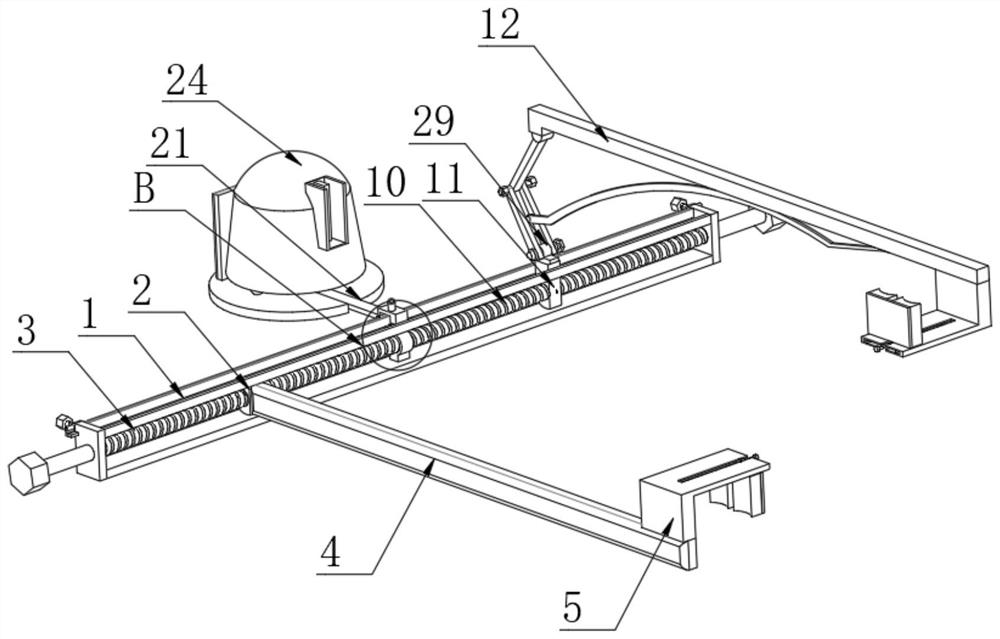

Precise concrete test block manufacturing method and tool mold

PendingCN114147840AAdjustable inner volume of mold cavityAvoid damageMouldsMould auxillary partsStructural engineeringMechanical engineering

The invention relates to the technical field of concrete processing, in particular to a precise concrete test block manufacturing method and further relates to a precise concrete test block manufacturing tool mold which comprises at least three sets of mold inner cavities horizontally arranged in an adjustable mold in parallel, and the mold inner cavities penetrate through the adjustable mold. A sealing door used for sealing an inner cavity of the mold is installed at one end of the adjustable mold in a hinged mode, a movable adjusting plate used for adjusting the volume of concrete filled in the inner cavity of the mold is installed in the inner cavity of the mold, and the shape of the movable adjusting plate is matched with the shape of the section of the inner cavity of the mold. And a plurality of feeding holes communicated with the upper part of the adjustable mold are formed in the inner cavity of the mold. According to the technical scheme, the technical problems that the manufacturing volume of a concrete test block can be adjusted by one tool mold according to different test requirements and a plurality of concrete test blocks can be manufactured at the same time are solved.

Owner:PUTIAN UNIV

Positioner for orthognathic surgery based on intelligent control

ActiveCN114224514AQuick Relative Squeeze Offset OperationFast implementation of relative extrusion offset operationsInstruments for stereotaxic surgeryApparatus instrumentsReoperative surgery

The invention discloses a positioner for orthognathic surgery based on intelligent control, and particularly relates to the technical field of medical instruments, the positioner comprises a positioning frame, a first moving screw ring is mounted in the positioning frame, and a positioning mechanism is arranged in the first moving screw ring; and the positioning mechanism comprises a rotating screw rod arranged in the first movable screw ring, one side of the first movable screw ring is connected with a linkage plate, and a fixing plate is installed on the portion, close to the upper portion of the free end, of the linkage plate. The positioning mechanism and the limiting fixing plate are adopted to enable the second molars of the maxillary bone to move leftwards, so that the side surfaces of the maxillary bone and the mandible are relatively extruded and deviated quickly, the maxillary bone and the mandible are butted and positioned quickly, and the device is not only suitable for patients with different maxillary bones and mandible bones, but also low in manufacturing cost and high in practicability. The positioning device can be repeatedly used, stable positioning is achieved in the positioning process, deviation is not prone to being generated, and efficient and high-stability positioning operation is achieved.

Owner:SICHUAN UNIV

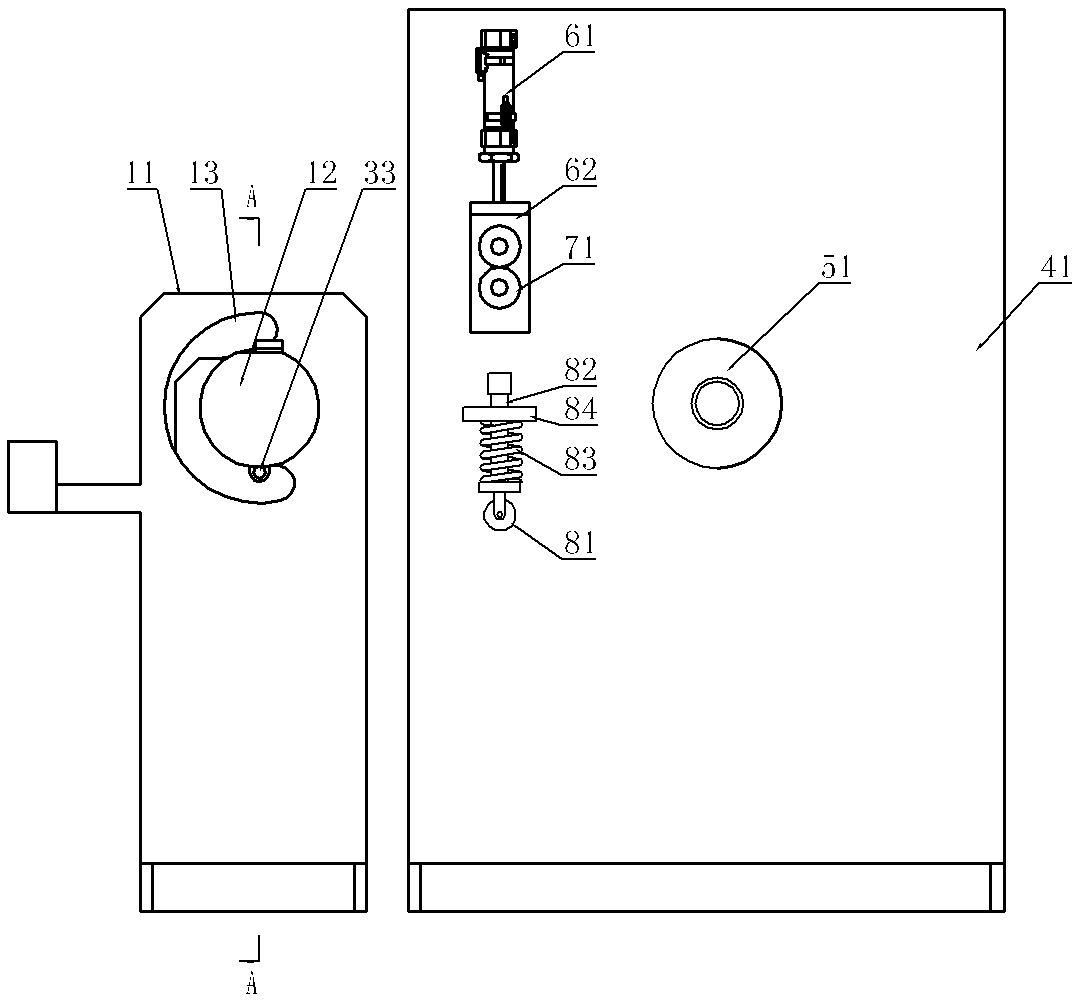

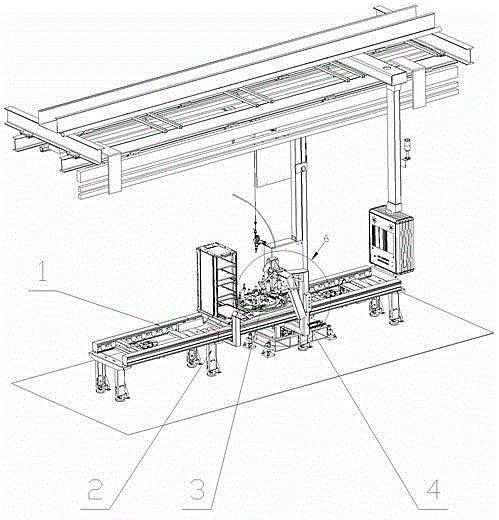

The device used for the positioning of the second roll of the steel strip

ActiveCN106623658BFast rounding operationQuick positioning operationMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention provides a secondary edge rolling and positioning device for steel strips. The device is easy and convenient to operate and high in processing efficiency. The device comprises a first support frame and a second support frame, wherein a simulation block and an edge rolling mechanism are arranged on the first support frame; a supporting roller, a steel strip tensioning mechanism, a steel strip lifting mechanism and a steel strip pressing mechanism are arranged on the second support frame; the supporting roller and the simulation block are positioned on the same horizontal plane; and the steel strip tensioning mechanism, the steel strip lifting mechanism and the steel strip pressing mechanism are positioned between the simulation block and the supporting roller.

Owner:WUXI KAIHAN TECH

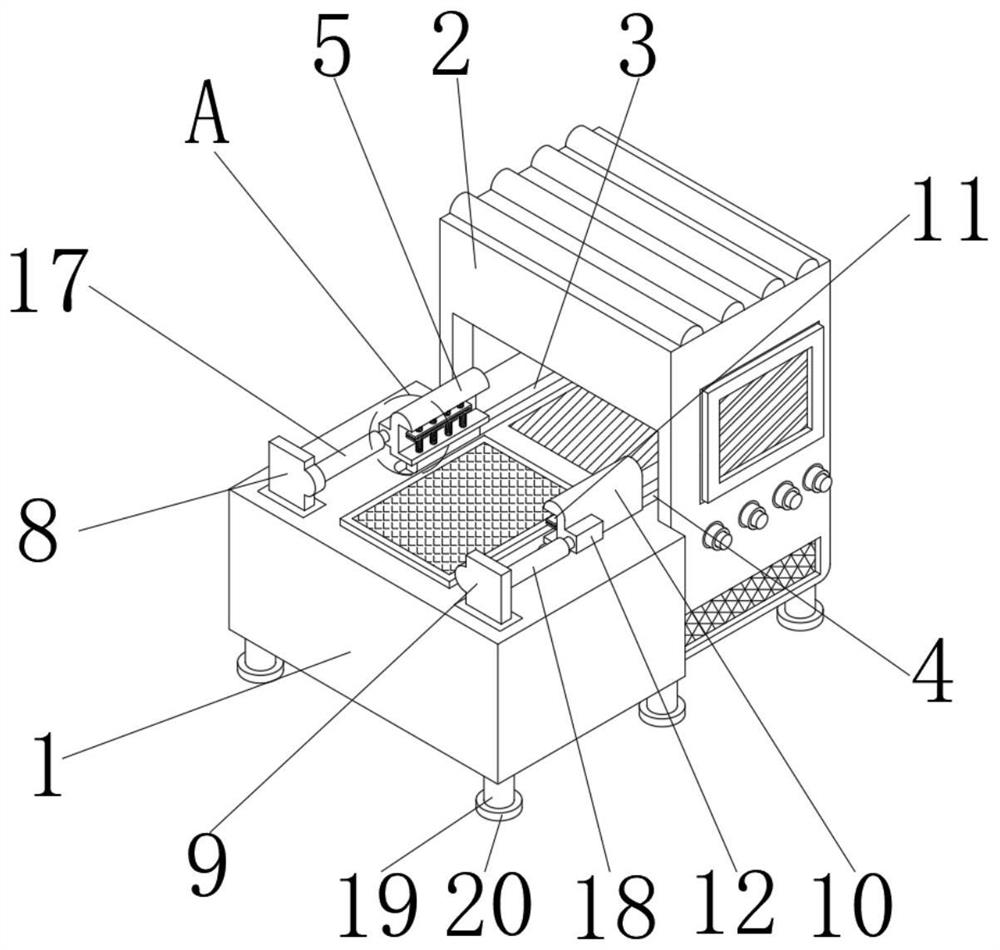

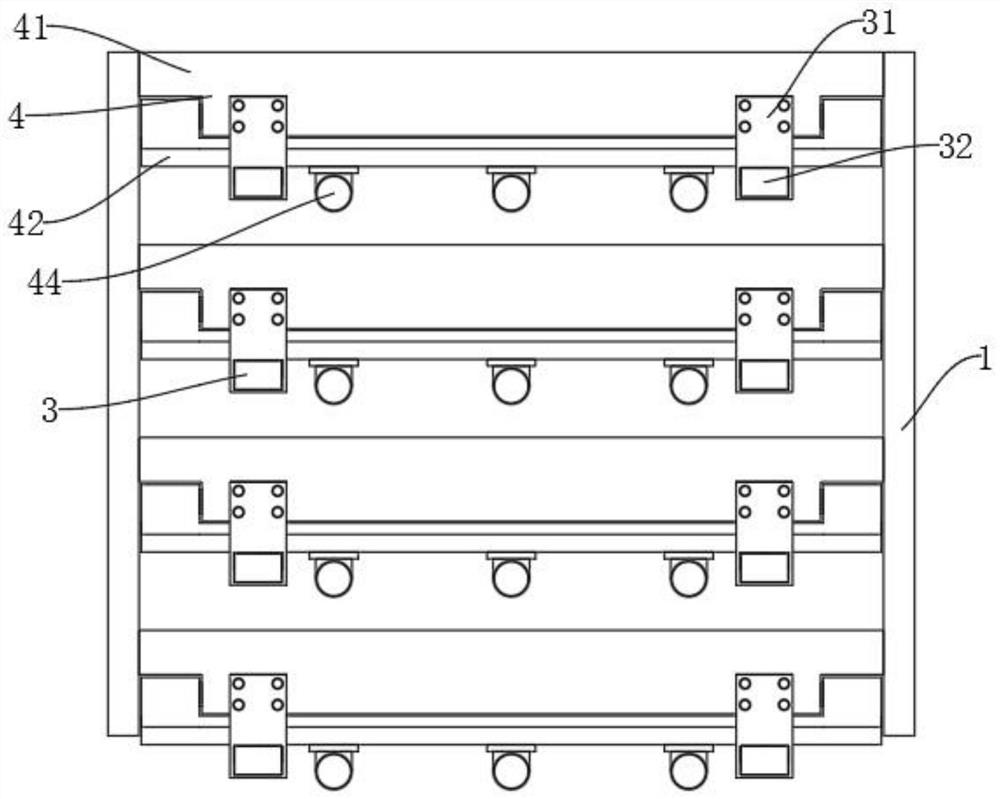

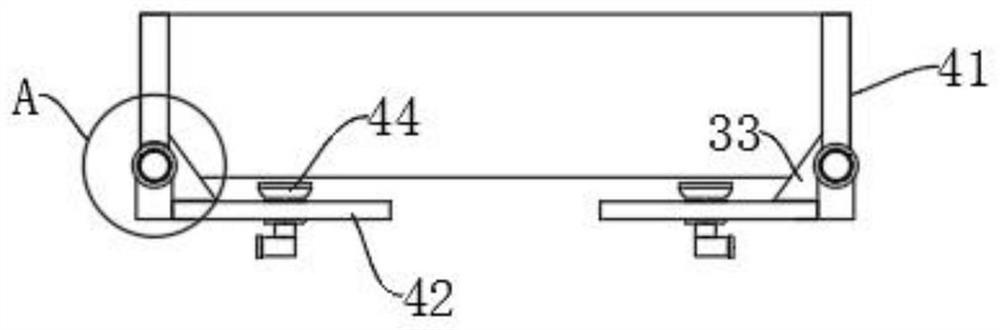

An acrylic plate chamfering cutting device

ActiveCN112277049BQuick positioning operationSave the operation of manual block fixingMetal working apparatusTorsion springIndustrial engineering

The invention discloses an acrylic plate chamfering cutting device, which comprises a vertical support, and a plurality of acrylic plate positioning units are horizontally and fixedly arranged on the inner side of the vertical support from top to bottom; the acrylic plate positioning unit is two pieces of side plate, a bottom plate rotatably mounted on the lower end of the side plate, a torsion spring, and multiple vacuum suction cups arranged on the upper end of the bottom plate; the side plate is provided with a bottom plate positioning mechanism; the side plate is inserted through a fixed pin fixed at the end The inside of the pin sleeve at one end of the bottom plate is rotatably connected with the bottom plate. A torsion spring is sleeved on the outside of the fixed pin, and the two ends of the torsion spring are fixedly connected with the fixed pin and the inner wall of the pin sleeve respectively. The restoring force of the torsion spring can only An acrylic plate is placed on the support base. The device can quickly perform interval positioning operations on multiple acrylic panels, so that multiple panels can be chamfered at the same time, eliminating the need for manual block-fixing operations, saving trouble and effort, and speeding up the processing efficiency.

Owner:安徽美高美高分子材料有限公司

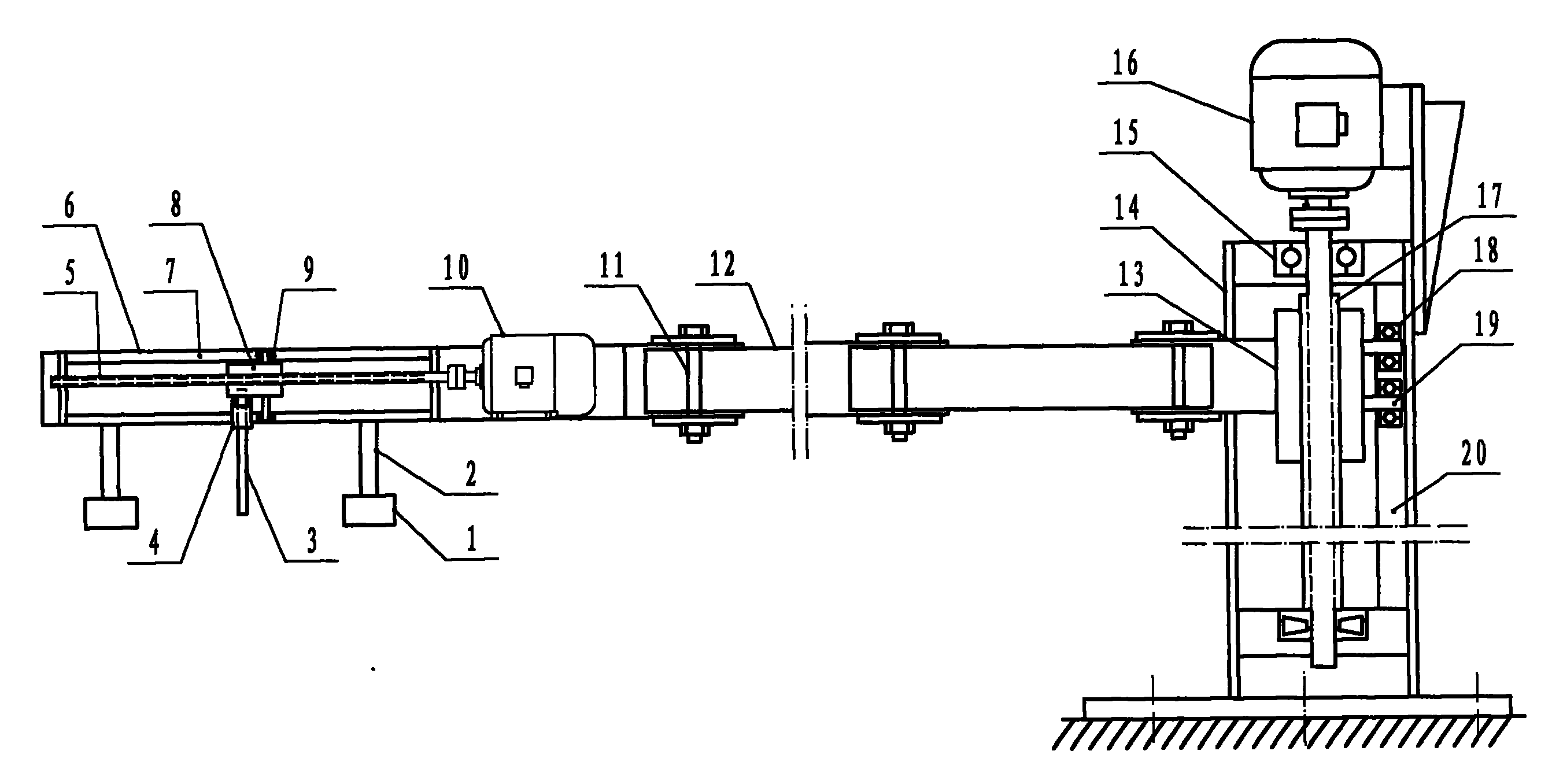

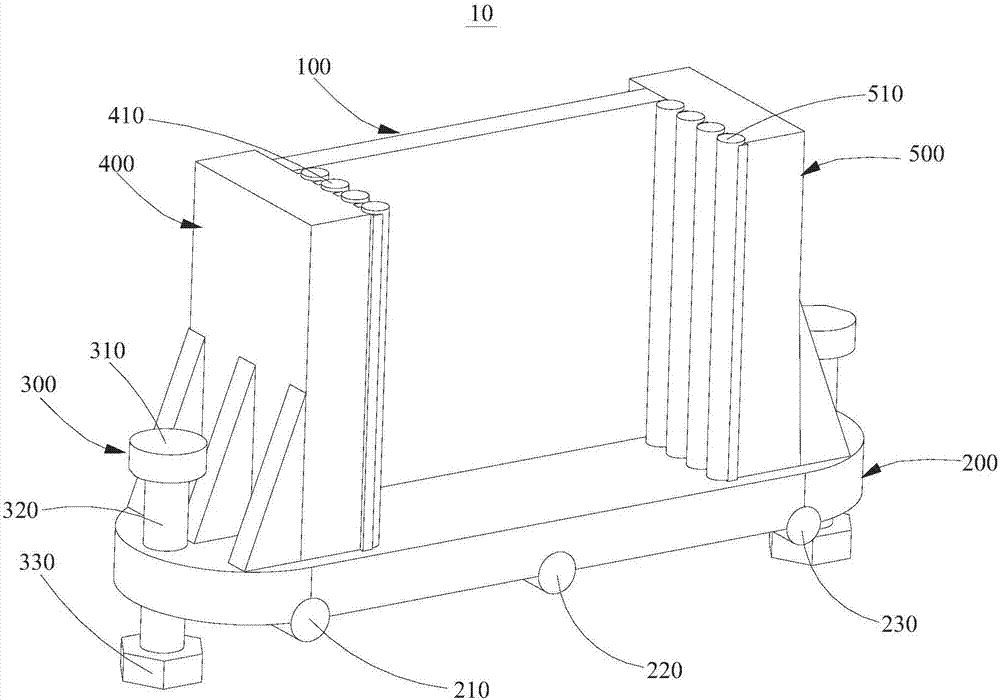

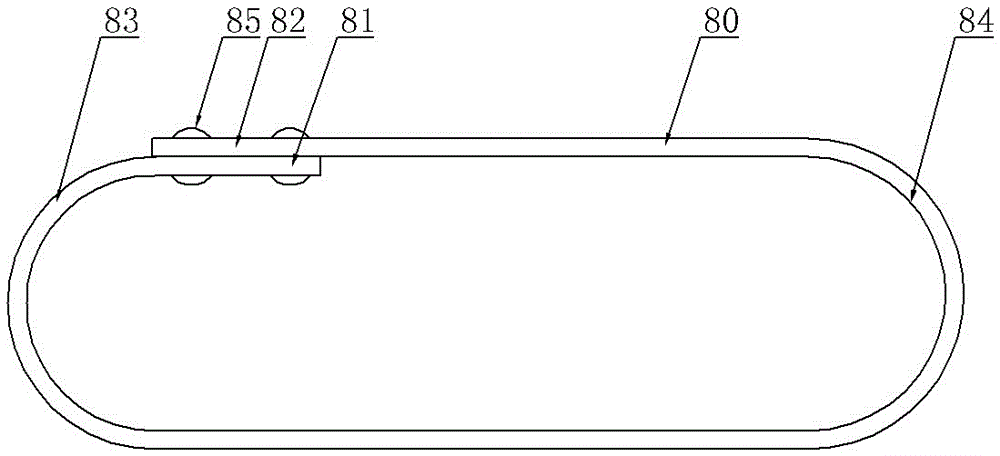

Secondary edge rolling and positioning device for steel strips

ActiveCN106623658AFast rounding operationQuick positioning operationMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention provides a secondary edge rolling and positioning device for steel strips. The device is easy and convenient to operate and high in processing efficiency. The device comprises a first support frame and a second support frame, wherein a simulation block and an edge rolling mechanism are arranged on the first support frame; a supporting roller, a steel strip tensioning mechanism, a steel strip lifting mechanism and a steel strip pressing mechanism are arranged on the second support frame; the supporting roller and the simulation block are positioned on the same horizontal plane; and the steel strip tensioning mechanism, the steel strip lifting mechanism and the steel strip pressing mechanism are positioned between the simulation block and the supporting roller.

Owner:WUXI KAIHAN TECH

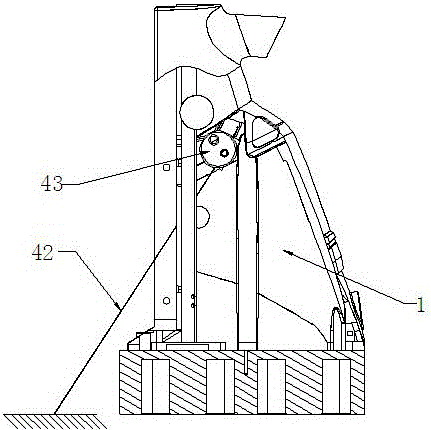

Drilling rig with mechanical positioning device

ActiveCN104209548BEasy to fixZero degrees of freedomAutomatic control devicesLarge fixed membersEngineeringFuselage

The invention discloses a drilling machine provided with a mechanical positioning device. The drilling machine comprises a fixed machine body and a machine head which is perpendicular to the bottom of the machine body and moves back and forth relative to the machine body. The machine head is provided with a main shaft provided with a cutter. The drilling machine is further provided with the mechanical positioning device which has a motion limit position, the mechanical positioning device is provided with a positioning needle, and when the mechanical positioning device moves to a limit position, the center line of the length direction of the positioning needle and the axis of the main shaft are on the same line. By means of the drilling machine, positioning of drilling can be conveniently and quickly finished by means of the mechanical positioning device.

Owner:ZHEJIANG XINXING TOOLS CO LTD

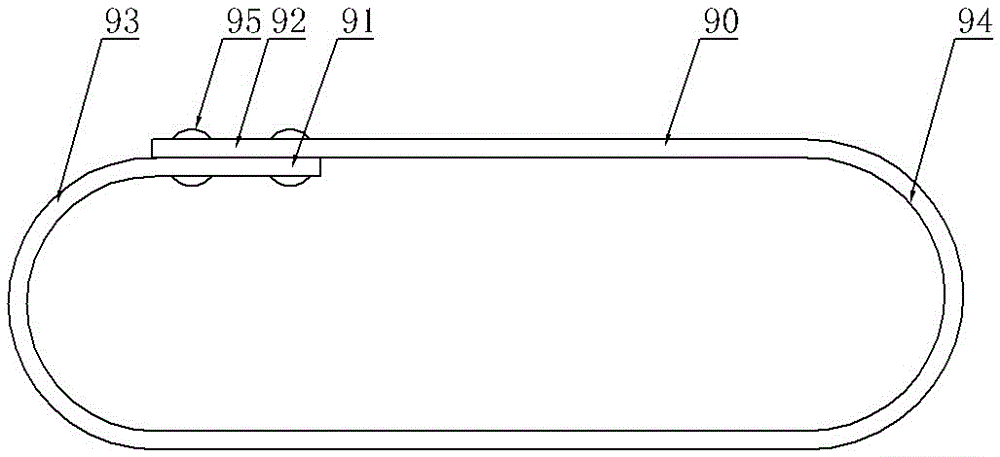

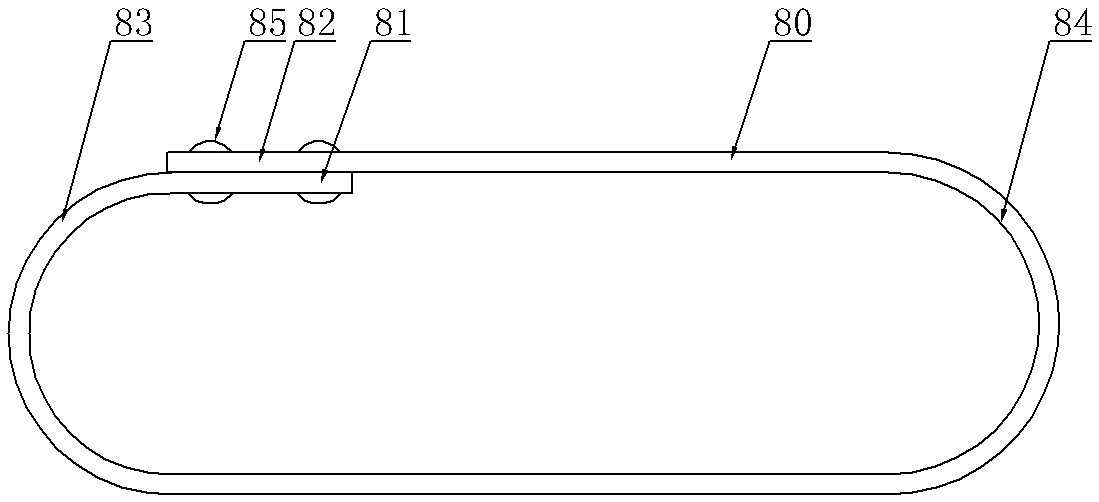

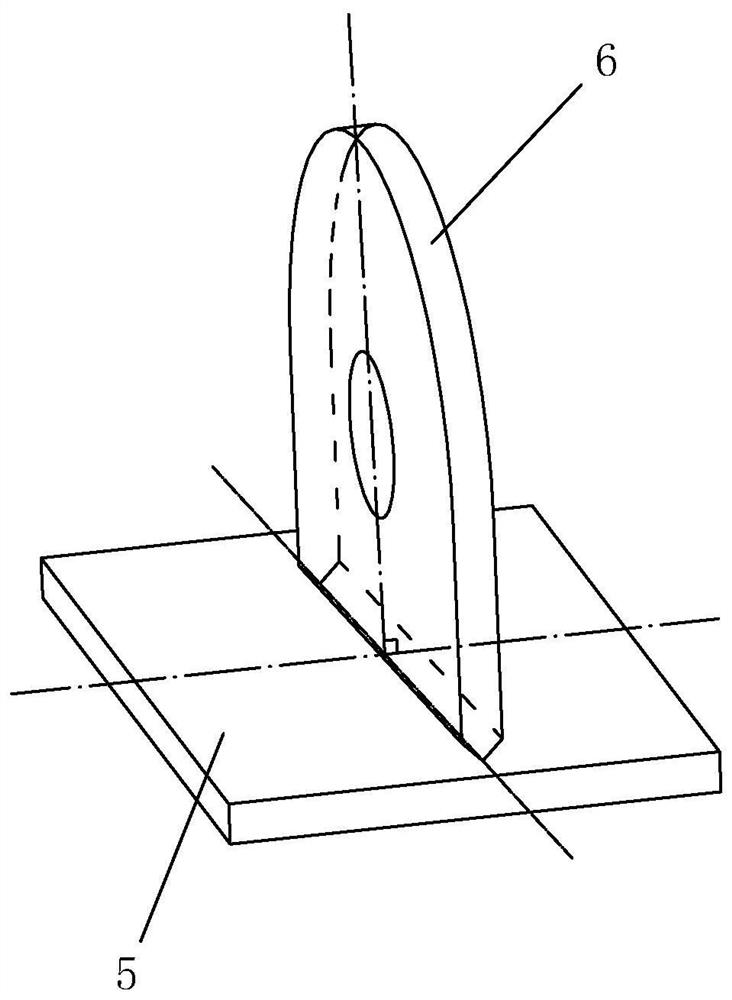

Coiling and positioning device of steel band

ActiveCN106583576AFast rounding operationQuick positioning operationMetal-working feeding devicesPositioning devicesEngineering

The invention provides a coiling and positioning device of a steel band, which has the advantages of simplicity and convenience in operation and high processing efficiency. The coiling and positioning device comprises a first support frame and a second support frame, wherein a first simulation block and a coiling mechanism are arranged on the first support frame, and a second simulation block, a steel band lifting mechanism and a steel band pressing mechanism are arranged on the second support frame; the first simulation block is vertically fixed to the first support frame, the side surface, which is perpendicular to the first support frame, of the first simulation block is formed by an arc-shaped curved surface and a first plane which is connected to both ends of the top of the arc-shaped curved surface, and an arc-shaped through groove is formed in a position in the outer side of the side surface of the first support frame; and the coiling mechanism comprises a servo motor, a connecting rod and a pressing rod, both ends of the connecting rod are fixedly connected with a rotating shaft of the servo motor and the pressing rod respectively, and the pressing rod penetrates through the arc-shaped through groove and can be driven to move along the arc-shaped through groove by the servo motor.

Owner:WUXI KAIHAN TECH

Device and method for positioning and blocking steady rests for rolling milly cylinders in grinding machines and grinding machines employing the same

ActiveCN101605632AEasy positioningQuick positioning operationPermanent magnetsLarge fixed membersEngineeringGrinding mill

Positioning and blocking device (20) for steady rests (10) comprising a substantially flat carriage (21) provided with translation means (23) and blocking means (22) characterised in that said blocking means are magnetic.

Owner:TENOVA

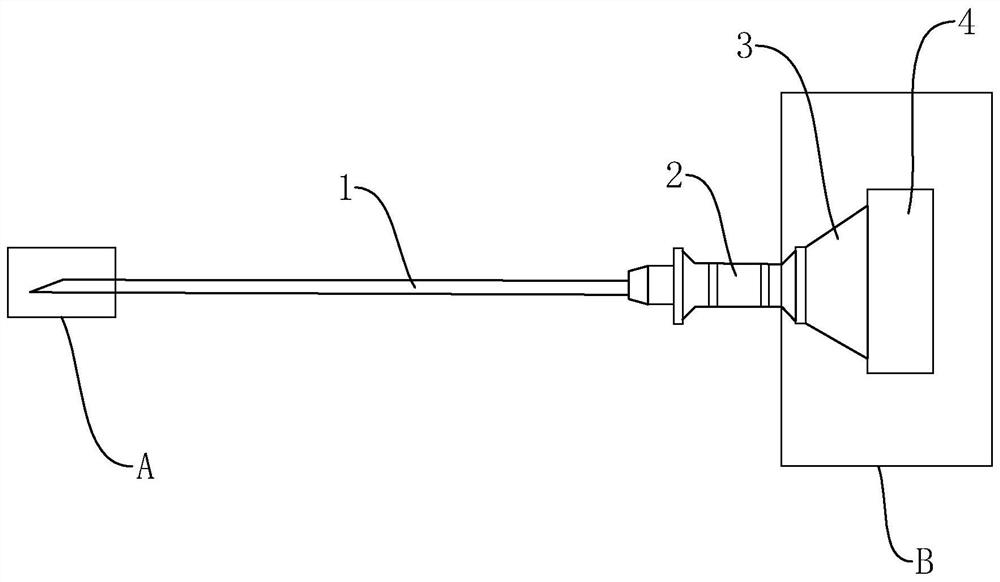

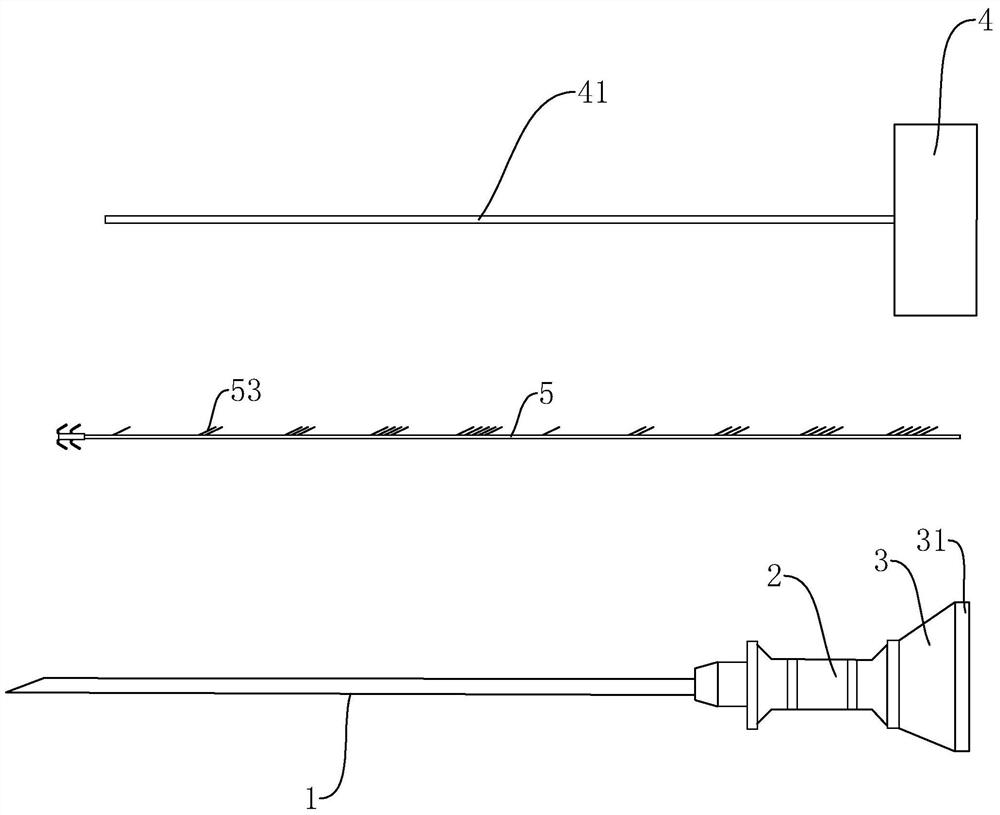

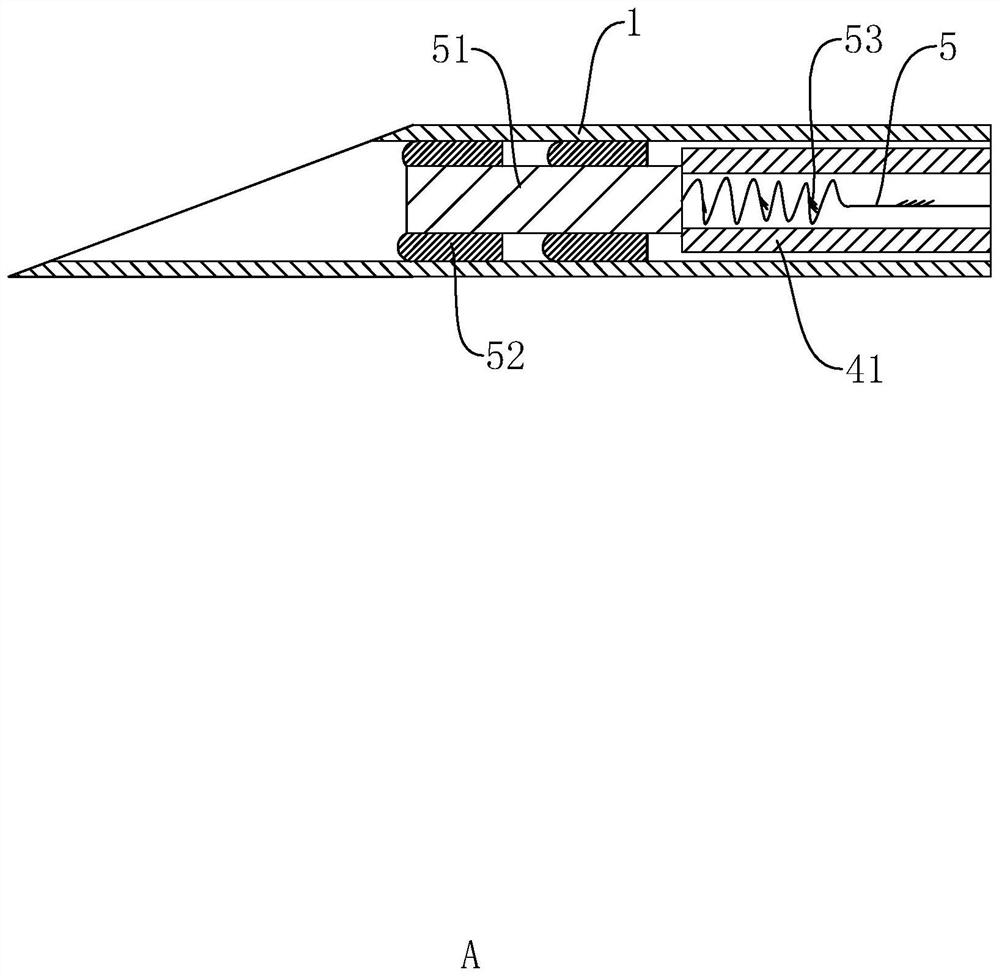

Pulmonary nodule positioning puncture needle

PendingCN113648074AImprove gripReduced Possibility of DisplacementSurgeryDiagnostic markersPulmonary noduleAnatomy

The invention discloses a pulmonary nodule positioning puncture needle, relates to the technical field of medical puncture positioning instruments, and aims to solve the problems that the depth of a focus is judged through color block distribution on a positioning line, the judgment precision is low, hands are not easy to master, and a positioning mark moves. According to the technical scheme, at least one set of markers are distributed on a positioning line in the axial direction of the positioning line, each marker comprises a plurality of barb sets distributed in the axial direction of the positioning line, each barb set comprises barbs of different numbers, and openings of the barbs face the direction away from an anchoring positioning pin. In the same group of markers, the number of barbs contained in the barb groups in the direction far away from the anchoring positioning needle forms an arithmetic progression, and the first barbs, close to the anchoring positioning needle, in each barb group are uniformly distributed on the positioning line. The depth of the focus can be judged by simply counting the number of the barbs, the operation is fast, and the accuracy is guaranteed due to the anchoring effect of the barbs on the positioning line.

Owner:南京普立蒙医疗科技有限公司

Drilling rig with optical positioning device

ActiveCN104209549BEasy to fixZero degrees of freedomAutomatic control devicesLarge fixed membersLight beamEngineering

The invention discloses a drilling machine with an optical positioning device. The drilling machine comprises a fixed machine body and a machine head, the machine head moves back and forth by being perpendicular to the bottom of the machine body, and the machine head is provided with a spindle where a tool is installed. The drilling machine further comprises the optical positioning device. The optical positioning device comprises an optical positioning lamp, and the intersection point between light beams emitted by the optical positioning lamp in a power-on state and the bottom plane of the machine body is located on the axis of the spindle. The drilling machine can finish drilling positioning operation conveniently and rapidly.

Owner:ZHEJIANG XINXING TOOLS CO LTD

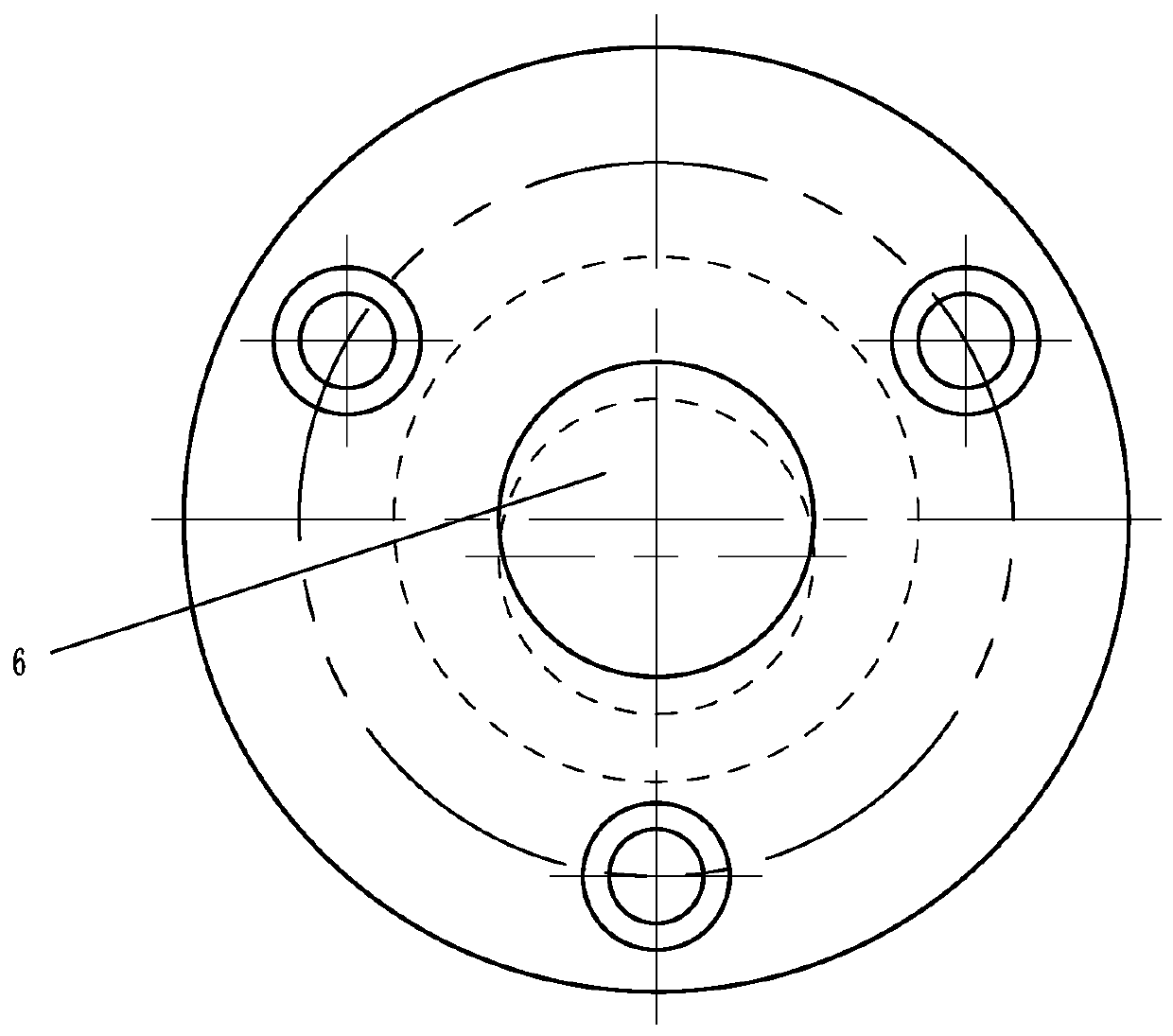

Cone keyway machining fixture

PendingCN109759878APrecise positioningEasy positioningPositioning apparatusMetal-working holdersEngineeringBlind hole

The invention provides a cone keyway machining fixture. The cone keyway machining fixture can quick position a workpiece to be processed and has higher position accuracy. The technical scheme is thatthe cone keyway machining fixture comprises a transit plate as a mounting main body; the front end face of the transit plate is a slope, and a guiding hole is formed perpendicularly in the middle of the front end face of the transit plate; the rear end face of the transit plate is a vertical face, and a positioning hole is formed perpendicularly in rear end face of the transit plate; the guiding hole is a through hole, the positioning hole is a blind hole, and the guiding hole passes through the middle of the bottom of the positioning hole; a positioning ring is arranged in the positioning hole; the positioning ring is of a ring-shaped structure; a part of the positioning ring is inserted into the positioning hole, and the part, out of the positioning hole, of the positioning ring fits with the external to form the positioning of the transit plate; a guiding sleeve is inserted in the guiding hole; and the middle section of the guiding sleeve is attached to the front end face of the transit plate, the rear section of the guiding sleeve is in a cylinder shape and inserted into the guiding hole, and the first section of the guiding sleeve is in a cone shape.

Owner:HENGDIAN GRP INNUOVO ELECTRIC

Coiling and positioning device for steel strip

ActiveCN106583576BFast rounding operationQuick positioning operationMetal-working feeding devicesPositioning devicesEngineeringSteel belt

The invention provides a coiling and positioning device of a steel band, which has the advantages of simplicity and convenience in operation and high processing efficiency. The coiling and positioning device comprises a first support frame and a second support frame, wherein a first simulation block and a coiling mechanism are arranged on the first support frame, and a second simulation block, a steel band lifting mechanism and a steel band pressing mechanism are arranged on the second support frame; the first simulation block is vertically fixed to the first support frame, the side surface, which is perpendicular to the first support frame, of the first simulation block is formed by an arc-shaped curved surface and a first plane which is connected to both ends of the top of the arc-shaped curved surface, and an arc-shaped through groove is formed in a position in the outer side of the side surface of the first support frame; and the coiling mechanism comprises a servo motor, a connecting rod and a pressing rod, both ends of the connecting rod are fixedly connected with a rotating shaft of the servo motor and the pressing rod respectively, and the pressing rod penetrates through the arc-shaped through groove and can be driven to move along the arc-shaped through groove by the servo motor.

Owner:WUXI KAIHAN TECH

A page positioning method and device for a mobile terminal

InactiveCN103034451BQuick positioning operationImprove reading efficiencyInput/output processes for data processingComputer scienceLocation systems

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

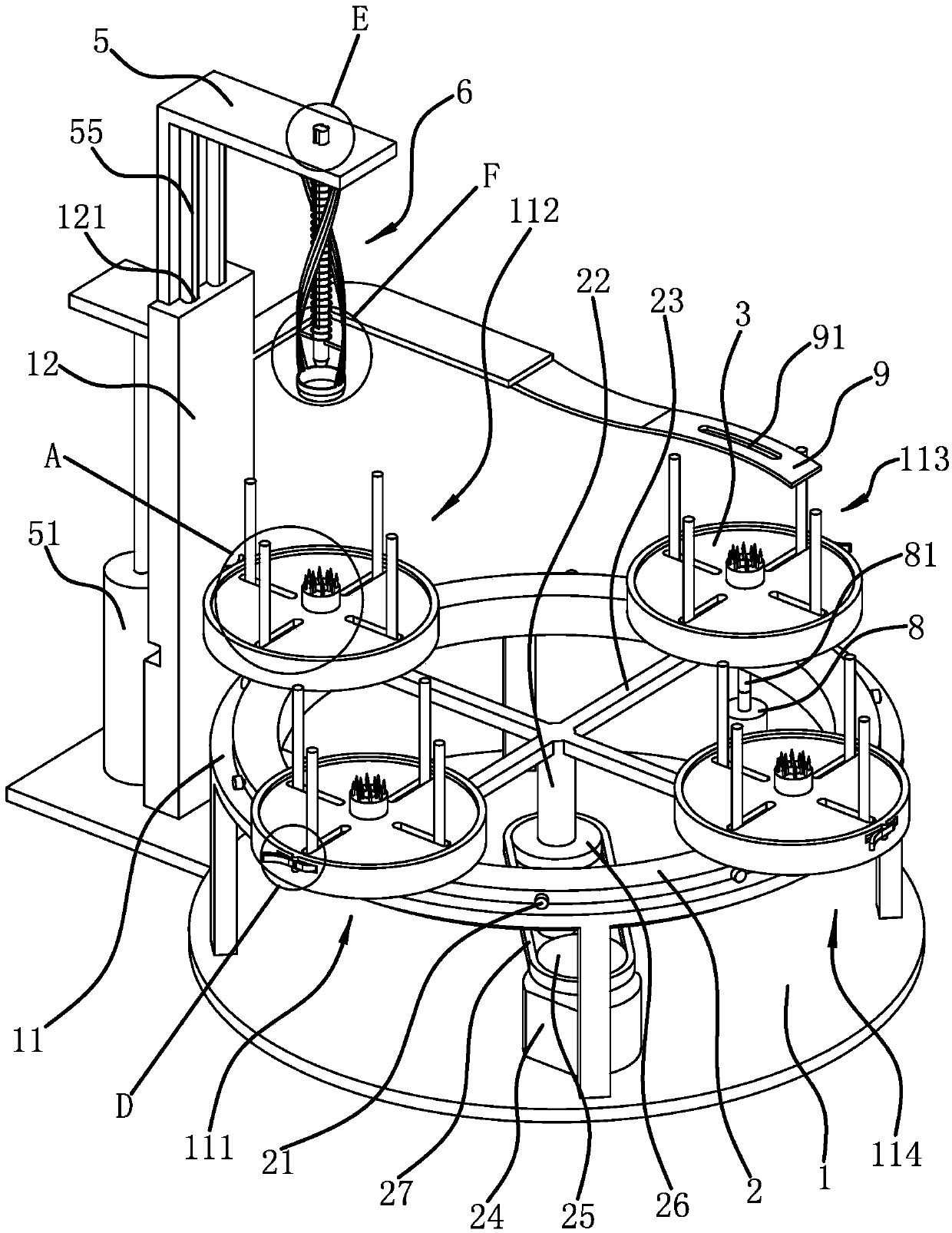

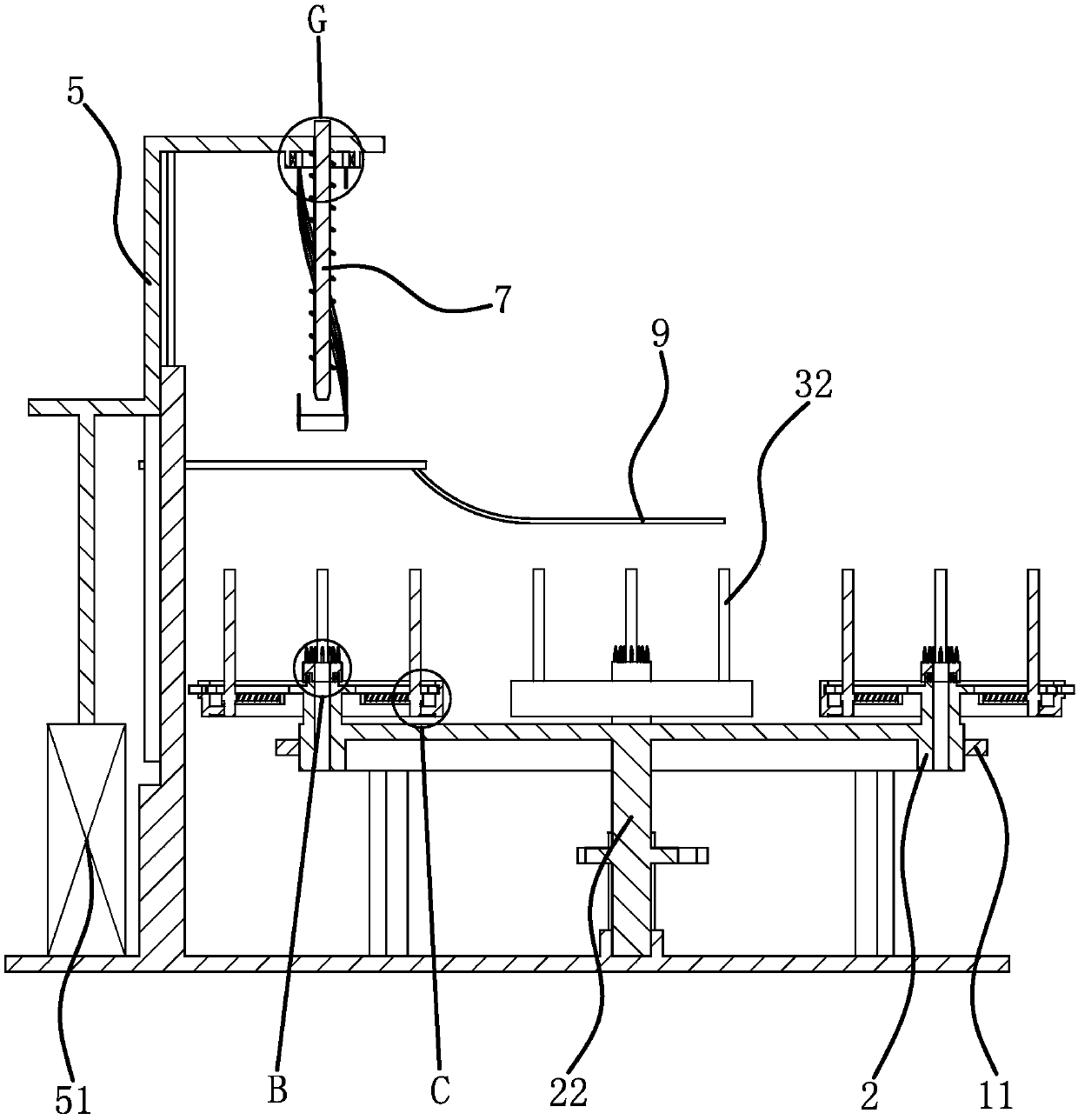

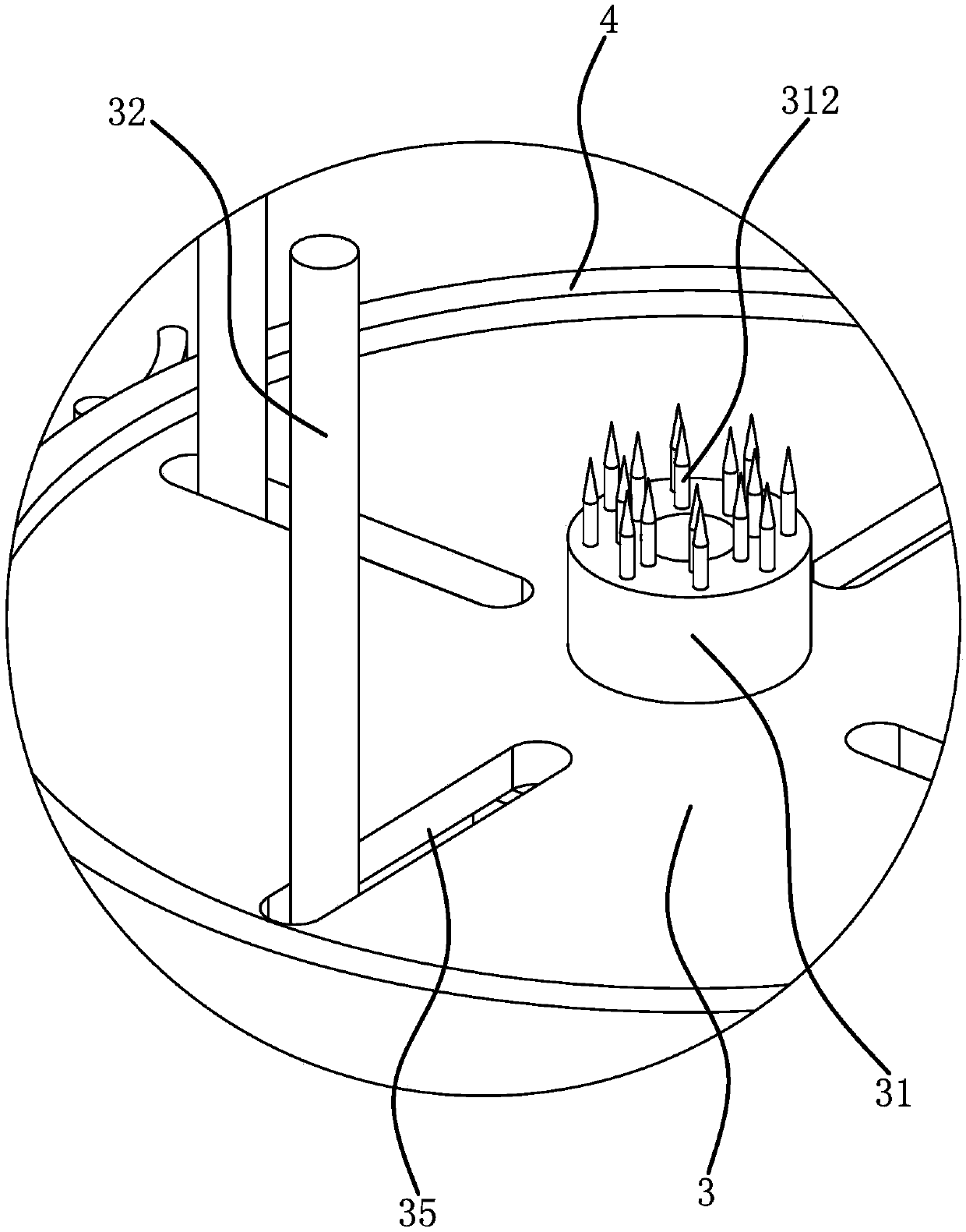

A pineapple heart removal device

The invention provides a pineapple core removing device, belongs to the technical field of food processing equipment, and solves the problem of juice wastage in a conventional pineapple core removing method. The pineapple core removing device comprises a machine frame, wherein a supporting platform is fixedly connected to the machine frame; a conveying frame is rotatably connected to the supporting platform; four positioning disks are circumferentially and fixedly connected to the conveying frame; a positioning seat is connected to each positioning disk; a plurality of positioning columns are in sliding connection to each positioning disk; a control ring is also rotatably connected to each positioning disk; a lifting frame is connected to the machine frame in a sliding manner; a cutting knife is rotatably connected to the lifting frame, and comprises a cutting part and a connecting part; a limiting push rod is connected to the lifting frame; and a transmission structure which can drive the cutting knife to rotate circumferentially when the cutting knife moves downwards is arranged between the limiting push rod and the cutting knife. According to the pineapple core removing device disclosed by the invention, the core part of a pineapple can be automatically cut off, and the juice wastage is reduced.

Owner:CHANGZHOU INST OF DALIAN UNIV OF TECH

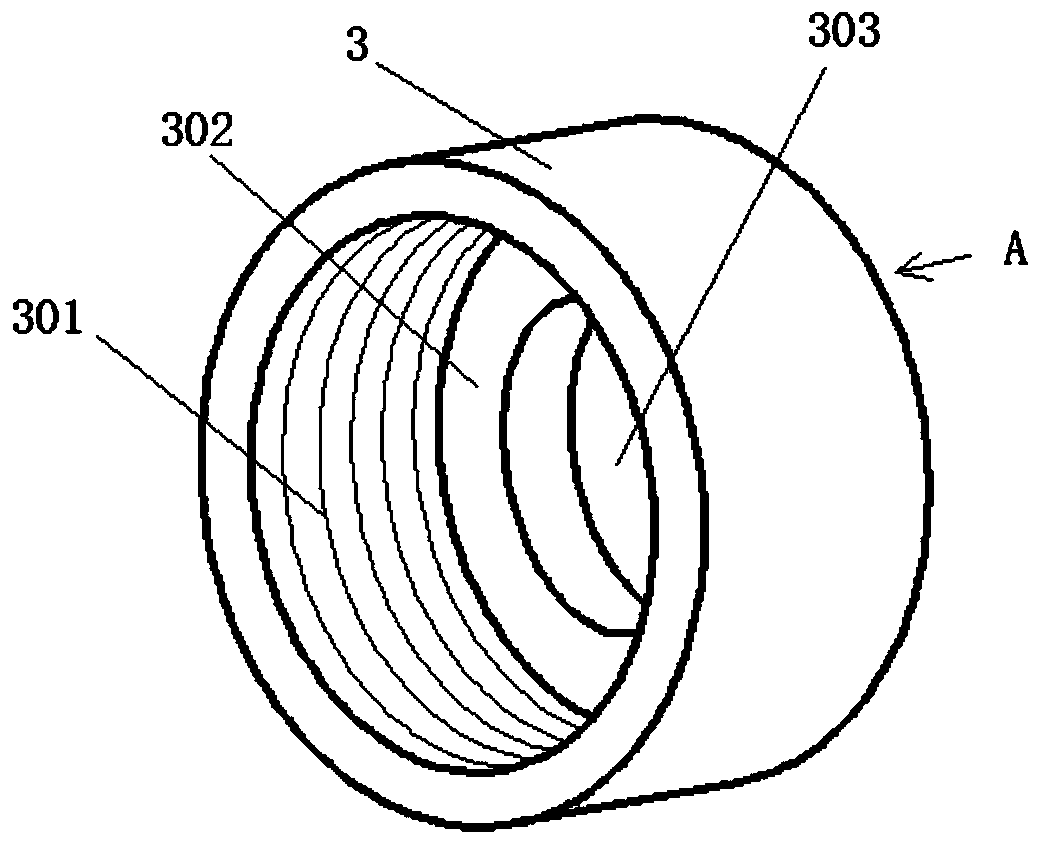

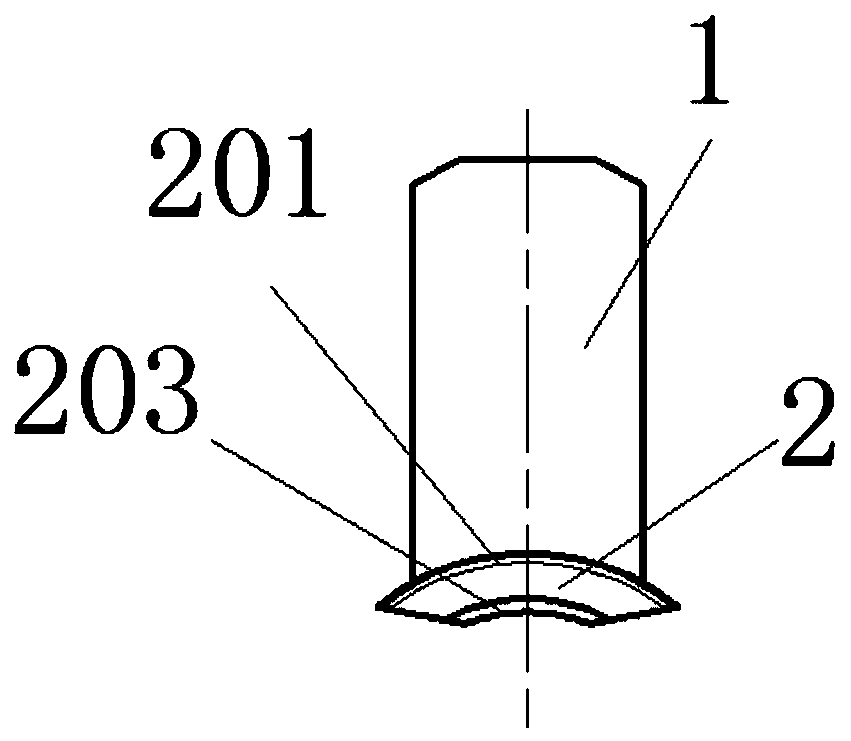

Soft three jaws with thread

ActiveCN109570540BPreserve machining accuracyPreserve the advantages of machining accuracyChucksAxial compressionEngineering

A threaded soft three-claw is provided, which has a soft three-claw body, and the soft three-claw body is vertically fixed to an arc-plate type threaded connector with an axial height h>2 / 3h1, and the arc-plate type threaded connector is used for leaning on the support And it is suitable for the outer peripheral side wall of the thin-walled sleeve parts to be processed, wherein the arc plate type threaded connector is made of external threads, and the screw connection is made of internal threads and is the same as the central axis of the three-jaw chuck body The compression nut of the shaft axially compresses the thin-walled sleeve parts to be processed and at the same time radially clamps the thin-walled sleeve parts to be processed on the three-jaw chuck body. The invention has good anti-deformation effect of parts, high processing precision, low cost, convenient manufacture and simple operation.

Owner:广东华顺鹏机械有限公司

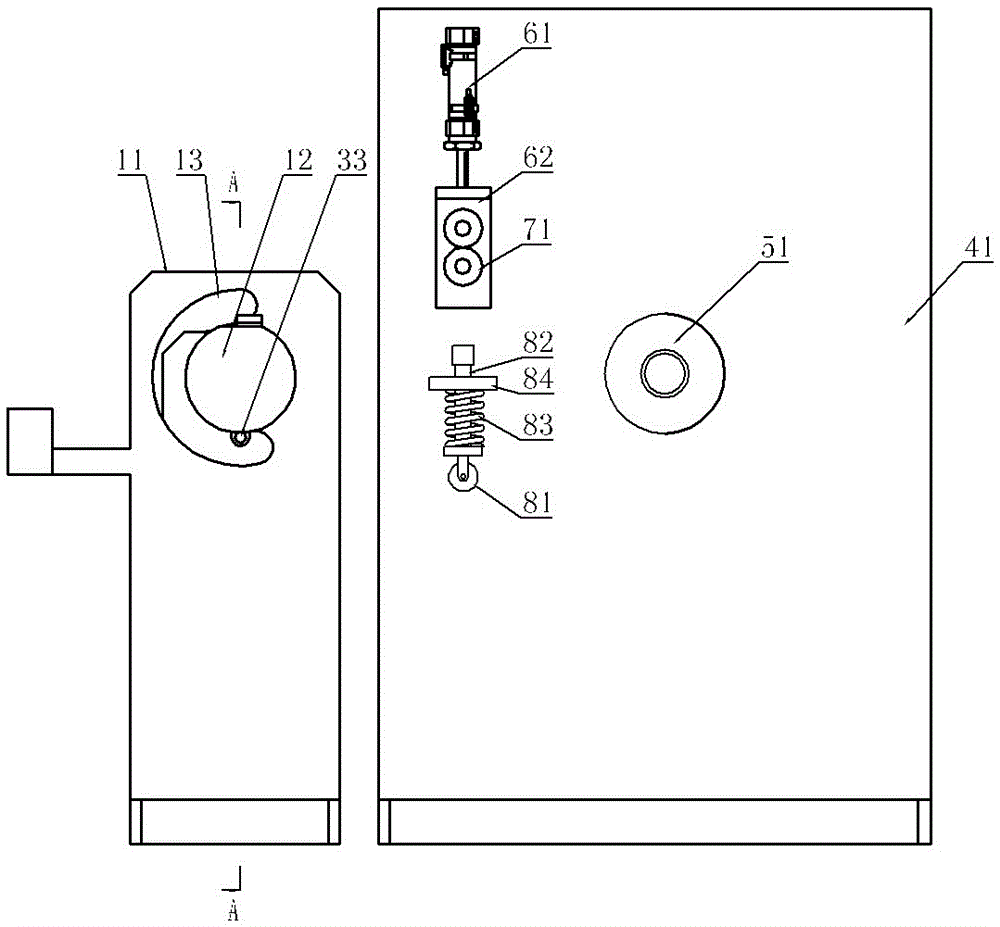

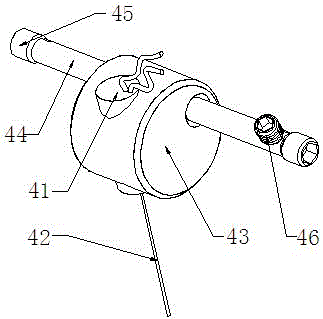

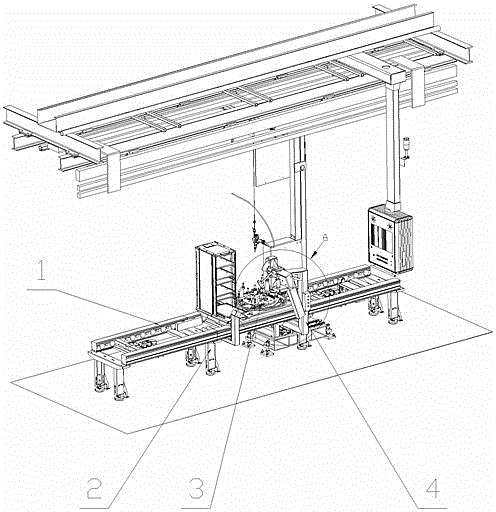

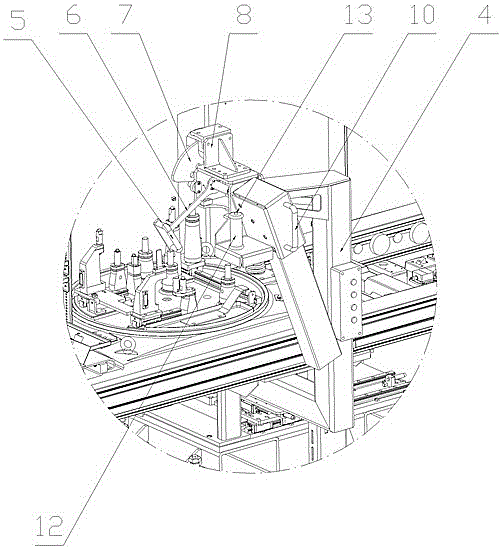

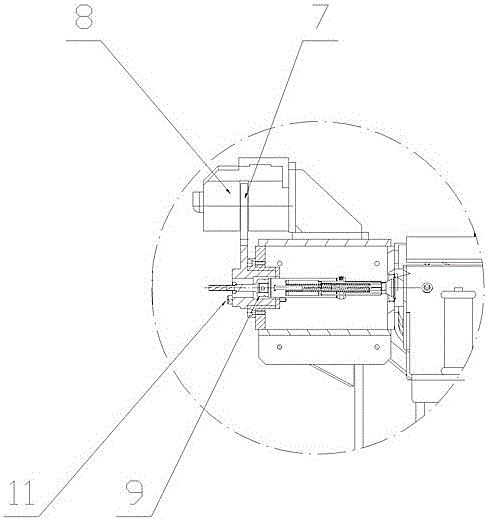

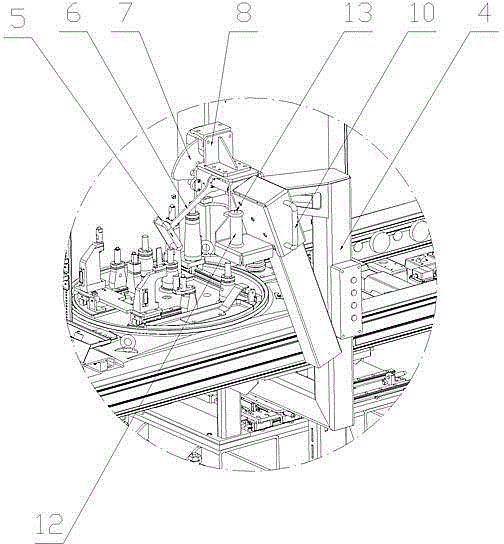

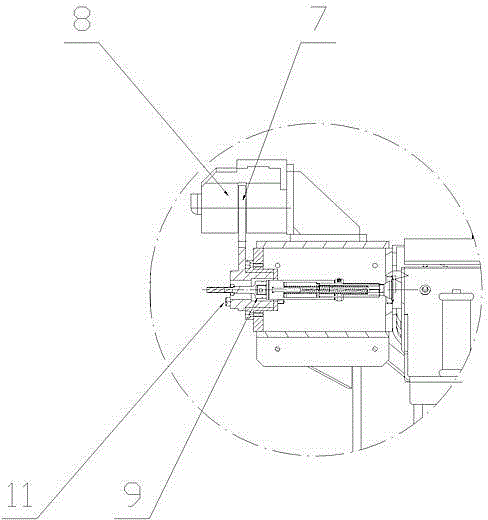

Swing type pneumatic clamping reaction arm mechanism

The invention discloses an oscillating type pneumatic clamping reverse force arm mechanism. The oscillating type pneumatic clamping reverse force arm mechanism comprises a rack (2) provided with a roller bed (1), and a tray (3) for conveying workpieces is arranged on the roller bed (1). The oscillating type pneumatic clamping reverse force arm mechanism is characterized in that a supporting frame (4) is arranged on the rack (2), an oscillating bar (6) with an oscillating handle (5) is rotationally supported by the supporting frame (4), the oscillating bar (6) can drive a sector-shaped disk (7) to rotate, an air locking device (8) matched with the sector-shaped disk (7) is arranged, a reverse force arm screwing mechanism (9) which is arranged on the supporting frame (4) and can axially float can rotate along with the oscillating bar (6) at the same time, a pushing handle (10) is arranged at the tail end of the reverse force arm screwing mechanism (9), at least two positioning shafts (11) are arranged at the front end of the reverse force arm screwing mechanism (9), a working handle (12) is arranged on the supporting frame (4), and a button (13) capable of controlling the work of the reverse force arm screwing mechanism (9) is arranged at the top end of the working handle (12).

Owner:DALIAN HAOSEN EQUIP MFG

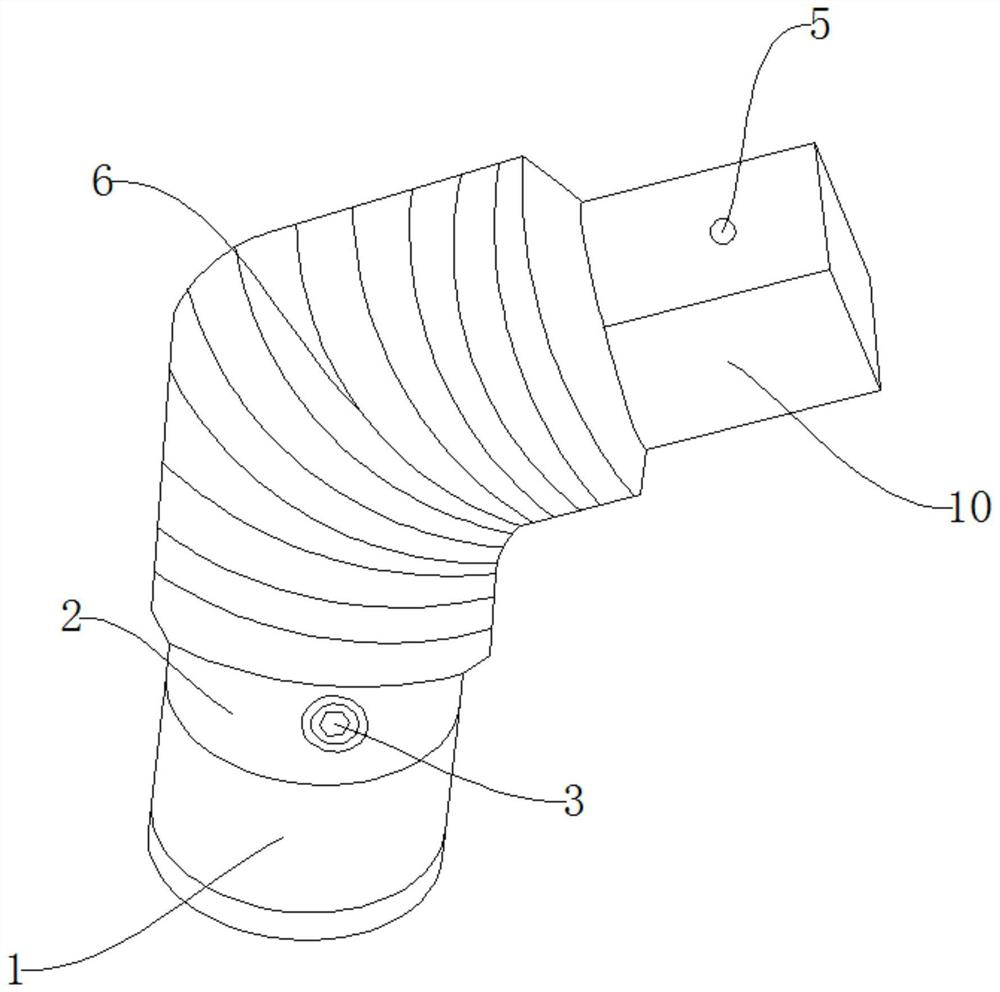

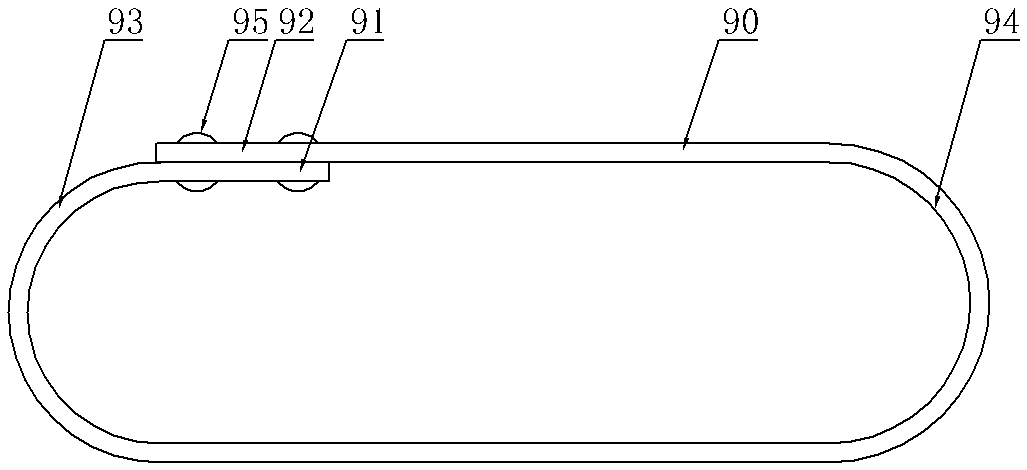

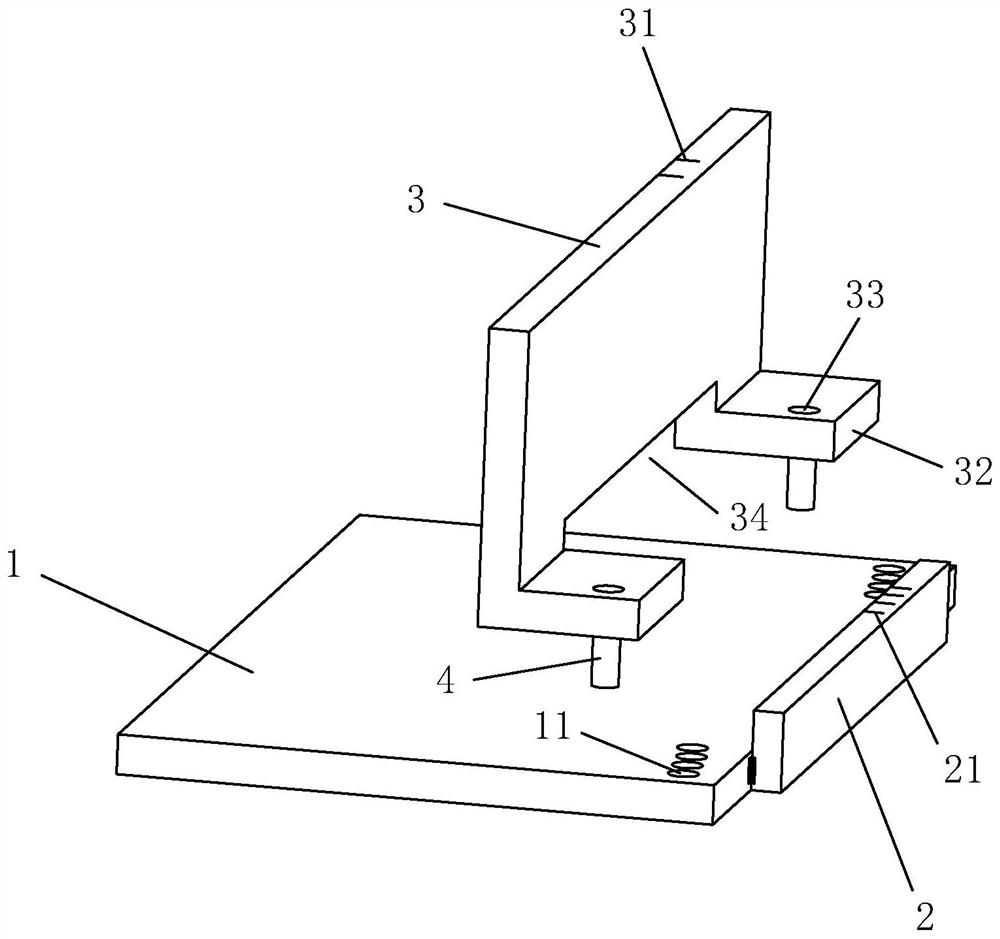

A b-shaped lifting ring assembly and positioning tool

ActiveCN107877430BSimple structureQuick positioning operationWork holdersMetal-working hand toolsClassical mechanicsStructural engineering

The invention discloses a B-type lifting ring assembly and positioning tool, which includes an assembly platform, a positioning baffle is vertically installed on the upper surface of the assembly platform, and a limit block parallel to the positioning baffle is installed on the side of the assembly platform. Higher than the upper surface of the assembly platform, there is at least one first centering scale line on the positioning baffle, at least one second centering scale line on the limit stopper, and a notch on the bottom of the positioning baffle . Locate the lug plate and the backing plate of the B-type lifting ring. The side of the backing plate is fitted with the limit stopper and the large end surface of the ear plate is fitted with the positioning baffle, so that the backing plate and the lug plate are perpendicular to each other and in the width direction. For centering, align the vertical side of the lug plate and the short side of the backing plate with the first centering scale line and the second centering scale line respectively, so as to realize the centering of the backing plate and the ear plate in the length direction, and the whole structure The design is simple, the positioning operation is fast, and the precision is high, and the invention is used in the field of ship accessories.

Owner:GUANGZHOU WENCHONG SHIPYARD CO LTD

Oscillating type pneumatic clamping reverse force arm mechanism

The invention discloses an oscillating type pneumatic clamping reverse force arm mechanism. The oscillating type pneumatic clamping reverse force arm mechanism comprises a rack (2) provided with a roller bed (1), and a tray (3) for conveying workpieces is arranged on the roller bed (1). The oscillating type pneumatic clamping reverse force arm mechanism is characterized in that a supporting frame (4) is arranged on the rack (2), an oscillating bar (6) with an oscillating handle (5) is rotationally supported by the supporting frame (4), the oscillating bar (6) can drive a sector-shaped disk (7) to rotate, an air locking device (8) matched with the sector-shaped disk (7) is arranged, a reverse force arm screwing mechanism (9) which is arranged on the supporting frame (4) and can axially float can rotate along with the oscillating bar (6) at the same time, a pushing handle (10) is arranged at the tail end of the reverse force arm screwing mechanism (9), at least two positioning shafts (11) are arranged at the front end of the reverse force arm screwing mechanism (9), a working handle (12) is arranged on the supporting frame (4), and a button (13) capable of controlling the work of the reverse force arm screwing mechanism (9) is arranged at the top end of the working handle (12).

Owner:DALIAN HAOSEN EQUIP MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com