Cone keyway machining fixture

A keyway and fixture technology, used in manufacturing tools, metal processing equipment, metal processing mechanical parts, etc., can solve the problems of low accuracy of the outer circumference, low positioning accuracy of the keyway, and insufficient consistency of the keyway accuracy, and achieve good consistency. The effect of stability, positioning stability and accurate positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

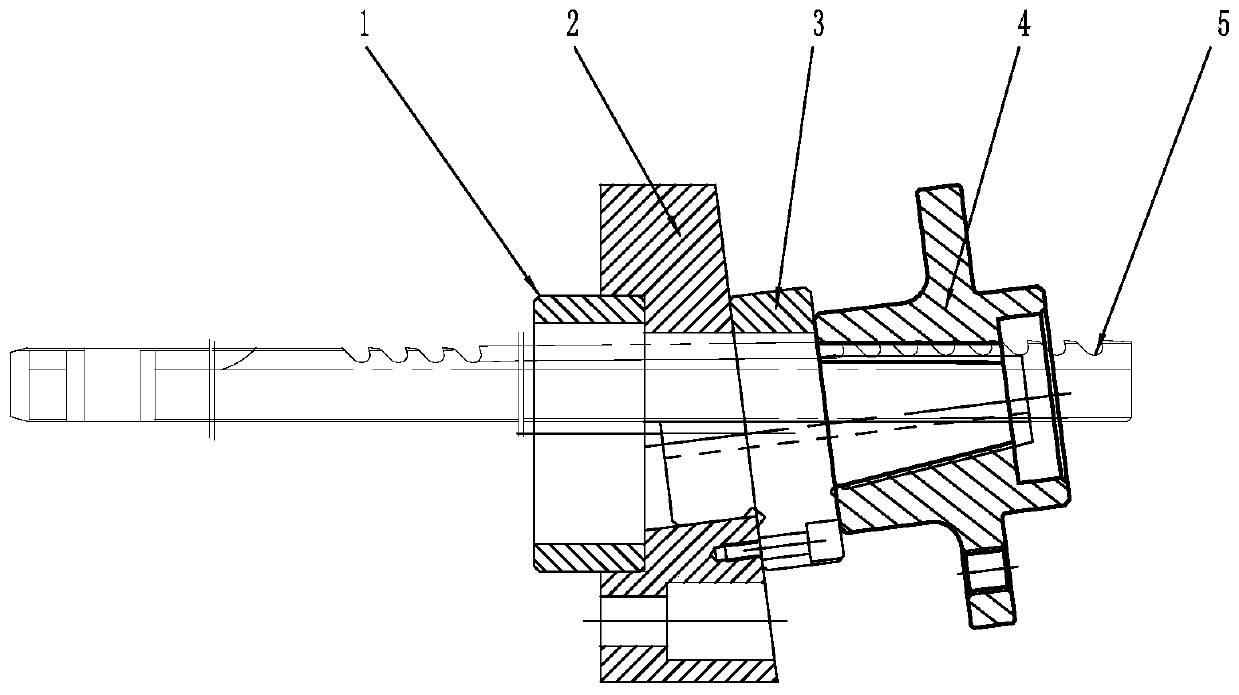

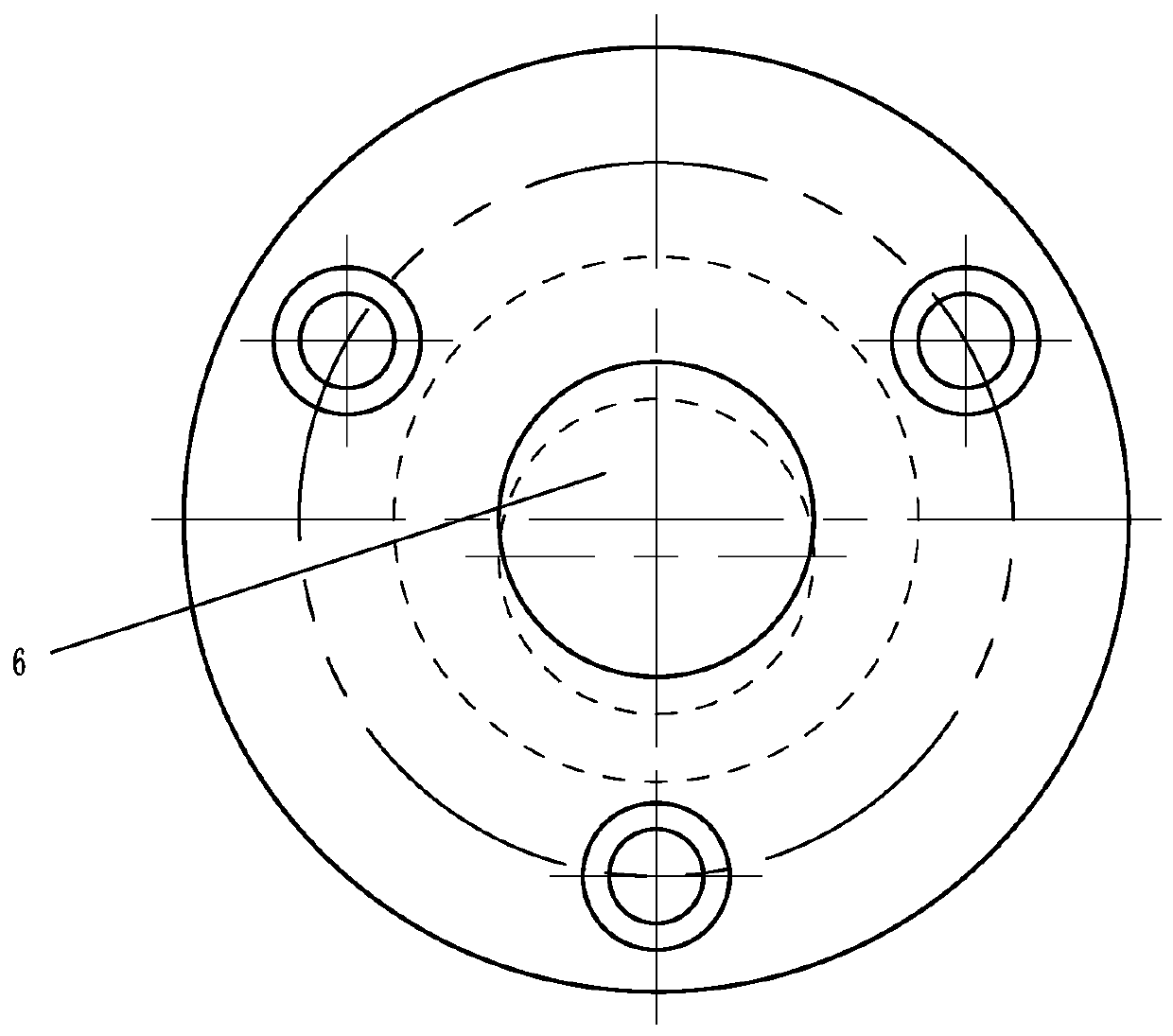

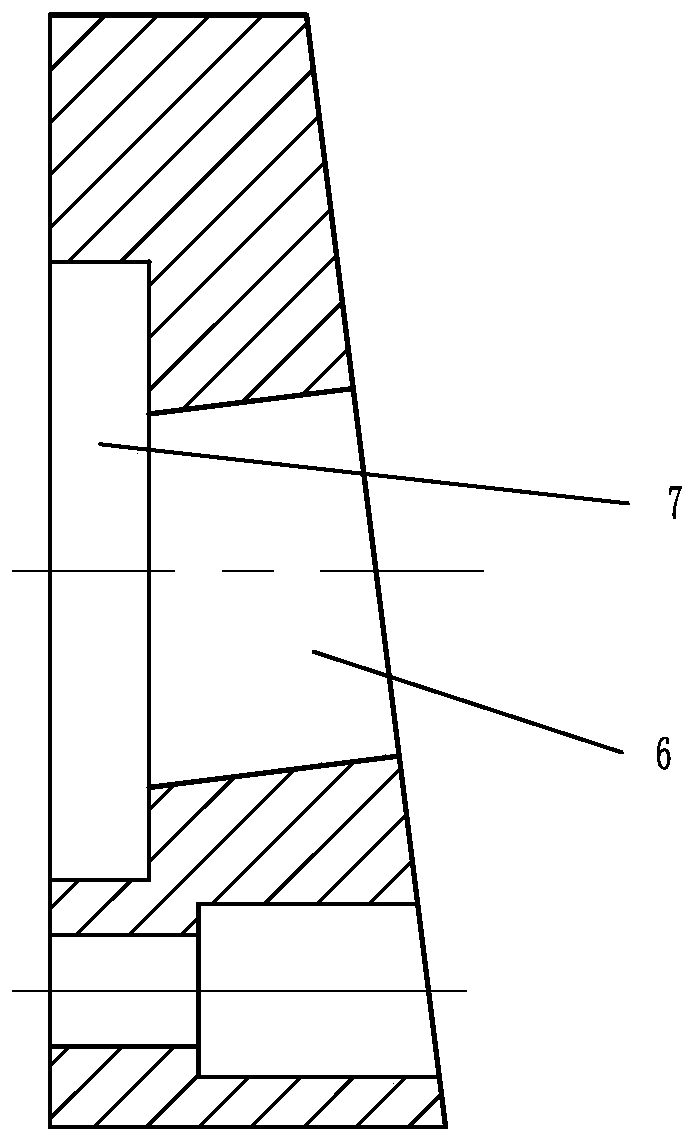

[0015] Embodiment: The tapered hole keyway processing fixture of the present invention, as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 As shown, it includes a transition plate 2 as the installation main body; the front end face of the transition plate 2 is a slope, and the middle part is vertically provided with a guide hole 6; the rear end face of the transition plate 2 is a vertical surface, and a positioning hole 7 is vertically provided; The guide hole 6 is a through hole, the positioning hole 7 is a blind hole, and the guide hole 6 runs through the middle part of the hole bottom of the positioning hole 7; the positioning ring 1 is set in the positioning hole 7, and the positioning ring 1 It is a ring structure with an inner hole for the keyway broach 5 to pass through; the positioning ring 1 is partially inserted into the positioning hole 7, and the part exposed outside the positioning hole 7 cooperates with the outside to form the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com