Precise concrete test block manufacturing method and tool mold

A technology of concrete test block and production method, which is applied in the direction of manufacturing tools, molds, mold auxiliary parts, etc., to achieve the effects of ensuring precise processing, simplifying structure, and stabilizing the direction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

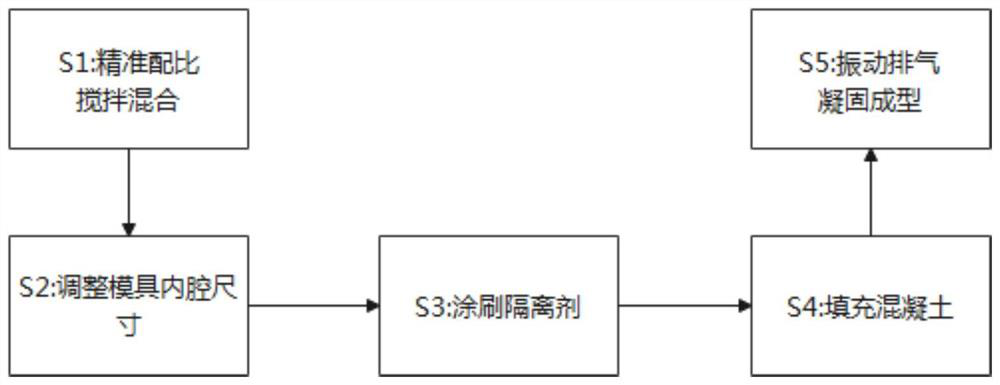

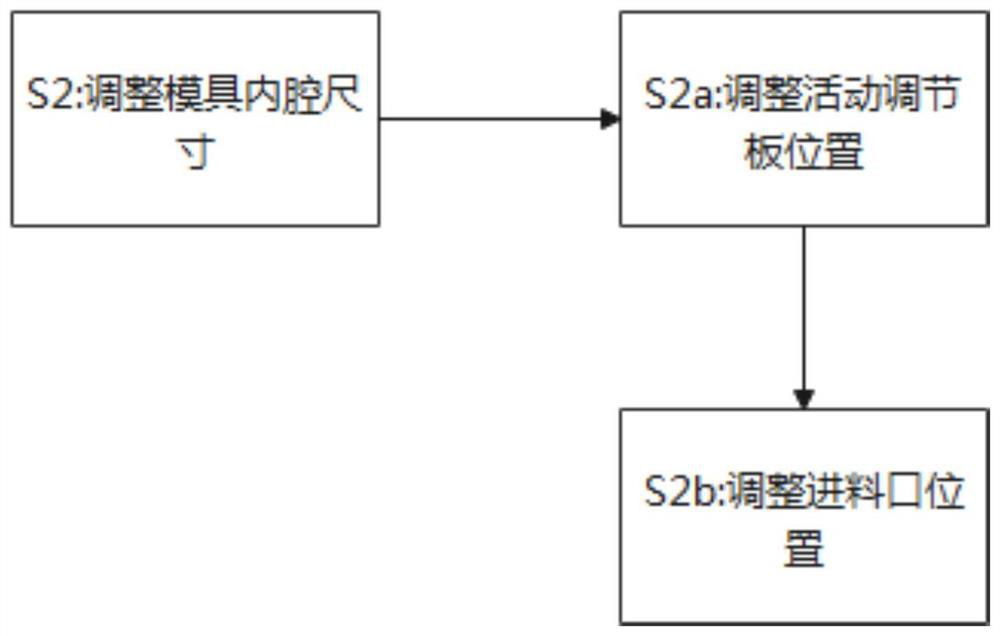

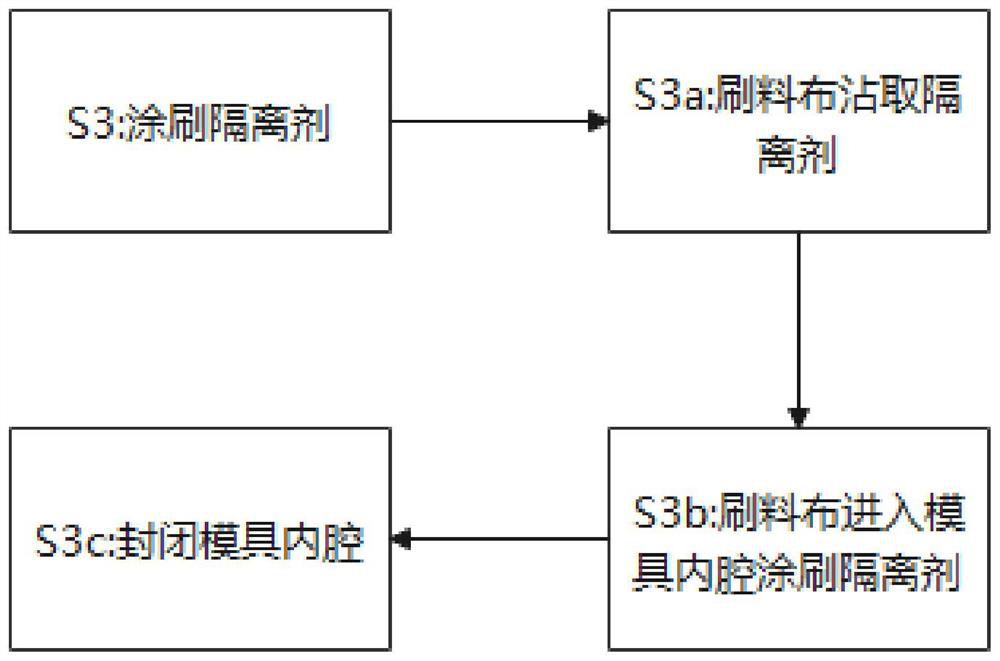

[0048] In order to solve the technical problem of how to realize a tooling mold that can adjust the production volume of concrete test blocks according to different test requirements and make multiple concrete test blocks at the same time, such as Figures 1 to 5 As shown, the following preferred technical solutions are provided:

[0049] A method for making a precise concrete test block and a tooling mold, including a concrete mixing box and an adjustable mold 1, the discharge port of the concrete mixing box is connected to the adjustable mold 1, and at least three groups of molds are arranged horizontally and parallel in the adjustable mold 1 Inner cavity 1a, the mold inner cavity 1a runs through the adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com