Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Process controlled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

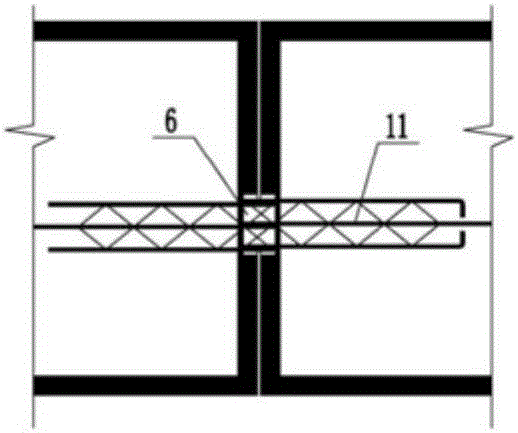

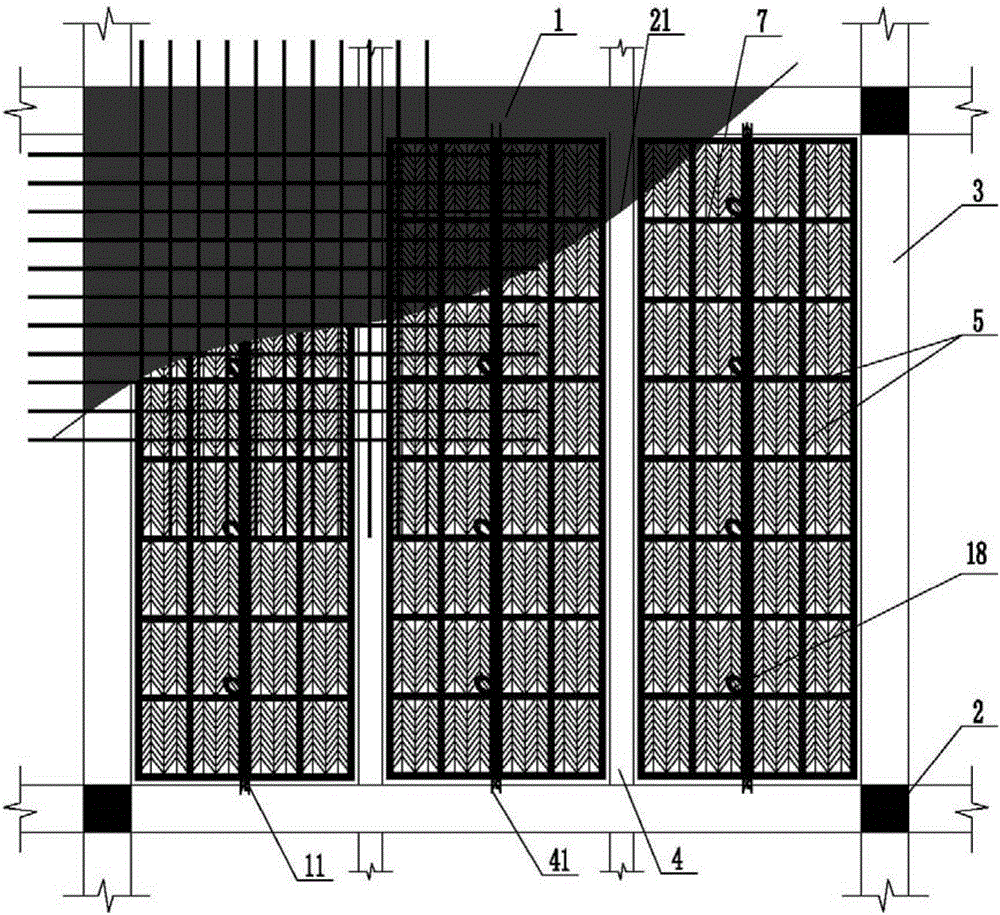

Assembling type overlapped cavity floor cover

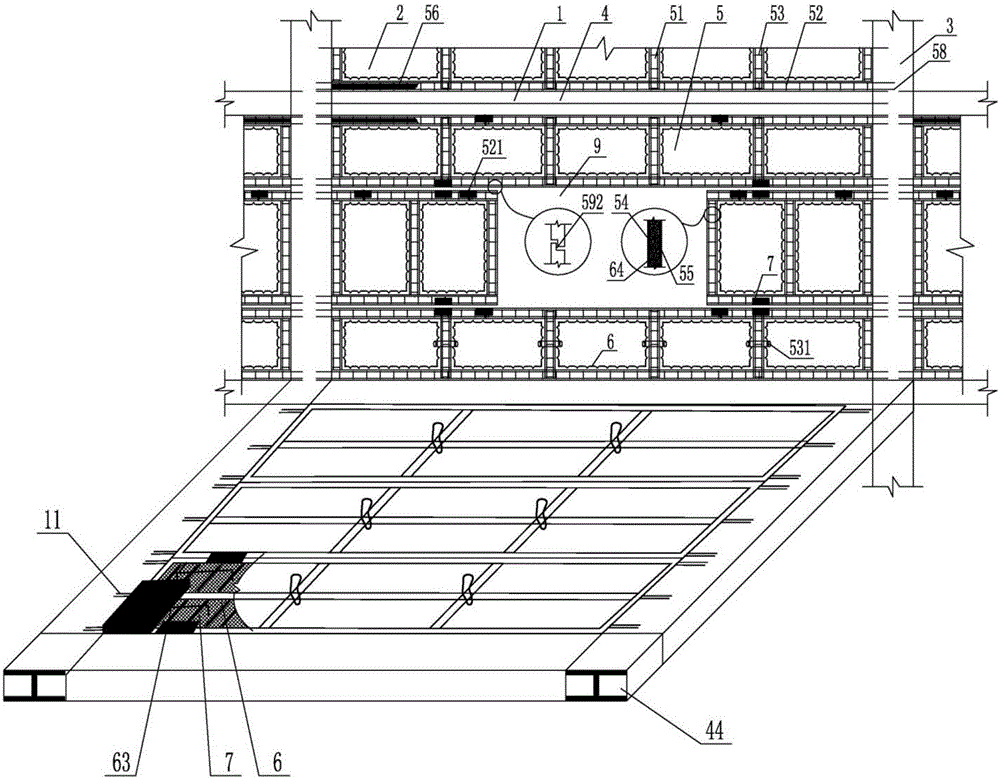

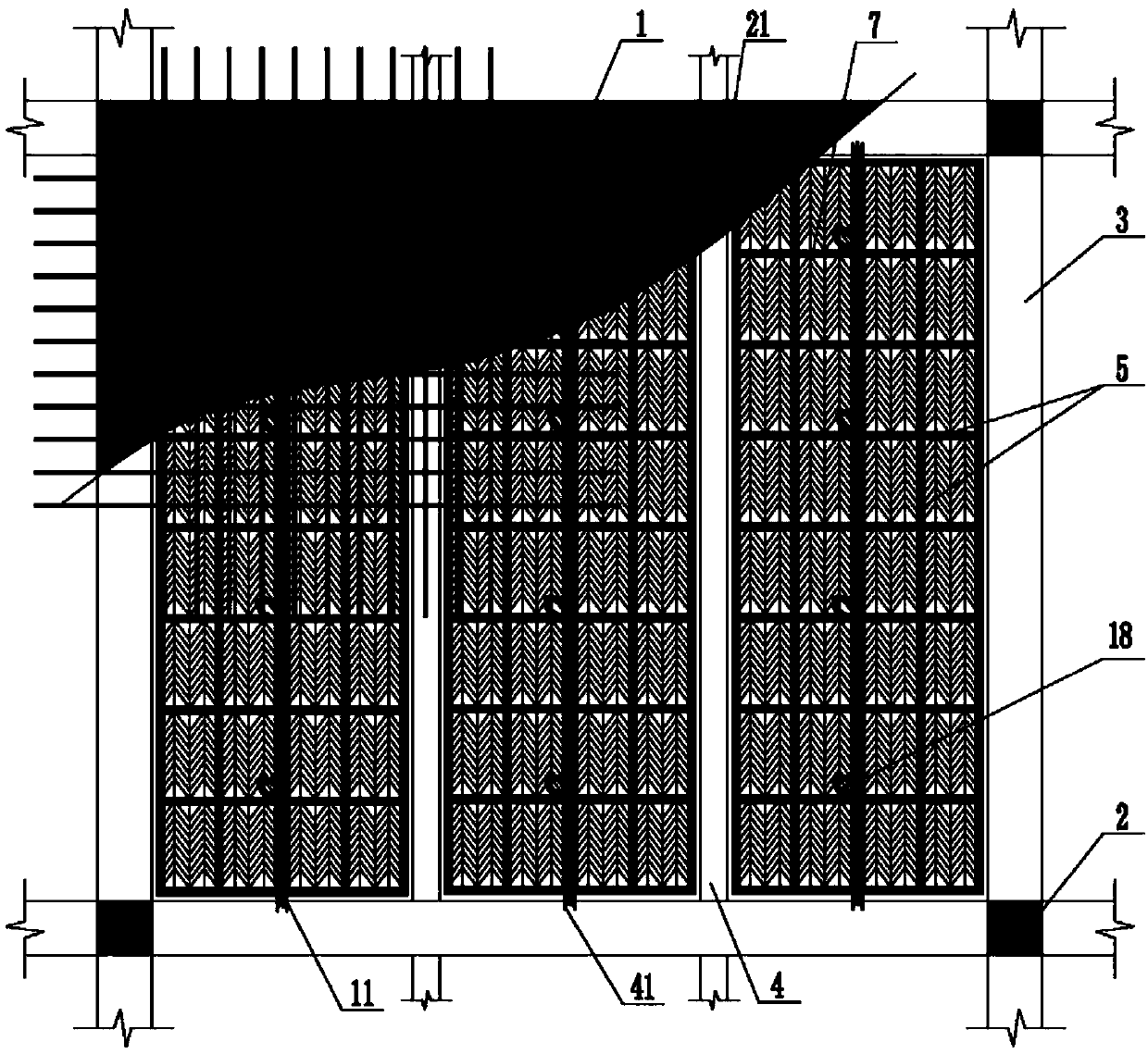

The invention provides an assembling type overlapped cavity floor cover. The assembling type overlapped cavity floor cover comprises columns, a main beam, an auxiliary beam, upper-flange-free cavity plate components and cast-in-situ reinforced concrete floor cover upper flange plates. The assembling type overlapped cavity floor cover is characterized in that the auxiliary beam is arranged in a column net formed by the columns and the main beam; the upper-flange-free cavity plate components are arranged on a framework of the auxiliary beam; the assembling type upper-flange-free cavity plate components and the beams are arranged in a vertical or horizontal overlapping manner, the vertical overlapping manner is to overlap the assembling type upper-flange-free cavity plate components to the top surfaces of the beams, and the horizontal overlapping manner is to overlap the assembling type upper-flange-free cavity plate components to the horizontal surfaces of the beams; and reinforced concrete is poured on the upper surfaces of the upper-flange-free cavity plate components to form assembling type cavity floor cover upper flange plates through overlapping, so as to form the assembling type overlapped cavity floor cover.

Owner:王海崴 +2

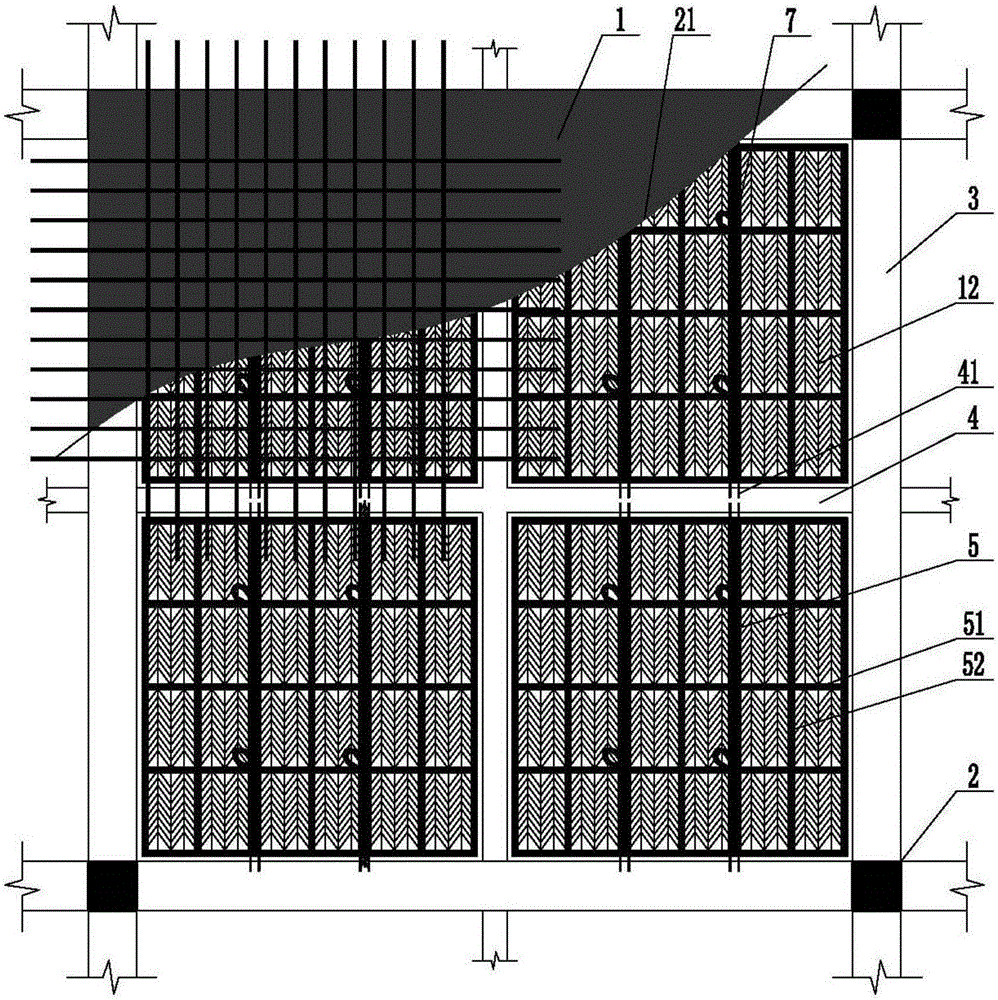

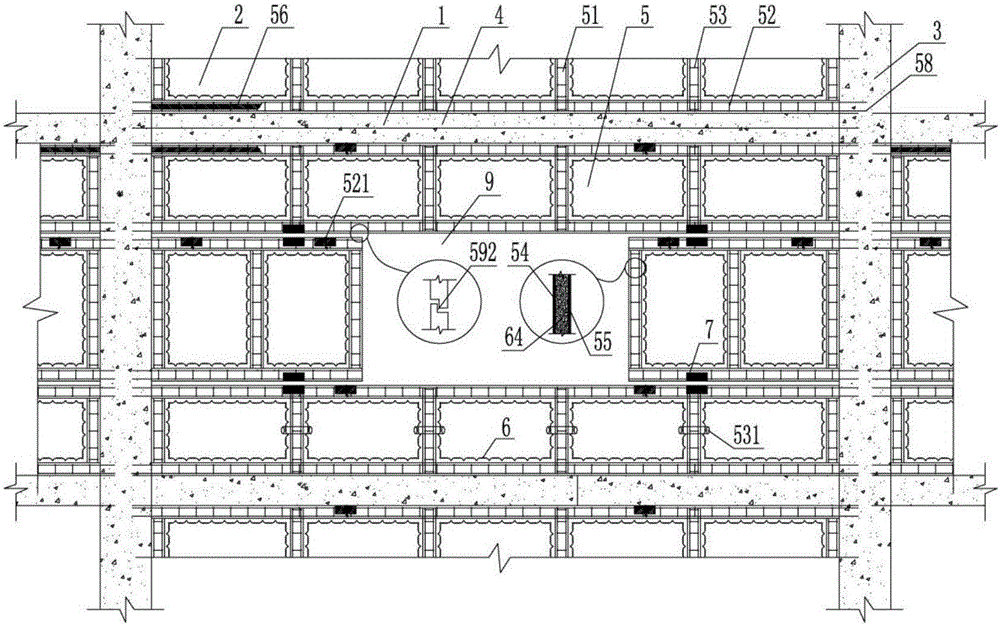

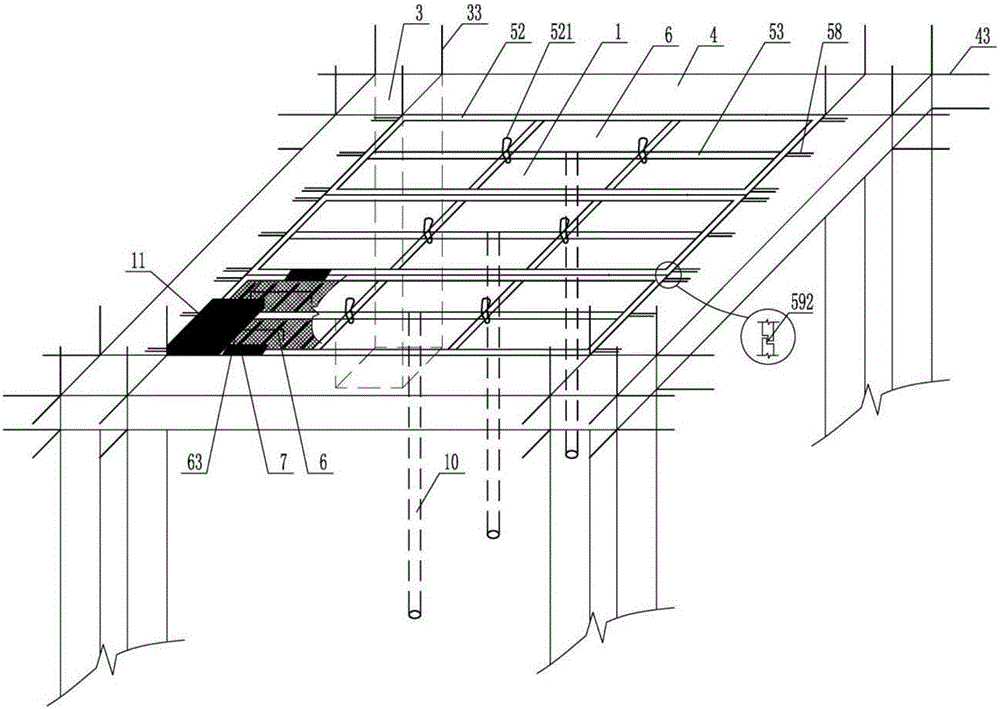

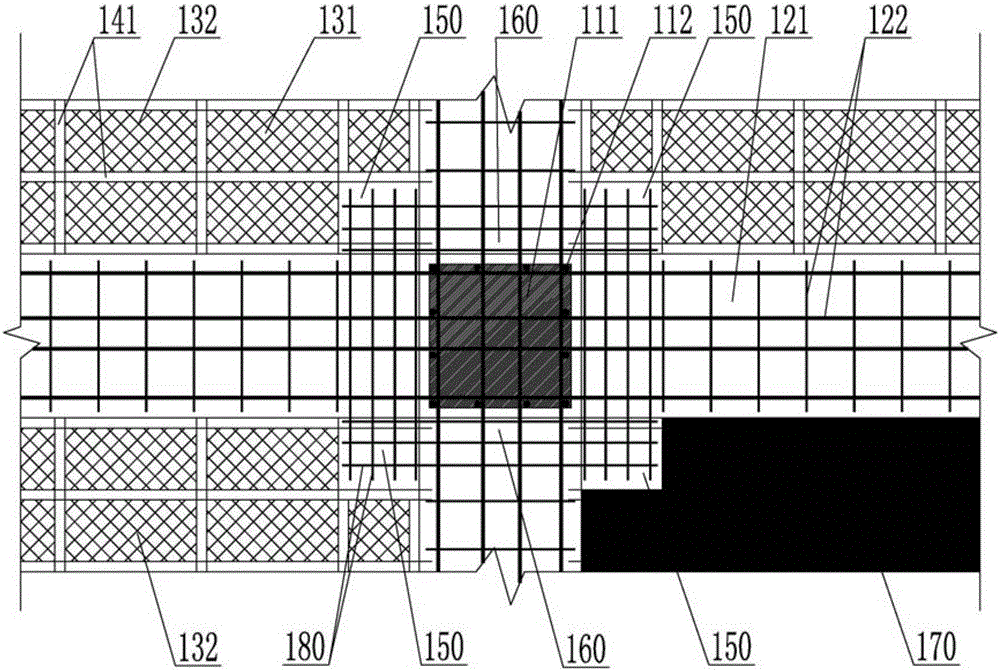

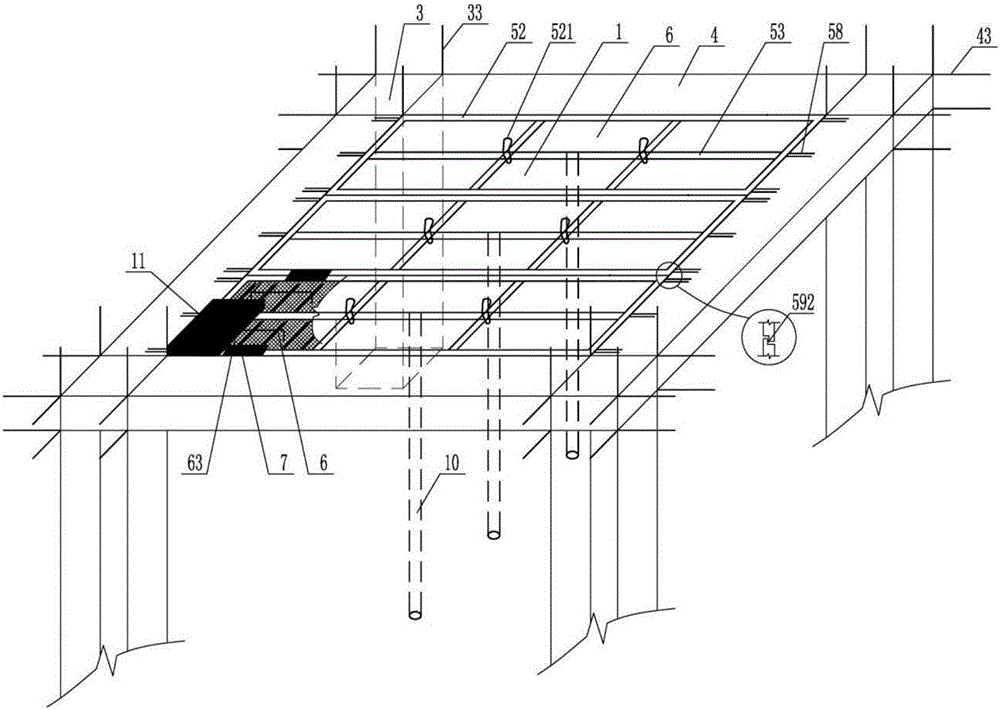

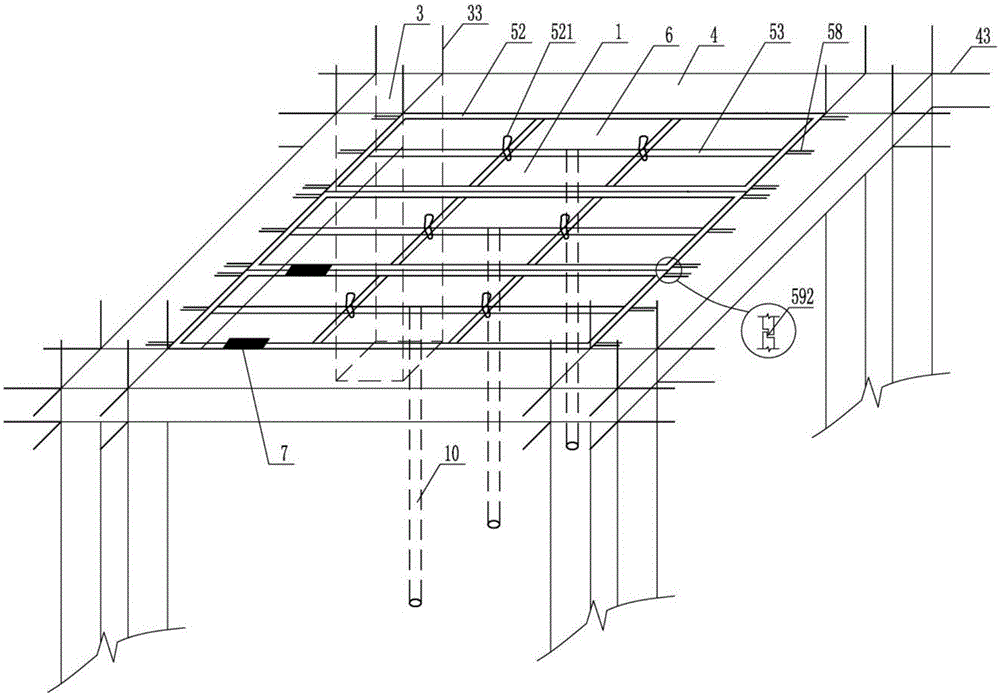

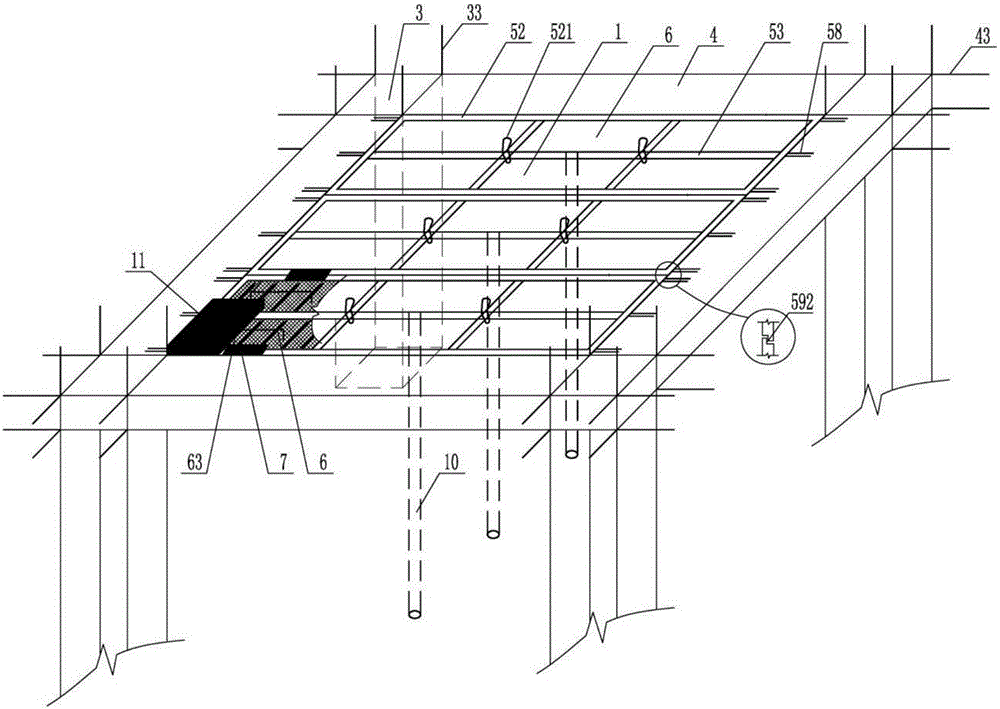

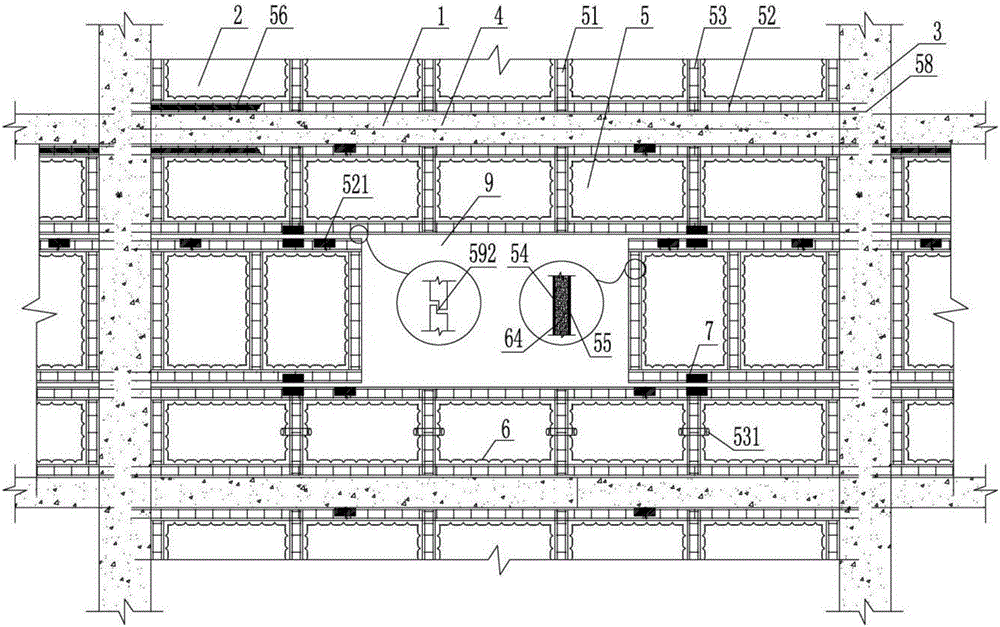

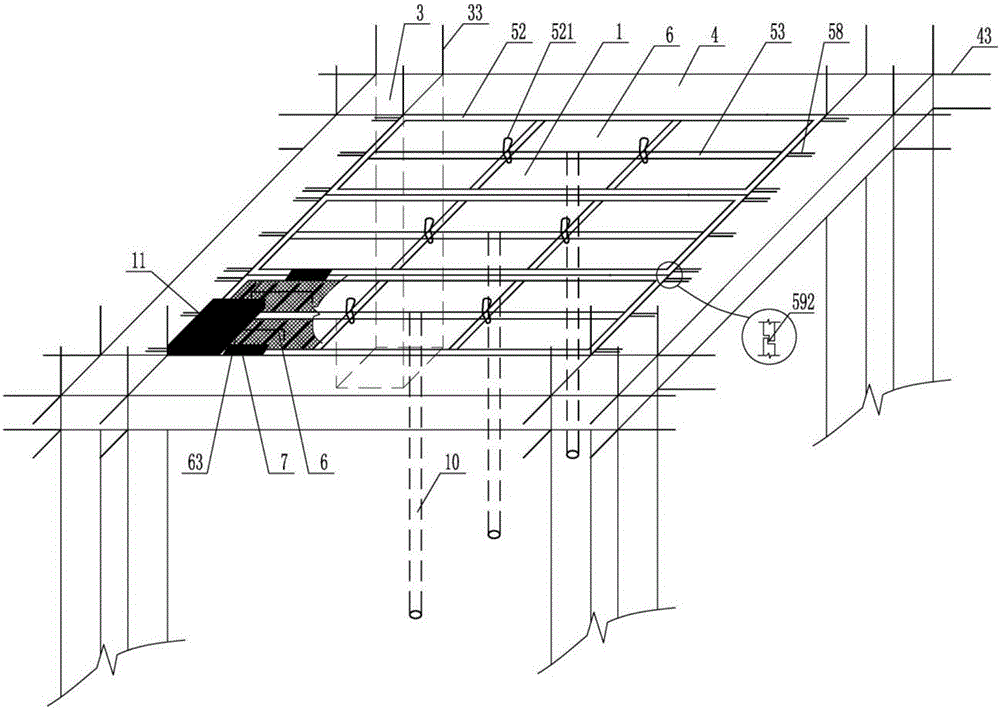

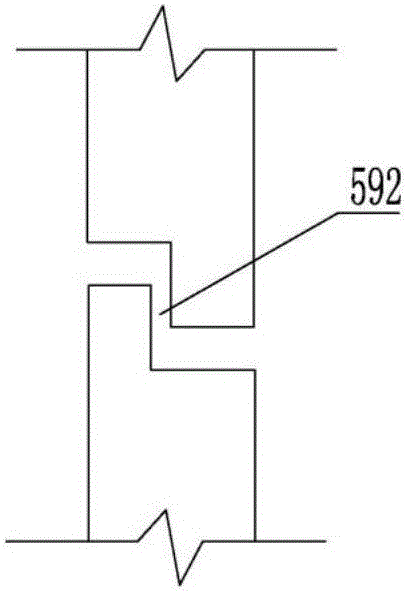

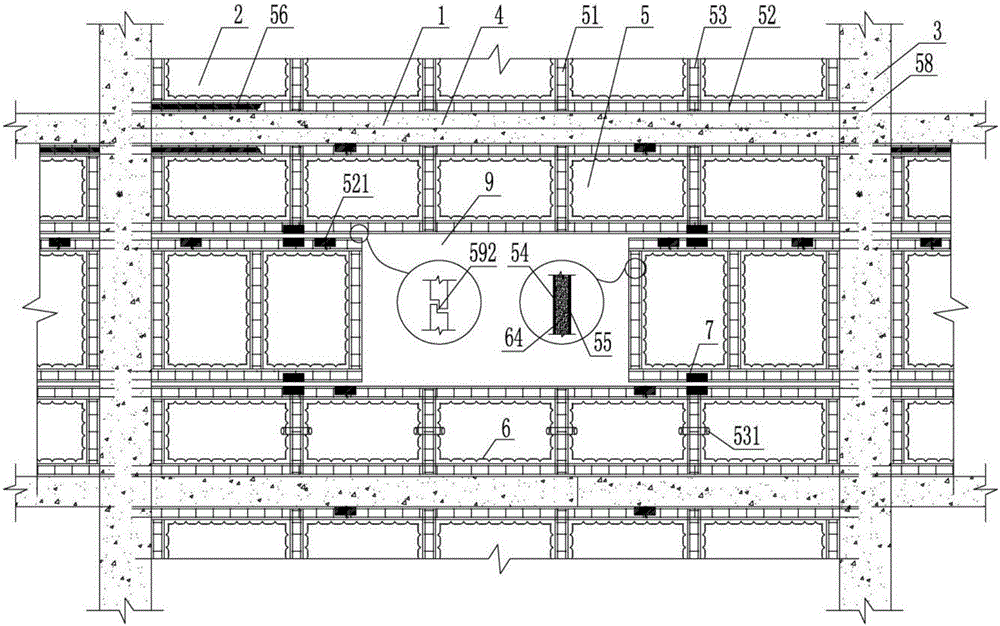

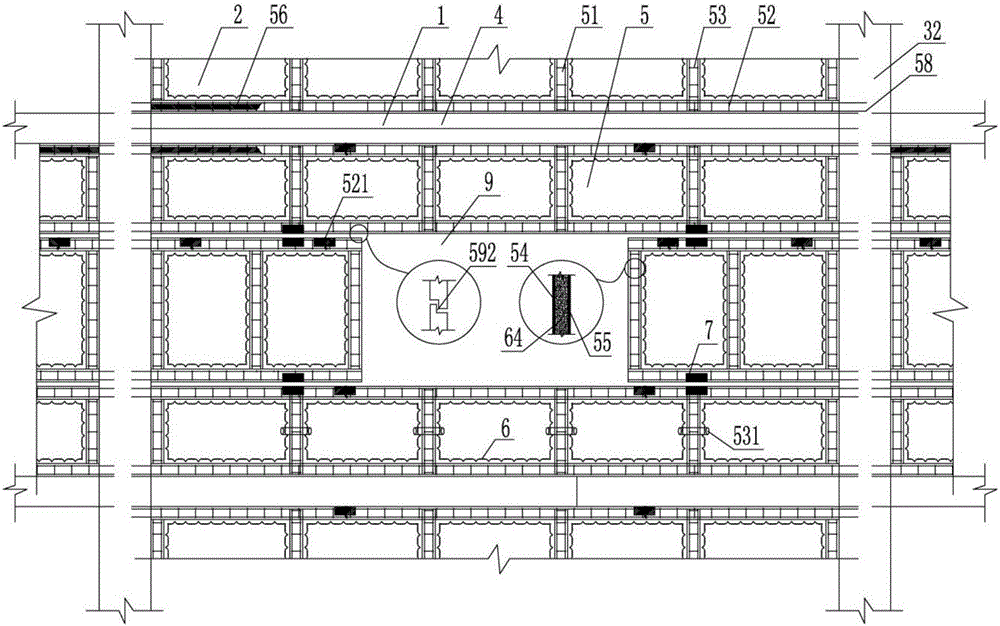

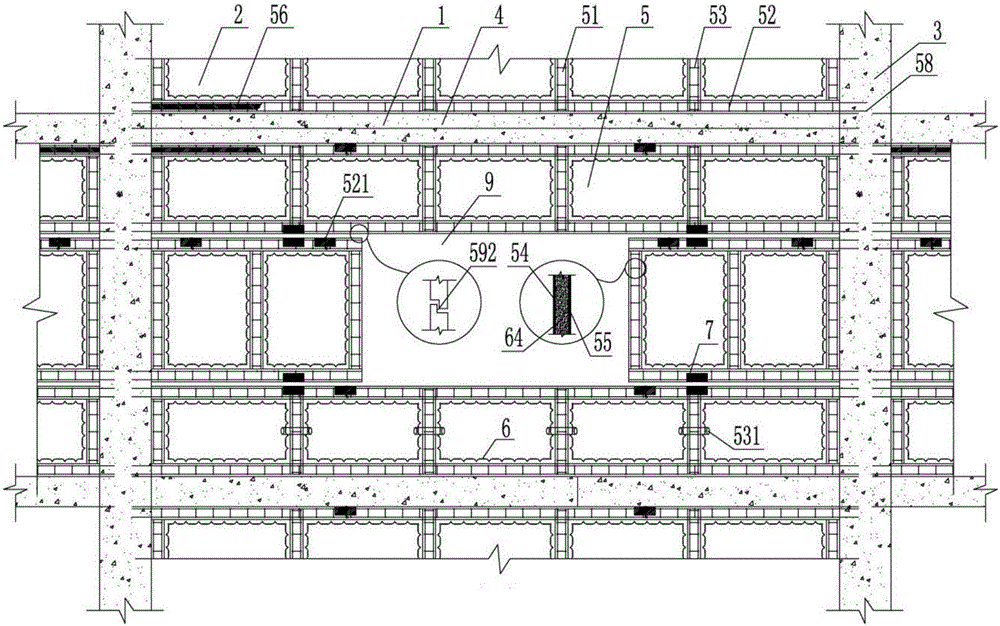

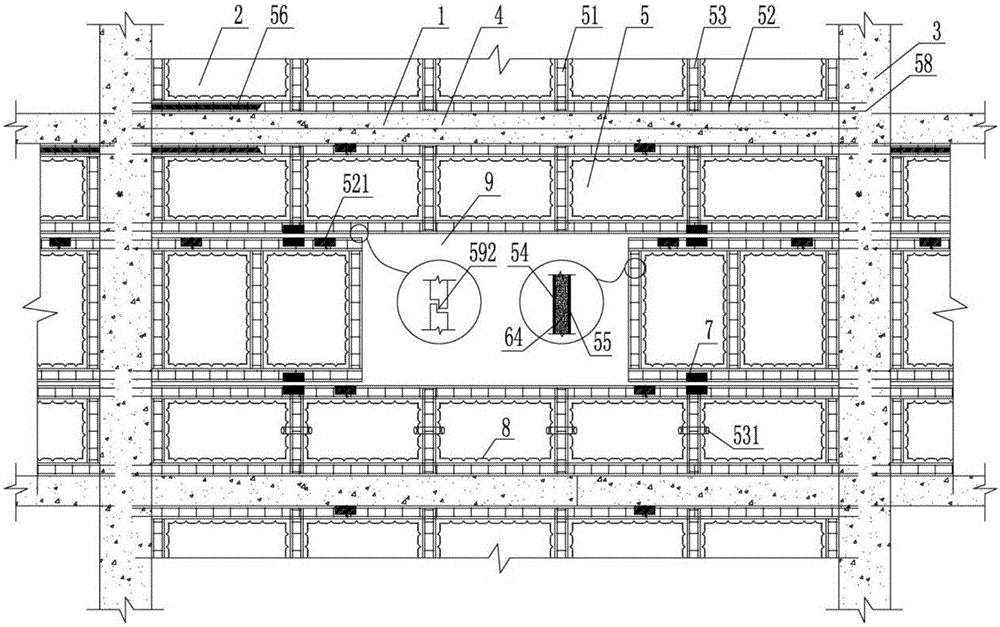

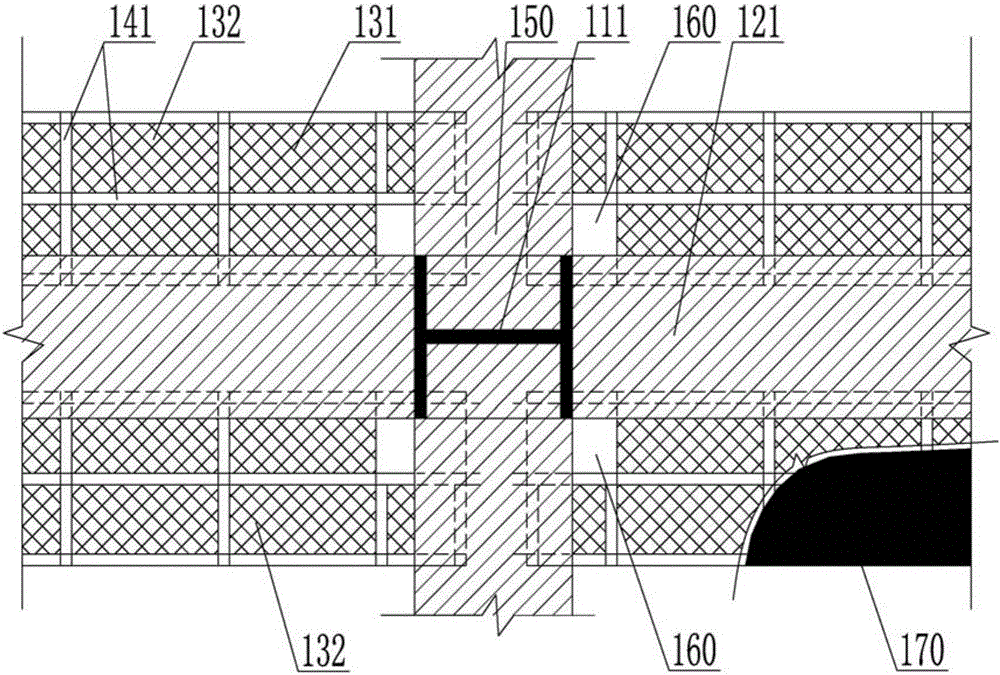

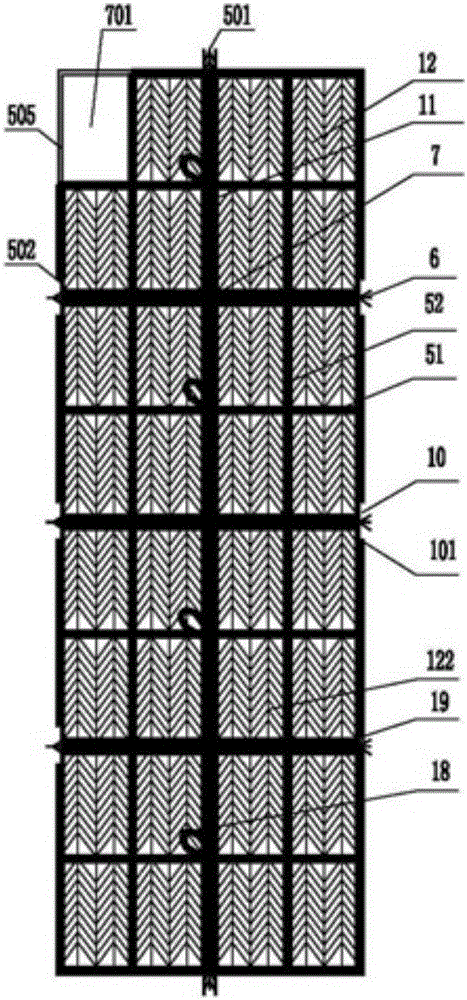

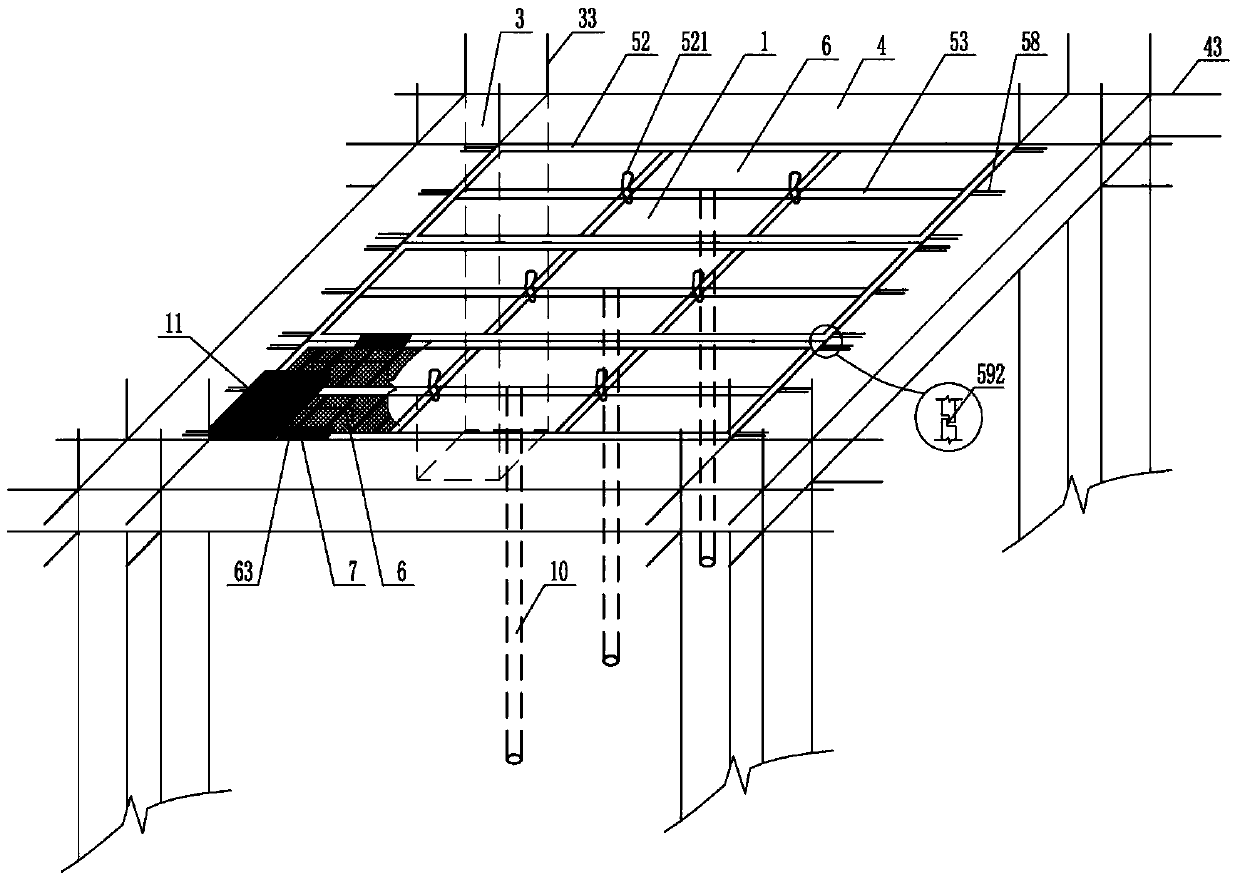

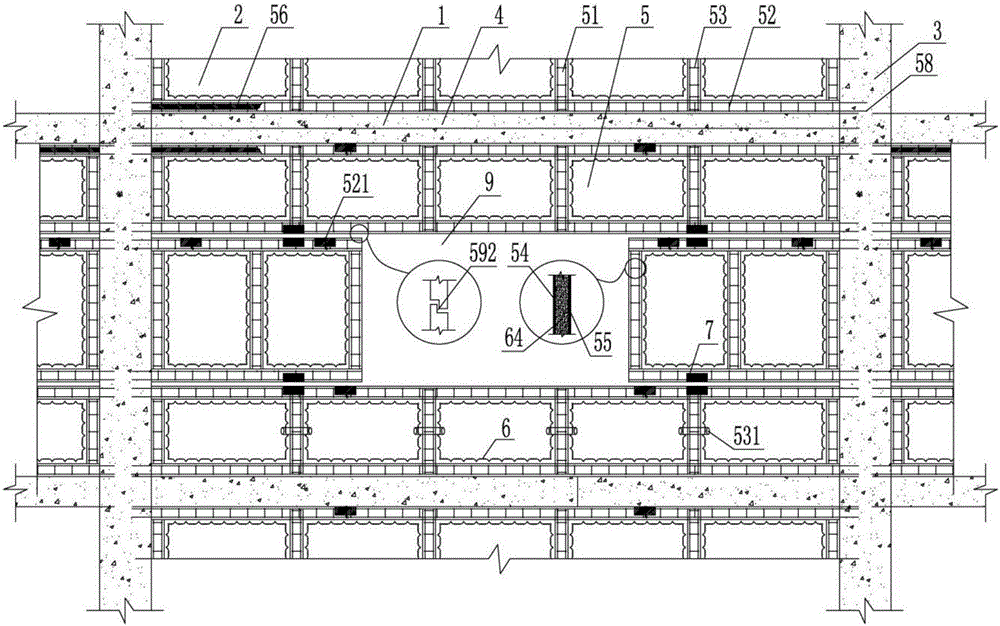

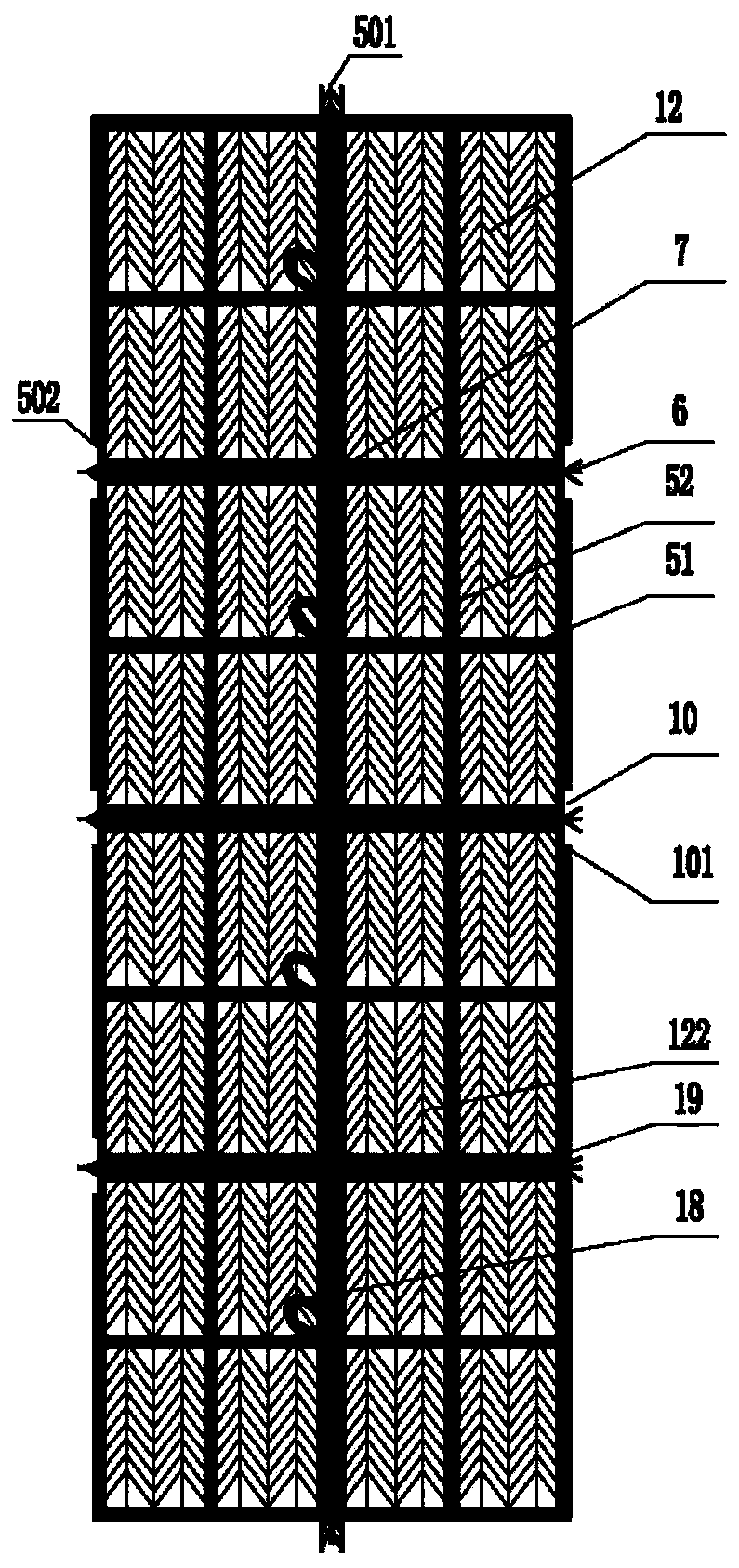

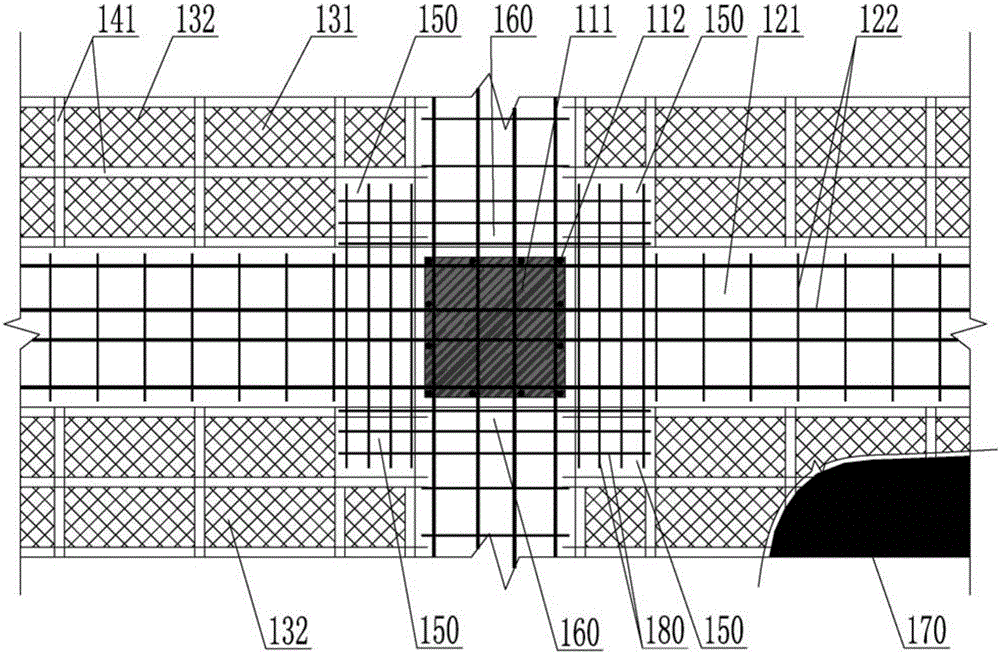

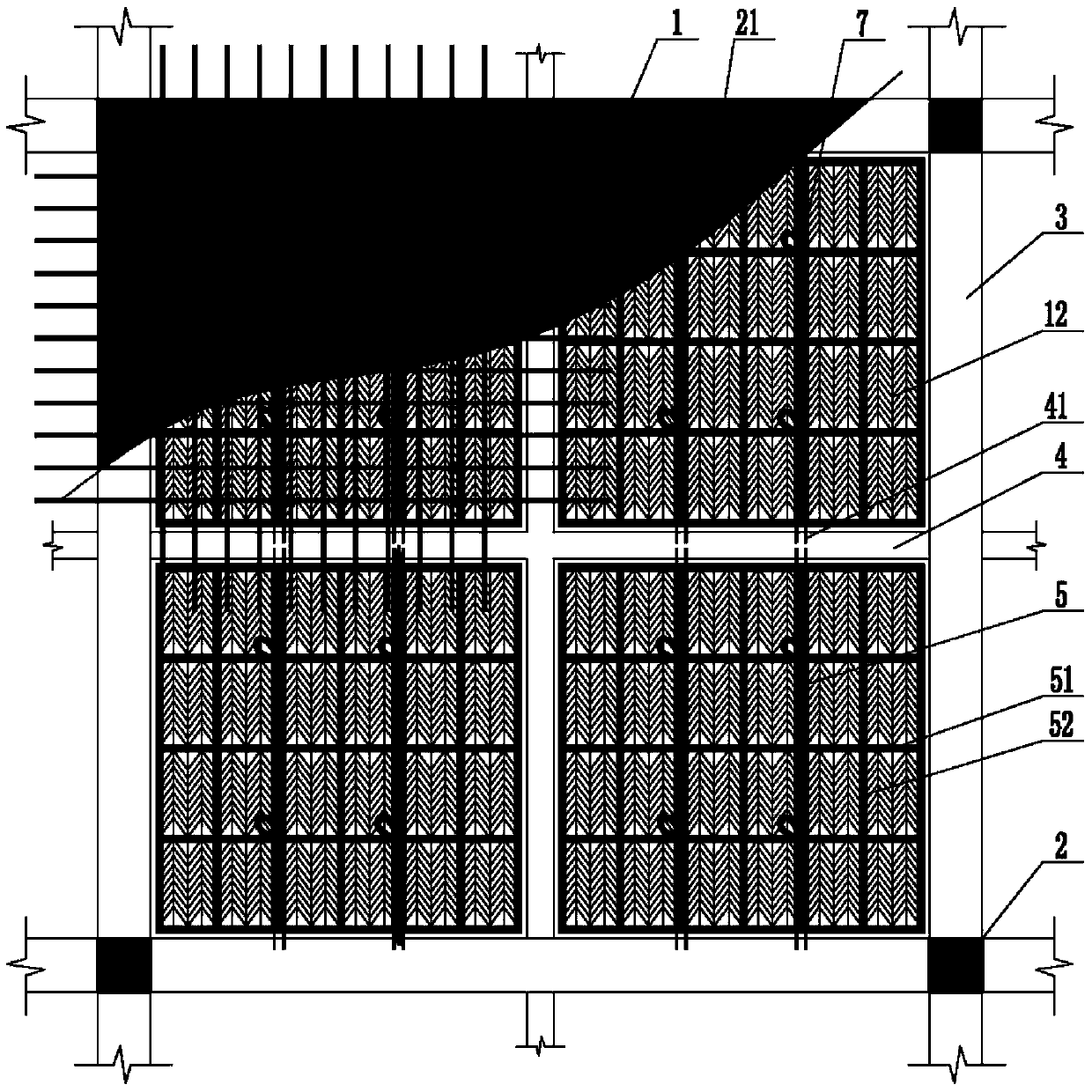

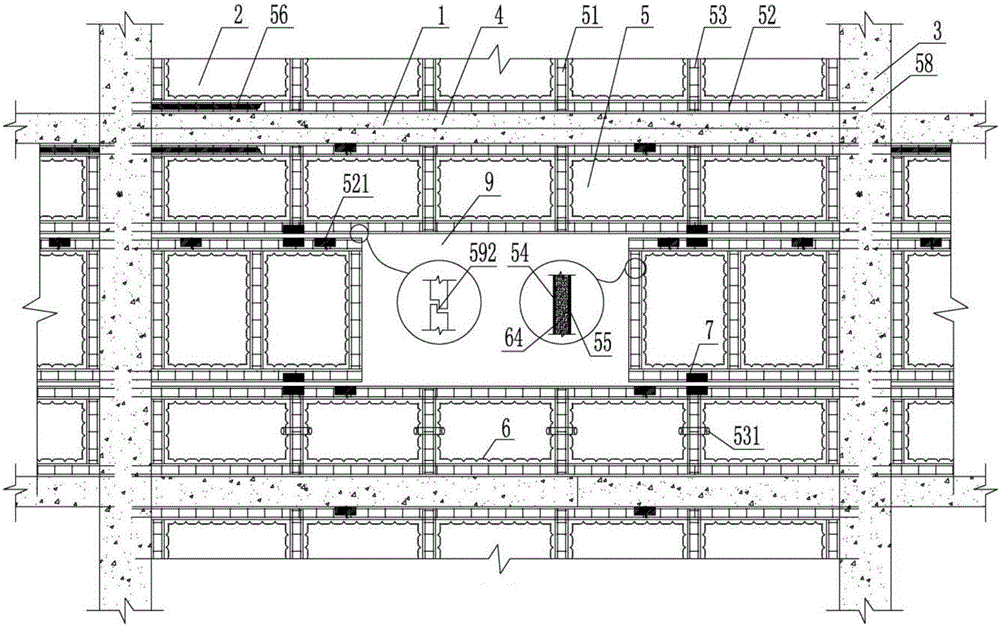

Fabricated stressed island reinforced concrete cavity floor system

InactiveCN106013567ABalance gapReduce resistanceConstruction materialFloorsReinforced concreteOn column

The invention provides a fabricated stressed island reinforced concrete cavity floor system. The fabricated stressed island reinforced concrete cavity floor system comprises a cast-in-situ column, a main beam, prefabricated cavity components for the stressed island reinforced concrete cavity floor system, a cast-in-situ reinforced concrete stressed island and a cast-in-situ reinforced concrete floor system upper flange plate. The cavity components for the stressed island reinforced concrete cavity floor system are prefabricated in a factory firstly; four column grid corners are formed by longitudinal and transverse main beam steel bar cross points on column steel bars, and non-concrete corners of the four cavity components form a cavity floor system stressed island space; and constructional steel bars are laid on the upper surfaces of the main beam steel bars and the upper surfaces of the cavity components for the stressed island reinforced concrete cavity floor system, steel bars are constructed and assembled in the cavity floor system stressed island space formed by the non-concrete corner at the same time, concrete is poured, and vibrating, curing and framework removal are conducted, so that the stressed island reinforced concrete cavity floor system is formed.

Owner:HUNAN BDF ENERGY SAVING TECH +2

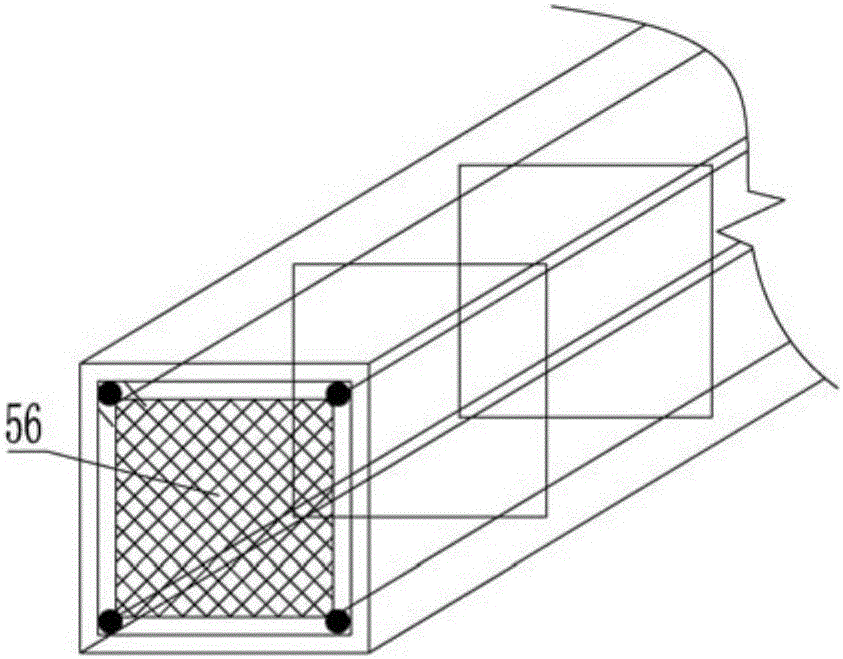

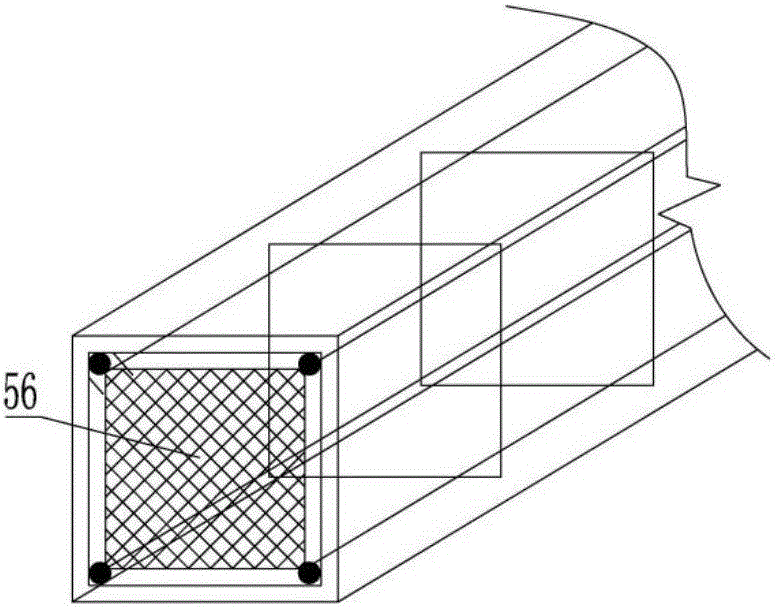

Assembly type wallboard component prefabricated through rib steel mesh plates for engraving

The invention provides an assembly type wallboard component prefabricated through rib steel mesh plates for engraving. The assembly type wallboard component comprises ribs, an inner wallboard, inner wallboard concrete and the rib steel mesh plates for engraving. The ribs include assembly type wallboard component edge ribs and middle density ribs. The inner wallboard and the inner wallboard concrete are internally provided with steel meshes of the rib steel mesh plates for engraving. The rib steel mesh plates for engraving are composed of engraving meshes, engraving end meshes and supporting meshes. The circumference of the rib steel mesh plates for engraving is formed by the engraving meshes, the engraving end meshes support the engraving meshes to form the end cross sections of the rib steel mesh plates for engraving, the supporting meshes control the height of the internal space of the rib steel mesh plates for engraving, the engraving meshes and the engraving end meshes are made of steel mesh bodies, the supporting meshes are reinforcing mesh bodies, N rows of flat marks are arranged on reinforcing bars in the length direction of the reinforcing mesh bodies, and the length of the flat marks is larger than 4 millimeters. The assembly type wallboard component prefabricated through the rib steel mesh plates for engraving belongs to a building assembly type wall. The assembly type wallboard component produced through the procedure is strong in integrity, reasonable in structure, high in quality standard, controllable in working procedure and good in self heat preservation performance.

Owner:HUNAN BDF ENERGY SAVING TECH +2

Wall for prefabricated wallboard component assembling

The invention provides a wall for prefabricated wallboard component assembling. The wall is formed by transporting prefabricated wallboard components produced industrially to a construction site and assembling the wallboard components with in-situ casting columns and beams. The wall is composed of columns, beams, doors or windows, heat insulation materials and the prefabricated wallboard components. The columns and beams are of reinforced concrete structures or formed steel structures. The prefabricated wallboard components include reinforced concrete ribs, an inner wallboard, an outer wallboard and ribbed steel mesh hollow parts. The reinforced concrete ribs include the prefabricated wallboard side ribs and the prefabricated wallboard middle ribs. The inner sides of the inner wallboard and the outer wallboard are provided with the ribbed steel mesh hollow parts. The ribbed steel mesh hollow parts are composed of a hollow net, a hollow end net and a supporting net. The self-insulation material is formed by foaming cement paste poured into the ribbed steel mesh hollow parts. The prefabricated wallboard components are high in integrity, reasonable in structure, high in quality standard, controllable in working procedure and good in self-insulation.

Owner:HUNAN BDF ENERGY SAVING TECH +2

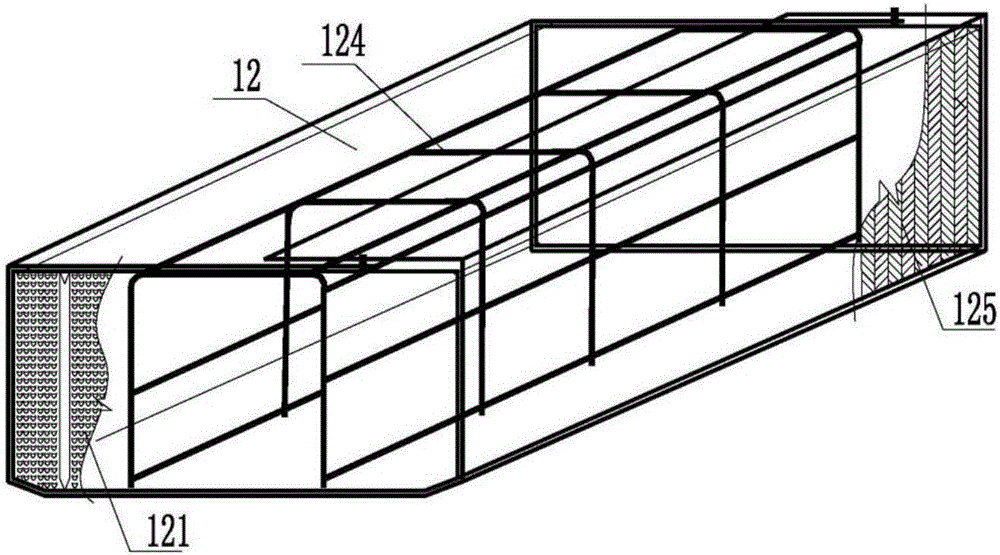

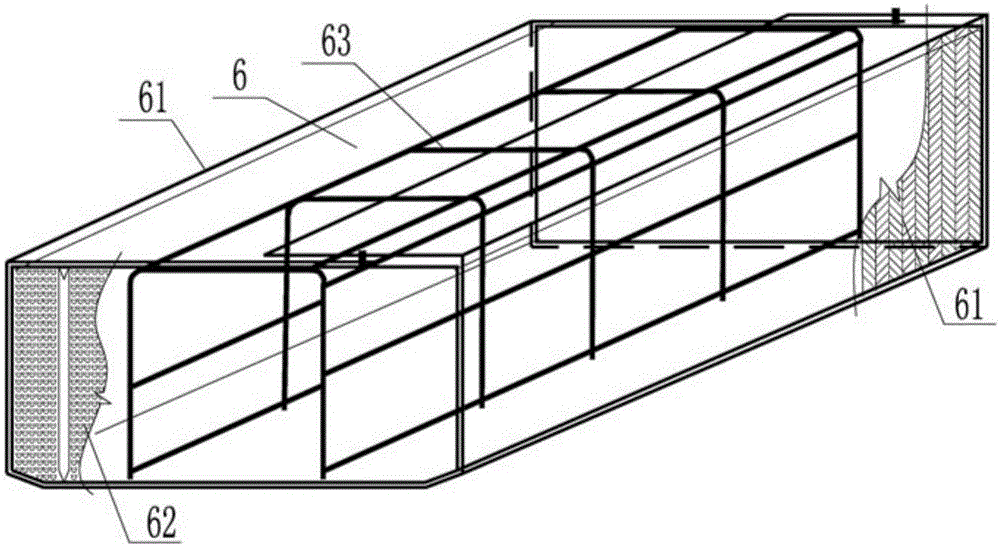

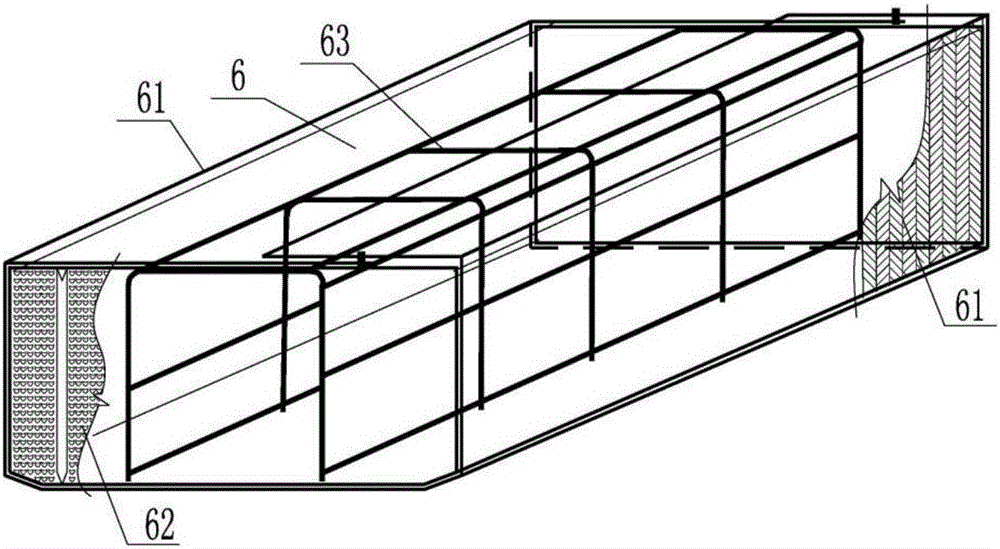

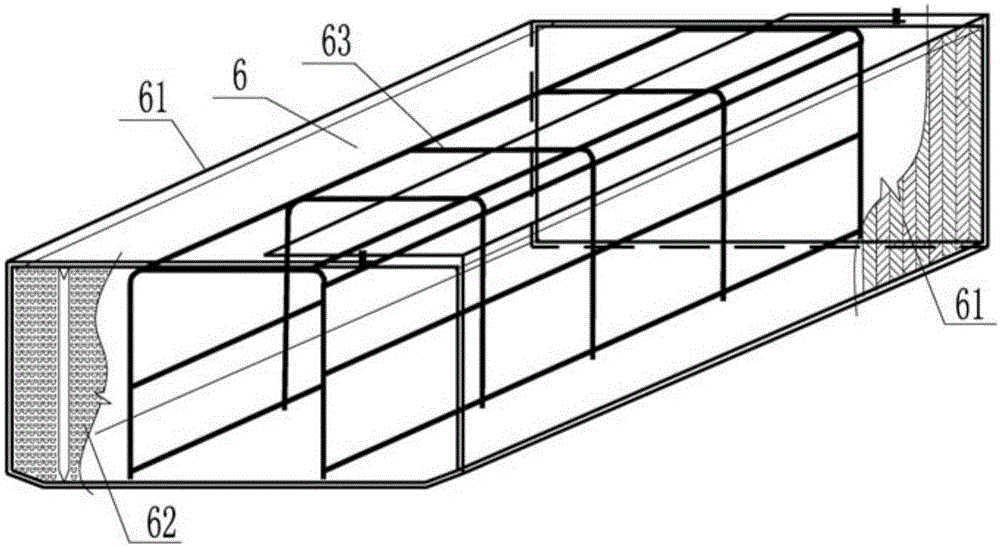

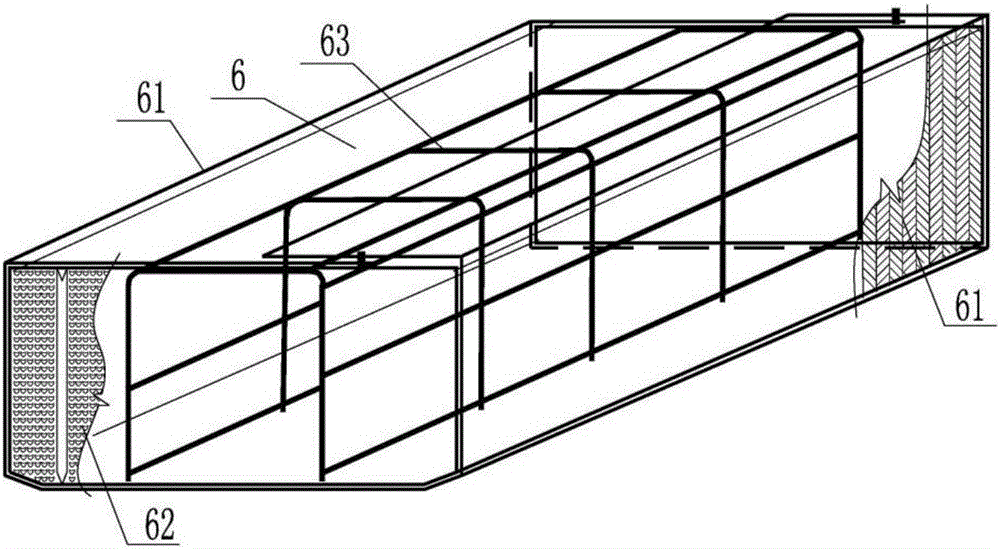

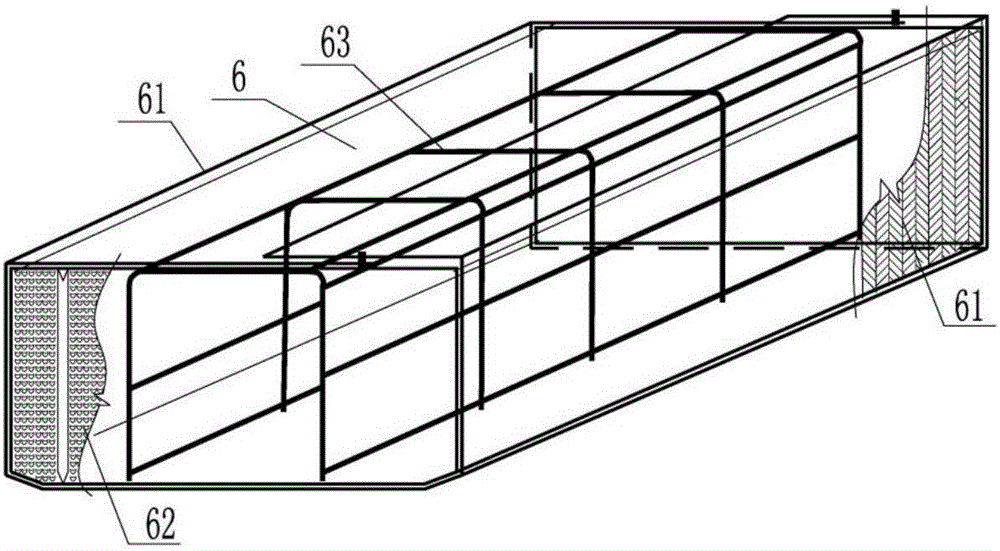

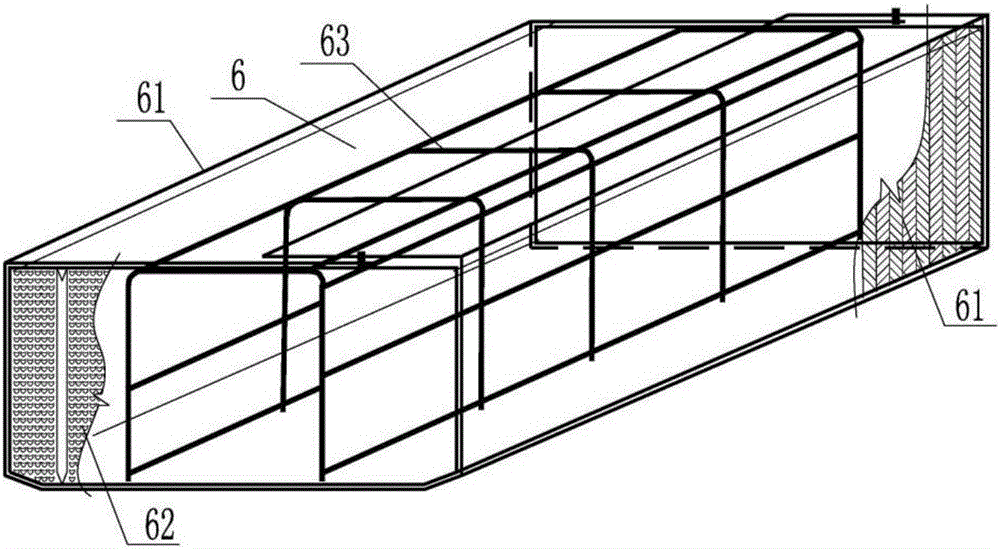

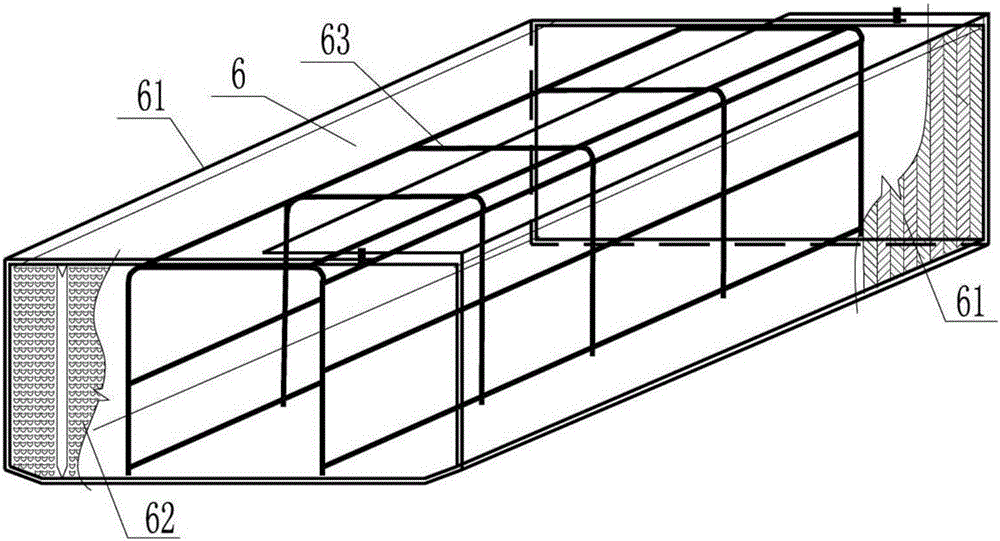

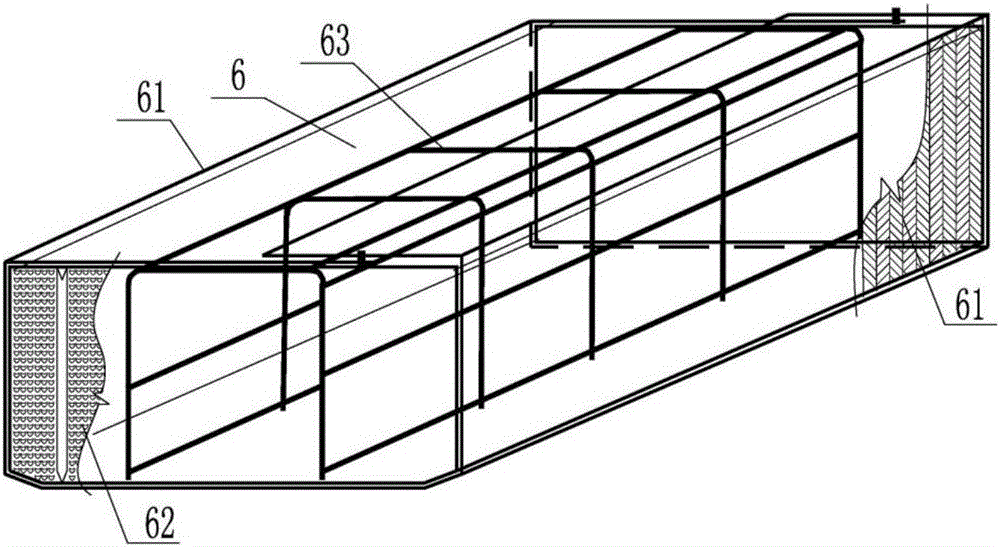

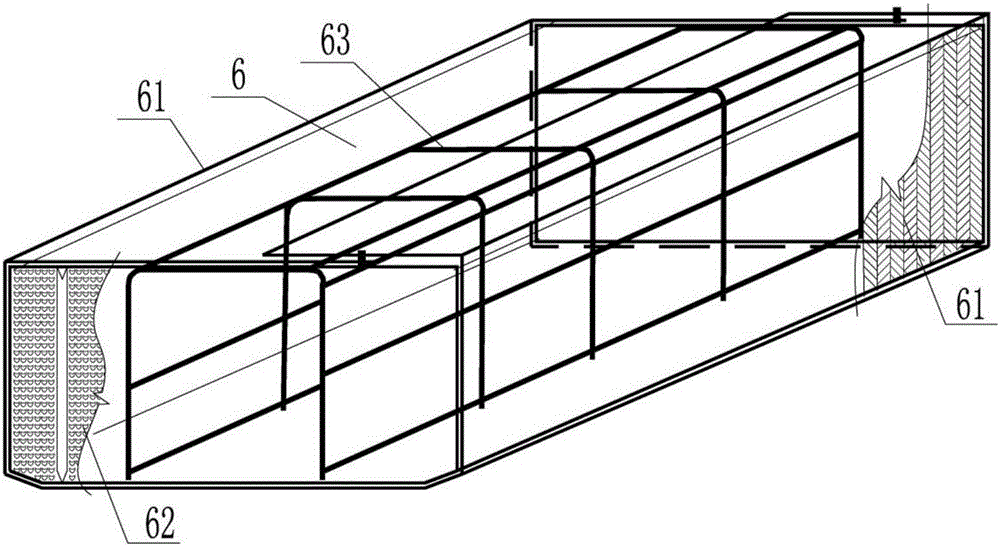

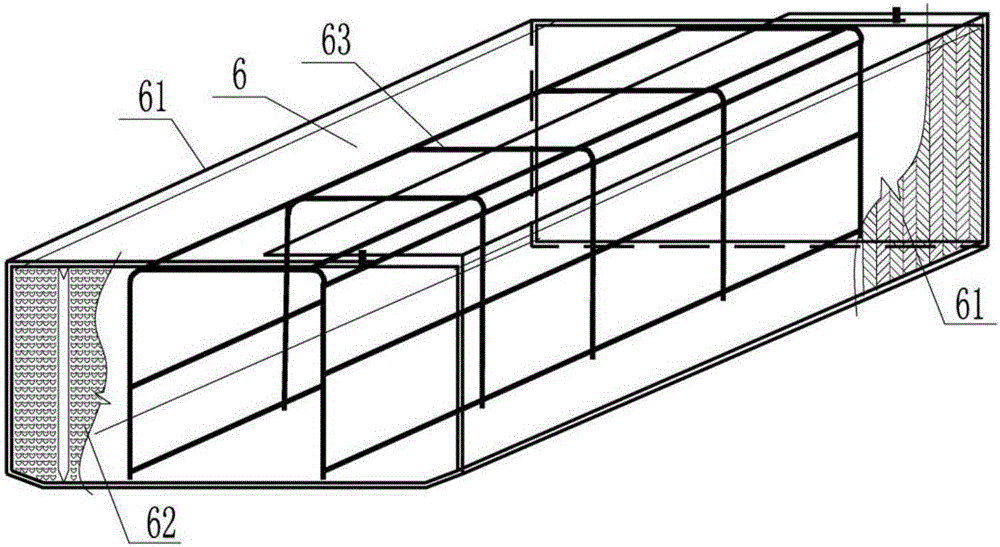

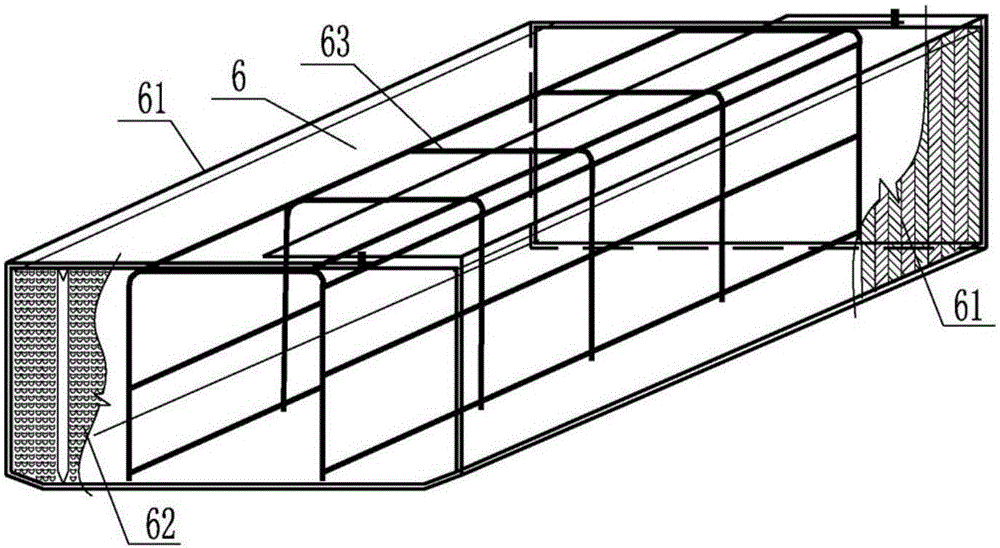

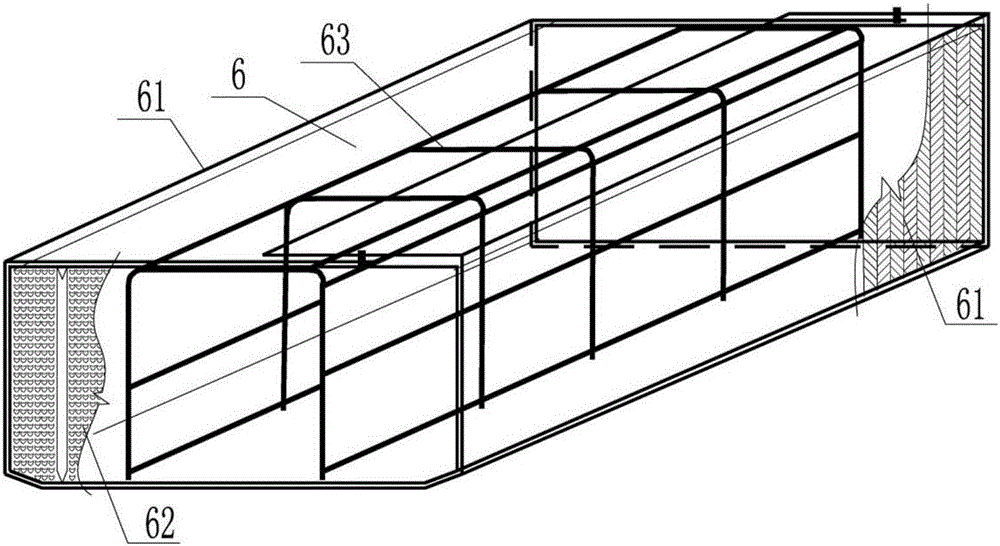

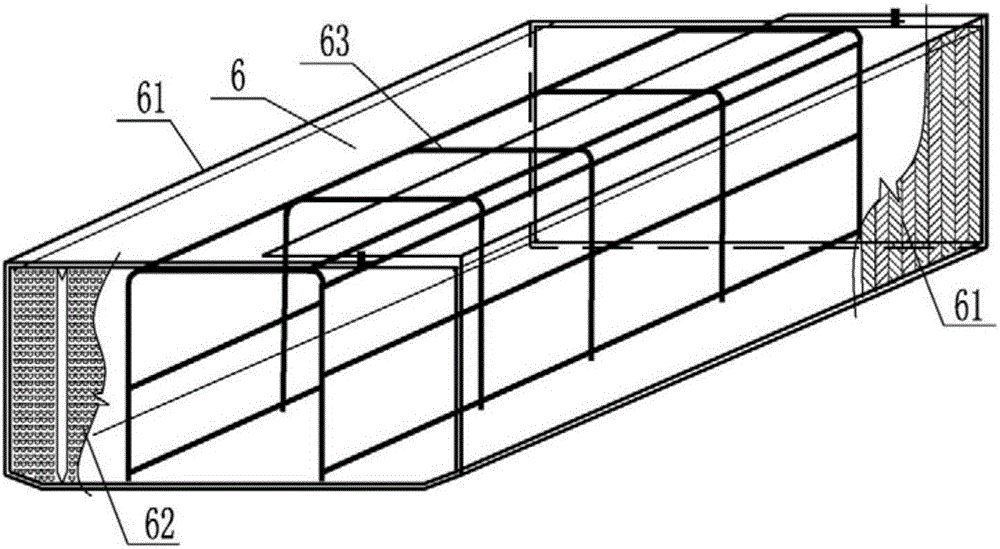

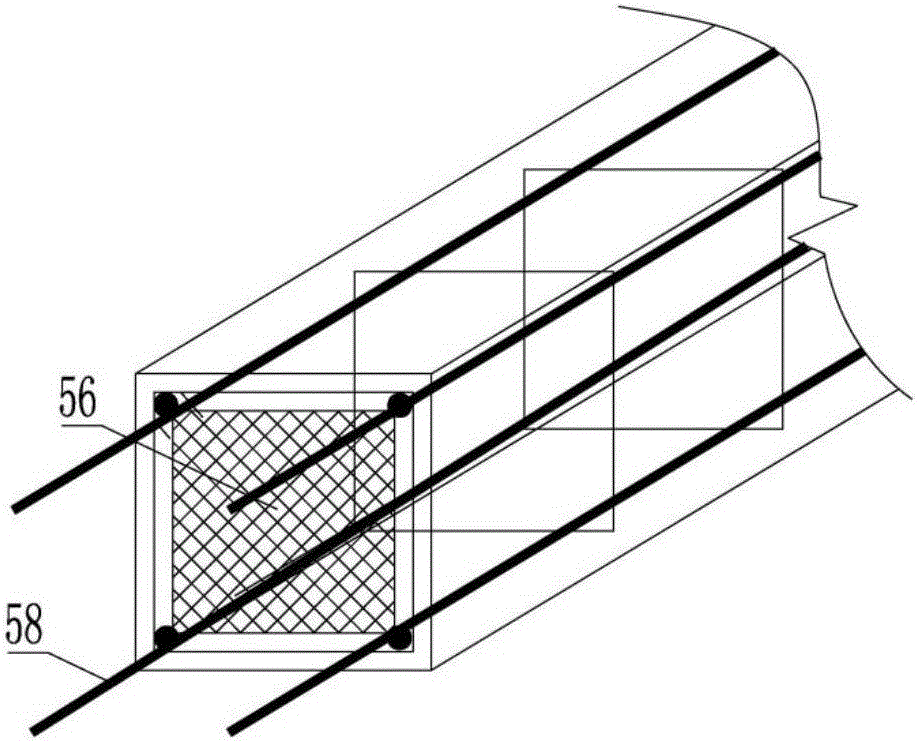

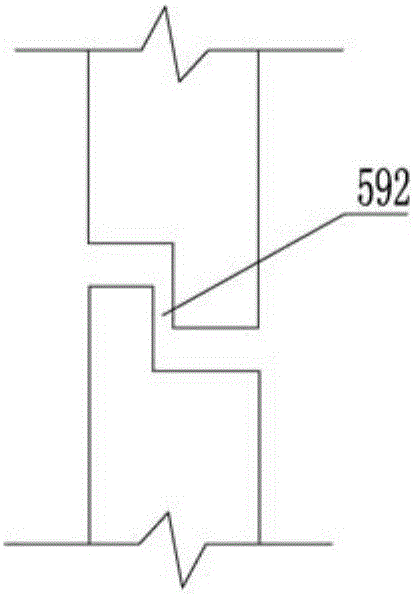

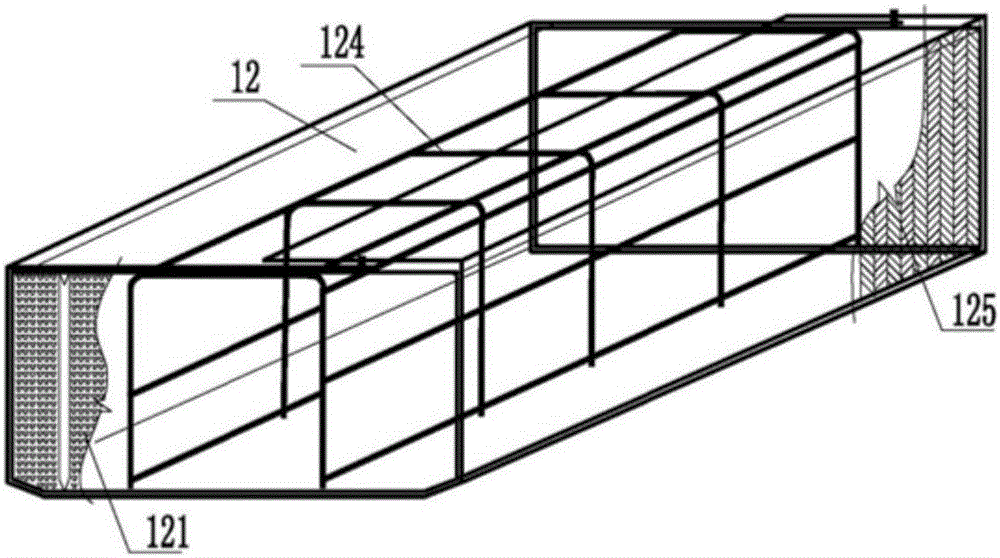

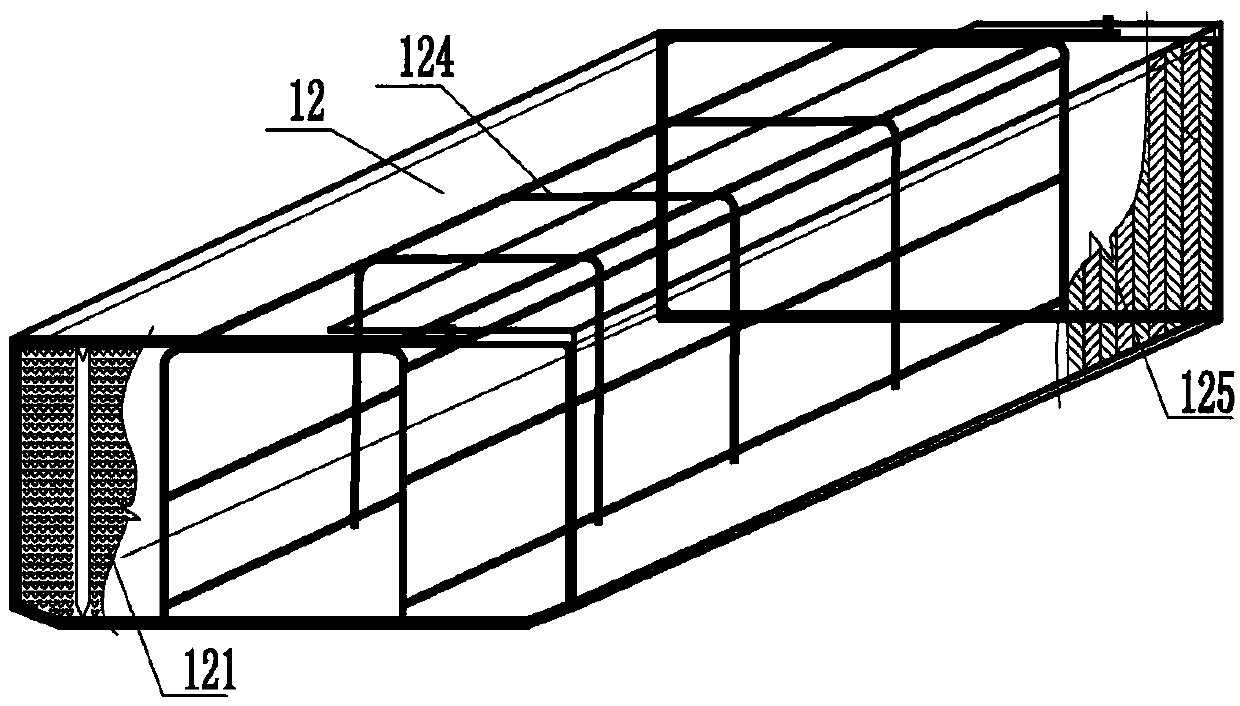

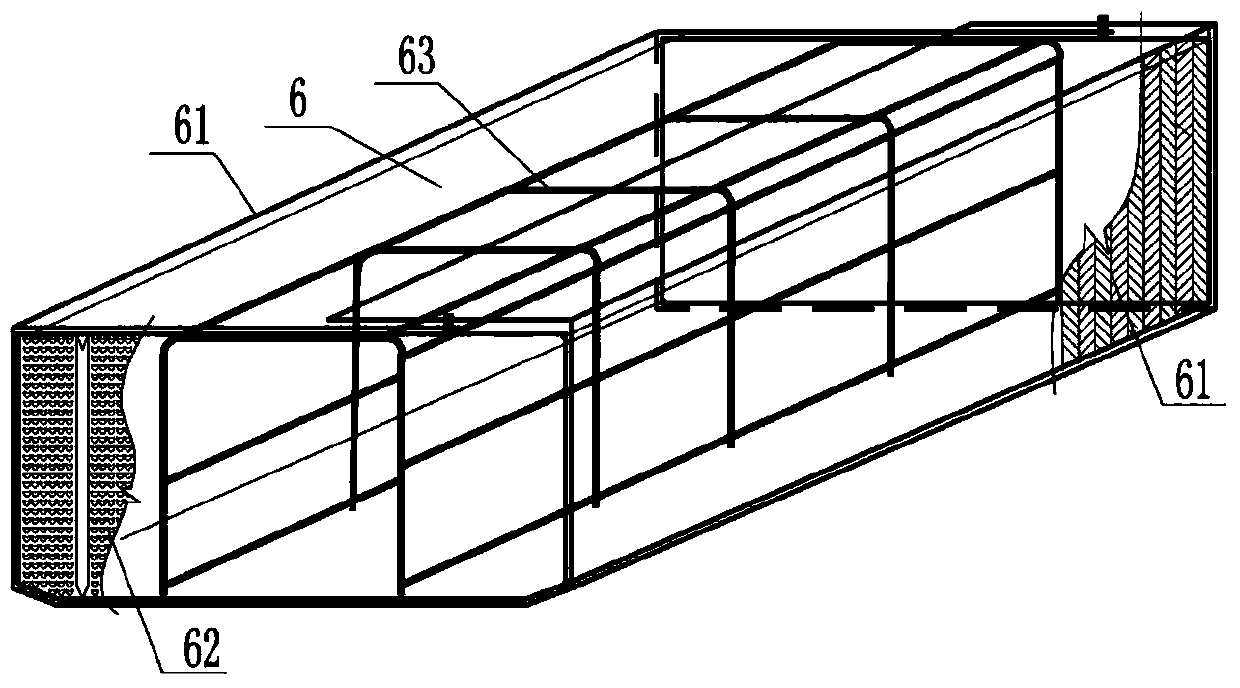

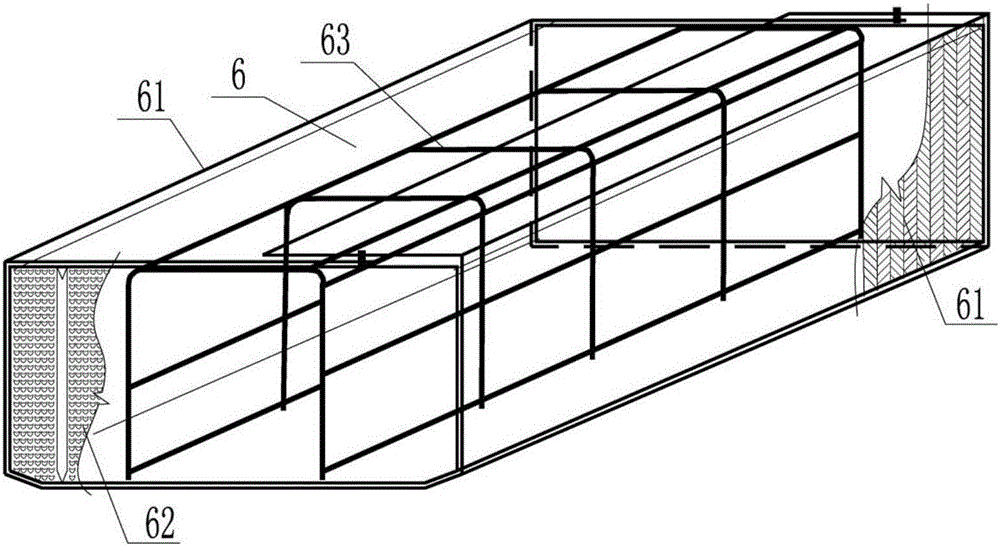

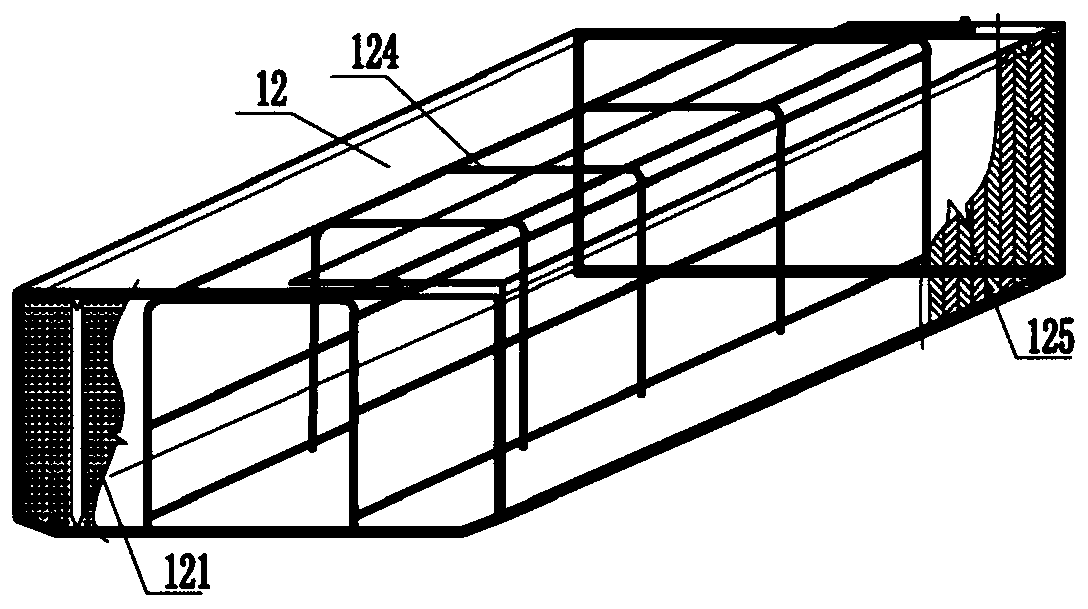

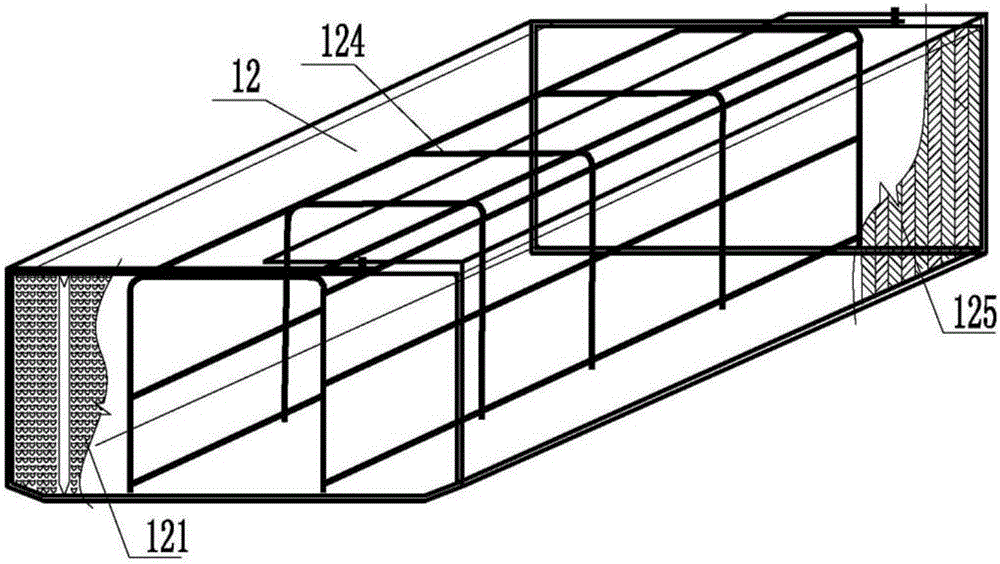

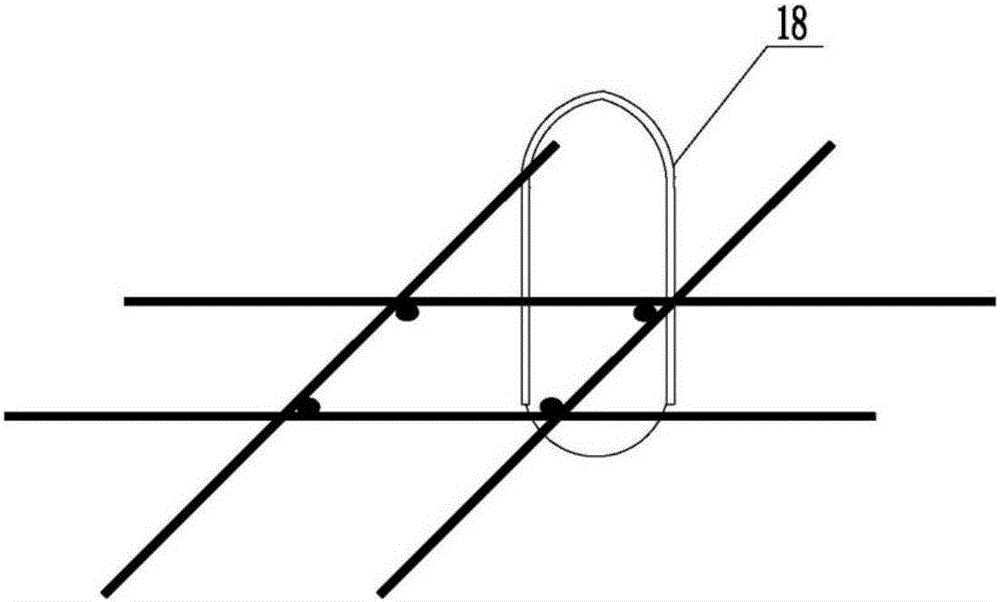

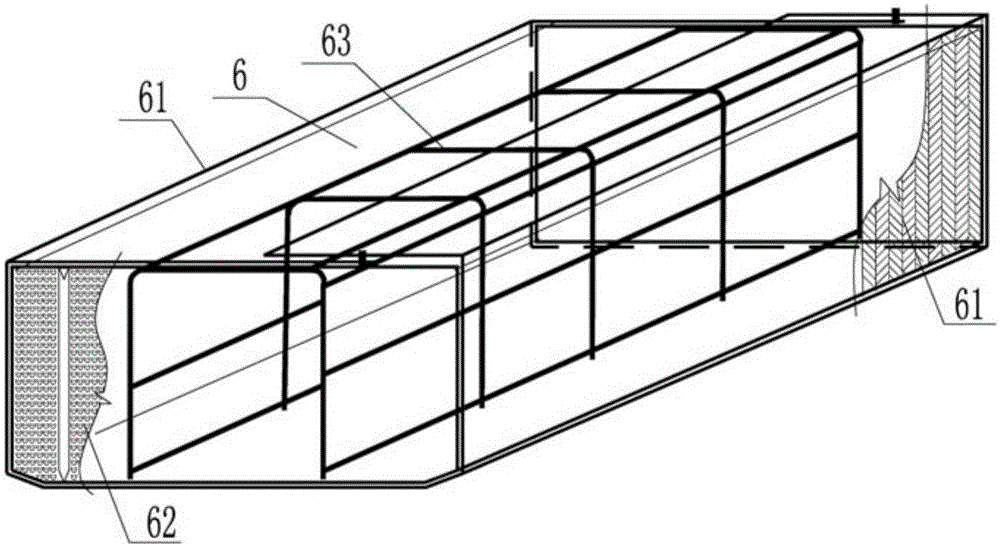

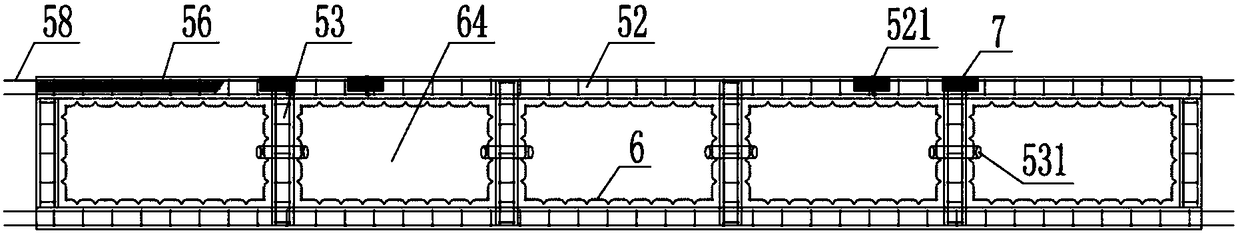

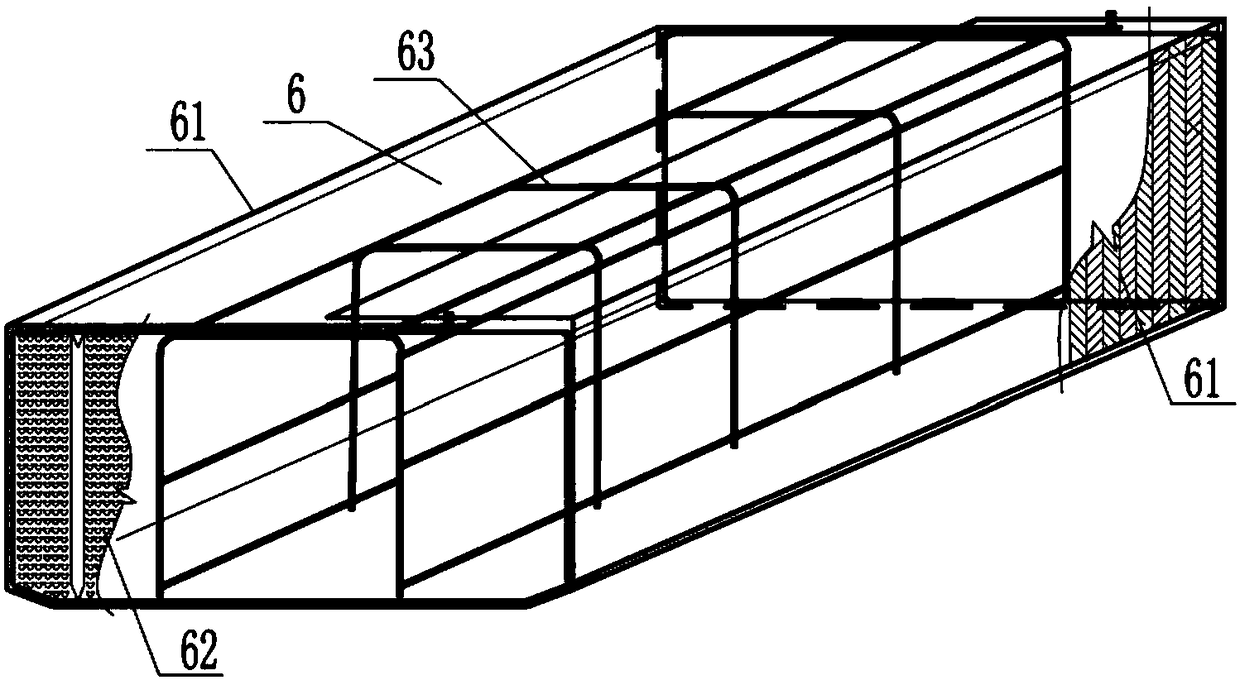

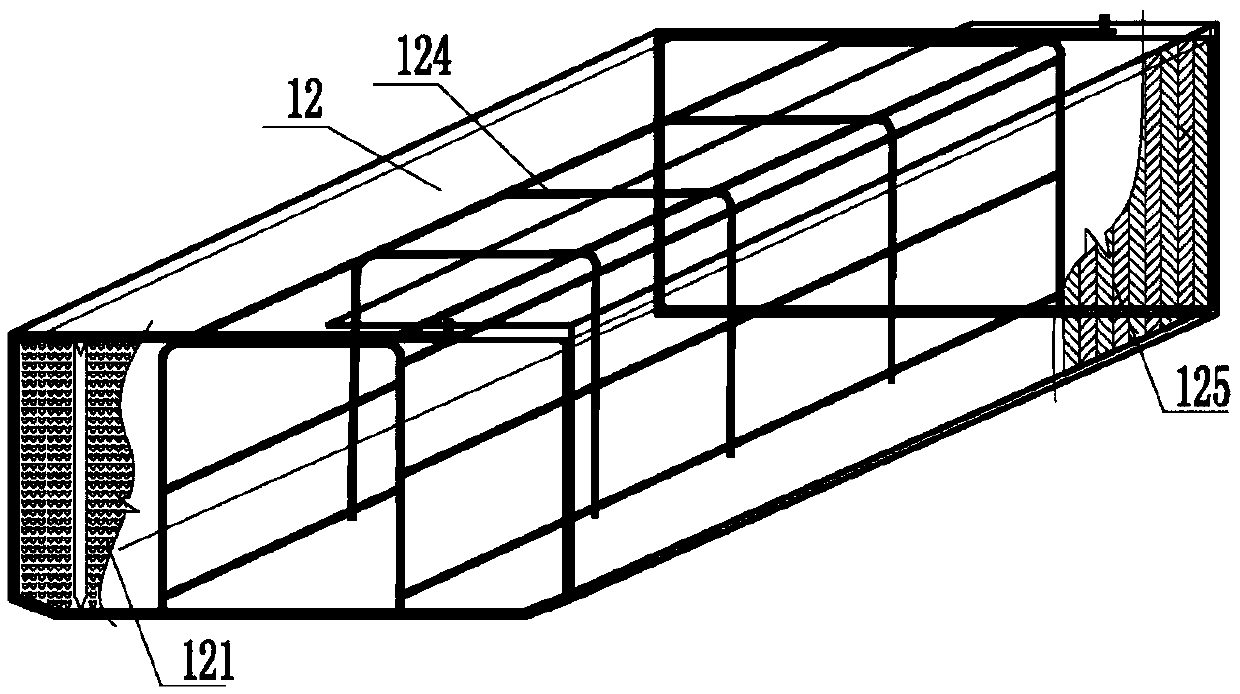

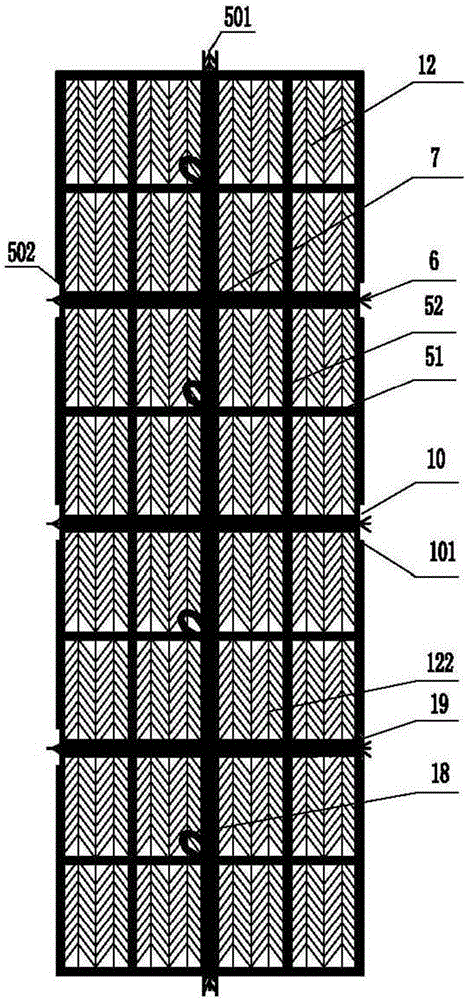

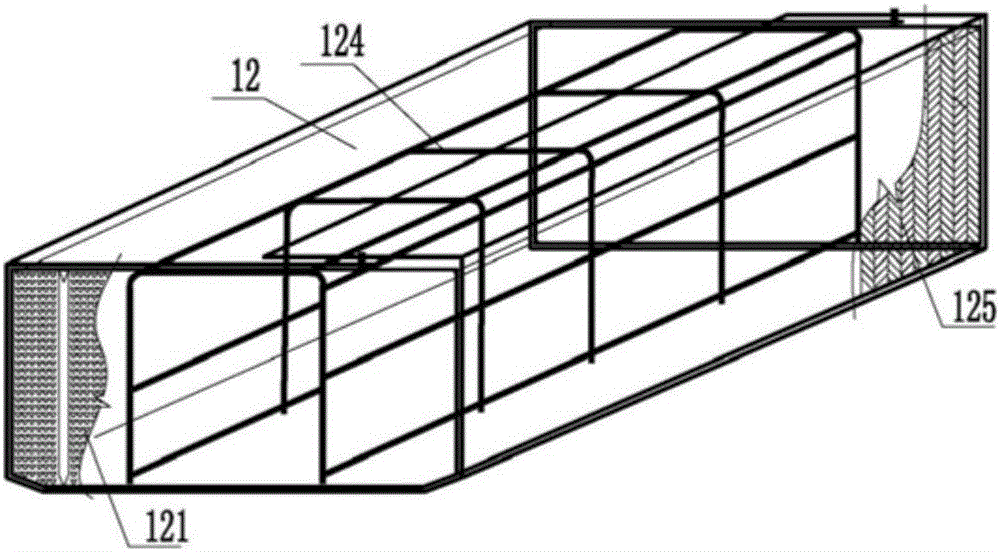

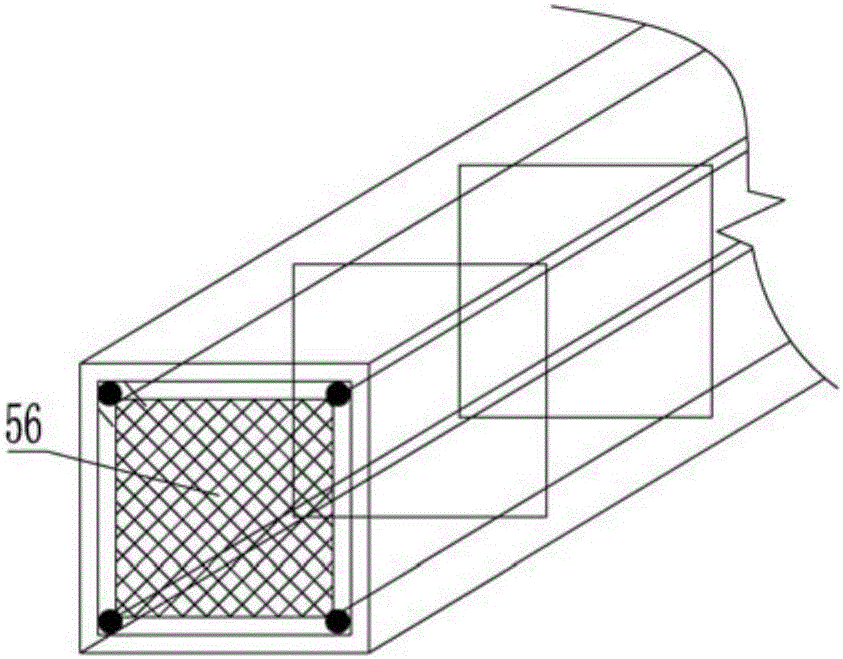

Assembly type prefabricated part for cavity floor system

The invention provides an assembly type prefabricated part for a cavity floor system. The assembly type prefabricated part comprises reinforced concrete ribbed beams, an upper reinforced concrete flange plate, a lower reinforced concrete flange plate and a filling body. The reinforced concrete ribbed beams include at least two longitudinal reinforced concrete ribbed beams and a plurality of transverse reinforced concrete ribbed beams. The two rebar ends of each longitudinal reinforced concrete ribbed beam are exposed. A plurality of U-shaped rebars are arranged on reinforced concrete ribs. The filling body is a polyphenyl block or a plastic cavity or a cement cavity or a plate. The assembly type hollow floor produced through the procedures is strong in integrity, reasonable in structure, high in quality standard and good in self-heat preservation performance and sound insulation performance, and the working procedures are controllable.

Owner:HUNAN BDF ENERGY SAVING TECH +2

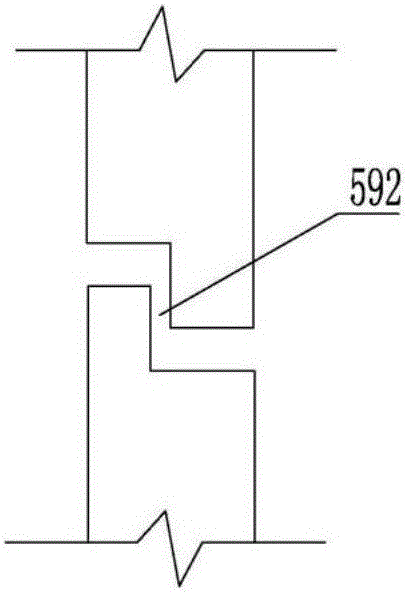

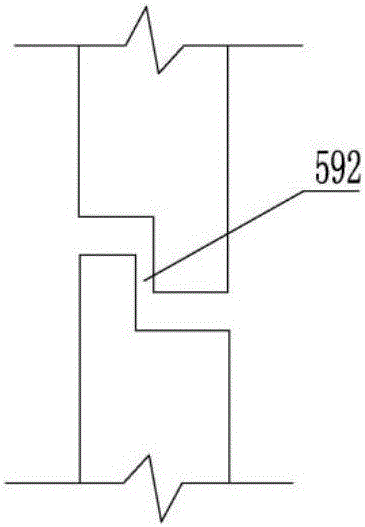

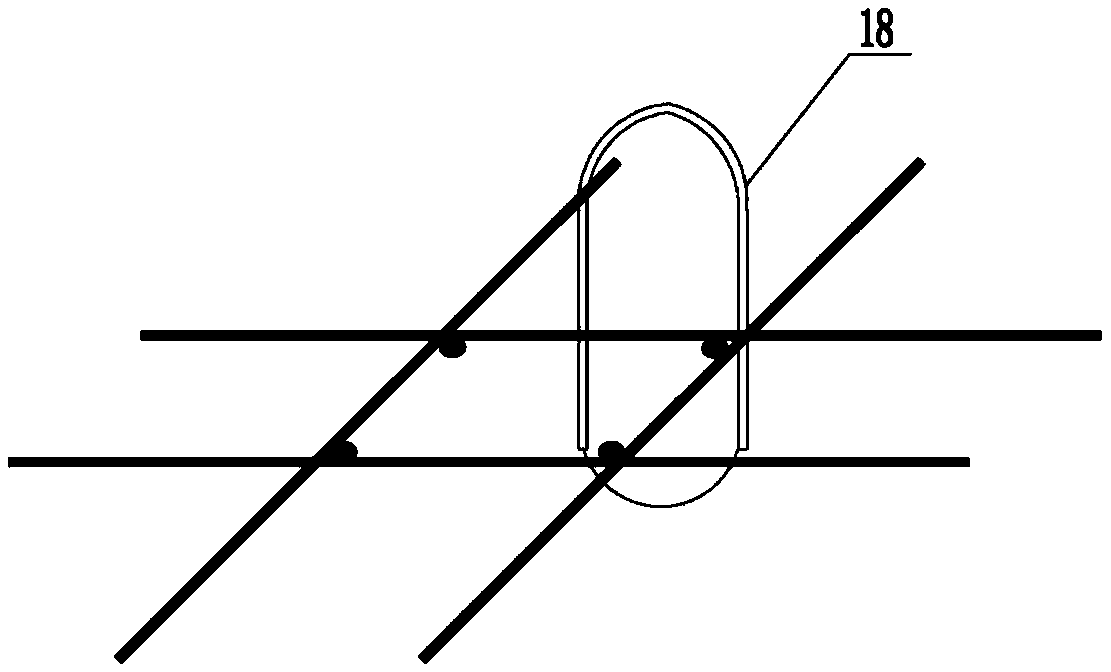

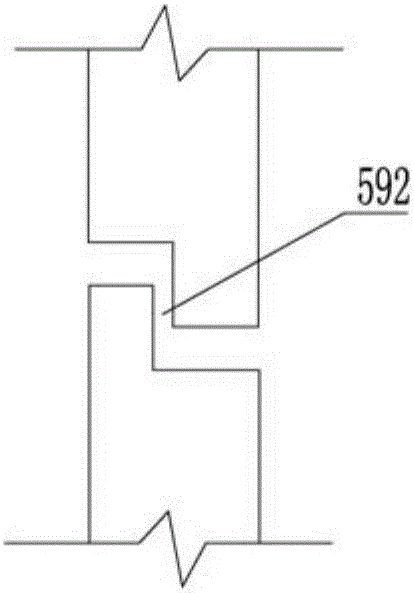

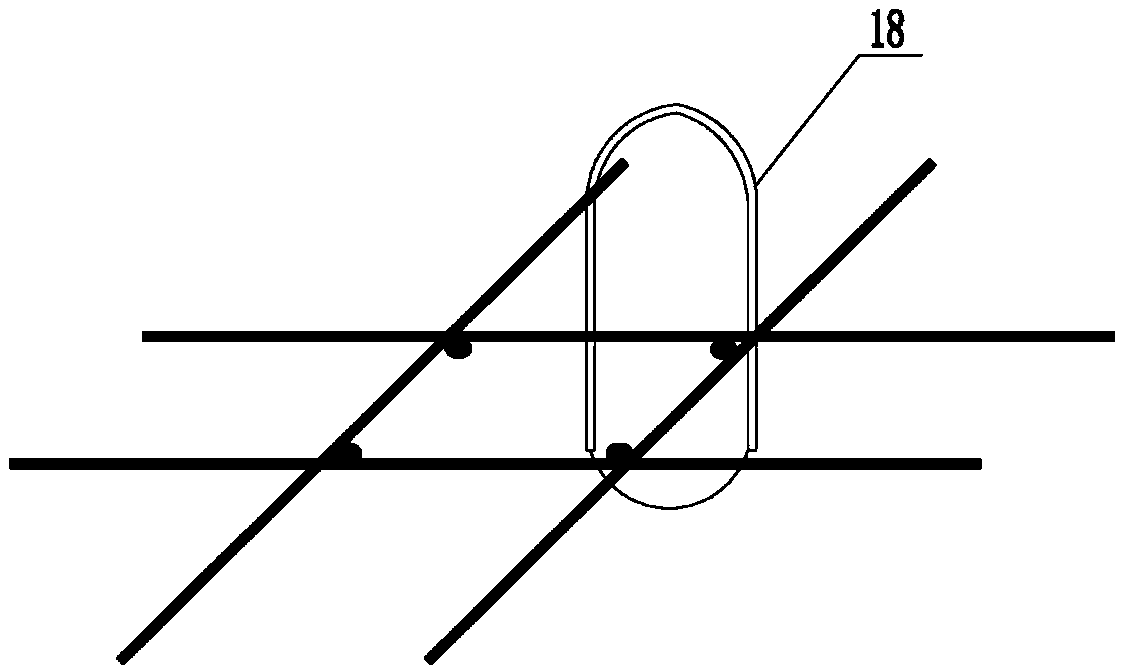

Precast hollow floor's component for stress island based hollow floor system

The invention provides a precast hollow floor's component for a stress island based hollow floor system. The precast hollow floor's component comprises a precast hollow floor's component body consisting of reinforced concrete ribbed beams, steel mesh concrete lower flange slabs and ribbed steel mesh hollows. The precast hollow floor's component body comprises at least two longitudinal reinforced concrete ribbed beams, a plurality of transverse reinforced concrete ribbed beams and two corners not subjected to concrete casting, two ends of the longitudinal reinforced concrete ribbed beams are exposed, a plurality of steel bar rings are arranged on the upper surface of every reinforced concrete ribbed beam, ribbed steel meshes are composited in the steel mesh concrete lower flange slabs, are formed by punching and pressing sheet steel and are made into the ribbed steel mesh hollows consisting of hollowed-out meshes, hollowed-end meshes and supports, and reinforced concrete is cast on the upper surface of the precast hollow floor's component body.

Owner:HUNAN BDF ENERGY SAVING TECH +2

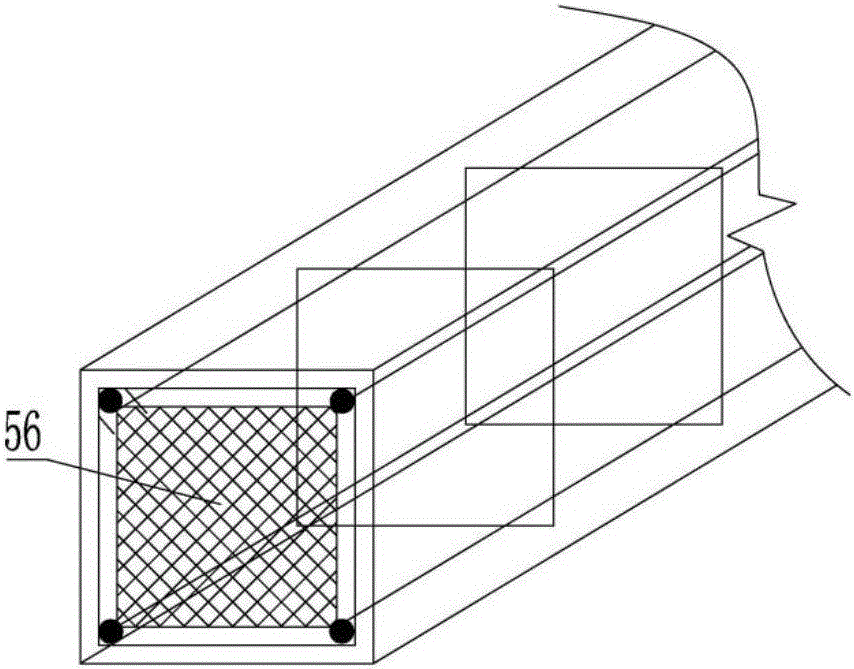

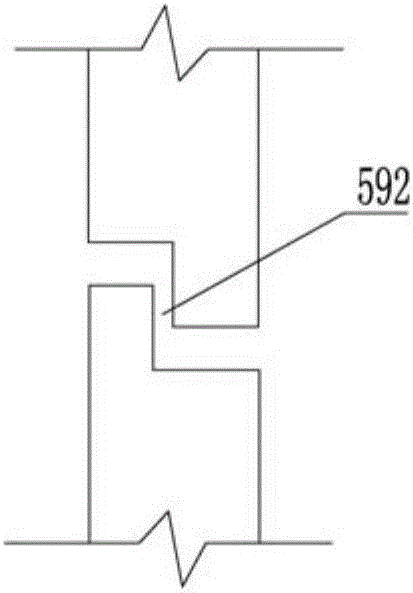

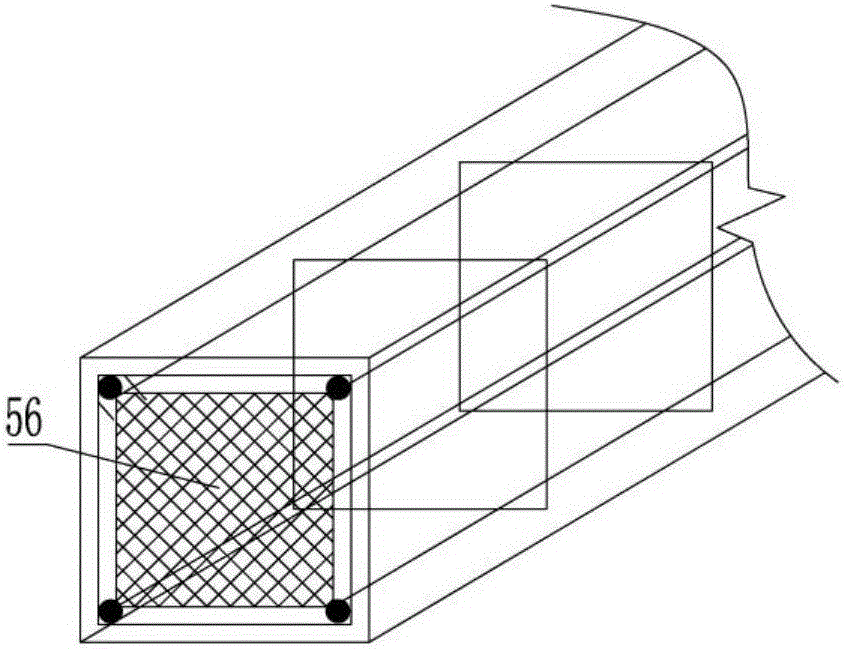

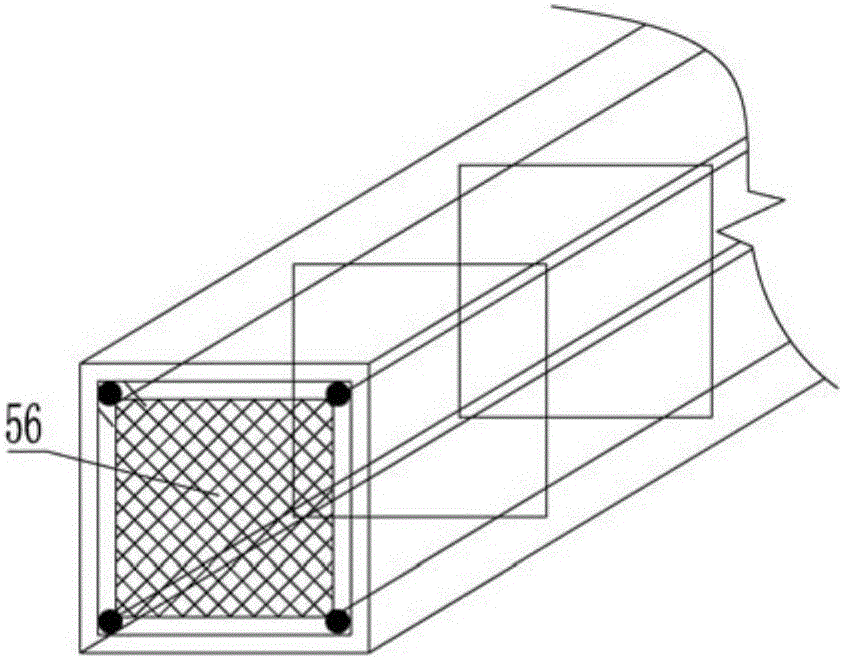

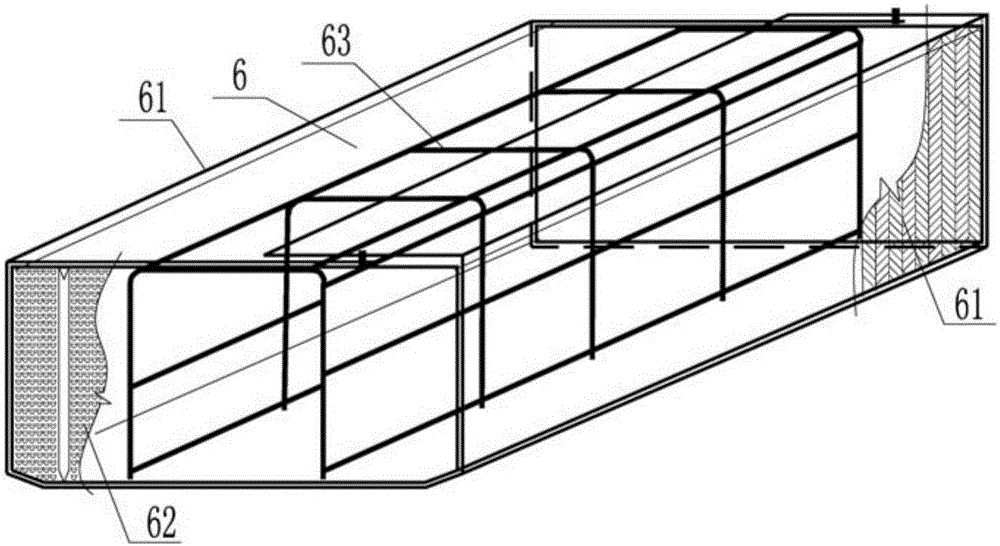

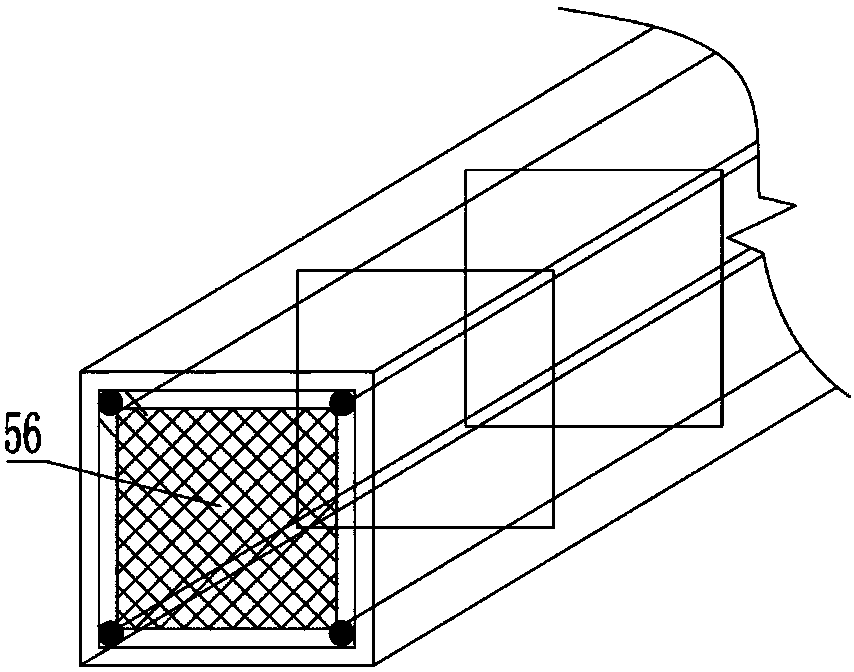

Formwork-free prefabricated assembly type cavity plate

The invention provides a formwork-free prefabricated assembly type cavity plate which comprises reinforced concrete rib beams, a steel mesh concrete bottom flange plate and a prefabricated component made from a ribbed steel mesh carving plate, wherein the reinforced concrete rib beams include at least two reinforced concrete longitudinal rib beams and multiple reinforced concrete transverse rib beams; the two ends of the rebar of the reinforced concrete longitudinal rib beam are exposed; multiple annular rebars are arranged on the upper surface of the reinforced concrete rib beam; a ribbed steel mesh body is compounded in the steel mesh concrete bottom flange plate and produced from sheet steel by die cutting and compression moulding and used for producing the ribbed steel mesh carving plate; the ribbed steel mesh carving plate is composed of a carving mesh, a carving end mesh and a support object; and the ribbed steel mesh carving plate is exposed on the upper surface of the formwork-free prefabricated assembly type cavity plate. The assembly type cavity floor slab produced by the flow has the advantages of high integrity, reasonable structure, high quality standard, controlled processes and good self-insulation and sound insulation performance.

Owner:HUNAN BDF ENERGY SAVING TECH +2

Prefabricated assembly type cavity floor slab for cavity floor system

The invention provides a prefabricated assembly type cavity floor slab for a cavity floor system. The prefabricated assembly type cavity floor slab comprises reinforced concrete rib beams, a reinforced concrete top flange plate, a reinforced concrete bottom flange plate and a filling body, wherein the reinforced concrete rib beams include at least two reinforced concrete longitudinal rib beams and multiple reinforced concrete transverse rib beams; the two ends of the rebar of the reinforced concrete longitudinal rib beam are exposed; multiple annular rebars are arranged on the surface of the reinforced concrete top flange plate; and the length is greater than 5800m, and the thickness is greater than 200mm. The assembly type cavity floor slab produced by the flow has the advantages of high integrity, reasonable structure, high quality standard, controlled processes and good self-insulation and sound insulation performance.

Owner:HUNAN BDF ENERGY SAVING TECH +2

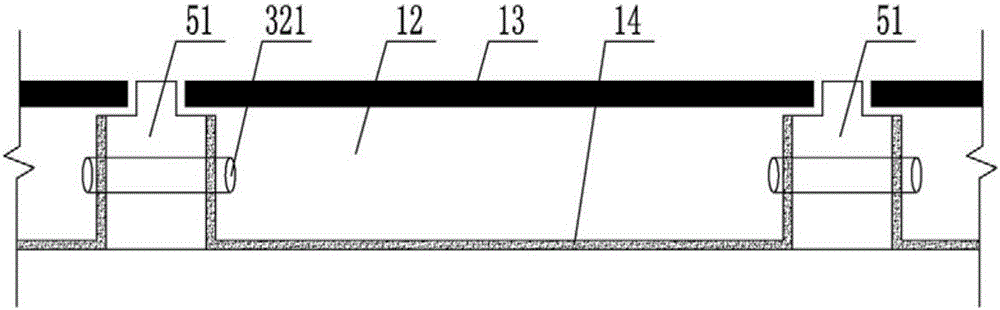

Building method for assembly type cast-in-place cavity building cover

The invention provides a method for assembling a prefabricated cast-in-place cavity cover, the steps of which are as follows: making the prefabricated cavity plate on site, and transporting the prefabricated cavity plate to the construction site; For beam reinforcement, the width of the formwork is 200mm greater than the width of the beam; the lower surface of the formwork is supported vertically by the support rods; The exposed rib beam reinforcement at both ends of the cavity slab extends into the beam reinforcement, and the rib beam reinforcement extending into the beam reinforcement is bound or welded; and then the process of the upper flange plate of the cast-in-place reinforced concrete floor is completed. The structural steel bars are laid on the beam steel bars and the assembled cavity slab, and the concrete is poured to form an assembled cast-in-place cavity floor. The assembled cavity panel produced by the above process has strong integrity, reasonable structure, high quality standard, controlled process, and good self-insulation and sound insulation performance.

Owner:HUNAN BDF ENERGY SAVING TECH +2

Self-thermal insulation wall assembled by prefabricated wallboard components

InactiveCN105839812AImprove flatnessImprove integrityRoof covering using slabs/sheetsConstruction materialReinforced concreteThermal insulation

The invention provides a self-insulating wall composed of prefabricated assembled wall panels, which is composed of columns, beams, doors or windows, thermal insulation materials and prefabricated assembled wall panels; the columns and beams are reinforced concrete structures or Sectional steel structure; prefabricated wall panels include reinforced concrete ribs, interior wall panels, exterior wall panels and ribbed steel mesh; reinforced concrete ribs include side ribs of prefabricated wall panels and middle ribs of prefabricated wall panels; The reinforced concrete rib is a cavity rib, and the cavity rib is formed by a ribbed steel mesh cylinder, and the self-insulation material formed by cement slurry foaming is poured into the ribbed steel mesh cylinder; Steel mesh hollow body; self-insulation material formed by foaming cement slurry is poured in the ribbed steel mesh hollow. Strong integrity, reasonable structure, high quality standard, controlled process, good self-insulation.

Owner:HUNAN BDF ENERGY SAVING TECH +2

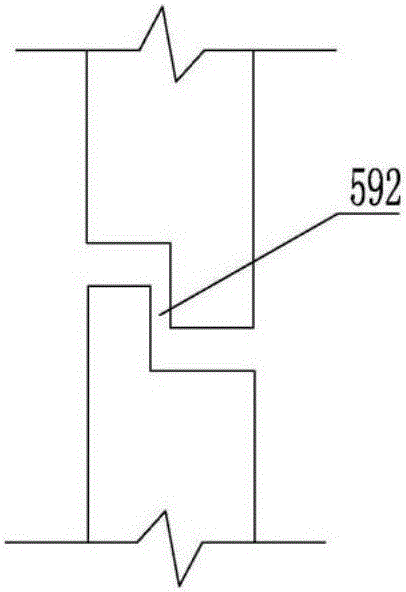

Assembly type cavity prefabricated slab of formwork-erecting-free cast-in-situ cavity floor system

The invention provides an assembly type cavity prefabricated slab of a formwork-erecting-free cast-in-situ cavity floor system. The assembly type cavity prefabricated slab comprises a reinforced concrete ribbed beam, a reinforced concrete upper flange plate, a reinforced concrete lower flange plate and filler. The reinforced concrete ribbed beam internally comprises at least two longitudinal reinforced concrete ribbed beam bodies and multiple transverse reinforced concrete ribbed beam bodies. The two ends of reinforcements of the longitudinal reinforced concrete ribbed beam bodies are exposed out. Multiple annular reinforcements are arranged on the upper surface of the reinforced concrete ribbed beam. The filler is a polyphenyl block or a plastic cavity or a cement cavity or a slab cavity or an empty net cage. The filler of the assembly type cavity prefabricated slab of the formwork-erecting-free cast-in-situ cavity floor system is exposed out of the upper surface. The assembly type cavity floor slab produced through the process is high in integrity, reasonable in structure, high in quality standard, controlled in procedure and good in self-heat-preservation and self-sound-insulation performance.

Owner:HUNAN BDF ENERGY SAVING TECH +2

Self-insulation exterior wall combined by assembled wall panel components

InactiveCN105821988AImprove flatnessImprove integrityRoof covering using slabs/sheetsRoof covering using tiles/slatesRebarQuality standard

The invention provides a self-insulation external wall composed of assembled wall panel components, which is composed of columns, beams and prefabricated assembled wall panel components; the columns and beams are reinforced concrete structures or section steel structures; the assembled The wall panels include reinforced concrete ribs, inner wall panels, outer wall panels and ribbed steel mesh; the reinforced concrete ribs include side ribs and middle ribs of fabricated wall panel components; the reinforced concrete ribs are cavity ribs, and the hollow ribs The cavity rib is formed by a ribbed steel mesh cylinder, and the foamed cement self-insulation material is poured into the ribbed steel mesh cylinder; the inner wall panel and the outer wall panel are made of steel mesh concrete; the inside of the inner wall panel and the outer wall panel The ribbed steel mesh is poured with foamed cement self-insulation material. The prefabricated wall panel components produced by the above process have strong integrity, reasonable structure, high quality standards, controlled process, and good self-insulation. The weight of the insulation wall panel is reduced sharply.

Owner:HUNAN BDF ENERGY SAVING TECH +2

Outer wall for prefabricated wallboard and steel structure assembling

The invention provides an outer wall for prefabricated wallboard and steel structure assembling. The outer wall is composed of section steel columns, section steel beams, door and window openings and prefabricated wallboards. The section steel columns are static concrete type section steel columns. The section steel beams are in an H shape. The prefabricated wallboard comprises reinforced concrete ribs, an inner wallboard or an outer wallboard and ribbed steel mesh hollow parts. The reinforced concrete ribs include the prefabricated wallboard side ribs and the prefabricated wallboard middle ribs. The reinforced concrete ribs are cavity ribs. The cavity ribs are formed by ribbed steel mesh cylinder. Exposed reinforcing bars are arranged on at least one side face in the side ribs of the prefabricated wallboard. The exposed reinforcing bars are connected with the section steel columns. According to the prefabricated wallboard components, the problems that an existing structural system is poor in overall on-site casting controllability and high in implementation technology, environmental pollution is caused by on-site operation, quality is poor, energy-saving and heat insulation functions are lost, and an insulating layer needs to be added are solved.

Owner:HUNAN BDF ENERGY SAVING TECH +2

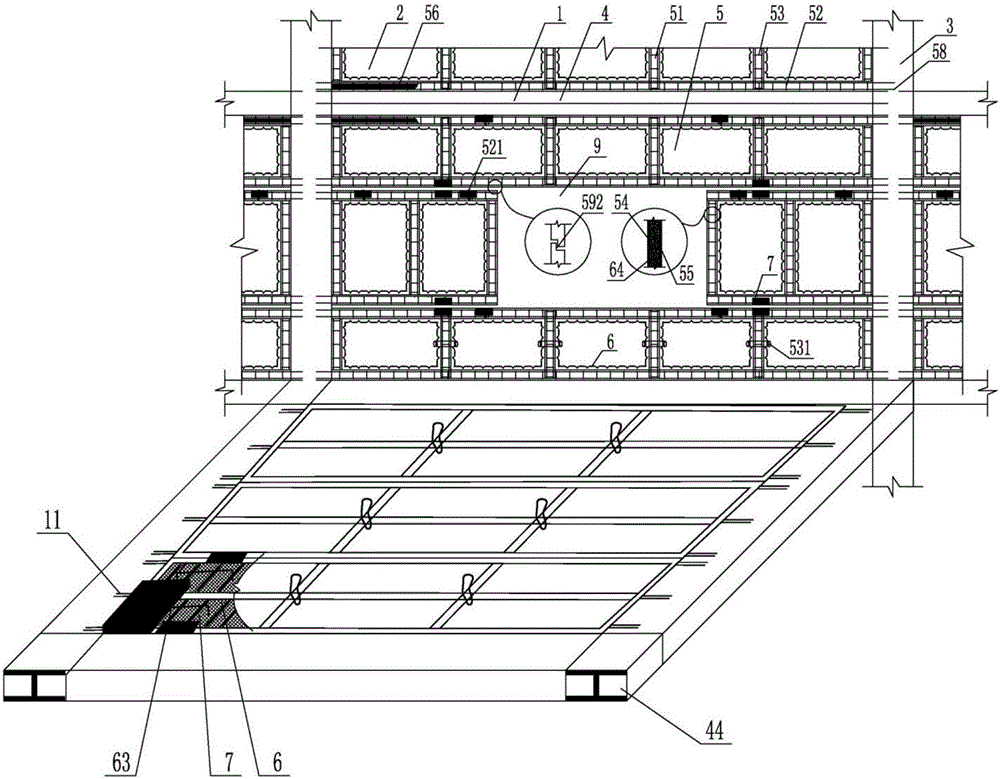

Passive type building energy conservation integration system

InactiveCN106121030ABalance gapReduce resistanceConstruction materialFloorsFloor slabReinforced concrete

The invention provides a passive building energy-saving integrated system, which includes a main body of a building structure, a floor slab in a horizontal direction, a wall panel in a vertical direction, and doors and windows; the main body of the building structure is a reinforced concrete structure or a steel-concrete composite structure; It is a prefabricated cavity floor or a cast-in-place reinforced concrete cavity floor; the prefabricated frame member of the prefabricated cavity floor is manufactured in the factory, and the upper flange plate is poured on site; the wall panels in the vertical direction are made of prefabricated wall panels The components are assembled; the assembled prefabricated wall panel components are produced by the factory according to the geometric dimensions and specifications determined by decomposing the design drawings; the assembled prefabricated wall panel components have self-insulation function; Formed when wall panel members are assembled. The assembled prefabricated wall panel components produced by the above process have strong integrity, reasonable structure, high quality standard, controlled process, and good self-insulation and sound insulation performance.

Owner:HUNAN BDF ENERGY SAVING TECH +2

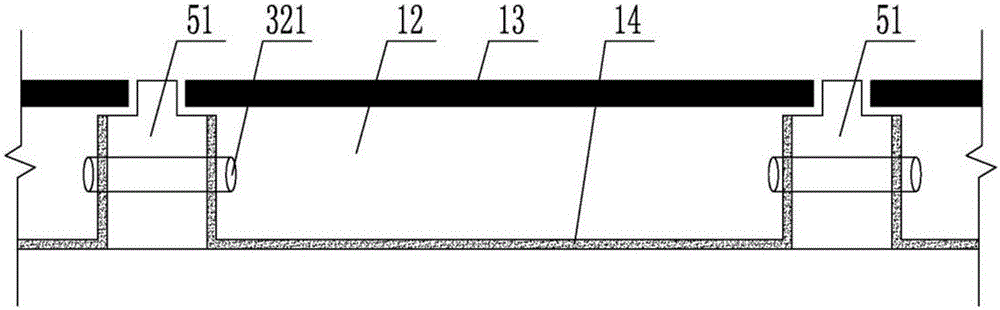

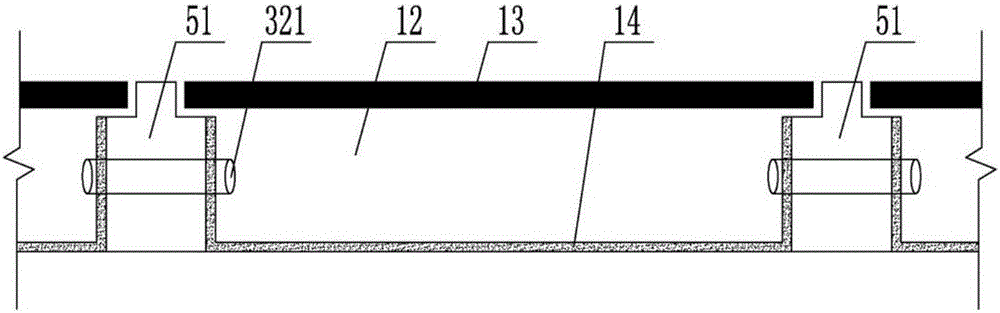

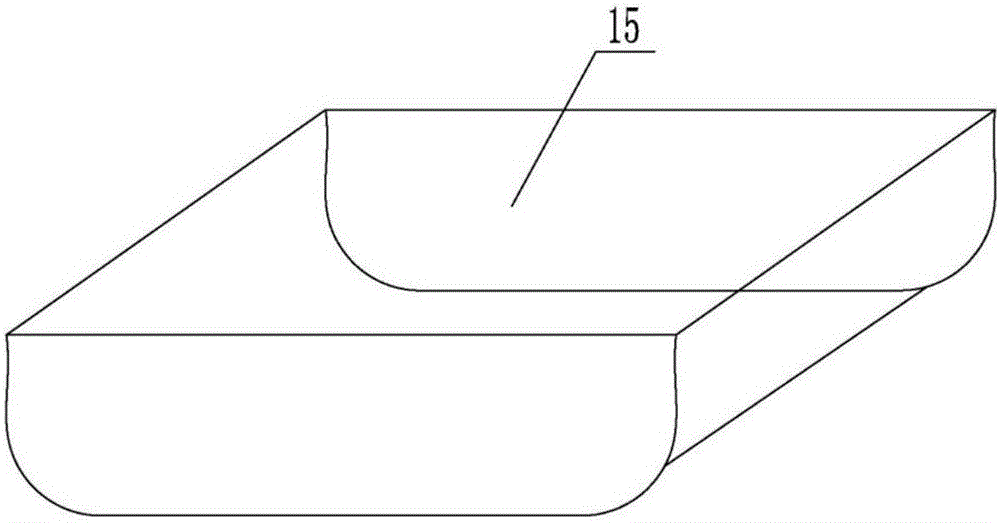

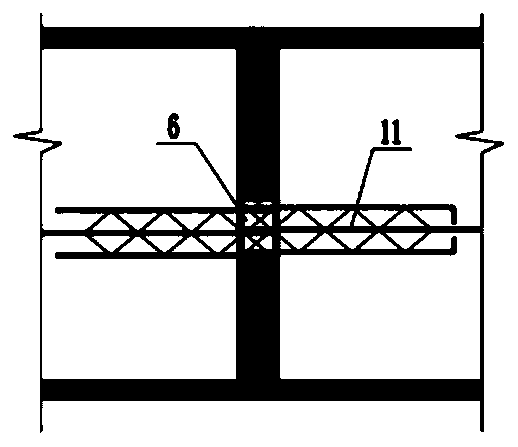

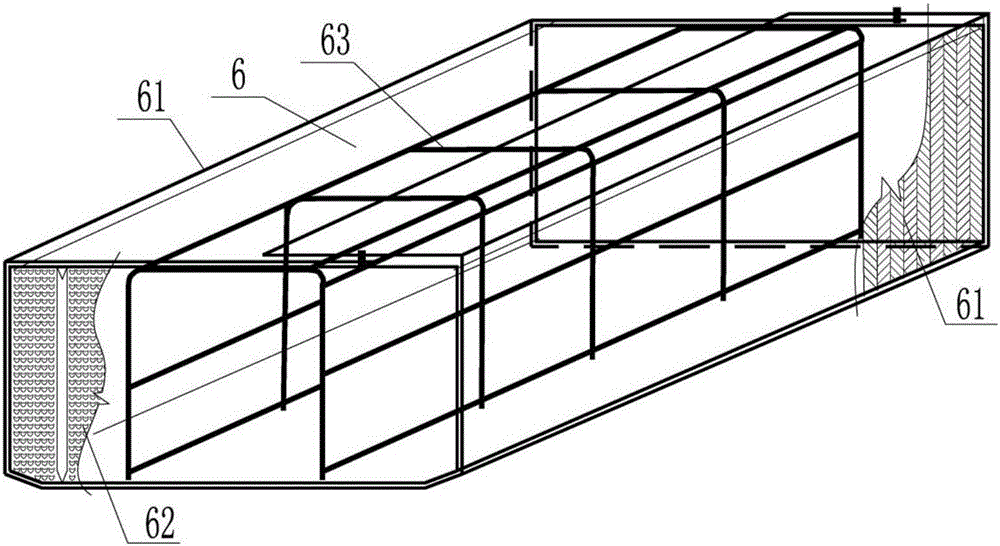

Open-type cavity prefabricated slab for cast-in-place cavity floor cover

InactiveCN105804301AImprove efficiencyReduce resistanceConstruction materialFloorsRebarQuality standard

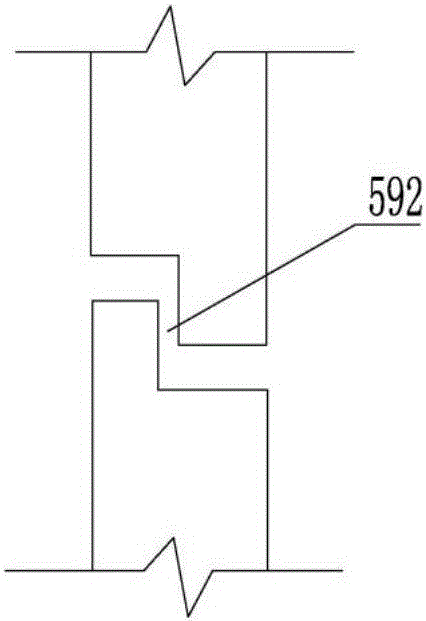

The invention provides an open-type cavity prefabricated slab for a cast-in-place cavity floor cover. The open-type cavity prefabricated slab comprises a reinforced concrete ribbed beam, an opening mold, a permanent thin cover plate and a reinforced concrete bottom flange plate. At least two reinforced concrete longitudinal ribbed beams and a plurality of reinforced concrete transverse ribbed beams are arranged in the reinforced concrete ribbed beam. The two ends of reinforced bars of the reinforced concrete longitudinal ribbed beams are exposed out. A plurality of reinforced rings are arranged on the upper surface of the reinforced concrete ribbed beam. The upper corner of the reinforced concrete ribbed beam inside the prefabricated slab is a willow angle. The opening mold is a steel mold or a bamboo wood mold or a plastic mold. The geometric dimension of the permanent thin cover plate is larger than that of the caliber of the opening mold. The cross section of a reinforced concrete bottom flange is in an H shape or a T shape. The T-shaped cross section is of a steel mesh concrete structure. The open-type cavity prefabricated slab produced in the process is high in integrity, reasonable in structure, high in quality standard, controllable in working procedure and good in self-insulation and sound-insulation performance.

Owner:HUNAN BDF ENERGY SAVING TECH +2

Self-heat-insulation wall body system of prefabricated assembling type wallboard component

InactiveCN105804238AImprove flatnessImprove integrityWallsHeat proofingReinforced concreteEngineering

The invention provides a self-heat-insulation wall body system of a prefabricated assembling type wallboard component. The self-heat-insulation wall body system is composed of a column, a beam, a door or window, a heat-insulation material and the prefabricated assembling type wallboard component, wherein the column and the beam are of a reinforced concrete structure or a profile steel structure; a reinforced concrete rib comprises a prefabricated assembling type wallboard component edge rib and a middle rib; the reinforced concrete rib is a hollow cavity rib; the hollow cavity rib is formed by a ribbed steel net barrel; a foaming cement self-heat-insulation material is poured into the ribbed steel net barrel; an inner wallboard and an outer wallboard are formed through pouring steel net concrete; the foaming cement self-heat-insulation material is poured into ribbed steel net hollow parts at the inner sides of the inner wallboard and the outer wallboard; the prefabricated assembling type wallboard component is realized through a bottom die system with a surrounding track. The assembling type wallboard component is strong in integrity, reasonable in structure, high in quality standard and good in self-heat-insulation property, and has controllable procedure; after the reinforced concrete rib is changed into the hollow cavity rib and the reinforced concrete wallboard is changed into the steel net concrete self-heat-insulation wallboard, the weight is greatly reduced.

Owner:HUNAN BDF ENERGY SAVING TECH +2

Manufacturing method for wallboard of steel-concrete combination structure

InactiveCN106436968ABalance gapLower runWallsBuilding material handlingReinforced concreteSteel columns

The invention provides a manufacturing method for a wallboard of a steel-concrete combination structure. The manufacturing method comprises the following steps that the geometric dimension and the specification of a wallboard component of each main body frame are decomposed; an assembly type prefabricated wallboard component extends into the inner edge of a section steel column, ribbed beam rebars exposed out of the two ends of the assembly type prefabricated wallboard component are welded to a steel body at the inner edge of the section steel column, or the assembly type prefabricated wallboard component is hung in preserved openings formed in the two sides of a project mold of tied column rebars, the ribbed beam rebars exposed out of the two ends of the assembly type prefabricated wallboard component extend into the inner edge of the section steel column, then concrete is casted in place, and section steel column static concrete is formed; and after the horizontal side surface of the assembly type prefabricated wallboard component is combined with a section steel beam again, or cast-in-place reinforced concrete beams and slabs are completed, the steps are repeated, and the wallboard of the steel-concrete combination structure is formed. The assembly type prefabricated wallboard component produced in the process is high in integrity, reasonable in structure, high in quality standard, controllable in procedure and good in self heat preservation and sound insulation performance.

Owner:HUNAN BDF ENERGY SAVING TECH +2

Prefabricated assembly type self-insulation wallboard component

InactiveCN105888127AImprove flatnessImprove convenienceBuilding componentsInsulation layerReinforced concrete

The invention provides a prefabricated assembly type self-insulation wallboard component. The prefabricated assembly type self-insulation wallboard component comprises ribs, a structure layer board, an insulation layer board, an insulation filler and a bottom die system with a ring-shaped track, wherein the ribs comprise assembly type self-insulation wallboard side ribs and assembly type self-insulation wallboard middle ribs; the structure layer board is built by reinforced concrete; the insulation layer board is compounded by steel mesh sheets; the insulation filler is built by polyphenyl blocks; the prefabricated assembly type self-insulation wallboard component adopts the bottom die system with the ring-shaped track; the ring-shaped track maintains a balanced fall head. The assembly type wallboard component produced by the process is high in integrality, reasonable in structure, high in quality standard, controllable in process and high in self-insulation performance.

Owner:HUNAN BDF ENERGY SAVING TECH +2

Stress island steel structure assembly type cavity floor

The invention provides a stress island steel structure assembly type cavity floor. The stress island steel structure assembly type cavity floor comprises steel columns, an I-shaped steel beam, prefabricated cavity floor components with reserved corners, a cast-in-situ reinforced concrete stress island and a cast-in-situ reinforced concrete floor upper flange plate; the steel columns or static concrete steel columns are assembled in site; the prefabricated cavity floor components with the reserved corners are lifted and installed on the inner side of a flange plate of the I-shaped steel beam; and exposed rib beam reinforcing steel bars at the two ends of the prefabricated cavity floor components with the reserved corners stretch into web reserved holes or the inner side of the flange plate of the I-shaped steel beam and are welded or tied. During manufacturing of the prefabricated cavity floor components with the reserved corners, in the rib beam reinforcing steel bars, concrete is not poured when a corner is reserved and prefabricated; when the corner is assembled in site, a stress island cavity is formed between column-beam combination areas, and the concrete is poured in a main beam steel band, an upper flange plate rib and the stress island cavity; and the required stress island steel structure assembly type cavity floor is obtained.

Owner:HUNAN BDF ENERGY SAVING TECH +2

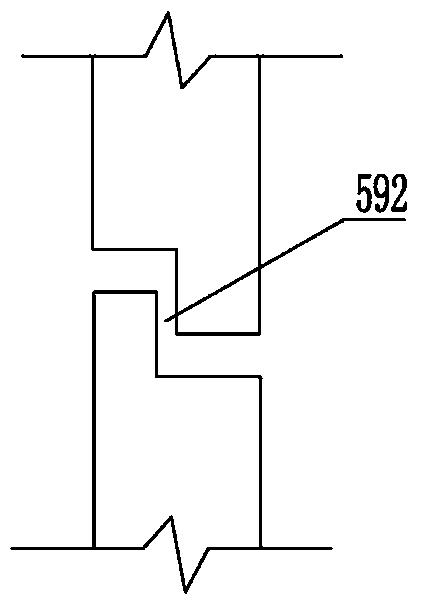

Fabricated type cavity board for stress island cavity floor system

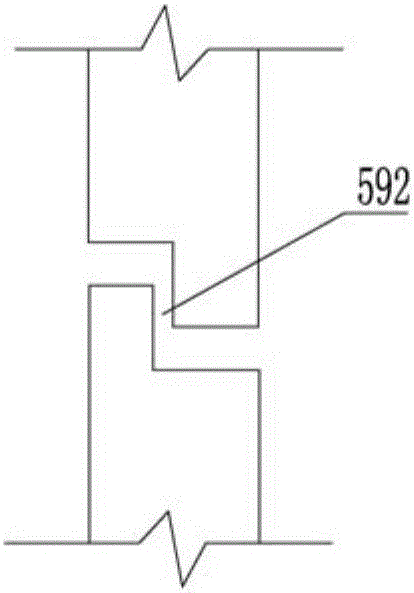

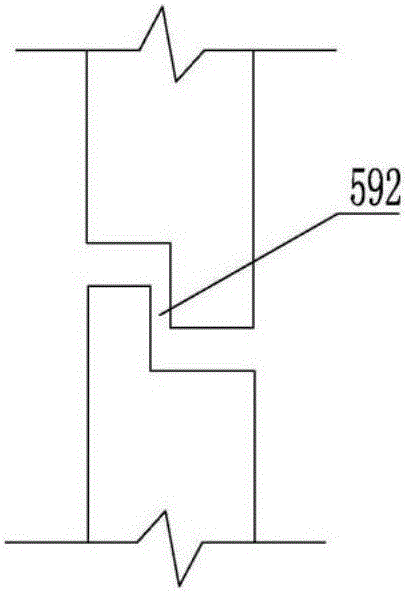

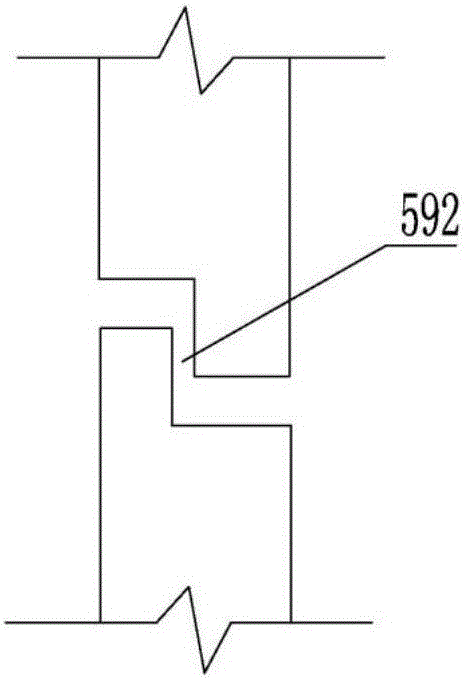

InactiveCN106368378AImprove efficiencyReduce resistanceConstruction materialFloorsEngineeringStructural engineering

The invention provides a fabricated type cavity board for a stress island cavity floor system. The fabricated type cavity board is a concrete prefabricated member and comprises longitudinal ribs, end exposing devices for transverse short ribs for bidirectional loading, cavity hole forming components, lower flange plates, ribs or locally-exposed stirrups of the ribs, and stress island reserved corners. The fabricated type cavity board is characterized in that the two ends of each longitudinal rib of the fabricated type cavity board are exposed; according to the end exposing devices for the transverse short ribs, the ends of the transverse short ribs are temporarily wrapped by vulnerable light materials, so that transverse ribs of the fabricated type cavity board are locally concave; five faces of each cavity hole forming component are located in the cavity board, and the upper surfaces of the cavity hole forming components are exposed; the lower flange plates are compounded with the bottom surfaces of the cavity hole forming components or anti-cracking steel meshes; and according to the stress island reserved corners, a stress island space which is larger than 0.18 mm2 is reserved when the fabricated type cavity board for contact columns is manufactured, and concrete is not poured into the reserved stress island space.

Owner:王本淼 +2

A prefabricated concealed beam floor

Owner:王海崴 +2

A formwork-free prefabricated cavity panel

The invention provides a formwork-free prefabricated assembly type cavity plate which comprises reinforced concrete rib beams, a steel mesh concrete bottom flange plate and a prefabricated component made from a ribbed steel mesh carving plate, wherein the reinforced concrete rib beams include at least two reinforced concrete longitudinal rib beams and multiple reinforced concrete transverse rib beams; the two ends of the rebar of the reinforced concrete longitudinal rib beam are exposed; multiple annular rebars are arranged on the upper surface of the reinforced concrete rib beam; a ribbed steel mesh body is compounded in the steel mesh concrete bottom flange plate and produced from sheet steel by die cutting and compression moulding and used for producing the ribbed steel mesh carving plate; the ribbed steel mesh carving plate is composed of a carving mesh, a carving end mesh and a support object; and the ribbed steel mesh carving plate is exposed on the upper surface of the formwork-free prefabricated assembly type cavity plate. The assembly type cavity floor slab produced by the flow has the advantages of high integrity, reasonable structure, high quality standard, controlled processes and good self-insulation and sound insulation performance.

Owner:HUNAN BDF ENERGY SAVING TECH +2

Wall for prefabricated cavity rib wallboard component assembling

The invention provides a wall for prefabricated cavity rib wallboard component assembly. The wall is composed of columns, beams, doors or windows and prefabricated cavity rib wallboard components. The columns and the beams are of a reinforced concrete structure or a formed steel structure. The prefabricated cavity rib wallboard components include reinforced concrete ribs, an inner wallboard, an outer wallboard and ribbed steel mesh hollow parts. The reinforced concrete ribs include the prefabricated cavity wallboard component side ribs and middle ribs. The reinforced concrete ribs are cavity ribs. The cavity ribs are formed by ribbed steel mesh cylinders. The inner wallboard is formed by compositing ribbed steel mesh hollow bodies and concrete. The outer wallboard is formed by compositing a reinforcing mesh and concrete. The prefabricated wallboard components produced in the process are high in integrity, reasonable in quality standard, controllable in working procedure and good in self-insulation, the reinforced concrete ribs are changed into cavity ribs, and after the reinforced concrete wallboards are changed into the self-insulation wallboard with steel mesh concrete, the weight is lowered.

Owner:HUNAN BDF ENERGY SAVING TECH +2

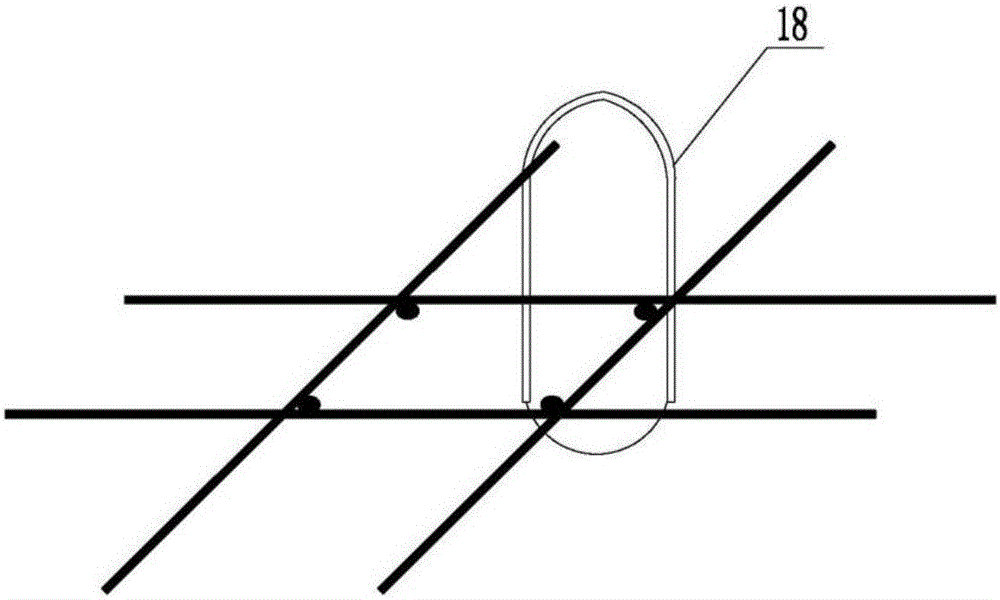

A prefabricated cavity panel forming a two-way stressed floor

The invention provides a fabricated type cavity board for forming a bidirectional-loading floor system. The fabricated type cavity board is a concrete prefabricated member and comprises longitudinal ribs, end exposing devices for transverse short ribs for bidirectional loading, cavity hole forming components, lower flange plates, and ribs or locally-exposed stirrups of the ribs. The fabricated type cavity board is characterized in that the two ends of each longitudinal rib of the fabricated type cavity board are exposed; according to the end exposing devices for the transverse short ribs, the ends of the transverse short ribs are temporarily wrapped by vulnerable light materials, so that transverse ribs of the fabricated type cavity board are locally concave; the upper surfaces of the cavity hole forming components are exposed; the lower flange plates are compounded with the bottom surfaces of the cavity hole forming components or anti-cracking steel meshes; and steel meshes are prearranged on the portions, located in the locally concave positions of the ends of the transverse short ribs, of the bottom surface of the fabricated type cavity board.

Owner:王本淼 +2

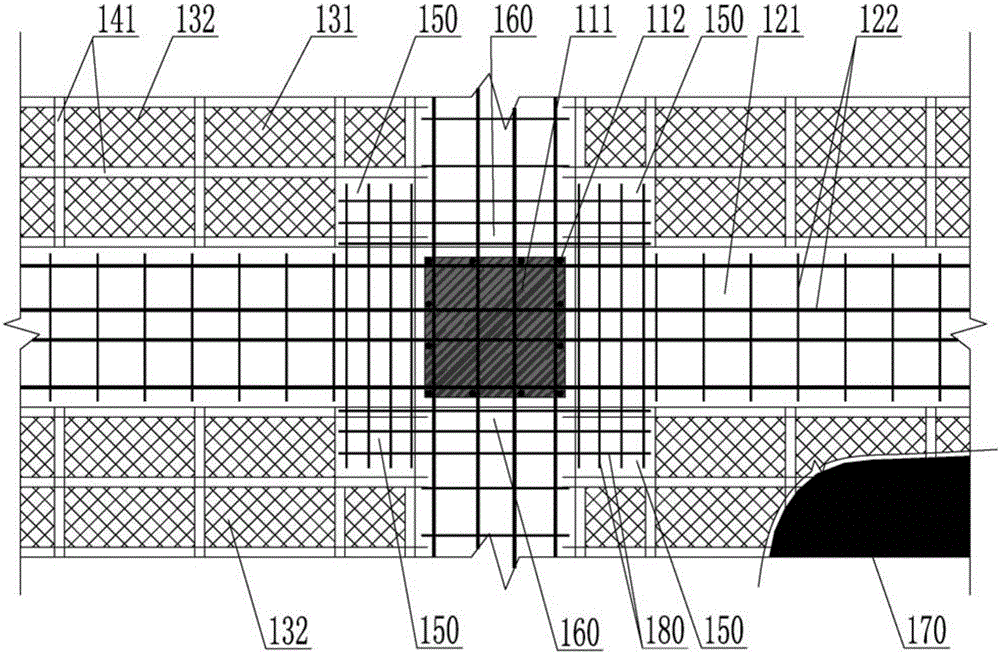

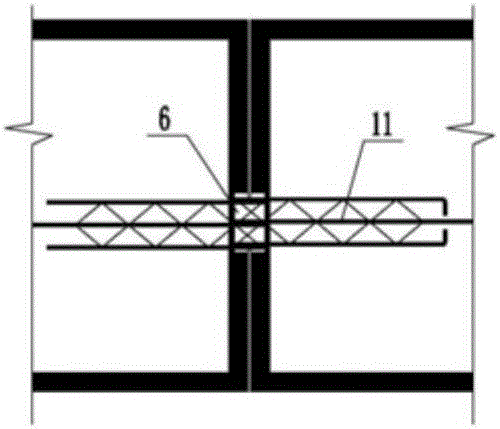

Assembly type hidden beam floor system

The invention provides an assembly type hidden beam floor system. The assembly type hidden beam floor system comprises columns, main beams, secondary beams, assembly type cavity plate components and cast-in-place reinforced concrete floor system upper flange plates and is characterized in that the secondary beams are arranged in a column net formed by the columns and the main beams and are located on the same horizontal plane with the assembly type cavity plate component lower flange plates; the assembly type cavity plate components are installed in a secondary beam frame; each assembly type cavity plate component ribbed beam is formed by pouring a lattice girder, a hole forming component and concrete; assembly type cavity plate component upper surface rebars penetrate through beam rebars and form an assembly type cavity floor system upper flange plate with beam simultaneous pouring concrete; and the assembly type hidden beam floor system is constructed.

Owner:王海崴 +2

Precast hollow floor for stress island based hollow floor system

The invention provides a precast hollow floor for a stress island based hollow floor system. The precast hollow floor comprises a precast hollow floor body consisting of reinforced concrete ribbed beams, steel mesh concrete lower flange slabs and ribbed steel mesh hollows. The precast hollow floor body comprises at least two longitudinal reinforced concrete ribbed beams and a plurality of transverse reinforced concrete ribbed beams, wherein two ends of the longitudinal reinforced concrete ribbed beams are exposed. At least one corner not subjected to concrete casting exists in every ribbed beam steel bar. A plurality of steel bar rings are arranged on the upper surface of every reinforced concrete ribbed beam, and ribbed steel meshes are composited in the steel mesh concrete lower flange slabs, are formed by punching and pressing sheet steel and are made into the ribbed steel mesh hollows consisting of hollowed-out meshes, hollowed-end meshes and supports. The ribbed steel mesh hollow bodies on the upper surface of the precast hollow floor body are exposed, and the surfaces of the exposed ribbed steel mesh hollow bodies and the upper surfaces of the reinforced concrete ribbed beams are kept on the same horizontal plane.

Owner:HUNAN BDF ENERGY SAVING TECH +2

A prefabricated wall panel component with ribbed steel mesh

The invention provides an assembly type wallboard component prefabricated through rib steel mesh plates for engraving. The assembly type wallboard component comprises ribs, an inner wallboard, inner wallboard concrete and the rib steel mesh plates for engraving. The ribs include assembly type wallboard component edge ribs and middle density ribs. The inner wallboard and the inner wallboard concrete are internally provided with steel meshes of the rib steel mesh plates for engraving. The rib steel mesh plates for engraving are composed of engraving meshes, engraving end meshes and supporting meshes. The circumference of the rib steel mesh plates for engraving is formed by the engraving meshes, the engraving end meshes support the engraving meshes to form the end cross sections of the rib steel mesh plates for engraving, the supporting meshes control the height of the internal space of the rib steel mesh plates for engraving, the engraving meshes and the engraving end meshes are made of steel mesh bodies, the supporting meshes are reinforcing mesh bodies, N rows of flat marks are arranged on reinforcing bars in the length direction of the reinforcing mesh bodies, and the length of the flat marks is larger than 4 millimeters. The assembly type wallboard component prefabricated through the rib steel mesh plates for engraving belongs to a building assembly type wall. The assembly type wallboard component produced through the procedure is strong in integrity, reasonable in structure, high in quality standard, controllable in working procedure and good in self heat preservation performance.

Owner:HUNAN BDF ENERGY SAVING TECH +2

A prefabricated laminated cavity floor

The invention provides an assembling type overlapped cavity floor cover. The assembling type overlapped cavity floor cover comprises columns, a main beam, an auxiliary beam, upper-flange-free cavity plate components and cast-in-situ reinforced concrete floor cover upper flange plates. The assembling type overlapped cavity floor cover is characterized in that the auxiliary beam is arranged in a column net formed by the columns and the main beam; the upper-flange-free cavity plate components are arranged on a framework of the auxiliary beam; the assembling type upper-flange-free cavity plate components and the beams are arranged in a vertical or horizontal overlapping manner, the vertical overlapping manner is to overlap the assembling type upper-flange-free cavity plate components to the top surfaces of the beams, and the horizontal overlapping manner is to overlap the assembling type upper-flange-free cavity plate components to the horizontal surfaces of the beams; and reinforced concrete is poured on the upper surfaces of the upper-flange-free cavity plate components to form assembling type cavity floor cover upper flange plates through overlapping, so as to form the assembling type overlapped cavity floor cover.

Owner:王海崴 +2

Fabricated type cavity board for forming bidirectional-loading floor system

The invention provides a fabricated type cavity board for forming a bidirectional-loading floor system. The fabricated type cavity board is a concrete prefabricated member and comprises longitudinal ribs, end exposing devices for transverse short ribs for bidirectional loading, cavity hole forming components, lower flange plates, and ribs or locally-exposed stirrups of the ribs. The fabricated type cavity board is characterized in that the two ends of each longitudinal rib of the fabricated type cavity board are exposed; according to the end exposing devices for the transverse short ribs, the ends of the transverse short ribs are temporarily wrapped by vulnerable light materials, so that transverse ribs of the fabricated type cavity board are locally concave; the upper surfaces of the cavity hole forming components are exposed; the lower flange plates are compounded with the bottom surfaces of the cavity hole forming components or anti-cracking steel meshes; and steel meshes are prearranged on the portions, located in the locally concave positions of the ends of the transverse short ribs, of the bottom surface of the fabricated type cavity board.

Owner:王本淼 +2

Cast-in-place combined outer wall body of prefabricated assembling type wallboard component

The invention provides a cast-in-place combined outer wall body of a prefabricated assembling type wallboard component. The cast-in-place combined outer wall body is composed of a column body steel bar, a beam body steel bar, a door and window hole and the prefabricated assembling type wallboard component, wherein a die-entering hole of the prefabricated assembling type wallboard component is reserved in a die surface of the column body steel bar; the prefabricated assembling type wallboard component comprises a reinforced concrete rib, an inner wallboard and an outer wallboard; the reinforced concrete rib comprises a prefabricated assembling type wallboard component edge rib and an assembling type wallboard middle rib; a steel bar is exposed on at least one side face in the prefabricated assembling type wallboard component edge rib; the exposed steel bar of the prefabricated assembling type wallboard component and the column body steel bar are bundled or welded and then concrete is poured into a die of the same column. The assembling type wallboard component is strong in integrity, reasonable in structure, high in quality standard and good in self-heat-insulation property, and has controllable procedure; after the reinforced concrete rib is changed into a hollow cavity rib and the reinforced concrete wallboard is changed into the steel net concrete self-heat-insulation wallboard, the weight is greatly reduced.

Owner:HUNAN BDF ENERGY SAVING TECH +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com