Wall for prefabricated cavity rib wallboard component assembling

A prefabricated, cavity technology, applied in building components, walls, building structures, etc., can solve problems such as poor controllability, loss of energy-saving and thermal insulation functions, and mitigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The invention will be further described below in conjunction with the accompanying drawings.

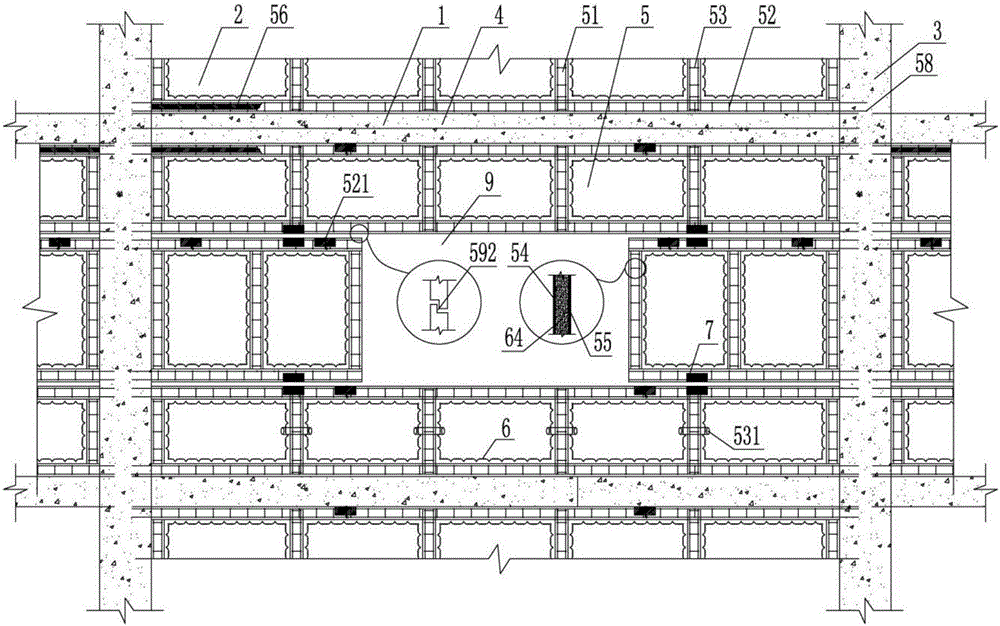

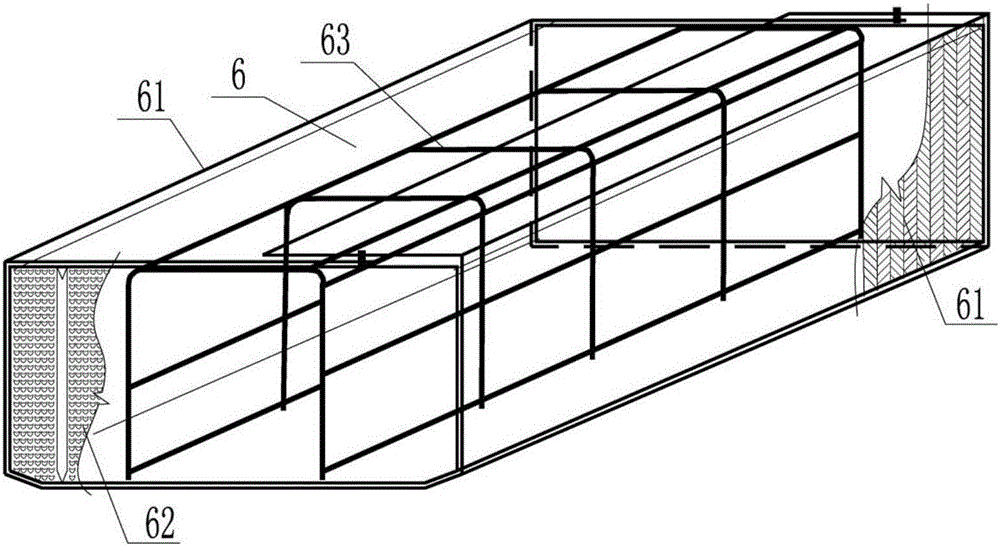

[0022] figure 1 It is a wall plan view of a combination of prefabricated cavity rib assembled wall panels of the present invention. When the present invention is implemented, the prefabricated assembled wall panels 2 produced in the factory assembly line are hoisted to the pouring site of the frame columns 3, and the prefabricated Some components 2 and exposed rib steel bars 58 of the assembled wall panel component 2 are embedded in the column mold for on-site casting. When the columns and beams are shaped steel structures, the exposed rib steel bars are directly welded to the shaped steel columns and shaped steel beams; the prefabricated assembled wall panel member 2 can be designed as a horizontal slab in the best state or as a vertical slab; two pieces The adjacent joints of the components 2 are set as willows 592 or slopes 591 to prevent the rainwater from the outer wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com