Self-heat-insulation wall body system of prefabricated assembling type wallboard component

A prefabricated, self-insulating technology, applied in thermal insulation, building components, walls, etc., can solve the problems of loss of energy-saving thermal insulation function, strong implementation technology, and environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention will be further described below in conjunction with the accompanying drawings.

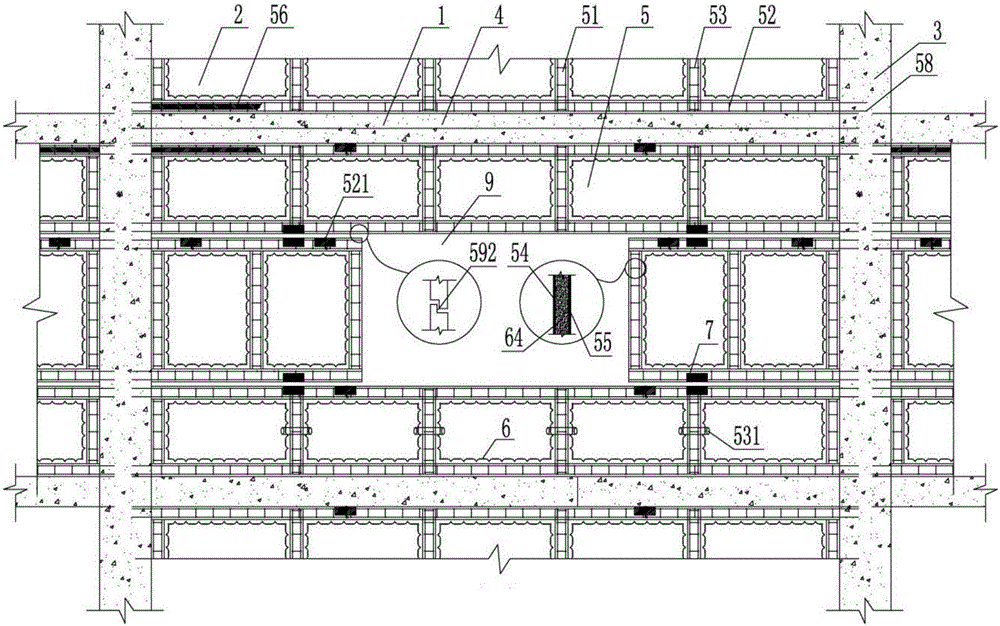

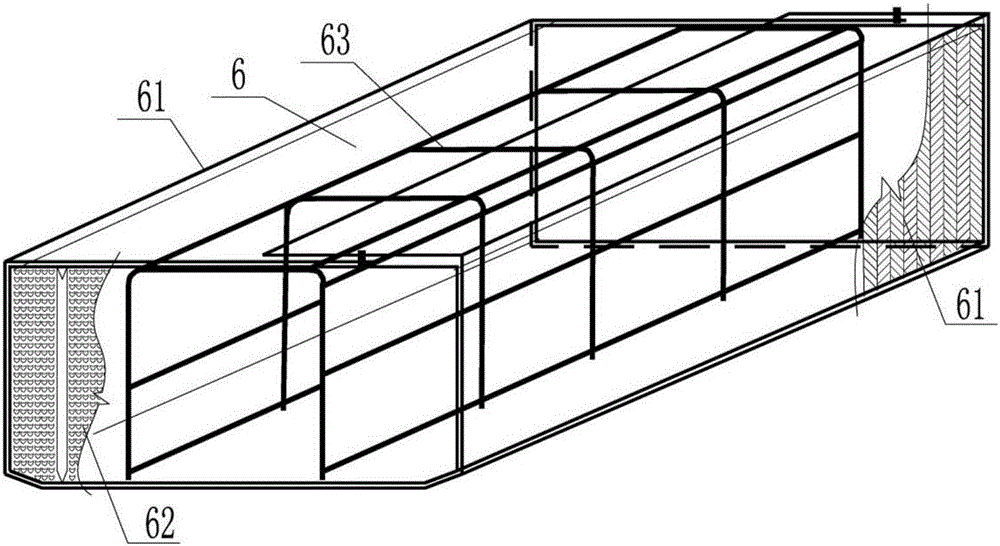

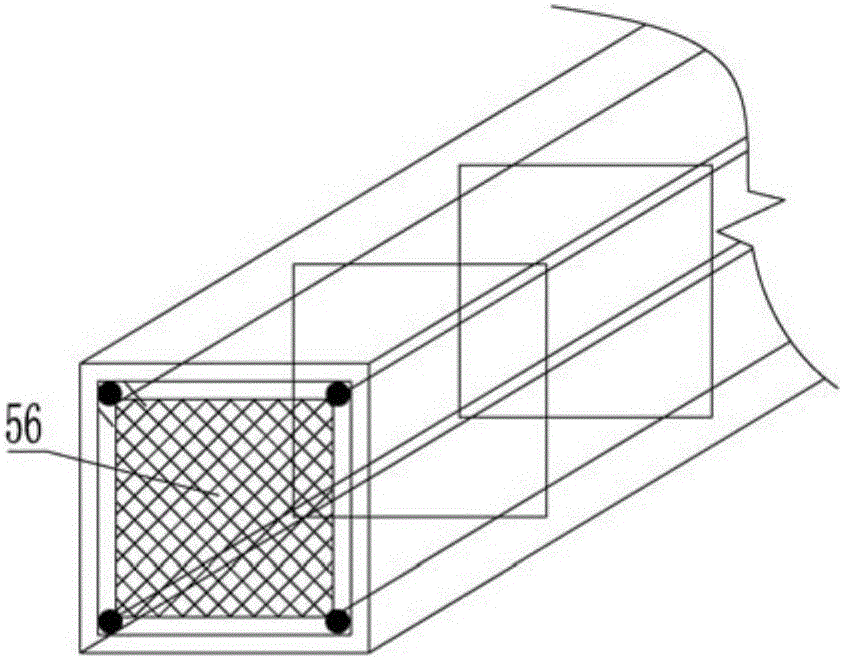

[0024] figure 1 It is a plan view of a self-insulating wall system of a prefabricated assembled wall panel member of the present invention. When the present invention is implemented, the prefabricated assembled wall panel member 2 produced in the factory assembly line is hoisted to the pouring site of the frame column 3, and the prefabricated assembled wall panel member 2 is lifted to the casting site of the frame column 3, and the prefabricated assembled wall panel member The partial members 2 of the type wall panel member 2 and the exposed rib steel bars 58 are embedded in the column mold for on-site casting. When the columns and beams are shaped steel structures, the exposed rib steel bars are directly welded to the shaped steel columns and shaped steel beams; the prefabricated assembled wall panel member 2 can be designed as a horizontal slab in the best state or as a vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com