Fabricated stressed island reinforced concrete cavity floor system

A cavity floor and reinforced concrete technology, applied to floors, building materials, building components, etc., can solve the problems of strong technical implementation, poor controllability, and long molding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

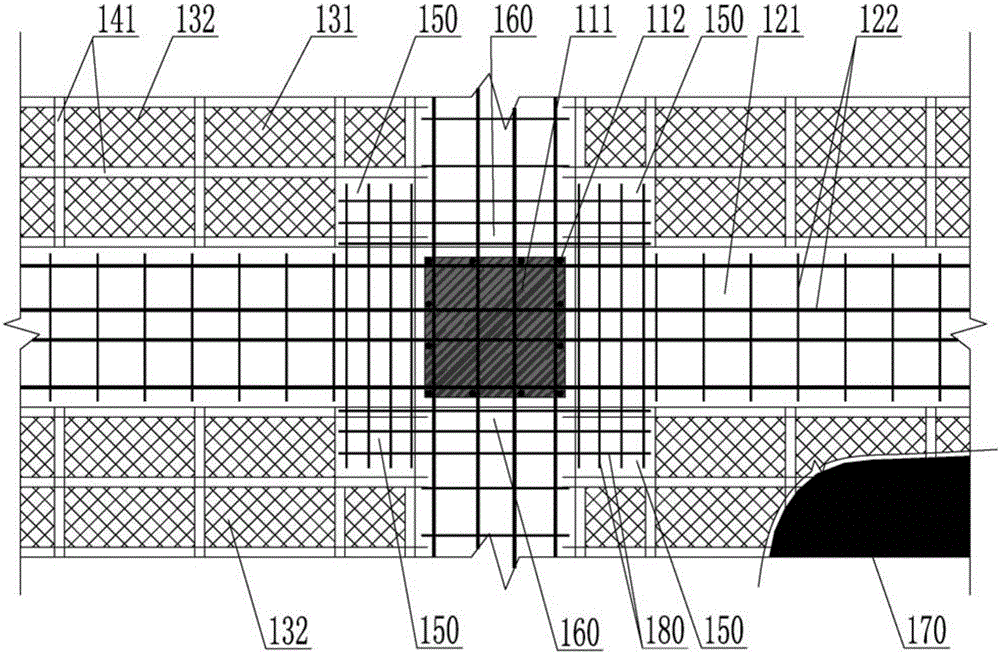

[0029] figure 1 This is an assembly plan view of the reinforced concrete cavity floor of a stress island of the present invention. When the present invention is implemented, the prefabricated assembly cavity component 131 will be produced in the factory assembly line; the reserved angle 150 of the prefabricated assembly cavity component 131 Unpoured concrete, and reserve its rib beam reinforcement 141; its production process is to transfer the prefabricated cavity component with a surrounding track bottom mold system to the mold assembly workshop and the rib reinforcement and filler body workshop; match the bottom mold Install the vertical formwork to form the open base form frame of the required specification and model, and place the ribbed steel bar, ribbed steel mesh, willow mold, and the through pipe between the rib beams in the open base formwork; then place the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com