Precast hollow floor for stress island based hollow floor system

A cavity floor and cavity floor technology, which is applied to floors, building components, buildings, etc., can solve problems such as long molding time, slow progress of projects, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The invention will be further described below in conjunction with the accompanying drawings.

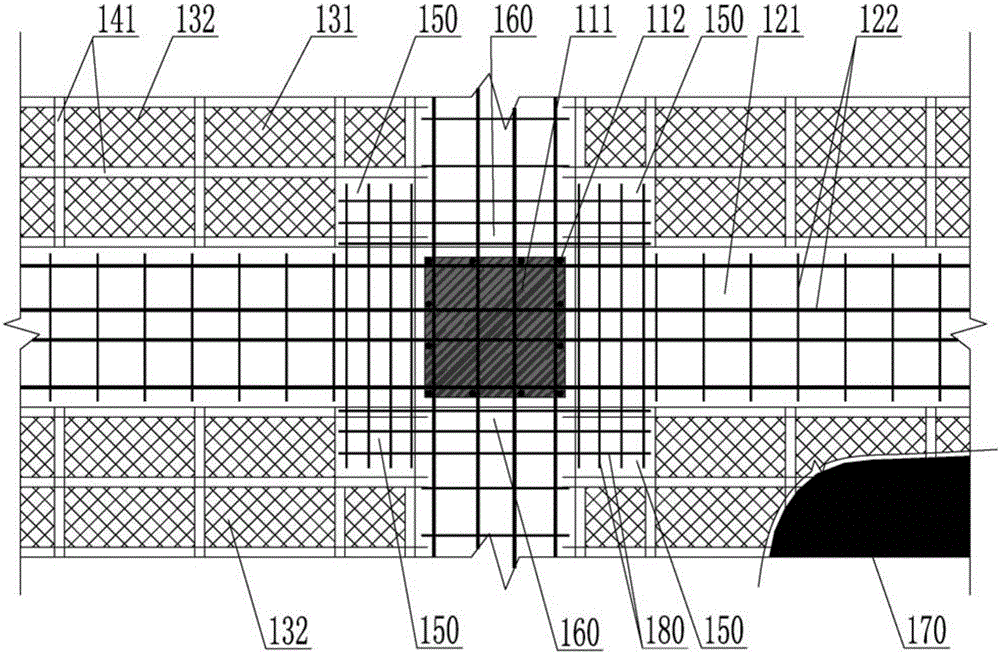

[0023] figure 1It is a plan view of a prefabricated cavity floor slab for a force-bearing island cavity floor of the present invention. When the present invention is implemented, it is a prefabricated prefabricated cavity prefabricated component 131 that will be produced on the factory assembly line; the prefabricated cavity prefabricated component 131 The corner 150 is not poured with concrete, and the rib beam reinforcement 141 is reserved; the production procedure is to transfer the bottom form system of the prefabricated cavity prefabricated component with a surrounding track to the formwork workshop and the rib reinforcement and filling body workshop; The mold is equipped with a vertical formwork to form an open basic formwork frame of the required specification and model, and rib beam steel bars, ribbed steel mesh engravings, willow molds, through-pipes between rib beams...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com