Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

328results about How to "Improve weighing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

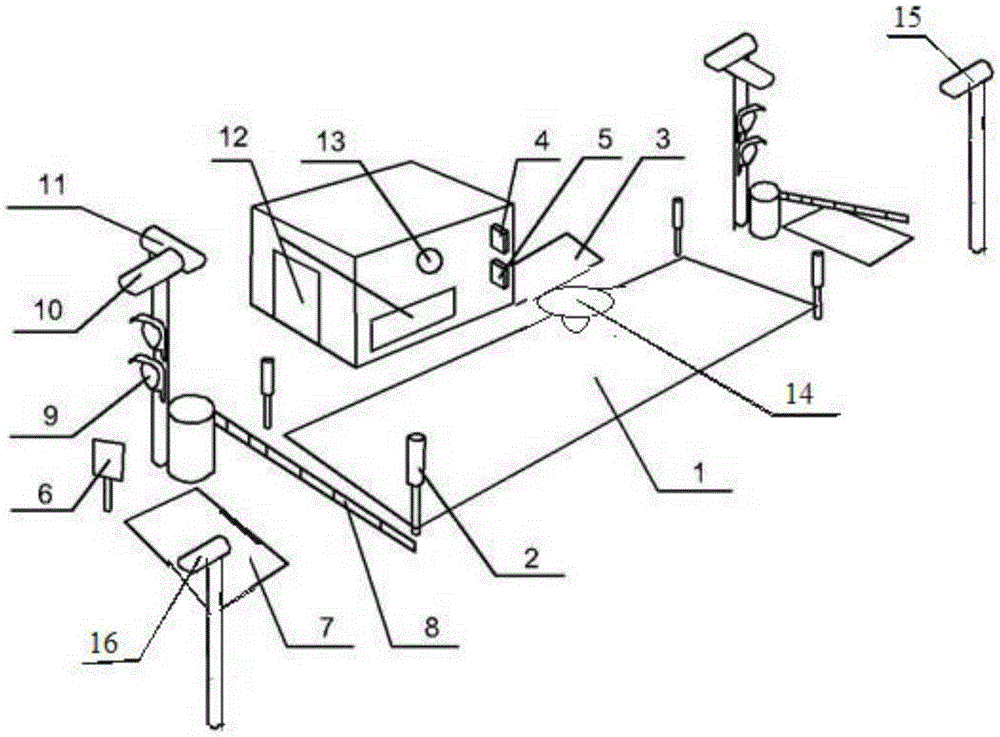

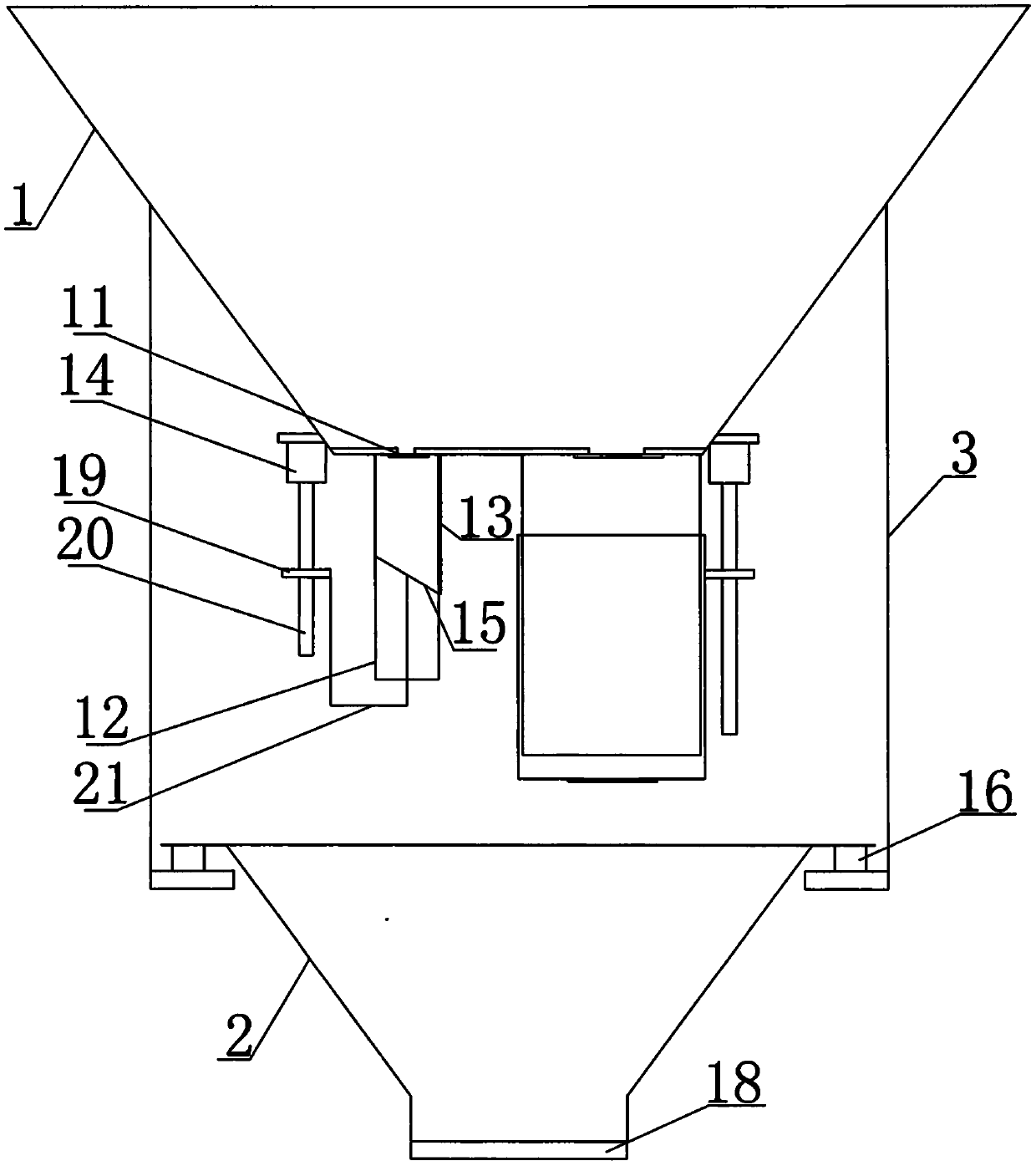

Automatic weighing metering system and method for granary

ActiveCN105241533AImprove accuracyImprove efficiencyData processing applicationsCo-operative working arrangementsParking areaComputer science

The invention discloses an automatic weighing metering system for a granary. The system comprises a weighbridge. Multiple infrared light curtain detectors limit a vehicle parking area. A host computer, a waiting area and a camera unit are arranged near the weighbridge. The host computer is configured in a way that after a grain carrier worker stays in the waiting area and the face information of the worker is verified, an RFID card is swiped, the weighbridge records weighing data and the camera unit captures current video frames at the same time after a grain carrying vehicle stays in the vehicle parking area, the camera unit does not capture the face and the weighing data by the weighbridge is steady, and the data and the video frames are uploaded to the host computer; and if the grain carrying vehicle does not stay in the vehicle parking area, or the camera unit captures the face or the weighing data by the weighbridge is not steady, the weighbridge does not have a weighing effect and will emit reminding sound. The invention also discloses an automatic weighing metering method for a granary. Man-made cheating can be prevented in many ways, smooth information operations of a whole course during which a grain carrying vehicle enters a granary and exits from the granary can be achieved, the number of workers can be reduced, operating procedures can be standardized, and highly efficient and automatic weighing metering is achieved.

Owner:HUBEI YE WEI INTELLIGENT TECH

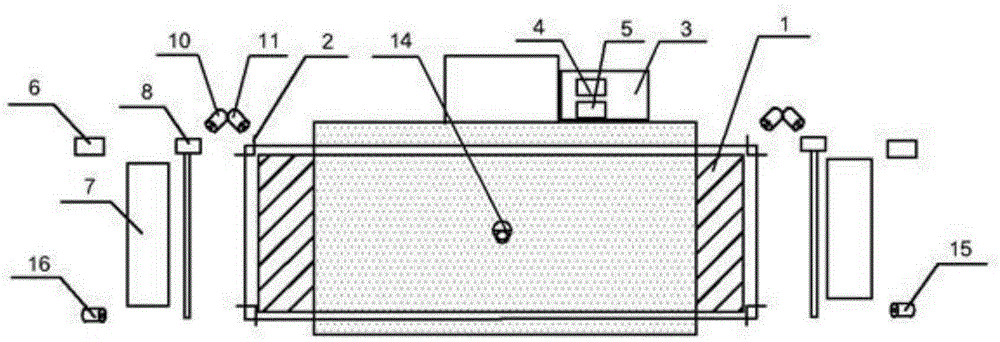

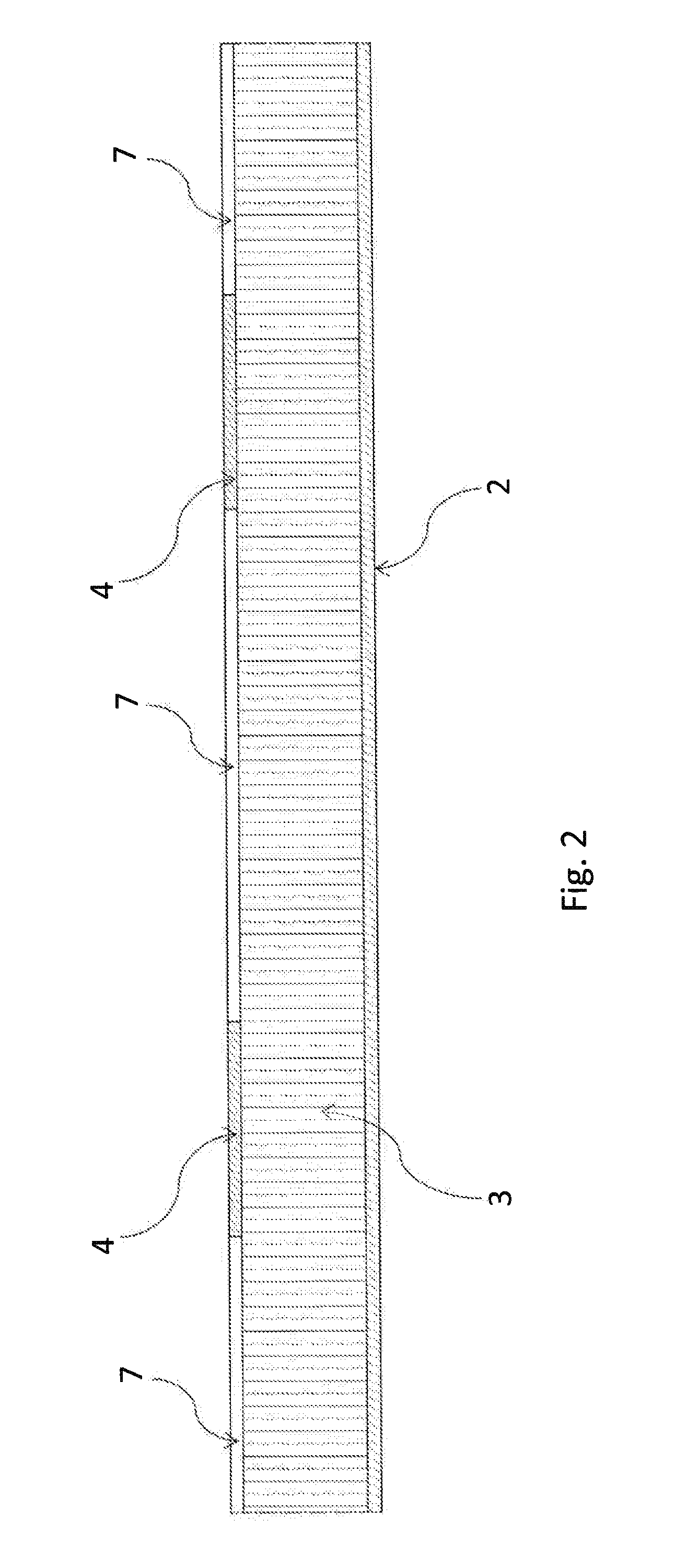

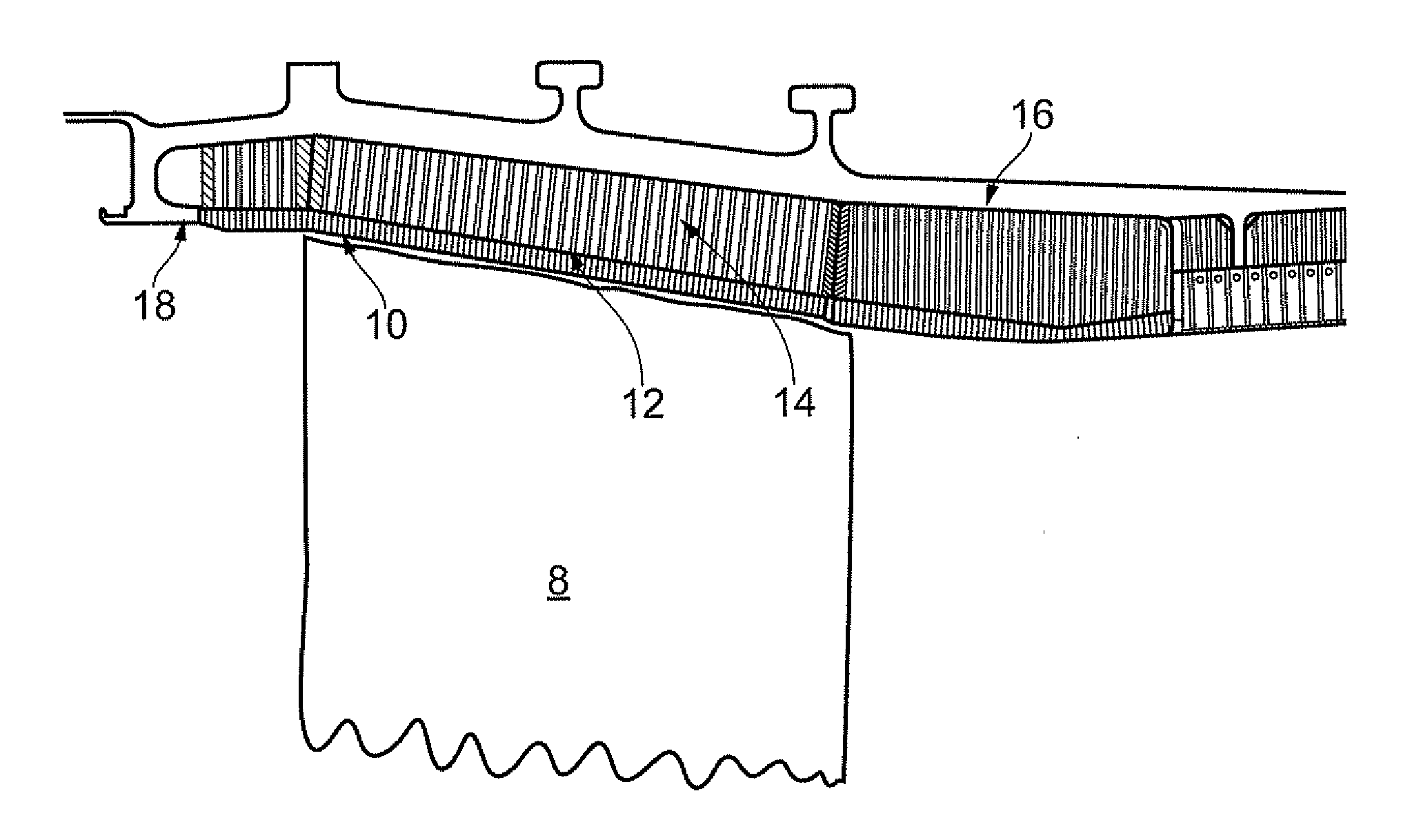

Sandwich type load bearing panel

InactiveUS20150030806A1Effective and easy implementationHigh bending stiffnessBuilding componentsVehicle componentsEngineeringMechanical engineering

A sandwich type load bearing panel (1) with a transversely shear stiff core (3) and a plurality of individual unidirectional plies respectively for a first and a second composite layer (2, 4), bonded each to one of the main surfaces of the core (3). The first composite layer (2) is a continuous and monolithic assembly and the second layer (4) is an open net of intercrossing strips (4a, 4b, 4c) running along at least three directions and being laid up of said plurality of individual unidirectional plies.

Owner:AIRBUS HELICOPTERS DEUT GMBH

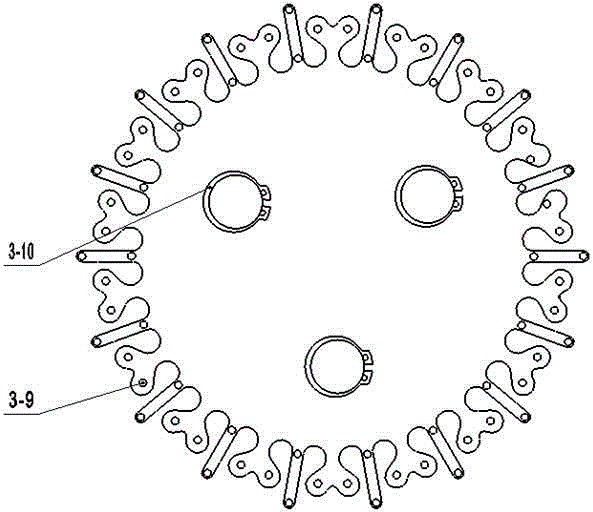

Helicopter rotor operation method and system

InactiveCN101376433BImprove weighing efficiencyEasy to controlPropellersUsing optical meansControl systemAnimal sting

The invention relates to a control method and a system of a helicopter rotor, which belongs to the technical field of helicopter operation. The control method is characterized in that the distance changing of a blade is realized by adopting an actuator positioned on the stinger of each propeller boss to drive a flap positioned at the rear edge of the blade, so as to realize the control of a rotorsystem. The system comprises a demountable flap (1) installed at rear edge of the blade, torque soft propeller bosses (14), an actuator (13) installed on the stinger of torque soft propeller bosses, a flap control mechanism (1) with one end being connected with actuator (13) and the other end thereof being connected with the flap (1), and a test control system (59). The control method and the system have the advantages that the screw piston of each blade can be independently controlled, the structure is simple, the weight is light, the controllability is good, and the reliability and the security are high.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

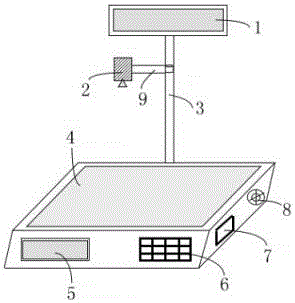

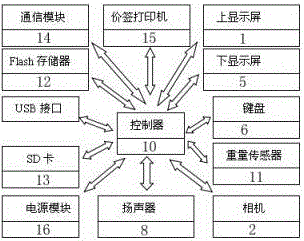

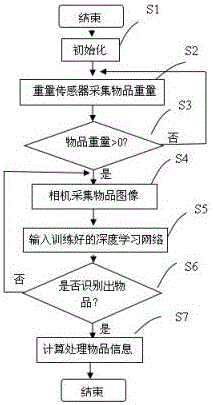

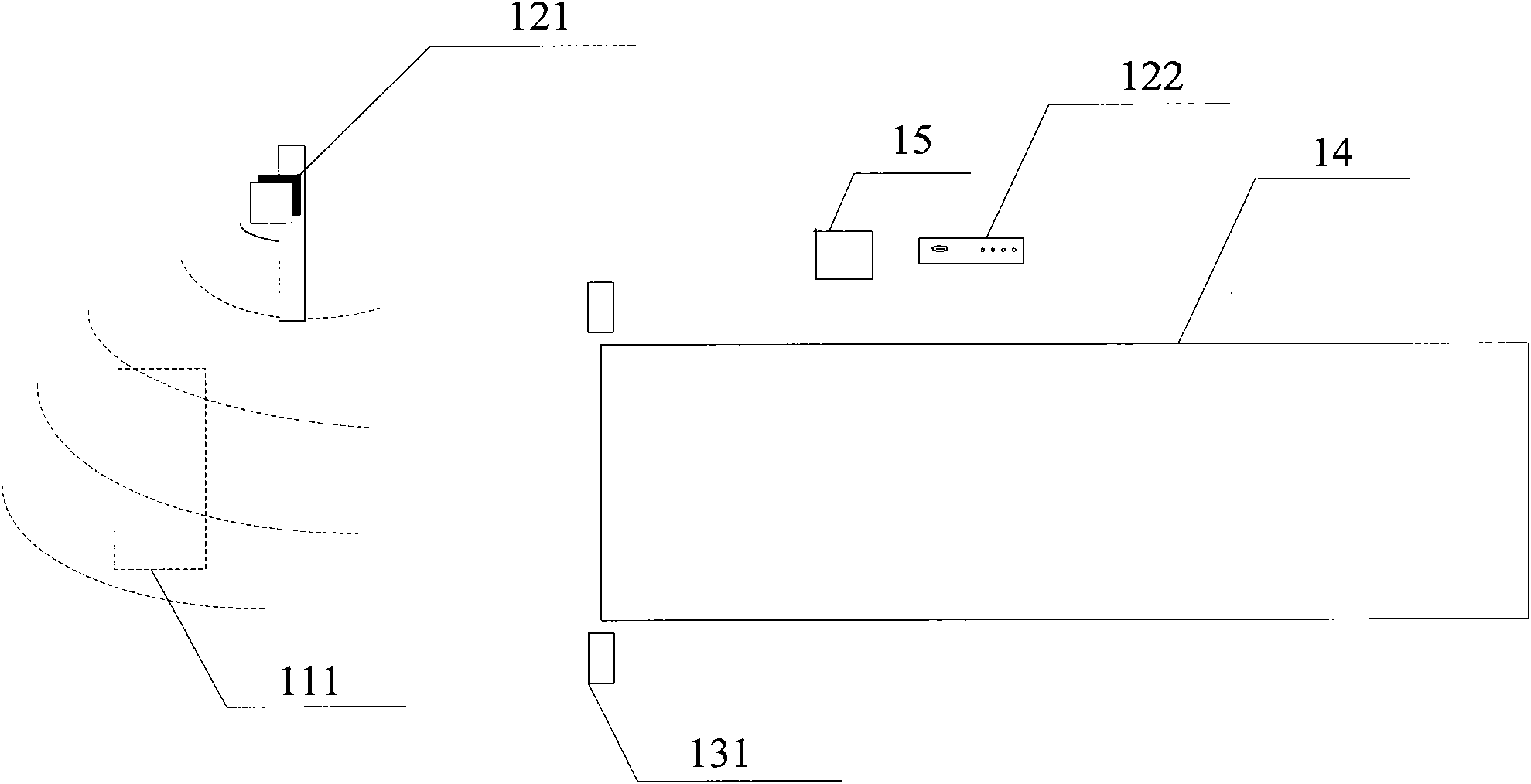

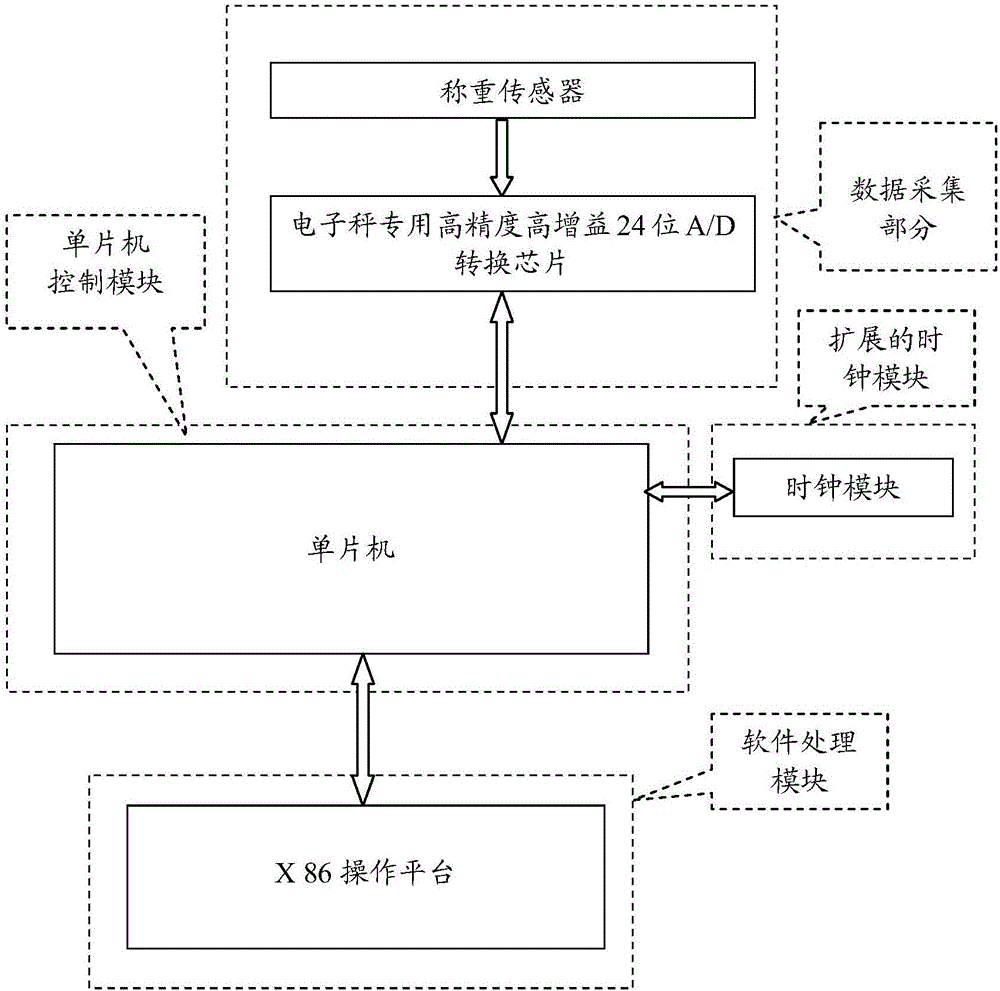

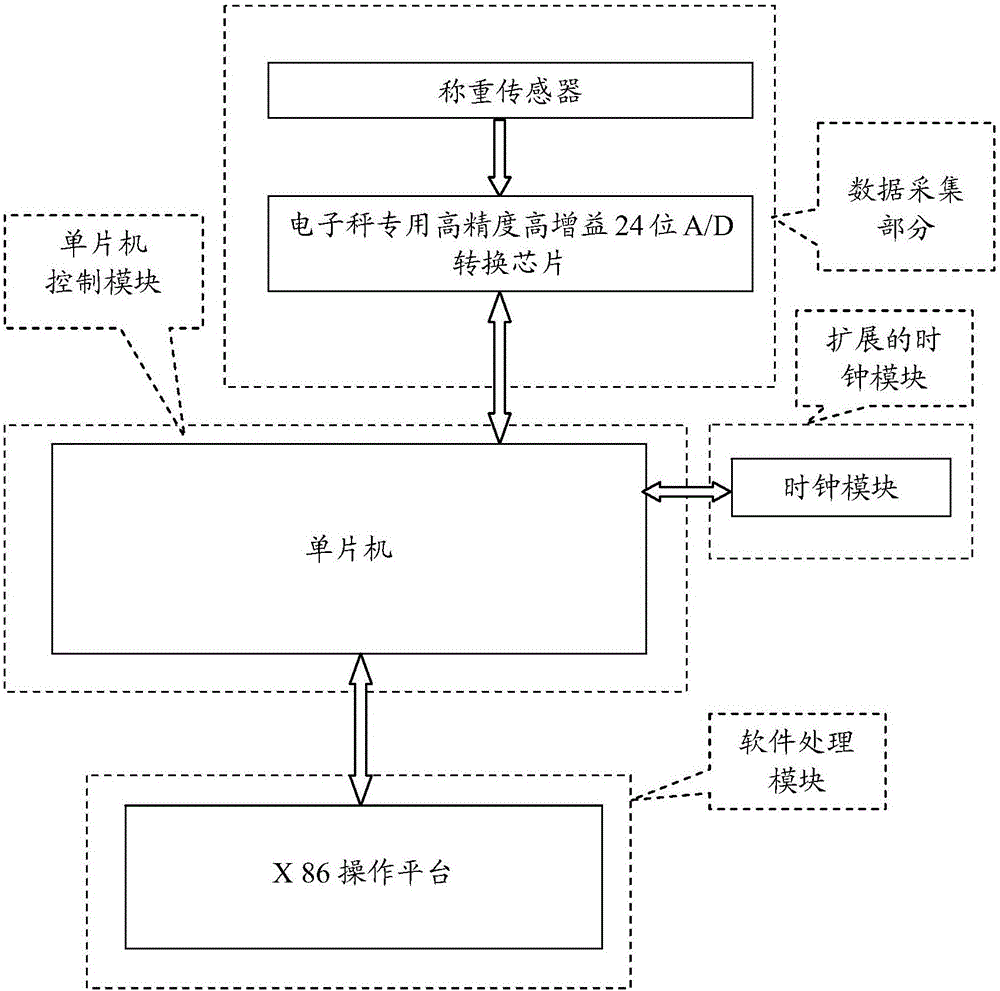

Automatic weighing machine based on deep learning and program control method thereof

InactiveCN106340137ARealization of automatic weighingReduce workloadApparatus for meter-controlled dispensingWorkloadData mining

The invention discloses an automatic weighing machine based on deep learning and a program control method thereof. The method relates to an image recognition technology and an internet of things technology based on the depth learning. The method mainly solves the problems of various kinds of artificial weighing articles, price numbers difficult to rememer, low operation efficiency and the like. By constructing the article recognition depth learning model, the weight of the weighing article is collected by the weight sensor and the image of the weighing article is collected. The corresponding information can be inquired out, such as the unit price, the manufacturer, the production date and the like, so as to reduce the workload of the operation personnel and improve the weighing efficiency.

Owner:GUIZHOU EDUCATION UNIV

Automatic weighing system and method

InactiveCN102313590AConvenient summaryEasy to summarize statisticsSpecial purpose weighing apparatusRadio frequencyAutomatic testing

The invention relates to an automatic weighing system and method. The system comprises a first vehicle sensing unit, a first radio frequency identification unit, a control unit, a first infrared mutual-emission unit and an electronic weighing scale, wherein the first vehicle sensing unit is used for detecting whether a first vehicle weighed currently enters the automatic weighing system or not; the first radio frequency identification unit is used for acquiring the radio frequency identification tag of the first vehicle weighed currently after the first vehicle sensing unit detects that the first vehicle weighed currently enters the automatic weighing system; the control unit is used for the radio frequency identification tag acquired by the first radio frequency identification unit; the first infrared mutual-emission unit is used for detecting whether the first vehicle weighed currently is completely located on the electronic weighing scale or not under the control of the control unit; and the electronic weighing scale is used for acquiring the weight information of the first vehicle weighed currently under the control of the control unit after the first infrared mutual-emission unit detects that the first vehicle weighed currently is completely located on the electronic weighing scale. According to the invention, the weighing efficiency can be increased, the summary statistics of the weight information is facilitated, and illegal behaviors in the weighing process can be completely eradicated.

Owner:AEROSPACE INFORMATION

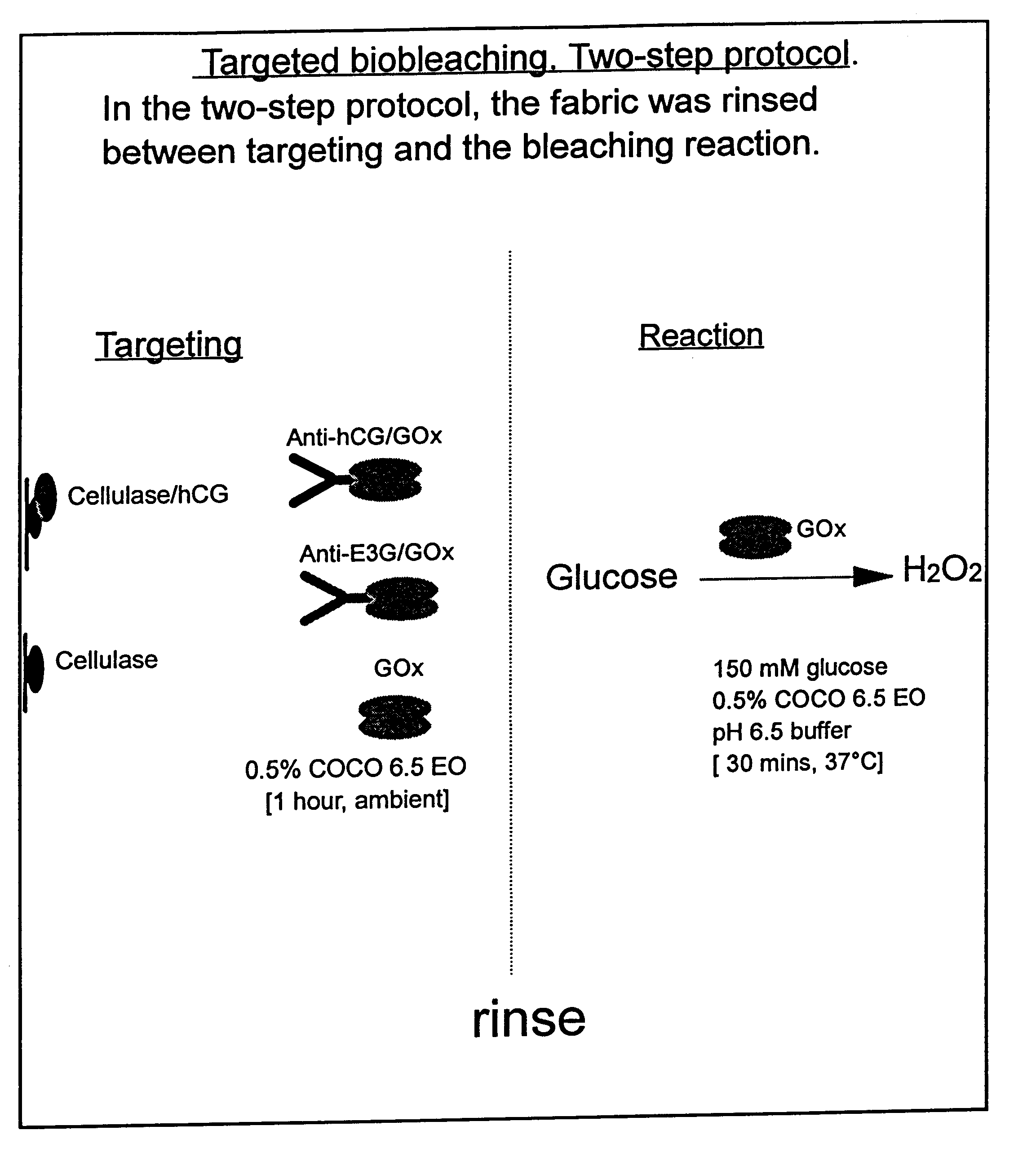

Bleaching enzymes

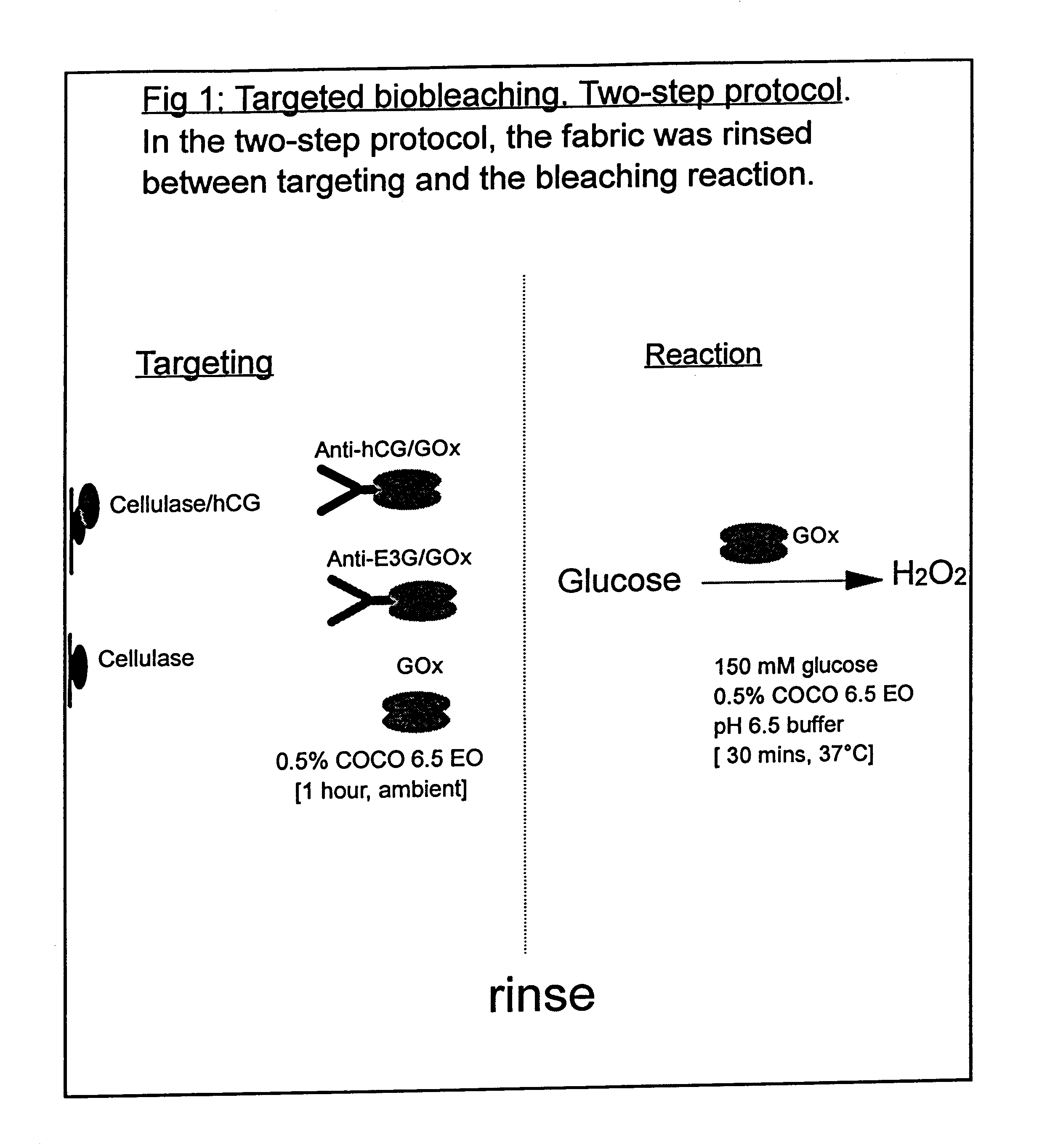

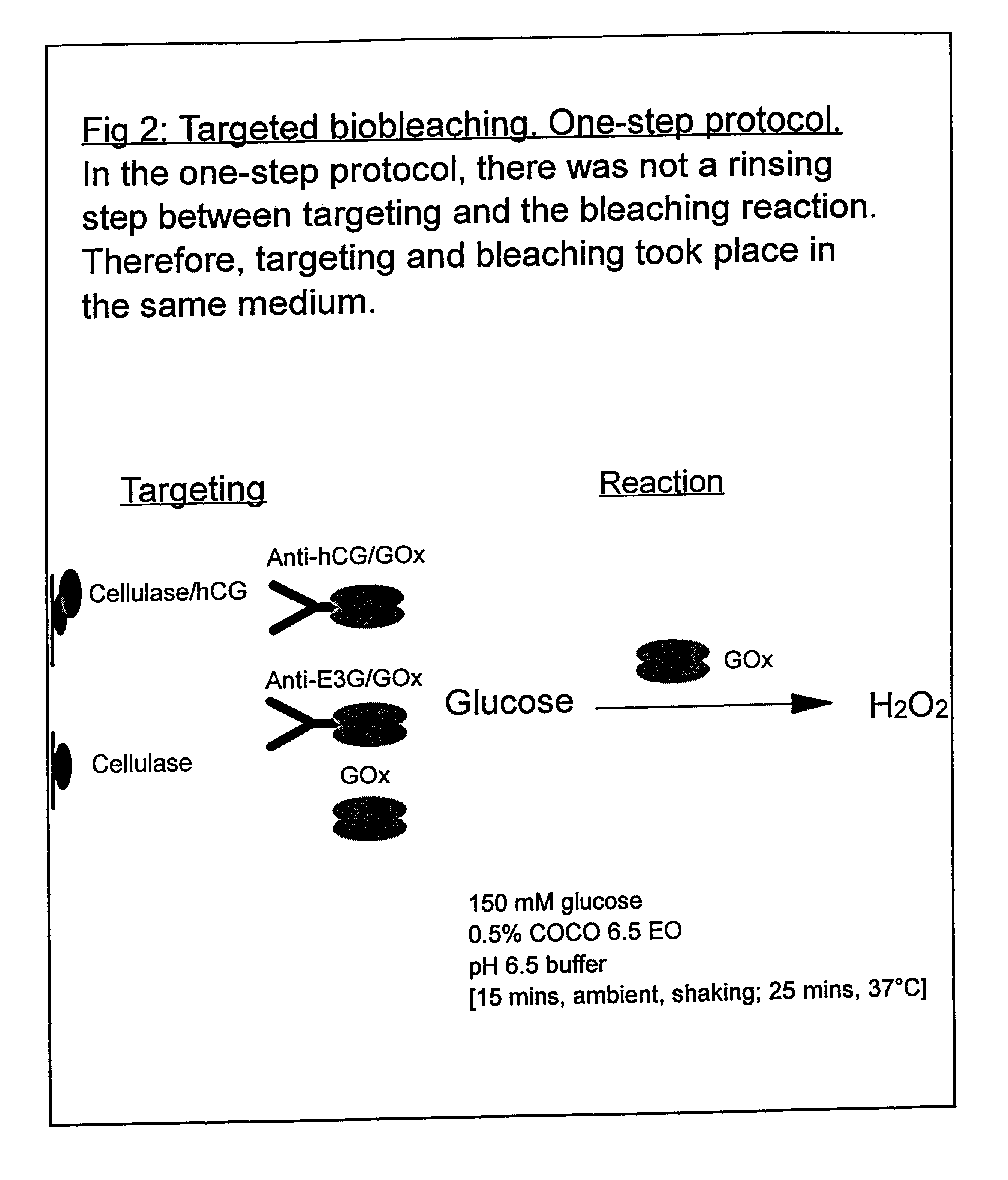

InactiveUS6218350B1High selectivitySmall amount of compoundOrganic detergent compounding agentsPeptide/protein ingredientsSURFACTANT BLENDEnzyme

There is provided a bleaching enzyme capable of generating a bleaching chemical and having a high binding affinity for stains present on fabrics. Furthermore, there is provided an enzymatic bleaching composition comprising the bleaching enzyme and a surfactant and a process for bleaching stains present of fabrics.

Owner:LEVER BROTHERS

Turbomachine casing assembly

InactiveUS20130136577A1Reduce weightEasy to manufacturePump componentsEfficient propulsion technologiesEngineering

A turbomachine casing assembly includes a first casing element locatable radially outward of one or more rotating aerofoil elements of a turbomachine and a second casing element located radially distal to the first casing element, with a void being defined between the first and second casing elements. Each of the first and second casing elements includes, at a first end thereof, respective co-operating first and second interface portions. In the event that an aerofoil element becomes detached from the turbomachine and impacts the first casing element, the second interface portion; slides along the first interface portion and the first end of the first casing element enters the void.

Owner:ROLLS ROYCE PLC

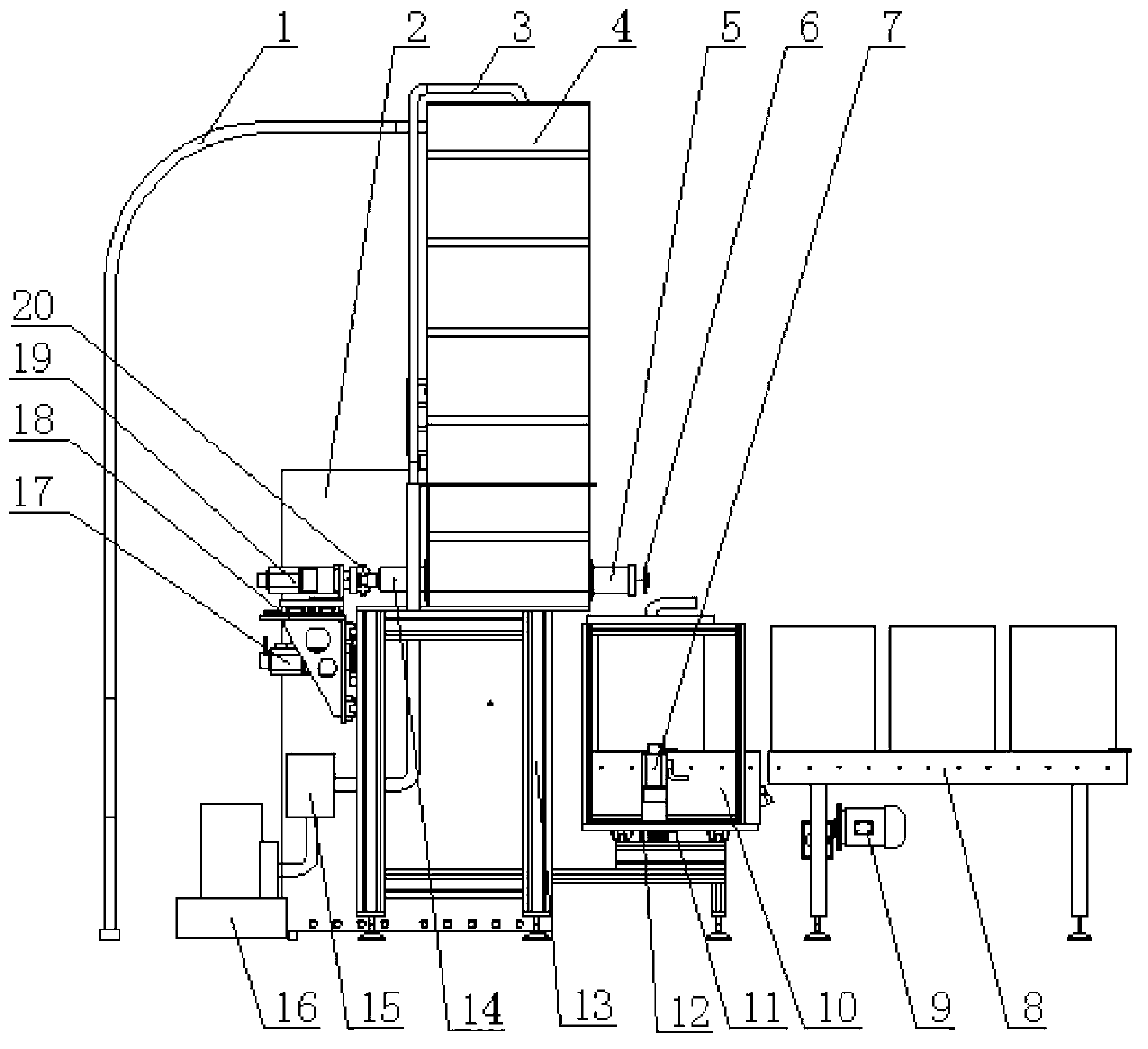

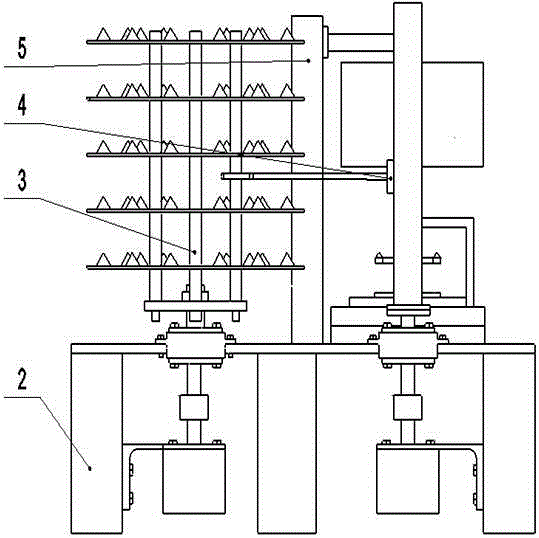

Automatic powdery dye weighing system

ActiveCN103276545AImprove weighing efficiencyAvoid pollutionTextile treatment machine partsWeighing apparatus for materials with special property/formWorking environmentEngineering

The invention relates to an automatic powdery dye weighing system. The automatic powdery dye weighing system comprises a frame, a plurality of feeding devices, a movable rotary-shifting manipulator, a movable receiving trolley and an electric control cabinet, the feeding devices are arranged on the frame side by side, the movable receiving trolley is correspondingly arranged below the front ends of the feeding devices, the movable rotary-shifting manipulator is correspondingly arranged at the rear ends of the feeding devices, the electric control cabinet is arranged on one side of the frame, each feeding device comprises a dye box and a screw feeder, each screw feeder is mounted on the lower portion of each dye box, a discharge hole is made at the front end of each screw feeder, the rear end of each screw feeder is matched with the movable rotary-shifting manipulator so as to achieve discharging, the upper portions of the dye boxes are connected with a feeding pipe and a negative pressure pipe, and the negative pressure pipe is connected with a negative pressure fan. The automatic powdery dye weighing system has the advantages that the automatic powdery dye weighing system is simple in structure, scientific and reasonable in design, capable of effectively improving dyeing recipe weighing efficiency and good in weighing repeatability, pollution of powder to working environments is avoided, labor is freed, and the working environments are improved.

Owner:杭州三拓科技有限公司

Volume and weight measuring system and work method thereof

PendingCN107328364AImprove weighing efficiencySave human effortUsing optical meansSpecial purpose weighing apparatusTest objectBarcode

The invention discloses a volume and weight measuring system and a work method thereof; the measuring system comprises a bar code scanning subsystem, a weight measuring device, a volume measuring device, a control system and a power supply system; the control system is respectively connected with the bar code scanning subsystem, the weight measuring device, and the volume measuring device; the power supply system is respectively connected with said systems; the bar code scanning subsystem is used for scanning a tested object bar code and collecting the tested object logistics information; the weight measuring device is used for measuring the object weight; the volume measuring device is used for measuring the tested object volume; the control system is used for synchronizing the volume measuring device, the weight measuring device and the bar code scanning subsystem, and receiving information from the subsystem; the work method can synchronically scan the tested object bar code, measure the tested object weight and measure the tested object volume, thus preventing troubles caused by three step works or three station works, and solving the confusion problems caused by separately processing data.

Owner:SF TECH

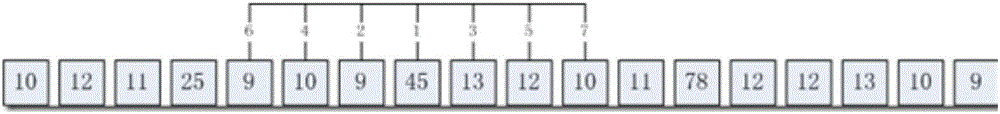

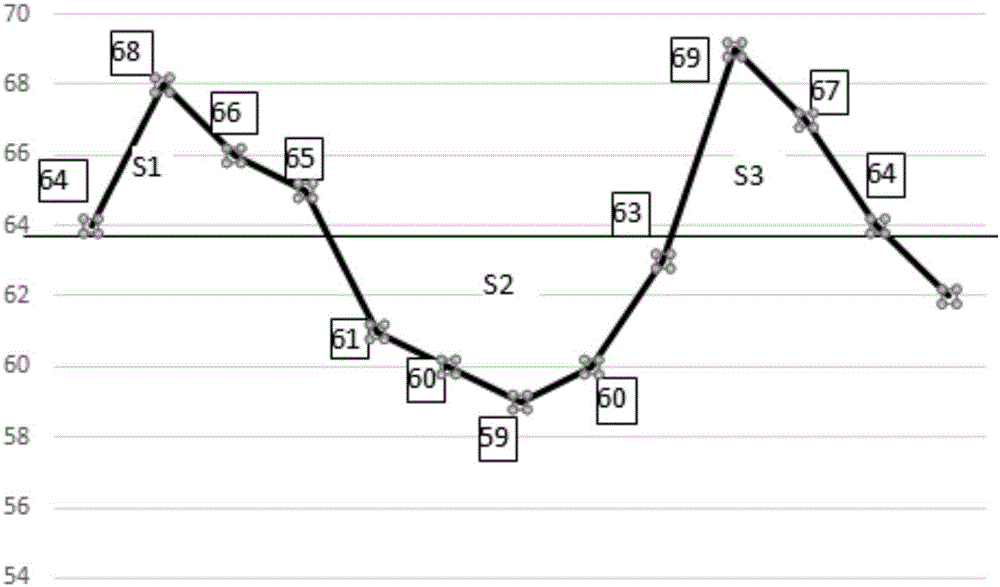

Method used for garbage dynamic weighing of sanitation truck

ActiveCN106840339AIncrease weight valueImprove weighing efficiencyRefuse vehiclesSpecial purpose weighing apparatusTemporal changeWave shape

The invention relates to the field of garbage weighing, and relates to a method used for garbage dynamic weighing of a sanitation truck. A weight sensor and a dip angle sensor are arranged on a supporting frame, and the sanitation truck is provided with a processor which is connected with the weight sensor and the dip angle sensor. One second after a garbage barrel lifts, during the period when the rotation angle of the garbage barrel around the supporting frame is 1-20 degrees, a weight sensor collects weight data, the dip angle sensor collects supporting frame overturning angle data at the same time, the processor collects data of the weight sensor and the dip angle sensor, a dynamic waveform displaying the change of the weight with the change of the location and time is drawn, and through a method for calculating the waveform average value, the weight value of lifted garbage at this time is calculated. According to the method, when the garbage weighing efficiency is greatly improved, the weighing result is basically accurate, and the weighing requirement of the sanitation truck is met.

Owner:ZHEJIANG LIANYUN ZHIHUI TECH CO LTD

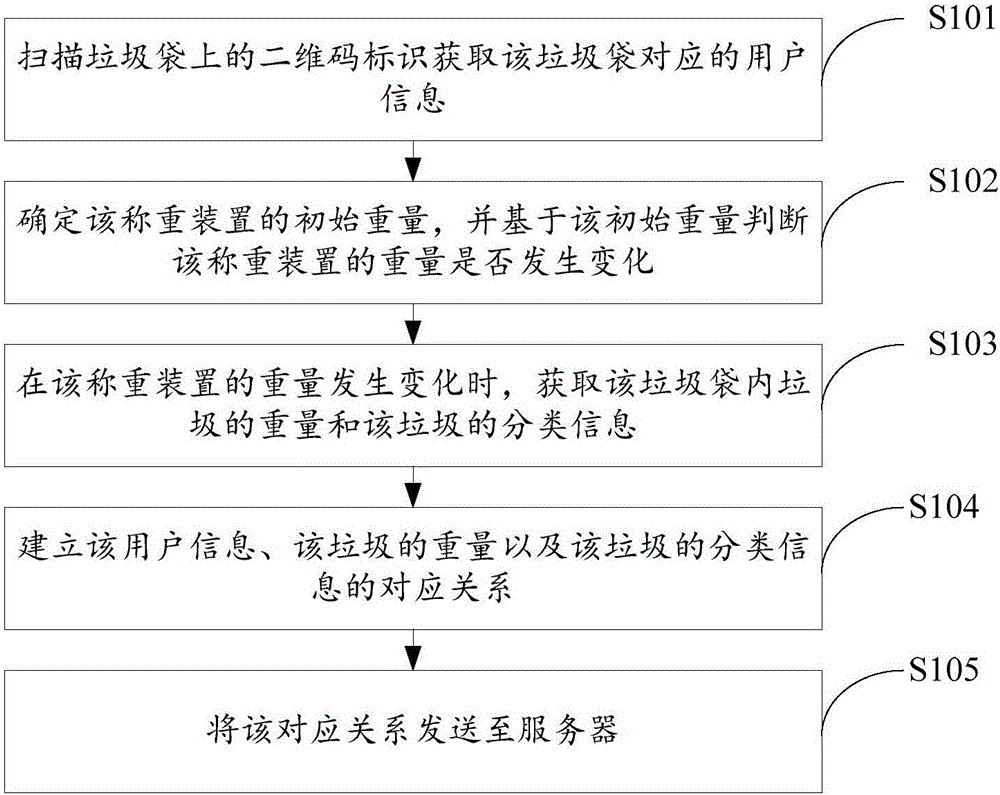

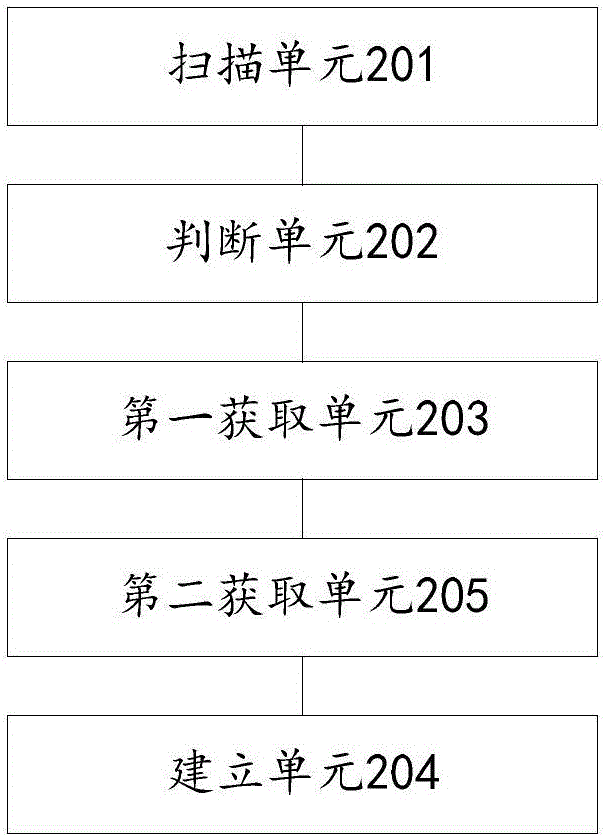

Garbage weighing method and device and garbage can

InactiveCN105858019AAchieve weighingImprove weighing efficiencyRefuse receptaclesOperating systemUser information

The application provides a method and device for weighing garbage and a garbage bin, including: scanning the two-dimensional code on the garbage bag to obtain the user information corresponding to the garbage bag; determining the initial weight of the weighing device, and judging the weight based on the initial weight Whether the weight of the device changes; among them, the weighing device is used to measure the weight of the garbage in the garbage bag; when the weight of the weighing device changes, obtain the weight of the garbage in the garbage bag and the classification information of the garbage; establish user information, garbage The corresponding relationship between the weight of the garbage and the classification information of the garbage; by sending the corresponding relationship to the server, the application can reduce manual operations, save human resources, and increase the efficiency of garbage weighing.

Owner:MODERN CITY ENVIRONMENTAL SERVICES SHENZHEN CO LTD

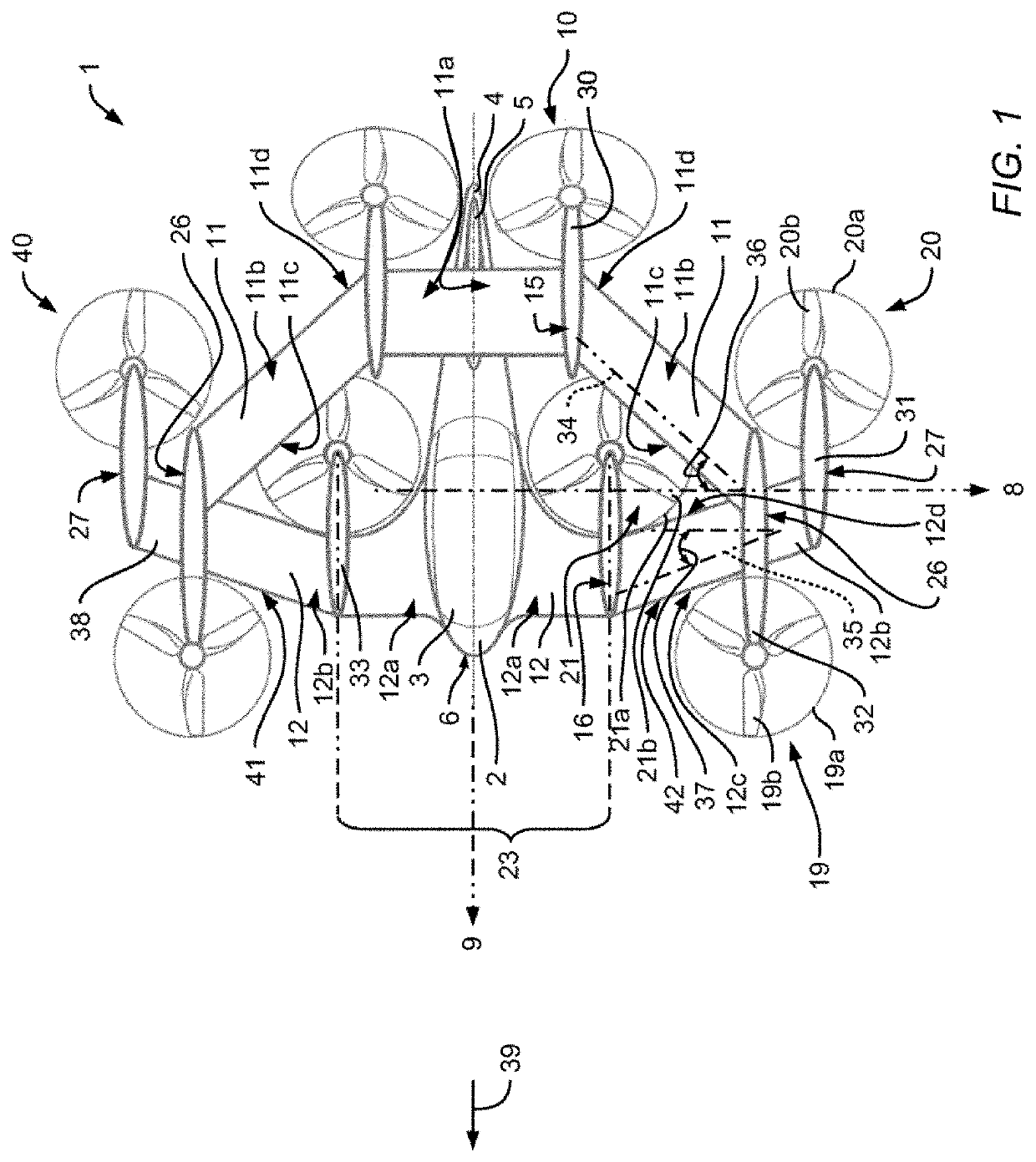

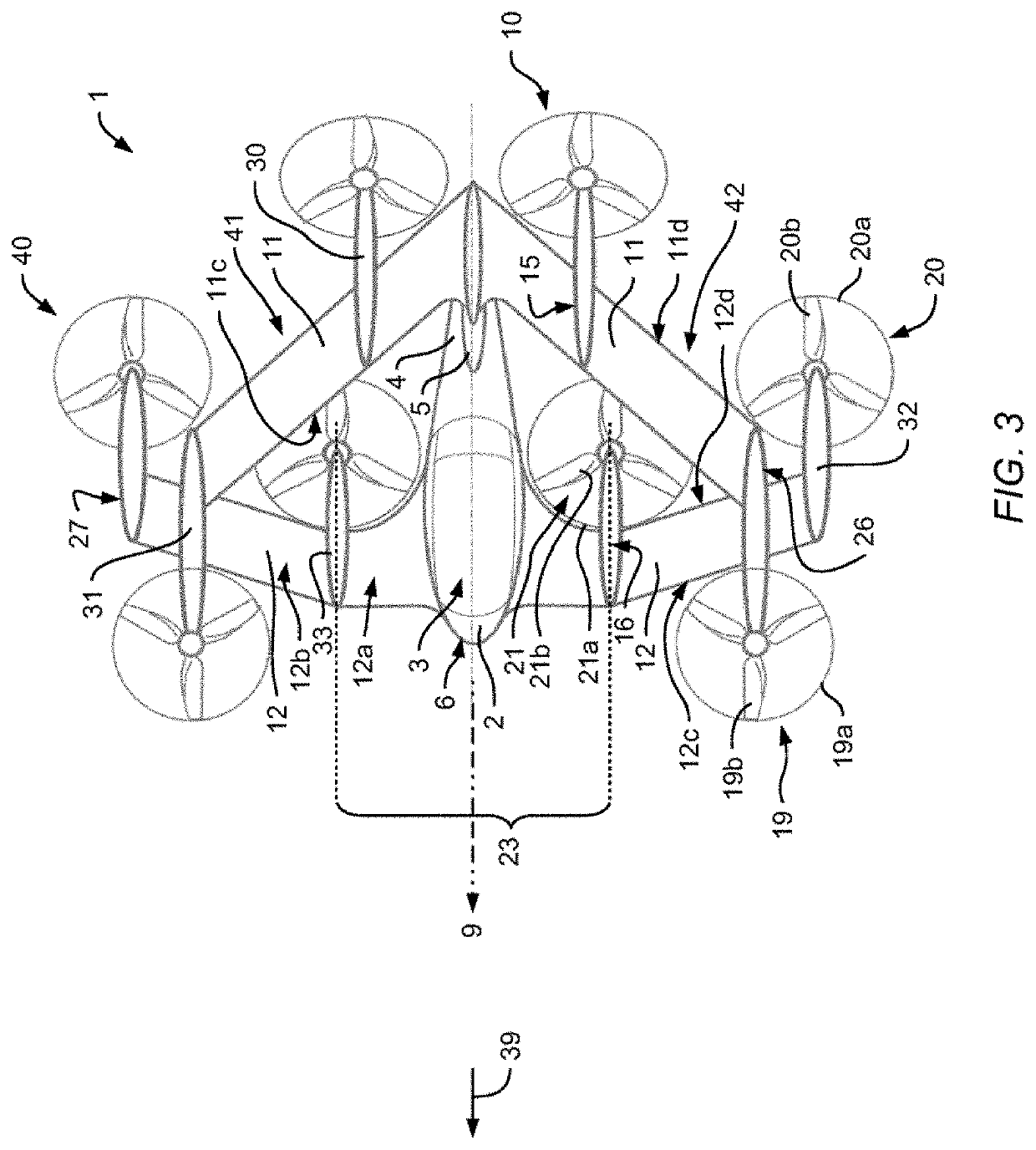

Multirotor joined-wing aircraft with vtol capabilities

ActiveUS20200269980A1Large load levelReduction of structural weight efficiencyPropellersPower plant constructionFlight vehicleClassical mechanics

A multirotor aircraft that is adapted for vertical take-off and landing. The multirotor aircraft comprises a fuselage, a tail boom that is provided with a vertical fin, a thrust producing units assembly that is provided for producing thrust in operation, at least one lower wing which comprises a lower wing inboard section that is connected to the fuselage and a lower wing outboard section that forms a lower wing tip, and at least one upper wing which is connected to the vertical fin and which forms an upper wing tip. The at least one upper wing is joined to the at least one lower wing in a joined-wing configuration.

Owner:AIRBUS URBAN MOBILITY GMBH

Hybrid hydrogen storage container and method of storing hydrogen in container

InactiveUS7681753B2Reduce uneven distributionImprove volumetric efficiencyLarge containersPressure vesselsEngineeringHydrogen absorption

A pressure container 1 composed of a reinforcing layer 2 and a liner layer 3, with a hydrogen charging pressure of 30 MPa or higher; and a hydrogen absorbing material and a carrier for holding said hydrogen absorbing material (hydrogen absorbing material portion 4) contained in the pressure container 1 are included, and a volume fraction X of the hydrogen absorbing material with αm≧100 kg / m3 with respect to an internal volume of the pressure container 1 is 5(%)≦X≦20(%), where αm denotes a maximum hydrogen absorption amount per unit volume of the hydrogen absorbing material (kg / m3); X=100 ·Vm / Vi (%); Vi is an internal volume of the pressure container (L); and Vm is a volume of the hydrogen absorbing material in the pressure container (L).

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Fire-extinguisher placing box

The invention relates to a fire-extinguisher placing box. The fire-extinguisher placing box comprises a box body, a sealing plate and a rotary disc, wherein the rotary disc is provided with a placing assembly; the placing assembly is movably connected with at least one locking tongue; the box body is internally provided with a locking fastener; the rotary disc is provided with a weight sensor; the sealing plate is provided with a display panel; a first baffle is provided with a power supply module; and the locking fastener is internally provided with a circuit breaker. The fire-extinguisher placing box has the advantages that real-time weighing is carried out on a fire extinguisher by the weight sensor arranged at the bottom end of the rotary disc, and weight reading and displaying are carried out by the display panel, so that the error caused by weighing of an existing electronic scale and the workload caused by weighing are effectively reduced, and the weighing efficiency is greatly improved; the existing capacity of the fire extinguisher is accurately evaluated by displayed values to judge whether the fire extinguisher can be continuously used, so that the potential hazard of fire-fighting safety can be reduced, simultaneously the working error rate of workers can be reduced, and the overall efficiency of fire-fighting work can be improved; and an empty tank is alarmed by an alarming device.

Owner:STATE GRID CORP OF CHINA +2

Hybrid hydrogen storage container and method of storing hydrogen in container

InactiveUS20050166992A1Easy to installReduce uneven distributionLarge containersPressure vesselsEngineeringHydrogen absorption

A pressure container 1 composed of a reinforcing layer 2 and a liner layer 3, with a hydrogen charging pressure of 30 MPa or higher; and a hydrogen absorbing material and a carrier for holding said hydrogen absorbing material (hydrogen absorbing material portion 4) contained in the pressure container 1 are included, and a volume fraction X of the hydrogen absorbing material with αm≧100 kg / m3 with respect to an internal volume of the pressure container 1 is 5(%)≦X≦20(%), where am denotes a maximum hydrogen absorption amount per unit volume of the hydrogen absorbing material (kg / m3); X=100 ·Vm / Vi (%); Vi is an internal volume of the pressure container (L); and Vm is a volume of the hydrogen absorbing material in the pressure container (L).

Owner:NAT INST OF ADVANCED IND SCI & TECH +1

Weighing system

InactiveCN105953885ASolve individual needsImprove weighing efficiencyWeighing indication devicesLogisticsComputer terminalLoad cell

The embodiment of the present invention discloses a weighing system. The weighing system is used for hotel purchase and out-put and in-put of warehouse management, and comprises a weighing terminal, a weighing sensor, a local database, a transmission server, a query server, a mobile terminal and a cloud database, wherein the weighing terminal is connected with the transmission server through a network; the weighing terminal is also connected with the weighing sensor in a physical mode; the weighing terminal is also connected with the local database and the mobile terminal; the mobile terminal is also connected with the query server; the transmission server is connected with the cloud database through the network; and the cloud database is connected with the query server. By means of the weighing system, the weighing efficiency can be improved and the input cost can be reduced.

Owner:北京智衡物联科技有限公司

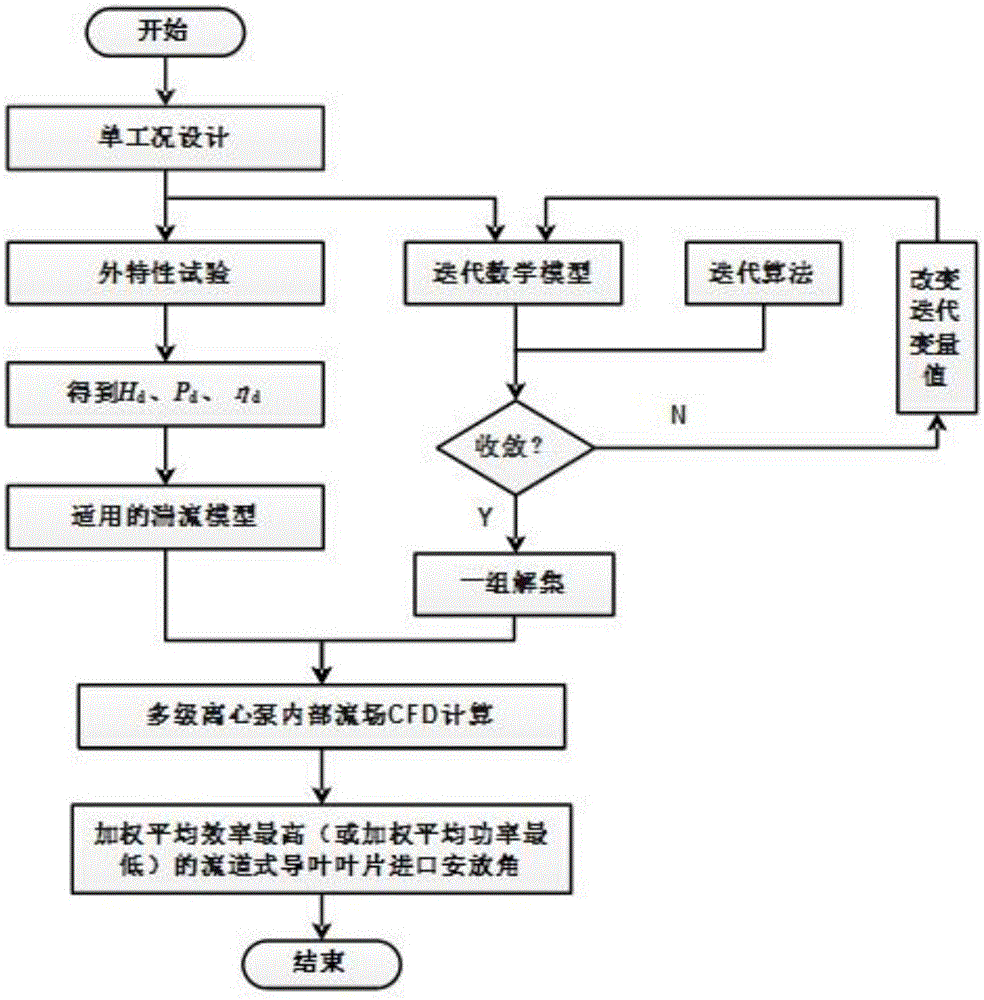

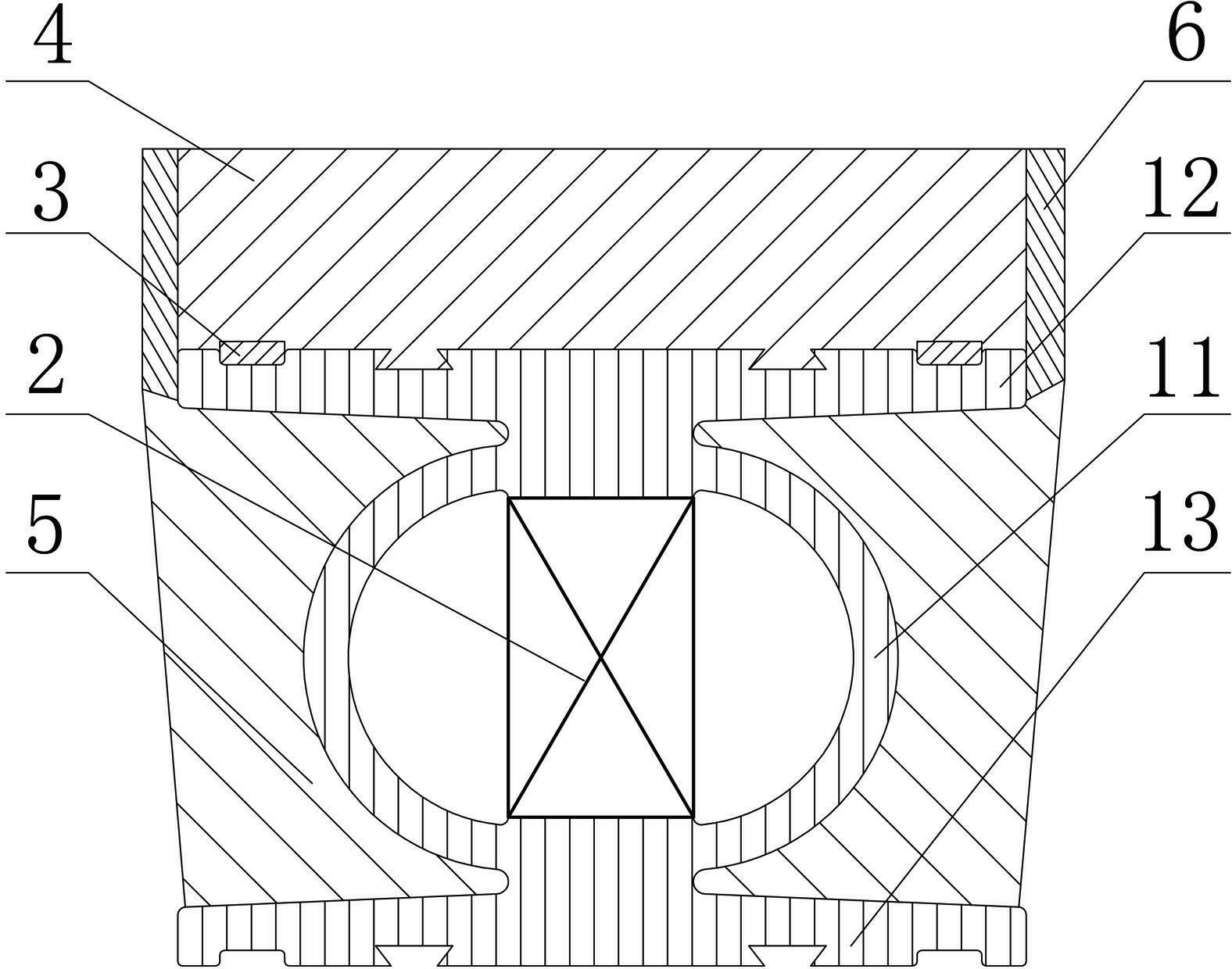

Hydraulic optimization method for flow channel type guide vane of multistage centrifugal pump under multiple working conditions

ActiveCN105156360AImprove weighing efficiencyWeighted average efficiency reductionPump componentsPumpsMathematical modelEngineering

The invention belongs to the field of fluid machinery design and discloses a hydraulic optimization method of a flow channel type guide vane of a multistage centrifugal pump under multiple working conditions. The hydraulic optimization method is mainly used for calculating out a vane inlet setting angle of the flow channel type guide vane of the multistage centrifugal pump with highest or lowest weighted average efficiency under the multiple working conditions. The hydraulic optimization method specifically comprises the followings steps: measuring the flow, lift, power and efficiency of the multistage centrifugal pump under the multiple working conditions; solving an iterative mathematical model of the vane inlet setting angle of the flow channel type guide vane by adopting an iterative algorithm and working out a set of solution sets of the inlet setting angle; and carrying out total flow field numerical-calculation on internal flow fields of the multistage centrifugal pump under the multiple working conditions by adopting a CFD technology so as to obtain an optimum value of the guide vane inlet setting angle. The vane inlet setting angle of the flow channel type guide vane of the multistage centrifugal pump, designed by the adopting the method provided by the invention, is more accurate than the inlet setting angle designed under a single working condition, the weighted average efficiency of the multistage centrifugal pump under the multiple working conditions is improved and a reference is provided for optimization of other geometric parameters of the impellers and guide vanes of the multistage centrifugal pump under the multiple working conditions.

Owner:JIANGSU UNIV

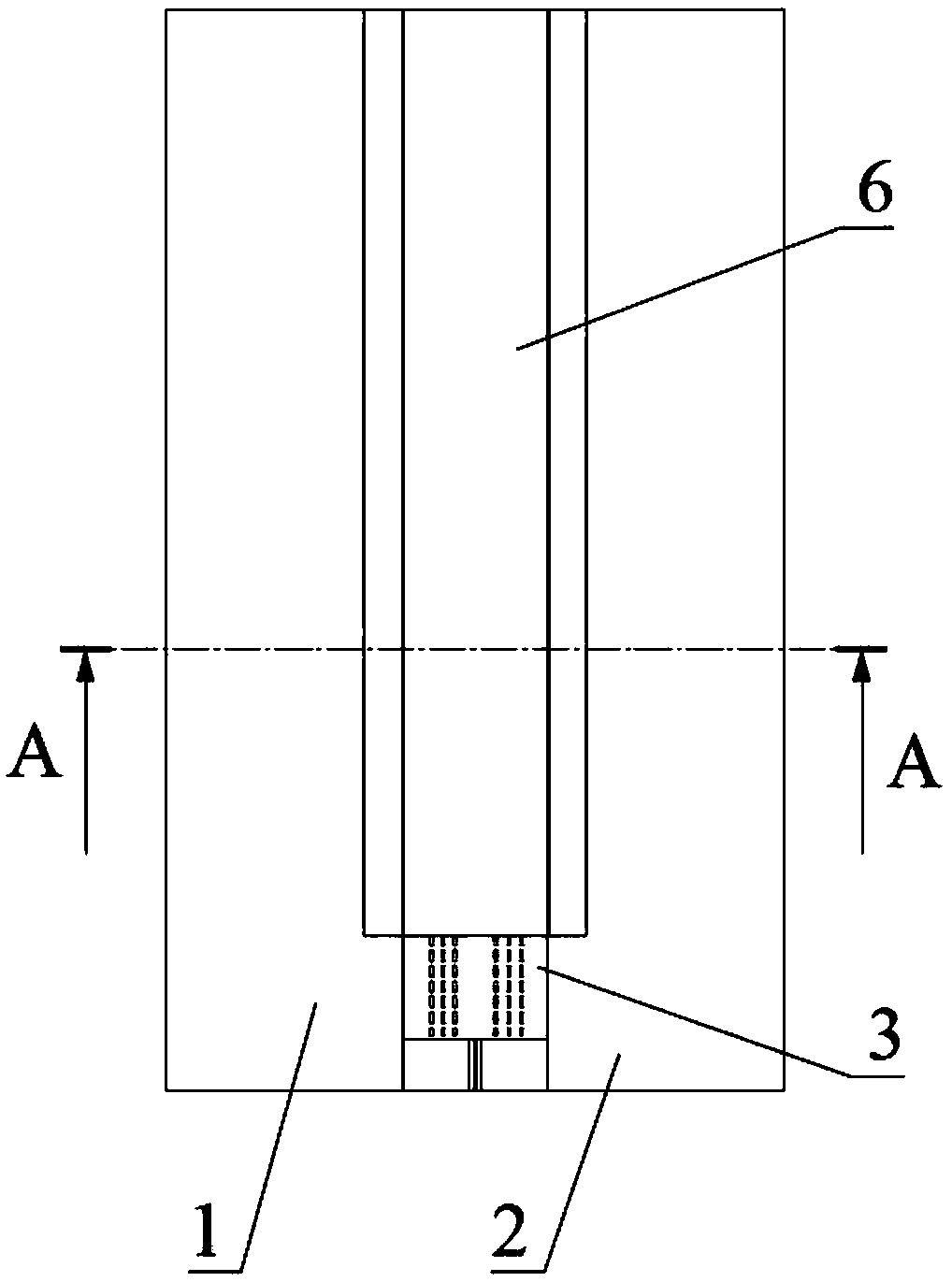

Dynamic weighing piezoelectric sensor for vehicle

ActiveCN102564548AAccurate dynamic measurementHigh precisionSpecial purpose weighing apparatusStress profileElectricity

The invention provides a dynamic weighing piezoelectric sensor for a vehicle. The dynamic weighing piezoelectric sensor comprises a weighing stress profile and a quartz piezoelectric sensor; the weighing stress profile comprises a stress deformation cavity, a weighing stress top plate and a weighing supporting bottom plate; the quartz piezoelectric sensor is arranged in the stress deformation cavity; the upper and lower stress surfaces of the quartz piezoelectric sensor are respectively in contact with the upper and lower deformation stress inner cavity surfaces of the stress deformation cavity; the weighing stress top plate is arranged in parallel to the weighing supporting bottom plate; the stress deformation cavity is arranged between the weighing stress top plate and the weighing supporting bottom plate; and the centers of the upper and lower outer cavity surfaces of the stress deformation cavity are respectively arranged in the centers of the weighing stress top plate and the weighing supporting bottom plate. The dynamic weighing piezoelectric sensor for the vehicle has the advantages of scientific design, capability of realizing dynamic measurement, high measurement value precision and high weighing efficiency, and is easy to produce and install.

Owner:郑州衡量科技股份有限公司

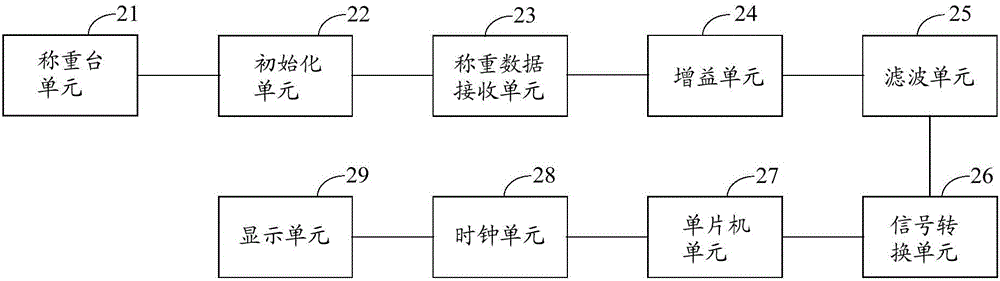

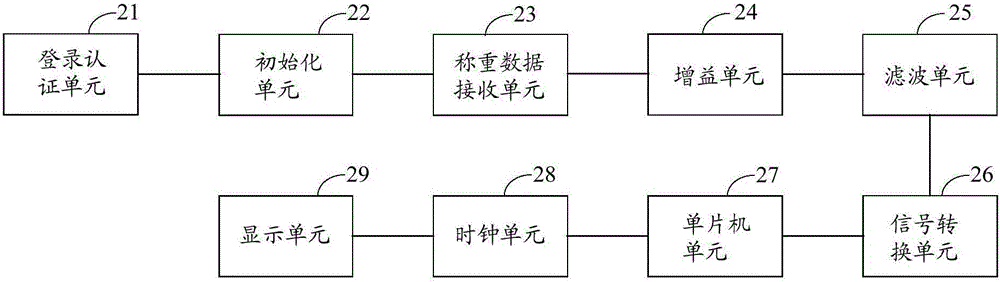

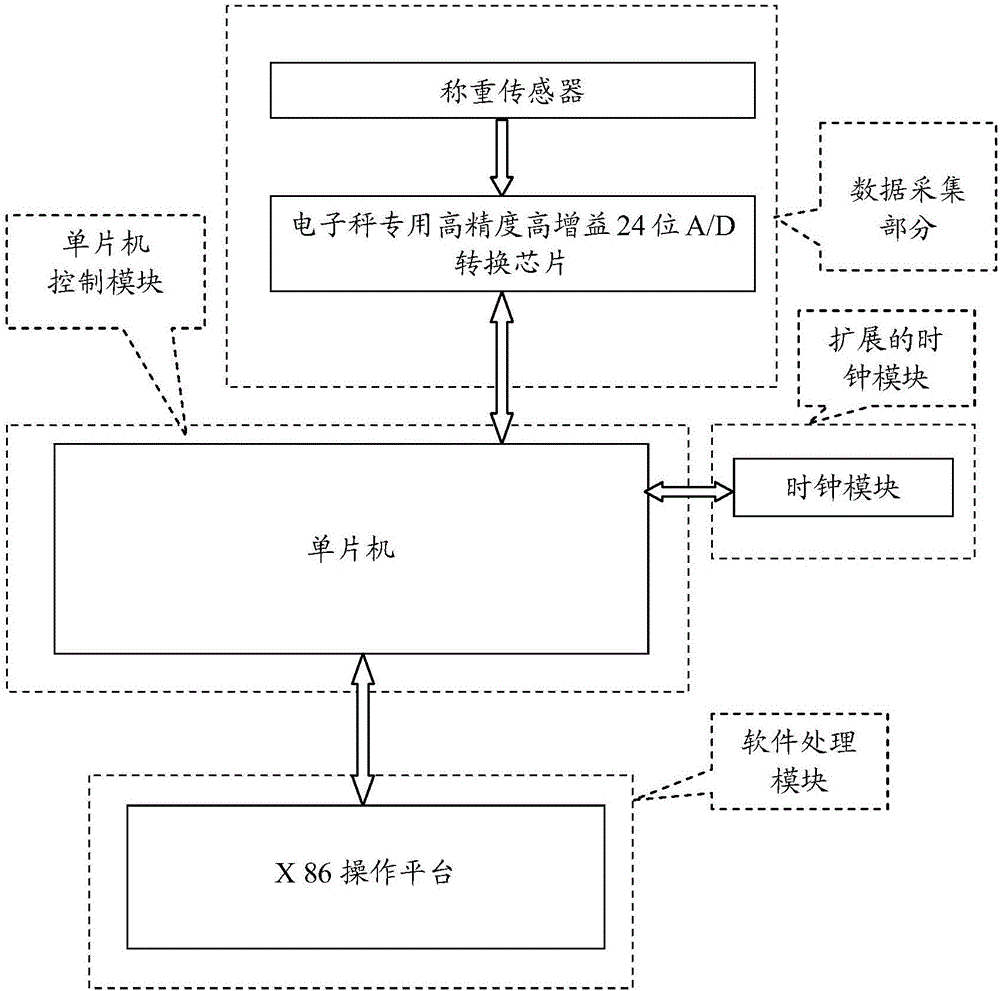

Weighing system

InactiveCN105953882ASolve individual needsImprove weighing efficiencyWeighing indication devicesLogisticsAdditive ingredientComputer terminal

The embodiment of the invention discloses a weighing system. The weighing system is applied to the weighing of materials in the factory, including: weighing terminals, weighing sensors and data servers. Among them, the weighing terminals, after startup, are initialized according to the information stored in the data server and receive operator input. The login information, after the login authentication is passed, read the bill of material information to start the weighing operation; receive the weighing data sensed by the weighing sensor, and store the weighing data and operator information in the data server; the weighing sensor receives the weighing The notification output by the weighing terminal collects the weighing data of the material placed in the weighing platform and outputs it to the weighing terminal; the data server is used to interact with the weighing terminal and initialize the weighing terminal; receive the information uploaded by the weighing terminal , update the corresponding stored information; receive the data query request, and return the result of the data query request. By applying the invention, the weighing efficiency can be improved and the input cost can be reduced.

Owner:北京智衡物联科技有限公司

System and method for differential weighing of items and reusable container for use therewith

InactiveUS20130232021A1Efficiently effectEliminate useDigital computer detailsCash registersEngineeringNet Weight

A differential weighing method for determining the weight of an item or a group of like items that must be weighed, and a reusable container for use in the differential weighing process. The reusable container may be, for example, a reusable basket or bag. The reusable container is sized to fit on the load receiving surface of the differential weighing scale or is equipped with a series of bottom locating projections that contact the load receiving surface and transfer the weight of the container and its contents thereto when the container sits on the scale. The scale is adapted for differential weighing, whereby the scale will report the weight of an item or group of like items that are removed from the reusable container as a positive net weight.

Owner:METTLER TOLEDO INC

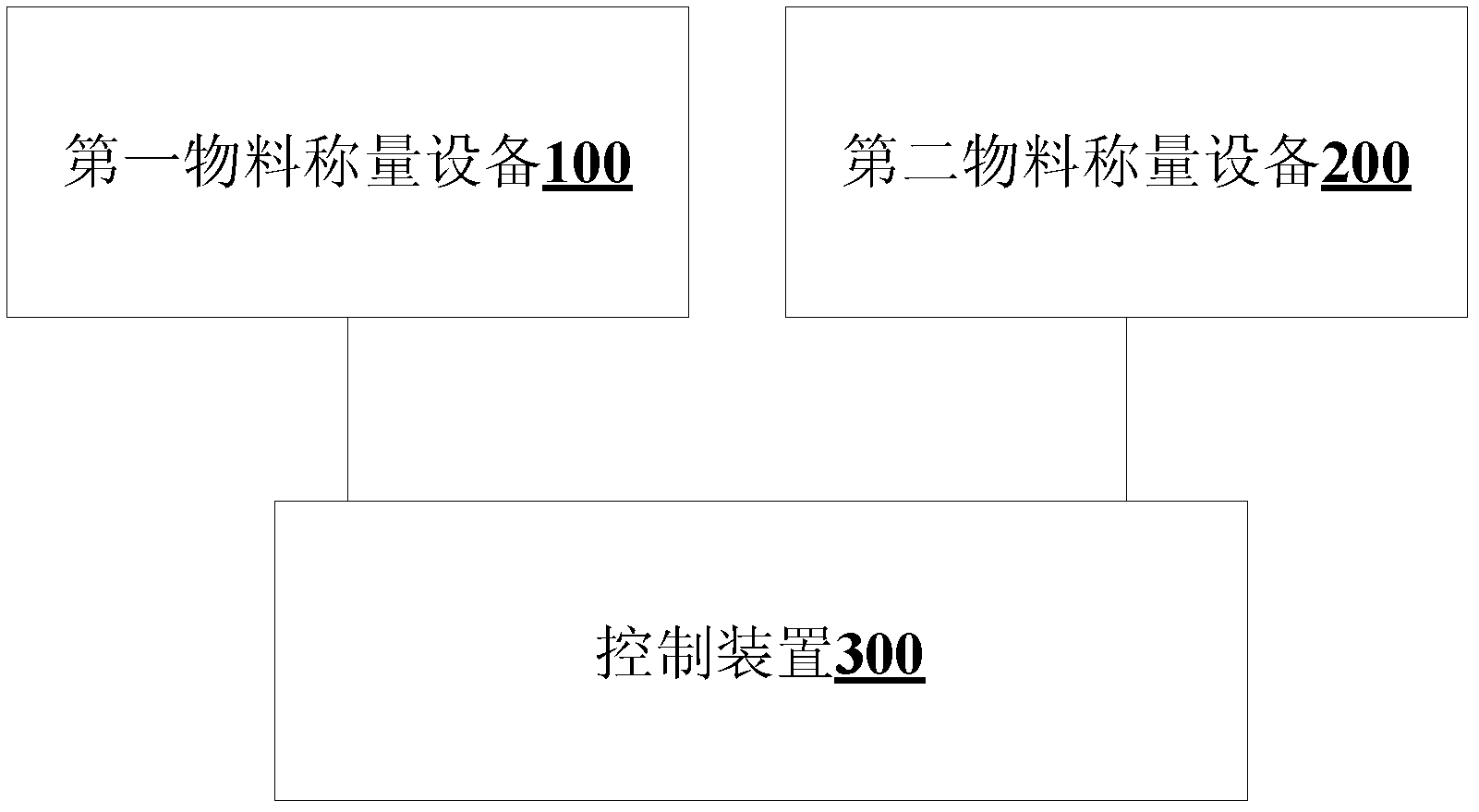

Powder ash material weighing system and weighing method

ActiveCN102680061AImprove weighing efficiencyRealize precisionWeighing apparatus with automatic feed/dischargeStart upMechanical engineering

The invention provides a powder ash material weighing system and a weighing method. The powder ash material weighing system comprises at least two pieces of material weighing equipment and a control device, wherein the control device is connected with each piece of material weighing equipment; different pieces of material weighing equipment are used for weighing material with different precisions; and the control device is used for sending weighing signals with different precisions according to the expected calculated value of powder ash material and the calculated value after powder ash material is weighed, and for driving start-up and closing of different pieces of material weighing equipment according to the weighing signals with different precisions. According to the invention, the control device is used for controlling the at least two pieces of material weighing equipment with different precisions, so that precise weighing of powder ash material is further realized when rough weighing is realized, the weighing efficiency is high, and therefore, high-precision and high-efficiency weighing of material is realized.

Owner:SANY HEAVY IND CO LTD (CN)

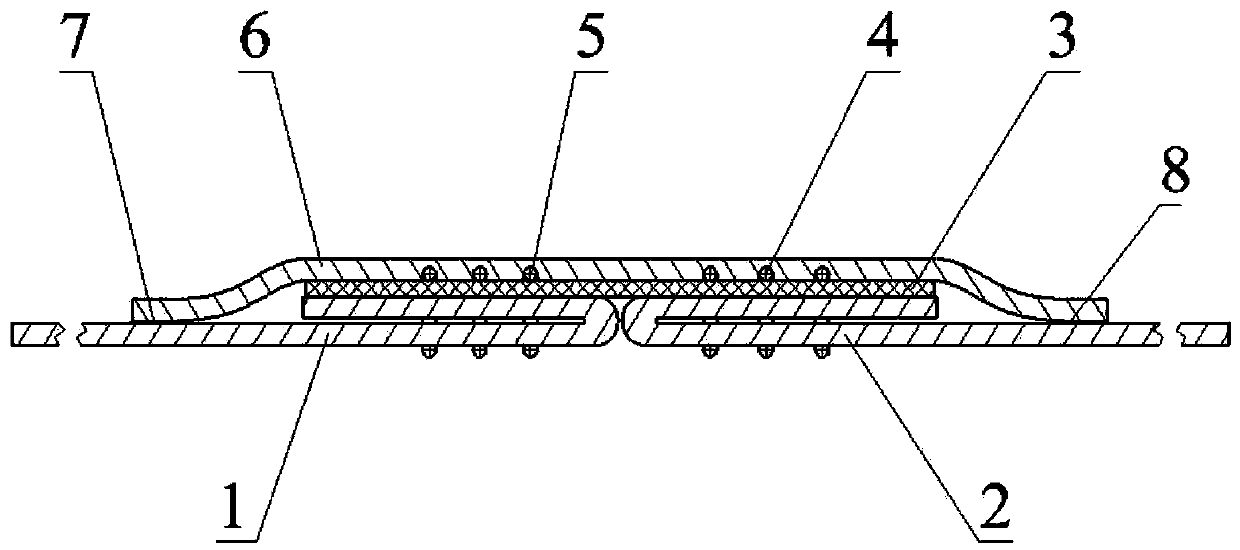

High-strength fiber reinforcement thin film sealing butt-joint structure universal for high altitude airship

Disclosed is a high-strength fiber reinforcement thin film sealing butt-joint structure universal for a high altitude airship. The high-strength fiber reinforcement thin film sealing butt-joint structure universal for the high altitude airship comprises left and right side butt-joint high-strength fiber reinforcement lamination composite universal skins, namely the left side skin and the right side skin, a middle reinforcement bearing layer, left side connecting sewing threads, right side connecting sewing threads, an inner side sealing film layer, a left side film layer sealing glue layer and a right side film layer sealing glue layer. The left side skin and the right side skin become the bottommost layers of the butt-joint structure. The middle reinforcement bearing layer, the left side skin and the right side skin are connected together through the left side connecting sewing threads and the right side connecting sewing threads. The inner side sealing film layer is the topmost layer of the butt-joint structure, covers connectors and then is in glue connection with the left side skin and the right side skin through the left side film layer sealing glue layer and the right side film layer sealing glue layer on the two sides, namely adhesive agents. According to the high-strength fiber reinforcement thin film sealing butt-joint structure universal for the high altitude airship, the technical difficult problems that in the butt-joint process of skin materials of the high altitude airship, the skin materials are high in welding intensity, and the helium leakage character is good are solved, the risk that the skin materials of the airship are torn and damaged at the butt joints of the skins in the high-altitude overpressure flying process of the high altitude airship is reduced, and the influence on the whole intensity of the airship in the skin high-frequency welding process is reduced.

Owner:BEIHANG UNIV

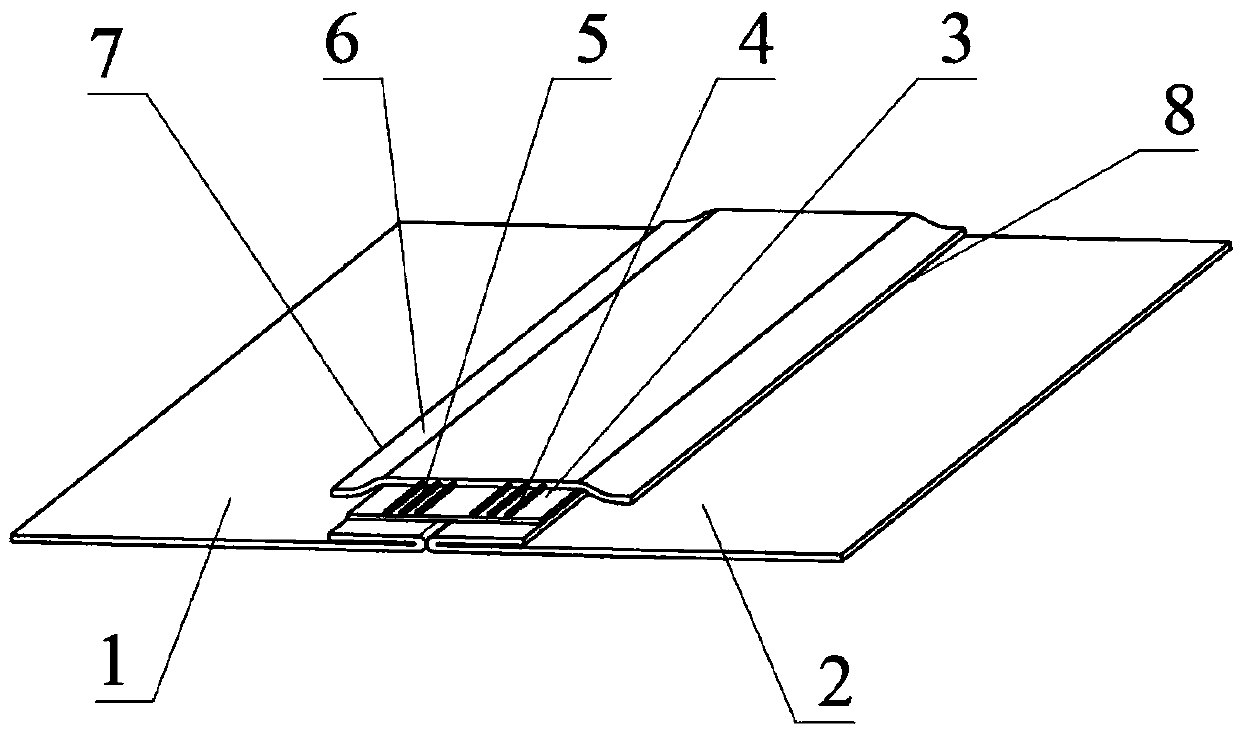

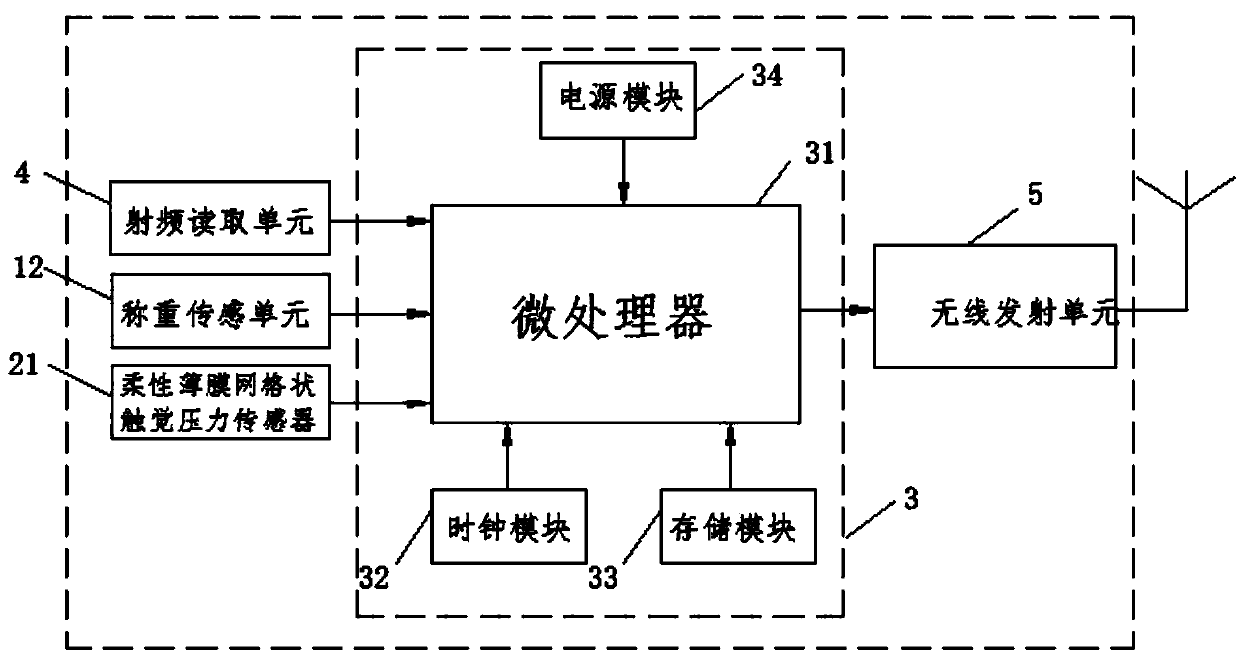

Automatic weight measuring device for cows

ActiveCN104198023AImprove efficiencySave human resourcesWeighing apparatus for materials with special property/formRadio frequencyWeight Unit

The invention relates to an automatic weight measuring device for cows. The automatic weight measuring device for cows comprises a weighting unit, a cow state sensing unit, a weighting and processing unit, a radio frequency reading unit, a wireless transmitting unit and a portable meter receiver, wherein the weighting unit comprises a weighting panel, a weighting base plate and a weighting sensor arranged between the weighting panel and the weighting base plate; a flexible thin film grid-shaped tactility pressure sensor is arranged in the cow state sensing unit and is placed on the weighting panel; a microprocessor is arranged in the weighting and processing unit; the information output end of the weighting sensor, the information output end of the flexible thin film grid shaped tactility pressure sensor and the information output interface of the radio frequency reading unit are connected to the input interface of the microprocessor; the output interface of the microprocessor is connected with the input interface of the wireless transmitting unit; the wireless transmitting unit is in wireless communication with a wireless receiving unit arranged on the portable meter receiver. The automatic weight measuring device for cows is simple to operate and convenient to maintain; massive human resources can be saved and real-time monitoring can be realized on the weight of cows.

Owner:北京东方联鸣科技发展有限公司

Feedstuff crushing and proportioning machine

ActiveCN105728122ARealize simultaneous weighingImprove weighing efficiencyGrain treatmentsEngineeringLoad cell

The invention discloses a feedstuff crushing and proportioning machine. A left weighing hopper and a right weighing hopper are mounted on a bracket platform through supporting columns, electromagnetic valves are respectively mounted at a discharge opening of the left weighing hopper and a discharge opening of the right weighing hopper, and weighing sensors are mounted at the lower ends of the supporting columns and are electrically connected with a PLC; a crushing casing is mounted under the bracket platform, and a crushing device is mounted in the crushing casing; the crushing device comprises a horizontal rotating shaft, vertical rotating shafts, vertical crushing blades and horizontal crushing blades, wherein the vertical crushing blades are integrally arranged on the outer wall of the horizontal rotating shaft, the vertical rotating shafts are integrally shaped at two ends of the horizontal rotating shaft, and the horizontal crushing blades are integrally shaped on the outer walls of the vertical rotating shafts. The machine has the advantages of being rapid in proportioning, high-efficient and thorough in crushing and the like, and is suitable for large-scale popularization.

Owner:ANHUI QUANJIAO WEILAI FEEDS CO LTD

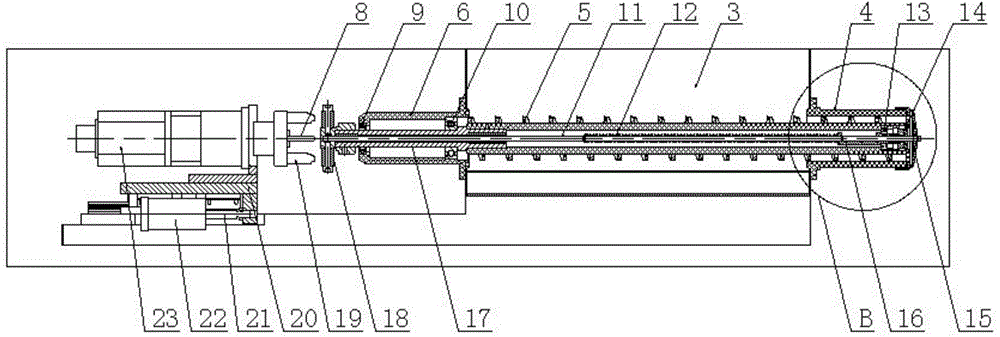

Powdery dyestuff feeding device with rotary-dialing mechanical arm

InactiveCN104803207AImprove weighing efficiencyAvoid pollutionConveyorsLoading/unloadingElectric machineryWorking environment

The invention relates to a powdery dye feeding device. The powdery dye feeding device comprises a dye box, a screw conveyor, a front feeding end cover, a rear feeding end cover and a rotary shifting manipulator, the front feeding end cover is fixedly mounted on one side of the dye box, the rear feeding end cover is fixedly mounted on the other corresponding side, the screw conveyor is arranged in the dye box and rotatably mounted between the front feeding end cover and the rear feeding end cover, the rotary shifting manipulator is correspondingly mounted on one side of the rear feeding end cover and drives the screw conveyor to feed rotatably, and a discharge hole is made on the front feeding end cover. The powdery dye feeding device has the advantages that the powdery dye feeding device is simple in structure, scientific and reasonable in design, capable of effectively improving dyeing recipe weighing efficiency and good in weighing repeatability, pollution of powder to working environments is avoided, labor is freed, and the working environments are improved.

Owner:杭州三拓科技有限公司

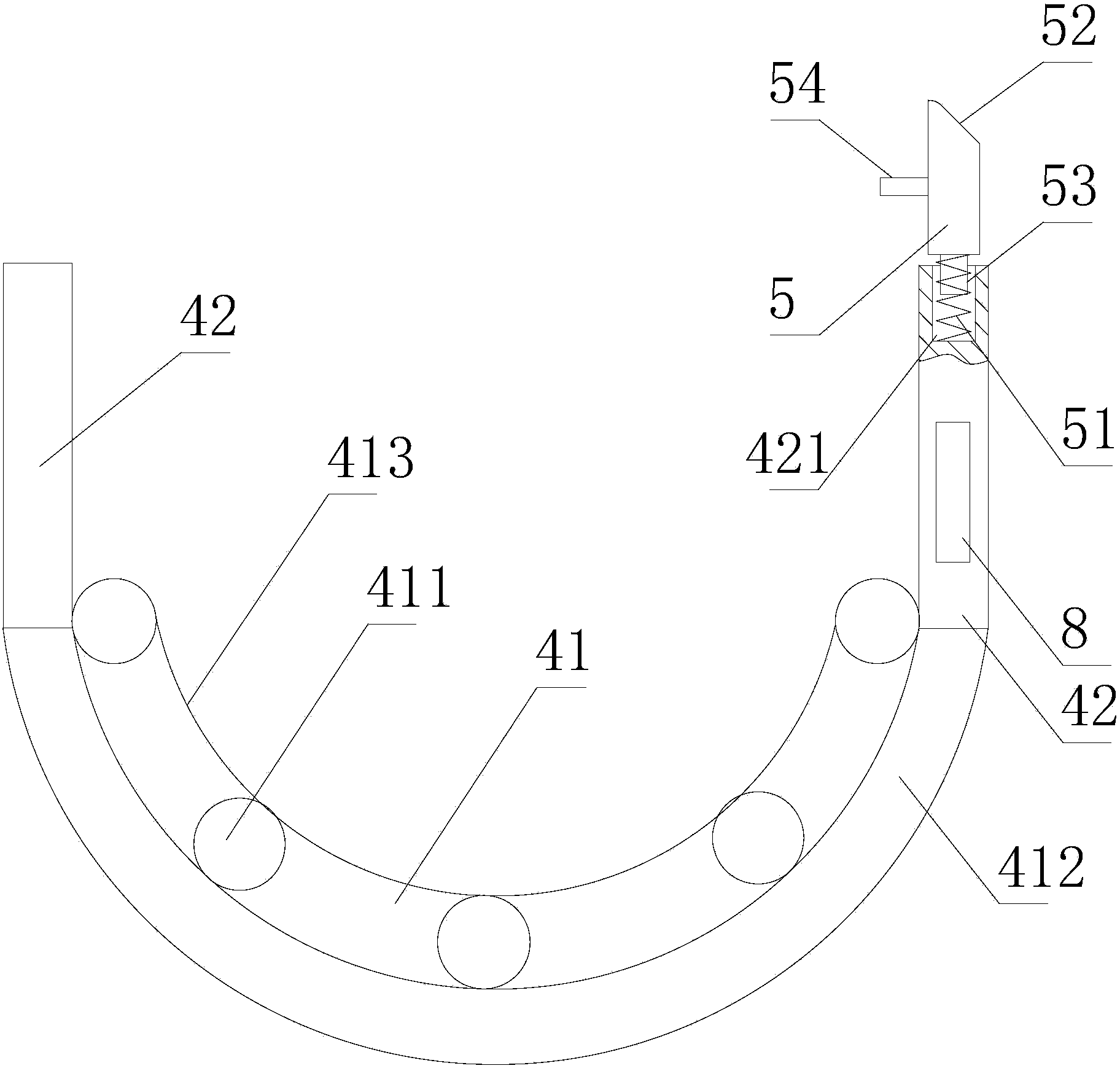

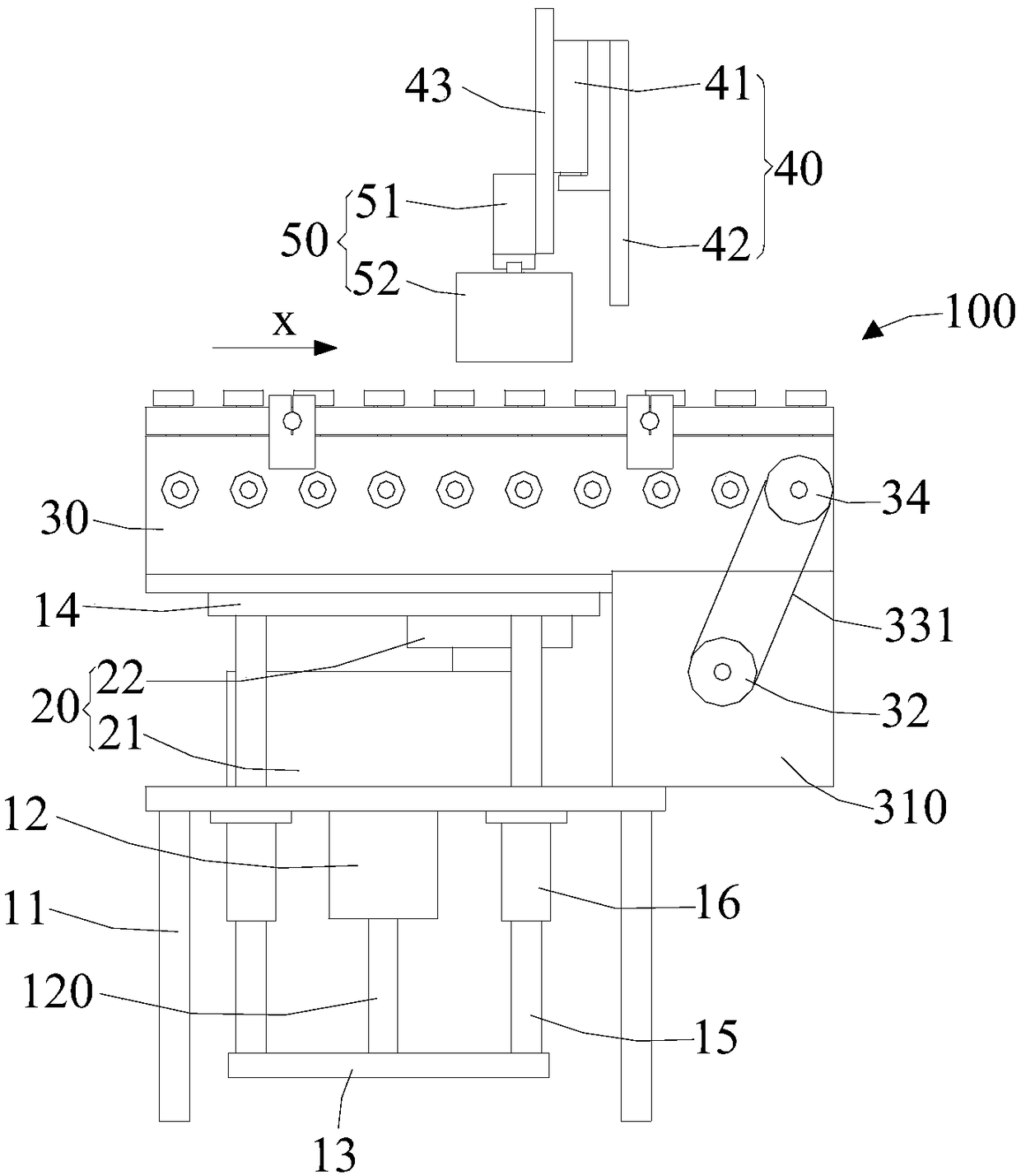

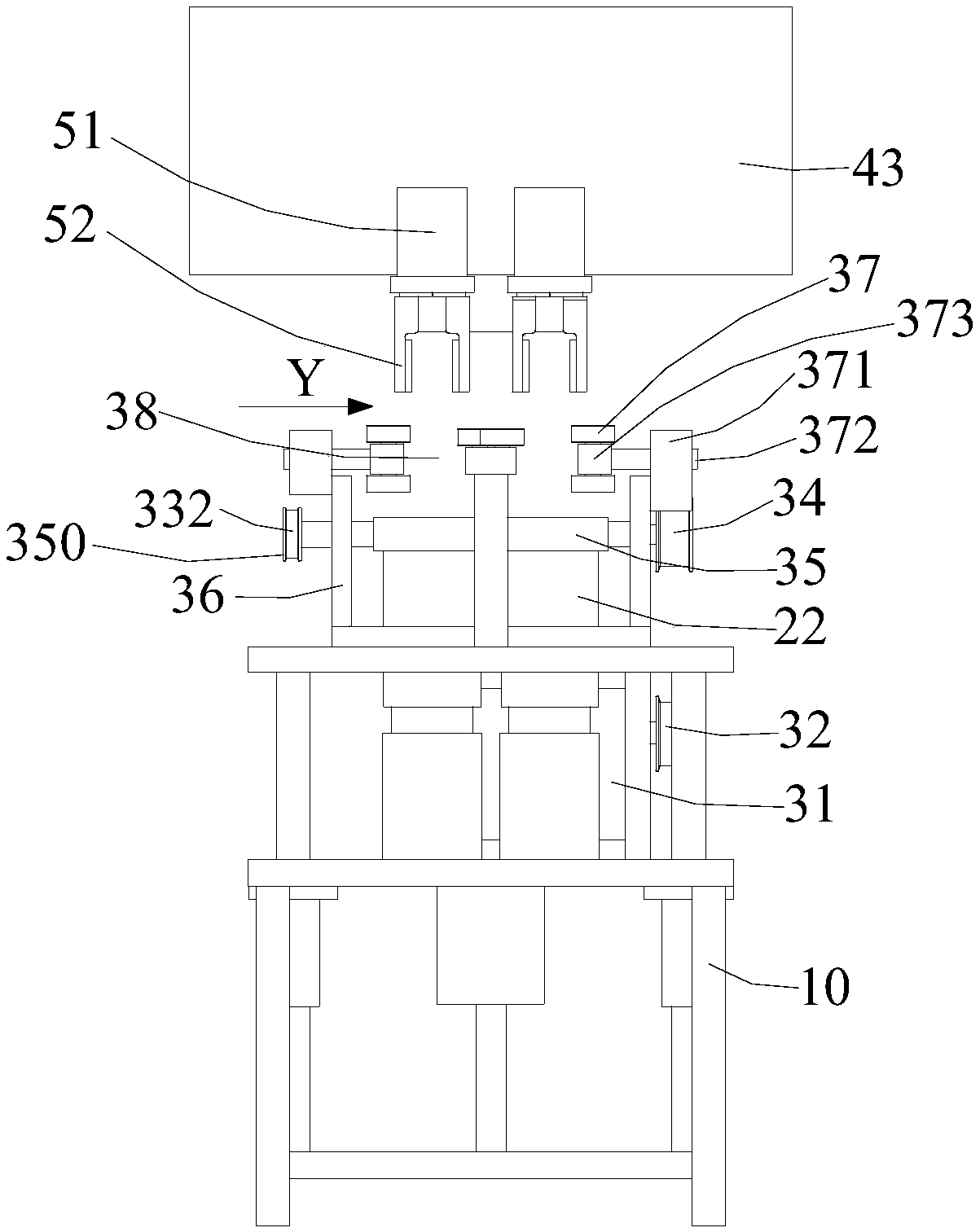

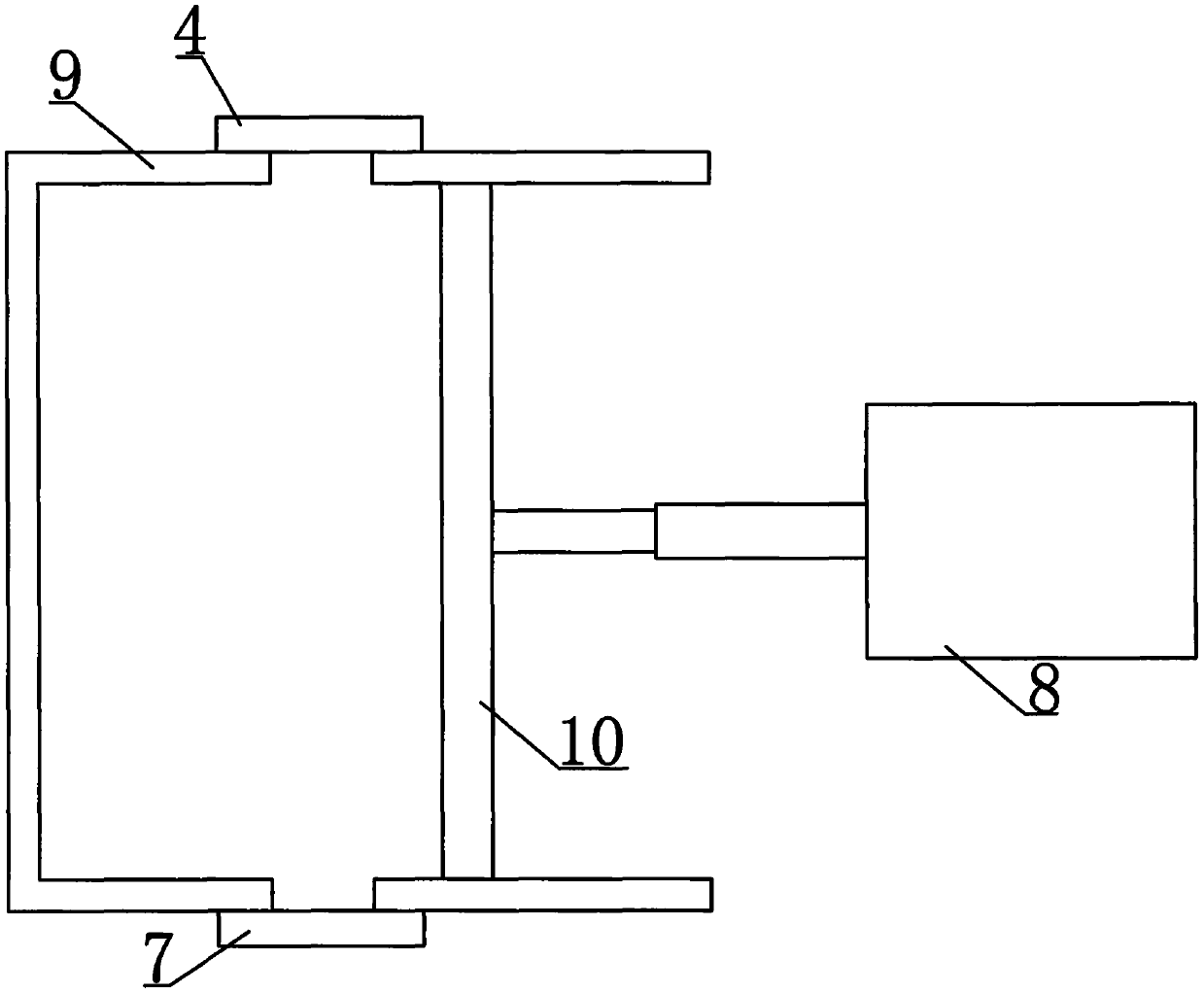

Automatic weighing system applicable to medium-low flow ambient air particulate filter membrane

InactiveCN105181518AReduce distractionsImprove weighing efficiencyWeighing by absorbing componentParticulatesUltimate tensile strength

The invention discloses an automatic weighing system applicable to a medium-low flow ambient air particulate filter membrane. The system comprises a constant temperature and constant humidity box (1), a supporting base (2), a storage rack (3), a manipulator (4) and a weighing device (5), wherein the supporting base (2), the storage rack (3), the manipulator (4) and the weighing device (5) are all arranged in the constant temperature and constant humidity box (1); the supporting base (2) is arranged at the bottommost in the constant temperature and constant humidity box (1); the storage rack (3) is mounted on the left side of the rear part of the upper surface of the supporting base (2); the weighing device (5) is mounted on the right side of the rear part of the upper surface of the supporting base (2); the manipulator (4) is mounted at the front part of the upper surface of the supporting base (2). The system is applicable to weighing a medium-low flow circular filter membrane sample; the whole weighing process is operated by a machine without manual intervention, the labor intensity of weighing workers is reduced, and the weighing accuracy and stability are improved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

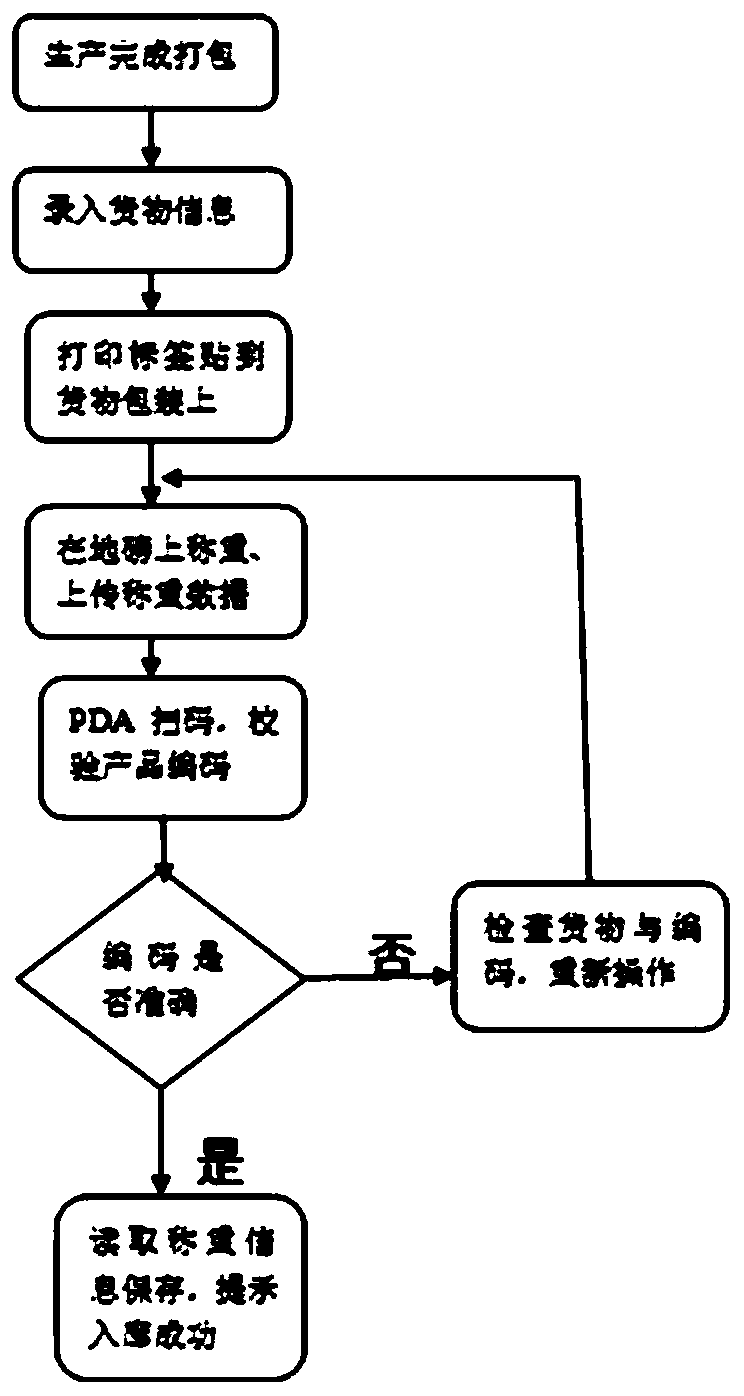

Intelligent logistics warehouse cargo weighing management method and system

InactiveCN110704701ASolution accuracy and low weighing efficiencyReduce stepsOther databases queryingLogisticsData miningInformation storage

The invention discloses an intelligent logistics warehouse cargo weighing management method. The method is used for weighing goods through a weighbridge and comprises: acquiring weighing information and warehousing goods code information of the warehousing goods, and when it is judged that the warehousing goods code information is consistent with a preset product production number, uploading the weighing information of the warehousing goods to a server; obtaining weighing information and warehouse-out goods coding information of warehouse-out goods; when it is judged that the warehouse-out goods code information is consistent with the warehouse-in goods code information through comparison, sending the warehouse-out goods code information to a server; identifying and comparing the weighinginformation of the warehouse-out goods with the weighing information of the warehouse-in goods, and uploading the weighing information of the warehouse-out goods to a server when the weighing information of the warehouse-out goods is consistent with the weighing information of the warehouse-in goods; detecting the current network transmission state in real time, and storing the weighing information of the warehouse-in goods and the weighing information of the warehouse-out goods in a local database when it is confirmed that the current network is offline.

Owner:广州市微嵌计算机科技有限公司

Online type automatic weighing device and method thereof

PendingCN109292431ASimple weighing methodHigh degree of automationWeighing apparatus for continuous material flowRollersIndustrial engineeringAutomation

Disclosed is an online type automatic weighing device and a method thereof. The online type automatic weighing device comprises a lifting mechanism, a weighing mechanism and a roller conveying line. The lifting mechanism comprises a lifting driving part and a lifting platform, and the lifting platform can do rising and falling motion under driving of the lifting driving part. The roller conveyingline is downwards supported on the lifting platform and comprises a plurality of rollers used for conveying products in the first direction. When the rollers fall along with the lifting platform, theproducts leave the rollers and then are supported on the weighing mechanism to be weighed, the products in the conveying process are automatically weighed on the roller conveying line, the weighing mode is simple, the automation degree is high, weighing efficiency is high, and production cost is lowered.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Weighing system

InactiveCN105953883AImprove weighing efficiencyLow input costWeighing indication devicesLogisticsComputer terminalLoad cell

The embodiment of the present invention discloses a weighing system. The weighing system comprises a weighing terminal, a weighing sensor, a transmission server and a cloud database, wherein the weighing terminal is connected with the transmission server through a network; the weighing terminal is also connected with the weighing sensor in a physical mode; and the transmission server is connected with the cloud database through the network. By means of application of the weighing system, the weighing efficiency can be improved and the input cost can be reduced.

Owner:北京智衡物联科技有限公司

Quantitative package scale and weighing method

The invention belongs to a quantitative package scale and a weighing method. The quantitative package scale comprises a material bin and a scale bucket. A quantitative discharging unit is arranged between the material bin and the scale bucket. The quantitative discharging unit comprises a volume changeable type quantitative discharging bin unit and a compensating type quantitative discharging binunit. The volume changeable type quantitative discharging bin unit and the compensating type quantitative discharging bin unit are arranged between the material bin and the scale bucket side by side.A shell is arranged on the outer side between the material bin and the scale bucket. The scale bucket is provided with a weighing sensor. A bottom discharging opening of the scale bucket is provided with a discharging baffle provided with an air cylinder. The shell is provided with a control unit for controlling the volume changeable type quantitative discharging bin unit and the compensating typequantitative discharging bin unit. The quantitative package scale has the advantages that the structure is simple, design is reasonable, operation is convenient, the package scale is applicable to particular materials, and the problem that the difference between the actual weight and the rated weight is too large can be solved effectively.

Owner:中能达(厦门)自动化科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com