Automatic weighing metering system and method for granary

An automatic weighing and metering system technology, applied in weighing, weighing equipment with special properties/forms of materials, calculations, etc., can solve problems such as increasing personal weight, fraudulent grain transporters, incomplete parking of vehicles, etc. Achieve the effect of avoiding large traffic flow, saving manpower and material resources and automation, and reducing manpower allocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

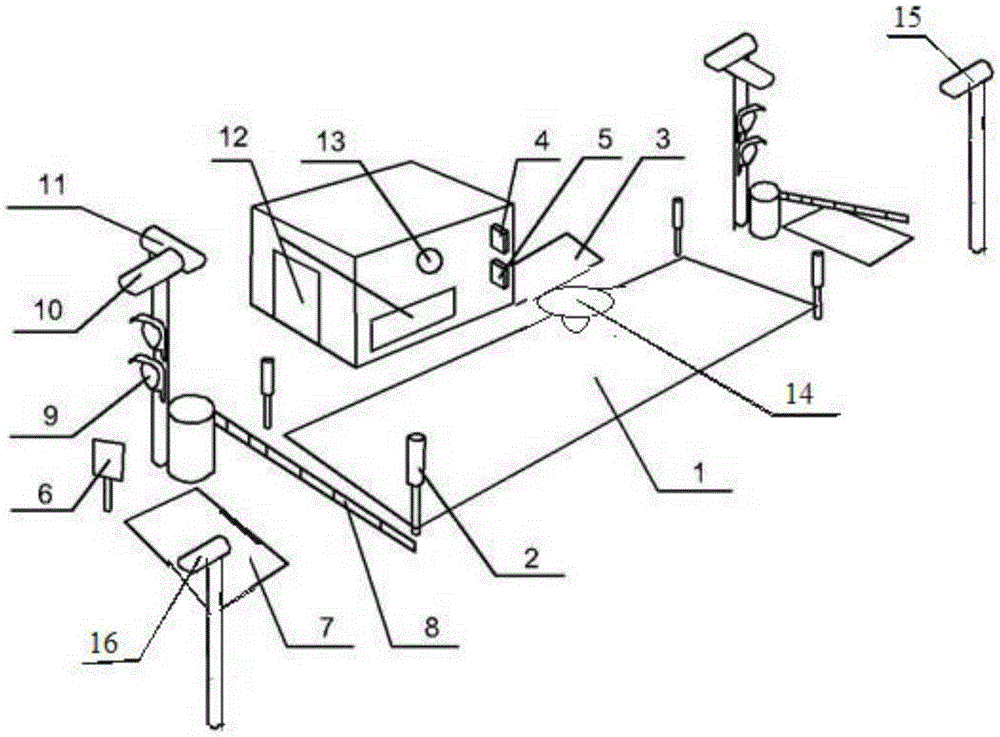

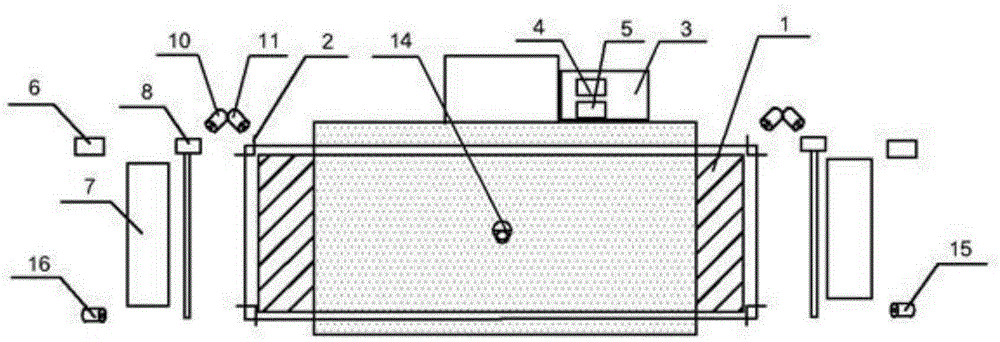

[0039] Such as Figure 1~2 As shown, the present invention provides an automatic weighing and measuring system for grain depots, comprising: a weighbridge 1, a plurality of infrared light curtain detectors 2 are arranged around it, and the plurality of infrared light curtain detectors 2 limit vehicles to enter the In the parking area behind the weighbridge 1, ensure that the vehicle is completely parked in the parking area before accurate weighing can be carried out. If the tire of the vehicle rolls outside the parking area, the broadcasting device 13 will automatically send a prompt sound to remind the driver that the vehicle is parked correctly. There is an upper computer, a waiting area 3 and a camera group next to the weighbridge 1. The upper computer can be installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com