Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37results about How to "Improve side impact performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

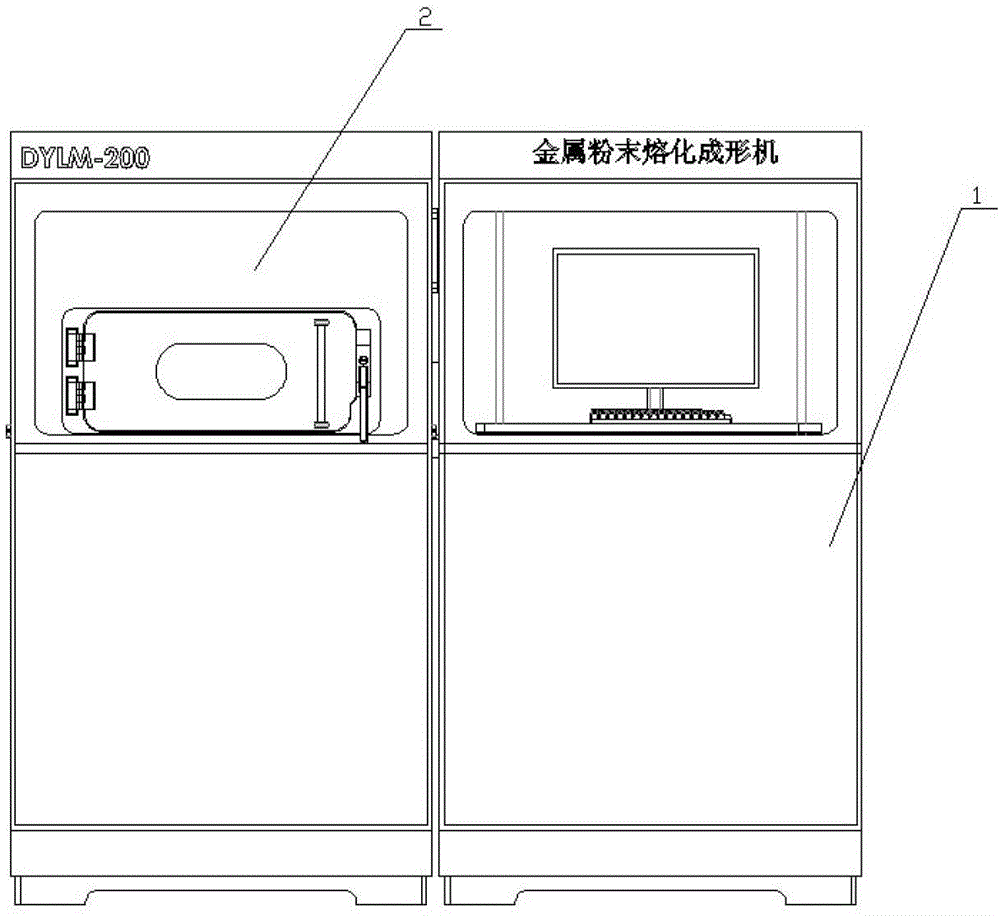

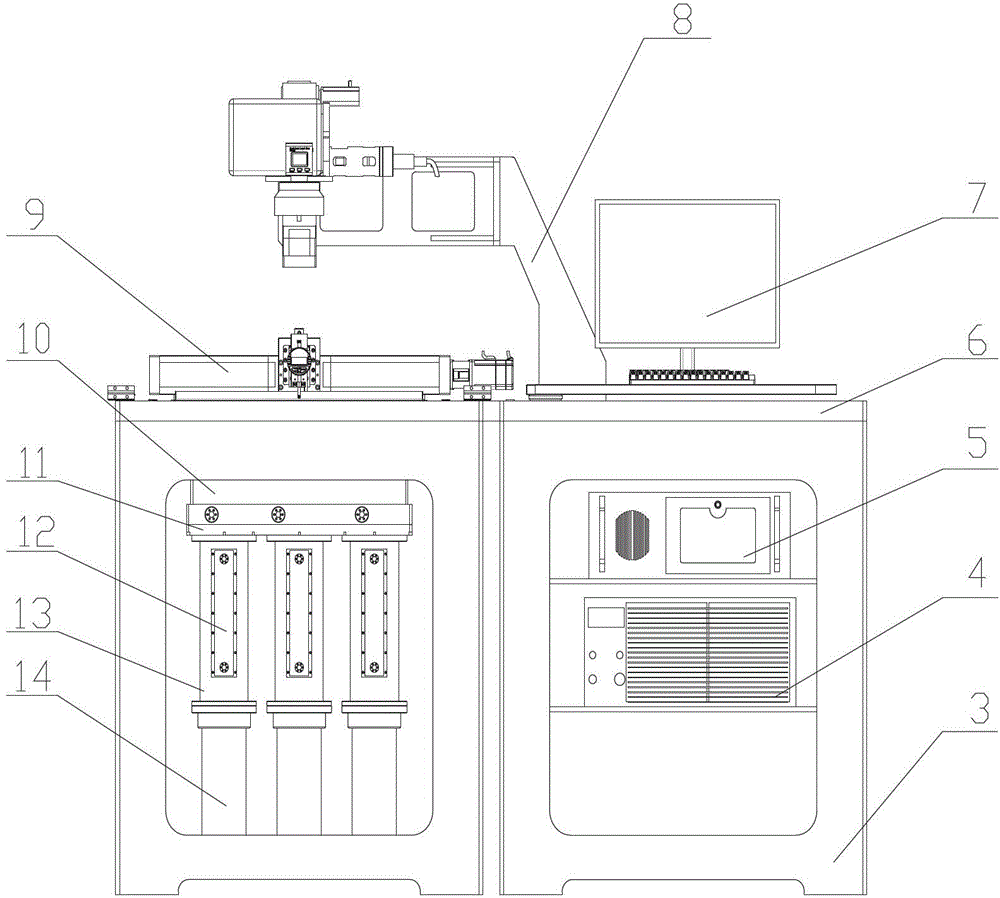

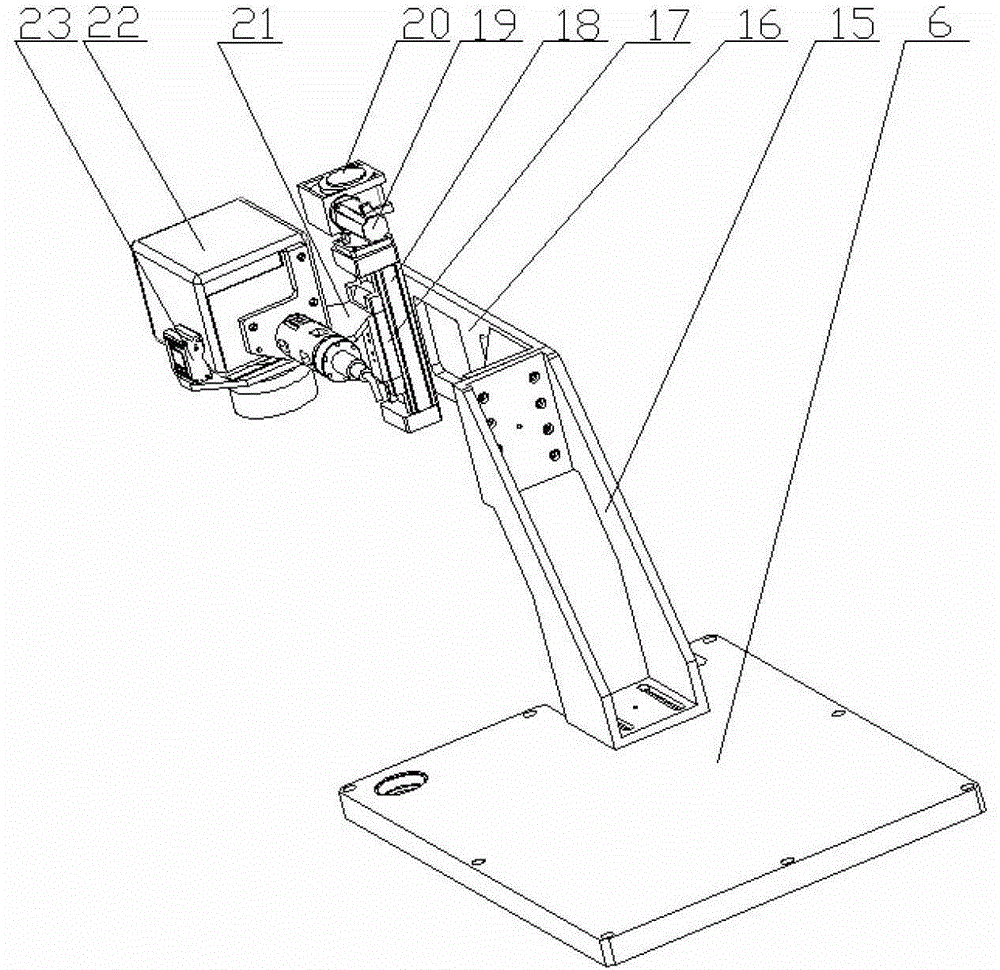

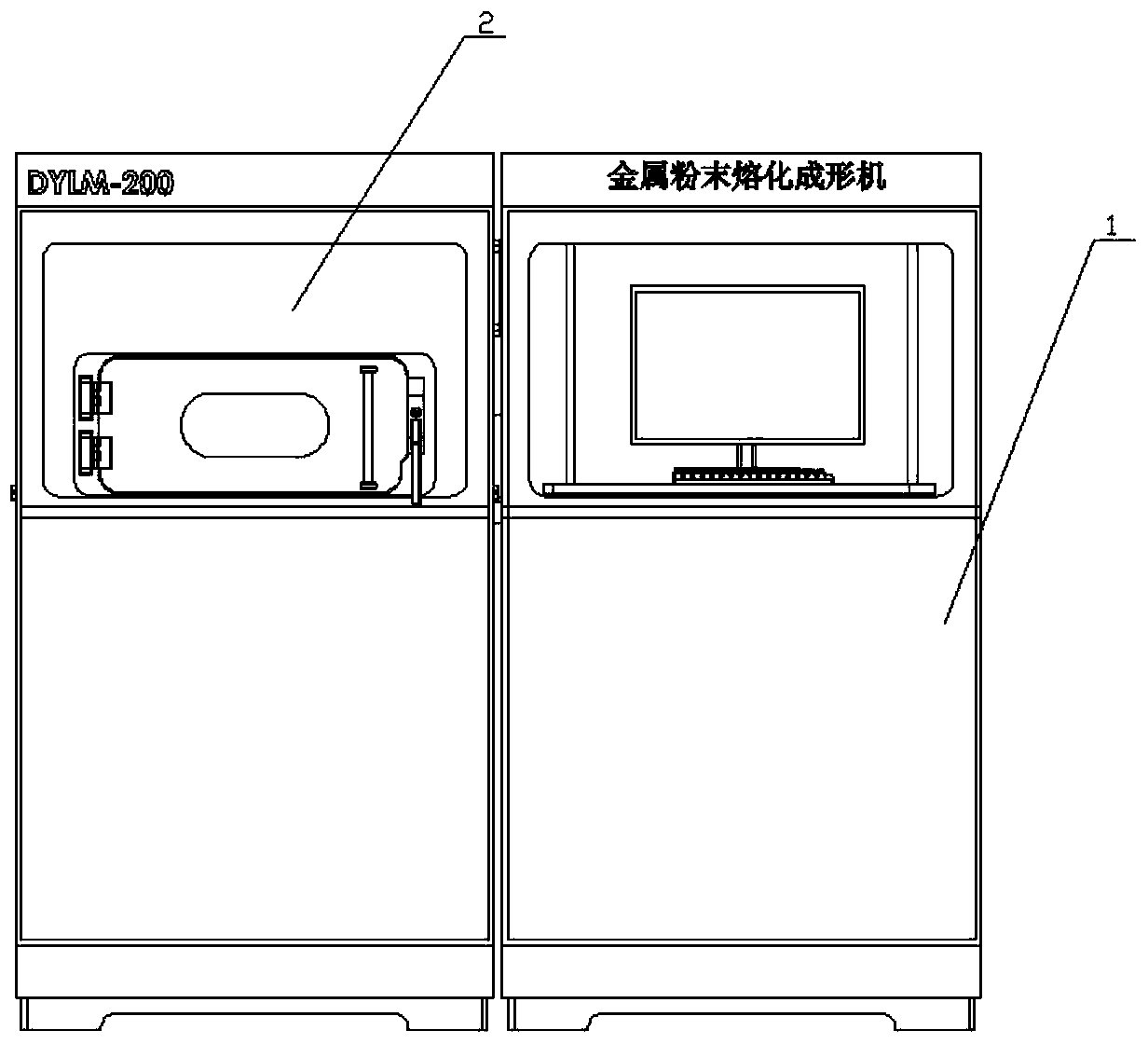

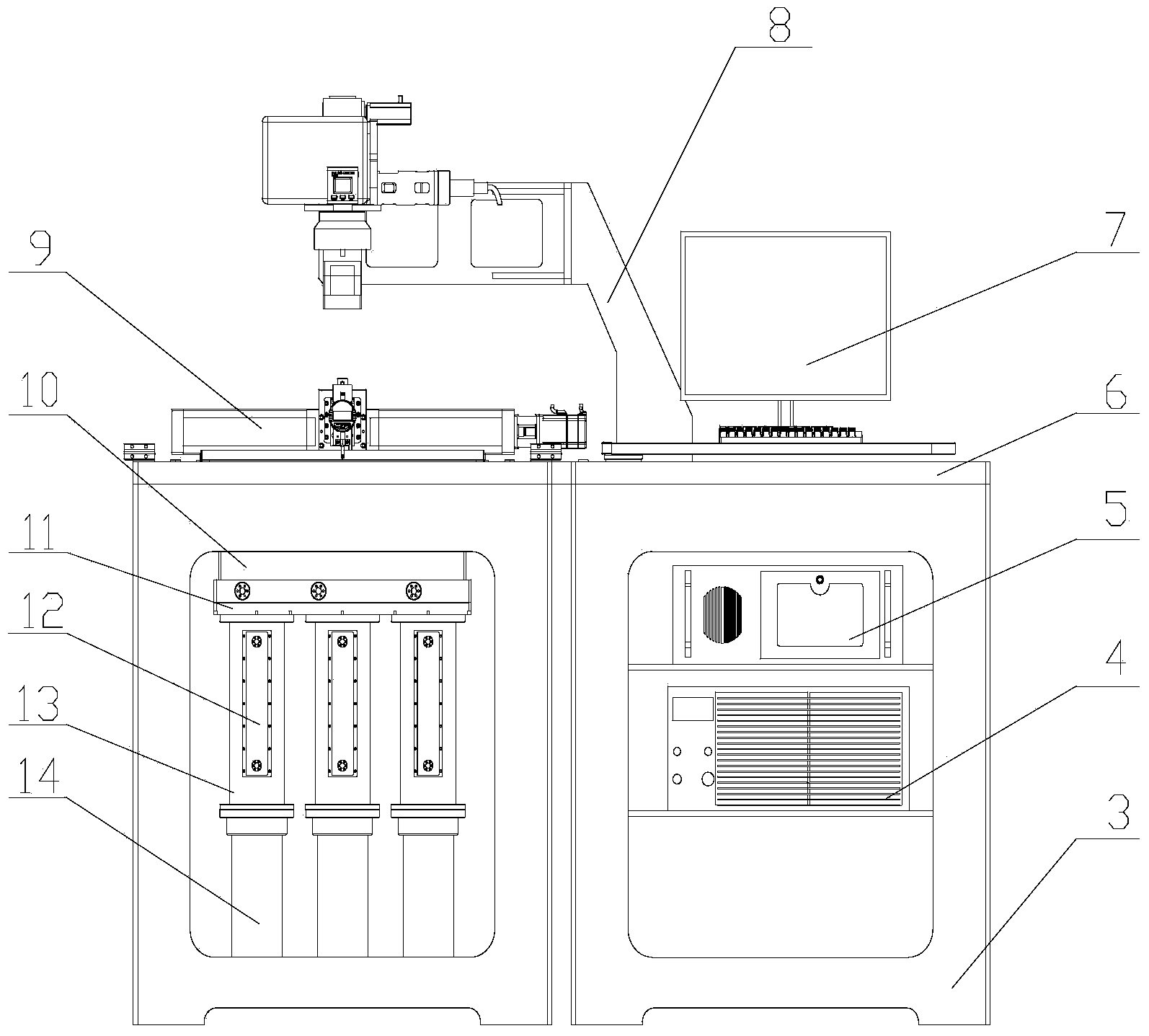

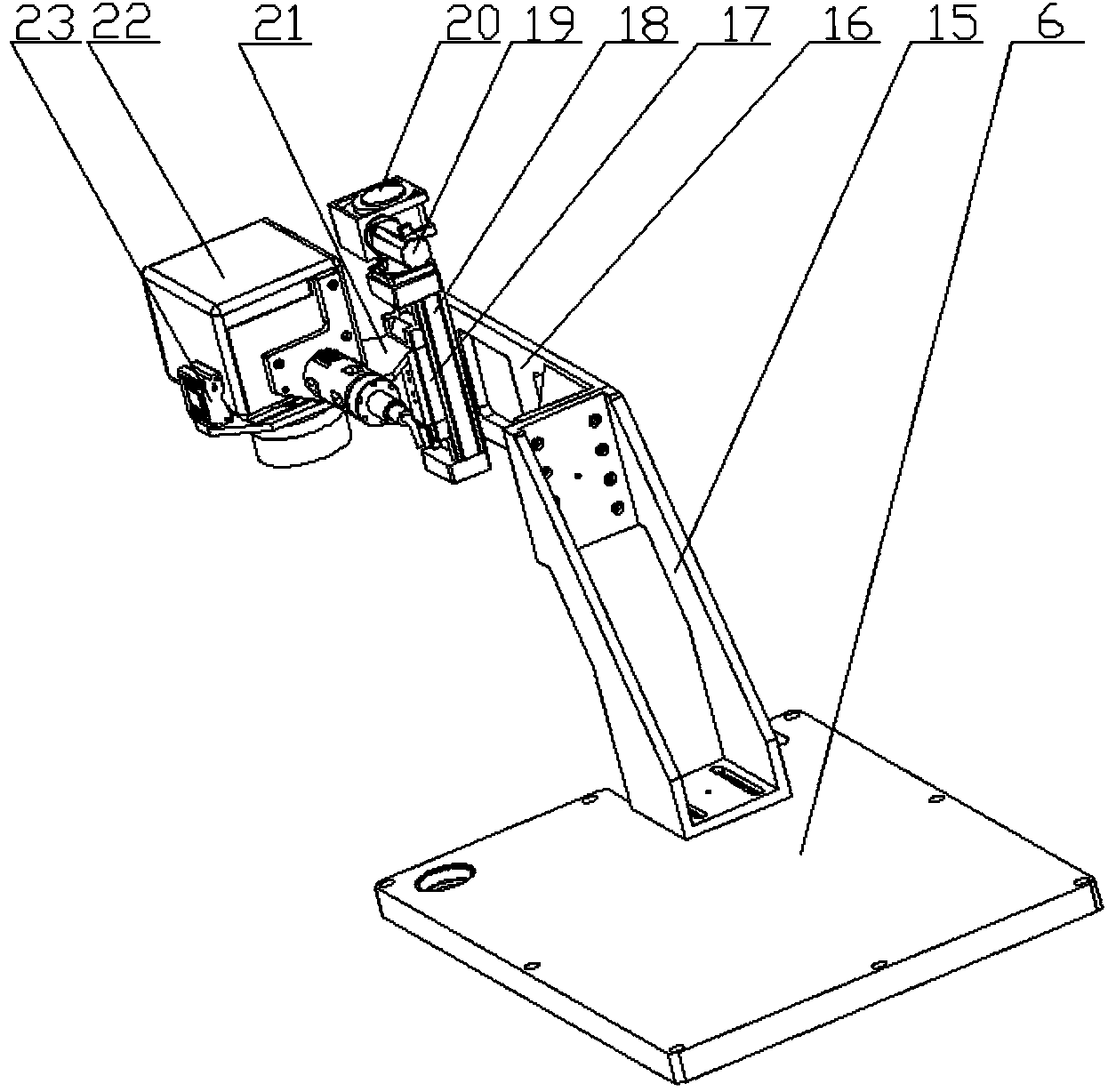

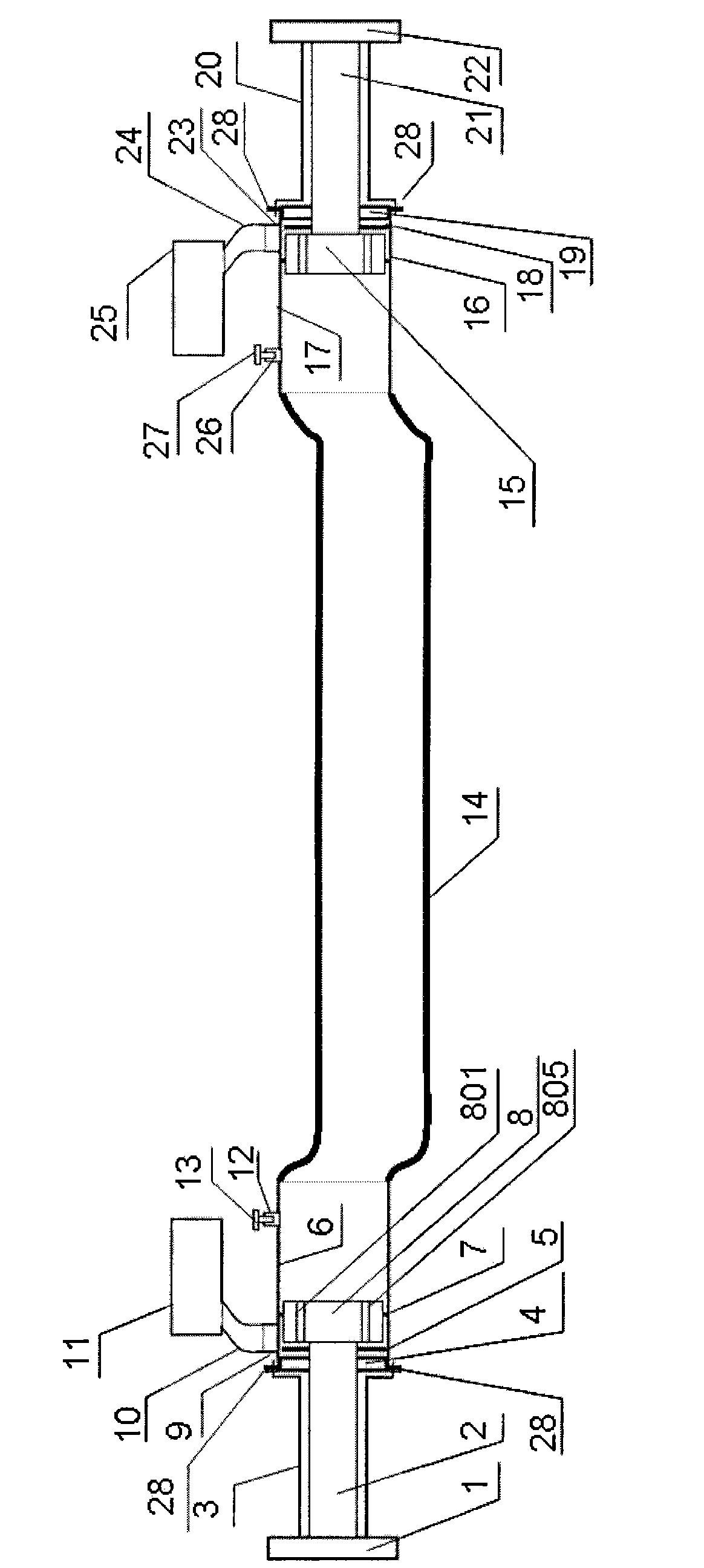

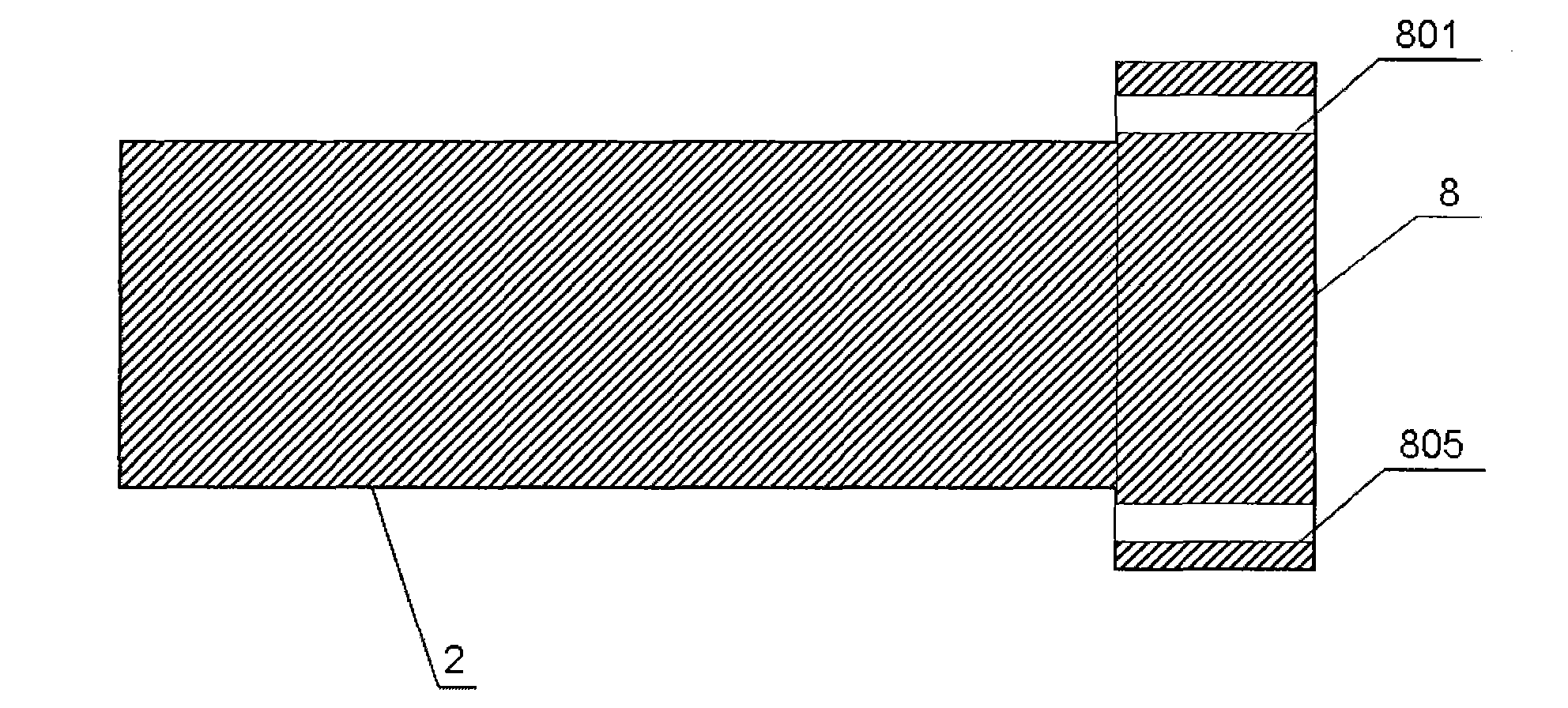

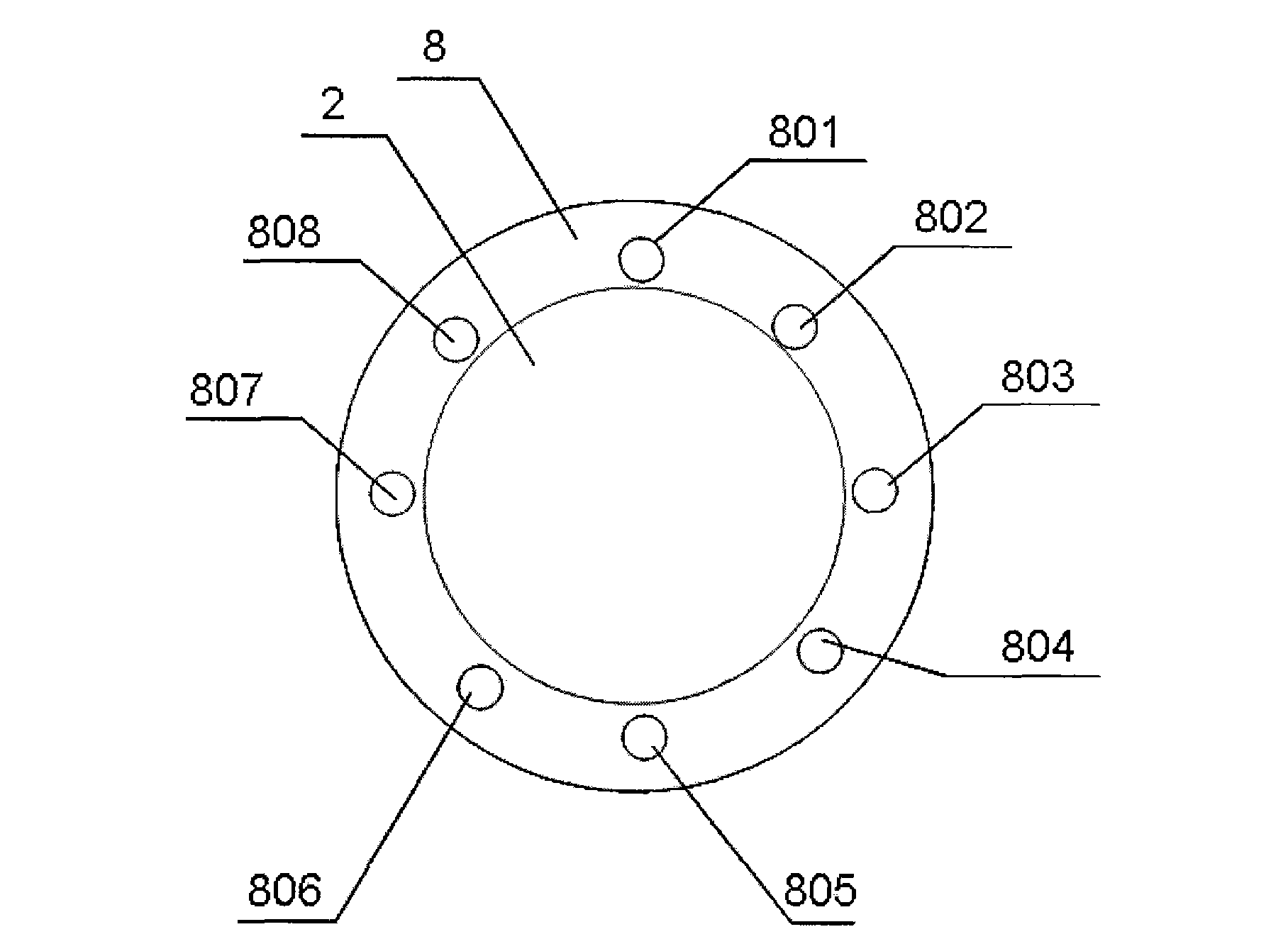

Novel metal powder melting and quick forming machine

InactiveCN103143707ASave processing time and costsShorten the development cycleGalvanometerAerospace

The invention relates to a novel metal powder melting and quick forming machine which comprises a frame, a control system, a laser galvanometer scanning device, a powder laying device, a three-cylinder body and a laser, wherein the control system, the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all arranged on the frame, the laser galvanometer scanning device is in optical connection with the laser, and the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all connected to the control system. The novel metal powder melting and quick forming machine has the advantages that a nonequilibrium supersaturated solid solution and uniform and fine metallographic structures can be obtained, the density of a formed part is close to 100%, the mechanical performance is equivalent to that of a forging part, the processing time and cost can be obviously reduced, and the development cycle of a new product is shortened. The novel metal powder melting and quick forming machine greatly adapts to the requirements of quick, individuated and flexible development of the modem manufacturing industry and has a broad application prospect in the manufacturing fields of aviation, aerospace, medicine, molds, weaponry and the like.

Owner:钱波

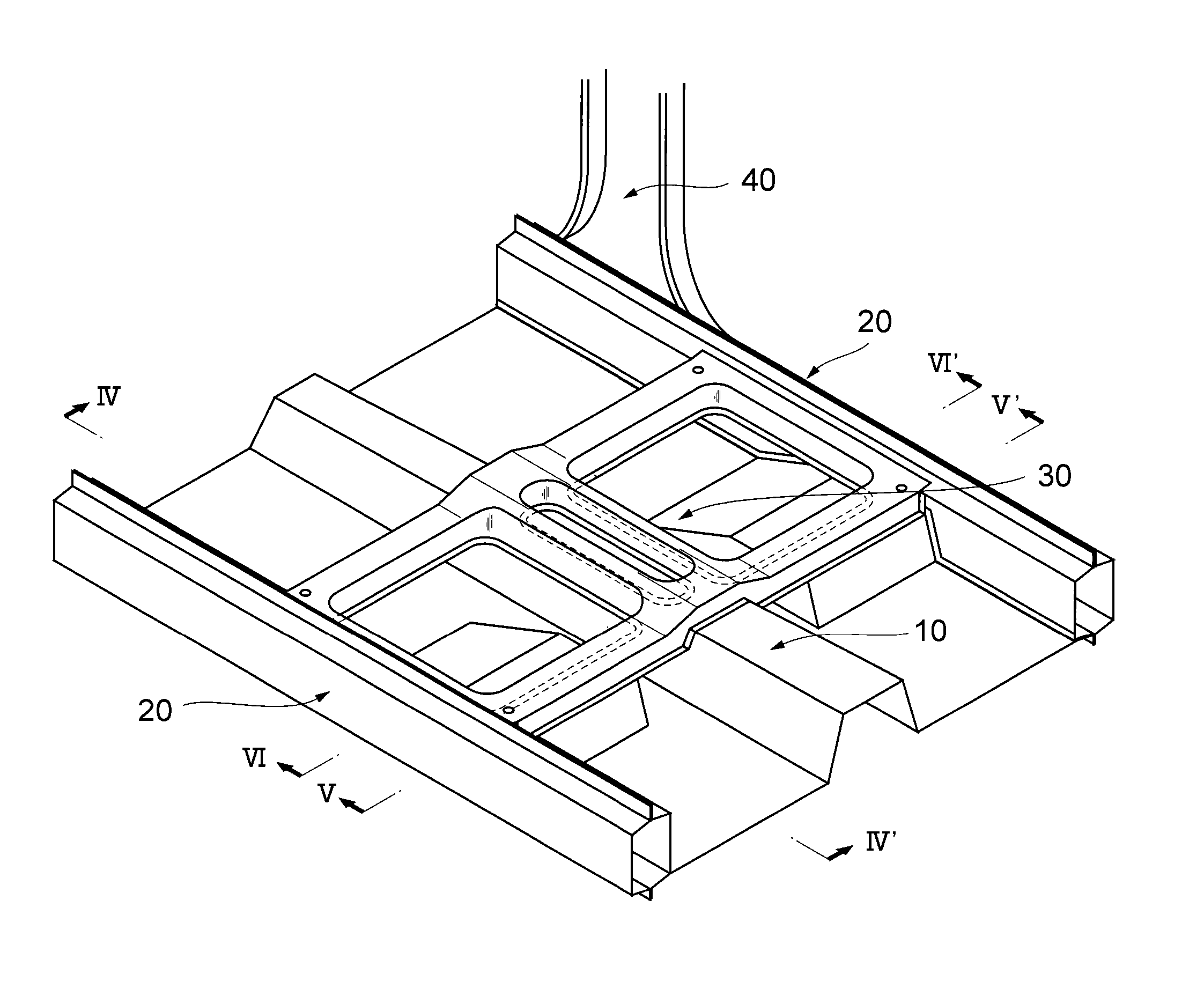

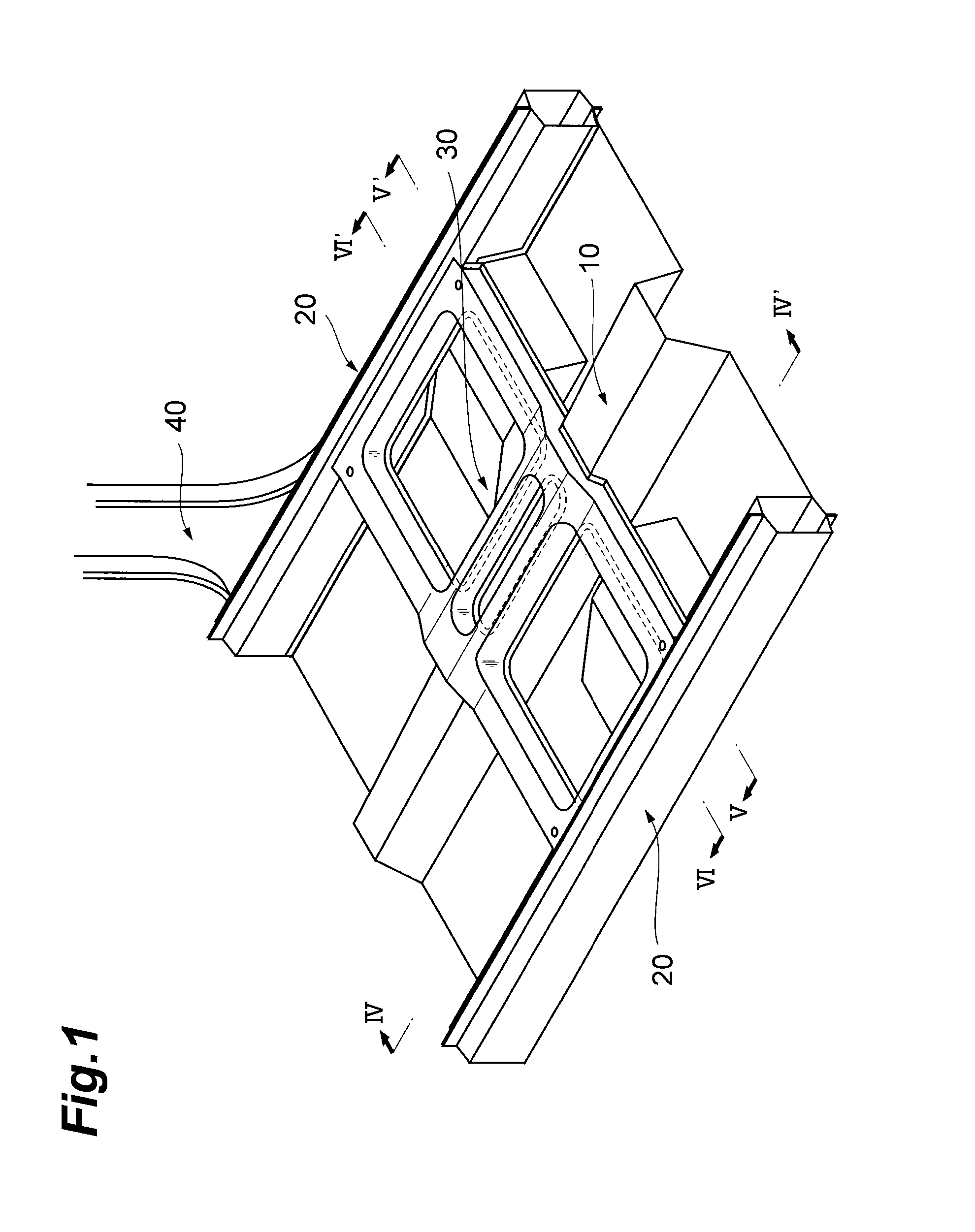

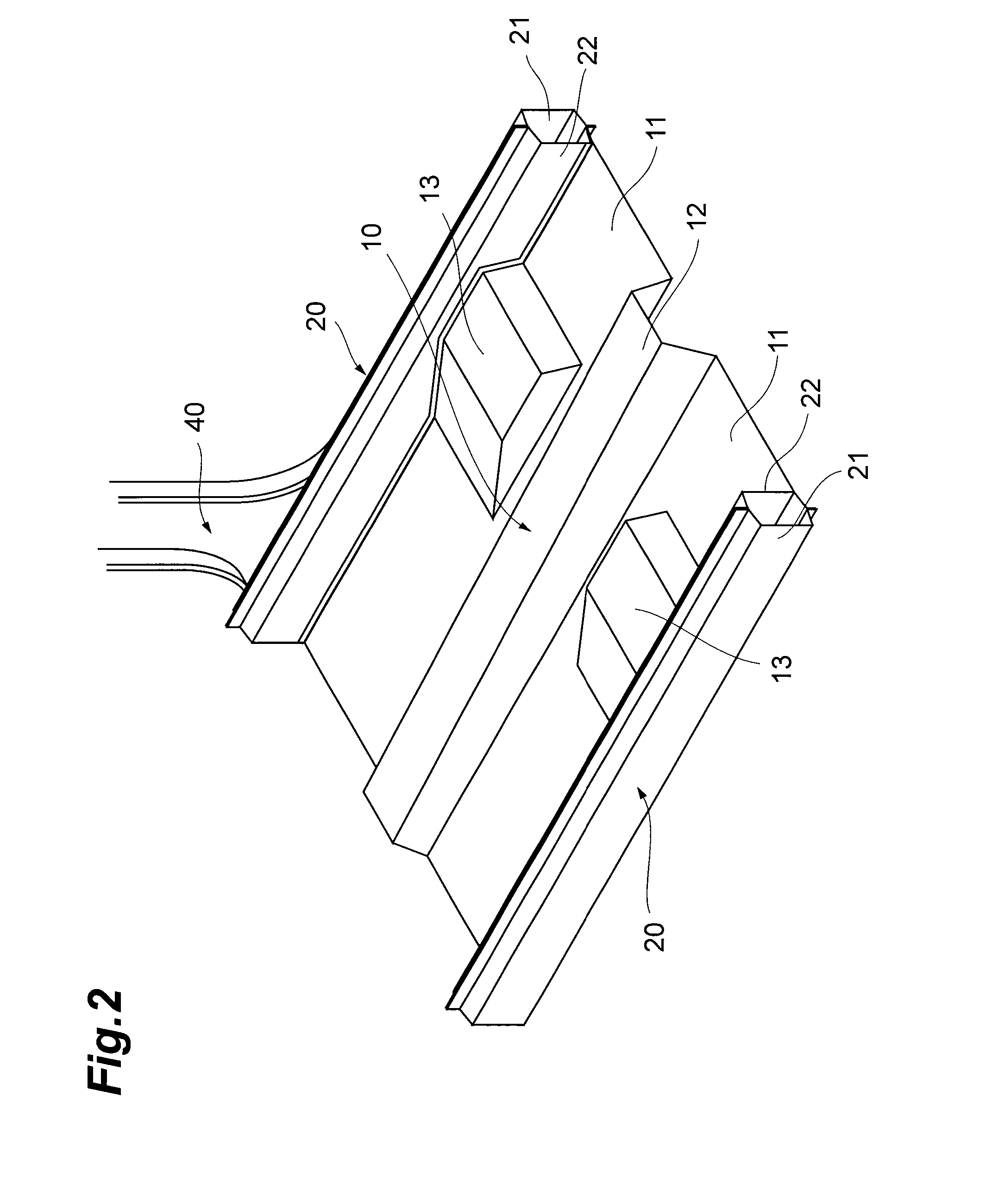

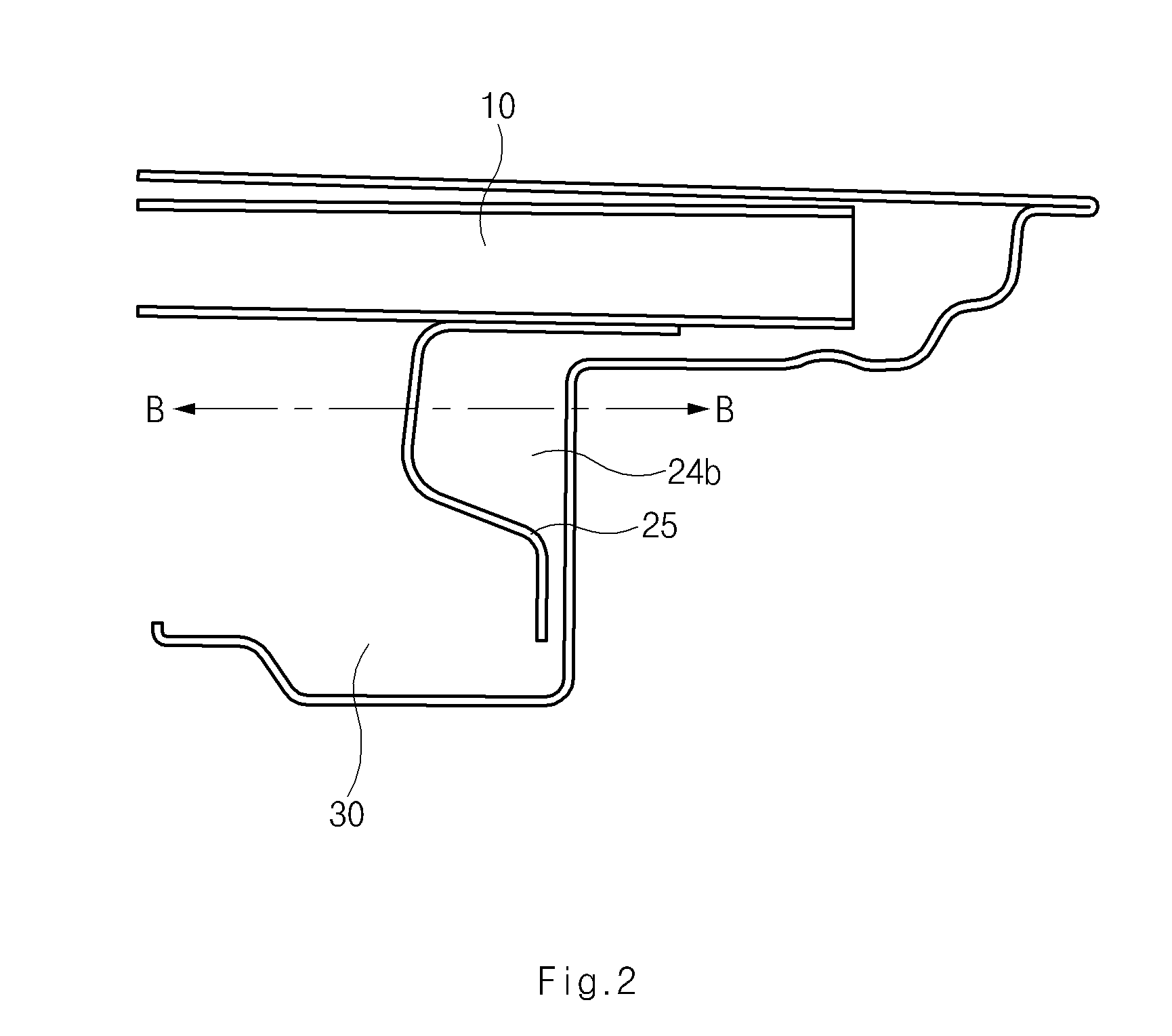

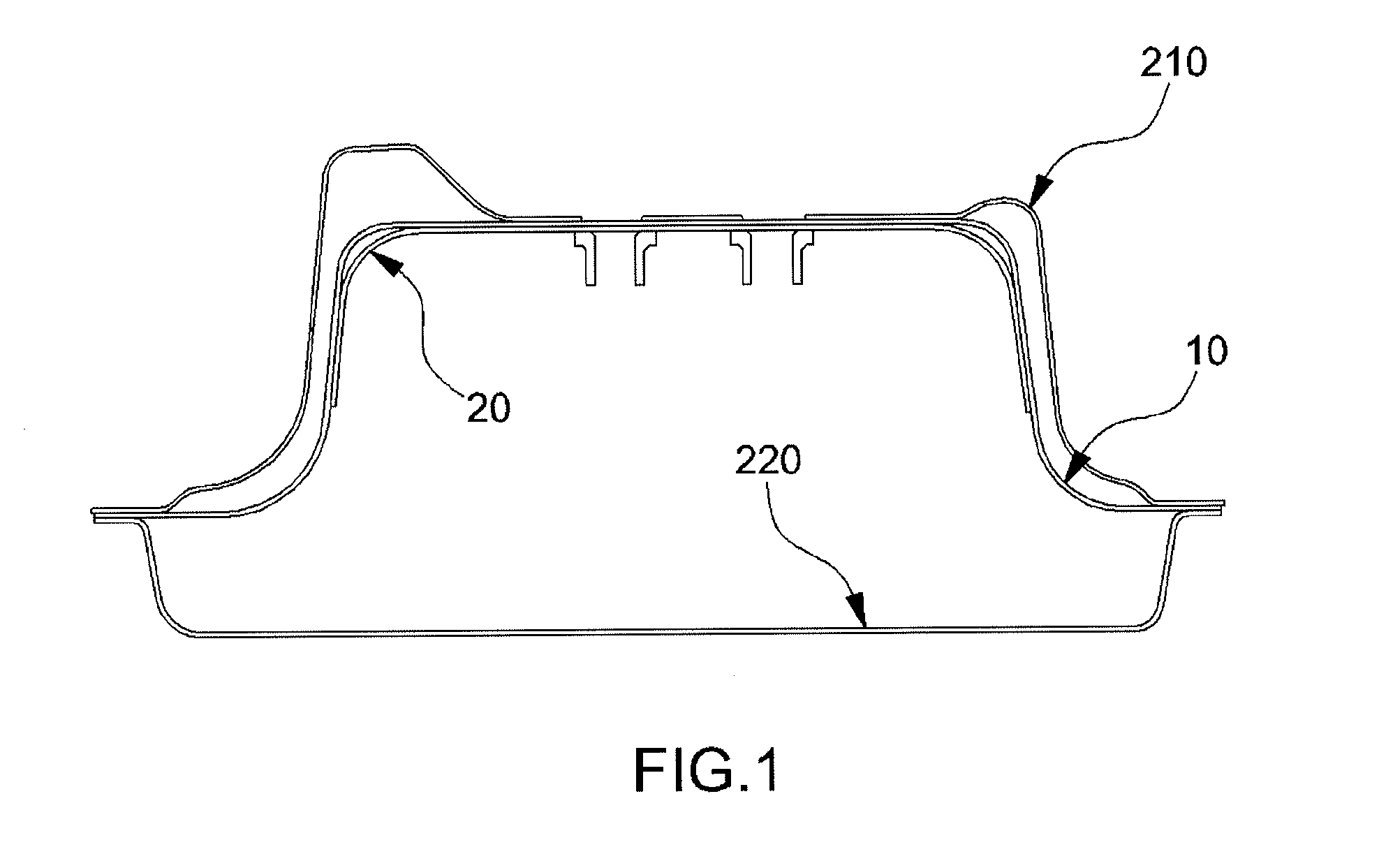

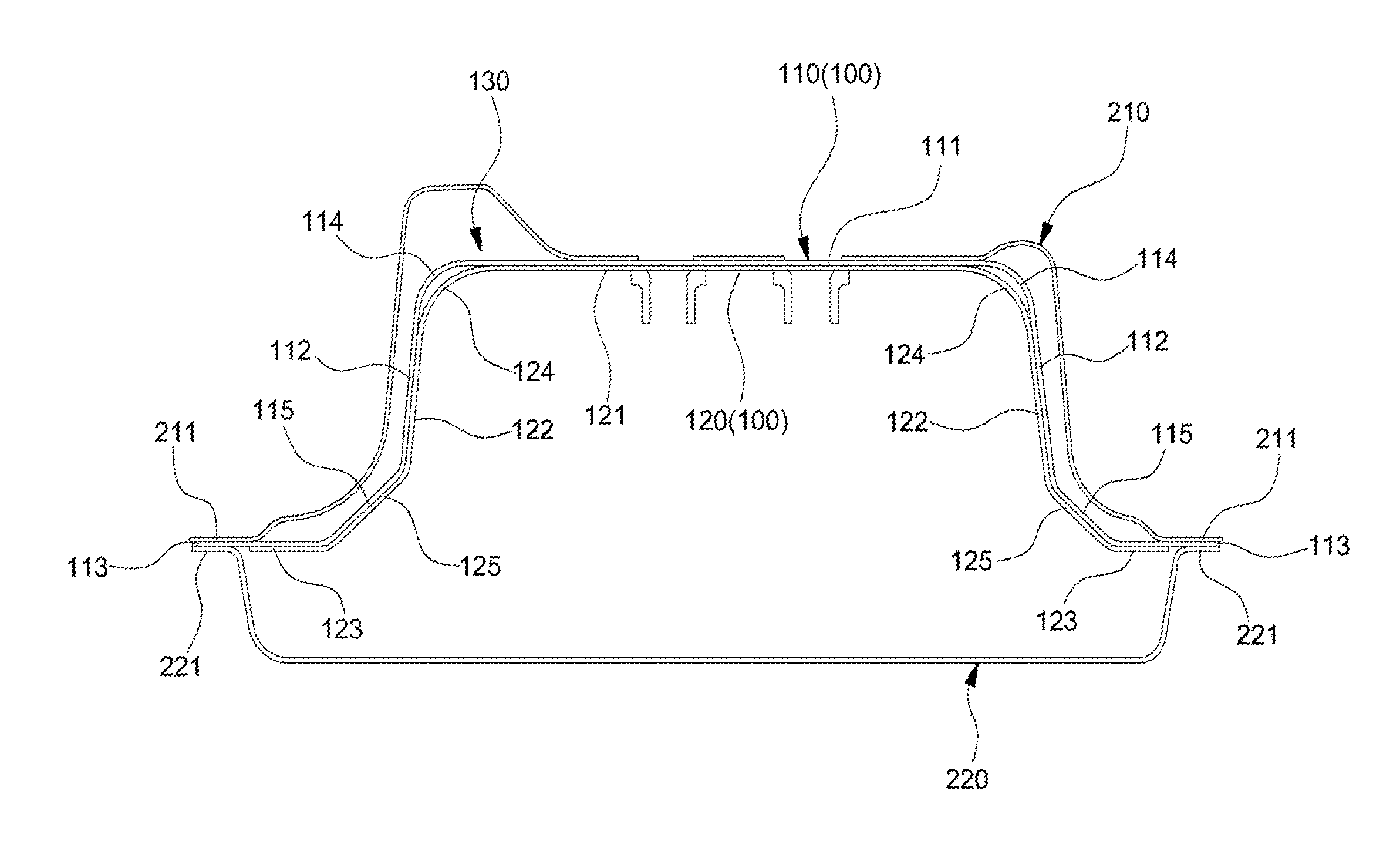

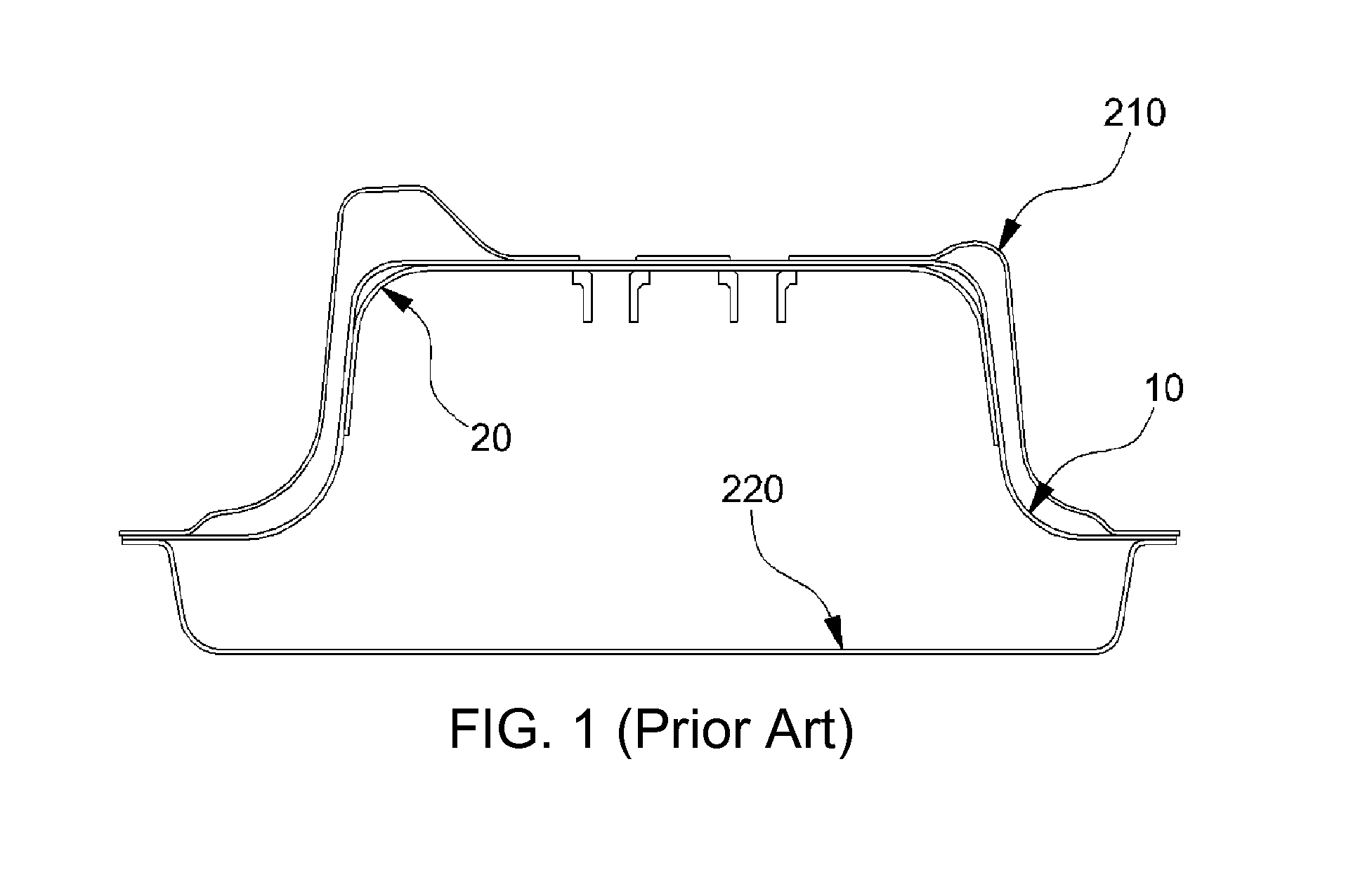

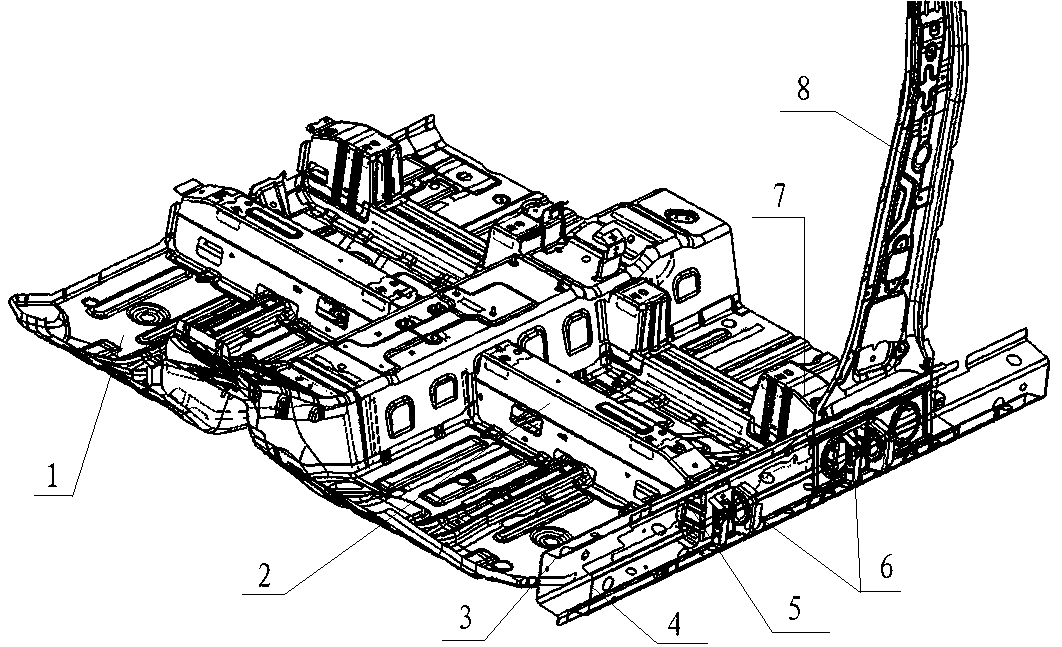

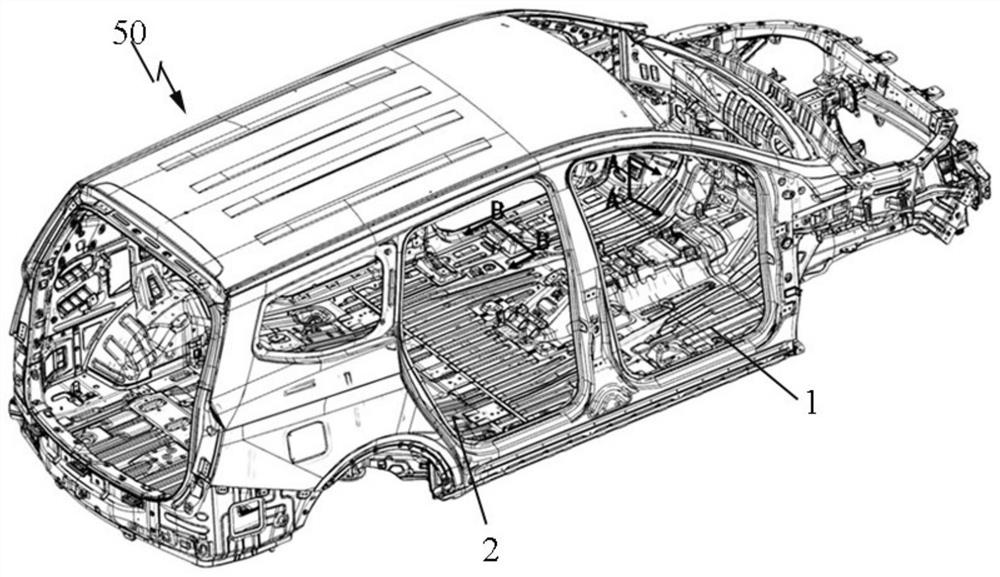

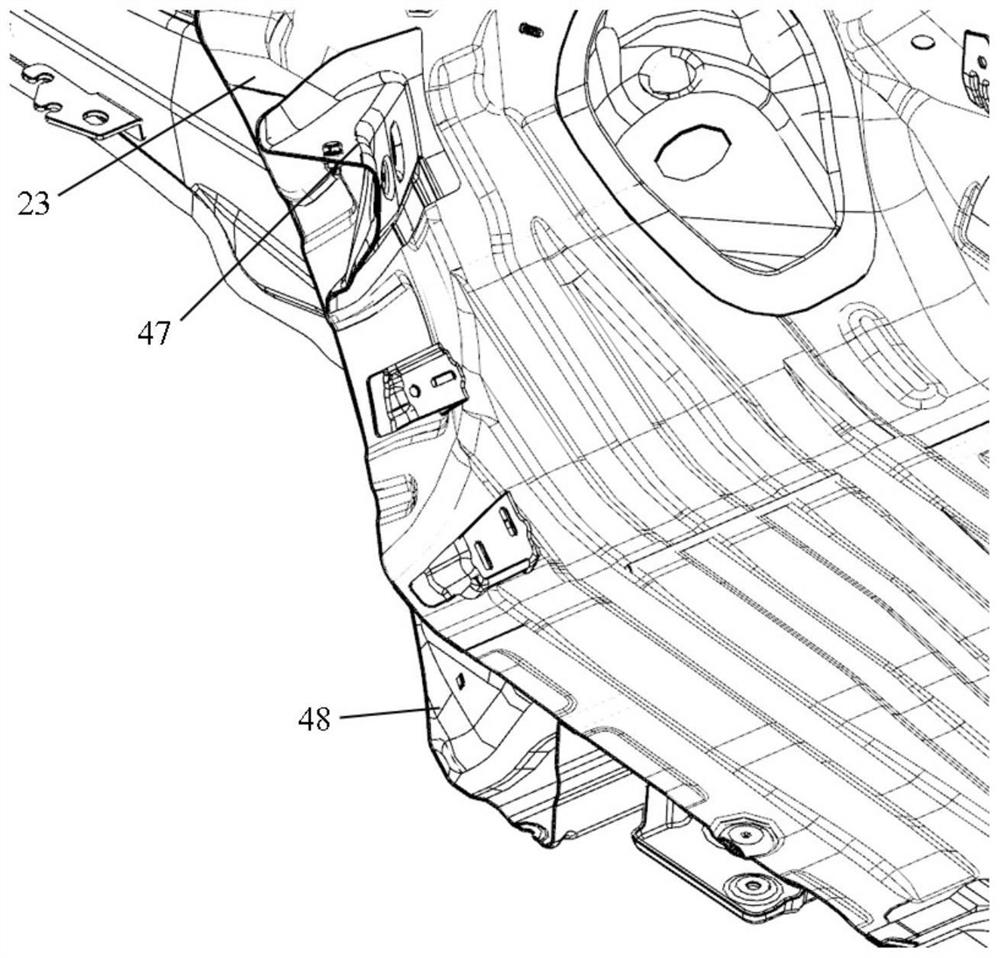

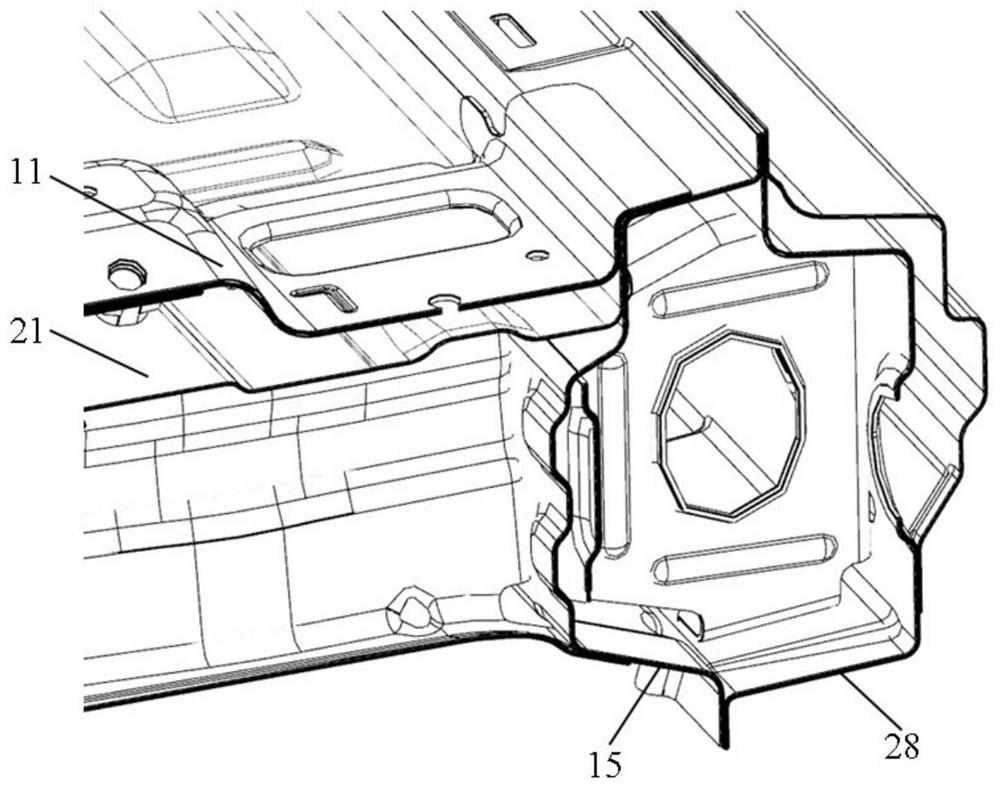

Vehicle underbody structure

InactiveUS20140327268A1Improve side impact performanceImprove performanceVehicle seatsUnderstructuresMechanical engineering

Owner:TOYOTA JIDOSHA KK

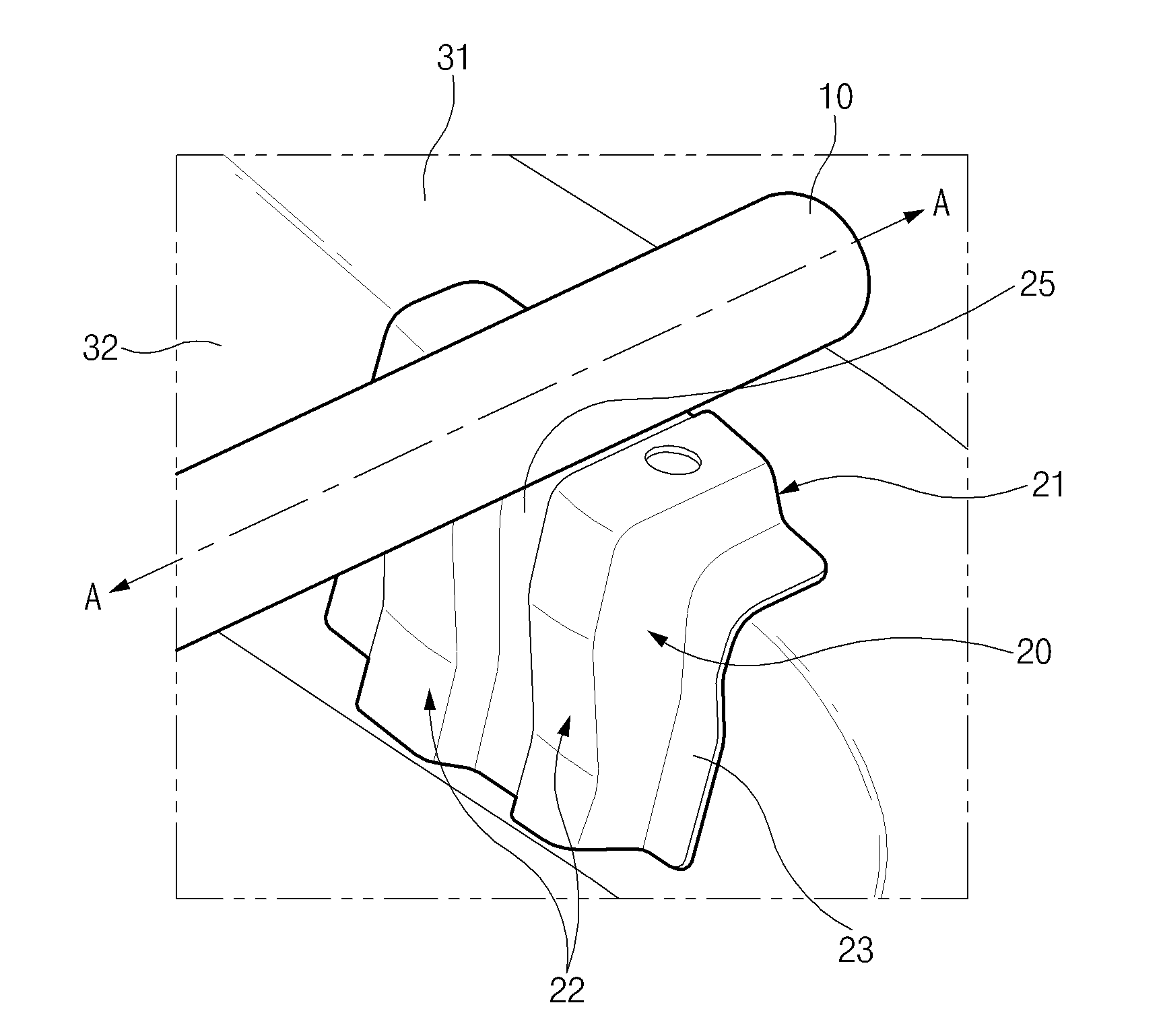

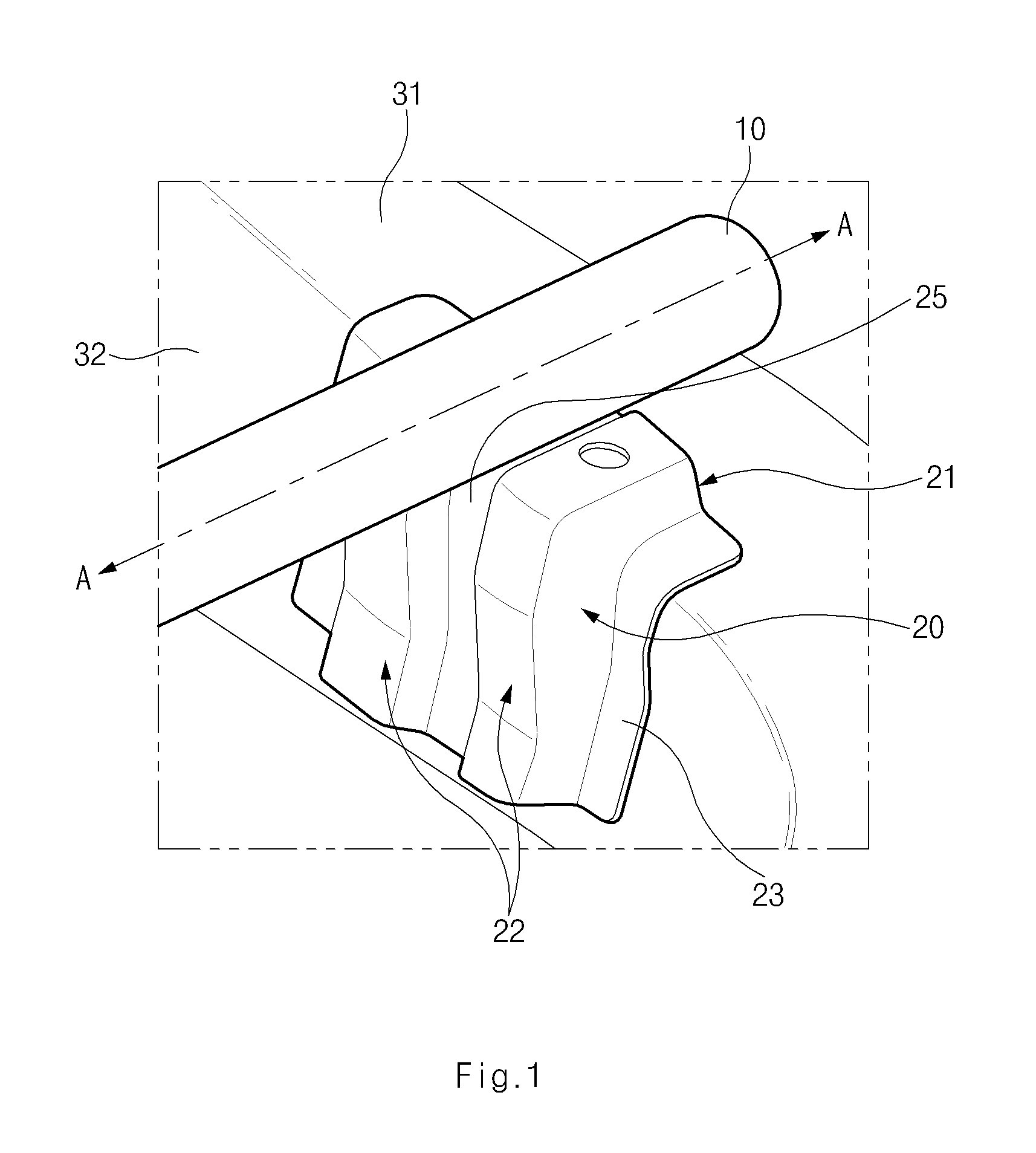

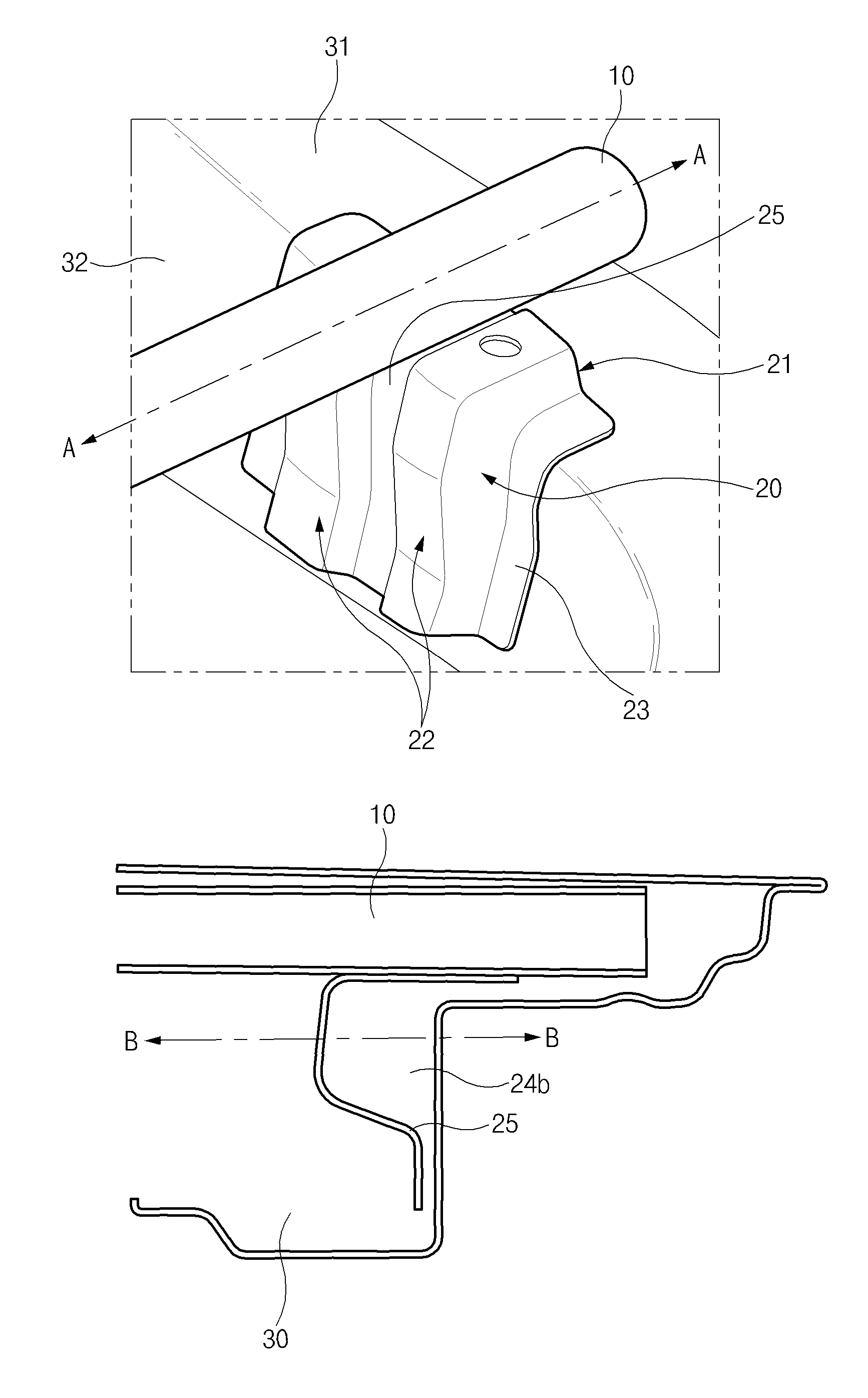

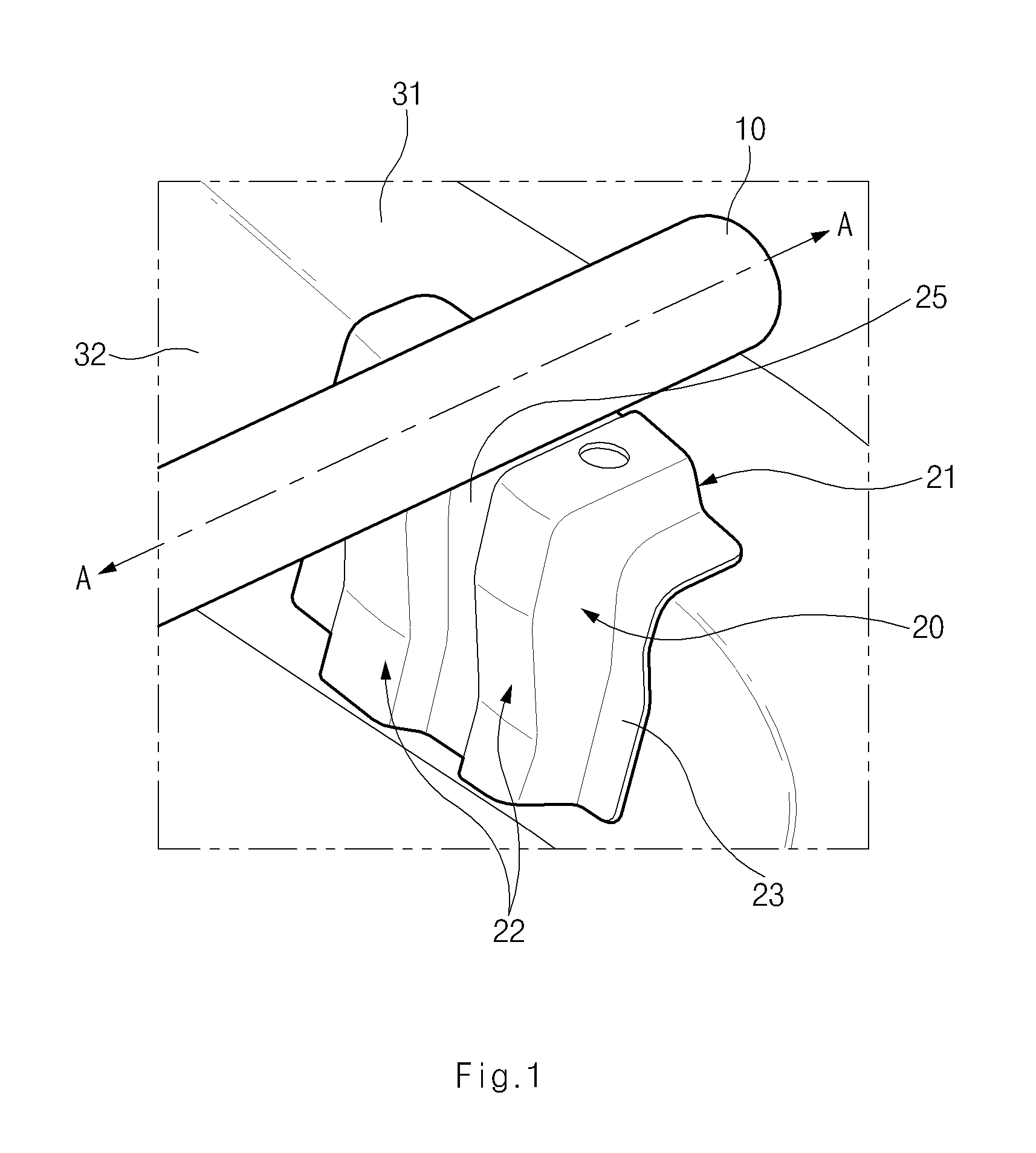

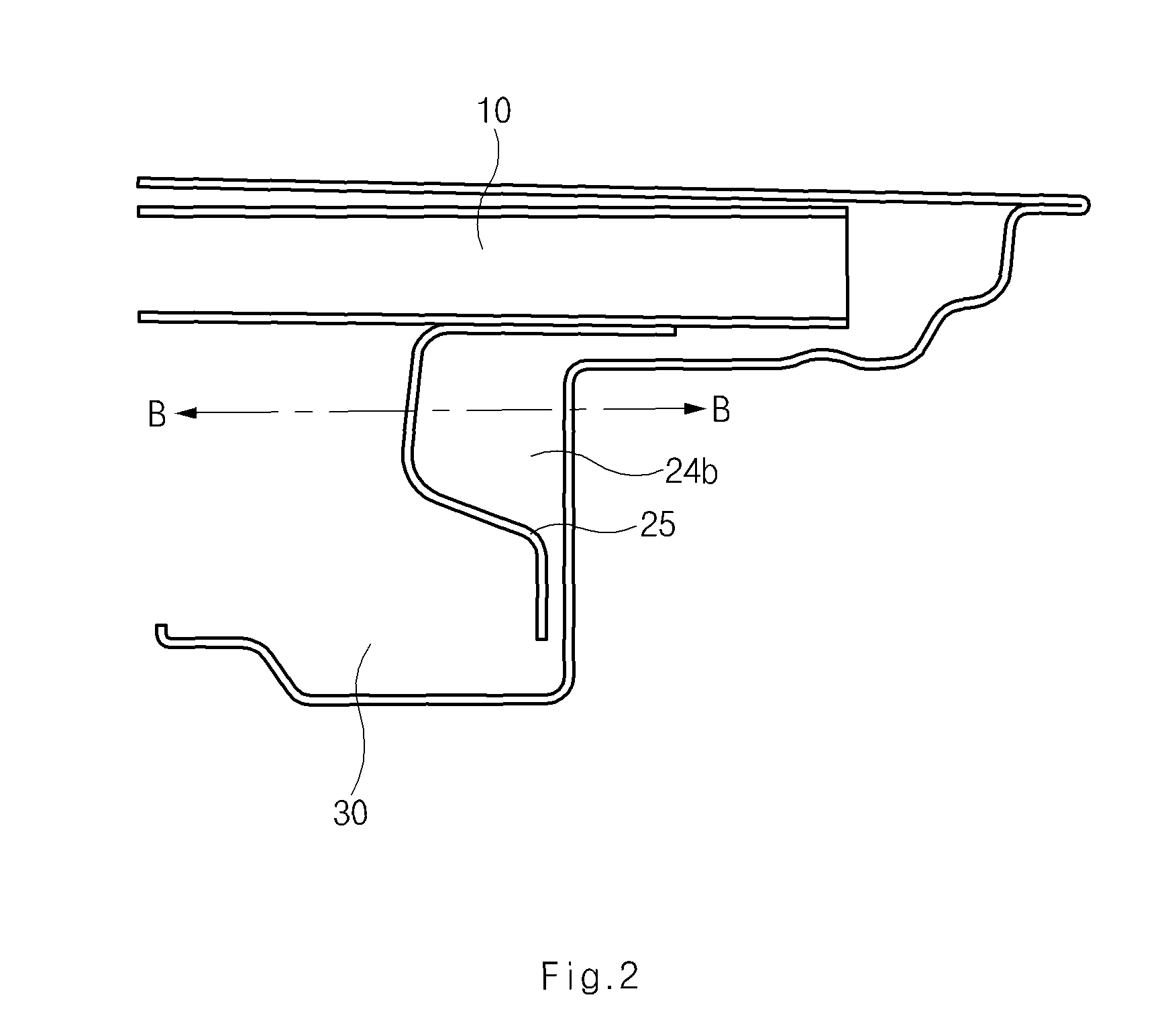

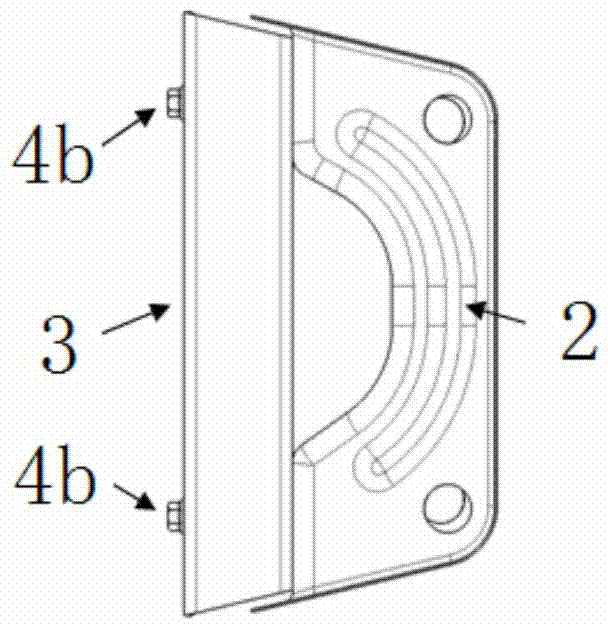

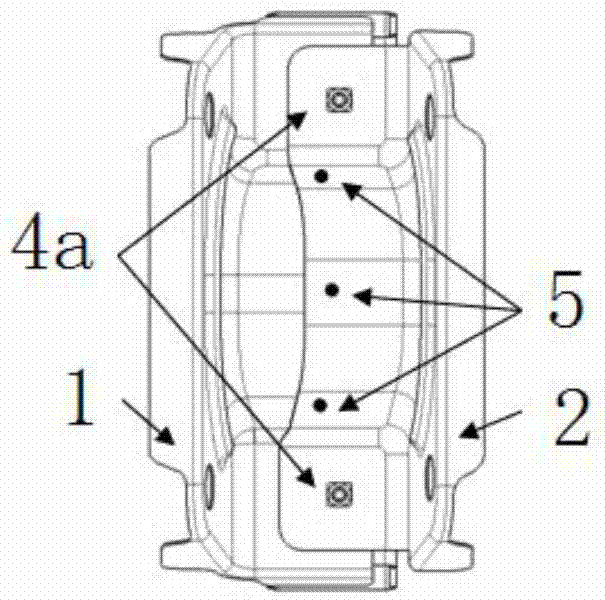

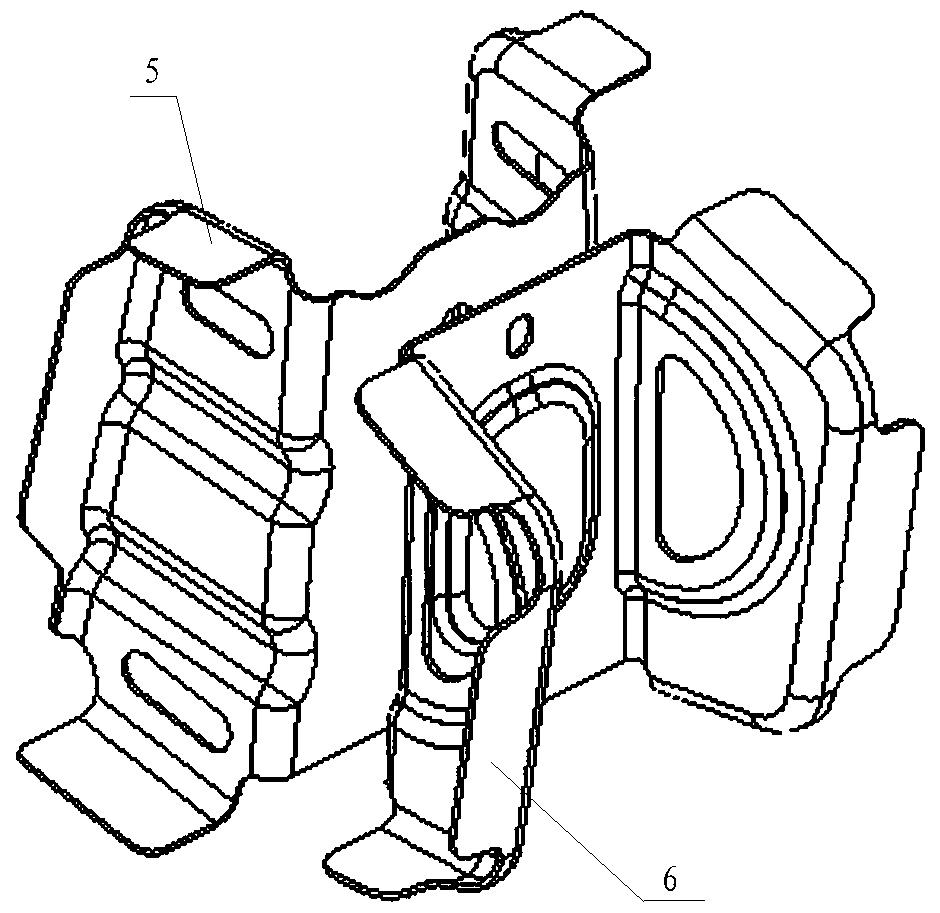

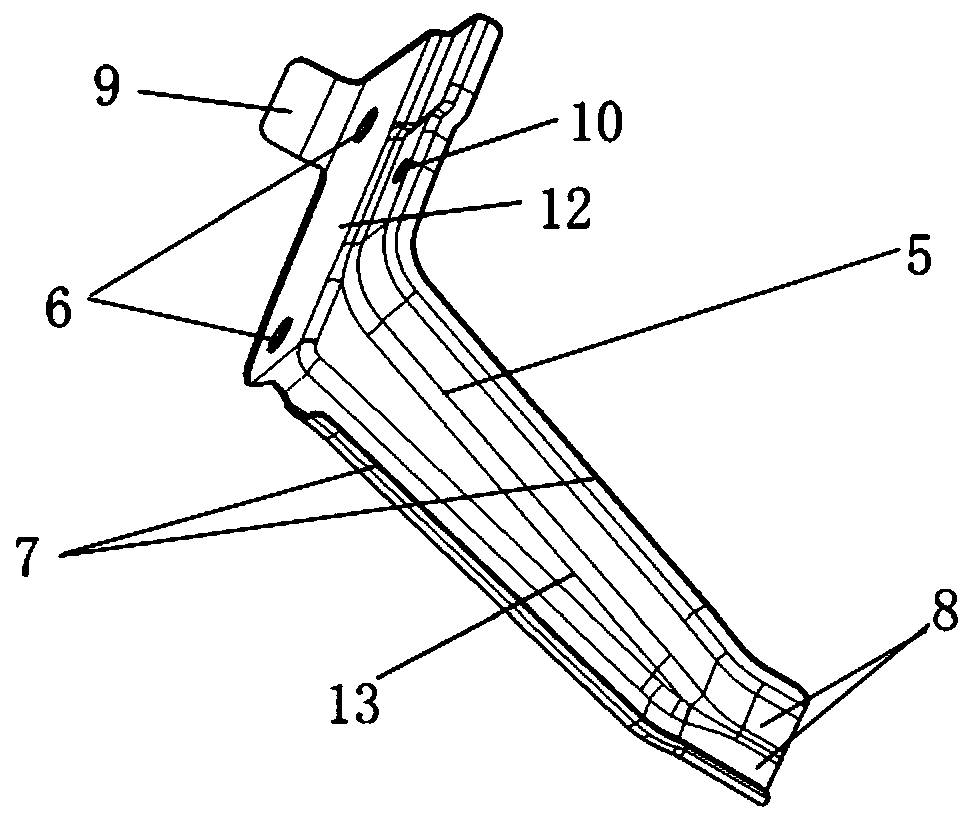

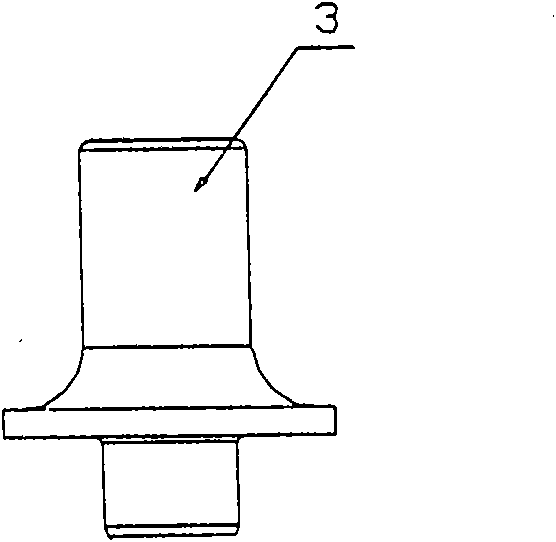

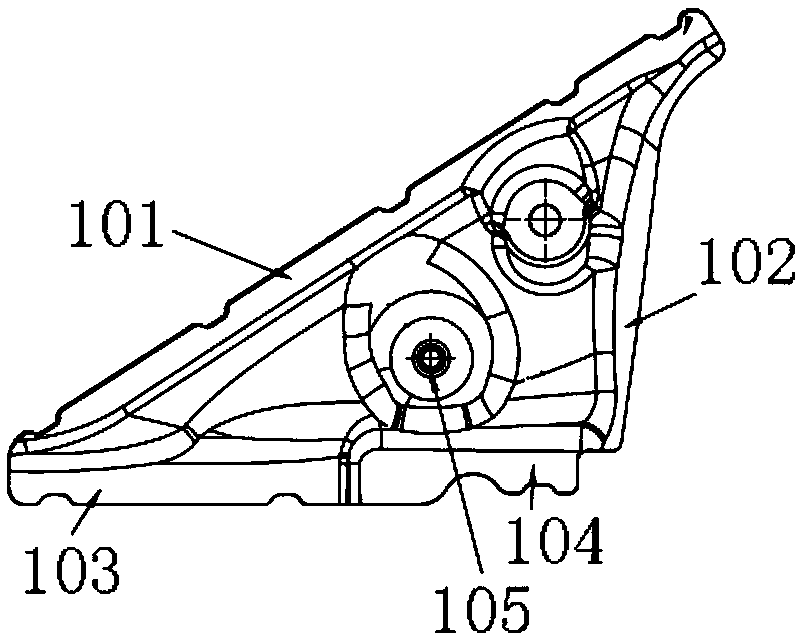

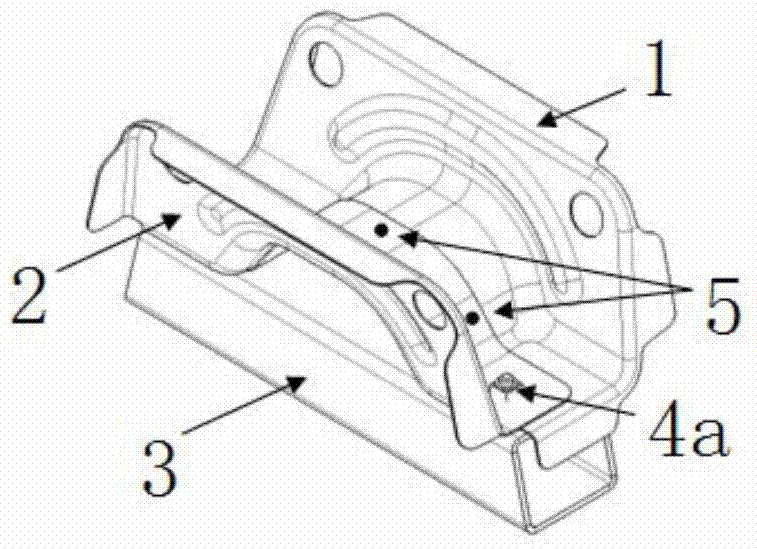

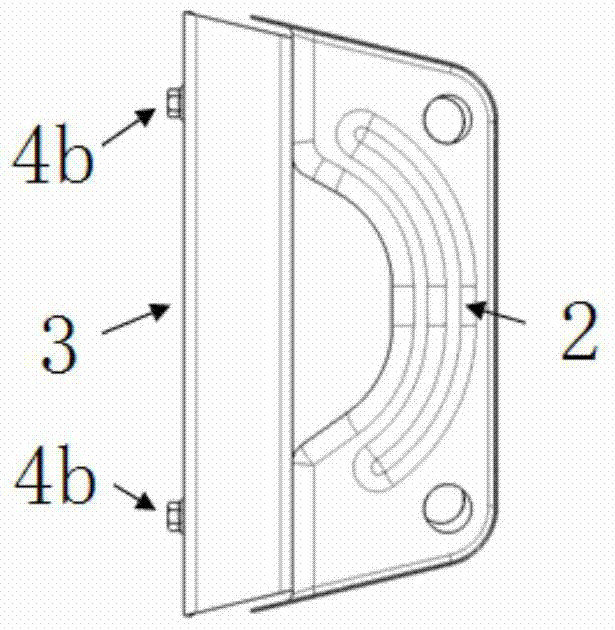

Supporting structure of door impact beam for vehicle

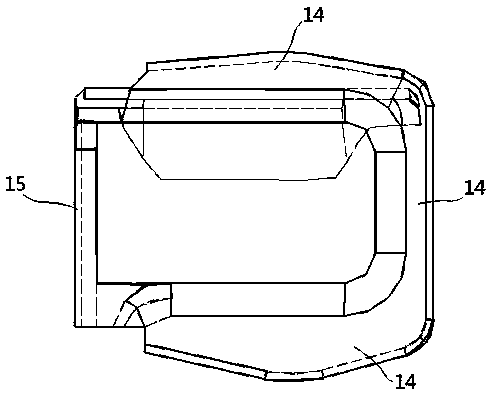

ActiveUS20130140845A1Improve side impact performanceImprove impact performancePedestrian/occupant safety arrangementMonocoque constructionsCouplingEngineering

A supporting structure of a door impact beam for a vehicle mounted on an inner panel of a door for the vehicle, may include a coupling part formed with a coupling groove to which the impact beam may be coupled, a supporting part bent downwardly from the coupling part and supporting the coupling part, and mounting parts provided along side portions of the coupling part and the supporting part and mounted on the inner panel of the door, wherein the coupling part, the supporting part, and the mounting part may be integrally formed, and the coupling part and the supporting part may be protruded from the inner panel of the door to form a reinforcing part.

Owner:HYUNDAI MOTOR CO LTD +1

Low-density wood plastic board and preparation method thereof

InactiveCN102875874AReduce material consumptionReduce manufacturing costFlat articlesMaleic anhydrideAzodicarbonamide

The invention discloses a low-density wood plastic board and a preparation method thereof and belongs to the technical field of decorative materials. The technical scheme is that: the low-density wood plastic board is prepared from the following raw materials in part by weight: 35 to 60 parts of plastic particles, 20 to 60 parts of wood meal, 0.3 to 1 part of azodicarbonamide (AC) foaming agent, 1 to 5 parts of maleic anhydride grafted coupling agent, 0.15 to 0.5 part of nucleating agent and 0.15 to 0.6 part of antioxidant; and the low-density wood plastic board is processed by the process steps of material weighing, material mixing, extrusion and calendaring. Compared with the prior art, the invention has the advantages that the low-density wood plastic board can be recycled and is renewable; and the overall weight of the low-density wood plastic board is reduced by the microfoaming process, so that the energy is saved, the cost is reduced, and the economic benefit of enterprises is improved.

Owner:山东只楚民营科技园股份有限公司

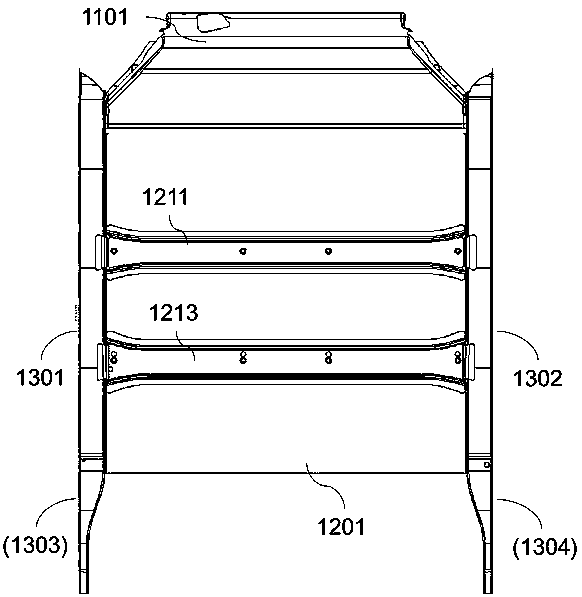

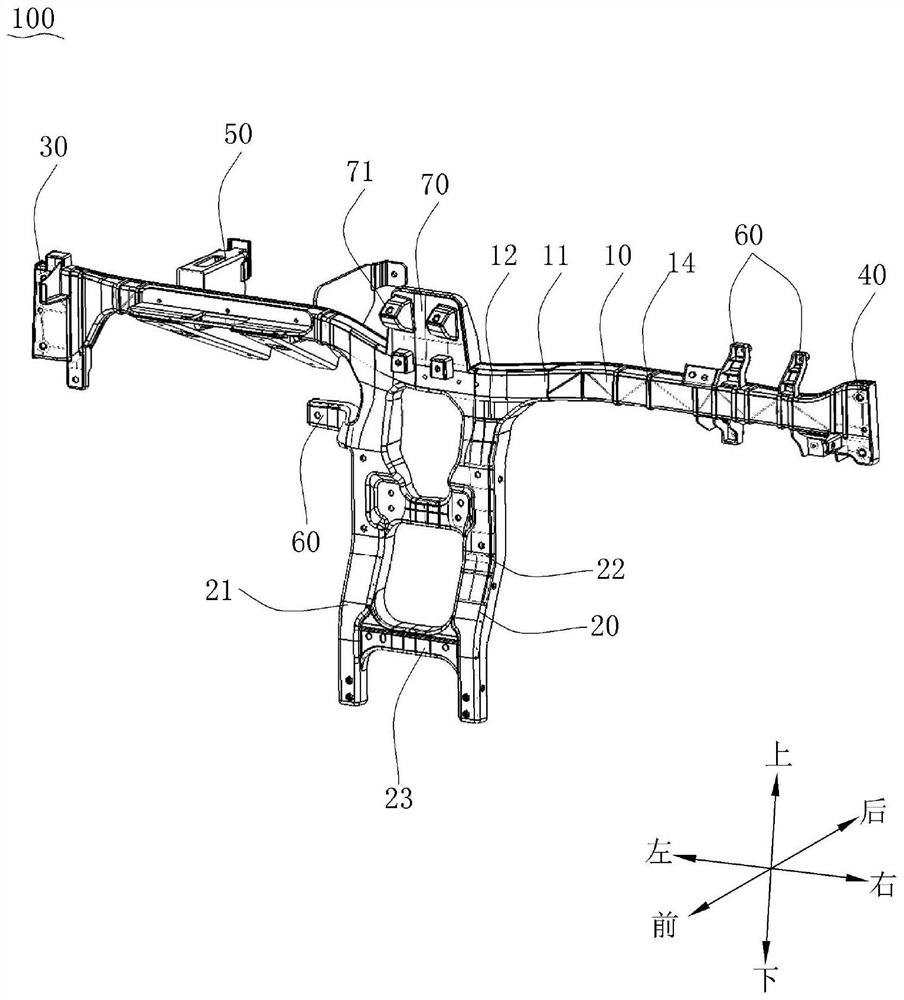

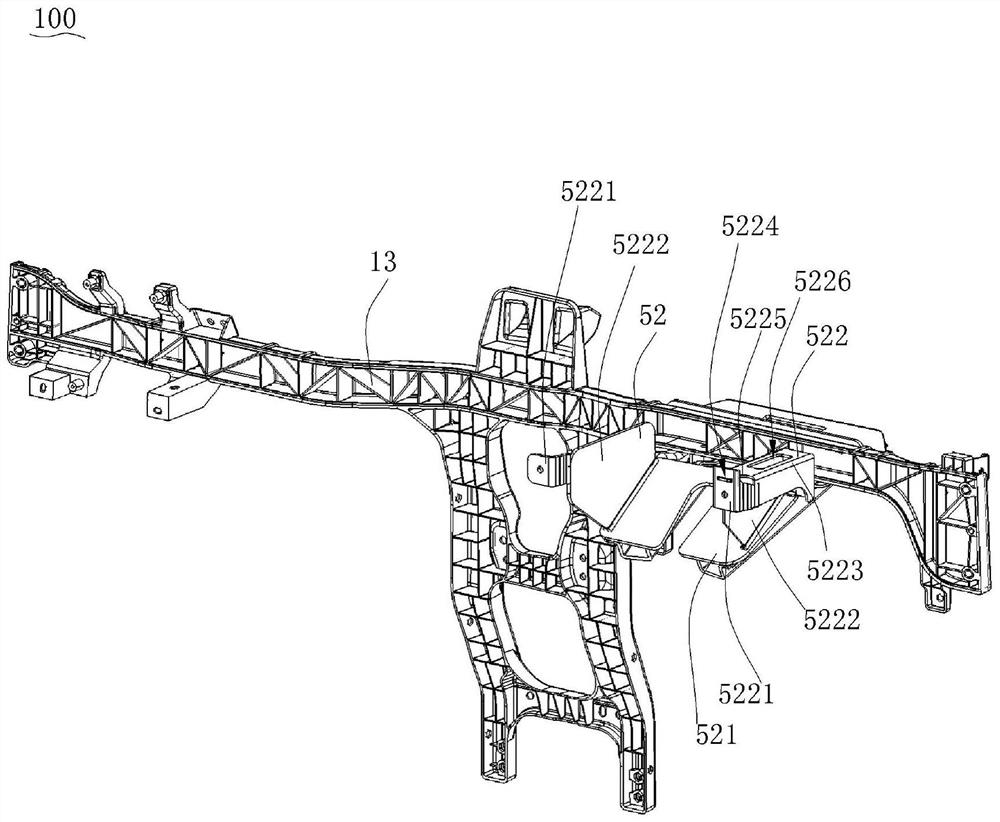

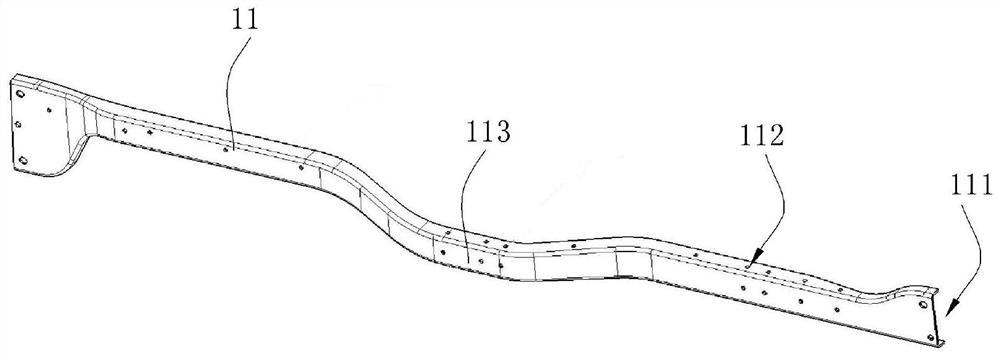

Multi-size multi-power platform vehicle body structure and platform vehicle with the same

PendingCN111017036AHigh energy storageResistance to side impact impactUnderstructuresSuperstructure subunitsHybrid typeFuel oil

The invention provides a multi-size multi-power platform vehicle body front wall floor structure, a multi-power multi-size platform vehicle body structure and a multi-power multi-size series platformvehicle. The power types comprise pure electricity, hybrid power and fuel oil. A middle floor, a seat cross beam and a threshold beam inner plate are shared. A front wall under-floor structure is configured according to requirements of a power energy storage and dissipation system. The floor is tiled, and the seat cross beam is communicated left and right. A front wall curved surface of the pure electricity type is flat and smooth, a front wall lower cross beam communicated in a left and right mode is arranged below the plate and hard points are additionally installed and hung. In order to avoid the exhaust system, the middle of the front wall of the hybrid type protrudes backwards, a floor longitudinal beam is in lap joint with a longitudinal beam and extends inwards and backwards, the torque box cover plate is supplemented, and the area is integrated to share hard points. And the fuel oil plate supplements a seat cross beam below the floor. The seat cross beam and the B column can move forwards and backwards, a torque box cover plate is supplemented, and shared hard points of the area are integrated. According to the fuel oil type, a seat cross beam under a floor is supplemented.The seat cross beam and a B column can move back and forth in a middle uniform-section area, so that the man-machine requirements of high-low vehicles and large and small vehicles for the driving position are met. Meanwhile, the floor and the doorsill beam can extend, retract or increase or decrease structures with uniform sections to increase or decrease the size of the passenger compartment, and one or more rows of seat cross beams can be additionally arranged on the extended vehicle body to increase the riding positions.

Owner:吴春涛

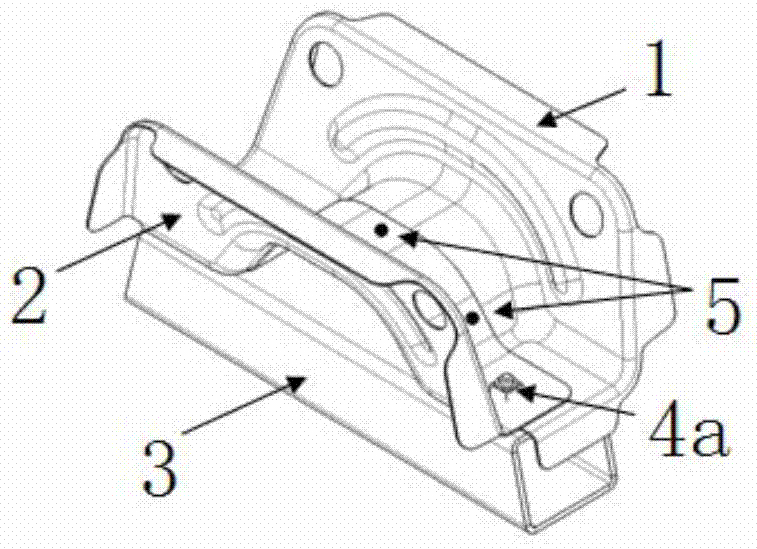

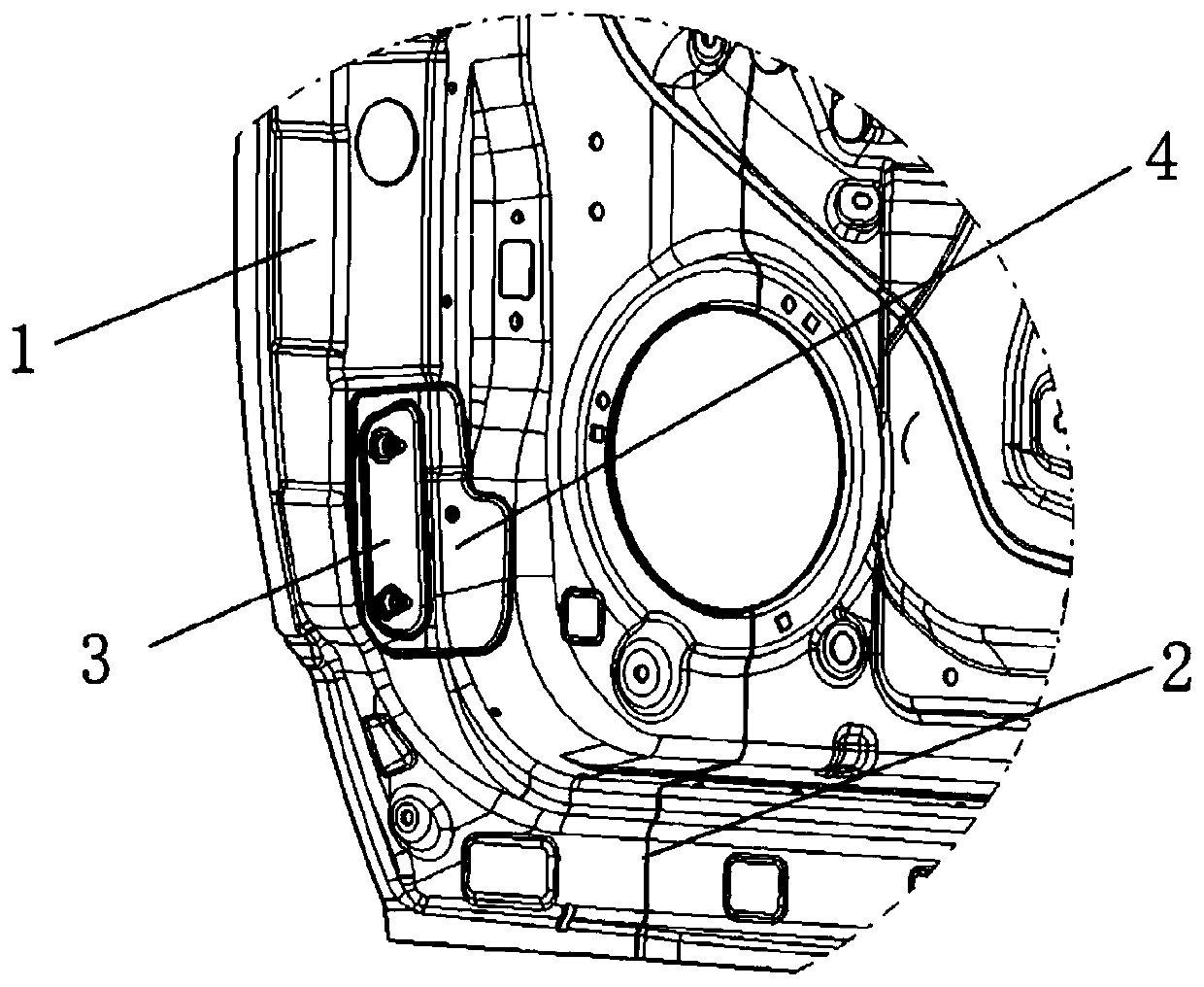

Engine bracket front mounting structure

ActiveCN101954852AEasy to shapeAvoid loose situationsJet propulsion mountingInternal combustion mountingVehicle frameEngineering

The invention discloses an engine bracket front mounting structure, comprising an engine bracket front amounting assembly which is composed of a front mounting support, a reinforcing plate and an auxiliary frame connecting pipe by connection; wherein the engine bracket front mounting assembly is a small cavity, and the engine bracket front mounting assembly is welded with an engine cabin boundarybeam front section and an engine cabin boundary beam front part shell plate, so as to form a larger cavity. The invention has the following advantages: forming of parts is simple, welding quality is easy to control, error is less, and product consistency is good; the engine bracket front mounting assembly is welded with the engine cabin boundary bean front section and the engine cabin boundary beam front part shell plate, so as to form a larger cavity, and the gravity of an engine bracket is timely transferred on the engine cabin boundary beam front section, thus ensuring strength and rigidity of the engine bracket front mounting structure, effectively improving direct impact and side impact performances and avoiding the condition that the engine bracket is loosened due to twisting, braking, bumping or impacting of car body.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Novel metal powder melting and quick-molding machine

The invention relates to a novel metal powder melting and quick forming machine which comprises a frame, a control system, a laser galvanometer scanning device, a powder laying device, a three-cylinder body and a laser, wherein the control system, the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all arranged on the frame, the laser galvanometer scanning device is in optical connection with the laser, and the laser galvanometer scanning device, the powder laying device, the three-cylinder body and the laser are all connected to the control system. The novel metal powder melting and quick forming machine has the advantages that a nonequilibrium supersaturated solid solution and uniform and fine metallographic structures can be obtained, the density of a formed part is close to 100%, the mechanical performance is equivalent to that of a forging part, the processing time and cost can be obviously reduced, and the development cycle of a new product is shortened. The novel metal powder melting and quick forming machine greatly adapts to the requirements of quick, individuated and flexible development of the modem manufacturing industry and has a broad application prospect in the manufacturing fields of aviation, aerospace, medicine, molds, weaponry and the like.

Owner:HARBIN FORWEDO MULTI DIMENSIONAL INTELLIGENT EQUIP CO LTD

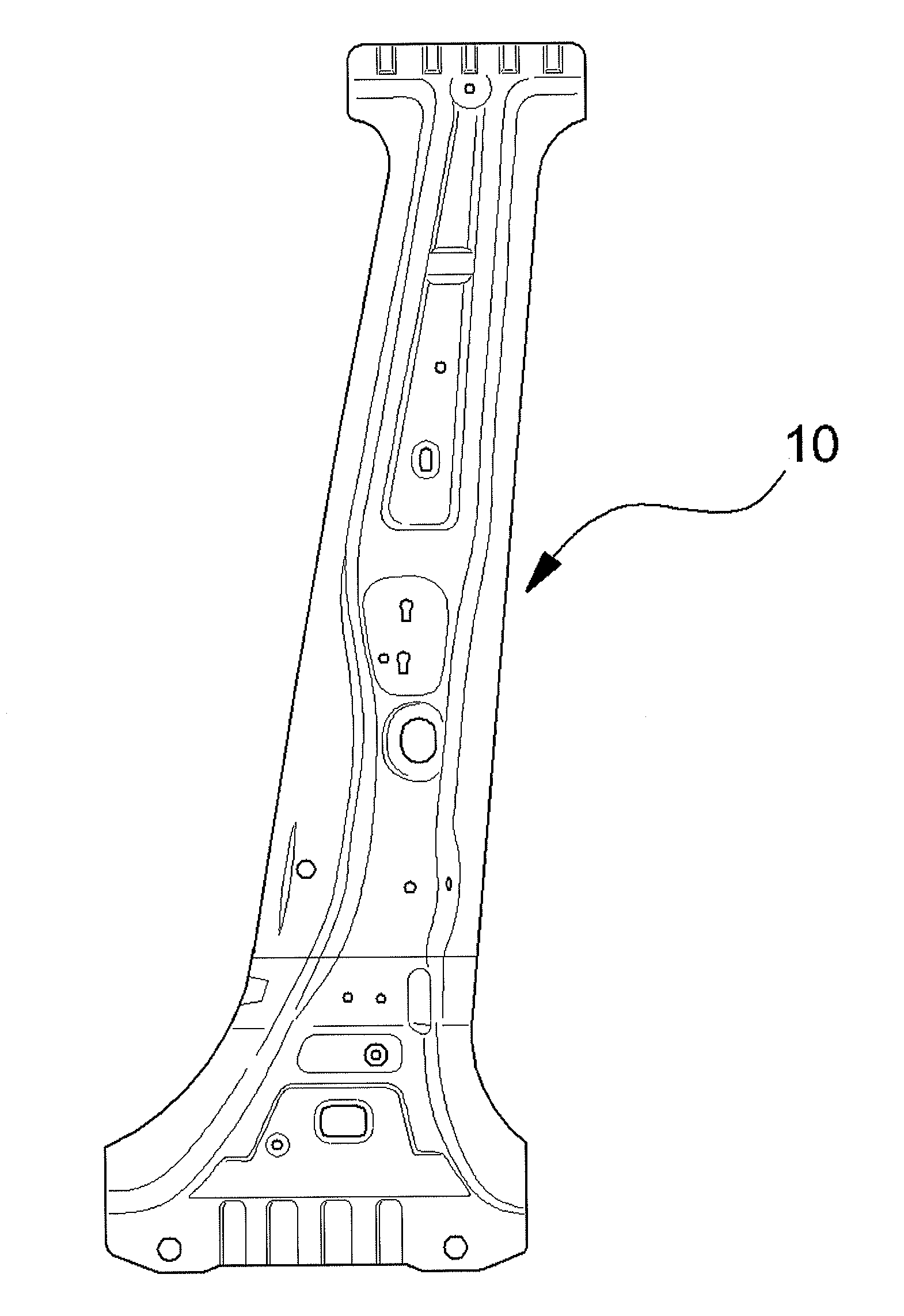

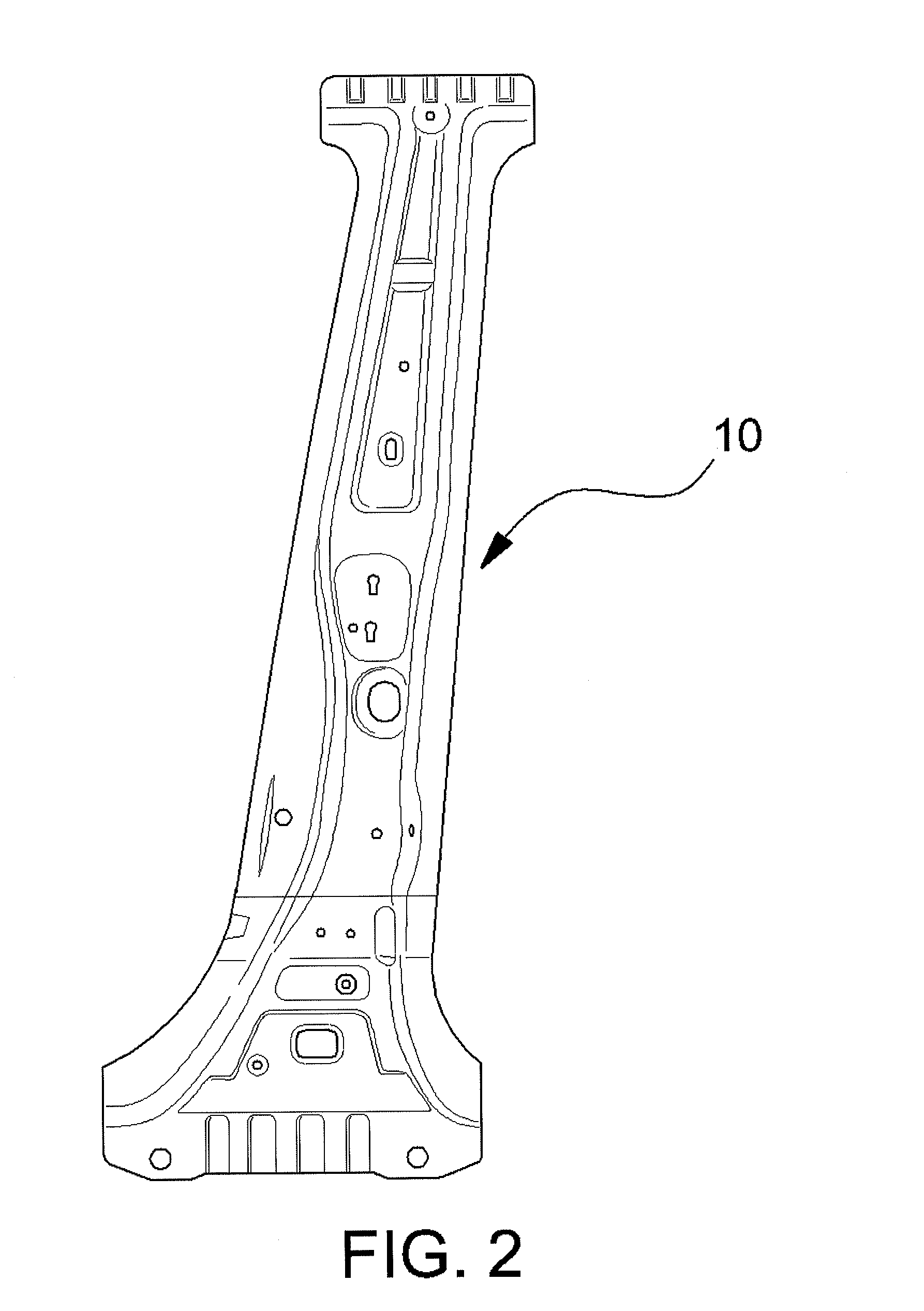

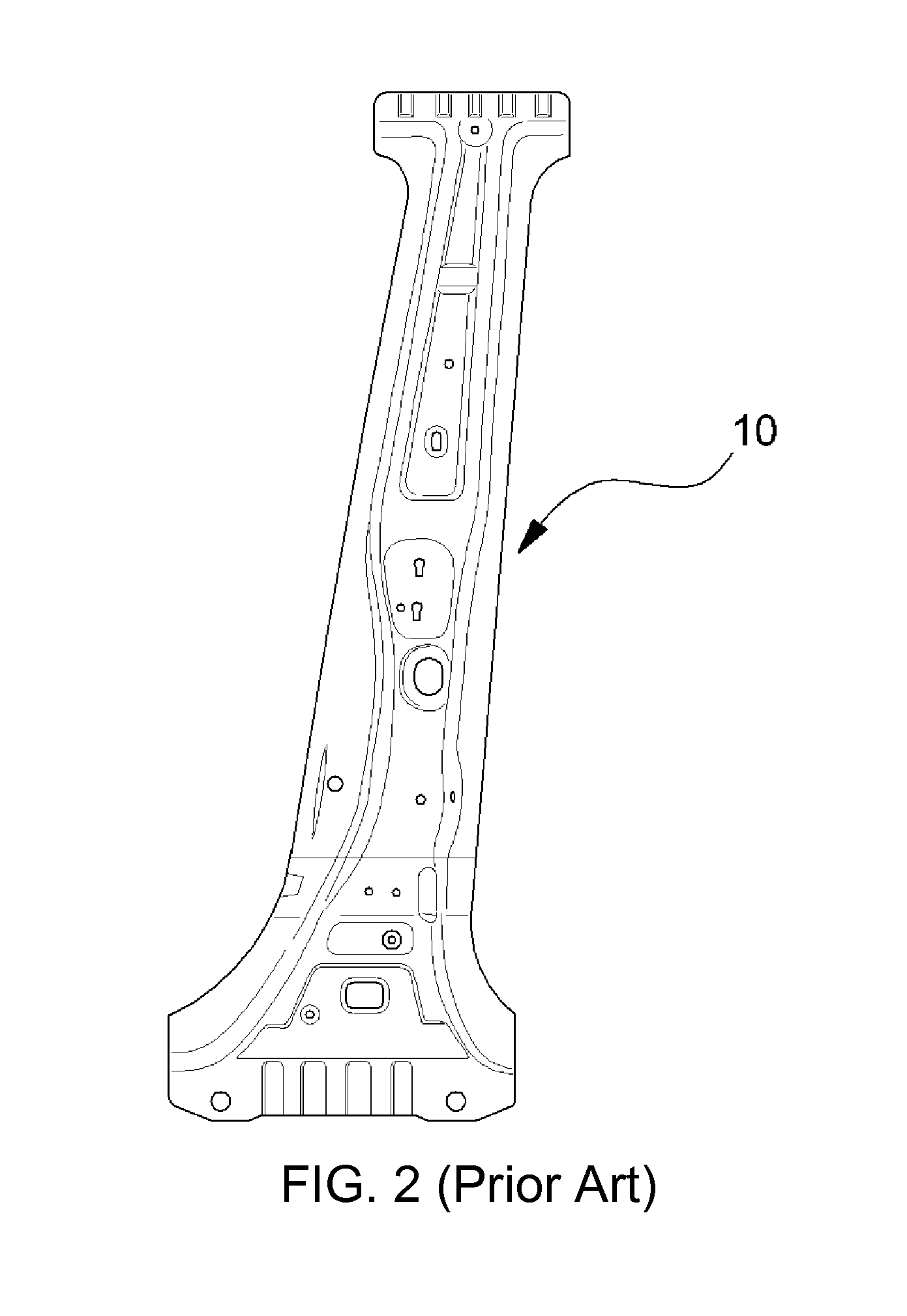

Center pillar outer and manufacturing method thereof

ActiveUS20150175212A1Improve side impact performanceAvoid fracturesVehicle seatsMetal-working apparatusEngineeringWelding

A center pillar outer, and a method of manufacturing a center pillar outer, may include an upper panel portion which forms an upper end portion of the center pillar outer, and a lower panel portion which forms a lower end portion of the center pillar outer. The upper and lower panel portions are molded using different methods. A lower end of the upper panel portion and an upper end of the lower panel portion are overlapped with each other, and the overlapping portions are coupled to each other, for example, through welding.

Owner:KIA MOTORS CORP

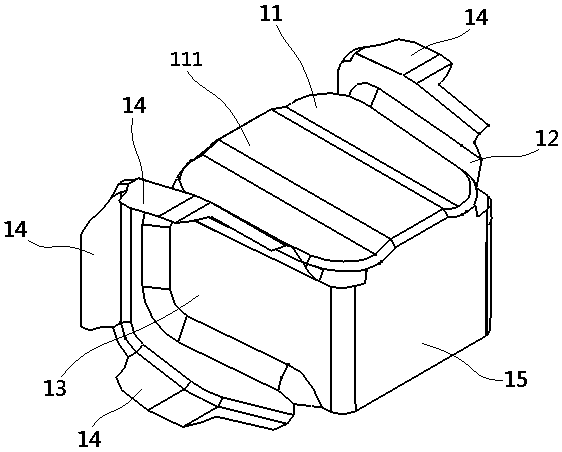

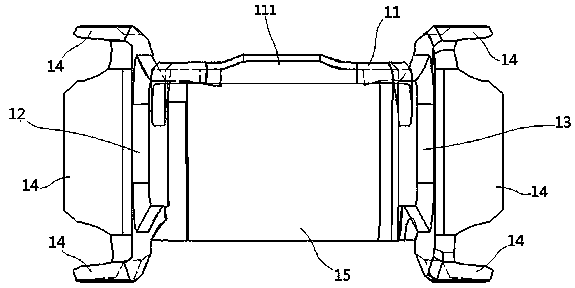

Supporting structure of door impact beam for vehicle

ActiveUS8857891B2Improve side impact performanceImprove impact performancePedestrian/occupant safety arrangementMonocoque constructionsCouplingEngineering

A supporting structure of a door impact beam for a vehicle mounted on an inner panel of a door for the vehicle, may include a coupling part formed with a coupling groove to which the impact beam may be coupled, a supporting part bent downwardly from the coupling part and supporting the coupling part, and mounting parts provided along side portions of the coupling part and the supporting part and mounted on the inner panel of the door, wherein the coupling part, the supporting part, and the mounting part may be integrally formed, and the coupling part and the supporting part may be protruded from the inner panel of the door to form a reinforcing part.

Owner:HYUNDAI MOTOR CO LTD +1

Center pillar outer and manufacturing method thereof

ActiveUS9315215B2Improve side impact performanceAvoid fracturesSuperstructure subunitsEngineeringWelding

A center pillar outer, and a method of manufacturing a center pillar outer, may include an upper panel portion which forms an upper end portion of the center pillar outer, and a lower panel portion which forms a lower end portion of the center pillar outer. The upper and lower panel portions are molded using different methods. A lower end of the upper panel portion and an upper end of the lower panel portion are overlapped with each other, and the overlapping portions are coupled to each other, for example, through welding.

Owner:KIA MOTORS CORP

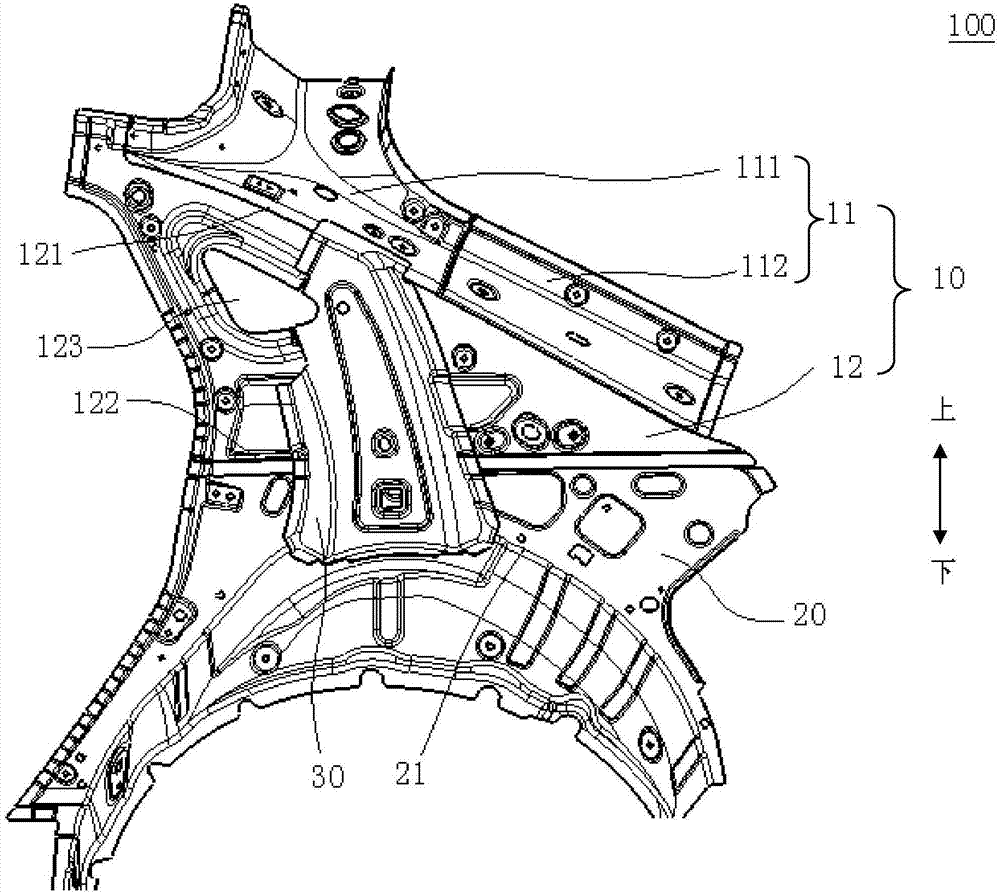

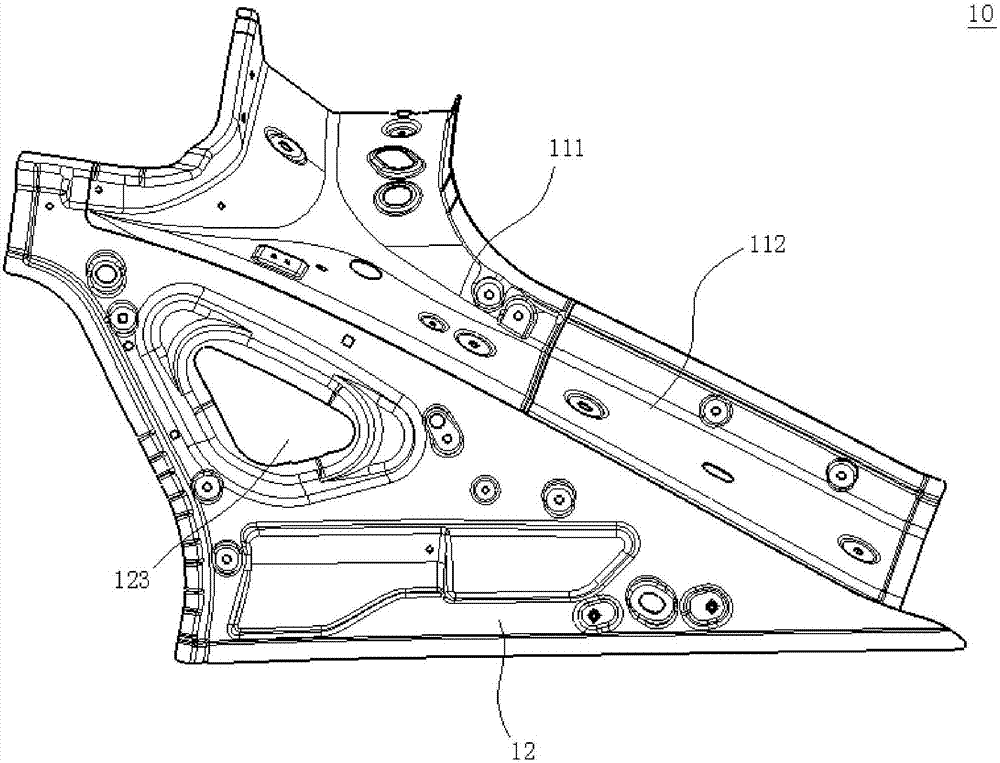

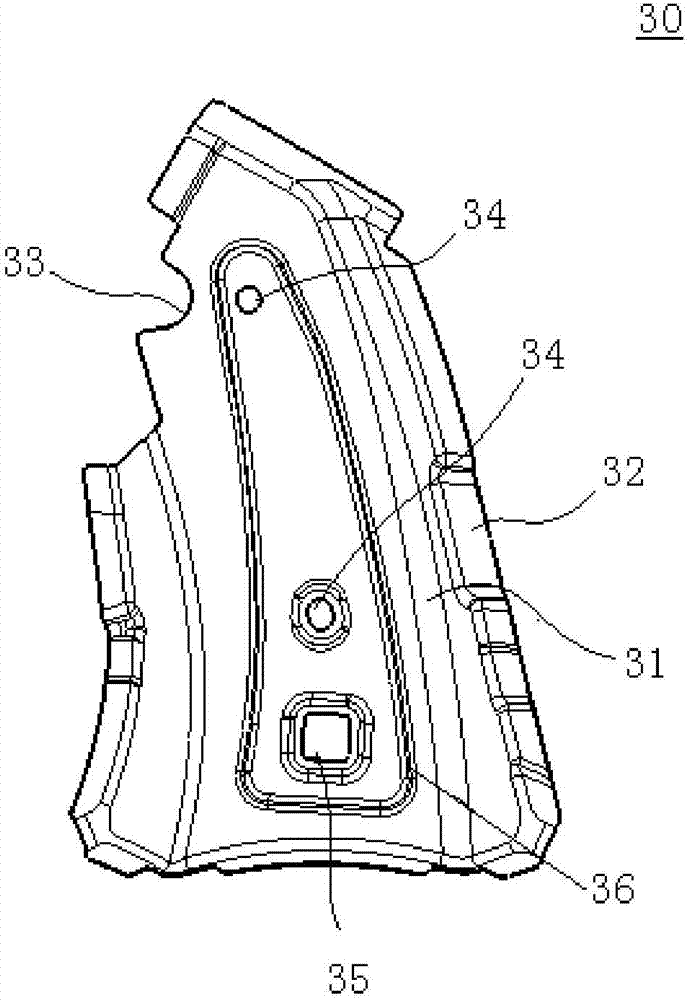

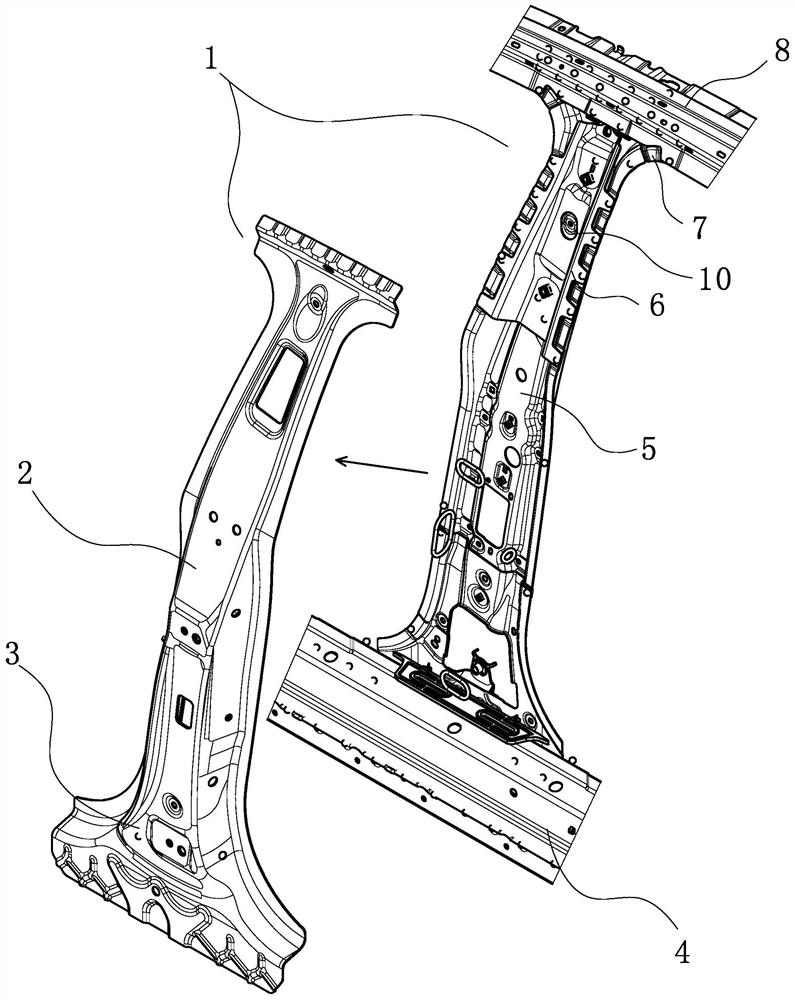

Side body structure on rear portion of vehicle body and vehicle provided with side body structure

InactiveCN107472364AHigh strengthImprove side impact performanceSuperstructure subunitsEngineeringMechanical engineering

The invention discloses a side body structure on the rear portion of a vehicle body and a vehicle provided with the side body structure. The side body structure on the rear portion of the vehicle body comprises a side body rear inner plate assembly, a rear wheel cover outer plate and a reinforcing plate; the rear wheel cover outer plate is fixedly connected with the side body rear inner plate assembly; and the reinforcing plate is located on the outer sides of a side body rear inner plate and the rear wheel cover outer plate, and fixedly connected with the side body rear inner plate assembly and the rear wheel cover outer plate. The side body structure on the rear portion of the vehicle body has good strength and torsional rigidity, and thus the integral strength and the side collision resistant property of the rear portion of the vehicle body are improved.

Owner:BEIQI FOTON MOTOR CO LTD

Automobile central channel reinforcement structure

ActiveCN104773210AImprove structural strengthEasy stampingSuperstructure subunitsAutomotive engineeringClosed loop

The invention discloses an automobile central channel reinforcement structure. The reinforcement structure is arranged in an automobile central channel, the reinforcement structure comprises supporting parts and a supporting crossbeam, both ends of each supporting part are connected through the supporting crossbeam, so that a closed-loop frame structure is formed, and the position of the closed-loop frame structure on the automobile central channel is aligned with a seat crossbeam of an automobile. The bearing capability of the central channel is enhanced greatly, the automobile central channel can be effectively prevented from being deformed greatly in the process of side collision, collision impact load transferred from the seat crossbeam can be transferred to the non-impacted side of the automobile body to the max, so the side collision performance of the automobile is increased, and the side-impact safety of the body of the automobile is improved.

Owner:CHERY AUTOMOBILE CO LTD

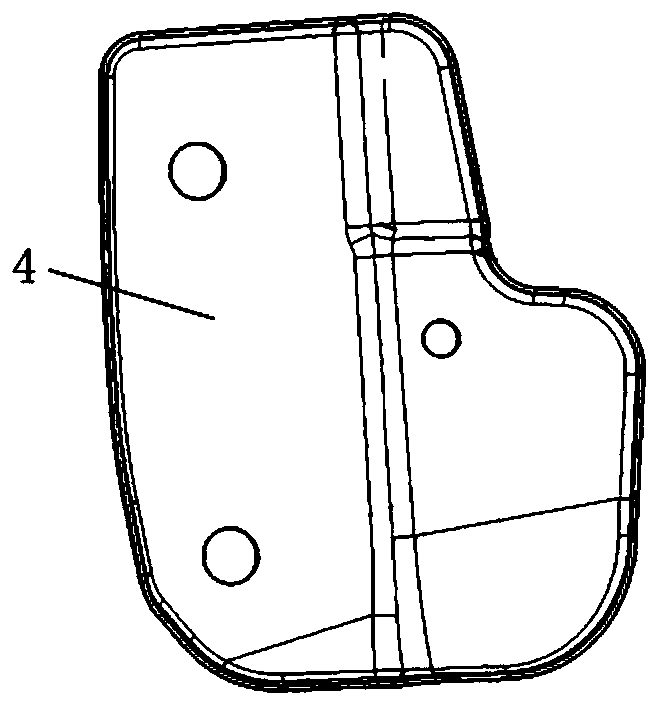

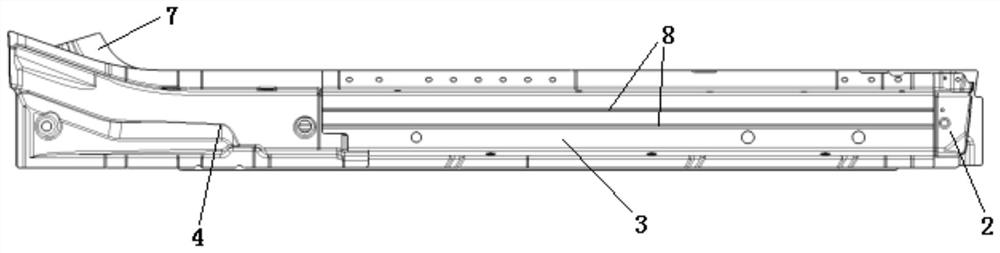

Threshold supporting plate capable of improving side impact performance

InactiveCN110654467ASimple structureAvoid flippingSuperstructure subunitsSide impactMechanical engineering

The invention discloses a threshold supporting plate capable of improving side impact performance, and relates to the field of automobiles. The threshold supporting plate comprises an automobile floor, wherein the edge of the automobile floor is provided with a threshold inner plate; after the threshold inner plate is welded with the automobile floor, and a seat front cross beam and a seat rear cross beam on the automobile floor, the threshold inner plate is welded with a threshold outer plate; a first U-shaped supporting plate and a second U-shaped supporting plate are arranged in a thresholdcavity formed by the threshold inner plate and the threshold outer plate; the first supporting plate is welded to the threshold outer plate, and the second supporting plate is welded to the thresholdinner plate; the first supporting plate and the second supporting plate both carry out centring with the seat front cross beam and the seat rear cross beam; the first supporting plate and the secondsupporting plate are subjected to centring to form a back-to-back structure form; and the center of the first supporting plate and the center of the second supporting plate are independently providedwith a gap for inserting a B pillar inner plate. By use of the threshold supporting plate, the problems that an existing supporting plate structure is complex, is too heavy and can not be universal orcertain supporting structures are too small and can not meet a five-star requirement in a C-NCAP (China-New Car Assessment Program) impact.

Owner:DONGFENG LIUZHOU MOTOR

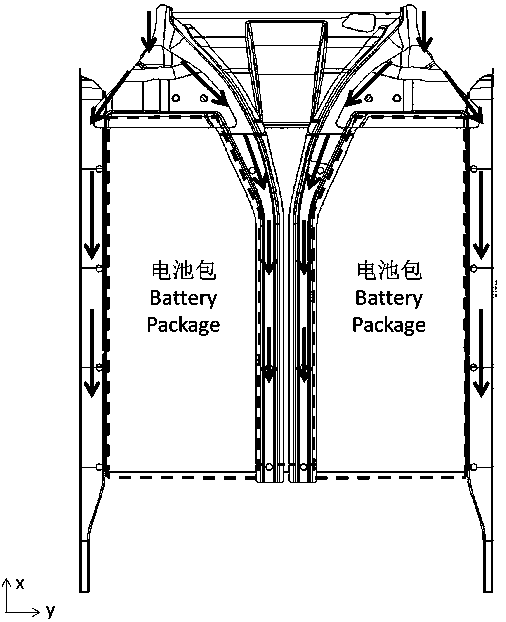

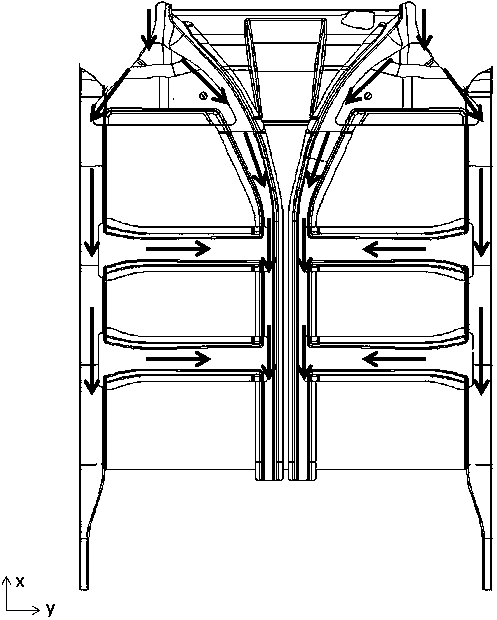

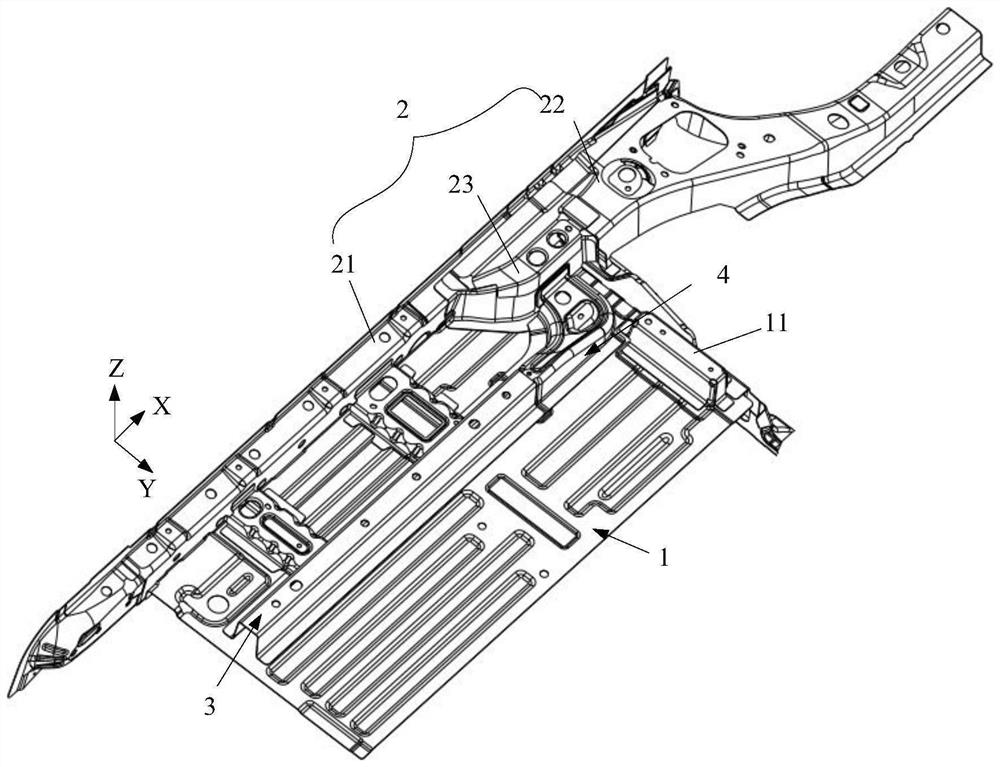

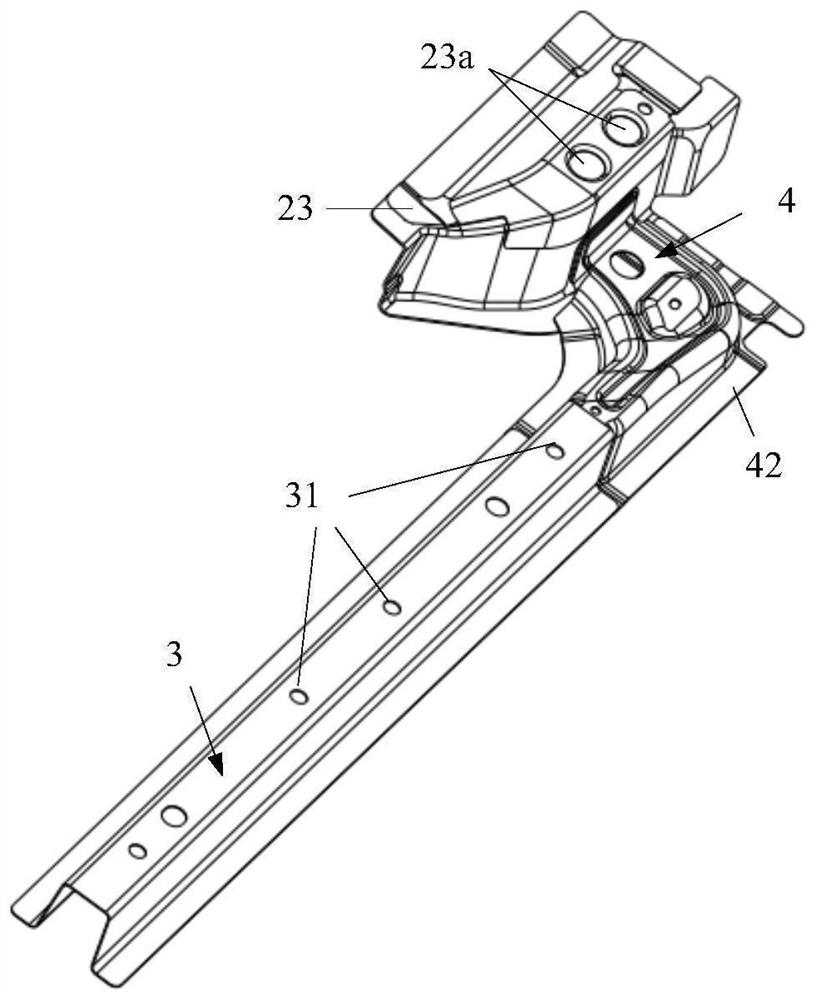

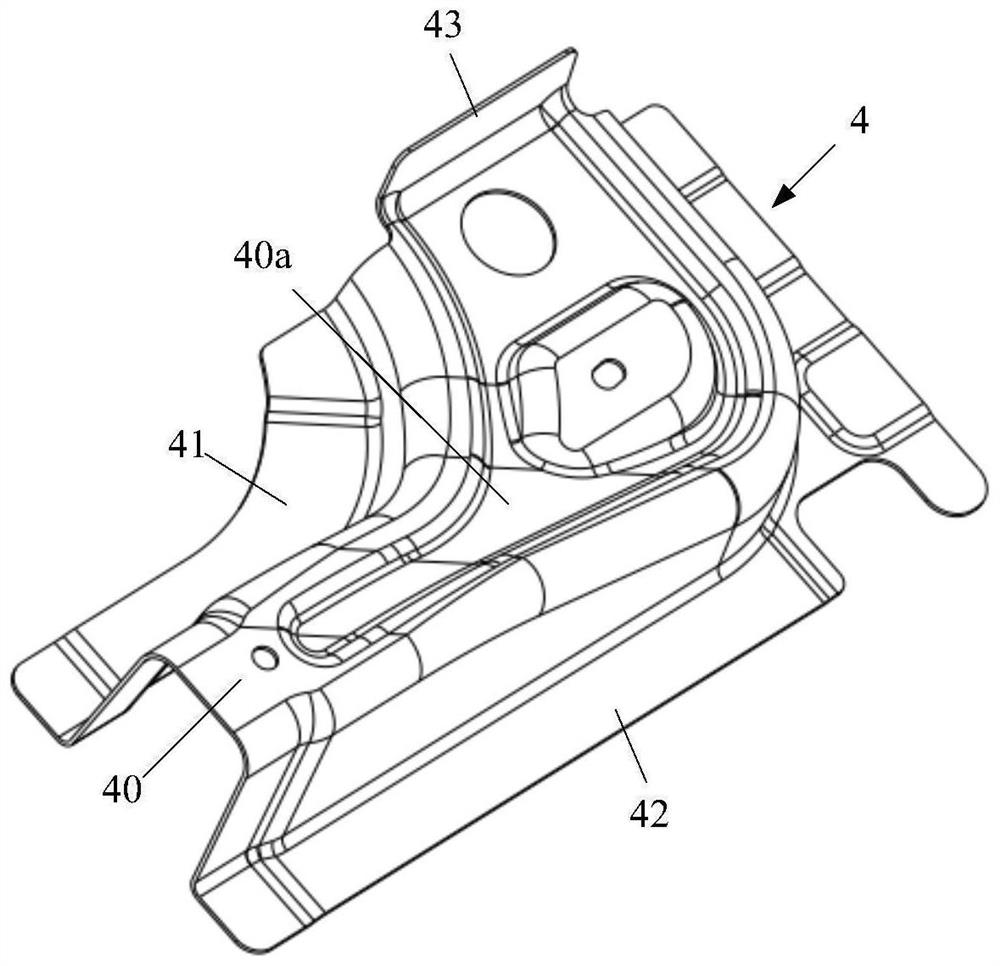

Vehicle body floor assembly and vehicle

PendingCN114802485AImprove side impact performanceImprove versatilitySuperstructure subunitsSide impactMechanical engineering

The invention provides a vehicle body floor assembly and a vehicle. The vehicle body floor assembly comprises a floor, a doorsill longitudinal beam and a floor longitudinal beam, wherein the doorsill longitudinal beam and the floor longitudinal beam are fixed to the floor. The connecting piece is fixed to the floor and located between the doorsill longitudinal beam and the floor longitudinal beam; wherein the doorsill longitudinal beam and the floor longitudinal beam are connected through the connecting piece. When side collision occurs, collision force is effectively transmitted to the floor longitudinal beam and the floor through the threshold longitudinal beam, the survival space of a driver and passengers is prevented from being excessively occupied, extrusion of side collision to the battery pack is reduced or avoided, and the side collision safety performance of the whole vehicle is improved.

Owner:ZHEJIANG GEELY HLDG GRP CO LTD +1

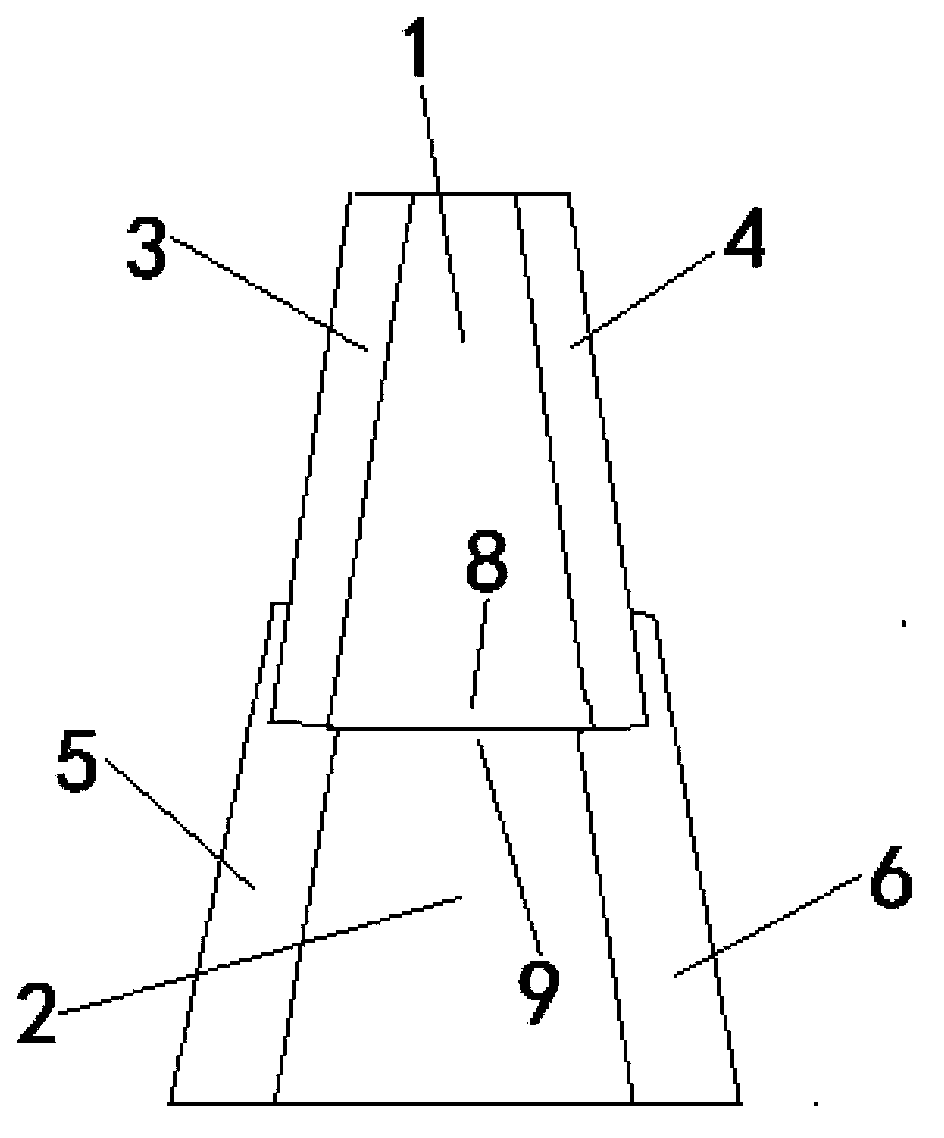

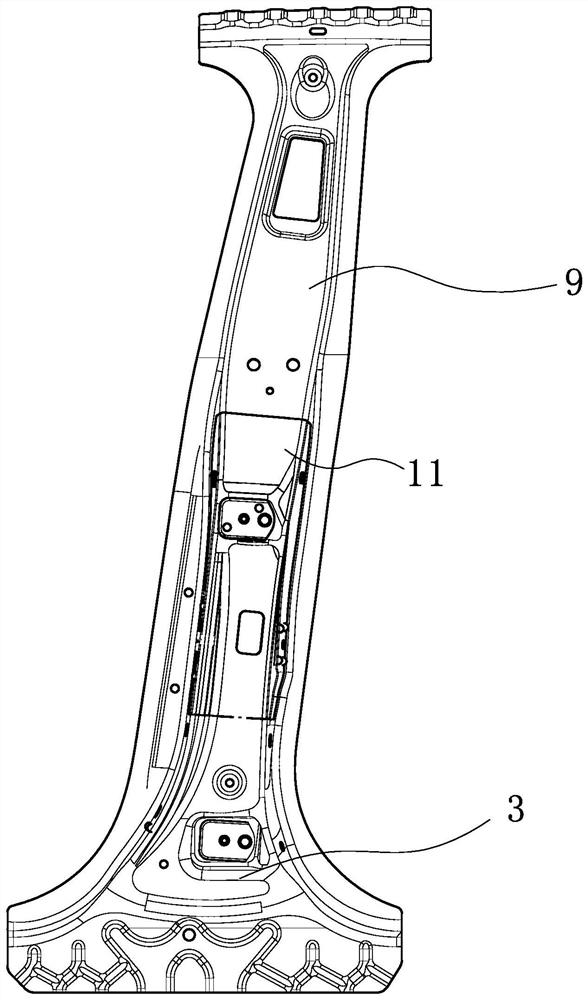

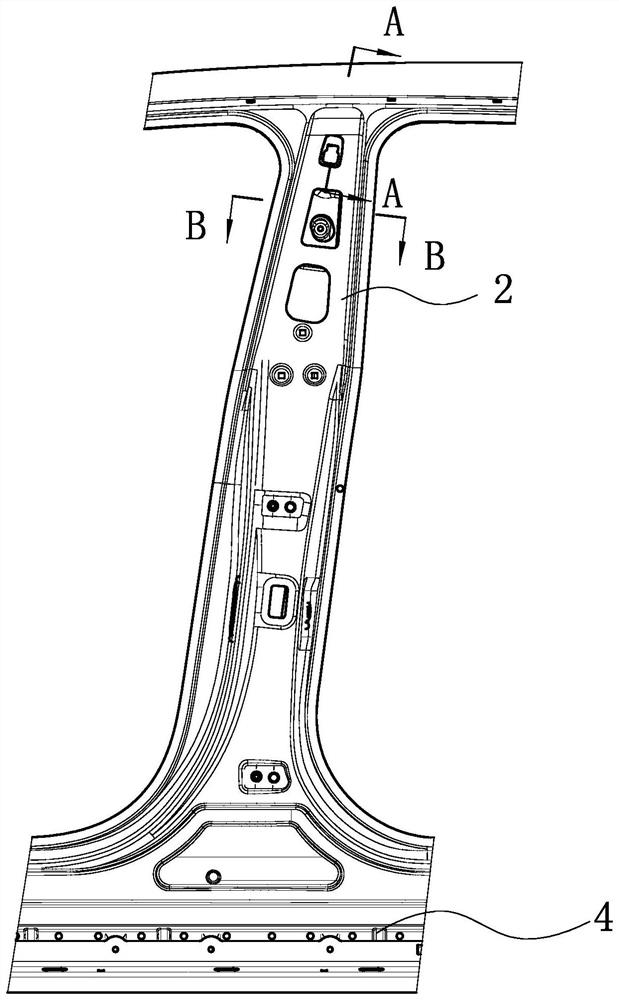

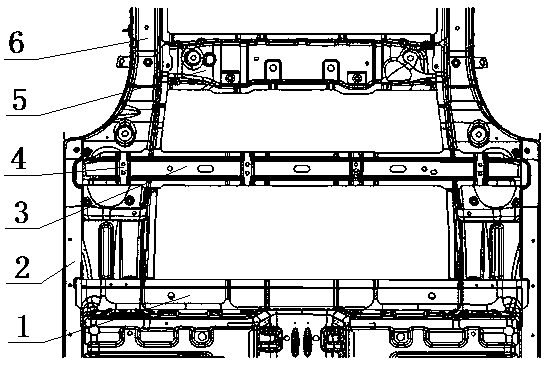

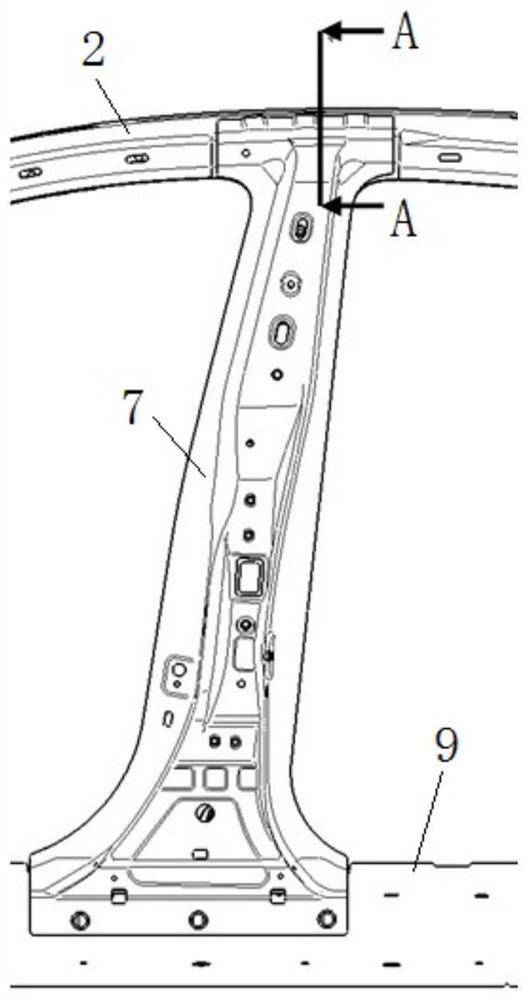

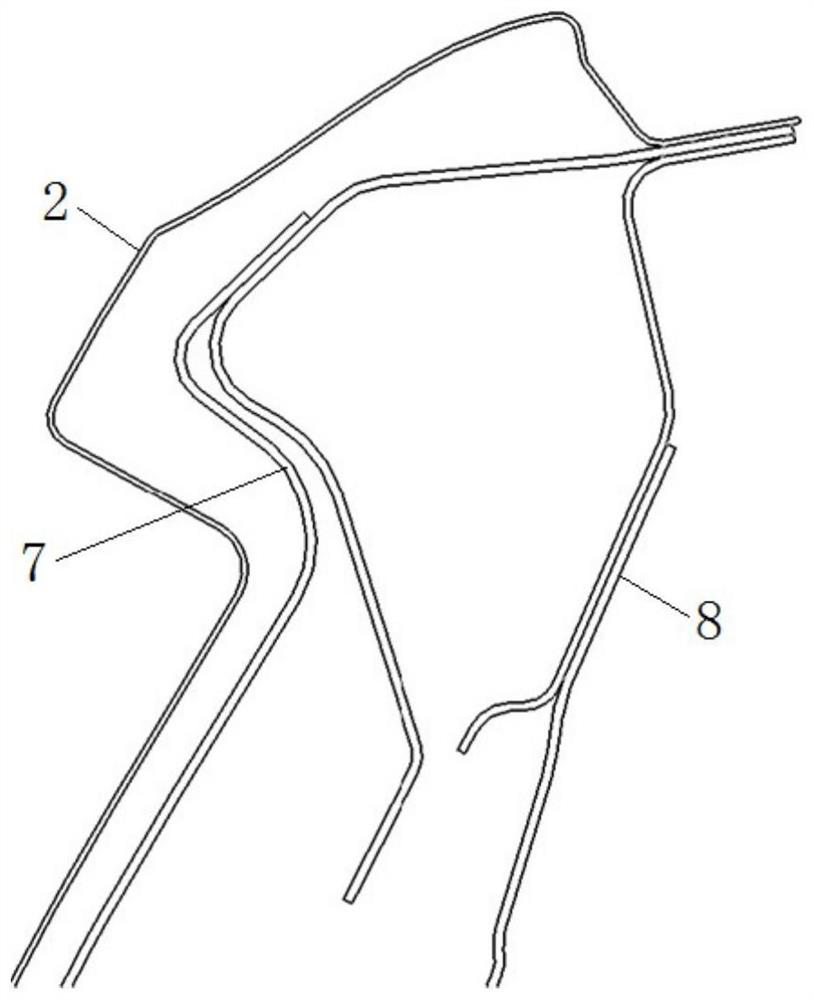

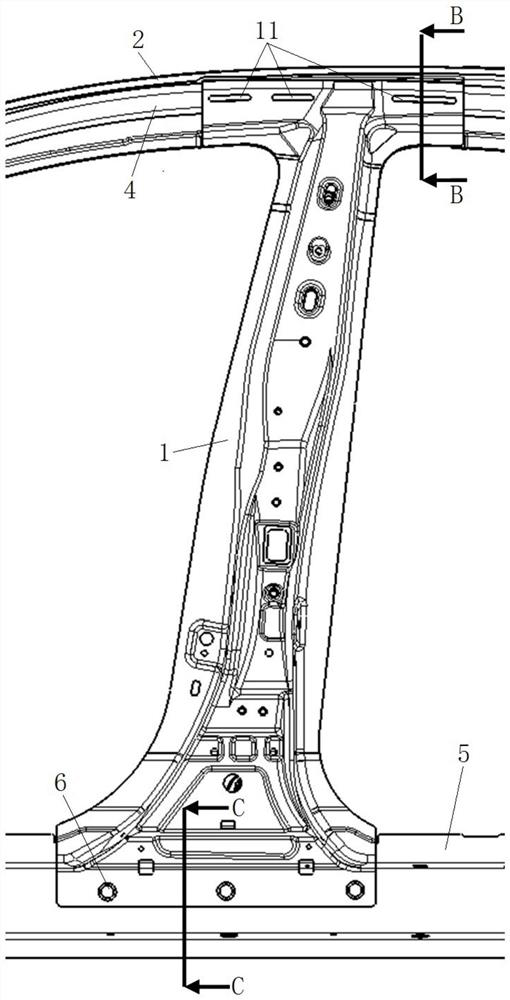

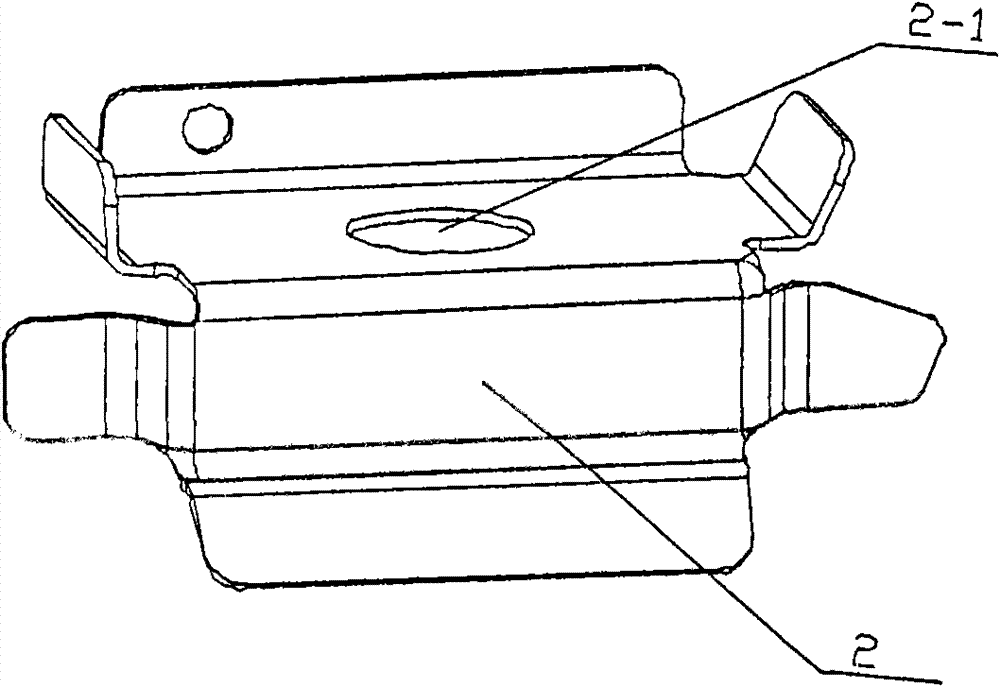

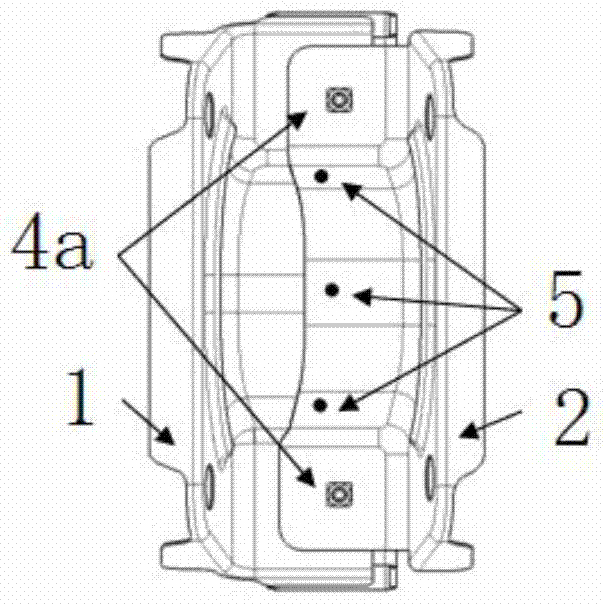

Reinforcing plate structure of automobile column B

InactiveCN103832479AImprove side impact performanceLess human injurySuperstructure subunitsEngineeringSide impact

The invention provides a reinforcing plate structure of an automobile column B, and belongs to the technical field of automobile body parts. The reinforcing plate structure comprises an upper reinforcing plate (1) and a lower reinforcing plate (2), the upper reinforcing plate (1) and the lower reinforcing plate (2) are set to be of a structure with a U-shaped section, and the lower end portion of the upper reinforcing plate (1) is connected with the upper end portion of the lower reinforcing plate (2) in a welding mode. According to the reinforcing plate structure, stress in the side impact process can be concentrated on the lap-jointpositionof the upper reinforcing plate and the lower reinforcing plate, therefore, the problem that the intrusion amount of the upper portion of the reinforcing plates is large in the side impact process is solved, the side impact performance of the reinforcing plates of the column B is improved, and the aim of reducing hurt to the human body by side impacts is achieved. Meanwhile, the reinforcing plate structure is simple in structure, low in cost and high in reliability.

Owner:ANHUI YUFENG AUTOMOTIVE TECH

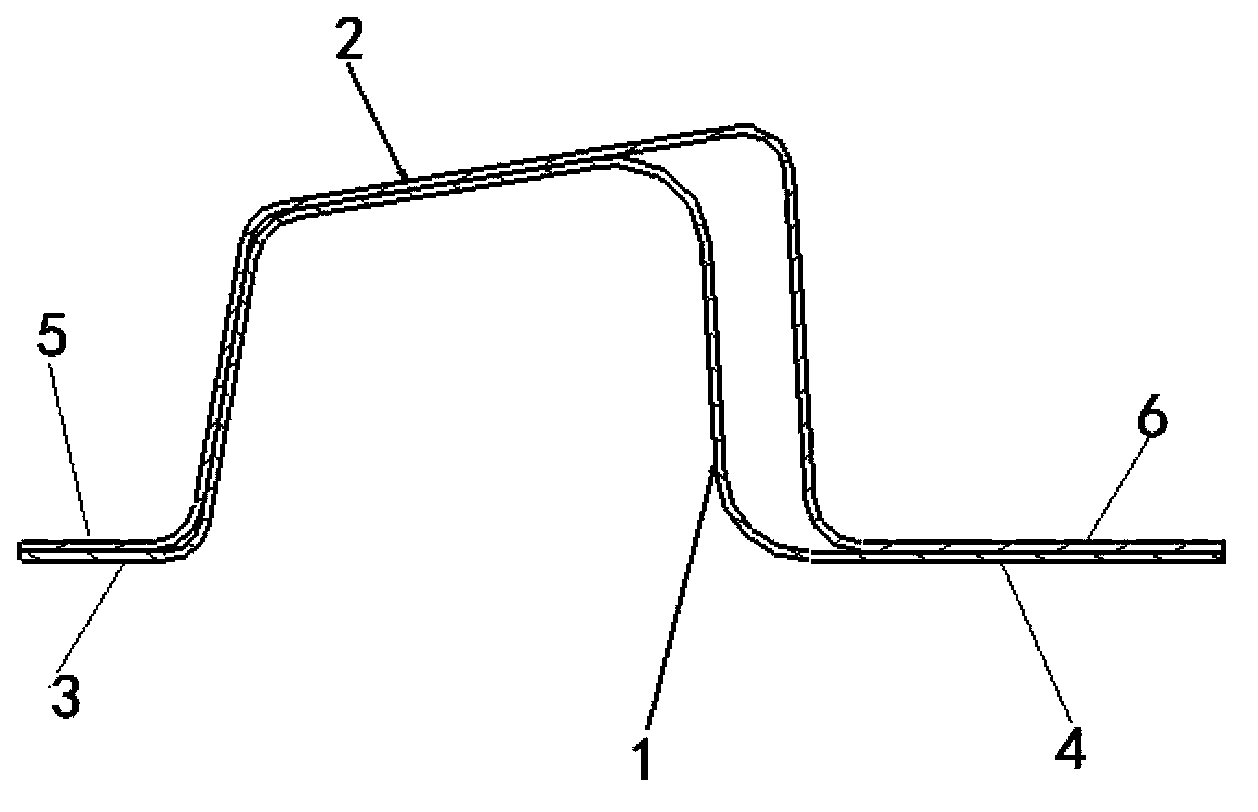

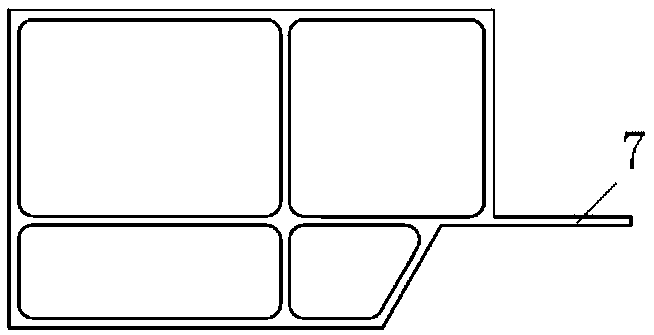

Automobile threshold reinforcing structure

InactiveCN108016500ASimple structureEasy stampingSuperstructure subunitsUltimate tensile strengthAssembly structure

The invention relates to an automobile threshold reinforcing structure. The automobile threshold reinforcing structure is characterized in that the automobile threshold reinforcing structure comprisesa top plate, a left side plate, a right side plate and a rear vertical plate; the top plate, the left side plate, the right side plate and the rear vertical plate form a semi-enclosing structure; flanging structures extending towards the outer sides are arranged at the upper ends, the front ends and the lower ends of the left side plate and the right side plate correspondingly; a groove structureis arranged on the top plate in the front-back direction, a groove opening of the groove structure faces downwards, and the outer surface of the groove bottom is higher than the upper plane of the top plate; and the threshold reinforcing structure is an integrated structure or a split type assembly structure. A same mould is used for the automobile threshold reinforcing structure in either of theintegrated structure or the split assembly structure, the design is reasonable, the structure is simple, stamping is easy, mechanical strength is high, safety performance is good, and side collisionperformance can be improved effectively; and compared with the prior art, the manufacturing cost is reduced.

Owner:CHERY AUTOMOBILE CO LTD

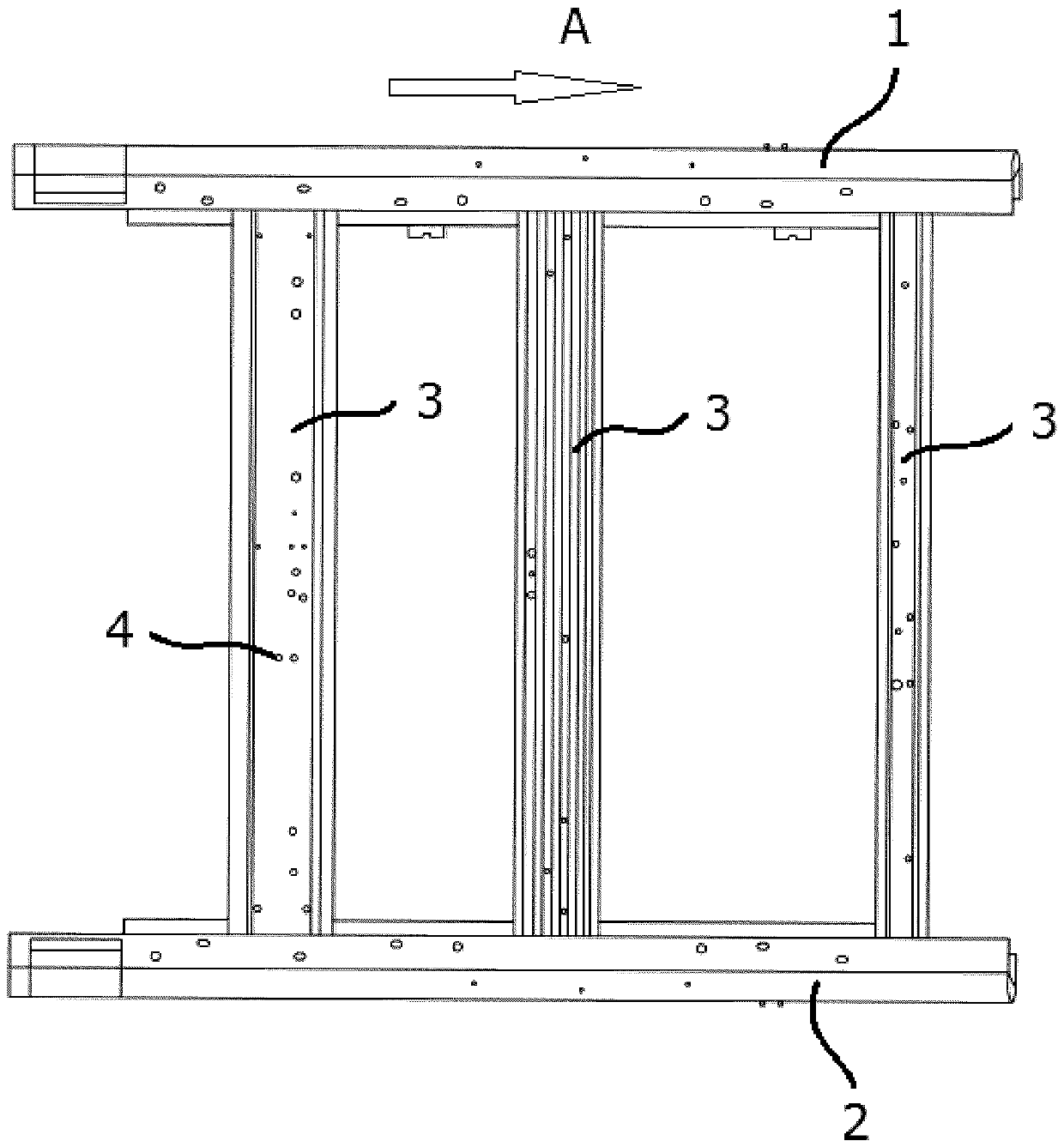

White vehicle body frame

PendingCN112373569AIncrease the X dimensionImprove wind resistanceSuperstructure subunitsInternal combustion piston enginesEngineeringBilateral symmetry

The invention discloses a white vehicle body frame. An upper surface of a front floor assembly is flush with the upper surface of a rear floor assembly, a concave spare wheel cabin is arranged on themiddle rear portion of the front floor assembly, and an upper left longitudinal beam and an upper right longitudinal beam are fixed to the upper surface of the front floor assembly in a bilateral symmetry mode. The left upper longitudinal beam and the right upper longitudinal beam are respectively arranged corresponding to the front parts of a left beam and a right beam up and down; a cross beam group comprises a first cross beam, a second cross beam and a cross beam outward extending component which are fixed on the lower surface of the front floor assembly and also comprises a spare wheel cabin upper cross beam, a left seat front cross beam, a right seat front cross beam, a left seat rear cross beam and a right seat rear cross beam fixed to the upper surface of the front floor assembly,the outer side of the left beam and the outer side of the right beam are fixedly connected with a threshold inner plate body through cross beam outer extending assemblies respectively. According to the white vehicle body frame, a multi-force-transmission-path frame structure is formed, the collision force is effectively dispersed, the safety performance of a vehicle is improved, the height of thevehicle is reduced, and the wind resistance of the whole vehicle is improved.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

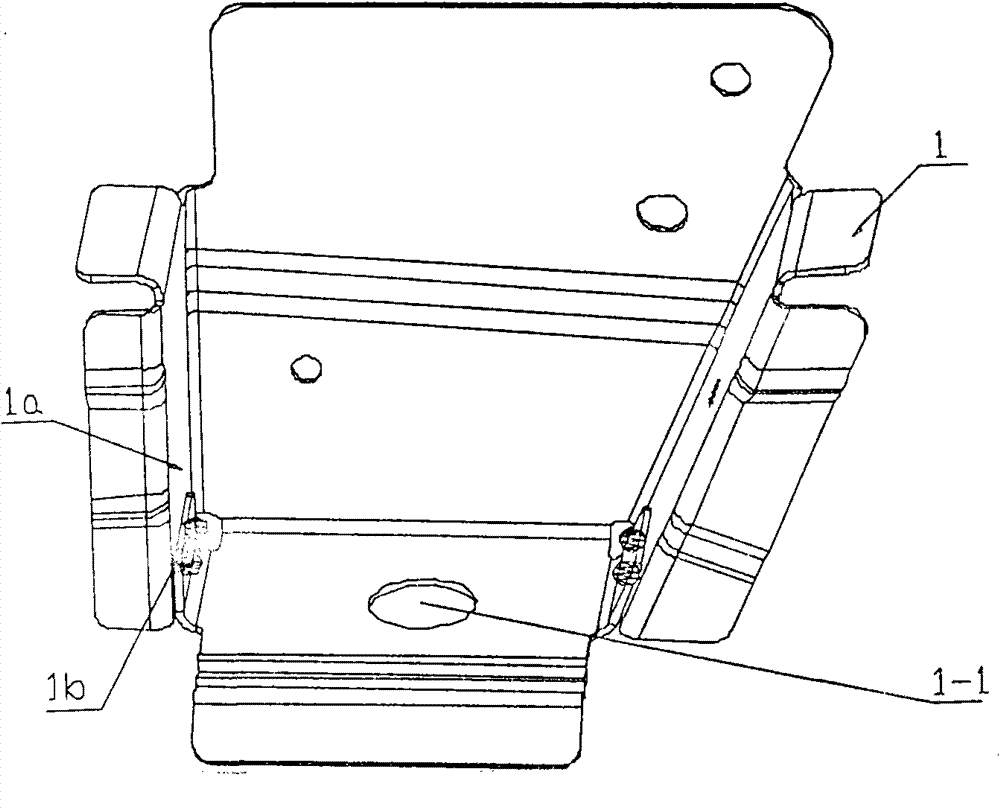

Automobile door lower hinge reinforcing piece

PendingCN110182025AReach the rigidity requirementMeet strength requirementsHingesDoorsUltimate tensile strengthFlange

Owner:SHANGHAI COTECH AUTOMOTIVE ENG CORP LTD

A B -pillar structure for installing the face recognition device

ActiveCN111547138BMeet the strength and rigidity requirementsImprove securityCharacter and pattern recognitionSuperstructure subunitsVehicle safetyColumn structure

Owner:ZHEJIANG LEAPMOTOR TECH CO LTD

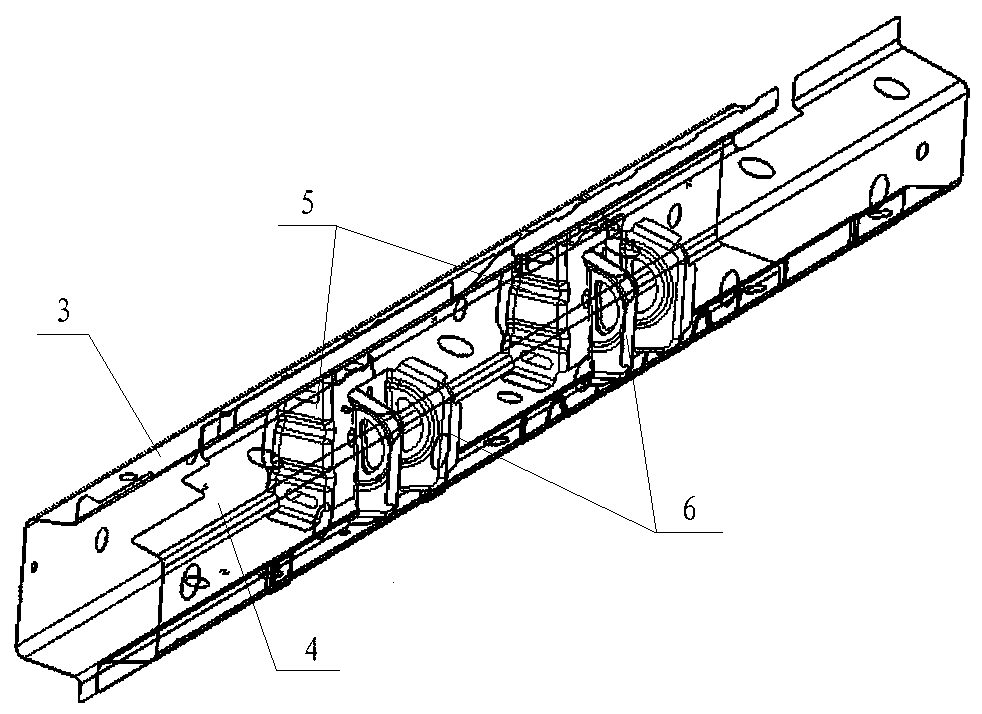

Middle row seat mounting cross beam

InactiveCN110789408AIncrease stiffnessIncreased torsional stiffnessSeat framesSuperstructure subunitsCantileverMechanical engineering

The invention discloses a middle row seat mounting cross beam, and relates to the technical field of automobile manufacturing. The middle row seat mounting cross beam comprises a seat cross beam located between a rear floor front cross beam and a rear floor lower cross beam. The two ends of the seat cross beam respectively penetrate through rear longitudinal beams to be fixedly connected with threshold beams. A plurality of seat mounting supports are arranged on the seat cross beam. Compared with the prior art, according to the middle row seat mounting cross beam, a seat in the middle and seats on two sides are mounted on the seat mounting supports, middle-row seats can be mounted through just two parts, few types of tools for production are required correspondingly, and the production cost is low. The seat mounting supports are arranged on the seat cross beam, a cantilever structure is eliminated, and the rigidity of a seat mounting point is improved. When a vehicle body is subjectedto side collision, through the rear floor front cross beam, the rear floor lower cross beam and the seat cross beam for force transmission, a side collision force transmission path is increased, sideimpact bearing performance is improved, and meanwhile, the torsional rigidity is effectively improved.

Owner:DONGFENG LIUZHOU MOTOR

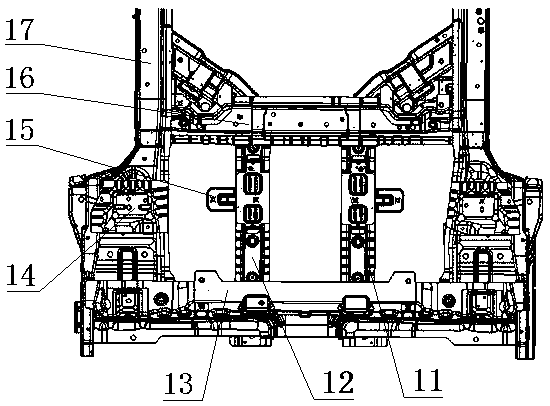

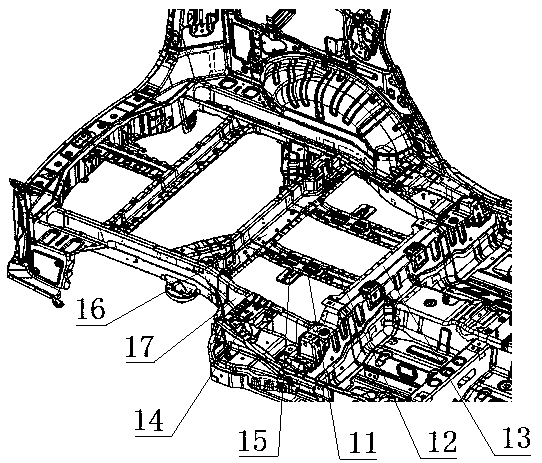

B-column reinforcing structure and vehicle

PendingCN113002632AImprove structural strengthStrong and reliable support structureSuperstructure subunitsAutomotive engineeringMechanical engineering

The invention discloses a B-column reinforcing structure and a vehicle. The B-column reinforcing structure comprises a B-column reinforcing piece arranged between a B-column inner plate and a side wall outer plate, the tensile strength of the B-column reinforcing piece is larger than or equal to 1800 Mpa, and the ductility of the B-column reinforcing piece is larger than or equal to 5%; a transverse containing cavity is defined by the upper portion of the B column reinforcing piece and the B column inner plate, a tubular reinforcing piece is arranged in the transverse containing cavity, and the outer side wall of the tubular reinforcing piece is partially attached to and fixedly connected with the transverse containing cavity. And the lower end of the B-column reinforcing piece is fixedly connected with the aluminum alloy doorsill boundary beam. Under the condition that the weight is not increased, the side collision performance of a passenger compartment is improved, and the invasion amount of the passenger compartment during side collision is reduced.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

Vehicle front floor structure, aluminum alloy extrusion molding part and vehicle

PendingCN109895866AImprove side impact performanceHigh strengthSuperstructure subunitsMaterials scienceSet distance

The invention relates to a vehicle front floor structure, an aluminum alloy extrusion molding part and a vehicle. The vehicle front floor structure comprises a left doorsill, a right doorsill, and a plurality of cross beams arranged between the left doorsill and the right doorsill; the cross beams comprise at least two first-type cross beams which are arranged at intervals; the at least two first-type cross beams are aluminum alloy extrusion molded parts and are configured to have different cross section shapes; the deformation amount of the left doorsill and / or the right doorsill meets the set requirements when the vehicle is subjected to a side collision impact, and the set requirements comprise the step that a set distance is kept between the left doorsill and / or the right doorsill after deformation and a vehicle part suspended on at least a part of the cross beam. By applying the structure, the strength of the automobile body beam can be remarkably enhanced, the side collision performance of the vehicle is improved, various automobile parts installed on the lower portion of the vehicle body can be protected, and the safety performance of the vehicle is improved.

Owner:NIO ANHUI HLDG CO LTD

Engine bracket front mounting structure

ActiveCN101954852BEasy to shapeAvoid loose situationsJet propulsion mountingInternal combustion mountingVehicle frameEngineering

The invention discloses an engine bracket front mounting structure, comprising an engine bracket front amounting assembly which is composed of a front mounting support, a reinforcing plate and an auxiliary frame connecting pipe by connection; wherein the engine bracket front mounting assembly is a small cavity, and the engine bracket front mounting assembly is welded with an engine cabin boundarybeam front section and an engine cabin boundary beam front part shell plate, so as to form a larger cavity. The invention has the following advantages: forming of parts is simple, welding quality is easy to control, error is less, and product consistency is good; the engine bracket front mounting assembly is welded with the engine cabin boundary bean front section and the engine cabin boundary beam front part shell plate, so as to form a larger cavity, and the gravity of an engine bracket is timely transferred on the engine cabin boundary beam front section, thus ensuring strength and rigidity of the engine bracket front mounting structure, effectively improving direct impact and side impact performances and avoiding the condition that the engine bracket is loosened due to twisting, braking, bumping or impacting of car body.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

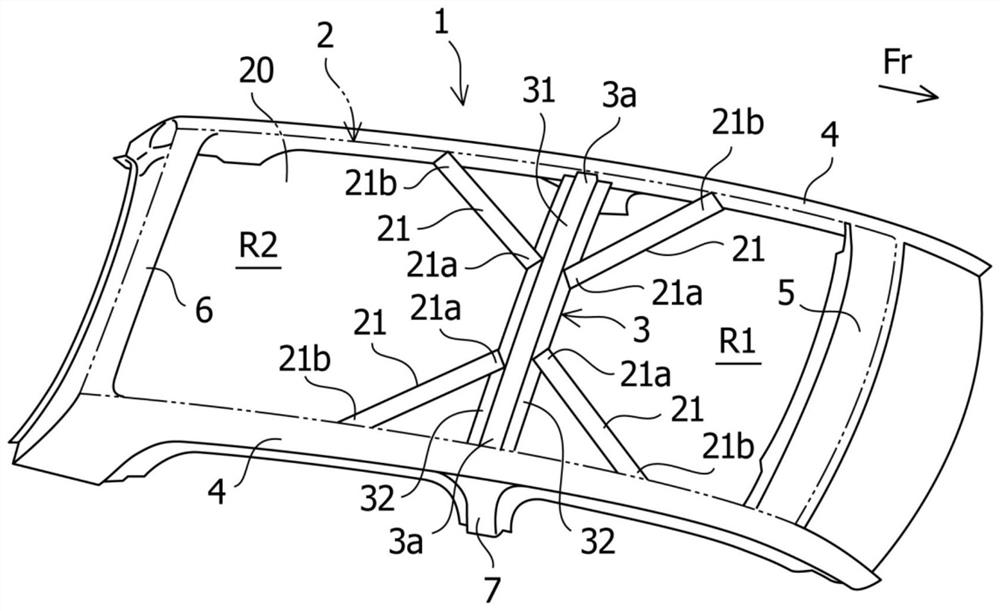

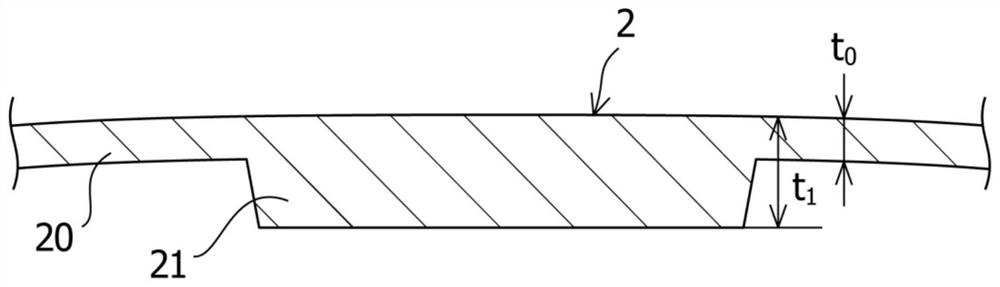

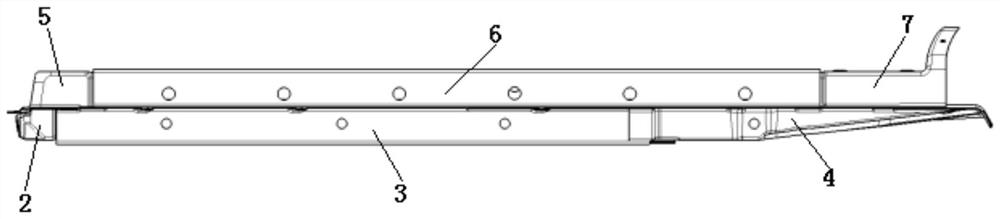

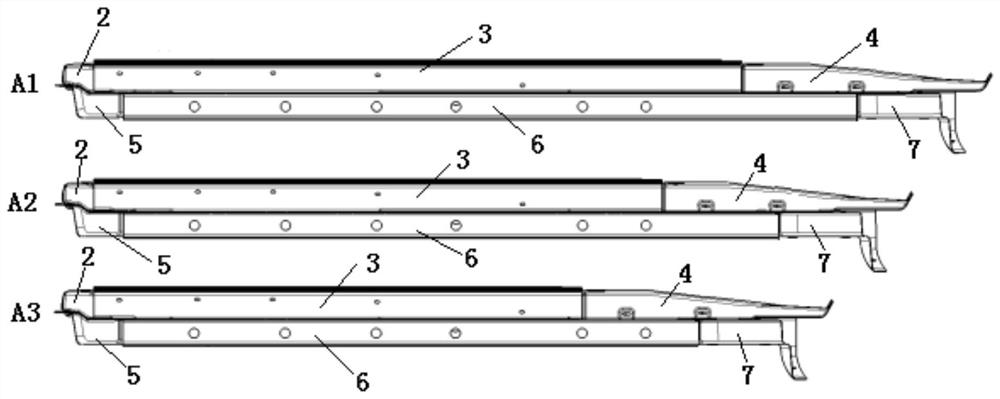

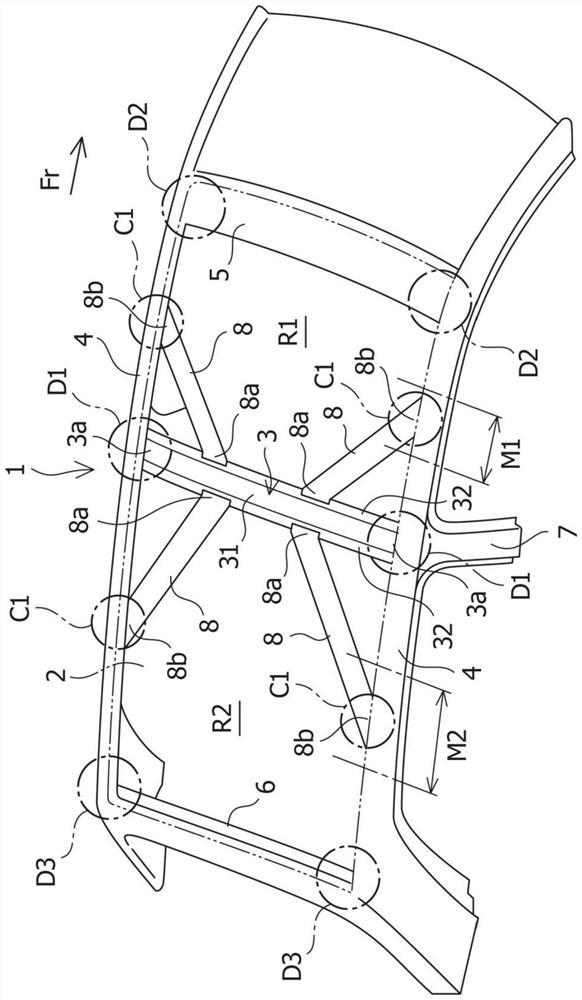

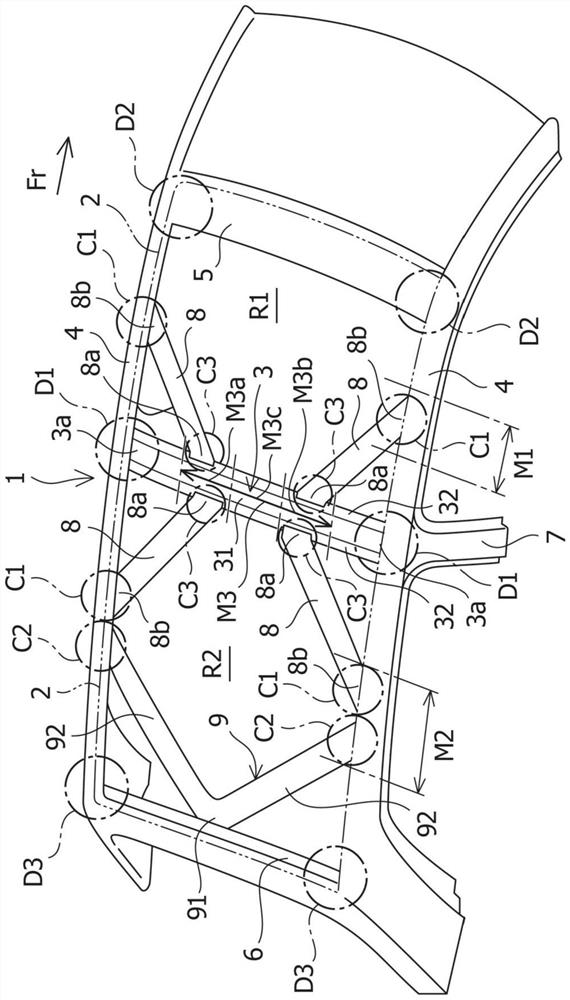

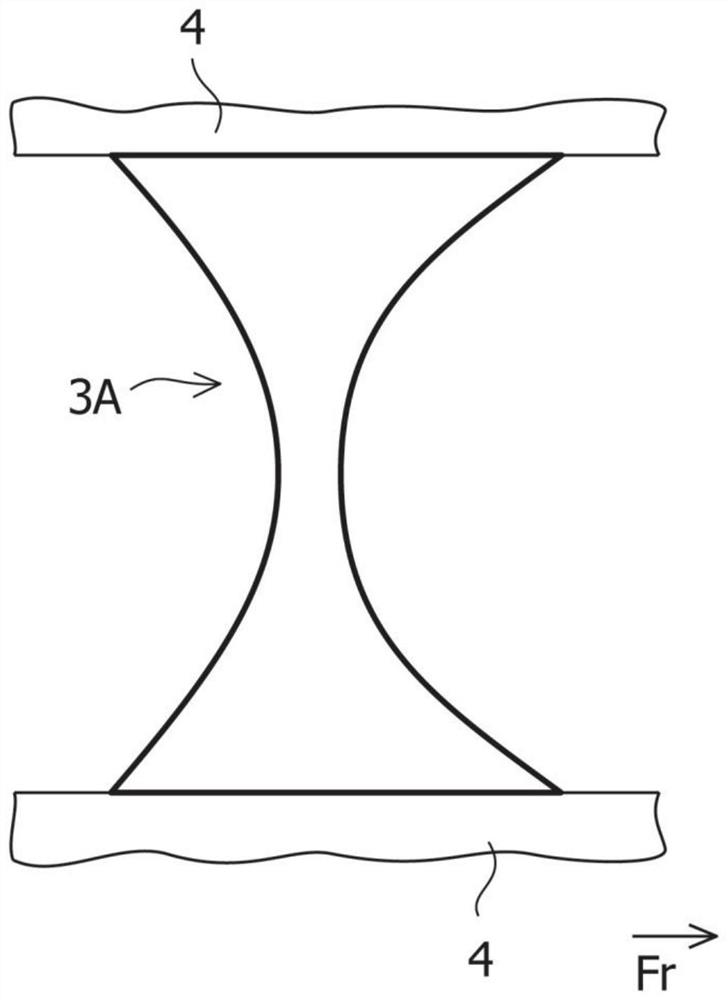

superstructure

ActiveCN107804374BImprove rigidityImprove side impact performanceSuperstructure subunitsHigh stiffnessClassical mechanics

The invention provides an upper structure of a vehicle bodywork. Torsional rigidity and side face collision performance of a vehicle bodywork can be improved and weight reduction of the vehicle bodywork is achieved in case that enhancement components are not increased. The upper structure includes a resin roof (2), a roof beam (3) in a vehicle width direction, and roof rails (4) on the right and left sides in a longitudinal direction of vehicle on the right and left sides of a vehicle body, the roof (2) having portions of high rigidity (21) each having greater rigidity than other normal portions (20) of the roof (2), each high stiffness portion (21) being at an angle of an intermediate portion of the roof beam (3) in the vehicle width direction to one of the corresponding roof rails (4) onthe right and left sides and each high rigidity portion (21) being in a vehicle front side region (R1) or a vehicle rear side region (R2) on each side of the roof beam (3).

Owner:SUZUKI MOTOR CORP

Motor vehicle chassis with anti-collision device

InactiveCN102050149ANo extrusion deformationProtect the headUnderstructuresSteering columnSteering wheel

The invention discloses a motor vehicle chassis with an anti-collision device. The motor vehicle chassis comprises a tubular longitudinal beam, a piston cylinder, a piston, a piston mandril, a pressure relief tube, a piston cylinder end cover, an anti-collision rod and energy dissipation liquid, wherein one end of the piston cylinder is fixedly connected with the tubular longitudinal beam, and the other end is connected with the piston cylinder end cover; one end of the piston mandril is connected with the top of the piston, and the other end penetrates through the piston cylinder end cover to connect the anti-collision rod; the energy dissipation liquid is filled in the tubular longitudinal beam and the piston cylinder; the pressure relief tube is reserved on the piston cylinder; the piston is provided with at least one jet hole; the jet hole penetrates from the bottom of the piston to the top of the piston, so the tubular longitudinal beam is in a stretched state in an anti-collision process so as to prevent a passenger room from being extruded and deformed and prevent a steering column and a steering wheel from moving backwards to smash the heads and the chests of a passenger. Therefore, the security of a motor vehicle can be improved extremely.

Owner:凌建军

Vehicle door threshold assembly and vehicle

ActiveCN113635978AImprove general performance of the platformReduce the input of manpower and material resourcesSuperstructure subunitsCar doorWheelbase

The invention relates to a vehicle door threshold assembly and a vehicle. The vehicle door threshold assembly comprises a floor threshold and a side wall threshold which are connected with each other; a closed cavity is formed between the floor threshold and the side wall threshold; the floor threshold comprises a floor threshold front section, a floor threshold middle section and a floor threshold rear section which are connected in sequence; the side wall threshold comprises a front side wall threshold section, a middle side wall threshold section and a rear side wall threshold section which are connected in sequence; and the floor threshold middle section and the side wall threshold middle section have different lengths so as to be matched with vehicle types with different wheelbases. The invention also discloses a vehicle which includes the vehicle door threshold assembly. The problems that an existing threshold assembly is low in universality, high in production cost, low in production efficiency and complex in working procedure are solved.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

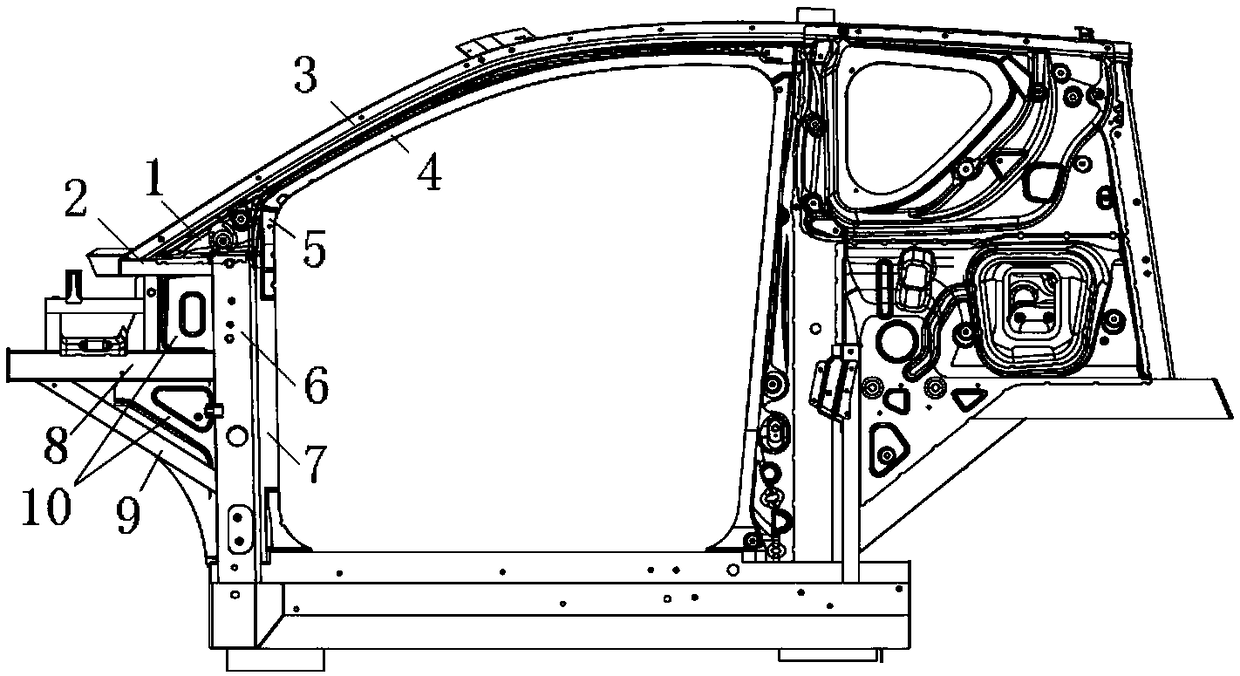

The connection structure between the a-pillar and the lower a-pillar of the vehicle body

ActiveCN106218724BMiniaturizationImprove battery lifeSuperstructure subunitsEngineeringElectric vehicle

The invention discloses a connection structure between the A-pillar and the A-pillar of a vehicle body, which includes a connecting plate and a connecting beam. The connecting beam is a longitudinal beam. One end of the connecting beam is fixed on the front side of the upper end of the A-pillar lower structure, and the other end of the connecting beam Connected to the front end of the A-pillar upper structure, the connecting plate is a triangular plate, the upper edge of the connecting plate is connected to the A-pillar upper structure, and the lower edge of the connecting plate is connected to the connecting beam and the upper end of the A-pillar lower structure. The connection structure is reasonably designed and the connection is reliable. All parts are made of aluminum and are light in weight. It has good frontal impact and side impact effects. Both collision and weight can be taken into consideration at the same time. It is conducive to the lightweight of electric vehicles and can effectively extend the electric vehicle life. Car mileage.

Owner:奇瑞新能源汽车股份有限公司

Instrument panel cross beam and automobile

PendingCN114852182AImprove frontal collisionImprove side impact performanceSuperstructure subunitsDashboardSteering column

The instrument panel cross beam is used for being connected with an automobile body, the instrument panel cross beam comprises a main beam, a supporting frame, a left end plate, a right end plate and a connecting frame, the main beam comprises a metal framework and a plastic part, the metal framework extends in the first direction, and the left end plate and the right end plate are located at the two ends of the metal framework correspondingly; the plastic part wraps one side of the metal framework, the plastic part, the left end plate, the right end plate and the supporting frame are integrally formed in an injection mode with the metal framework as an insert, the supporting frame extends in the second direction, the second direction is perpendicular to the first direction, the supporting frame is used for being connected with the middle channel, and the connecting frame is connected with the plastic part and used for being connected with a front wall and a steering column. The left end plate is connected with a left side wall, and the right end plate is connected with a right side wall. The instrument panel cross beam is supported and bears force through the metal framework, other structures are integrally formed in an injection molding mode with the metal framework as an insert, and meanwhile the requirements for rigidity and light weight of the instrument panel cross beam are met.

Owner:SHENZHEN SILVER BASIS TECH

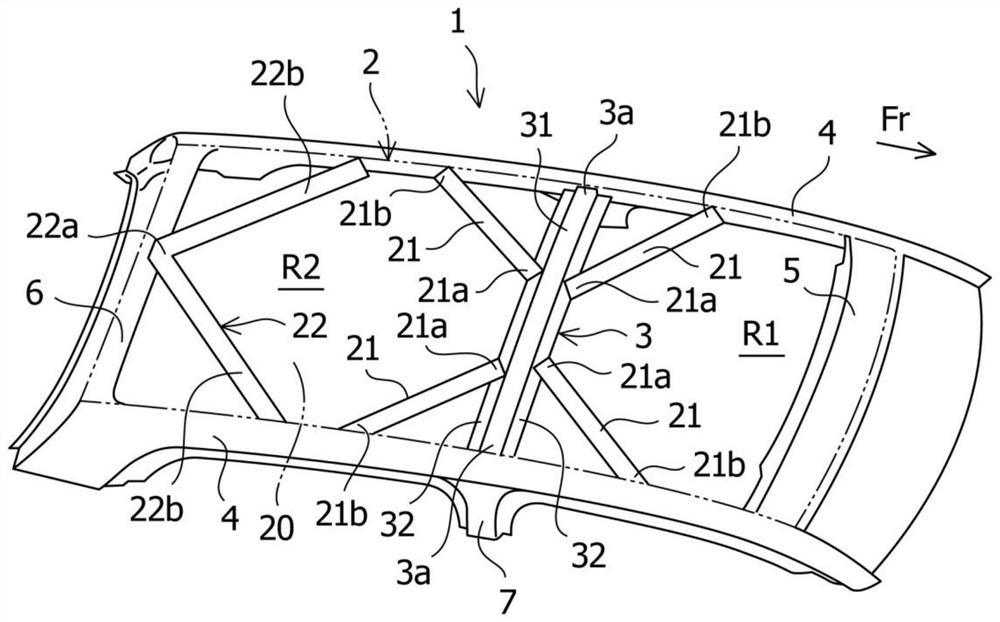

superstructure

ActiveCN107804373BImprove rigidityImprove side impact performanceSuperstructure subunitsSide impactControl theory

To provide a vehicle body upper structure, the purpose of which is to reduce the weight of the vehicle body and improve the torsional rigidity and side impact performance of the vehicle body. The upper structure of the car body includes: a roof (2); a roof beam (3), which extends along the width direction of the vehicle; and roof rails (4) located on the left and right sides, which extend along the Extending in the front-to-rear direction, the roof cross member (3) and the roof rail (4) are connected to each other by first reinforcement members (8), each first reinforcement member (8) being arranged from the vehicle width of the roof cross member (3) to The middle part of the direction extends to a corresponding one of the roof rails (4) located on the left and right sides along the inclined direction, and each first reinforcement member (8) is arranged on the roof rail ( 3) in the vehicle front side region (R1) or the vehicle rear side region (R2).

Owner:SUZUKI MOTOR CORP

A reinforced structure for the central passage of a car

ActiveCN104773210BImprove structural strengthEasy stampingSuperstructure subunitsClosed loopSide impact

The invention discloses an automobile central channel reinforcement structure. The reinforcement structure is arranged in an automobile central channel, the reinforcement structure comprises supporting parts and a supporting crossbeam, both ends of each supporting part are connected through the supporting crossbeam, so that a closed-loop frame structure is formed, and the position of the closed-loop frame structure on the automobile central channel is aligned with a seat crossbeam of an automobile. The bearing capability of the central channel is enhanced greatly, the automobile central channel can be effectively prevented from being deformed greatly in the process of side collision, collision impact load transferred from the seat crossbeam can be transferred to the non-impacted side of the automobile body to the max, so the side collision performance of the automobile is increased, and the side-impact safety of the body of the automobile is improved.

Owner:CHERY AUTOMOBILE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com