Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

70results about How to "Avoid accidental splash damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Plate wheel turntable rack camera bearing clamping plate nickel alloy glass test device

InactiveCN105527178AIncrease labor intensityOvercome the defect of no self-lockingStrength propertiesEngineeringNickel alloy

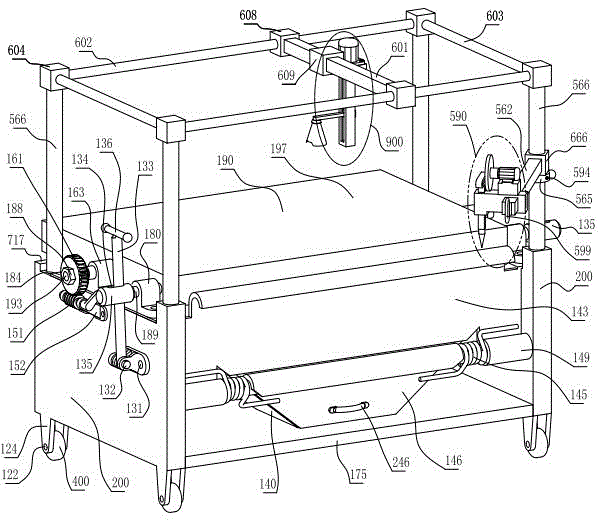

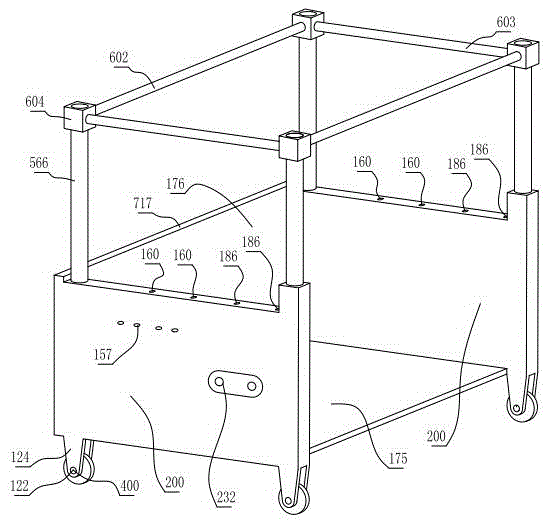

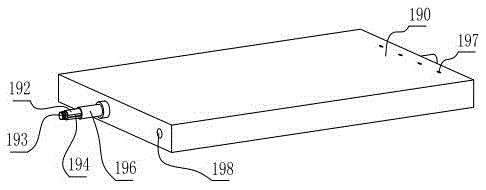

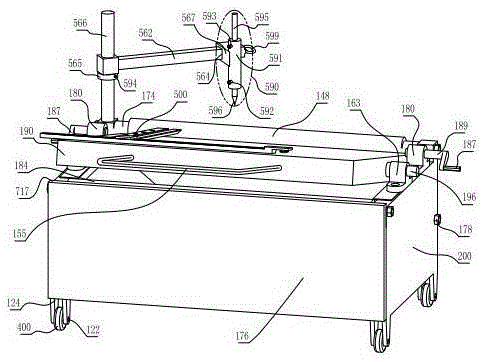

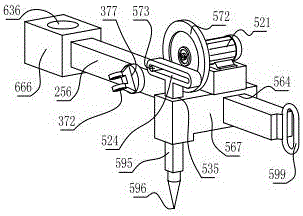

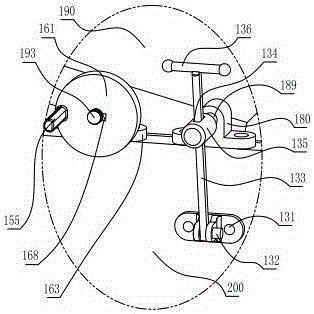

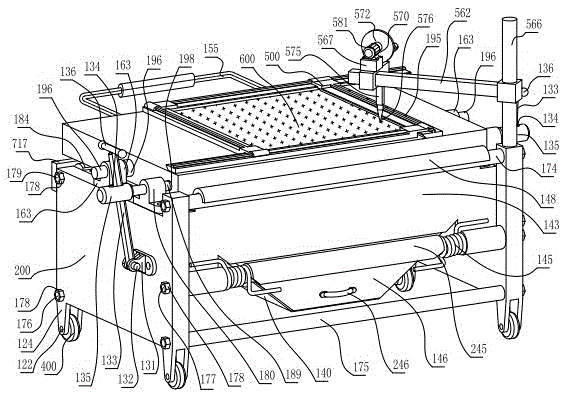

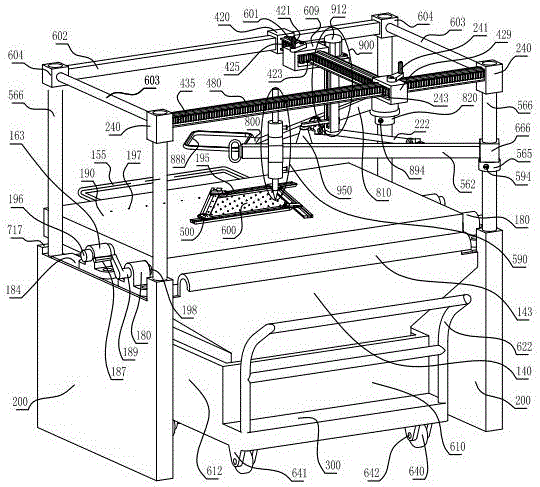

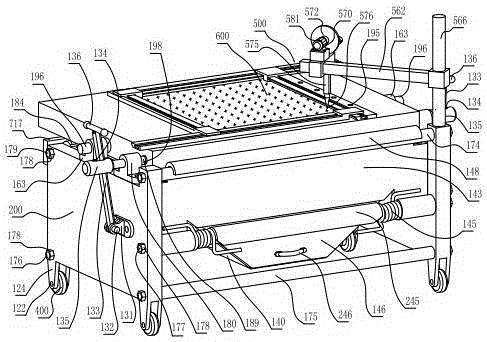

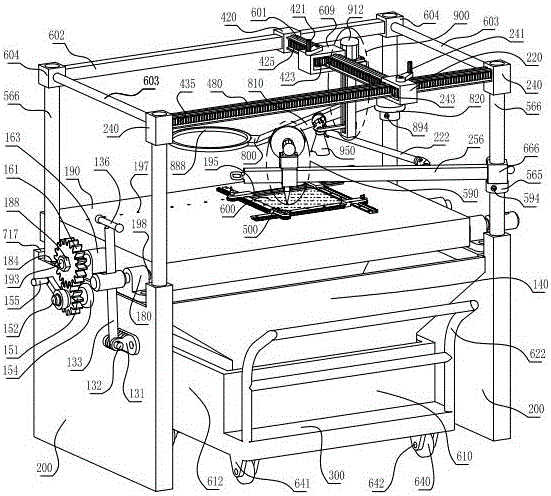

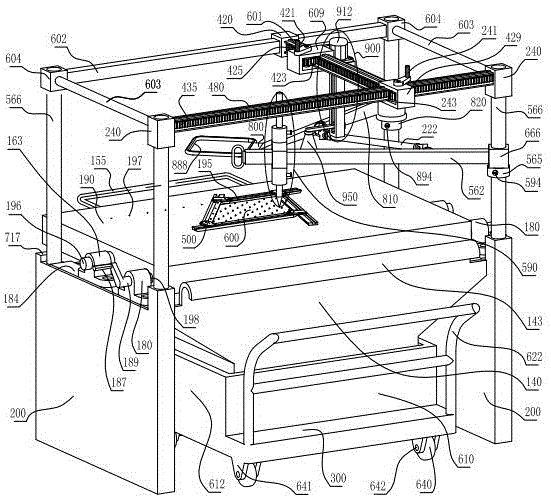

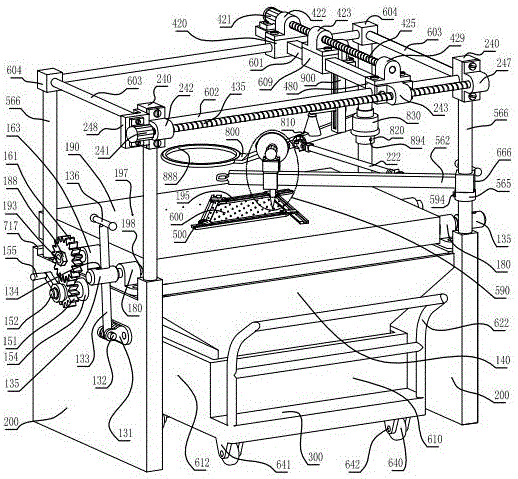

The present invention relates to a toughened glass test device, and particularly relates to a plate wheel turntable rack camera bearing clamping plate nickel alloy glass test device, improvements are as follows: a table plate rotation shaft on one side is fixedly provided with a manual operation plate wheel, a plate wheel flat key is arranged between the table plate rotation shaft and the manual operation plate wheel, the outer side surface of the manual operation plate wheel is provided with a plate wheel shaking handle; a movable camera component is arranged on a camera shooting square bar, an impact cross-bar is fixedly slidably provided with a rotary impactor, an upper plane of a test table plate is fixedly provided with a same plane bearing clamping plate component, a broken glass guider is arranged between a table plate support, together with a locking pin support, and an upper plane of a support side plate, and a broken glass guider lower port is in an upper port of a broken glass collection vehicle; the labor intensity of the detection can be improved, broken fragments are shot and photographed, and images of broken fragments are sent to a computer processing center; an upper plane of a manual operation plate wheel combination back plate supports a rear lower plane of the test table plate, and by combination of locking pin shaking handles at two sides, and the defect of no self-locking of the manual operation plate wheel itself can be overcome.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

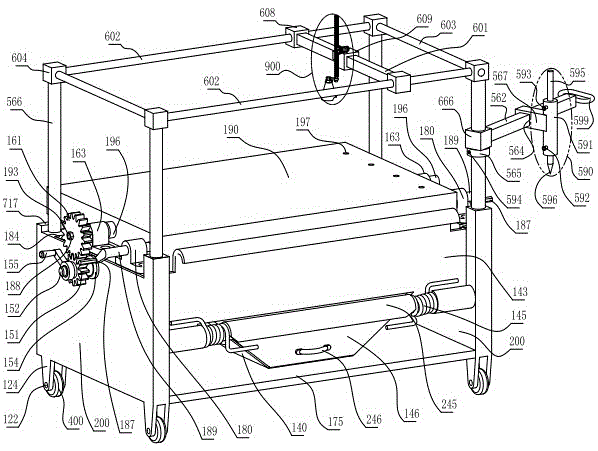

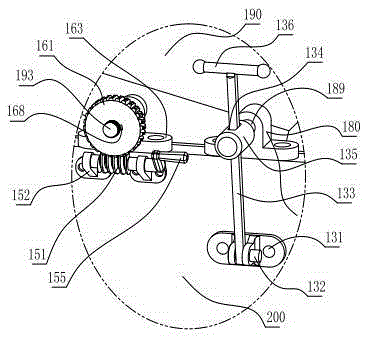

Glass detection instrument adopting worm gear bedplate, rack camera and bearing clamp plate with aluminum alloy plating

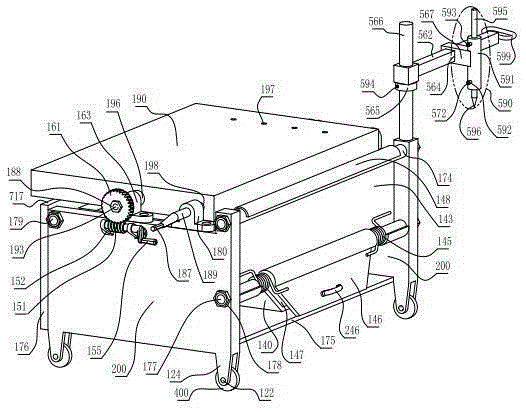

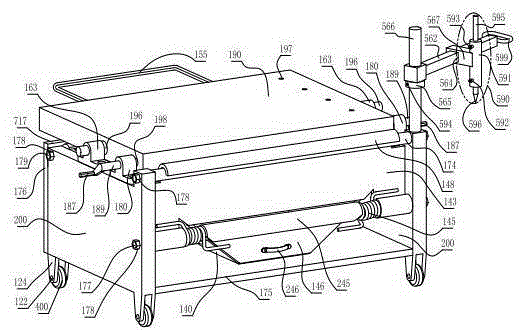

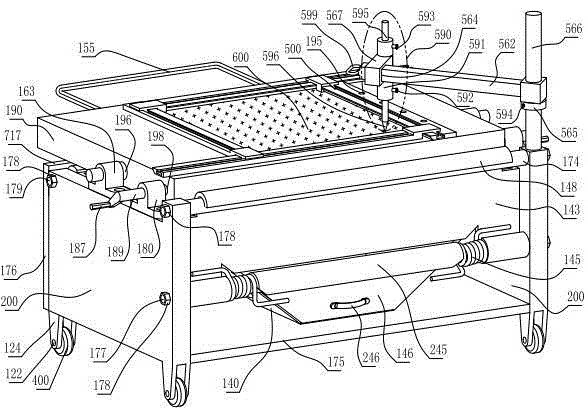

InactiveCN105606445AEasy to removeOvercoming the defects of fit clearanceToothed gearingsStrength propertiesMobile cameraToughened glass

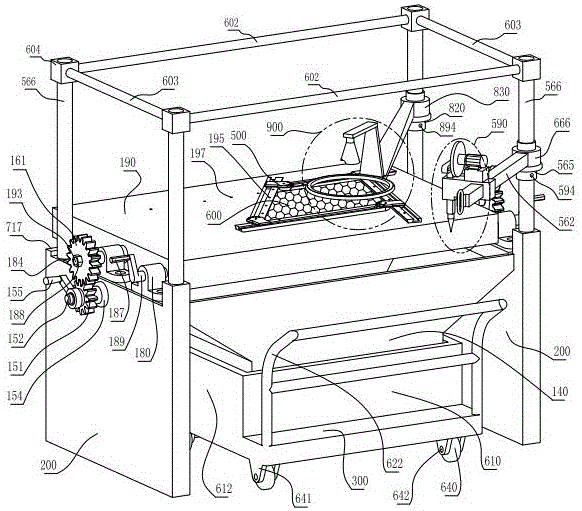

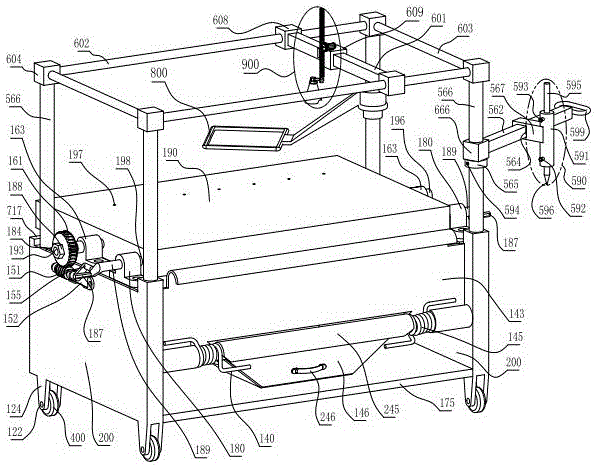

The invention relates to a tempered glass testing and checking instrument, in particular to a glass detection instrument adopting a worm gear bedplate, a rack camera and a bearing clamp plate with aluminum alloy plating. A drive worm gear is further fixed on a bedplate rotating shaft on one side and is matched with a worm shaft, two ends of the worm shaft are rotationally fixed in worm supports, the worm supports are fixed on the outer side surfaces of the corresponding support side plates, and a worm crank handle is further arranged at one end of the worm shaft; a mobile camera assembly is arranged on a camera square rod, a cylinder impactor is glidingly fixed on an impact cross rod, a coplanar bearing clamp plate assembly is fixed on the upper surface of the test bedplate, bedplate supports, lock pin supports are arranged on upper planes of the support side plates, and a broken glass recovery container is fixed between the support side plates; the condition that broken piece detection basically depends on workers is changed, and the camera takes pictures and transmits the pictures of broken pieces to a computer processing center. The coplanar bearing clamp assembly is adopted, accordingly, the probability of breaking of an adhesive tape due to explosion force of tempered glass is avoided, and body safety of an operator is better guaranteed.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Gear turntable rack camera shooting step pressing plate titanium alloy glass detection system

InactiveCN105547808AIncrease labor intensityEasy to removeMaterial strength using single impulsive forceEngineeringUltimate tensile strength

The invention relates to a tempered glass test check system, in particular to a gear turntable rack camera shooting step pressing plate titanium alloy glass detection system. As the improvement, a transmission gear is fixed to a table plate rotating shaft on one side and matched with a manual gear, the manual gear is fixed to a manual wheel shaft in a rotatable mode, a wheel shaft flange is arranged at the inner end of the manual wheel shaft, the wheel shaft flange is fixed to the outer side face of a corresponding supporting side plate, a shaft clamping spring is arranged at the outer end of the manual wheel shaft and located on the outer side face of the manual wheel shaft in a blocking mode, the outer side face of the manual gear is provided with a hand wheel step circle, a hand wheel transverse rod is fixedly connected to the hand wheel step circle, and a hand wheel crank handle is arranged at the outer end of the hand wheel transverse rod. The labor intensity needed for fragment detection is reduced, camera shooting is carried out, and a fragment image is transmitted to a computer processing center; the system is particularly suitable for mass glass detection processing, and can be applied and popularized in relevant production enterprises and detection technical organizations; by applying a rotary impact device, hammer driving strength is consistent all the time, and it is ensured that crushing tests are normative and unified.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

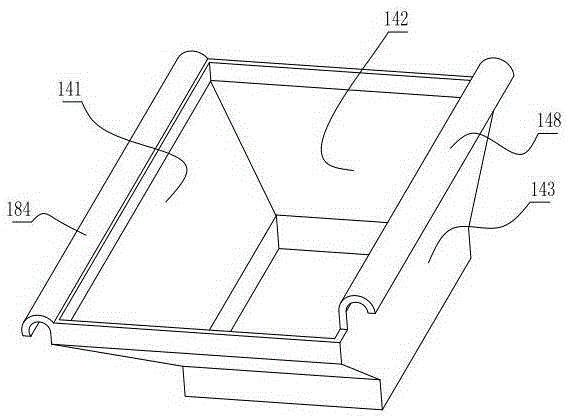

Method for testing glass by using worm wheel turntable rack photography and circular corner clamp plates

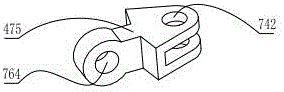

InactiveCN105651629AChange labor intensityAvoid accidental splash damageStrength propertiesEngineeringGlass fragment

The invention relates to a tempered glass testing method, in particular to a method for testing glass by using worm wheel turntable rack photography and circular corner clamp plates. Modifications include: one, an assembly process includes a clamp plate assembly process and a machine assembly process; two, a tempered glass fragmentation test includes the following steps: (one), a worm cranking handle at one end of a worm shaft is cranked by hand so that a test top plate is horizontal; (two), first, second, third and fourth clamp plates equal in structural size are placed on the test top plate; (three), a trapezoidal glass plate to be tested is placed on the test top plate within a surrounded space; (four), an impact motor is started to break the trapezoidal glass plate; (five), a photography motor is started to take photos and send fragment photos to a computer processing center; (six), the second and third clamp plates are moved so that tempered glass fragments can be conveniently cleared and dropped into a glass fragment recycling container.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Copper alloy handle rotating plate wheel clamping plate light ring auxiliary impact glass testing device

InactiveCN105890988AImprove operational efficiencyImprove labor intensityMaterial strength using single impulsive forceMotor driveEngineering

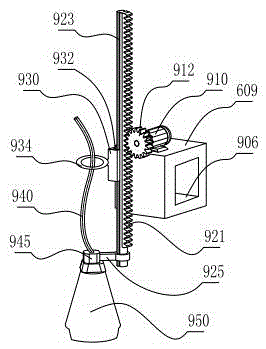

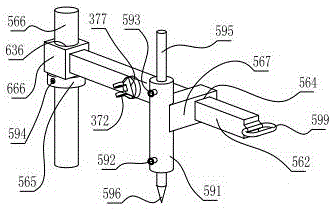

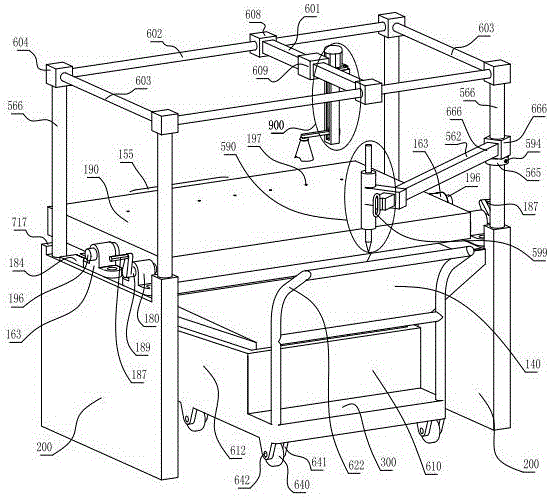

The invention relates to a tempered glass testing device, in particular to a copper alloy handle rotating plate wheel clamping plate light ring auxiliary impact glass testing device. As improvement, a wheel slideway rack clamping plate component is fixed to the upper plane of a testing rotating plate, a rotating plate handle is arranged on the vertical surface of the rear end of the testing rotating plate, and the two arched ends of the rotating plate handle serve as handle tips which are both fixed to the vertical surface of the rear end of the testing rotating plate; a longitudinal screw drives a longitudinal base nut to move forwards and backwards, a horizontal screw drives a horizontal base nut to move leftwards and rightwards, a camera motor drives a lifting rack to move up and down, a camera frame moves up and down accordingly, and finally three-dimensional free movement of an industrial camera is achieved; linkage between a cross rod universal joint on a rotation impact component and an oblique handle universal joint on a light ring component is achieved through a linkage connecting rod, and operation efficiency is improved; a wheel slideway rack clamping plate component is adopted, a cylindrical gear is meshed with a vertical face rack, and precise fine adjustment fixation of quadrilateral glass is achieved.

Owner:张志雄

Method for detecting glass through gear turntable rack shooting V-shaped clamping plate

InactiveCN105606470AEasy to removeOvercome the defect that the fit does not have self-lockingStrength propertiesEngineeringGlass fragment

The invention relates to a method for testing and inspecting tempered glass, in particular to a method for detecting glass through a gear turntable rack shooting V-shaped clamping plate. As an improvement: the steps for performing fragmentation testing on tempered glass are as follows: firstly, turning a hand wheel crank handle with a hand to enable a cylindrical bulb at one end of bolt lock pin to enter lock pin positioning holes in the two sides of a testing platform plate so as to be locked and positioned, and to enable the testing platform plate to be fastened horizontally; secondly, forming a surrounding space among a clamping plate fixed side, a clamping plate left side, a clamping plate opposite side and a clamping plate right side with the same structural sizes; thirdly, putting a tempered glass plate to be tested on the testing platform plate in the surrounding space; fourthly, ensuring that a cylinder impactor rotates around the excircle of an upper pillar type column with an impacting cross rod, so as to be deviated from the upper part of the tempered glass plate; sixthly, cleaning tempered glass fragments, and enabling the tempered glass fragments to fall into a broken glass recovery container.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Chromium alloy glass inspection machine with pull-out and plug-in lockpins, handle capable of turning over test bedplate and circular track pressing plates

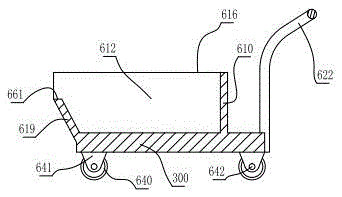

InactiveCN105352824AMake sure not to spillOvercome the defect of no self-lockingStrength propertiesGlass chipEngineering

The invention relates to a tempered glass inspection machine, in particular to a chromium alloy glass detection machine with pull-out and plug-in lockpins, a handle capable of turning over a test bedplate and circular track pressing plates. As an improvement, the bedplate handle is arranged on the vertical face of the rear end of the test bedplate; the two bent arc ends of the bedplate handle are handle ends; the handle ends namely the two bent arc ends are fixed on the vertical face of the rear end of the test bedplate; a broken glass guider is fixed by both a rack front upper pull rod and a rack rear upper pull rod; the lower end opening of the broken glass guider falls into the upper end opening of a broken glass collection trolley; an impact upright post is arranged on the upper plane of a supporting side plate on one side; an air cylinder impactor is fixed on the impact upright post in a sliding manner; a circular track pressing plate assembly is fixed on the upper plane of the test bedplate; a whole rack is integrally cast at one time by adopting grey cast iron. According to the invention, through the structure arrangement that the bedplate handle drives the test bedplate to turn over, the broken glass sheets are convenient to remove and that the broken glass sheets are not scattered is guaranteed as the broken glass guider and the broken glass collection trolley are equipped; the air cylinder impactor is adopted to realize consistency of hammer striking at each time, so that standardization and unification of a breaking test are guaranteed.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Glass detecting rack and method for carrying out glass detection by using glass detecting rack

InactiveCN105758750AEasy to removeReduce frictional resistanceMaterial analysis by optical meansMaterial strength using repeated/pulsating forcesTest specificationUltimate tensile strength

The invention relates to a toughened glass test rack, in particular to a glass detecting rack. As improvement, the glass detecting rack is characterized in that a transmission worm is matched with a worm shaft; the two ends of the worm shaft can be rotatably fixed in worm supporting bases separately; the worm supporting bases are fixedly arranged on the outer side surface of a corresponding supporting side plate; one end of the worm shaft is further provided with a worm cranking handle; a screw lifting camera group is arranged on a camera shooting square rod; a rotary impactor can be fixedly arranged on an impact cross rod in a sliding manner; a step corner pressure plate assembly comprises a first pressure plate, a second pressure plate, a third pressure plate and a fourth pressure plate which are the same in structural dimension; and each pressure plate is composed of a clamping part and a sliding corner part. According to the glass detecting rack, labor intensity of fragment detecting is changed, camera shooting is carried out, and fragment images are transmitted to a computer processing center; the rotary impactor is applied, so that hammering every time is consistent is force, and therefore, breaking test specifications are unified.

Owner:徐明

Method for detecting glass by disc wheel rotary table rack image pick-up step press plate

InactiveCN105651628AIncrease labor intensityOvercome the defect of no self-lockingStrength propertiesEngineeringNational standard

The invention relates to a toughened glass test inspection method, in particular to a method for detecting glass by a disc wheel rotary table rack image pick-up step press plate. Through improvement, the toughened glass fragment test comprises the following steps that 1, a disc wheel crank handle is anticlockwise rotated, and a test table plate is in a horizontal state; 2, a press plate fixing plate, a press plate right side, a press plate opposite side and a press plate left side with the same structures are put on the test table plate to surround an ambient surrounding space; 3, the toughened glass to be tested is put on the test table plate in the ambient surrounding space, so that a rubber press sheet on each press plate is attached to the outer edges of the four sides of the toughened glass to be tested; 4, when the conical tip of an impact hammer is downward moved to the lowest position, the toughened glass is crushed through impacting; 5, an image-pickup motor is started; image-pickup shooting is performed; a fragment image is transmitted to a computer processing center; whether the crushed toughened glass is qualified or not is judged according to national standard requirements; the fragment state test of the toughened glass is completed.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

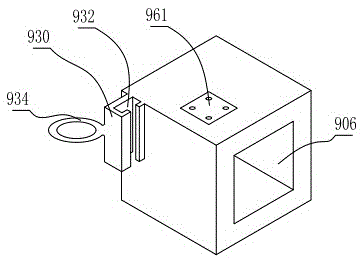

Assembling method for glass testing through air cylinder hammer with worm gear rotary table and threaded lock pins

InactiveCN105290783AAvoid the possibility of crackingLow costAssembly machinesStrength propertiesControl systemControl room

The invention relates to an assembling method for a glass testing hammer, in particular to an assembling method for glass testing through an air cylinder hammer with a worm gear rotary table and threaded lock pins. According to an improvement, the method for glass testing includes the following assembling and operation steps that firstly, sliding balls are mounted in ball seat stepped holes in a sliding plate lower plane; secondly, clamping plate portions and sliding plate portions on wheel coplanar clamping plates are assembled; and thirdly, entire assembling is carried out, the height of a height locating ring is adjusted so that when an air cylinder piston rod operates to the lowest position, an impact hammer conical tip can right make contact with a tempered glass plate fixed to a testing platen, an impact frame square hole in an impactor rack is in sliding fit with an impact cross bar, an air inlet and outlet pipe upper connector and an air inlet and outlet pipe lower connector are each connected with a high-pressure air pipe, and the high-pressure air pipes are connected to a high-pressure air source control system. An air cylinder impactor can be conveniently and remotely connected to an air pressure power source control room, and thus the dangerous step of breaking up the tempered glass plate is controlled remotely, and onsite operators are prevented from being injured by accidental splashing at the moment of glass breaking.

Owner:孙冬兰

Handle overall-bedplate screw pin wheel pressing plate copper base glass detection equipment

PendingCN105319125AEasy to removeOvercome the defect of no self-lockingStrength propertiesTest specificationStructural engineering

The invention relates to tempering glass testing and detecting equipment and provides handle overall-bedplate screw pin wheel pressing plate copper base glass detection equipment. As improvement, a vertical face of the rear end of a testing bedplate is provided with a bedplate handle, the two curved ends of the bedplate handle are handle end heads, and the handle end heads of the two curved ends are fixed to the vertical face of the rear end of the testing bedplate; an upper plane of a supporting side plate on one side is provided with an impact stand column, an impact cross rod is rotatably fixed to the impact stand column, a height positioning ring is liftably fixed to the impact stand column, the height positioning ring is provided with a tightening screw, and the height positioning ring supports the impact cross rod; an air cylinder impactor is fixed to the impact cross rod in a slidable mode, the knocking strength is consistent each time through the air cylinder impactor, and it is guaranteed that crushing test specifications are unified; a coplanar wheel pressing plate assembly is fixed to the upper plane of the testing bedplate, and tempering glass plates of different specifications and sizes are adjusted continuously at will; a middle pull rod in front of a rack, an upper pull rod in front of the rack and an upper pull rod behind the rack jointly fix a broken glass recycling container.

Owner:孙冬兰

Copper alloy hydraulic rotating plate bearing rack clamp impact image pick-up linkage glass detection device

InactiveCN105842064ARealize arbitrary movement in three dimensionsImprove operational efficiencyMaterial strength using single impulsive forceMotor driveUniversal joint

The invention relates to a toughened glass test inspection device, in particular to a copper alloy hydraulic rotating plate bearing rack clamp impact image pick-up linkage glass detection device. As the improvement, a bearing chute rack clamp assembly is fixed on a test rotating plate; a broken notch is formed in the upper plane of a back plate; the lower end of the broken notch is fixedly provided with a support bottom plate; a T-shaped guide rail is arranged in the center of the lower plane of the back end of the test rotating plate; a hydraulic executing mechanism is arranged between the T-shaped guide rail and the support bottom plate; a transverse jiggle bar drives a transverse rack to rotate in positive and reverse directions, so that an industrial camera leftwards and rightwards moves; a longitudinal jiggle bar drives a longitudinal gear to rotate in positive and reverse directions, so that the industrial camera forwards and backwards moves; the ascending and descending motor drives a vertical screw rod to rotate, and drives a screw nut slide block to vertically move; the three-dimensional free movement of the industrial camera is finally realized; a transverse rod universal joint and an inclined handle universal joint are connected by a linkage connecting rod to realize the linkage; the operation efficiency is improved; a bearing chute rack clamp assembly is used for precisely regulating and fixing a square glass plate.

Owner:张志雄

Method for detecting glass by using gears, rotary tablet, aperture camera and circular corner clamping plates

InactiveCN105910923AThe accuracy of boundary discrimination is improvedEasy to removeMaterial analysis by optical meansMaterial strength using single impulsive forceToughened glassCircular orbit

The invention relates to a toughened glass detection method, and concretely relates to a method for detecting glass by using gears, a rotary tablet, an aperture camera and circular corner clamping plates. An improved whole machine assembling process comprises the following steps: 1, installing a broken glass guider; 2, placing a circular corner clamping plate assembly; 3, installing, adjusting and fixing an aperture camera assembly; and 4, installing and fixing rotary impacters. A whole frame is provided with the aperture camera assembly, so shooting is carried out under the assistance of annular lights generated by a circular fluorescent tube; a gear transmission mechanism arranged on the whole frame can drive a test rotary tablet to overturn in order to conveniently remove broken glass, and arrangement of the broken glass guider and a broken glass collector ensures no sprinkling of broken glass; circular vertical columns are fixedly provided with impact cross bars in a liftable manner, the impact cross bars are fixedly provided with the rotary impacters in a slidable manner to avoid damages of accidental splashing of glass at the breaking time to onsite operators, and the rotary impacters are used to realize the weight consistence of every hamming in order to ensure standardized and unified breaking test.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

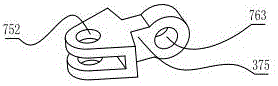

Plate wheel rotary table molybdenum alloy impact hammer step pressing plate glass detection device

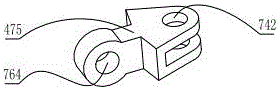

InactiveCN105241748AEasy to removeAvoid accidental splash damageStrength propertiesCrankStructural engineering

The invention relates to a tempered glass testing and inspecting device, in particular to a plate wheel rotary table molybdenum alloy impact hammer step pressing plate glass detection device. As an improvement, a manual plate wheel is further fixed to a platen rotary shaft on one side, a plate wheel flat key is arranged between the platen rotary shaft and the manual plate wheel, and a plate wheel crank handle is further arranged on the outer side face of the manual plate wheel; an impact vertical column is arranged on the upper plane of a plate type rack on one side, a rotary impactor is fixed to an impact cross rod in a sliding mode, pluggable lock holes are formed in the two sides of a testing platen, outer circles of light column lock pins are matched with inner hole slide ways of lock pin supports, and the light column lock pins on the two sides can enter the pluggable lock holes to lock and position the testing platen; an operating grab handle is arranged at one end of a long operating rod, and the other end of the long operating rod is connected and fixed to an operating support in a swinging and rotating mode. The strength of every time of hammering is consistent through the rotary impactor, and it is guaranteed that crushing tests are standard and uniform; a coplanar step pressing plate assembly is adopted, the periphery of a tested tempered glass plate is located in the same plane to be fixed, and it is guaranteed that the periphery of glass is uniformly stressed.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Glass detecting frame with worm wheel aperture linked camera shooting chromium alloy wheel slide way corner clamp

PendingCN105758712AThe accuracy of boundary discrimination is improvedImprove operational efficiencyStrength propertiesUniversal jointRotating disc

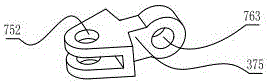

The invention relates to a test detection frame for tempered glass, in particular to a glass detecting frame with a worm wheel aperture linked camera shooting chromium alloy wheel slide way corner clamp.The glass detecting frame is characterized in that a transmission worm wheel is further fixed to a turning plate rotating shaft on one side and matched with a worm shaft, the two ends of the worm shaft are fixed inside worm supporting bases respectively in a rotatable mode, the worm supporting bases are fixed to the outer side faces of corresponding supporting side plates, and a worm crank handle is arranged at one end of the worm shaft; an aperture camera shooting assembly comprises an aperture camera shooting rotating disc and an aperture camera shooting inclined handle, and an industry camera is arranged on the front face below a camera end; a round fluorescent tube is arranged on a horizontal aperture frame, an inclined handle fixing joint is arranged on the aperture camera shooting inclined handle, a transverse rod fixing joint is arranged on an impact transverse rod, a transverse rod universal joint is connected with an inclined handle universal joint through a linkage connecting rod, and an air cylinder impactor is fixed to the impact transverse rod in a sliding mode.By the adoption of the wheel slide way corner clamp assembly, quadrilateral glass of different specifications and dimensions and different clamping angles can be continuously adjusted to be fixed.

Owner:JINJIANG CITY CHIDIAN TOWN XIAOQIU ELECTRICAL MACHINERY SPECIAL EQUIP DESIGN STUDIO

Glass detection framework with molybdenum alloy screw, halo camera, hydraulic mechanism, turning plate, inclined sliding groove and clamp

PendingCN106053261ARealize arbitrary movement in three dimensionsImprove operational efficiencyStrength propertiesMotor driveEngineering

The invention relates to a tempered glass testing and detection framework and provides a glass detection framework with a molybdenum alloy screw, a halo camera, a hydraulic mechanism, a turning plate, an inclined sliding groove and a clamp. As an improvement, an inclined sliding tank corner clamp assembly is fixed on the upper plane of the testing turning plate, a T-shaped guide rail is arranged in the center of the lower plane at the rear end of the testing turning plate, and the hydraulic execution mechanism is arranged between the T-shaped guide rail and a supporting bottom plate. By means of a transverse rocker, a transverse gear is driven to rotate forwards or reversely so that the industrial camera can move left and right. A longitudinal rocker drives a longitudinal gear to rotate forwards or reversely so that the industrial camera can move front and back. A lifting motor drives the vertical screw to rotate to drive a nut sliding block face to move up and down, and finally any three-dimensional movement of the industrial camera can be achieved. A transverse rod universal joint and an inclined handle universal joint are connected through a linkage connection rod to achieve linkage, and operation efficiency is improved. By means of the inclined sliding tank corner clamp assembly, quadrangular glass in different specifications and sizes and with different included angles can be continuously adjusted to be fixed.

Owner:WENZHOU ZHANGHENG SCI & TECH SERVICE CO LTD CO LTD

Glass testing method adopting handle, rotary table, stepped press plates and rotation impactor

InactiveCN105424508AOvercome the defect of no self-lockingEasy to removeMaterial testing goodsMaterial strength using single impulsive forceNational standardGlass fragment

The invention relates to an armored glass testing method, in particular to a glass testing method adopting a handle, a rotary table, stepped press plates and a rotation impactor. The glass testing method comprises the steps of 1, holding a handle skid resistance sleeve on the platen handle on the vertical surface of the rear end of a test platen with hands and exerting downward force to enable the test platen to be horizontal; 2, placing a press plate fixed side, a press plate left side, a press plate opposite side and a press plate right side with the same structure and size on the test platen; 3, making rubber press sheets on the press plates attached to the four edges of tested armorplate glass; 4, adjusting the height of an impact cross bar on an impact stand column to be proper; 5, testing the armorplate glass according to national standard requirements after the armorplate glass is broken, so that an armored glass fragmentation state test is completed; 6, clearing armored glass fragments and placing the fragments in a cullet recycling container after the fragments are inclined by 10-20 degrees by means of the test platen. By the adoption of the coplanar stepped press plate assembly, the four sides of the glass are stressed uniformly.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Gear rotary table titanium alloy impact hammer circular rail clamping plate glass detecting device

InactiveCN105241762AStandardizationEven by forceMaterial strength using single impulsive forceImpact hammerManufacturing engineering

The invention relates to a tempered glass testing and detecting device, and a gear rotary table titanium alloy impact hammer circular rail clamping plate glass detecting device. As an improvement, a transmission gear is fixed to a table plate rotary shaft on one side and matched with a hand-operated gear, a wheel shaft flange is arranged at the inner end of the hand-operated wheel shaft, a shaft clamping spring is arranged at the outer end of the hand-operated wheel shaft and blocked on the outer side face of the hand-operated wheel shaft, a hand wheel step circle is arranged on the outer side of the hand-operated gear, a hand wheel transverse rod is fixedly connected to the hand wheel step circle, a hand wheel rocking handle is arranged at the outer end of the hand wheel transverse rod, an impact stand column is arranged on the upper plane of a trigger machine frame on one side, a rotary impact device is fixed to the impact transverse rod in a slidable mode, light column locking pins on the two sides can enter a pulling and inserting locking hole to lock and position a test table plate, an operation handle is arranged at one end of an operation long rod, the other end of the operation long rod is fixedly connected with an operation support in a swinging and rotatable mode, a same-plane circular rail clamping plate assembly is fixed to the upper plane of the test table plate, and therefore tempered glass plates of different specifications and sizes can be continuously and freely adjusted.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Chromium alloy impact combination polished ring gear rotary table wheel backup clamp glass detection device

InactiveCN105890987ARealize arbitrary movement in three dimensionsImprove operational efficiencyMaterial strength using single impulsive forceUniversal jointToughened glass

The invention relates to a tempered glass testing and check device, in particular to a chromium alloy impact combination polished ring gear rotary table wheel backup clamp glass detection device. According to the improvement, a wheel sliding way corner backup clamp assembly is fixed to the upper plane of a testing rotary table, a rotary table rotating shaft on one side is fixedly provided with a transmission gear, the transmission gear is matched with a manual gear, the manual gear is rotationally fixed to a manual axle, the outer end of the manual axle is provided with a clamping spring for the axle, the clamping spring for the axle blocks the outer side face of the manual axle, the outer side face of the manual axle is provided with a hand wheel step circle, the hand wheel step circle is fixedly connected with a hand wheel transverse rod, the outer end of the hand wheel transverse rod is provided with a hand wheel rocking handle, a camera square rod is fixed between a camera rear sliding block and a camera front sliding block, a screw rod camera unit is fixed to a sliding block guide rail plate block, a circular stand column in the rear row is in rotary sliding fit with a polished ring component, a circular stand column in the front row is in rotary sliding fit with a rotary impact assembly, and a transverse universal joint and an inclined handle universal joint are connected through a linkage connecting rod.

Owner:QUANZHOU TAIWANESE INVESTMENT ZONE JIEXIONG MECHANICAL EQUIP DESIGN ROOM

Molybdenum alloy glass detection system with handle, table plate, screw rod photographing set and step corner clamping plate

InactiveCN105675387AChange labor intensityOvercome the defect of no self-lockingMaterial strength using single impulsive forceEngineeringAlloy

The invention relates to a testing and detection system of tempered glass and provides a molybdenum alloy glass detection system with a handle, a table plate, a screw rod photographing set and a step corner clamping plate. As improvements, the table plate handle is arranged on the vertical surface of the rear end of a testing table plate; two bent arc ends of the table plate handle are handle ends; the handle ends of the two bent arc ends are fixed on the vertical surface of the rear end of the testing table plate; the screw rod hoisting photographing set is arranged on a photographing square rod; an air cylinder impacting device is fixed on an impacting transverse rod in a sliding manner; a step rail clamping plate assembly is fixed on the upper plane of the testing table plate; a lower end opening of a crushed glass guiding device falls into an upper end opening of a crushed glass collection vehicle; photographing is carried out and a fragment image is transmitted to a computer processing center; the table plate handle can be used for directly overturning the testing table plate so that crushed glass can be conveniently cleaned; the air cylinder impacting device is applied so that the intensity of hammering each time is consistent, and crushing testing specifications are uniform; and by virtue of the step rail clamping plate assembly is adopted, the sizes and angles of trapezoid glass plates with different widths can be adjusted at the same time, and an explosion caused by non-uniform partial stress on the tempered glass plates is avoided.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Method for detecting glass by aid of impact camera shooting linkage plate wheel turning plate and fine adjustment clamp plates with oblique planes

InactiveCN106053207ARealize arbitrary movement in three dimensionsImprove operational efficiencyStrength propertiesUniversal jointElectric machinery

The invention relates to a method for testing and detecting tempered glass, and discloses a method for detecting glass by the aid of an impact camera shooting linkage plate wheel turning plate and fine adjustment clamp plates with oblique planes. The method is characterized in that critical components and assemblies include a three-dimensional movement component of an industrial camera and a linkage connecting rod component, and the method includes a fragment testing step; the critical components and assemblies are provided with the three-dimensional movement component of the industrial camera and the linkage connecting rod component; the fragment testing step includes horizontally fixing a test turning plate, fixing square glass plates, smashing the glass, carrying out camera shooting and carrying out glass fragment clearing work; a transverse gear can be driven by a transverse motor to rotate forwardly and reversely, so that the industrial camera can move left and right; a longitudinal gear can be driven by a longitudinal motor to rotate forwardly and reversely, so that the industrial camera can move back and forth; a lifting gear can be driven by a lifting motor to rotate forwardly and reversely, so that a lifting rack can be driven to move up and down, and the industrial camera can ultimately optionally move three-dimensionally; a universal joint of a transverse rod and a universal joint of an oblique handle are connected with each other by a linkage connecting rod so as to be in linkage with each other.

Owner:张志雄

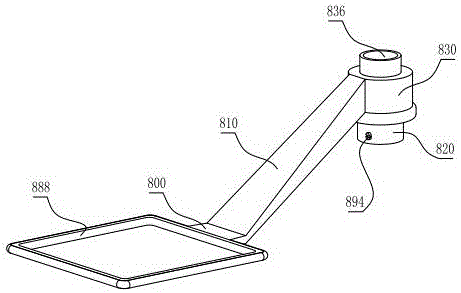

Glass detection device with titanium alloy screw, ring camera shooting handle overturning plate and round track clamping plate

PendingCN105806706ARealize arbitrary movement in three dimensionsImprove operational efficiencyStrength propertiesMotor driveUniversal joint

The invention relates to a tempered glass test and check device, in particular to a glass detection device with a titanium alloy screw, a ring camera shooting handle overturning plate and a round track clamping plate. As improvements, a round track corner clamping plate assembly is fixed to the upper plane of a test overturning plate, an overturning plate handle is positioned on the facade of the rear end of the test overturning plate, and the handle ends of the two arc ends are fixed to the facade of the rear end of the test overturning plate. A transverse crank handle is adopted to drive a transverse gear to perform forward and reverse rotation, so that an industrial camera moves in a left-right mode. A longitudinal crank handle drives a longitudinal gear to perform forward and reverse rotation, so that the industrial camera moves in a front-rear mode. A lifting motor drives a vertical screw to rotate and drives a nut sliding block surface to move up and down, and finally the industrial camera performs three-dimensional random movement. A universal joint of a cross rod is connected with a universal joint of an inclined handle through a linkage connecting rod to perform linkage, and the operation efficiency is improved. The round track corner clamping plate assembly is adopted, so that quadrilateral glass of different sizes and different included angles can be continuously adjusted to be fixed.

Owner:WENZHOU ZHANGHENG SCI & TECH SERVICE CO LTD CO LTD

Hydraulic rotary table glass testing machine with zinc alloy impact hammer and wheel pressing plate

InactiveCN105241763AEasy to removeAvoid accidental splash damageMaterial strength using single impulsive forceMaterial strength using repeated/pulsating forcesEngineeringStructural engineering

The invention relates to an armored glass testing and checking rack, in particular to a hydraulic rotary table glass testing machine with a zinc alloy impact hammer and a wheel pressing plate. According to the improvement, a T-shaped guide rail is arranged in the center of the lower plane of the rear end of a testing table plate, a hydraulic lifting mechanism is arranged between the T-shape guide rail and a supporting bottom plate, an impact stand column is arranged on the upper plane of a platy rack at one side, a rotary impactor is fixed to an impact cross rod in a slipping mode, a coplanar wheel pressing plate assembly is fixed to the upper plane of the testing table plate, a rack front middle pull rod is arranged between a rack front upper pull rod and a rack front lower pull rod, and the rack front middle pull rod, the rack front upper pull rod and a rack rear upper pull rod fix a broken glass recovery container together. A servo motor on the rotary impactor can control the risk step of smashing armor plate glass remotely, and therefore accidental splashing injuries to site operators at the moment of glass breaking are avoided; by the application of the rotary impactor, hammering force is uniform every time, and standardization and uniformity of breaking tests are ensured.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Glass detection machine provided with worm wheel, rotary table, rack optical-ring camera and molybdenum alloy wheel corner clamp

InactiveCN105758746AThe accuracy of boundary discrimination is improvedAvoid accidental splash damageStrength propertiesEngineeringAlloy

The invention relates to a tempered glass testing detection machine and provides a glass detection machine provided with a worm wheel, a rotary table, a rack optical-ring camera and a molybdenum alloy wheel corner clamp. As improvements, a rotary table rotary shaft on one side is further fixedly provided with a transmission worm wheel; the transmission worm wheel is matched with a worm rod shaft; the two ends of the worm rod shaft are respectively rotatably fixed in a worm rod support; the worm rod support is fixed on the outer side face of a corresponding supporting side plate; a worm rod crank handle is further arranged at one end of the worm rod shaft; two transverse horizontal rods are slidingly matched with photographing transverse slide blocks; a photographing square rod is fixed between the two photographing transverse slide blocks; a screw rod hoisting camera set is arranged on the photographing square rod; a square fluorescent tube is arranged on a movable optical ring; an optical ring inclined long handle is arranged on one side of a frame of the square fluorescent tube; a rotary table is arranged at the tail end of the optical ring inclined long handle; the rotary table is provided with a rotary table inner hole and a rotary table lower end face; a cylinder impacting device is fixed on an impacting transverse rod in a slipping manner; a wheel slide way corner clamp assembly is fixed on the upper plane of the testing rotary table, so that quadrilateral glass with different angles can be fixed.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Method for testing glass through impact image pickup in linkage with gear rotating plate stair rack clamping plates

InactiveCN105823679AImprove work efficiencyImprove operational efficiencyStrength propertiesMotor driveGlass fragment

The invention relates to a tempered glass testing and inspection method and discloses a method for testing glass through impact image pickup in linkage with gear rotating plate stair rack clamping plates. As improvement, a critical component assembly comprises an industrial video camera three-dimensional moving component and a linkage connecting rod component; a fragmentation test comprises the steps of horizontally fixing a testing rotating plate, fixing a square glass plate, breaking the glass, conducting camera shooting and clearing away glass fragments; a transverse cranking handle is adopted to drive a transverse gear to rotate in the forward and reverse direction, so that an industrial video camera is driven to move leftward and rightward; a longitudinal cranking handle drives a longitudinal gear to rotate in the forward and reverse direction, so that the industrial video camera is driven to move back and forth; a lifting motor drives a vertical threaded rod to rotate and drives a nut slide block face to move up and down, so that three-dimensional free movement of the industrial video camera is achieved; a cross bar universal joint is connected with an inclined handle universal joint through a linkage connecting rod, so that linkage is achieved, and operation efficiency is improved; a stair track rack clamping plate assembly is adopted, so that the square glass plate can be adjusted and fixed precisely.

Owner:张志雄

Titanium alloy gear rotating plate wheel tooth bar clamp impact shooting linkage glass detection apparatus

InactiveCN106066284ARealize arbitrary movement in three dimensionsImprove operational efficiencyStrength propertiesMotor driveUniversal joint

The invention relates to a toughened glass test examination apparatus, and concretely relates to a titanium alloy gear rotating plate wheel tooth bar clamp impact shooting linkage glass detection apparatus. The titanium alloy gear rotating plate wheel tooth bar clamp impact shooting linkage glass detection apparatus is characterized in that the upper plane of a test rotating plate is fixedly provided with a wheel slideway gear rack clamp assembly, a rotating plate rotating shaft at one side is fixedly provided with a transmission gear, the transmission gear cooperates with a manual gear, the manual gear can be fixed to a manual gear shaft in a rotatable manner, a gear shaft flange is fixed to a corresponding supporting side plate outside surface, and the outer end of a manual crossbar is provided with a manual gear crank handle; a transverse crank handle drives a transverse gear to rotate move forward and backward in order to make an industrial camera move to the left and the right; a vertical crank handle drives a vertical gear to rotate forward and backward in order to make the industrial camera move back and forth; a lifting motor drives a vertical screw to rotate in order to drive a nut sliding block surface to move up and down, so three-dimensional arbitrary movement of the industrial camera is finally realized; a transverse universal joint is connected with an oblique handle universal joint through a linkage connecting rod, so the operating efficiency is improved.

Owner:张志雄

Worm wheel rotary table tungsten alloy impact hammer bearing pressing plate glass detection machine frame

PendingCN105241764AEasy to removeMake sure not to spillMaterial strength using single impulsive forceMaterial strength using repeated/pulsating forcesCrankStructural engineering

The invention relates to a tempered glass test and checkout machine frame, in particular to a worm wheel rotary table tungsten alloy impact hammer bearing pressing plate glass detection machine frame. According to the improvement, a transmission worm wheel is fixed to a table plate rotary shaft on one side and matched with a worm shaft, the two ends of the worm shaft are rotationally fixed into worm supports respectively, one end of the worm shaft is provided with a worm crank handle, an impact stand column is arranged on the upper plane of a plate type machine frame on one side, a rotary impactor is fixed to an impact transverse rod in a sliding mode, light column lock pins on the two sides can enter pulling and inserting lock holes to lock and position test table plates, a long operation rod penetrates through a lock pin long slot, same-plane bearing pressing plate assemblies are fixed to the upper planes of the test table plates, a machine frame front middle pull rod is arranged between a machine frame front upper pull rod and a machine frame front lower pull rod, and the machine frame front middle pull rod, the machine frame front upper pull rod and the machine frame rear upper pull rod jointly fix a broken glass recycle container; by the adoption of the same-plane bearing pressing plate assemblies, tempered glass plates of different specifications and sizes can be continuously and freely adjusted.

Owner:WENZHOU ECONOMIC TECH DEV ZONE HAIZHIJIE ELECTROMECHANICAL PROD DESIGN STUDIO

Glass detection instrument with handle turntable, halo camera and nickel alloy ladder track corner splint

InactiveCN105758801AThe accuracy of boundary discrimination is improvedReduce labor intensityMaterial analysis by optical meansEngineeringNickel alloy

The invention relates to a tempered glass test detection instrument. The improvement of a glass detection instrument with a handle turntable, a halo camera and a nickel alloy ladder track corner splint is as follows: a platen handle is arranged on a rear-end vertical surface of a test turntable; two bent arc ends of the platen handle are arranged as handle heads; the handle heads at the two bent arc ends are fixedly arranged on the rear-end vertical surface of the test turntable; two horizontal rods are in sliding fit with horizontal shooting slide blocks; a square shooting rod is fixed between the two horizontal shooting slide blocks; a screw lifting camera unit is arranged on the square shooting rod; a square fluorescent tube is arranged on a moveable halo; a ladder track splint component is fixedly arranged on the upper surface of the test turntable; a broken glass guide is fixedly arranged between a turntable support base and a lock pin support base as well as the upper surface of a supporting lateral plate; a rotatable impacting device is slidably and fixedly arranged on a horizontal impacting rod; the ladder track splint component is applied to a direct turning structure of the platen handle of the test turntable, so that the fixing for quadrilateral glass at different included angles can be realized.

Owner:WENZHOU ECONOMIC TECH DEV ZONE BINHAI XIONGJIE ELECTROMECHANICAL RES & DEV STUDIO

Glass detection method applying screw rod halo camera shooting handle turnover plate bearing clamp plate

PendingCN106018136AImprove work efficiencyRealize arbitrary movement in three dimensionsStrength propertiesEngineeringGlass fragment

The invention relates to a toughened glass testing method, particularly a glass detection method applying screw rod halo camera shooting handle turnover plate bearing clamp plate. As improvement, key component assembly includes: an industrial camera three-dimensional moving part and a linkage connecting rod part. The fragment test steps include: holding a turnover plate handle on a vertical surface at the rear end of the test turnover plate by hand and exerting strength downward, locking and fixing the test turnover plate at a horizontal state; placing a bearing trough corner clamp plate assembly on the test turnover plate; fixing a to-be-tested trapezoid glass plate, then starting an air pressure power source to smash the trapezoid glass plate; starting the industrial camera to perform camera shooting, and transmitting the fragment image to a computer processing center; clearing away glass fragments, making toughened glass fragments fall into a broken glass collection vehicle through a broken glass guider; and carrying out resetting, and bringing the test turnover plate to a horizontal state again.

Owner:WENZHOU ZHANGHENG SCI & TECH SERVICE CO LTD CO LTD

Method for detecting glass by using combination of rotary impact assembly, light ring member, gear-driven rotary table and stepped clamping plates

InactiveCN106092782ASignificantly progressiveRealize arbitrary movement in three dimensionsStrength propertiesShaped beamGear drive

The invention relates to a testing and examination method for toughened glass, especially to a method for detecting glass by using a combination of a rotary impact assembly, a light ring member, a gear-driven rotary table and stepped clamping plates. According to an improved technical scheme, a fragment test comprises the following steps: (1) staring a camera motor to drive a vertical screw to carry out forward rotation and then to drive a nut slide block surface to ascend and lifting an industrial camera to prevent interference between the industrial camera and a linkage connecting rod; (2) rotating a handwheel crank handle with hand to allow the testing rotary table to be horizontal; (3) placing a stepped track corner clamping plate assembly on the testing rotary table; (4) breaking glass into pieces; (5) carrying out shooting, wherein a circular fluorescent tube is energized to generate ring-shaped beams to aid shooting; (6) clearing away broken glass pieces; and (7) carrying out resetting. The method provided by the invention improves labor intensity in detection toughened glass fragments; shooting is carried out and fragment images are transmitted to a computer processing center; and the rotary impact assembly and the light ring member are connected via the linkage connecting rod so as to realize linkage, so operation efficiency is improved.

Owner:WENZHOU ZHANGHENG SCI & TECH SERVICE CO LTD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com