Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Accurately press in" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

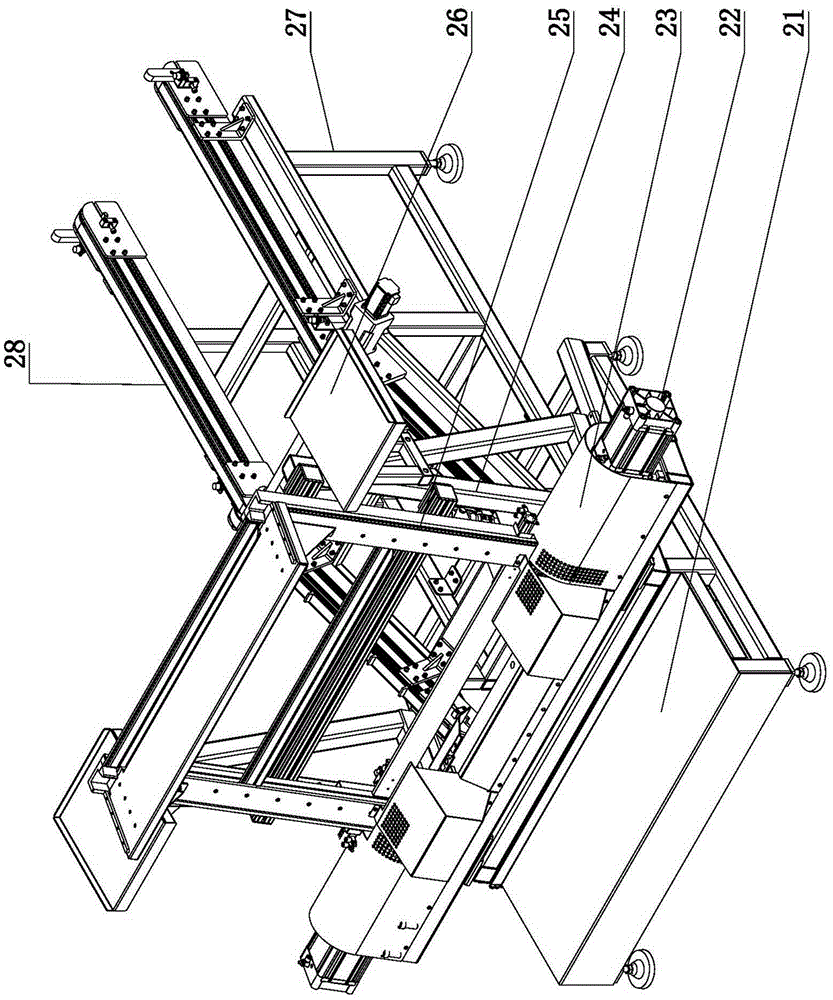

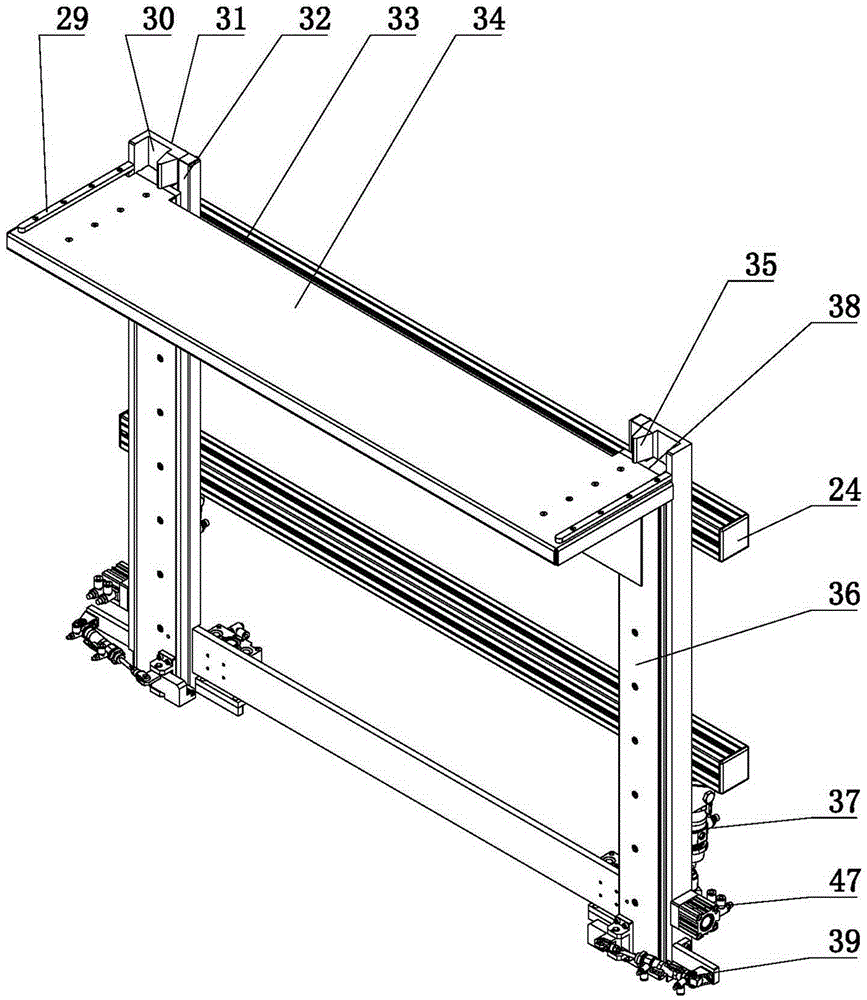

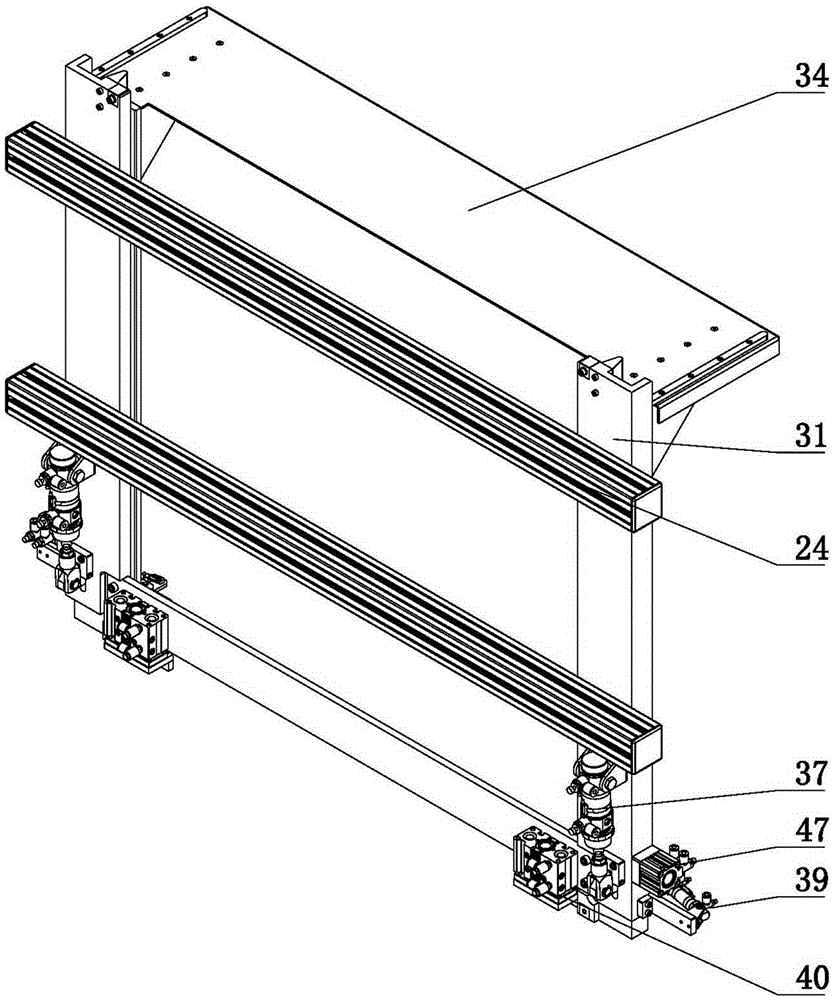

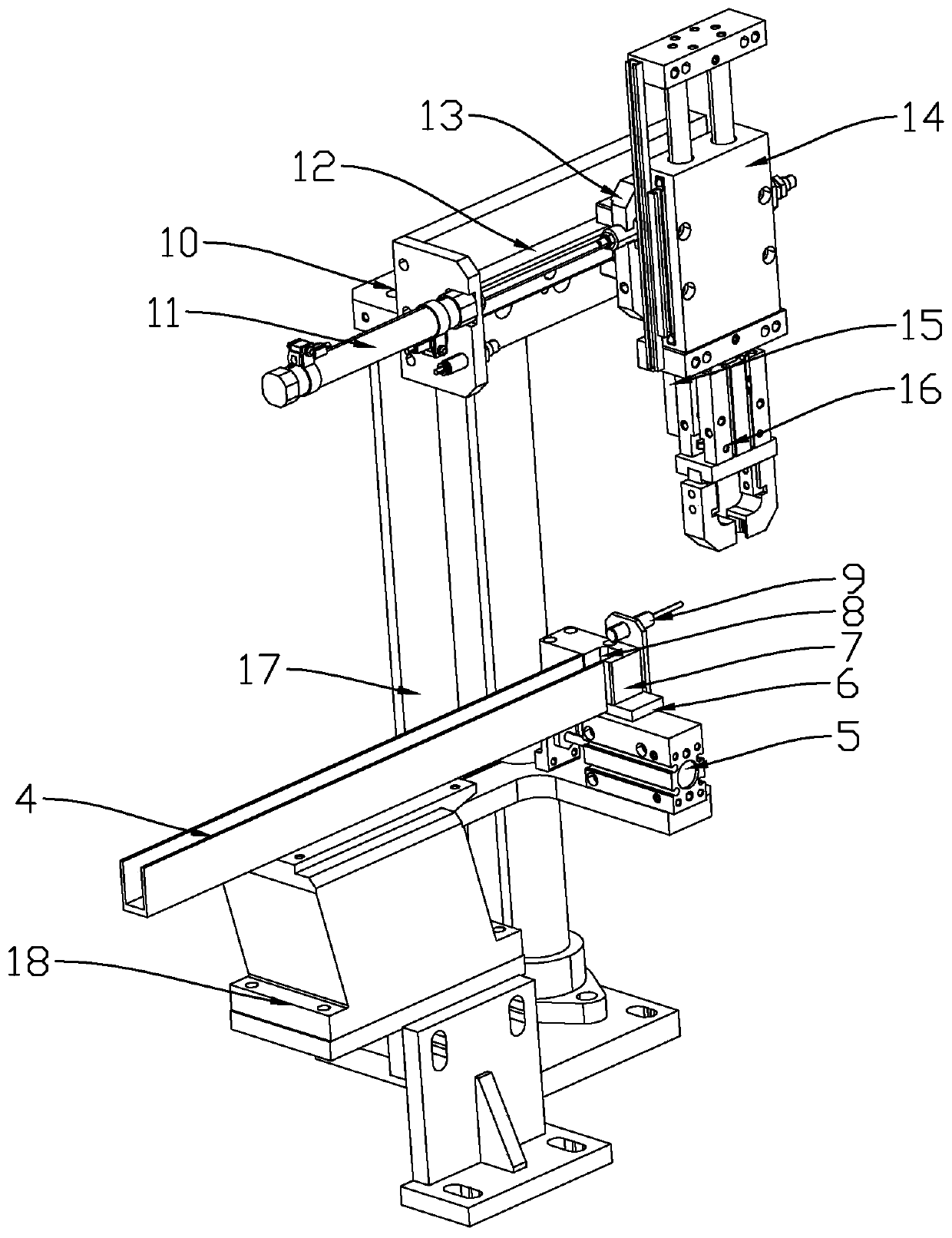

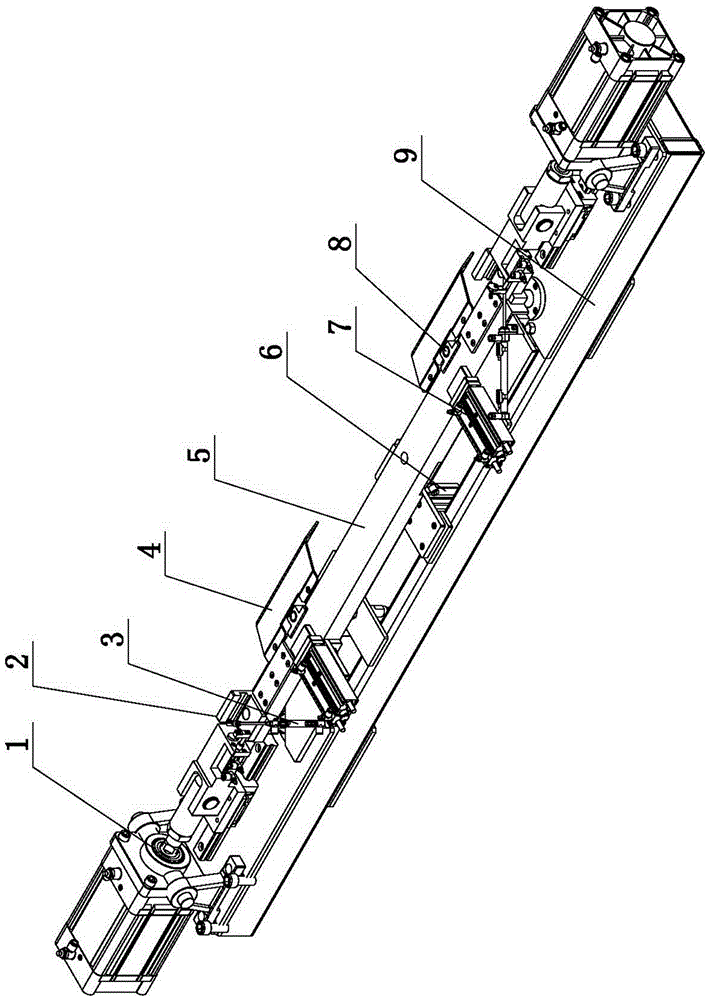

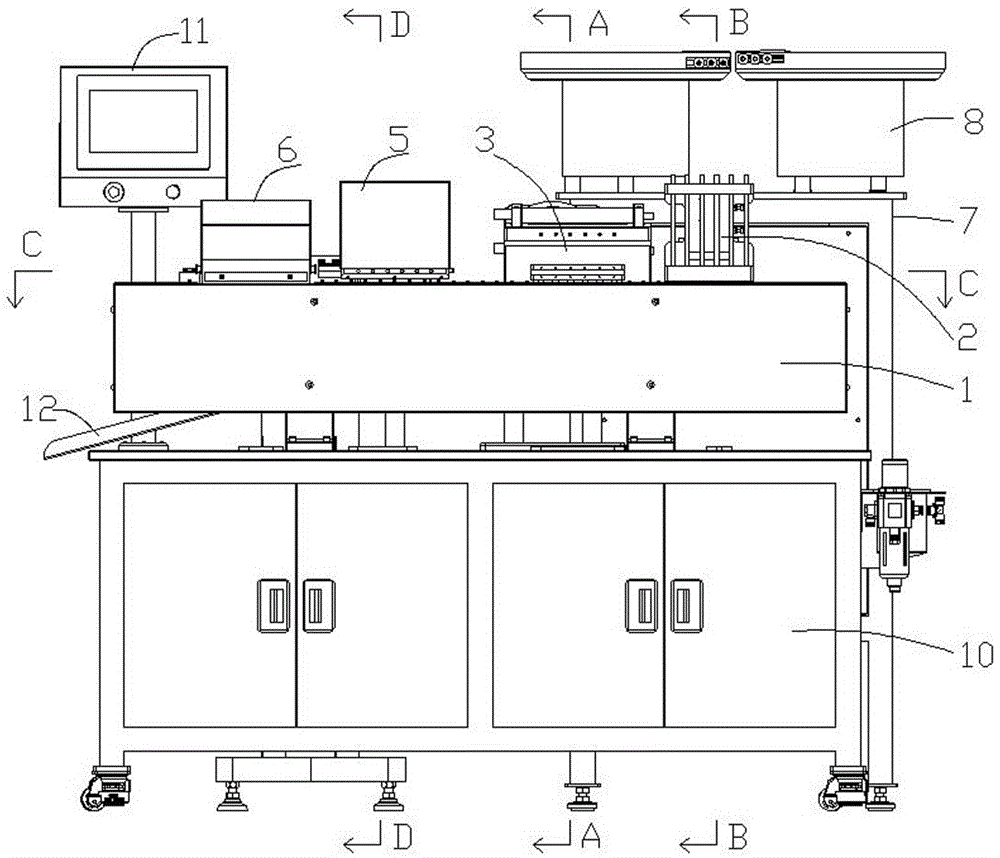

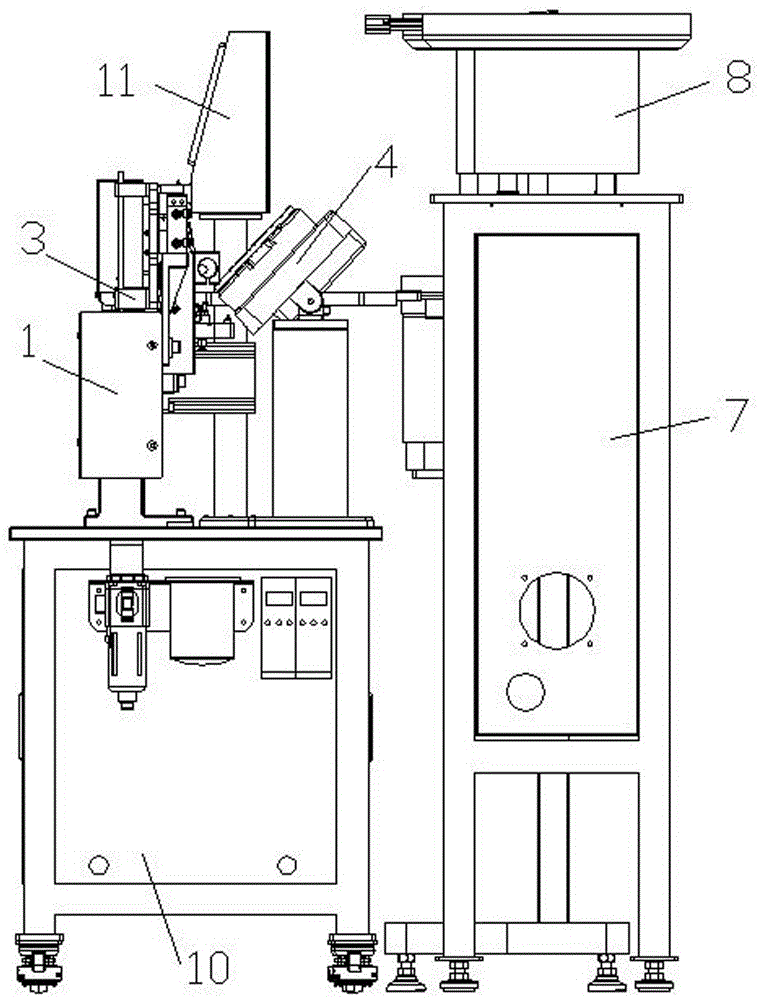

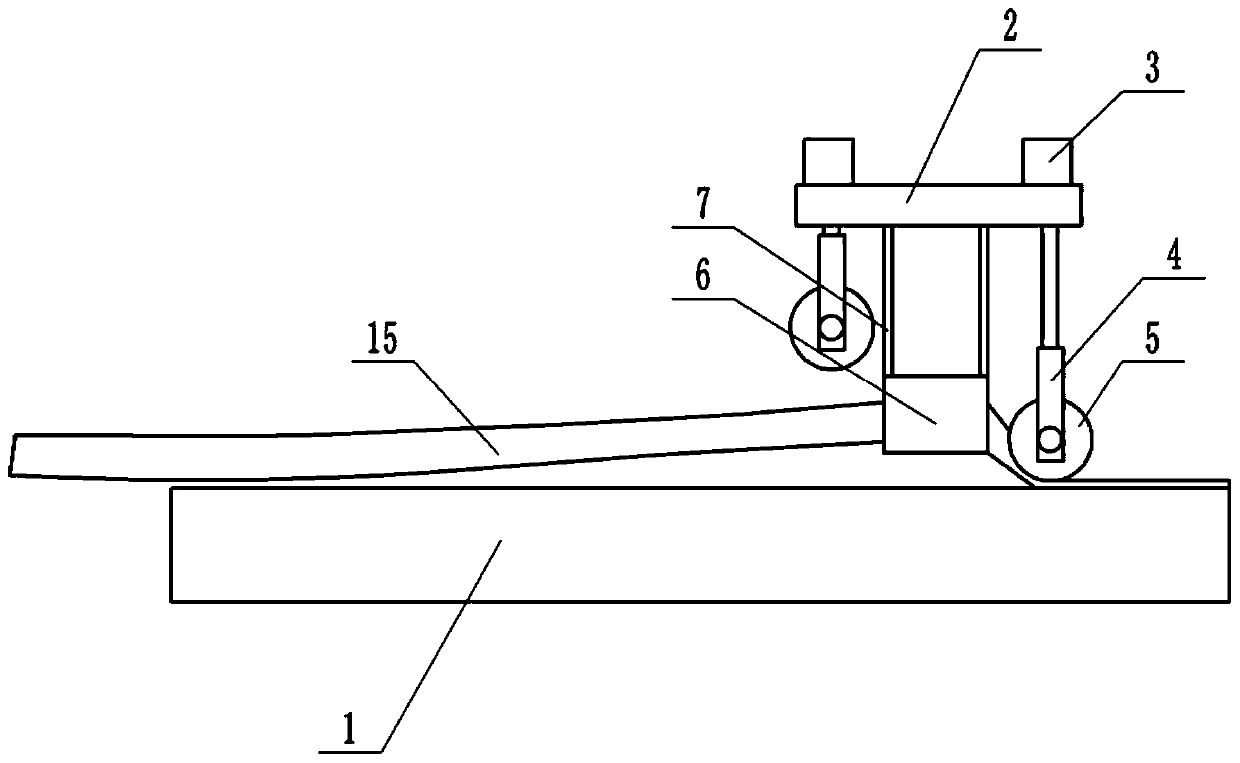

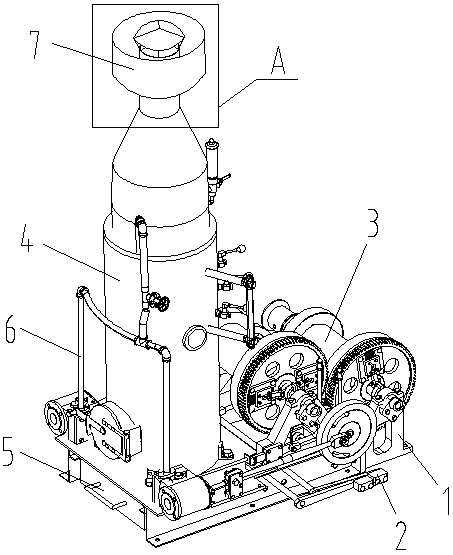

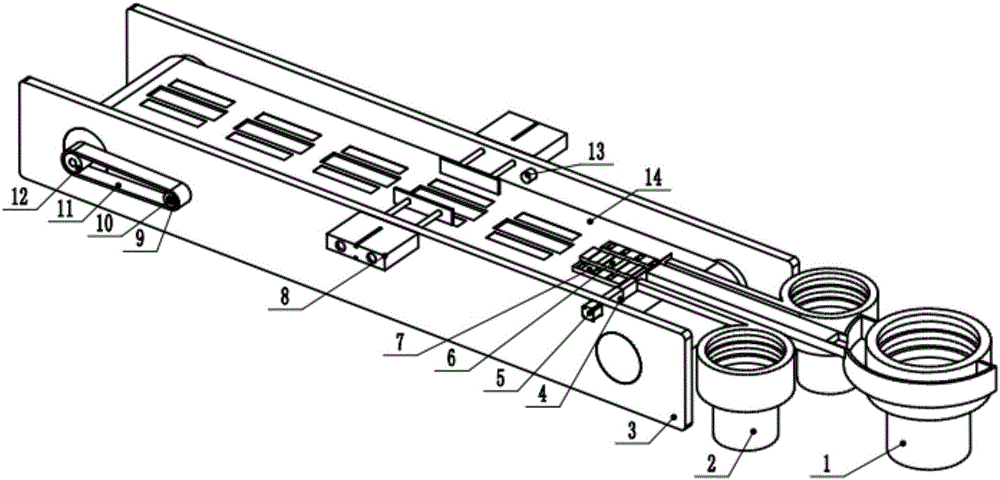

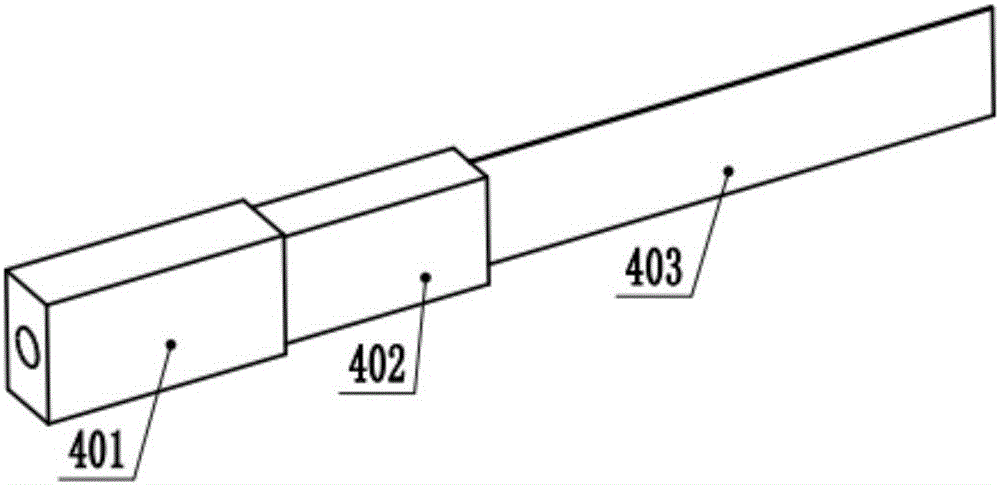

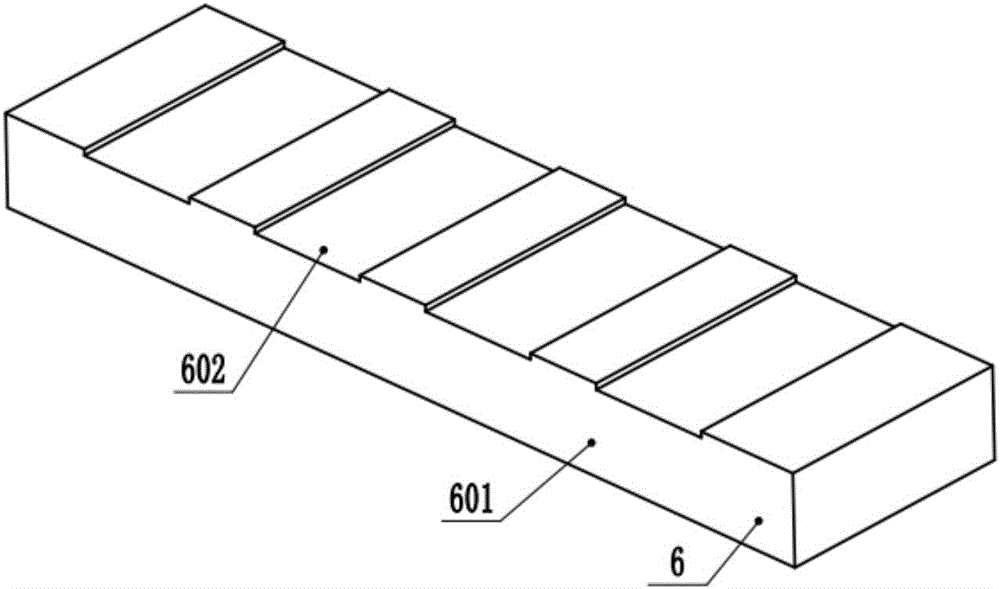

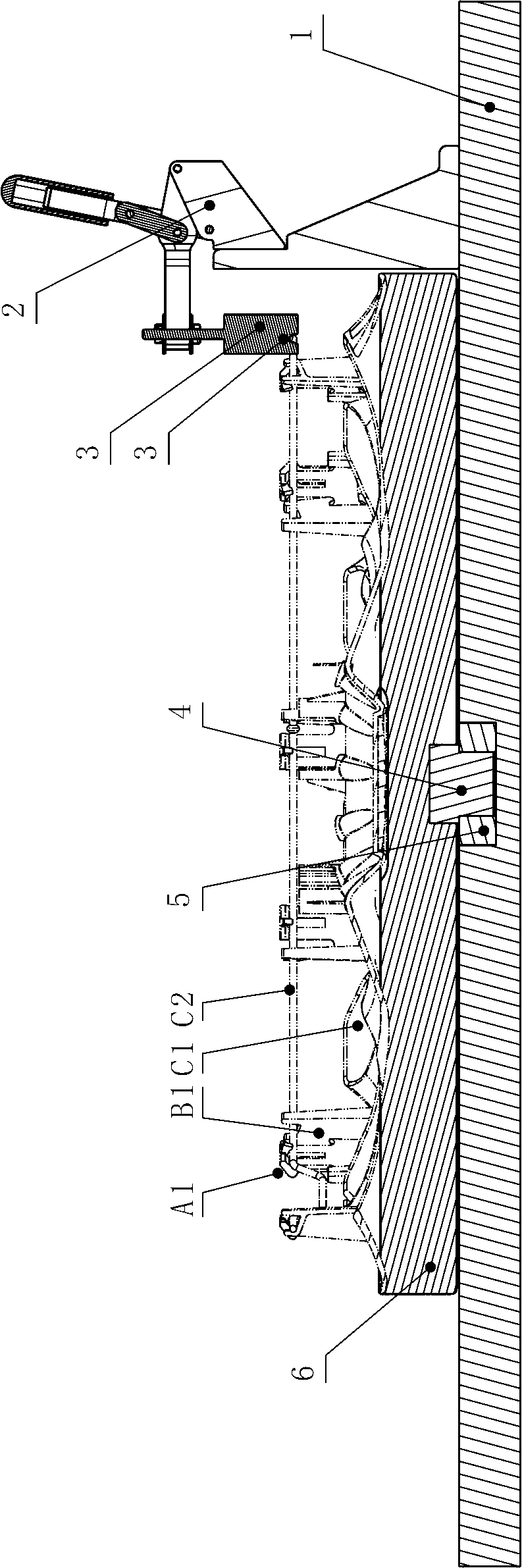

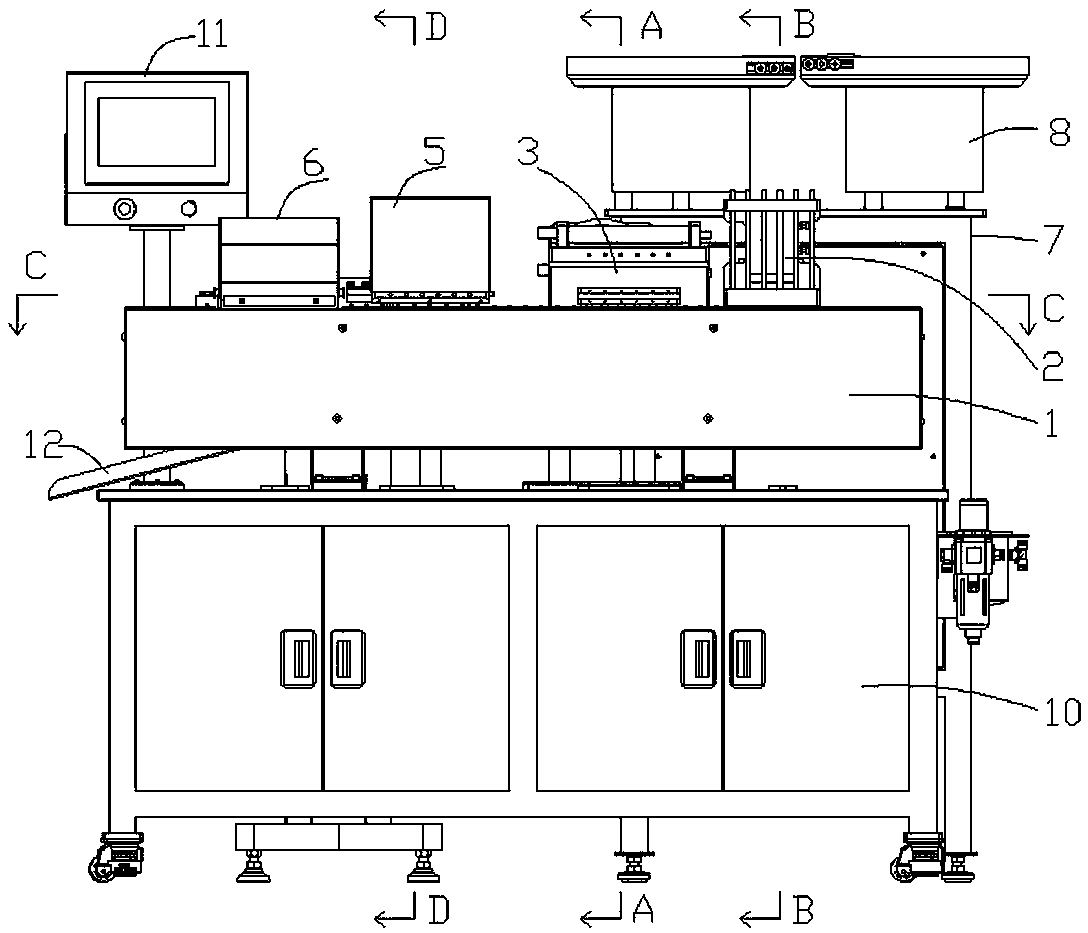

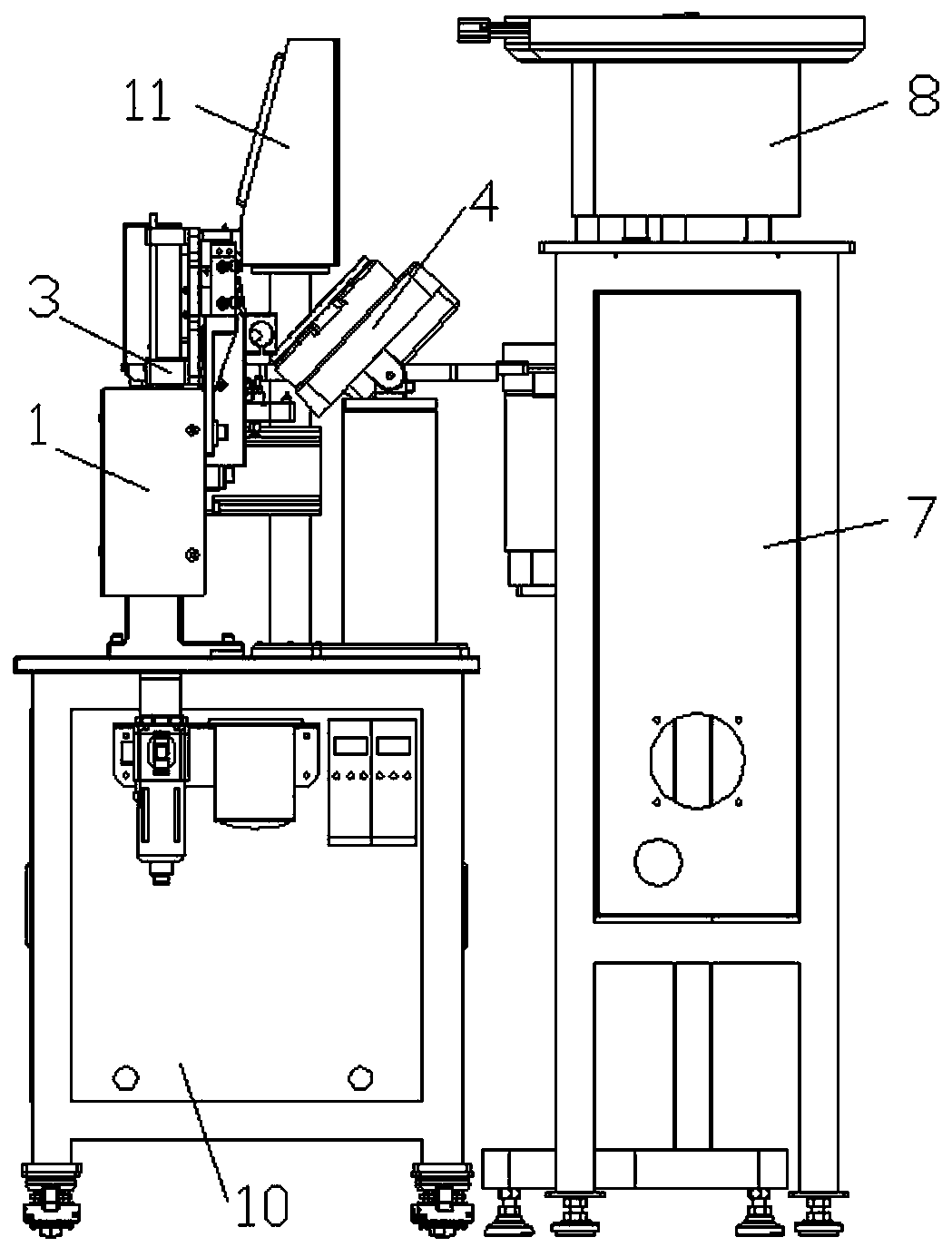

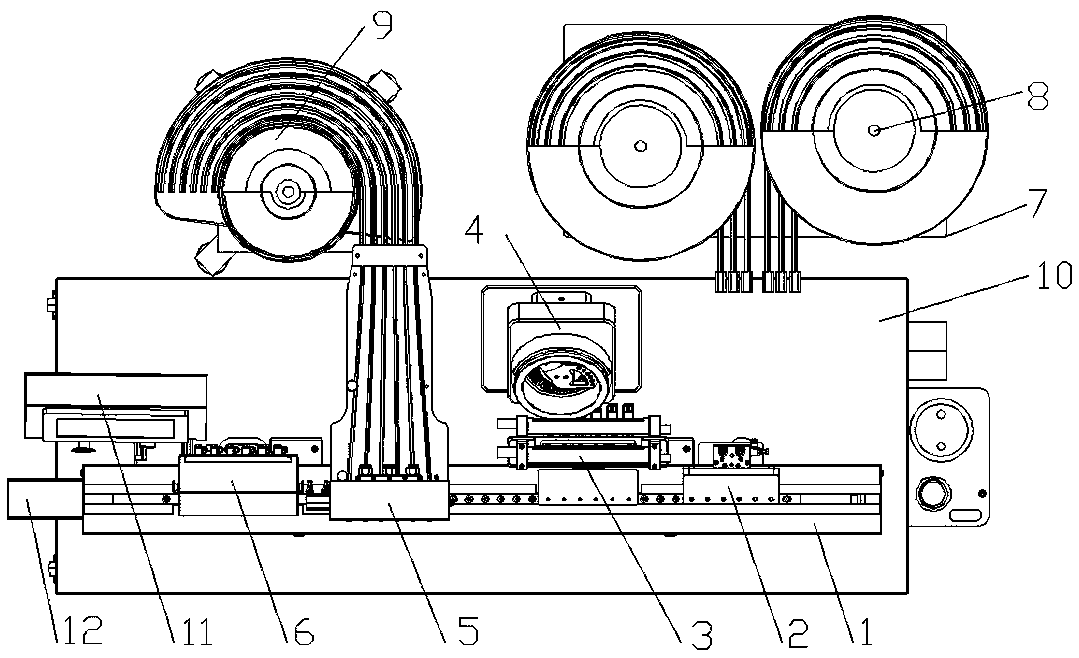

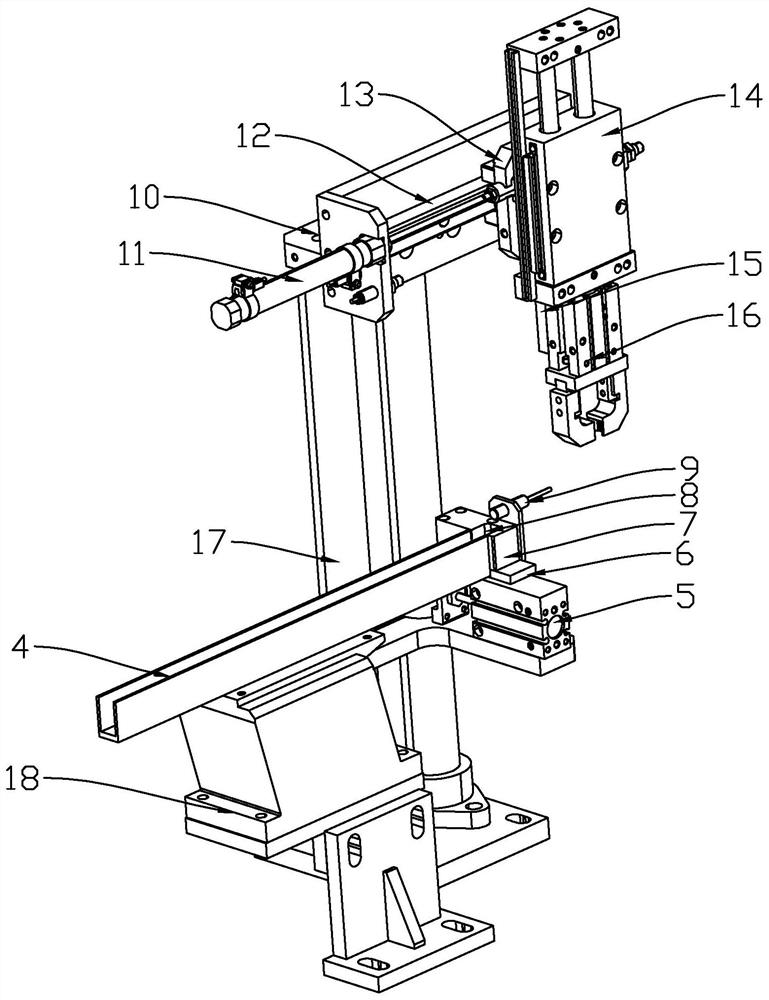

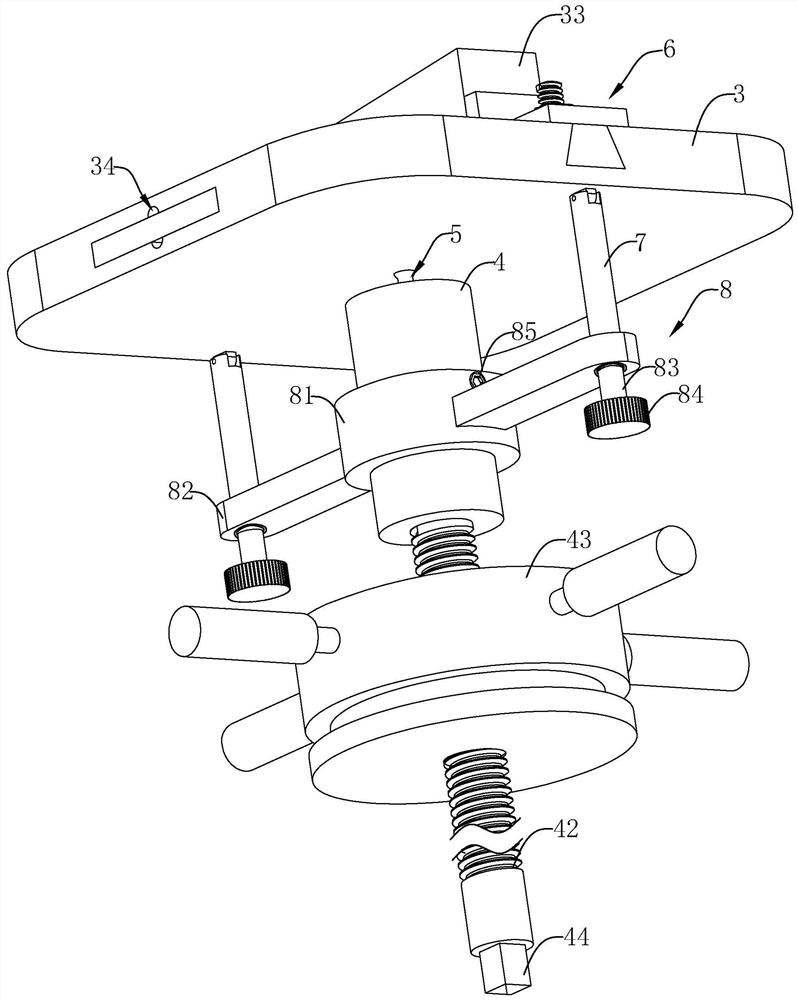

Automatic mounting machine for aluminum profile border corners

ActiveCN105345440ARealize automatic feedingSave human effortMetal working apparatusStructural engineeringMachine

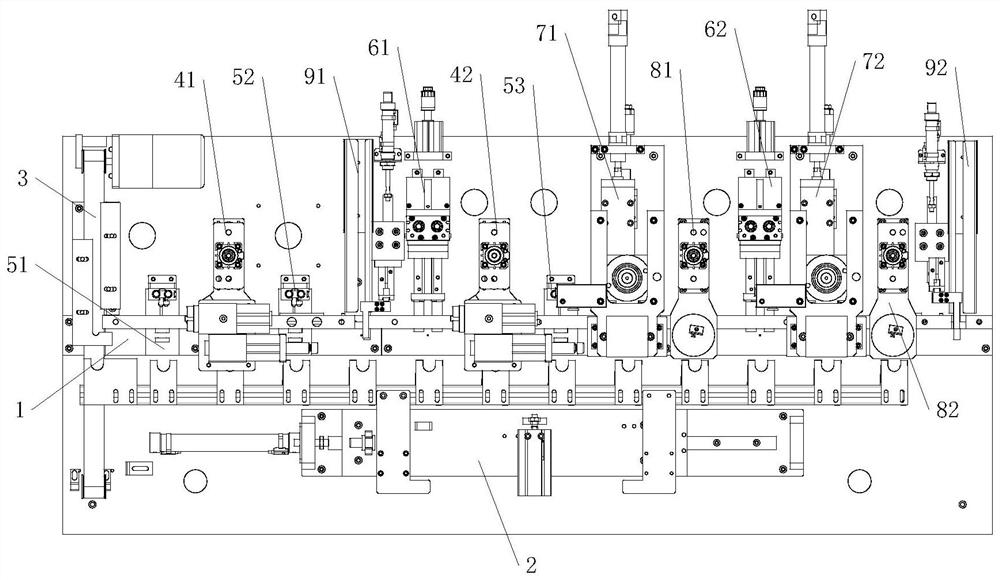

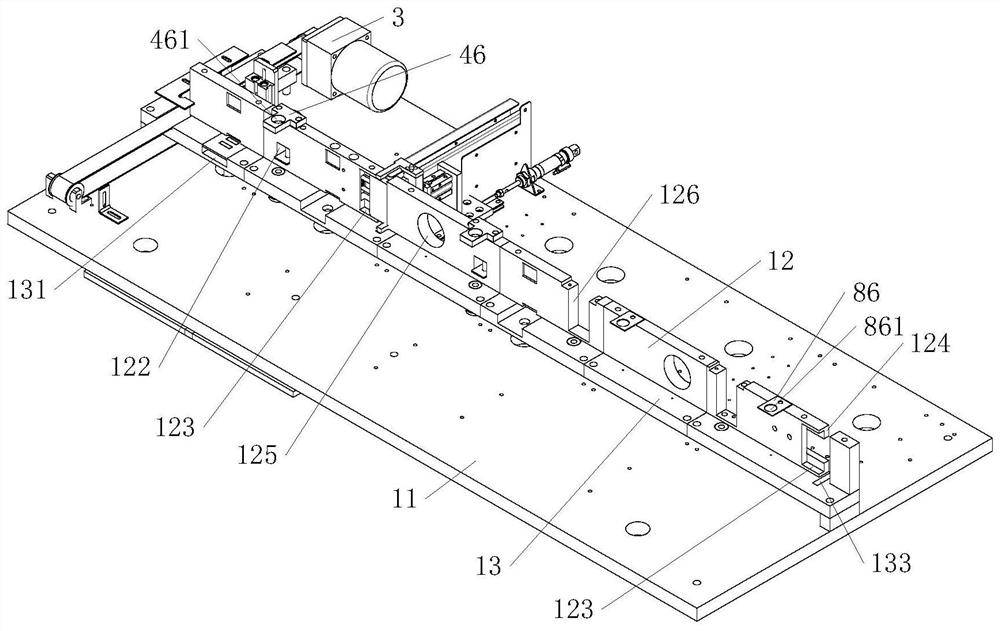

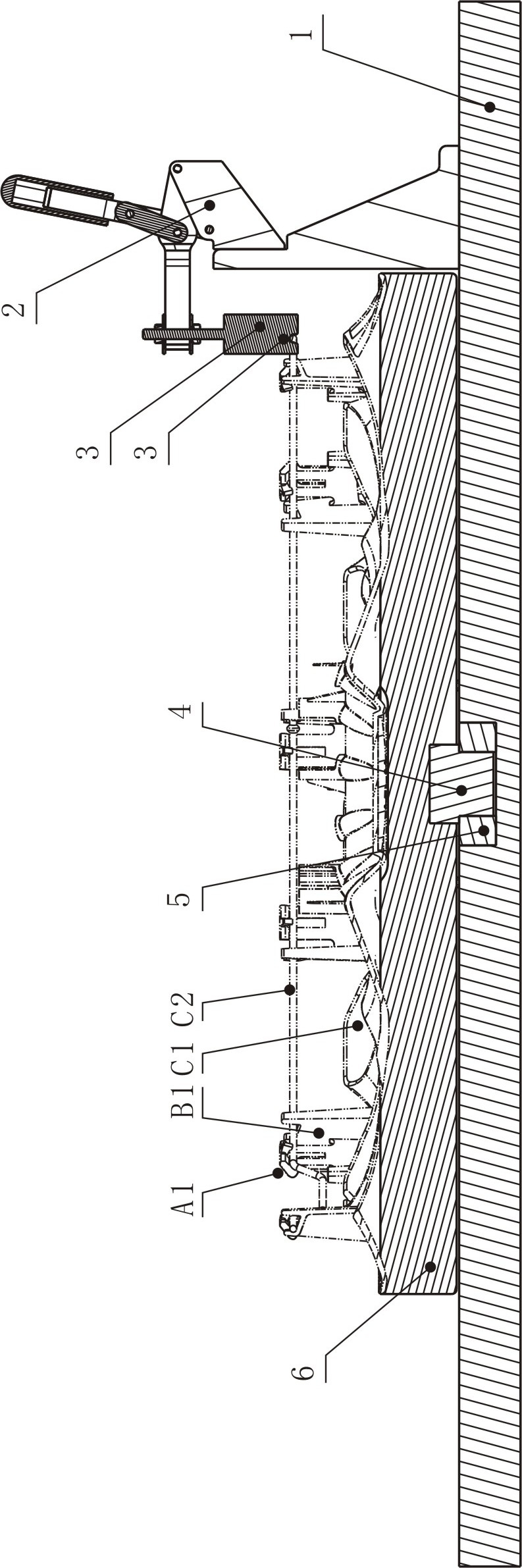

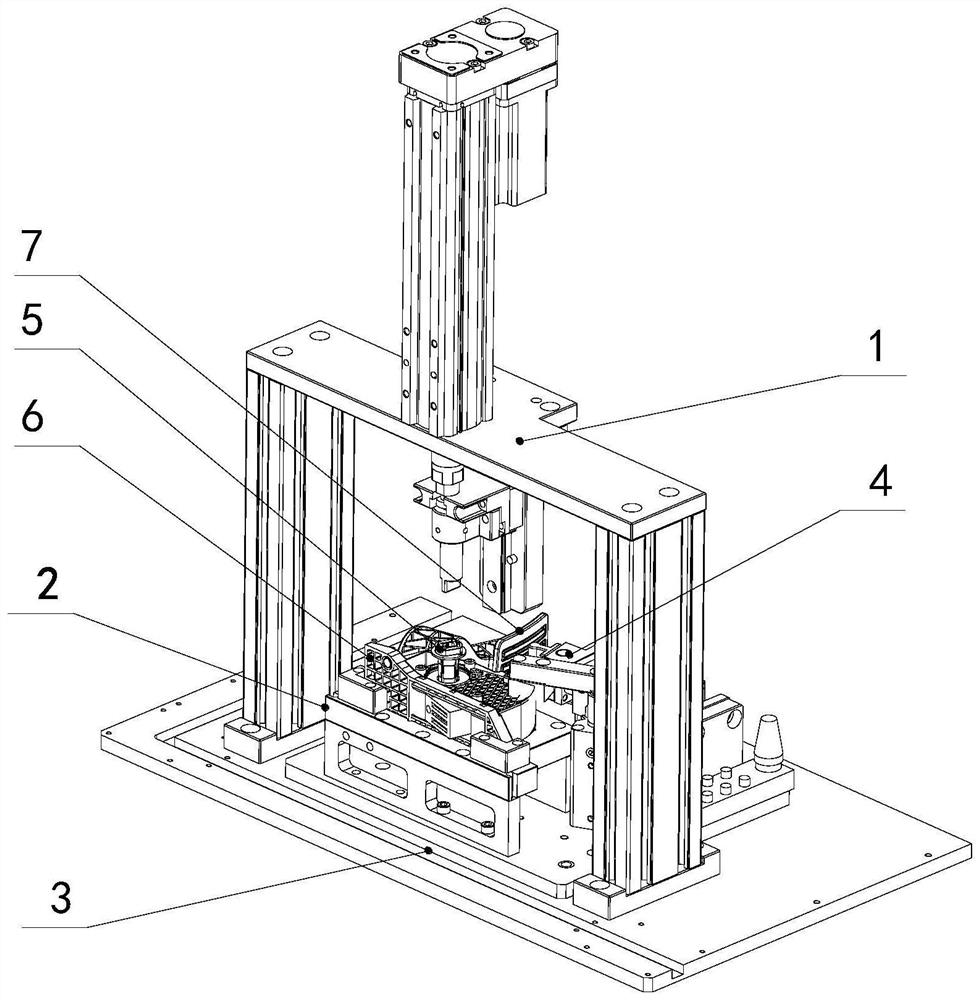

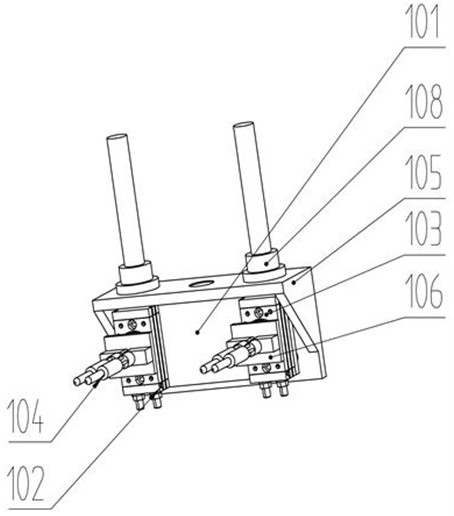

The invention relates to the technical field of automated production equipment of aluminum profiles, in particular to an automatic mounting machine for aluminum profile border corners. The automatic mounting machine for the aluminum profile border corners saves manpower, improves the production efficiency and improves product quality. The automatic mounting machine for the aluminum profile border corners is characterized in that a feeding device comprises a rack, wherein two bin stand columns are arranged on the rack; a loading plate is arranged between upper ends of the two bin stand columns; a border discharging trough is formed between the two bin stand columns and on the loading plate, and border slides are arranged on the bin stand columns and correspond to the border discharging trough; corner slides are arranged on the bin stand columns and correspond to two ends of the loading plate, and a corner discharging trough is formed in the loading plate and correspond to the corner slides; a border unloading device is arranged at the lower end of each bin stand column and corresponds to the corresponding border slide; a corner unloading device is arranged at the lower end of each bin stand column and corresponds to the corresponding corner slide; a corner pressing mechanism corresponds to the lower ends of the bin stand columns.

Owner:YINGKOU JINCHEN MACHINERY

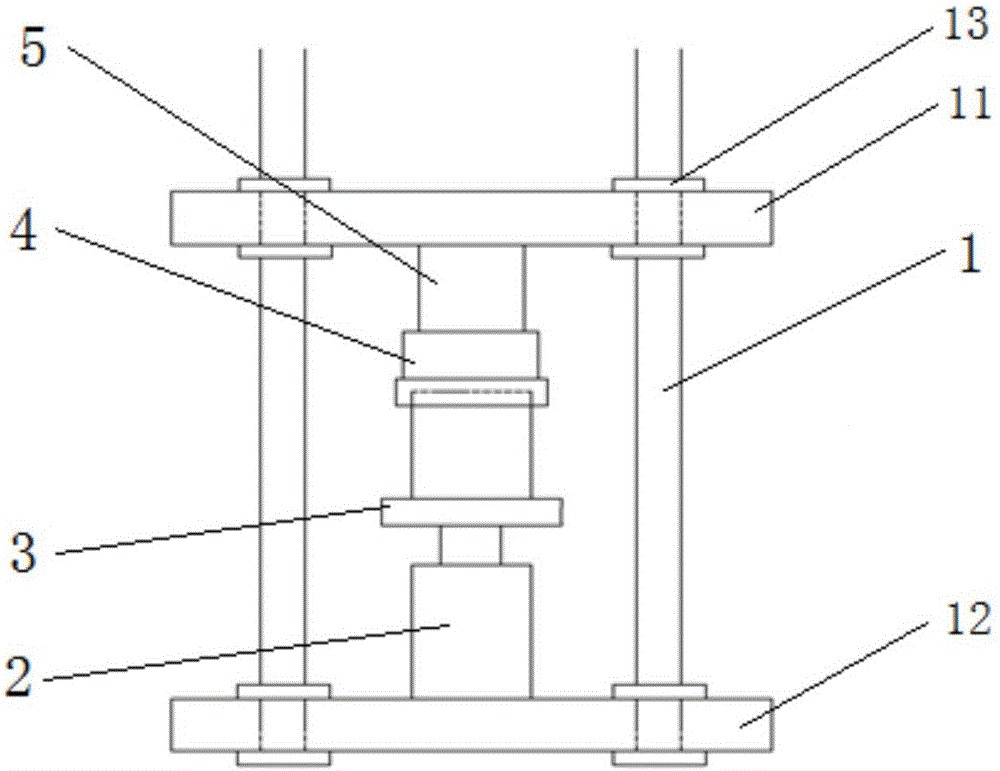

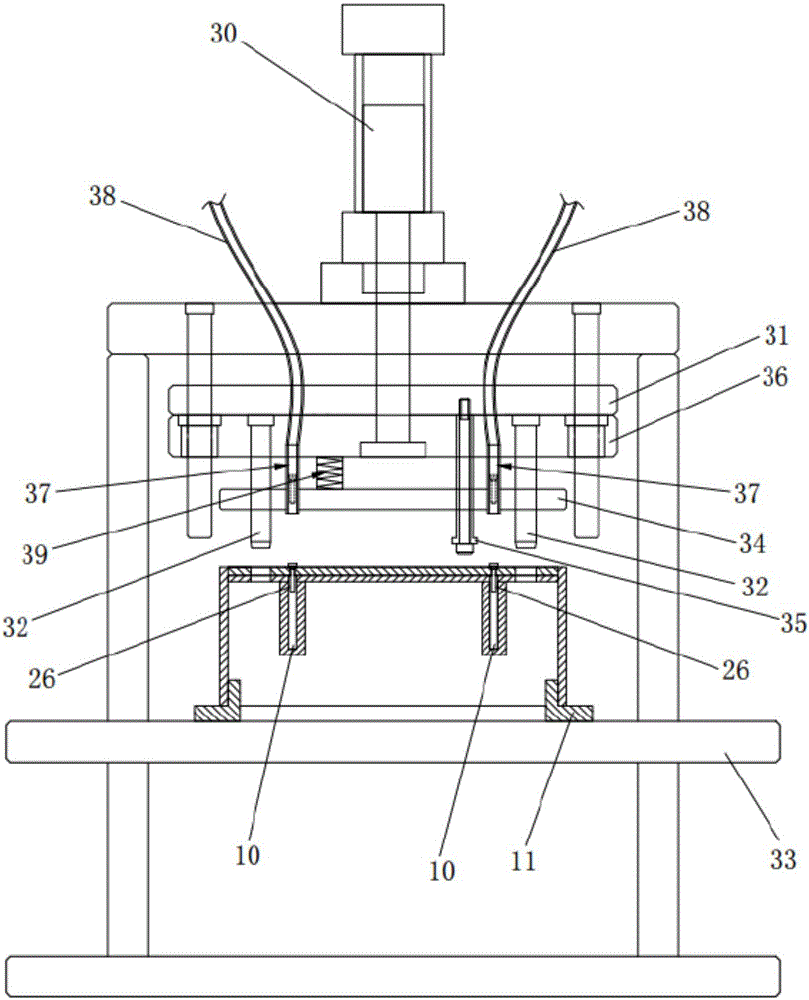

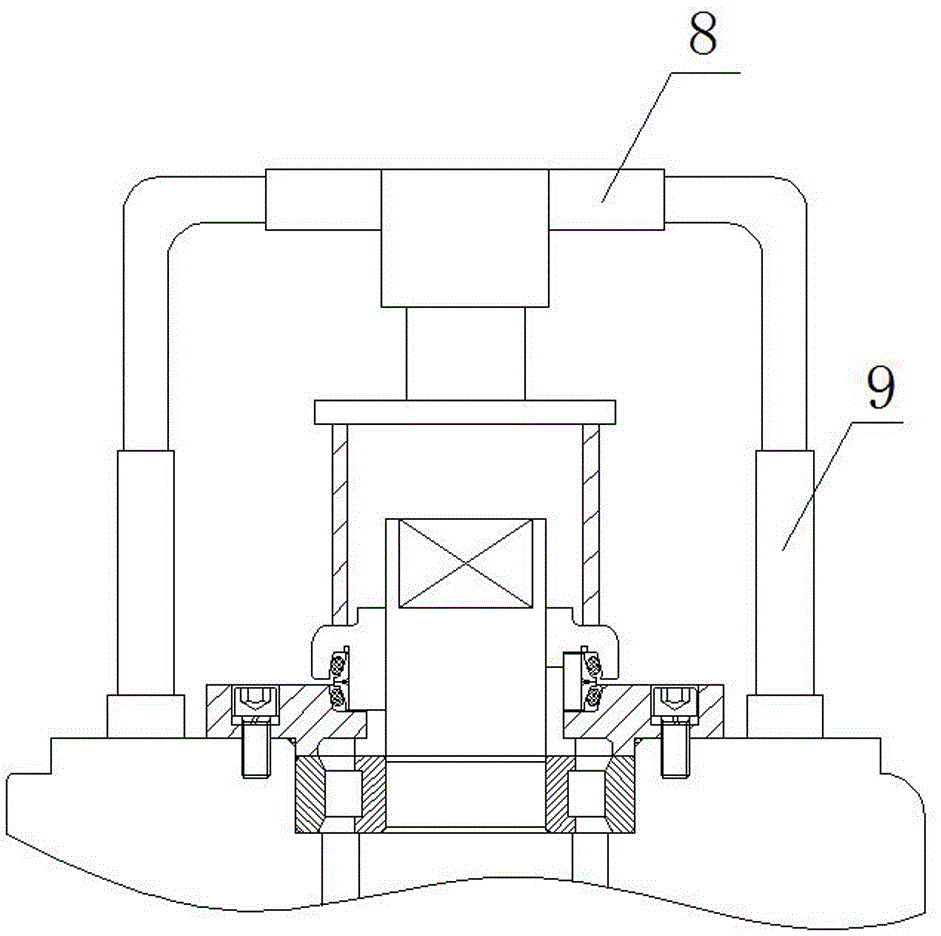

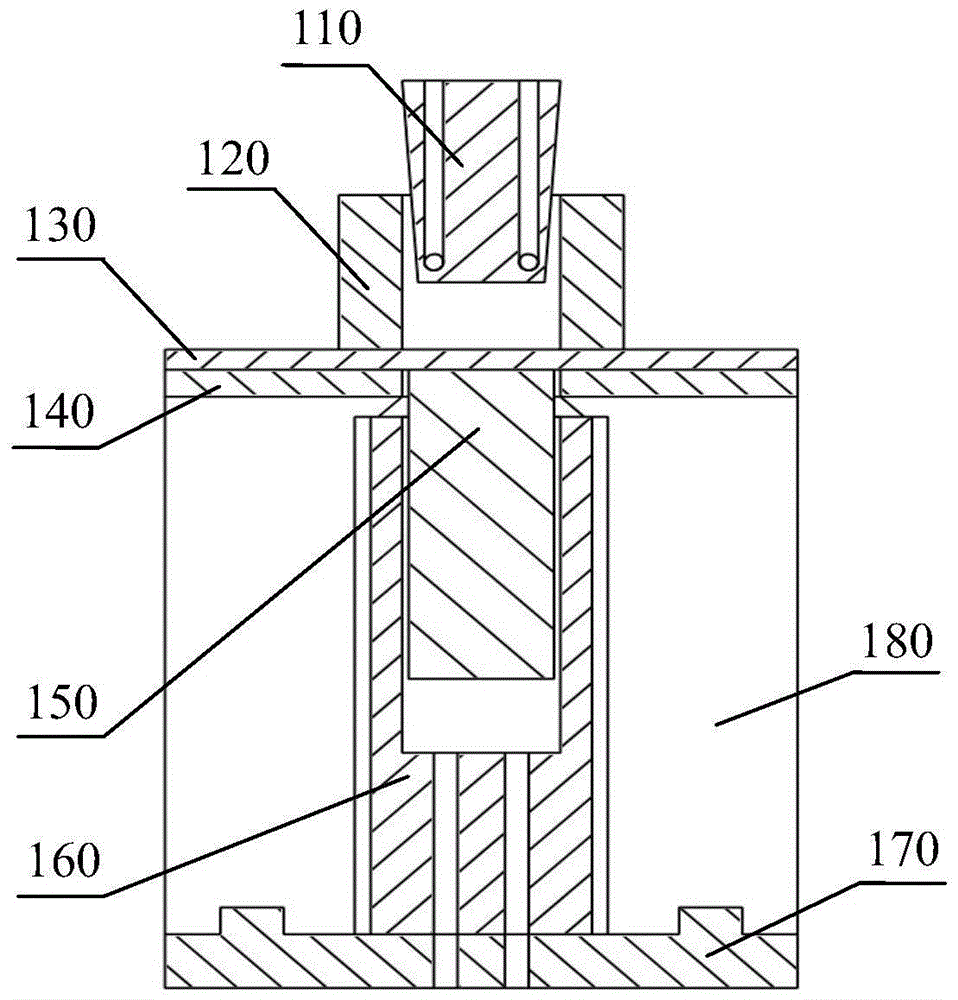

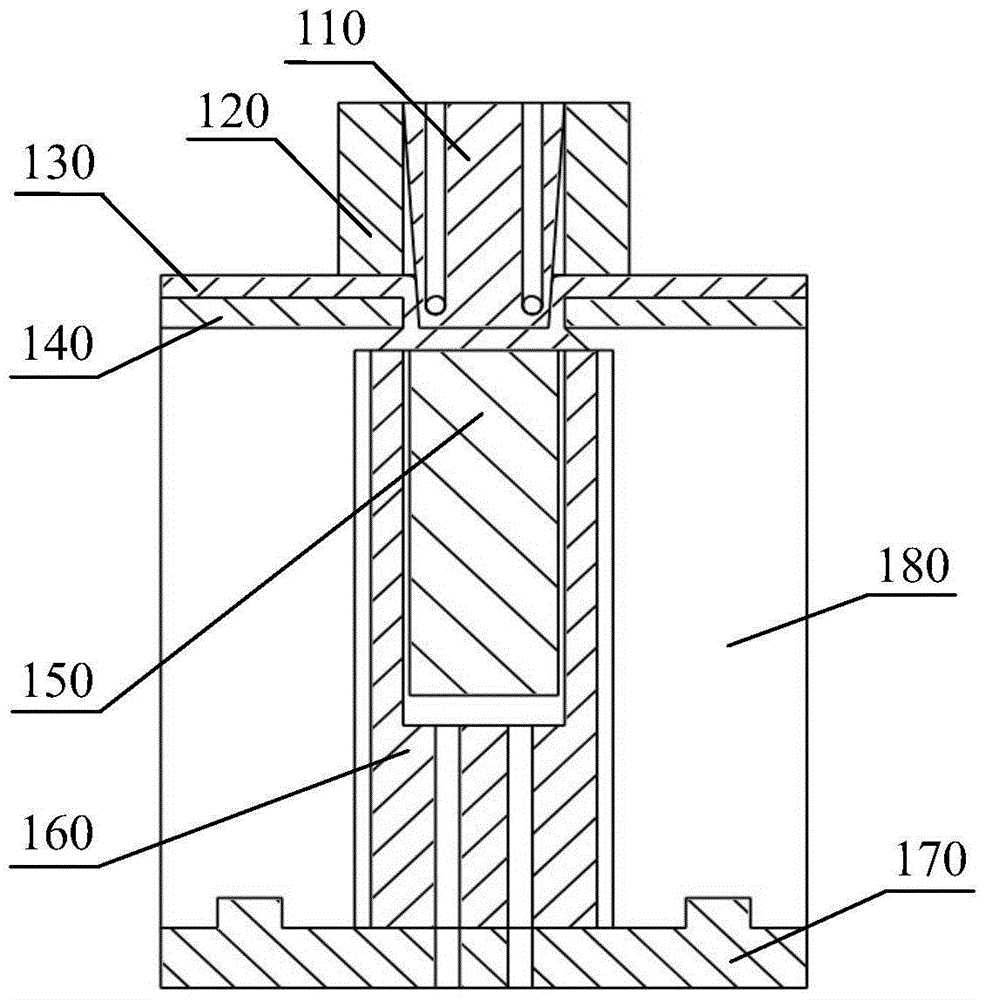

Sample preparation method and compaction device for immature soil base materials

ActiveCN105890961AStable compressive strengthGood densityPreparing sample for investigationDuctilityMaterials science

The invention discloses a sample preparation method and a compaction device for immature soil base materials. The method comprises the steps that the interior of a mold is coated with a lubricating oil layer, the immature soil base materials are put into the mold layer by layer, the immature soil base material layers in the mold are compacted through a jack every time one layer of immature soil base material is laid, and therefore a sample to be detected is obtained; the compaction speed of the jack is 0.5 mm / s, the compaction pressure of the jack is 18-19 K / N, and the compaction time of the jack is 3-5 min; the compaction device comprises a test bed, the test bed is sequentially provided with a first platform and a second platform in parallel in the horizontal direction from top to bottom, the second platform is coaxially provided with the jack, a gasket, the mold and a pressing column in sequence from bottom to top in the vertical direction, and the top end of the pressing column abuts against the first platform. Compared with a traditional hammer test, a press compaction test and a jack compaction test, the compressive strength of a test piece compacted by the jack is more stable than the compressive strength of a test piece compacted by the other two test methods, test piece overall deformation is good, and the test piece has good ductility when compacted.

Owner:CHANGAN UNIV

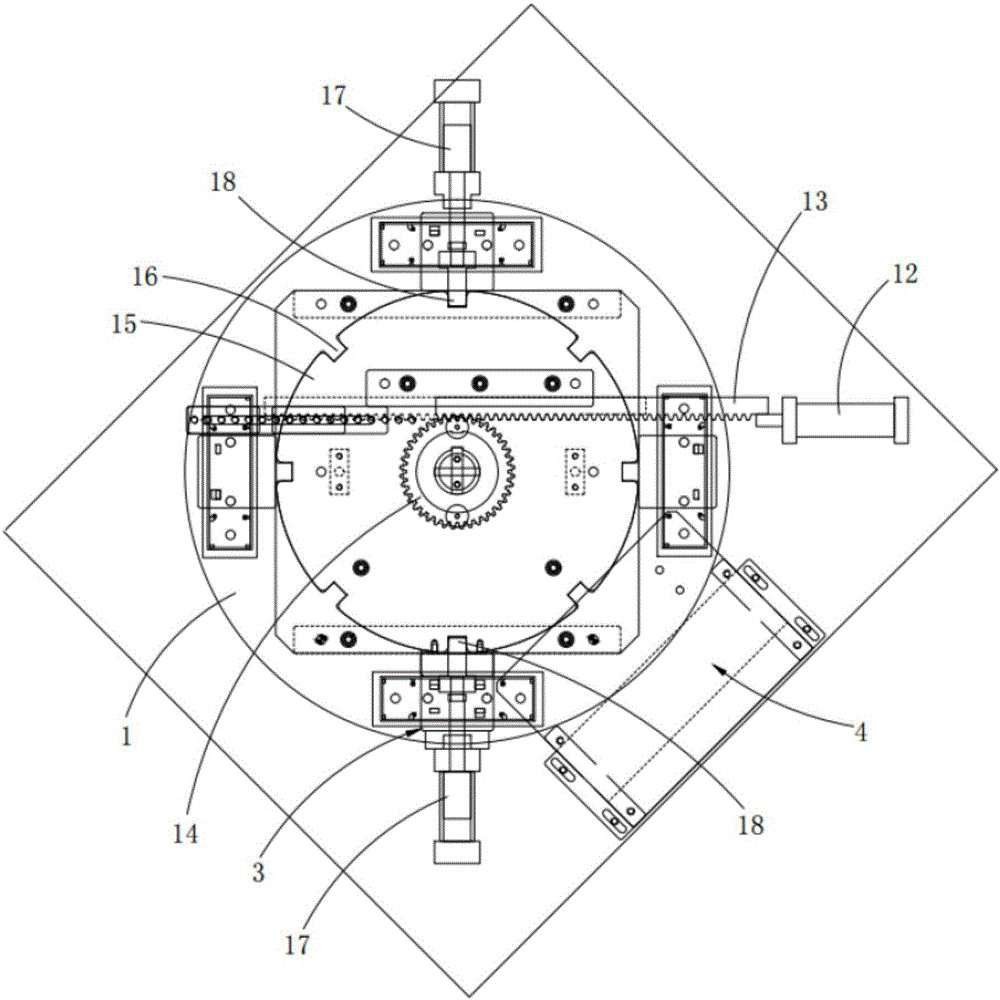

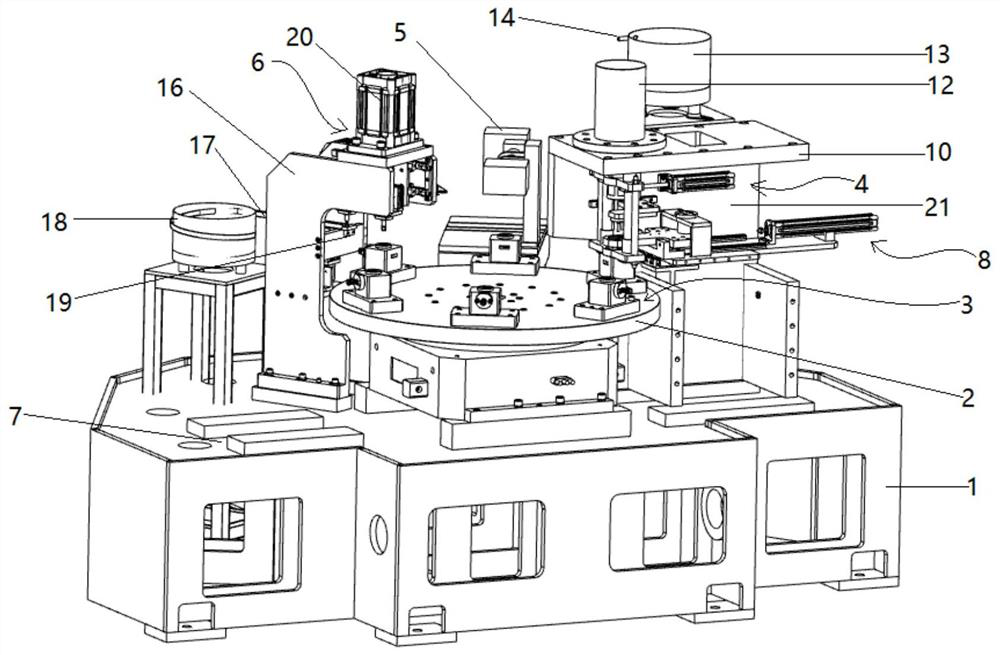

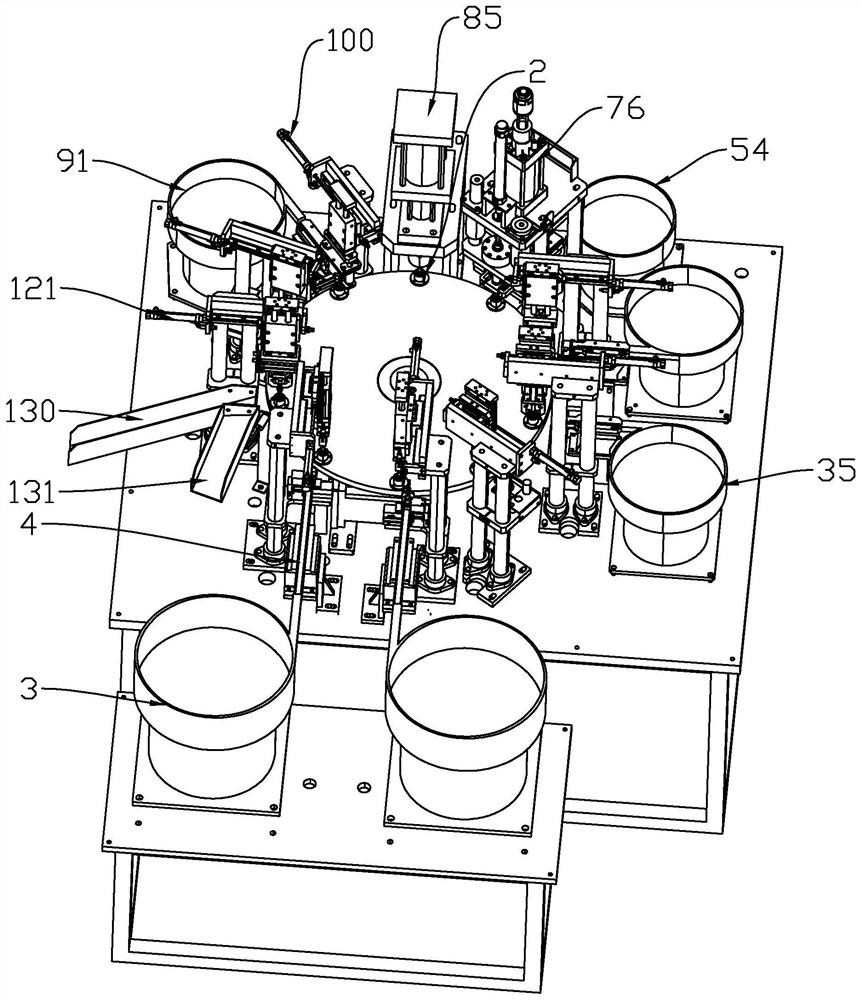

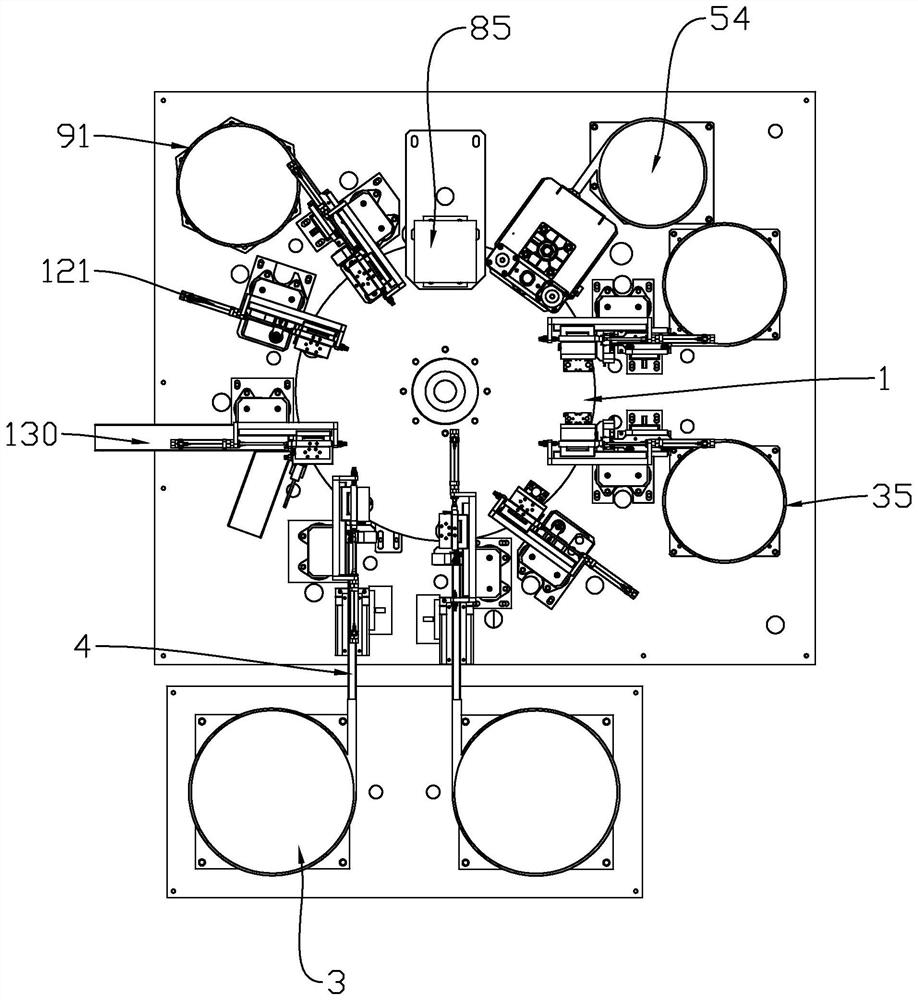

Automatic assembling equipment for valve body assembly of reading valve

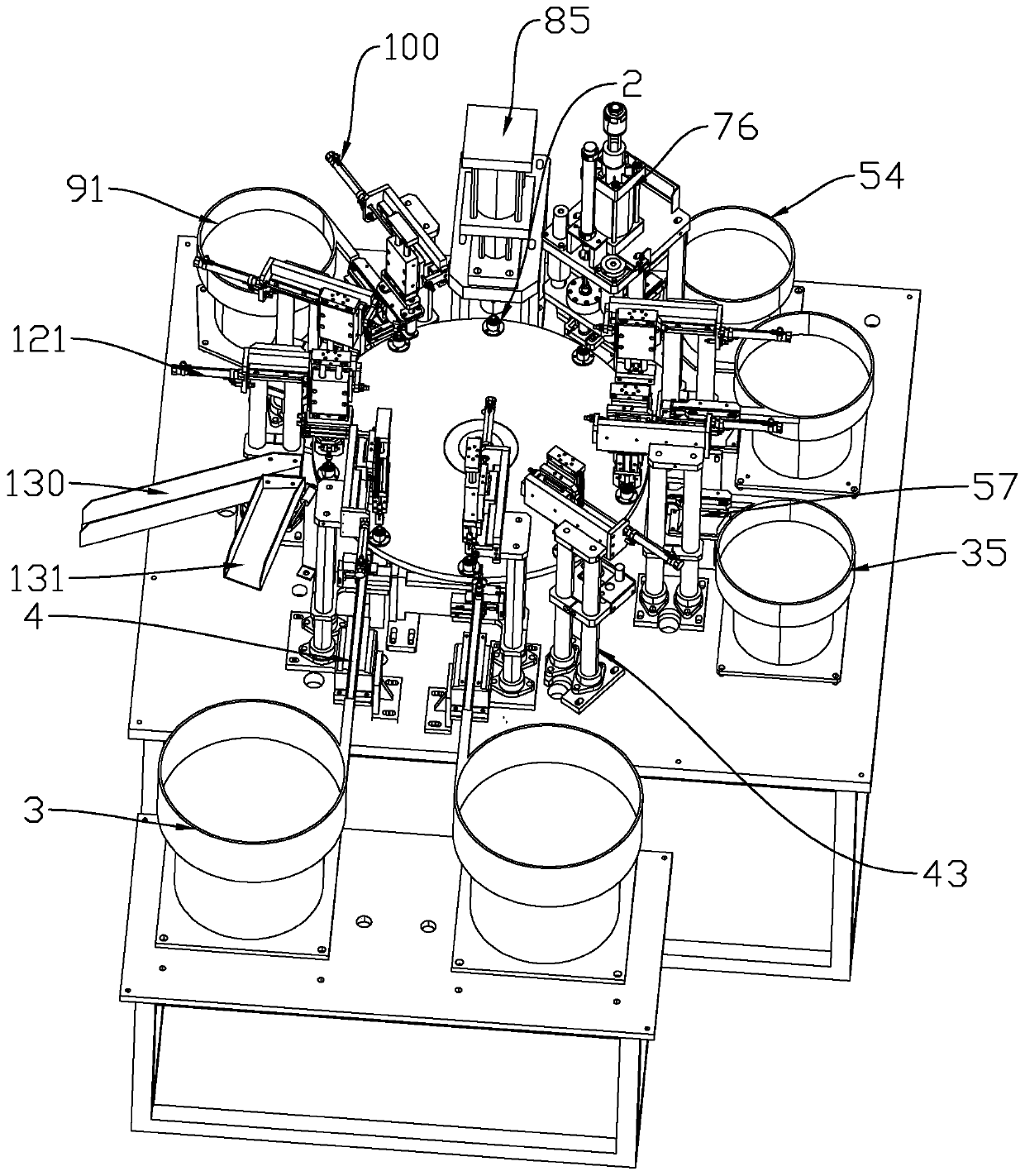

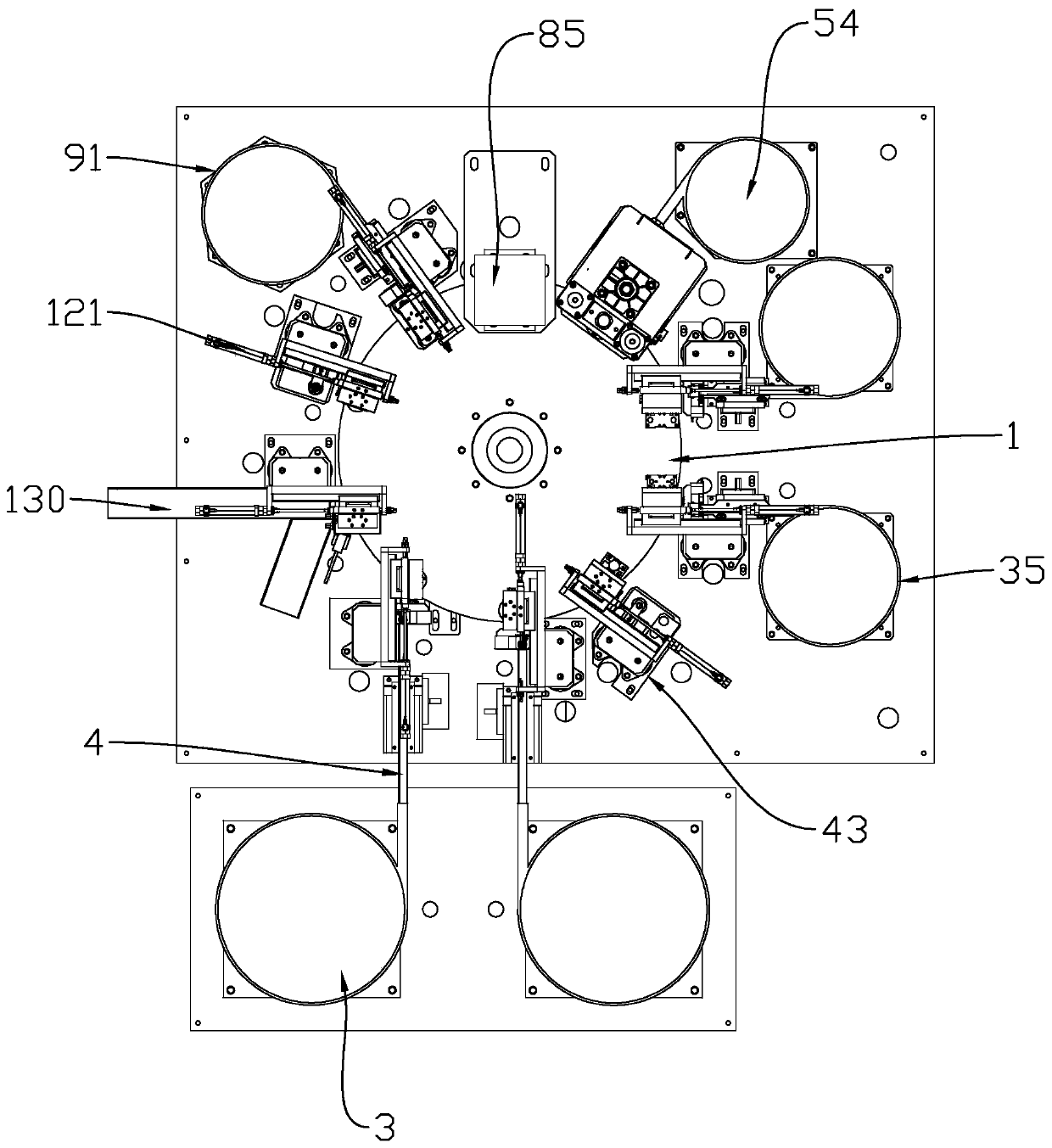

ActiveCN111185753AImprove work efficiencyReduce assembly failure rateAssembly machinesSortingStructural engineeringRotating disc

The invention relates to automatic assembling equipment, in particular to automatic assembling equipment for a valve body assembly of a reading valve. The automatic assembling equipment comprises a rotating disc, a first valve body feeding mechanism, a second valve body feeding mechanism, a valve body inner hole outer ring oiling mechanism, a first plastic inner ring feeding mechanism, a second plastic inner ring feeding mechanism, a knurled inner ring feeding mechanism, a valve body closing mechanism, an O-shaped ring feeding mechanism, an O-shaped ring outer ring oiling mechanism and a discharging mechanism, wherein the first valve body feeding mechanism, the second valve body feeding mechanism, the valve body inner hole outer ring oiling mechanism, the first plastic inner ring feeding mechanism, the second plastic inner ring feeding mechanism, the knurled inner ring feeding mechanism, the valve body closing mechanism, the O-shaped ring feeding mechanism, the O-shaped ring outer ringoiling mechanism and the discharging mechanism are sequentially arranged around the rotary disc in the circumferential direction. According to the automatic assembling equipment for the valve body assembly of the reading valve, by arranging a series of assembling mechanisms around the rotary disc, the assembling work of the valve body assembly of the reading valve can be automatically, accuratelyand reliably completed, and the assembling work efficiency is improved.

Owner:弗瑞斯阀门(宁波)有限公司

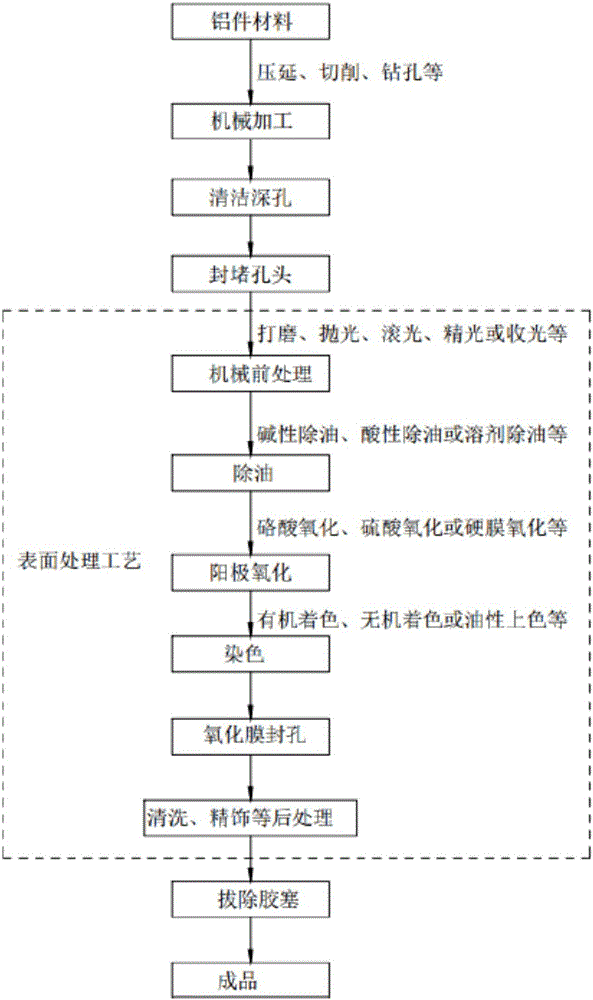

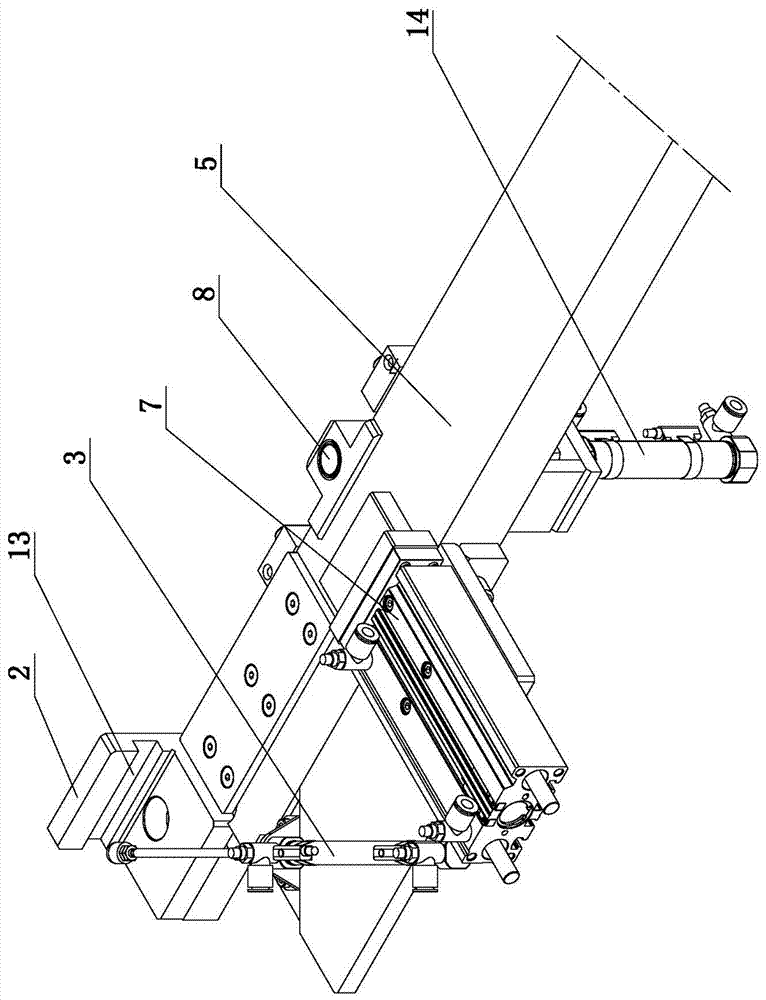

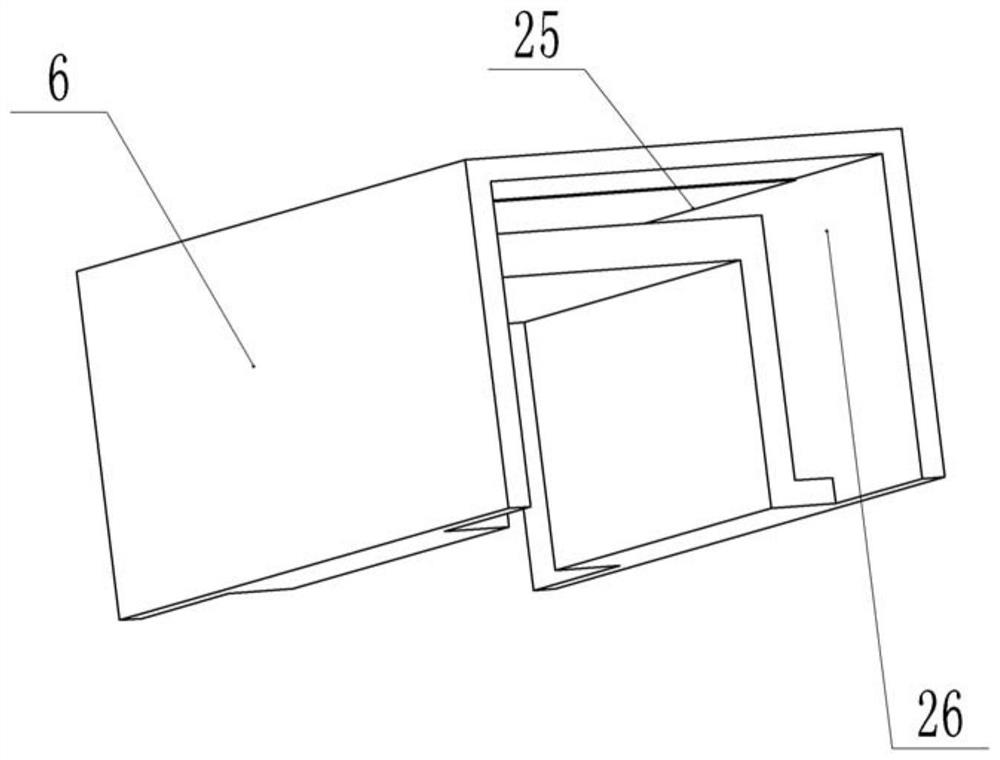

Processing technology of aluminum alloy workpiece and full-automatic binding machine

ActiveCN106584014ASimple processSimple structureMetal working apparatusSurface finishingSurface processing

The invention discloses a processing technology of an aluminum alloy workpiece and a full-automatic binding machine. The processing technology is characterized in that the steps of sealing and blocking a hole head and removing a rubber plug are added in an existing aluminum alloy workpiece technology, wherein pores in the workpiece are sealed and blocked through rubber nails after the mechanical processing, and the rubber nails are automatically removed through a clamp after the surface treatment processing is completely completed, so that the pores in the workpiece can be effectively protected and can be prevented from being polluted or blocked during the processing. The automatic blocking machine for the pores in the workpiece comprises a rubber nail positioning jig, a rubber nail blowing mechanism and a rubber nail pressing mechanism, wherein the rubber nail blowing mechanism and the rubber nail pressing mechanism are mounted on a rack; an elastic rubber nail clamping hole is formed in a position, corresponding to each pore in the workpiece, on the rubber nail positioning jig; the rubber nails are temporarily fixed above the pores in the workpiece through the rubber nail positioning jig, so that the rubber nails can be pressed into the corresponding pores in the workpiece through nail pressing needles, and as a result, the work of sealing and blocking the pores in the workpiece can be fully automatically finished; the rubber nails can be stably and reliably pressed, so that the production efficiency is improved, and the production cost is reduced.

Owner:DONGGUAN JIFU METALLIC PROD CO LTD

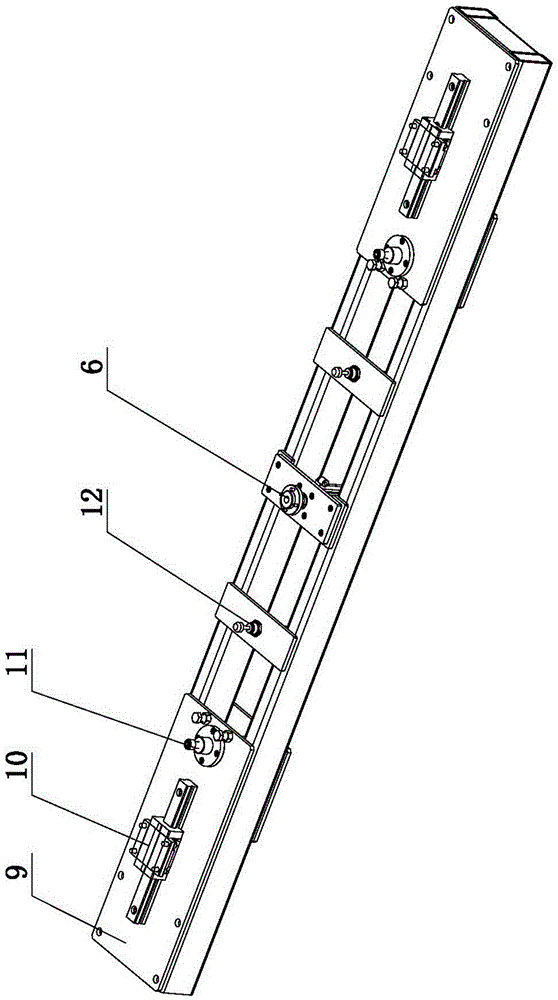

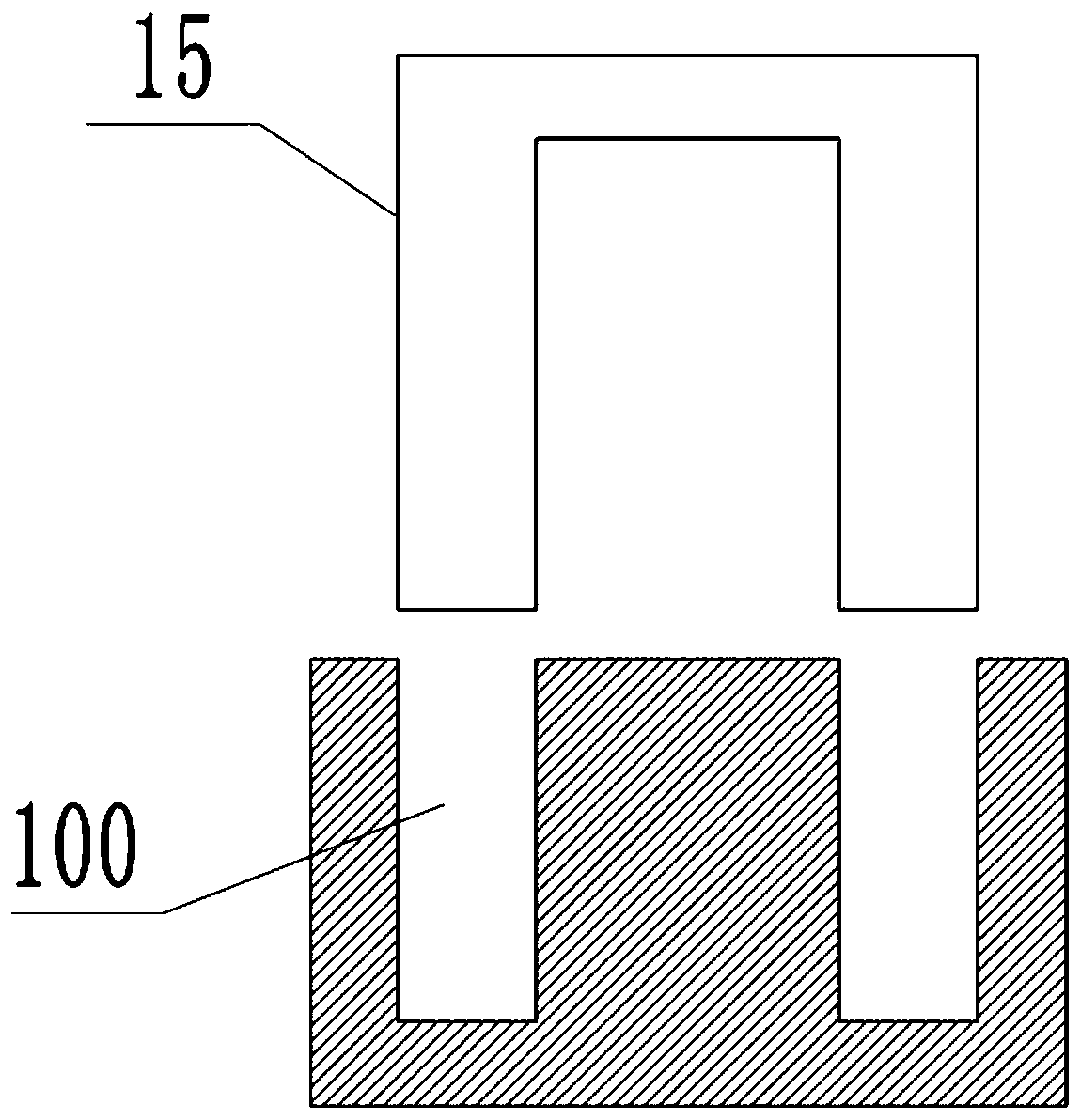

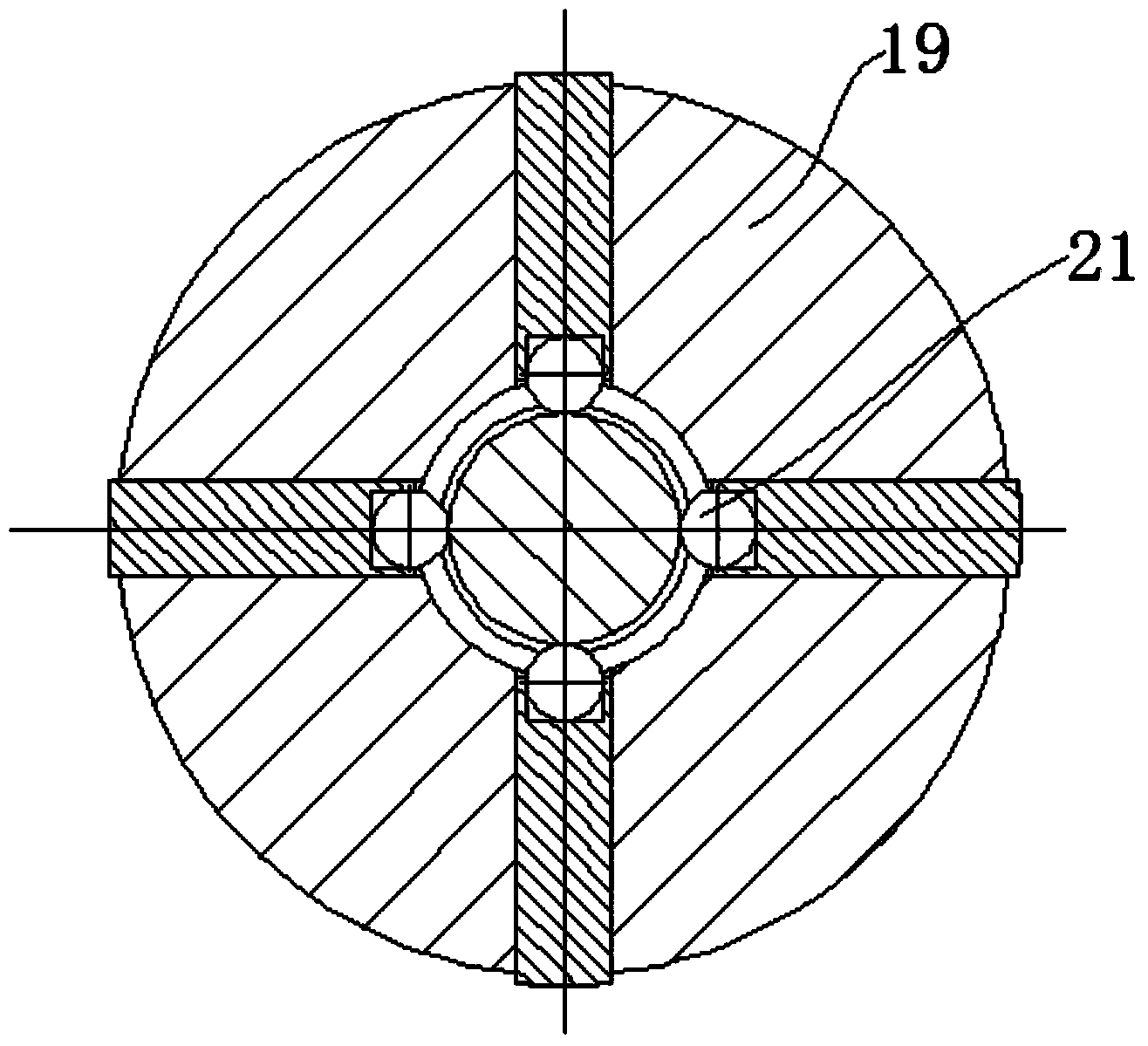

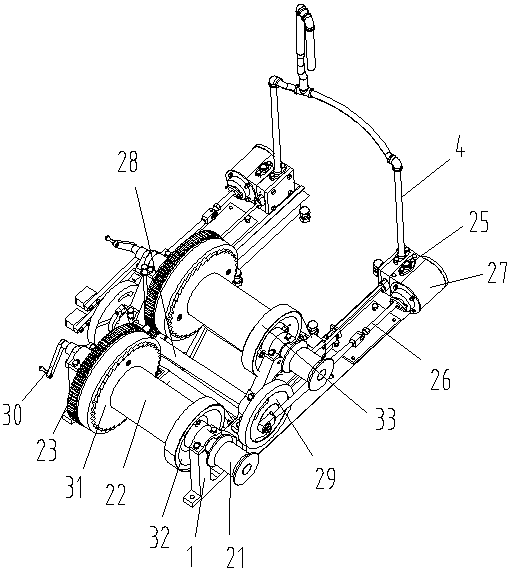

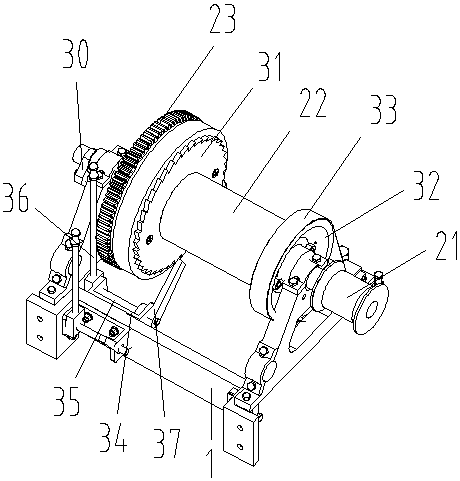

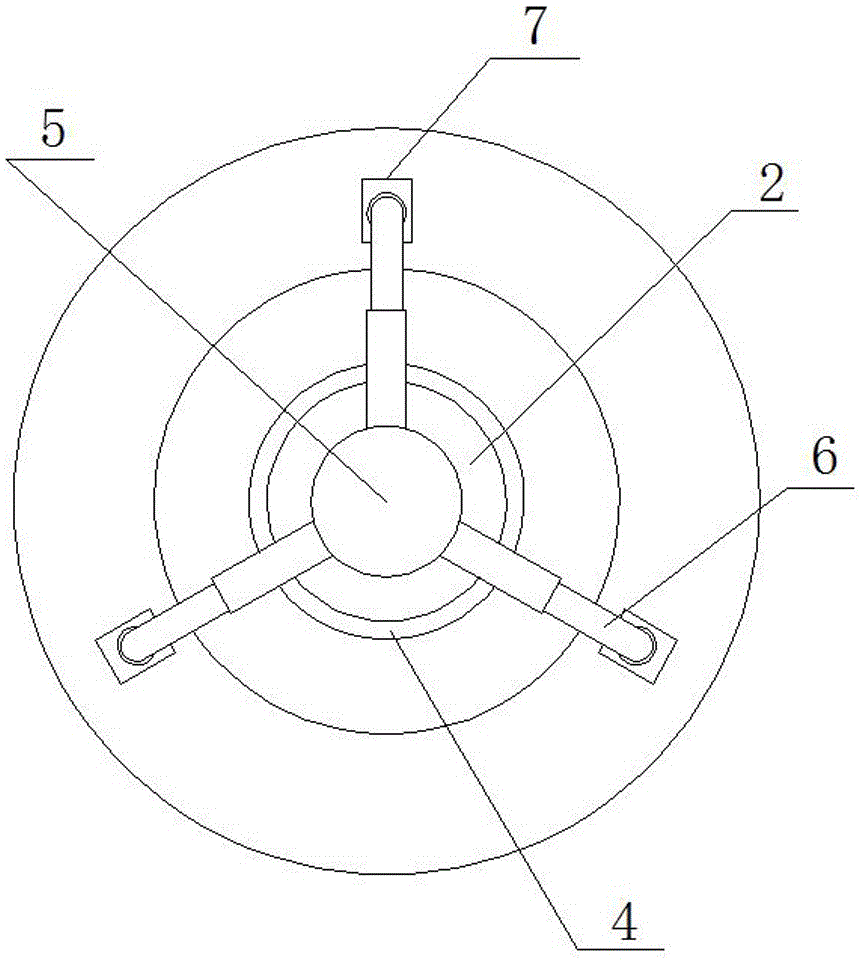

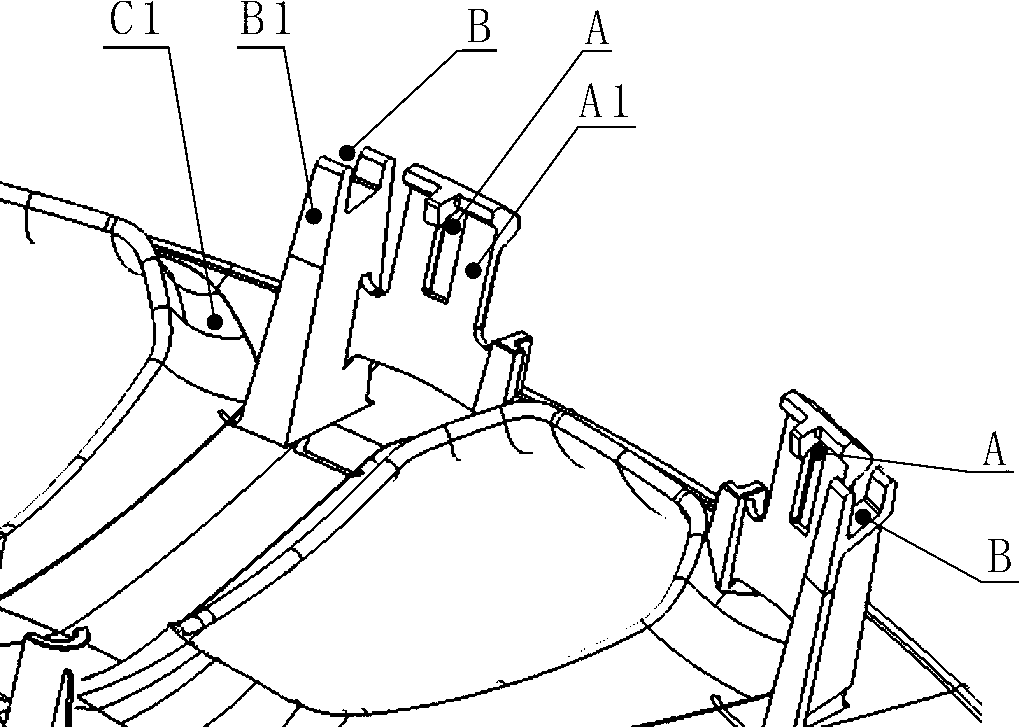

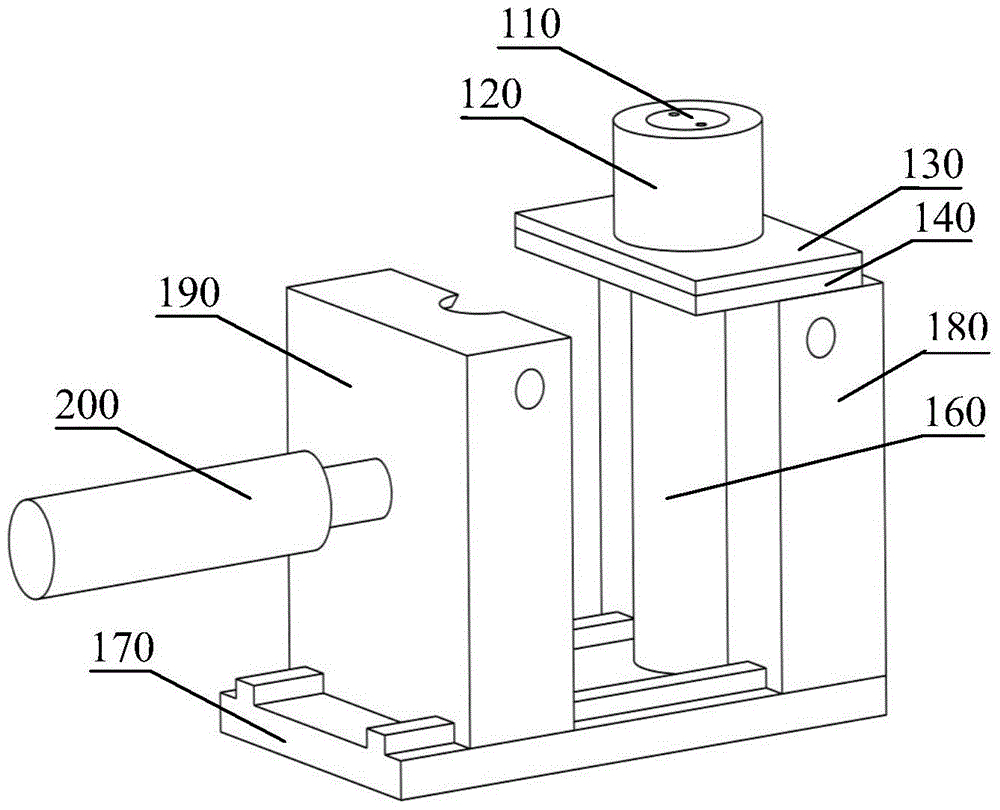

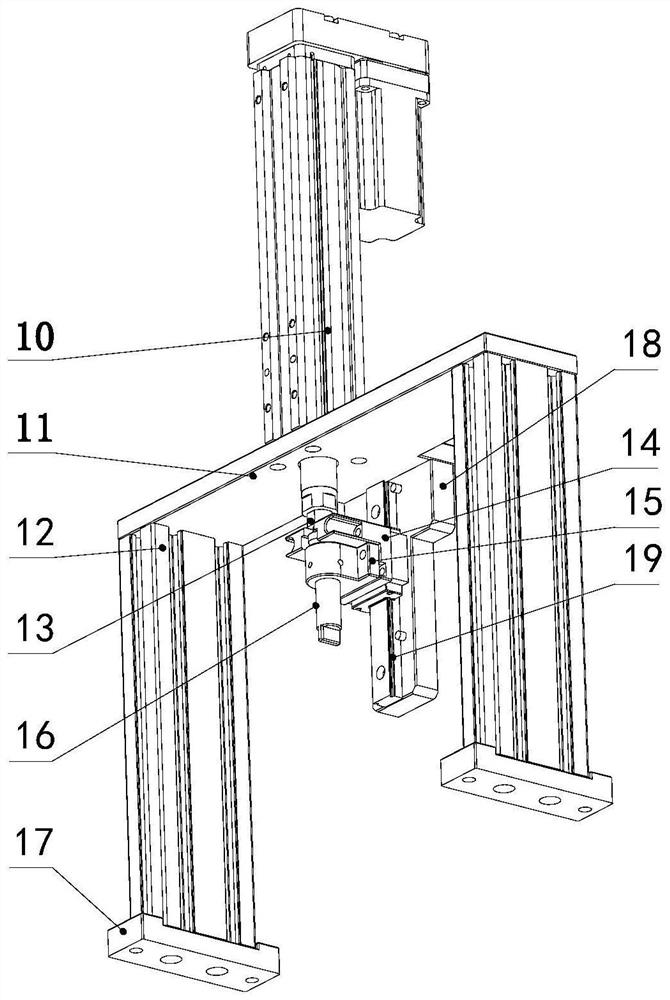

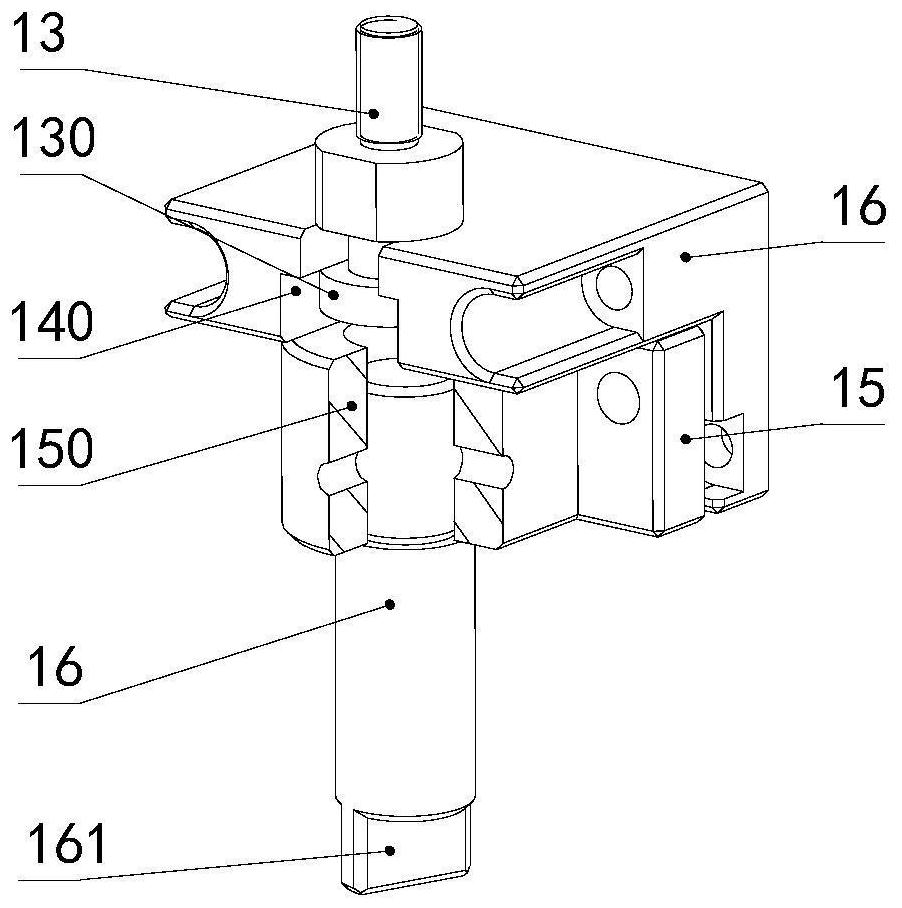

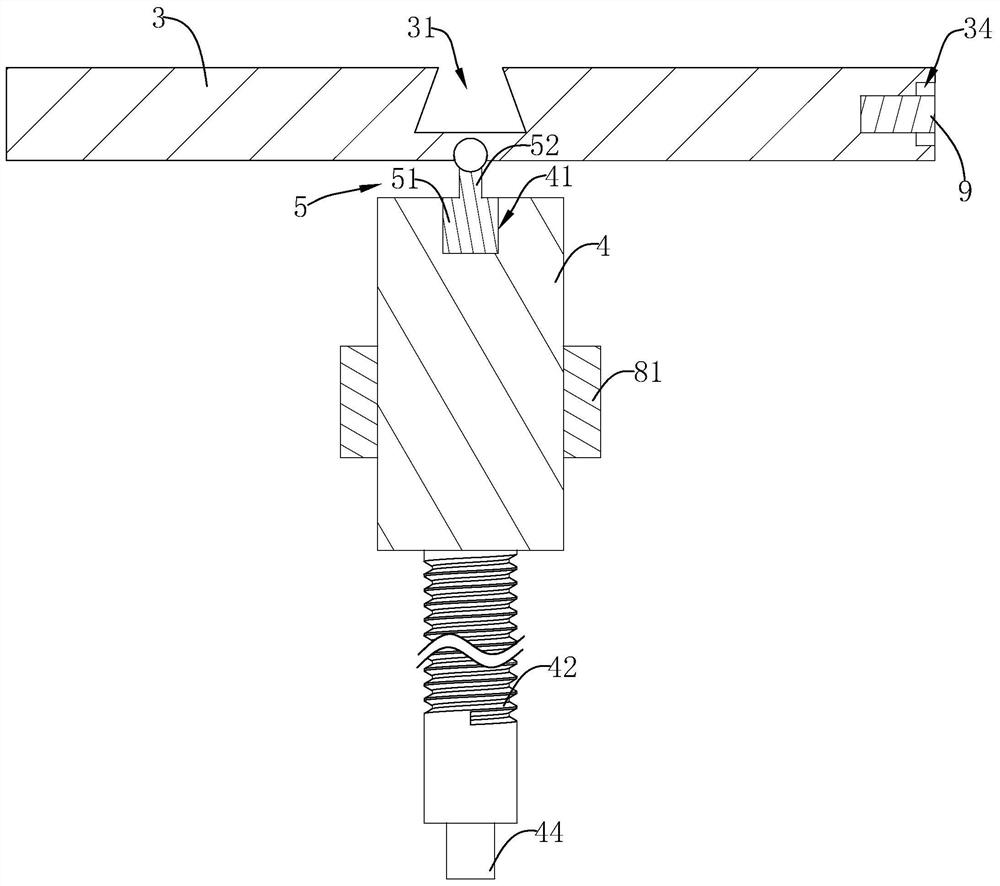

Corner pressing mechanism for corner connectors of aluminum profile frame

ActiveCN105583616ARealize automatic pressure angle functionSave human effortAssembly machinesEngineeringMechanical engineering

Owner:YINGKOU JINCHEN MACHINERY

Vacuum electronic multi-particle filling equipment

ActiveCN105730721AEnsure consistencyNo inversionsSolid materialPackaging automatic controlElectronDelivery system

The invention belongs to the technical field of medicine pill filling, and discloses vacuum electronic multi-particle filling equipment. The vacuum electronic multi-particle filling equipment comprises a conveying system, wherein the conveying system comprises a conveying belt; medicine bottle cups used for containing medicine bottles are arranged on the outer surface of the conveying belt at equal intervals; a medicine filling multi-particle system is arranged above the conveying belt; the medicine filling multi-particle system is provided with a turntable medicine supply system; the medicine filling multi-particle system comprises a medicine filling installing seat and a medicine filling head capable of vertically moving on the medicine filling installing seat; a medicine filling exhaust cap used for locating the medicine bottle is arranged on the medicine filling head; a vacuum generator casing is arranged on the medicine filling installing seat. The vacuum electronic multi-particle filling equipment has the advantages that medicine pills can be precisely sucked out and blown into the medicine bottles through a turntable medicine supply system and the medicine filling multi-particle system; the filling quantity of the medicine pills is controlled through the vacuum generator; the extrusion crushing of the medicine pills is avoided; the precise control on the medicine pill counting is improved; meanwhile, the equipment can be applicable to the filling of the medicine pills with different particle numbers and sizes.

Owner:CHENGDU HEDA AUTOMATION EQUIP

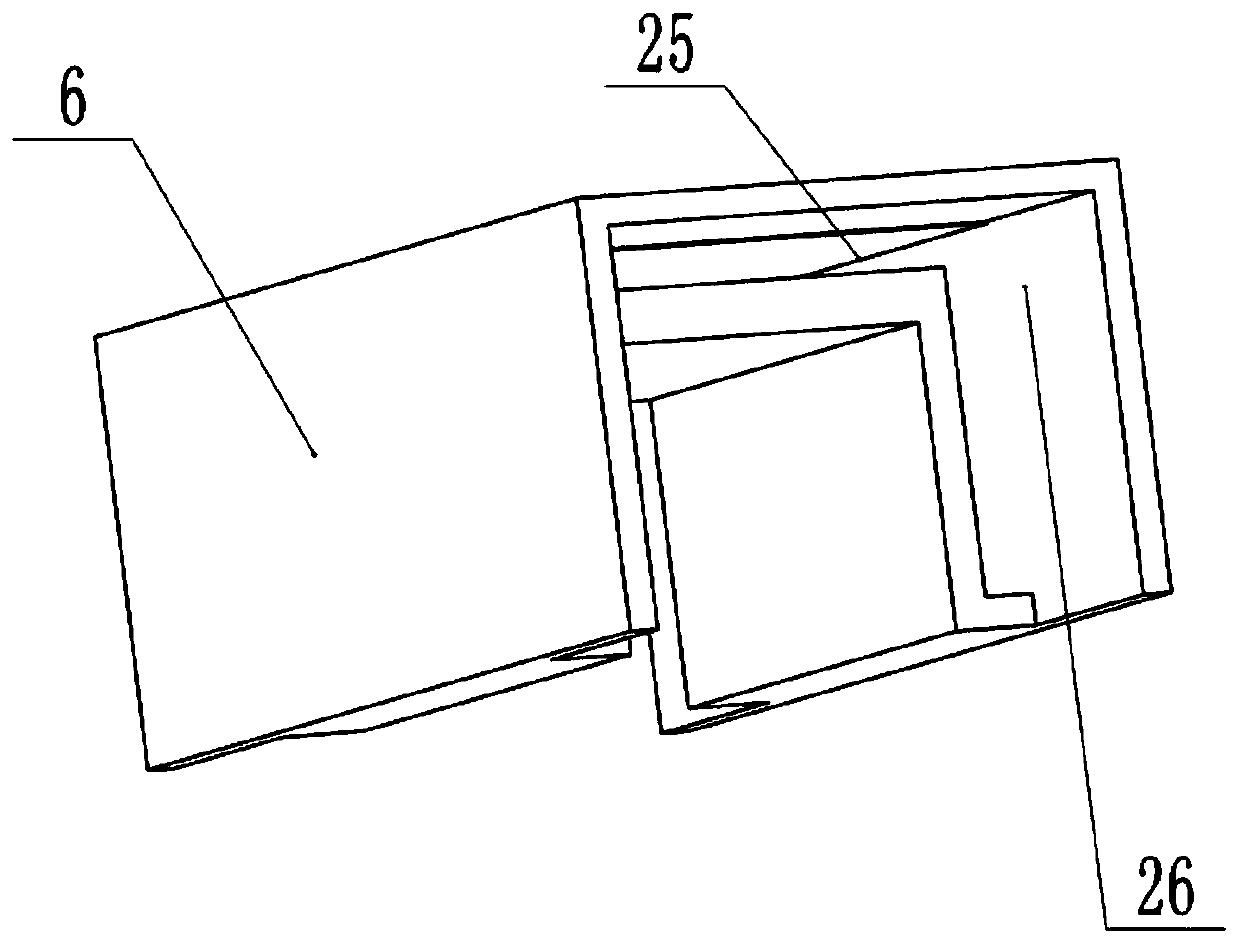

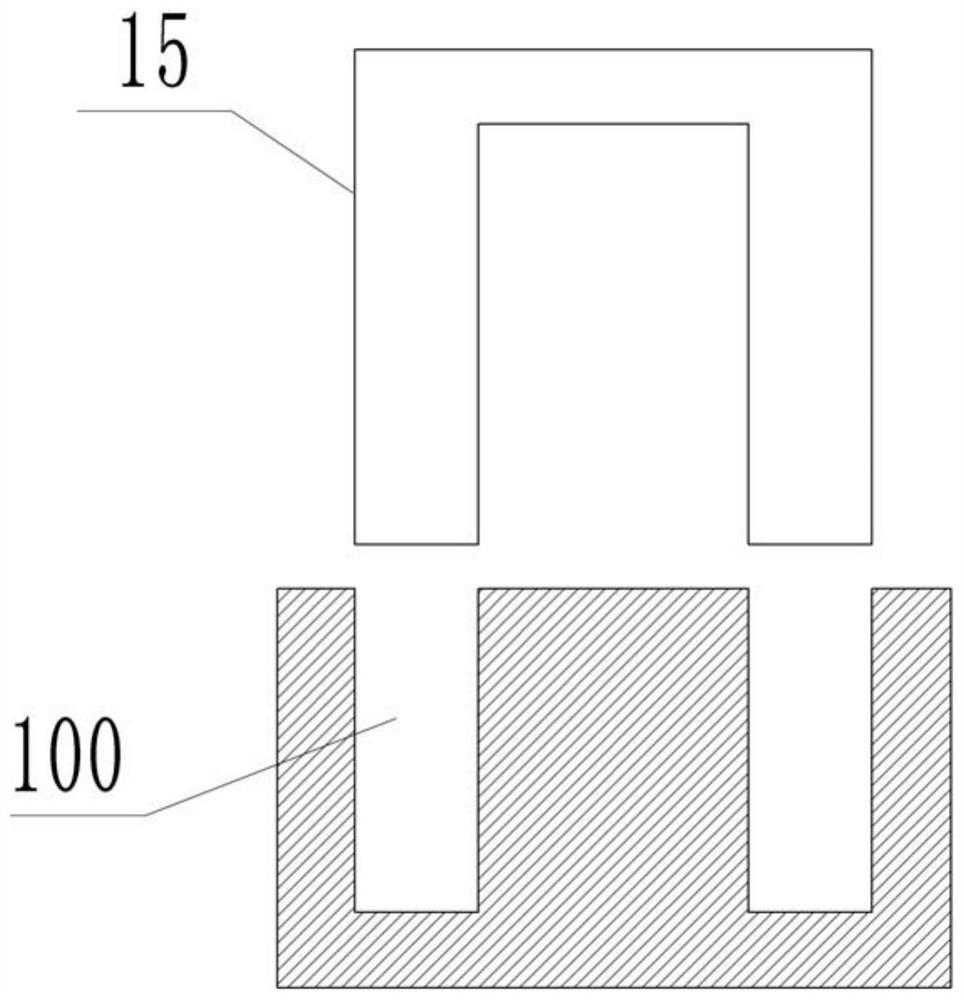

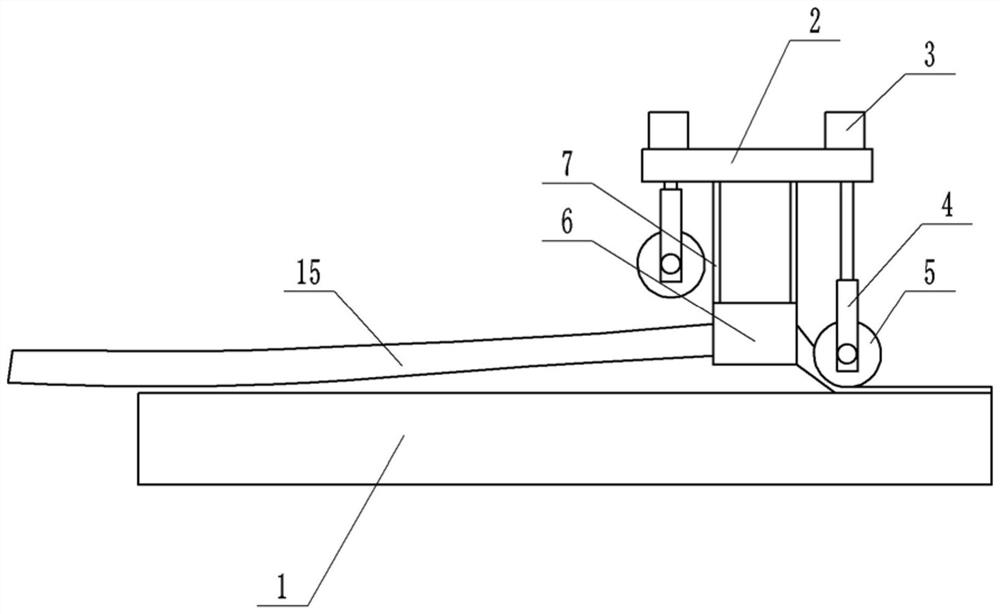

Aluminum alloy door and window sealing adhesive tape mounting device

ActiveCN110962070AAccurately press inEasy accessMetal-working hand toolsStructural engineeringMechanical engineering

The invention relates to the field of door and window machining, especially to an aluminum alloy door and window sealing adhesive tape mounting device. The aluminum alloy door and window sealing rubber strip mounting device comprises a placing table, a moving frame and a driving mechanism for driving the moving frame to transversely reciprocate are arranged above the placing table, the movable frame is provided with two pressing wheels and fixedly connected with a correcting block, the correcting block is provided with a through groove allowing an adhesive tape to penetrate through, the crosssection of the through groove is in a U shape, the two pressing wheels are located on the outer sides of the two ends of the through groove respectively, and the moving frame is provided with a firstair cylinder used for driving the pressing wheels to get close to or get away from the placing table. According to the scheme, the adhesive tape can be automatically mounted in slotted holes in the aluminum alloy door and window.

Owner:重庆市金久装饰工程有限责任公司

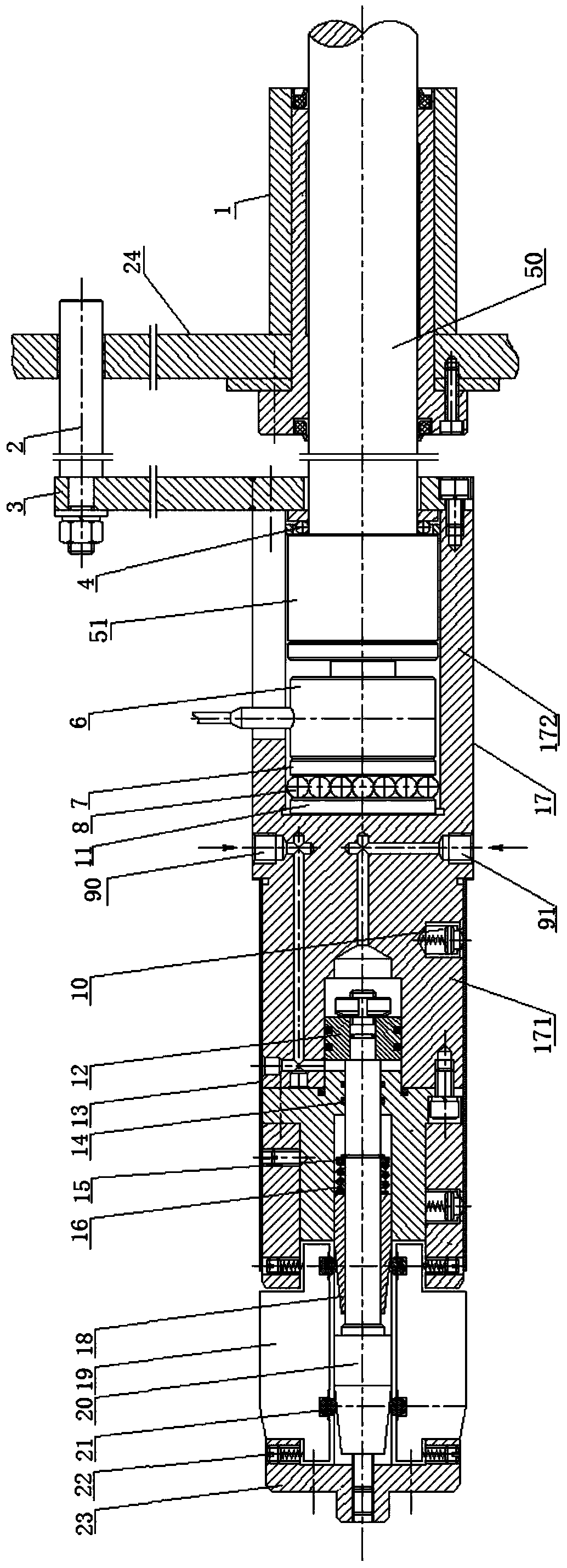

Cylinder sleeve pressing head device

ActiveCN103481052ARealize automatic reclaimingRealize the function of expansion and contractionMetal working apparatusEngineeringMechanical engineering

The invention discloses a cylinder sleeve pressing head device, and belongs to the field of cylinder sleeve press fitting tools. The cylinder sleeve pressing head device comprises a guiding block, a pressing head body, a guiding sleeve, an oil cylinder piston rod, an adjusting screw seat and a conical shaft, wherein the lower portion of the conical shaft is connected with the adjusting screw seat after penetrating in the guiding block; the lower portion of the guiding block is in the shape of an inverted cone; the lower portion of the pressing head body is connected with the guiding block through the upper portion of the conical shaft; the outer diameter of the lower portion of the pressing head body is the same with that of the guiding block when the pressing head body is in a contraction state; and the upper portion of the pressing head body is connected with the guiding sleeve through the oil cylinder piston rod. The cylinder sleeve pressing head device has the advantages that a cylinder sleeve cannot be out of round while the cylinder sleeve pressing head device takes materials automatically, a function of automatic centering can be realized, namely, the pressing head can be ensured to be pressed in the cylinder sleeve, and the cylinder sleeve can also be ensured to be accurately pressed in a cylinder body; and moreover, the pressure change condition can be timely and automatically fed back in a sleeve pressing process, can be monitored in real time, and then is controlled in real time.

Owner:金湖县综合检验检测中心

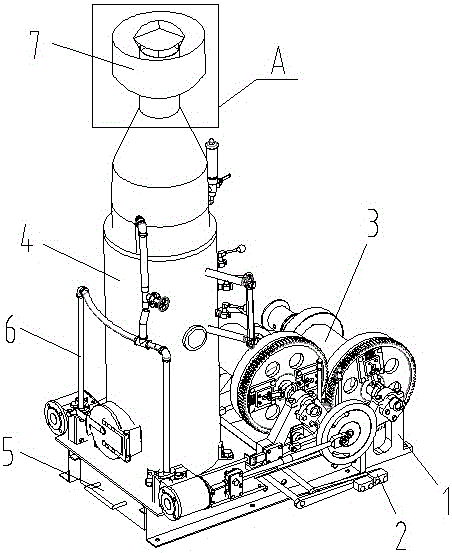

A Liquid Heating Device Preventing Smoke Pollution

ActiveCN106813258BAvoid pollutionSimple structureLighting and heating apparatusUsing liquid separation agentDust particlesPollution

Owner:安徽明亮面业股份有限公司

Assembling device of radiating piece

ActiveCN106736356AAccurately press inImprove assembly efficiencyMetal working apparatusDrive motorEngineering

The invention discloses an assembling device of a radiating piece, and belongs to the field of automatic assembly of the radiating piece. The assembling device consists of a radiating piece vibrating disk, insert needle vibrating disks, conveyor belt brackets, a telescopic device, a telescopic motor, telescopic cylinders, a main driving wheel, a driving motor, a synchronous belt, a secondary driving wheel, a camera and a conveying belt; there are two conveyor belt brackets; the assembling device is characterize by further comprising a radiating piece positioning block and an insert needle positioning block; the conveyor belt comprises a radiating piece positioning block and an insert needle positioning block; the conveyor belt comprises a conveyor belt body, a conveyor belt insert needle positioning block groove and a conveyor belt radiating piece positioning block groove structure; there are two insert needle vibrating disks, and two telescopic cylinders. The assembling device can realize the automatic assembly of the radiating piece, and the assembling efficiency is high.

Owner:安徽斯泰博电气有限公司

Dumbbell bearing automatic assembling device

PendingCN113275882AConsistent fill volumeAccurately press inLiquid surface applicatorsAssembly machinesDumbbellStructural engineering

The invention relates to a dumbbell bearing automatic assembling device. The device comprises an assembling frame, a transfer device parallel to the assembling frame and a feeding device located at one end of the transfer device; and the device further comprises a first weighing device, a first grease adding device, a second weighing device, a first sorting device, a first turnover device, a second grease adding device, a third weighing device, a first tabletting device, a first height detection device, a second turnover device, a second tabletting device, a third turnover device, a second height detection device and a second sorting device which are sequentially arranged along the assembling frame. According to the dumbbell bearing automatic assembling device, lubricating grease can be automatically and quantitatively added, the adding amount of the lubricating grease is consistent, the lubricating grease is evenly smeared, a dustproof cover can be automatically aligned to an outer ring, accurate pressing-in of the dustproof cover is achieved, the assembling efficiency is high, the percent of pass is high, and the assembling cost is effectively reduced.

Owner:无锡市亿涛自动化设备有限公司

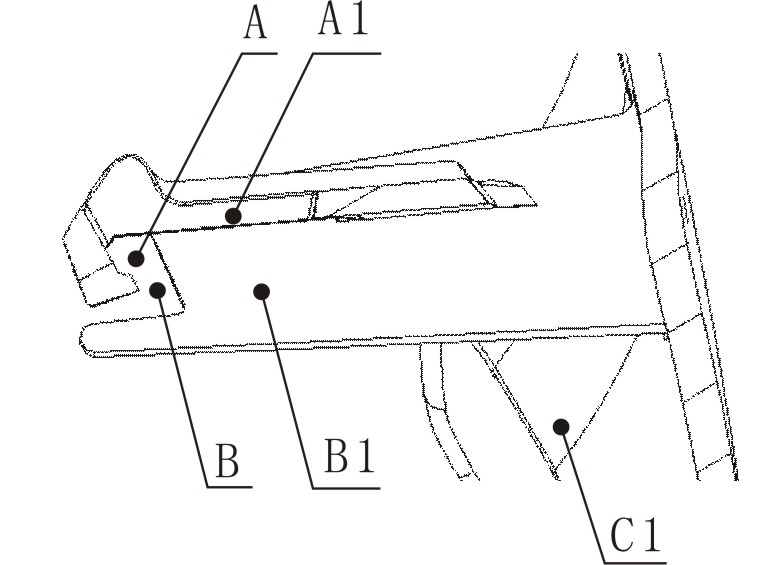

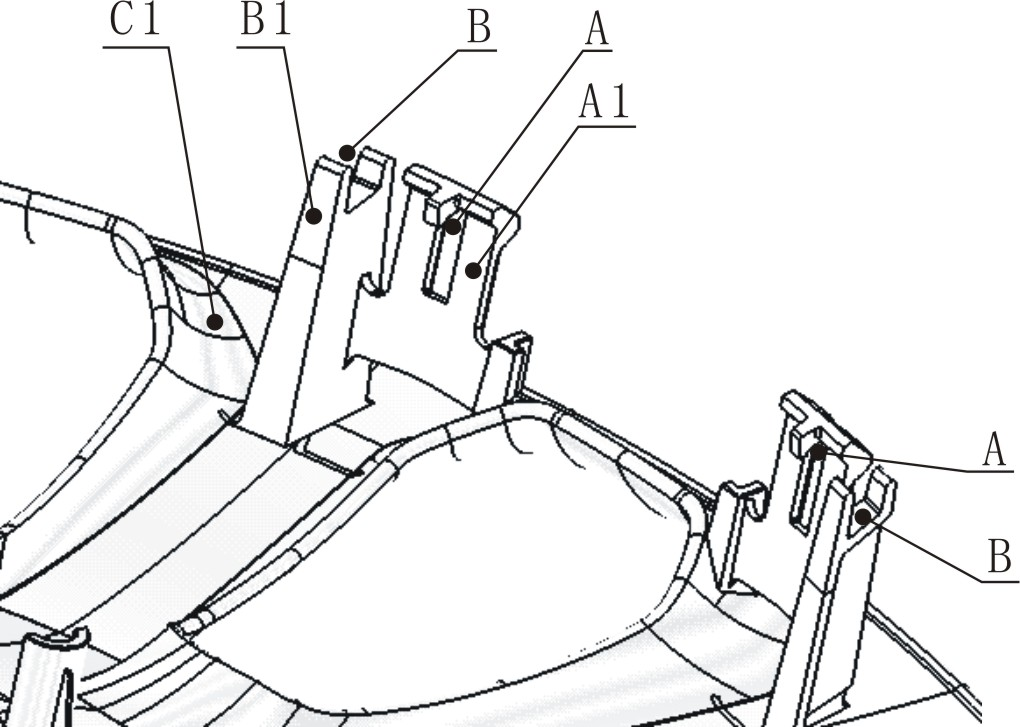

Special tool for assembling steel wire process of automobile wheel cover body

InactiveCN102490154ASimple structureLow costMetal-working hand toolsEngineeringUltimate tensile strength

The invention discloses a use method of a special tool for an assembling steel wire process of an automobile wheel cover body, including the following steps: 1, putting the wheel cover body on a moulding bed so that the wheel cover body and the moulding bed fully coinciding and not shaking; 2, after the wheel cover body is fixed, aligning a projection portion on the steel wire to a valve core groove portion of the wheel cover body, and manually pressing the steel wire in a clamping claw after manual position; 3, manually clamping welding points on the steel wire in a clamping claw verification position; 4, rotating the moulding bed to a proper position, pressing the steel wire to the clamping claw by using a rapid clamper, the loosening the clamper so as to make a pressure head to boost; 5, circulating the step 4 till the remained steel wire is fully pressed in the rest clamping claws; and 6, moving the wheel cover body. By adopting the method, the product has no pressed mark and scratch flaw, the steel wire can be rapidly and accurately pressed in an overhead hook, the steel wire can maintain good consistency when being placed in a clamping claw, and meanwhile the labor intensity can be greatly reduced and the production efficiency can be obviously improved. As the press-in direction and line are fixed, the used force can be basically consistent after skilled operation, and meanwhile the problems of frequently damaged clamping claw or supporting arm (caused by overlarge installation force and improper applied force direction) and occasional hand scratch of installers can be solved.

Owner:佛山航天华涛汽车塑料饰件有限公司

Automatic rocker arm assembling device for meter and assembling method

PendingCN111069884ARealize automatic feeding functionSave human effortMetal working apparatusControl theoryRocker arm

The invention discloses an automatic rocker arm assembling device for a meter. The automatic rocker arm assembling device comprises a rocker arm feeding mechanism, a rocker arm lifting mechanism, a rotary press-mounting mechanism and a movement assembly, the movement assembly comprises a vertical shaft, the rotary press-mounting mechanism comprises a rocker arm press-riveting mechanism and a rotary angle-finding mechanism, and the rocker arm lifting mechanism can drive the rotary press-mounting mechanism to move linearly in the vertical direction; and the rocker arm feeding mechanism moves a to-be-assembled rocker arm to a target position, the rocker arm press-riveting mechanism takes the rocker arm, the rocker arm lifting mechanism drives the rotary press-mounting mechanism to move linearly in the vertical direction till the rotary angle-finding mechanism is in butt joint with the vertical shaft, the rotary angle-finding mechanism drives the vertical shaft to rotate to the specified angle, and the rocker arm press-riveting mechanism fixes the rocker arm onto the vertical shaft in a press-riveting mode to complete assembling. The automatic rocker arm assembling device for the metercan accurately press the rocker arm into the movement assembly in the middle position of the rotating range of a membrane assembly, the adjustable margin of an error curve of the meter is increased,and thus the metering accuracy of the meter is improved.

Owner:CSIC PRIDENANJINGINTELLIGENT EQUIP SYST CO LTD

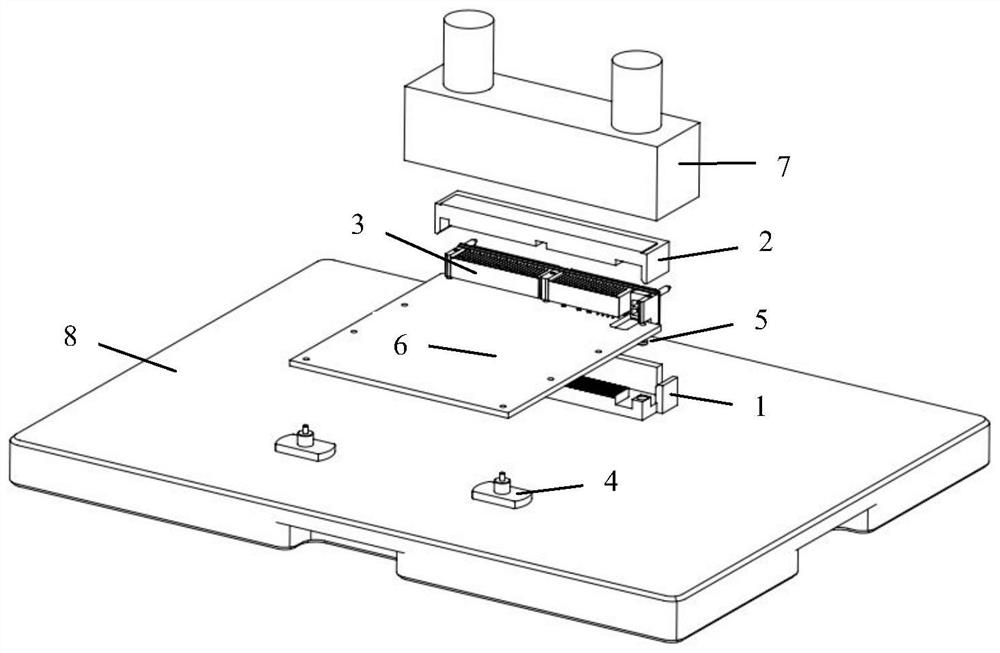

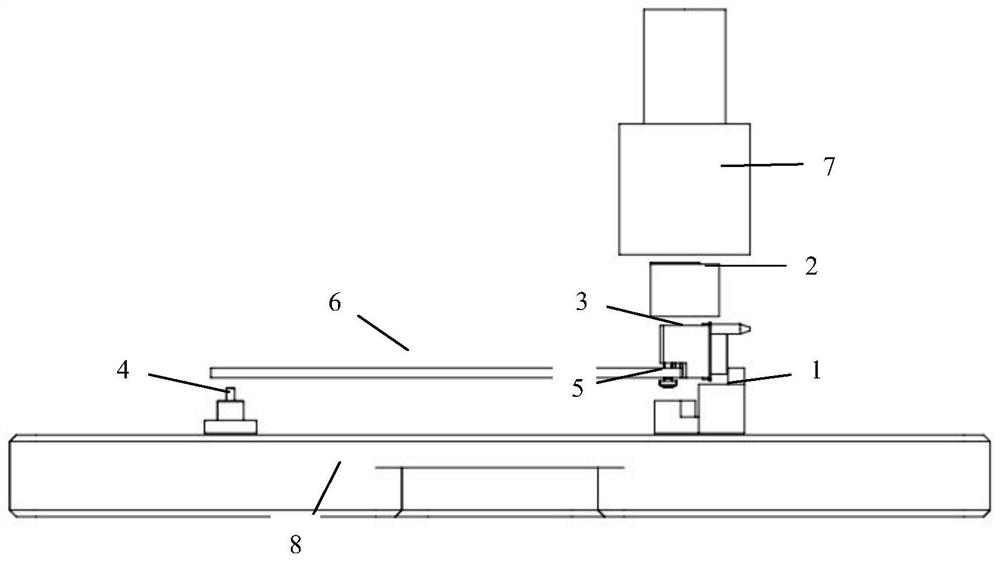

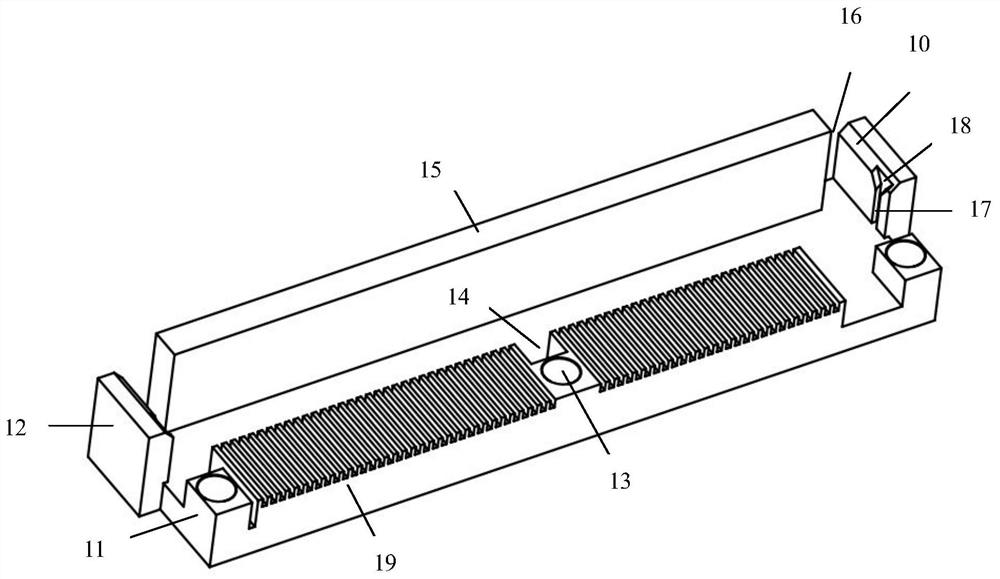

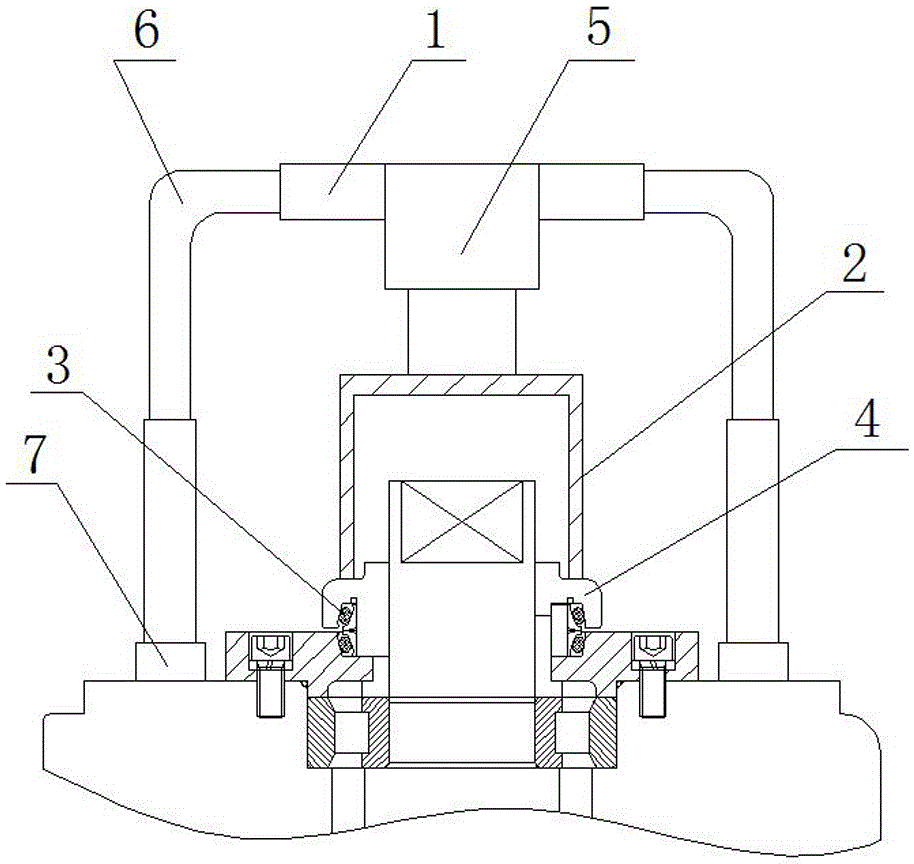

Welding-free crimping tool for inserting high-speed signal connector into high-density PCB

PendingCN112993720ACrimping efficiencyQuick pressPrinted circuit assemblingCoupling device engaging/disengagingHigh densityEngineering

The invention provides a welding-free crimping tool for inserting a high-speed signal connector into a high-density PCB. The crimping tool is quick and reliable in positioning and can be flexibly connected with different plugs and printed circuit boards. According to the technical scheme, one end of the PCB is in threaded connection with plug front side plug lugs to connect the PCB and a connector together, protruding rail sliding strips on the two sides of the connector plug are clamped into lower die limiting sliding grooves in a sliding mode from top to bottom, and the other end of the connector plug fixes the PCB to a bottom plate in a suspended mode through two movable positioning columns on the bottom plate; an upper pressing die is clamped into the connector plug from top to bottom along the protruding rail sliding strips on the two sides of the connector plug to quickly position a connector plug module, and through two crimping convex dies arranged in parallel in side plates at the two ends of the upper pressing die, the upper pressing die presses the PCB to the rectangular stand column and the crimping platform of a lower pressing die by avoiding three parallel and spaced plug front side plug lugs and an optical fiber plug module on the connector plug, so that the welding-free crimping of the high-density PCB inserted into the high-speed signal connector is completed.

Owner:10TH RES INST OF CETC

Device for eliminating mounting error of floating sealing ring

Owner:长治市永华机械有限公司

Aluminum profile frame corner code pressure angle mechanism

ActiveCN105583616BRealize automatic pressure angle functionSave human effortAssembly machinesMechanical engineeringEngineering

Owner:YINGKOU JINCHEN MACHINERY

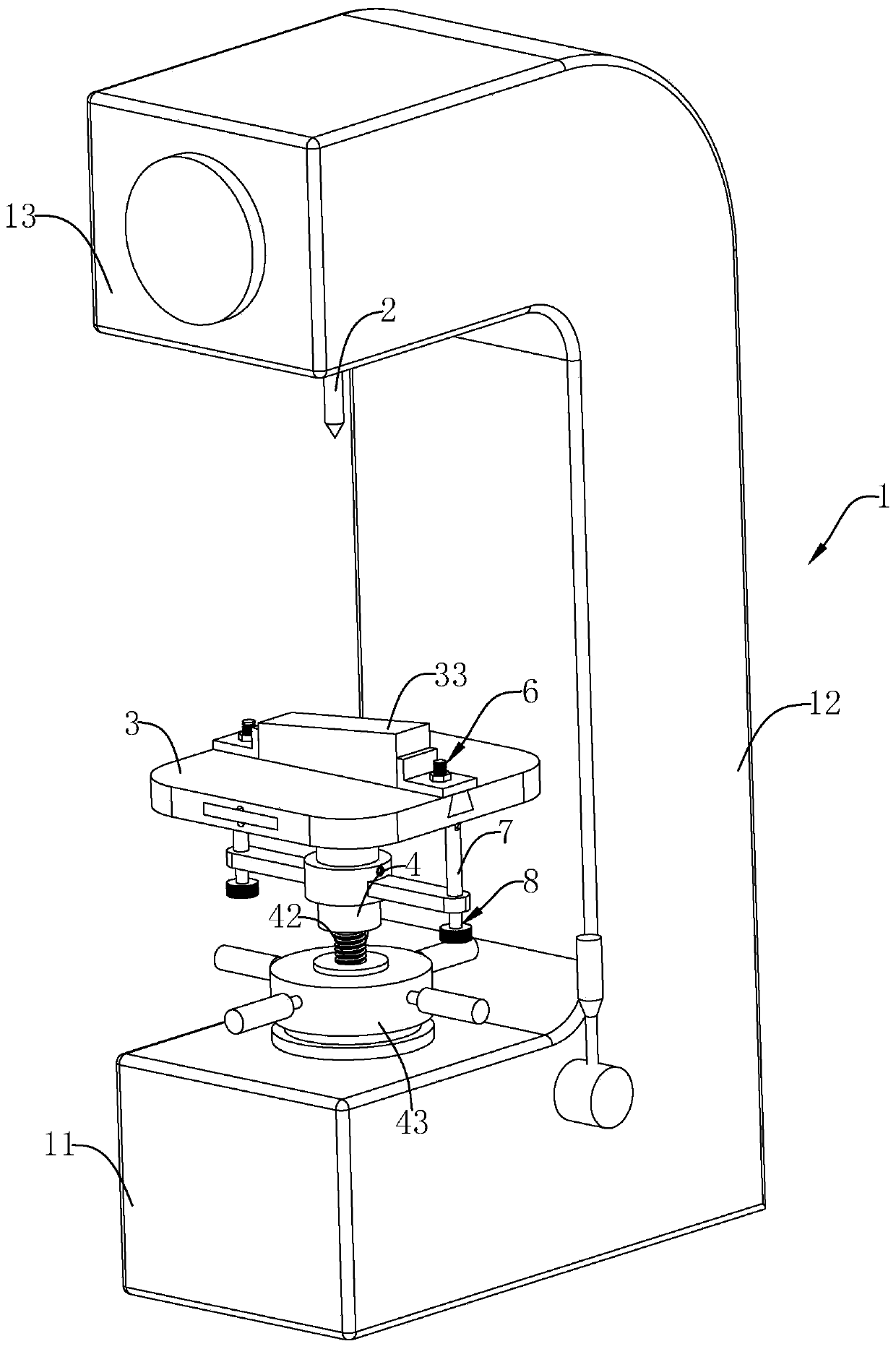

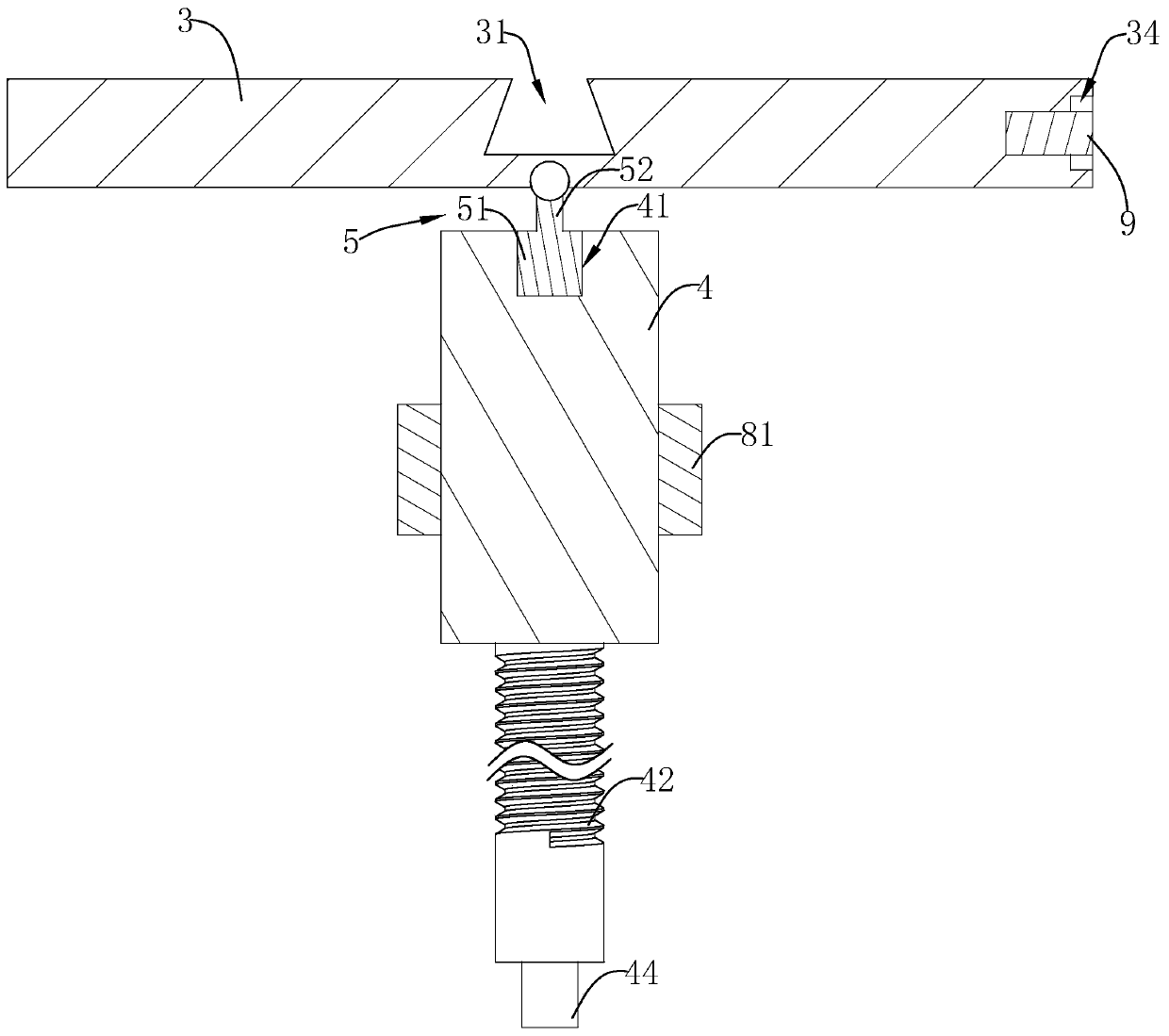

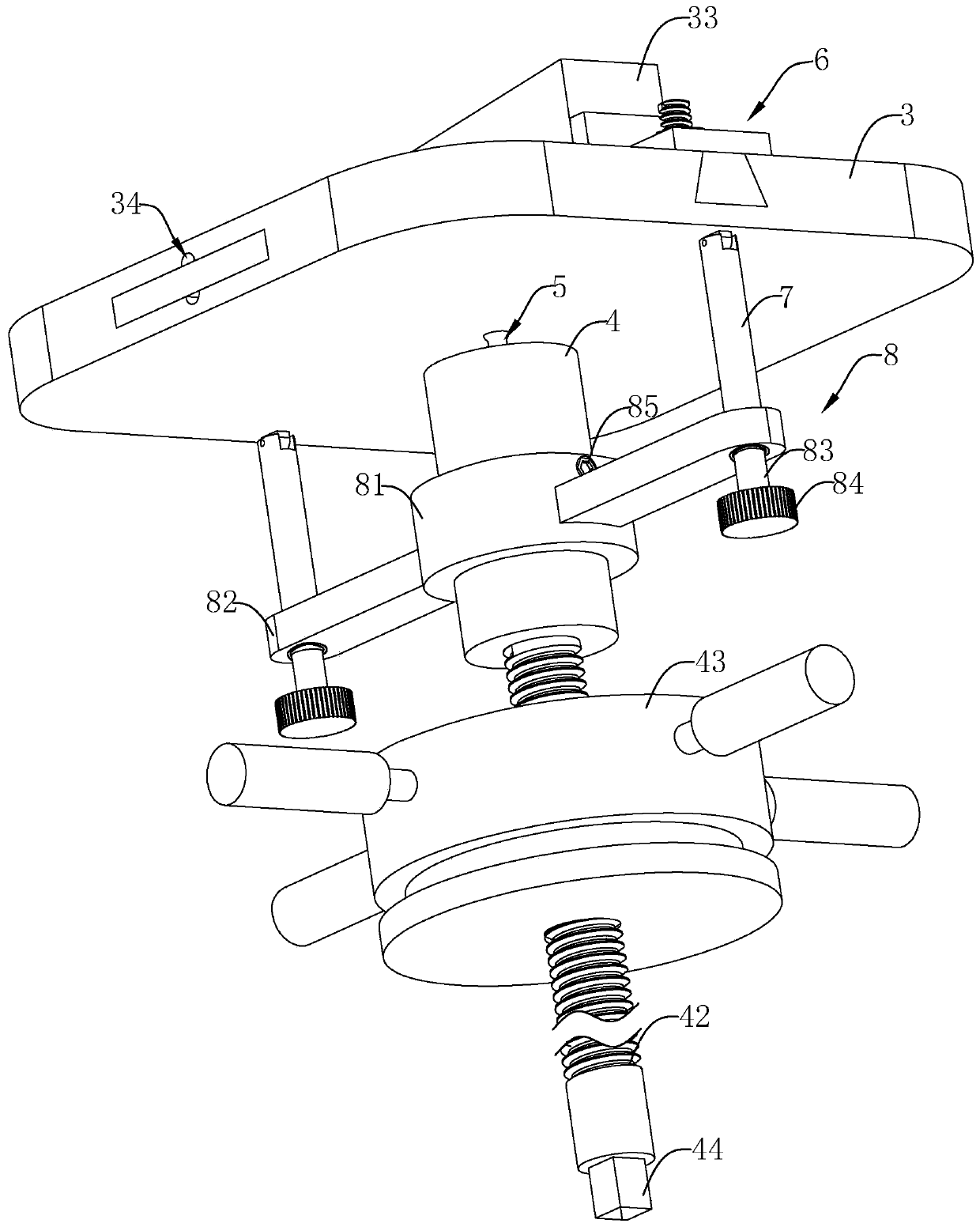

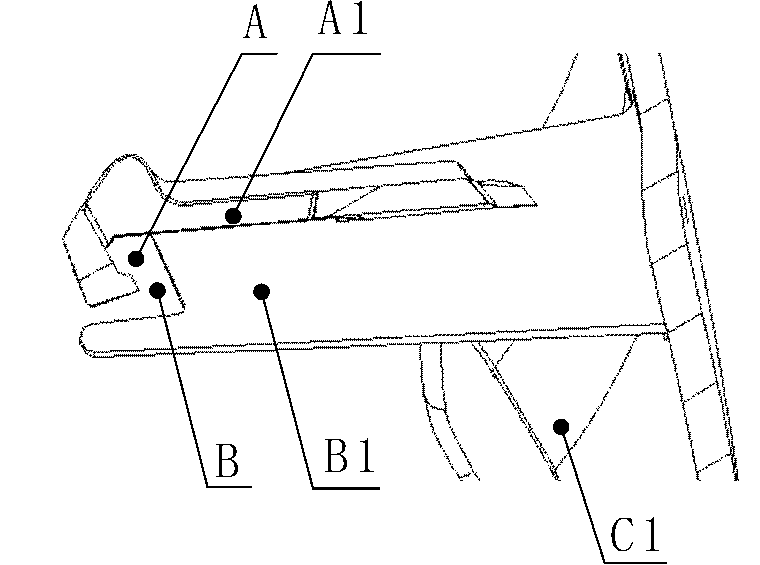

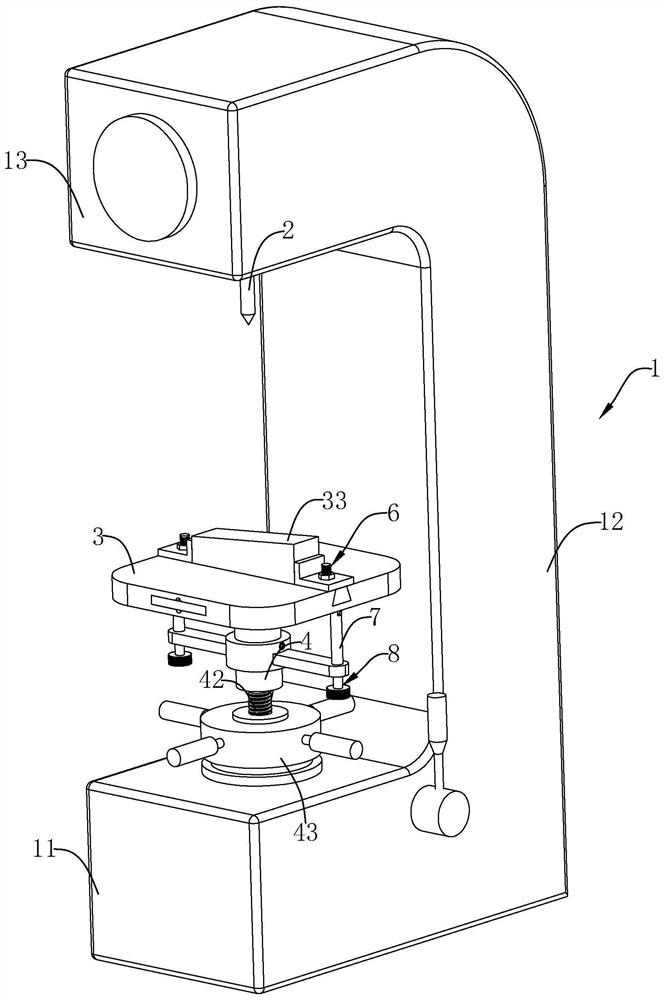

Rockwell hardness tester with function of adjusting angle of measuring platform

ActiveCN110411877AGuaranteed measurement accuracyHigh measurement accuracyInvestigating material hardnessEngineeringHardness

The invention relates to a Rockwell hardness tester with the function of adjusting the angle of a measuring platform. The Rockwell hardness tester comprises a tester body, a pressing head installed onthe tester body, a lifting column vertically arranged on the tester body and located under the pressing head and the measuring platform arranged on the lifting column for placing a to-be-tested block; a connecting piece hinged to the lifting column is arranged in the middle of the lower surface of the measuring platform, and an adjusting gap exists between the measuring platform and the lifting column; the upper surface of the measuring platform is provided with a clamping device for fixing the to-be-tested block; vertical sleeves are hinged to the portions, located at the two sides of the connecting piece, of the lower surface of the measuring platform, and the lifting column is provided with a driving assembly capable of driving the sleeves to move up and down to adjust the angle of themeasuring platform. The Rockwell hardness tester has the advantages that the angle of the measuring platform can be adjusted according to measuring demands to adapt to different types of to-be-testedblocks.

Owner:北京精诚恒通工程技术检测有限公司

Usage method of special tool for assembling steel wire process of automobile wheel cover body

InactiveCN102490154BSimple structureLow costMetal-working hand toolsUltimate tensile strengthForce direction

Owner:佛山航天华涛汽车塑料饰件有限公司

A positionable pre-punching rivetless constant temperature stamping die and its control method

InactiveCN105328045BAchieve connectionAccurately press inShaping toolsMetal working apparatusHydraulic cylinderEngineering

The invention discloses a pre-hole-punching rivet-free constant-temperature stamping die capable of performing positioning. The stamping die comprises a punch, a lower die holder and a hydraulic cylinder. The punch is of a circular truncated cone structure. The radius of the upper surface of the punch is larger than that of the lower surface of the punch. The center of the lower die holder is a containing cavity. The upper portion of the containing cavity is a regular circular truncated cone cavity, and the lower portion of the containing cavity is provided with a through hole. An upper end opening of the regular circular truncated cone cavity is formed in the upper plane of the lower die holder, and the lower end of the regular circular truncated cone cavity is communicated with the through hole. The hydraulic cylinder is located in the through hole. A piston of the hydraulic cylinder stretches out of the upper end opening of the regular circular truncated cone cavity in the non-stamping process. The punch and the lower die holder are both provided with a cooling channel and are provided with a temperature sensor and a controller. The invention further discloses a control method of the pre-hole-punching rivet-free constant-temperature stamping die capable of performing positioning. The pre-hole-punching rivet-free constant-temperature stamping die capable of performing positioning achieves connection between high-strength steel and aluminum alloy without rivets and has the advantages that accurate positioning can be achieved, and meanwhile riveting accuracy is not affected due to the cooling punch and the die.

Owner:JILIN UNIV

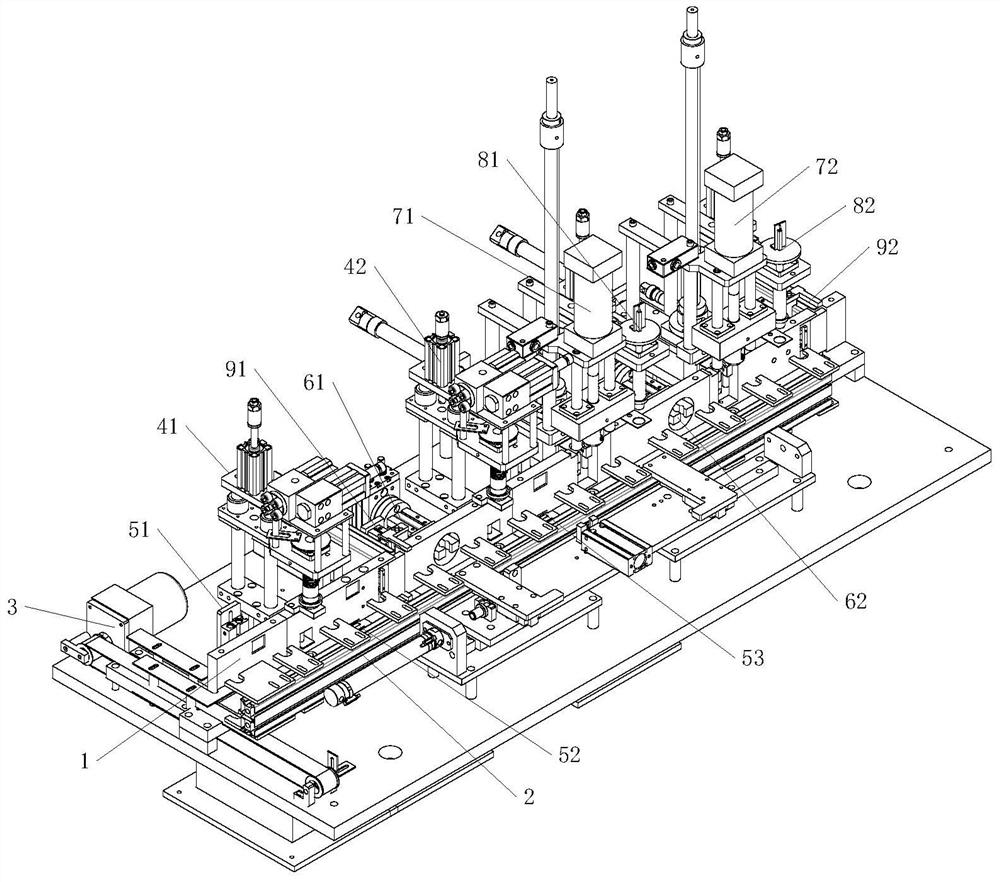

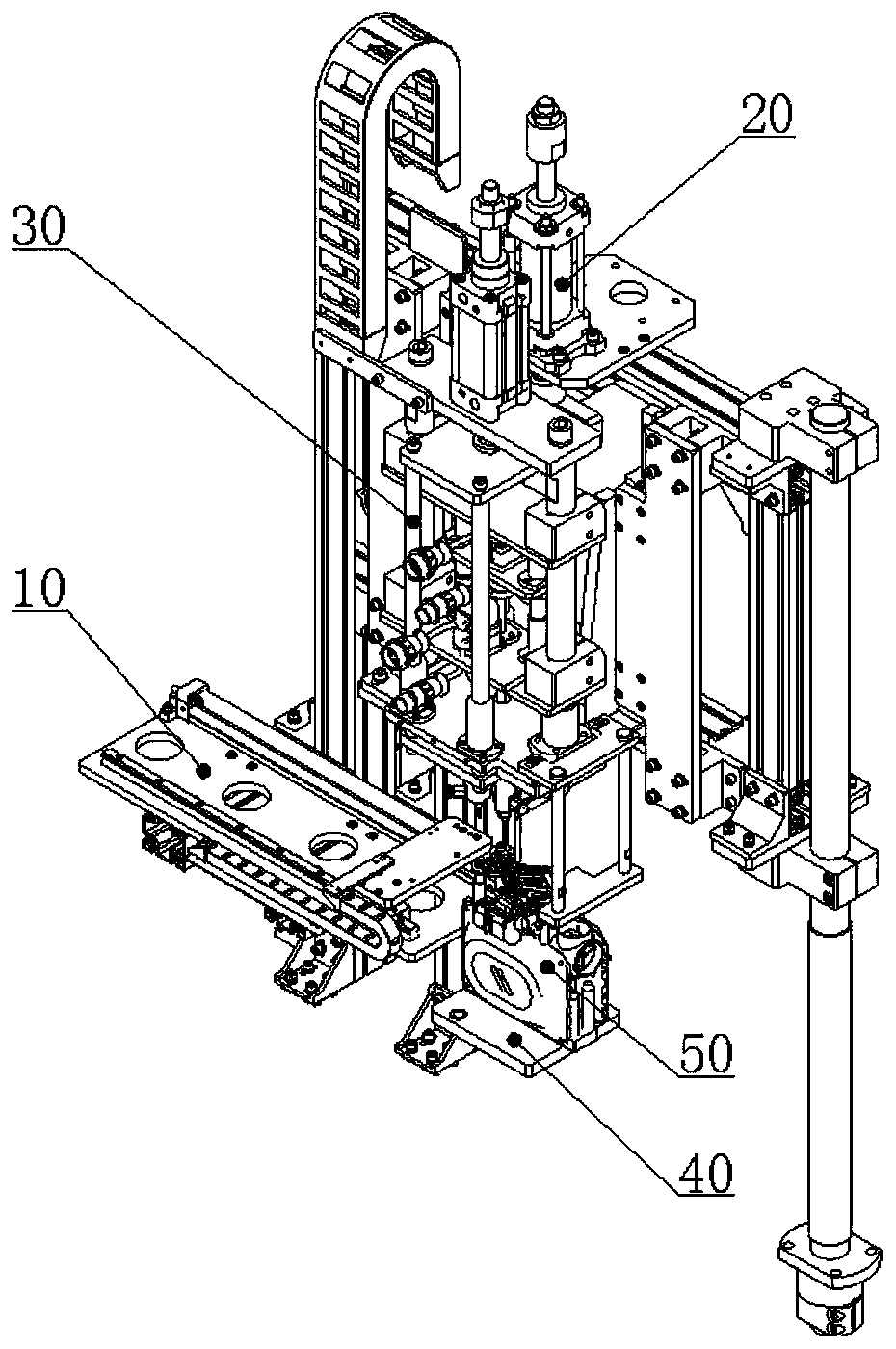

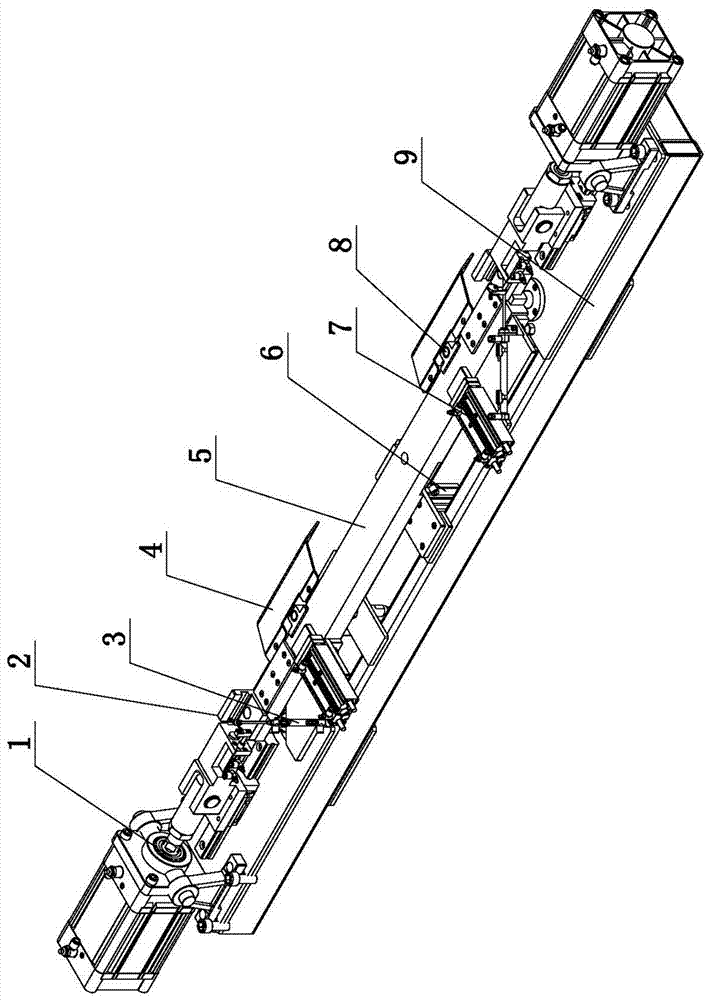

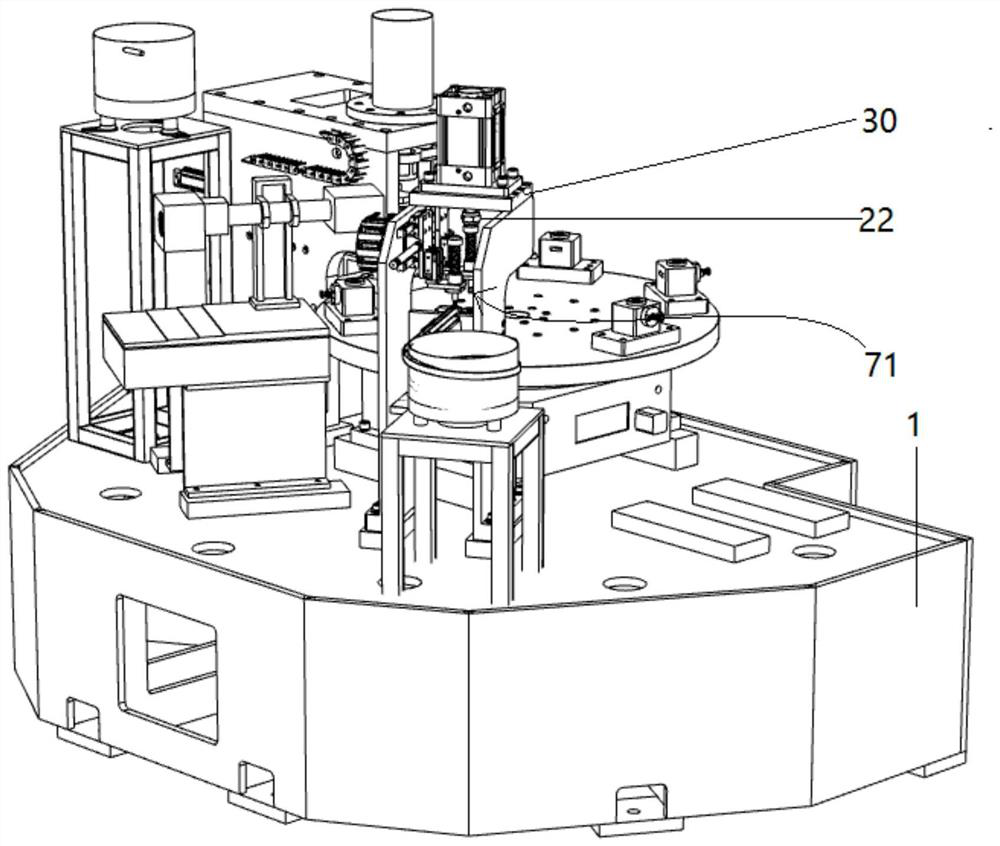

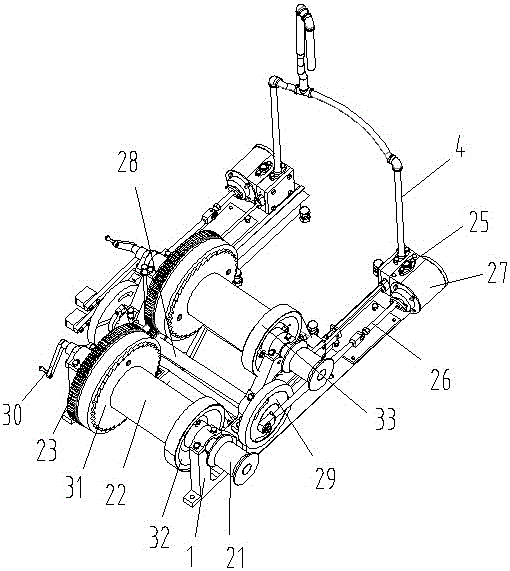

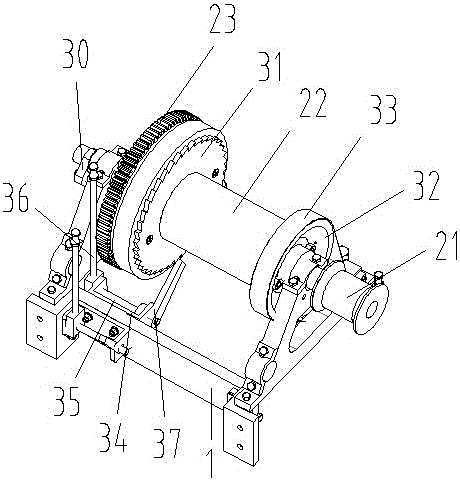

A starter planetary shaft automatic press-fitting device

ActiveCN109175955BMeet the requirements of automatic press-fitting production lineIncrease the level of automationMetal working apparatusHydraulic cylinderEngineering

The invention discloses an automatic press-fitting device of starter planetary shafts and belongs to the field of press-fitting devices. The automatic press-fitting device of the starter planetary shafts comprises a rack, a hydraulic rotary platform, a pin pressing component, a laser printing component and a bearing pressing component. Each station of the hydraulic rotary platform is provided witha planetary shaft clamping tool used for clamping the planetary shafts. The pin pressing component, the laser printing component and the bearing pressing component are installed at the correspondingstations of the hydraulic rotary platform. The pin pressing component comprises a hydraulic cylinder, a pin feeding mechanism, a pin positioning mechanism and a pin stabilizing mechanism and can complete the actions of pin taking, pin feeding, pin positioning, pin stabilizing and the like at the same time. The laser printing component is used for carrying out laser printing on the planetary shaftswhich are subjected to pin pressing. The bearing pressing component is used for pressing bearings for the planetary shafts. The automatic press-fitting device is mainly used for completing pin pressing, laser printing, bearing pressing and other working procedures on the planetary shafts at a time, the automation degree is high, the press-fitting speed and the precision are high, safe operation is easy, running is stable, and the reliability is high.

Owner:CHANGZHOU INST OF TECH

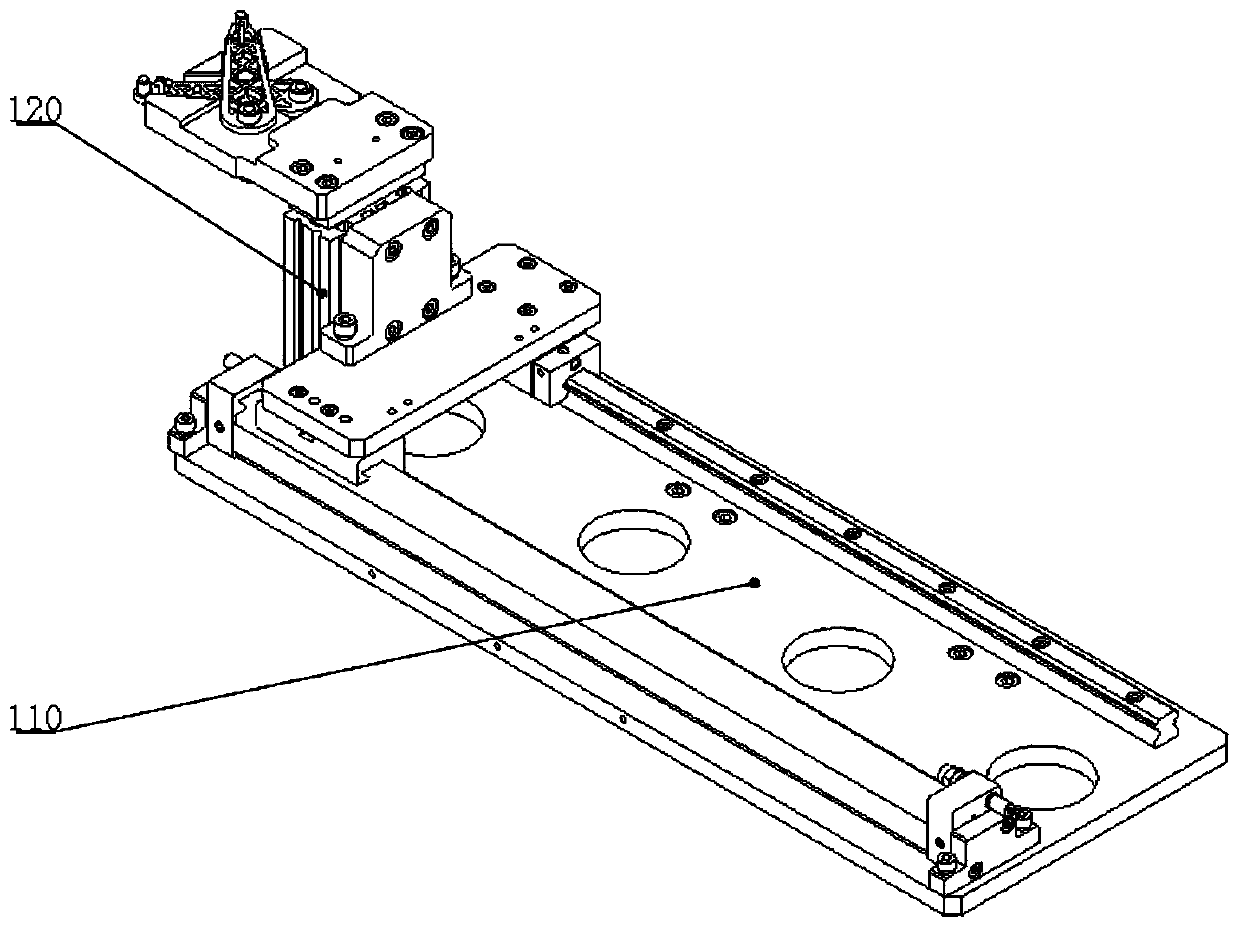

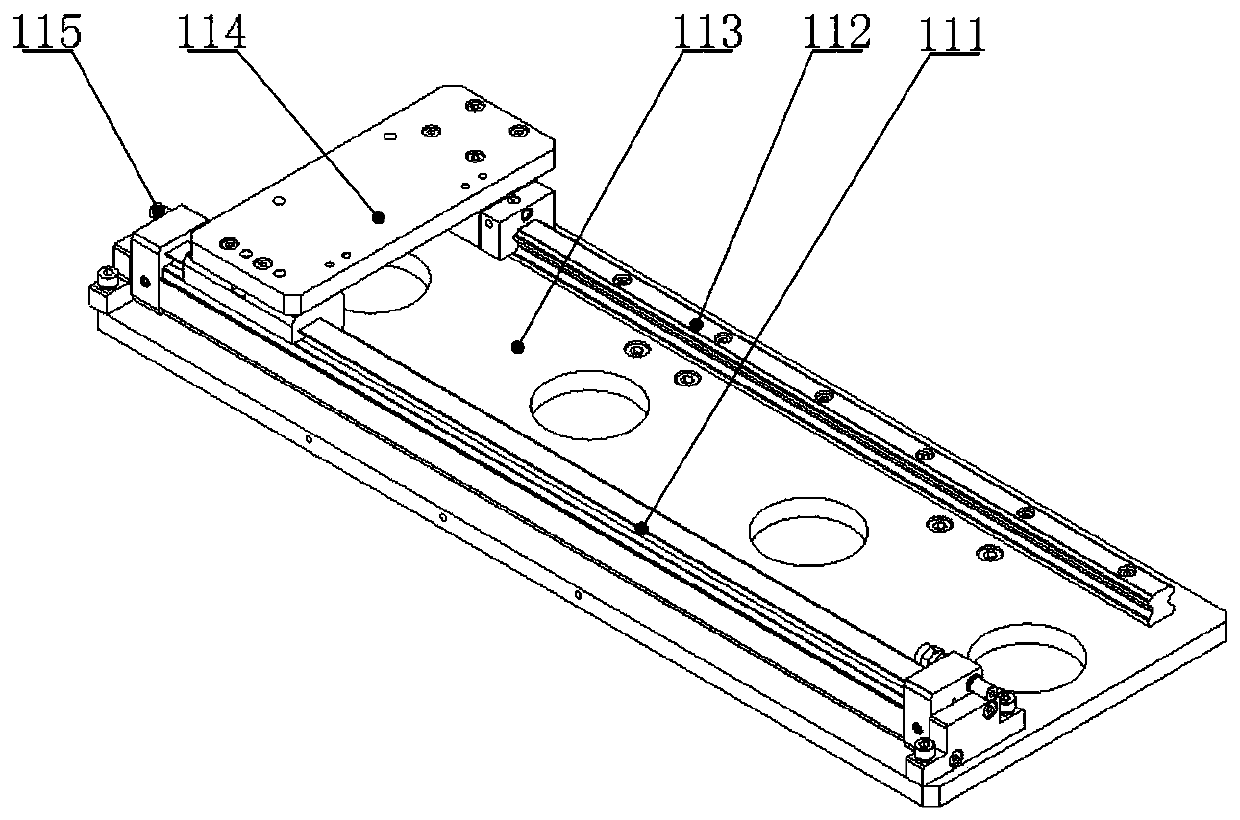

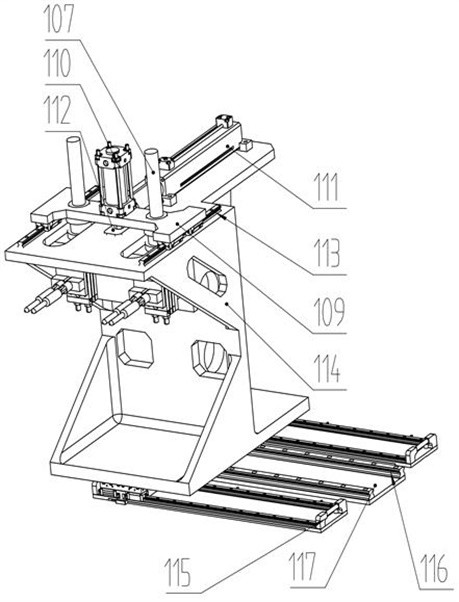

Suspension type accelerator pedal sensor shaft mounting device and method

PendingCN114669999ASave human effortImprove pressing efficiencyMetal working apparatusElectronic throttleEngineering

The invention discloses a suspension type accelerator pedal sensor shaft mounting device and method. The suspension type accelerator pedal sensor shaft mounting device comprises a base plate, a press fitting mechanism, a placing mechanism and a side pushing mechanism. The press-fitting mechanism is arranged right above the base plate, is in a portal frame form and is used for press-fitting the sensor shaft; the placing mechanism is arranged above the base plate and in the middle of the press-fitting mechanism and is used for fixing the electronic throttle bulk parts; the side pushing mechanism is arranged on the front portion of the upper portion of the placing plate and used for pushing a pedal below the electronic accelerator spare parts. The accelerator sensor shaft can be conveniently, efficiently, stably and safely mounted, the product quality is effectively improved, the workload of workers is reduced, and the working efficiency is improved.

Owner:NANJING AOLIAN AE&EA

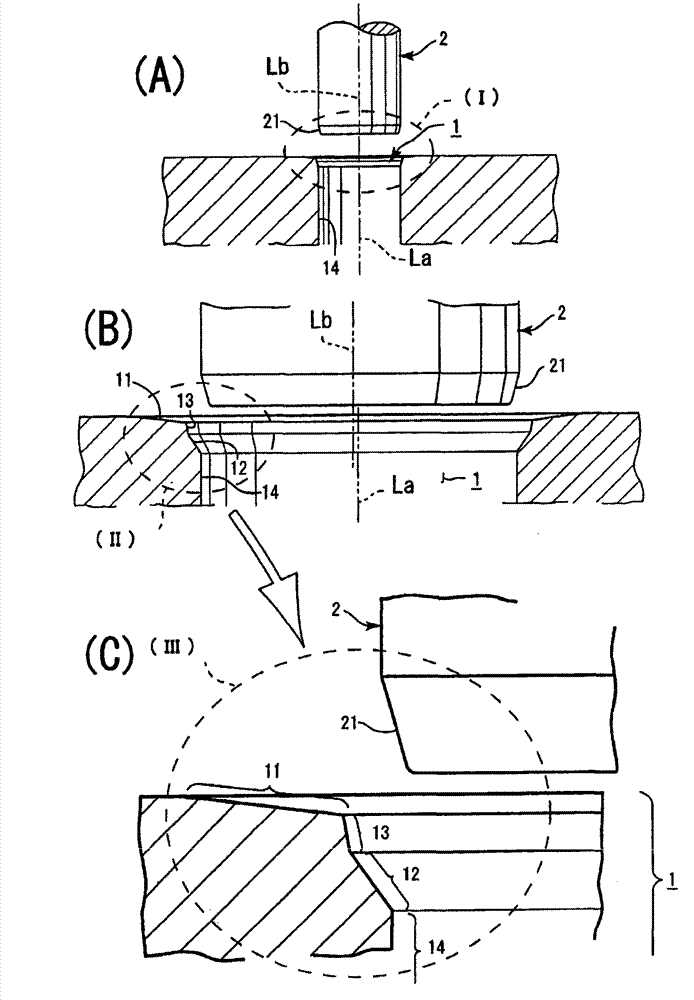

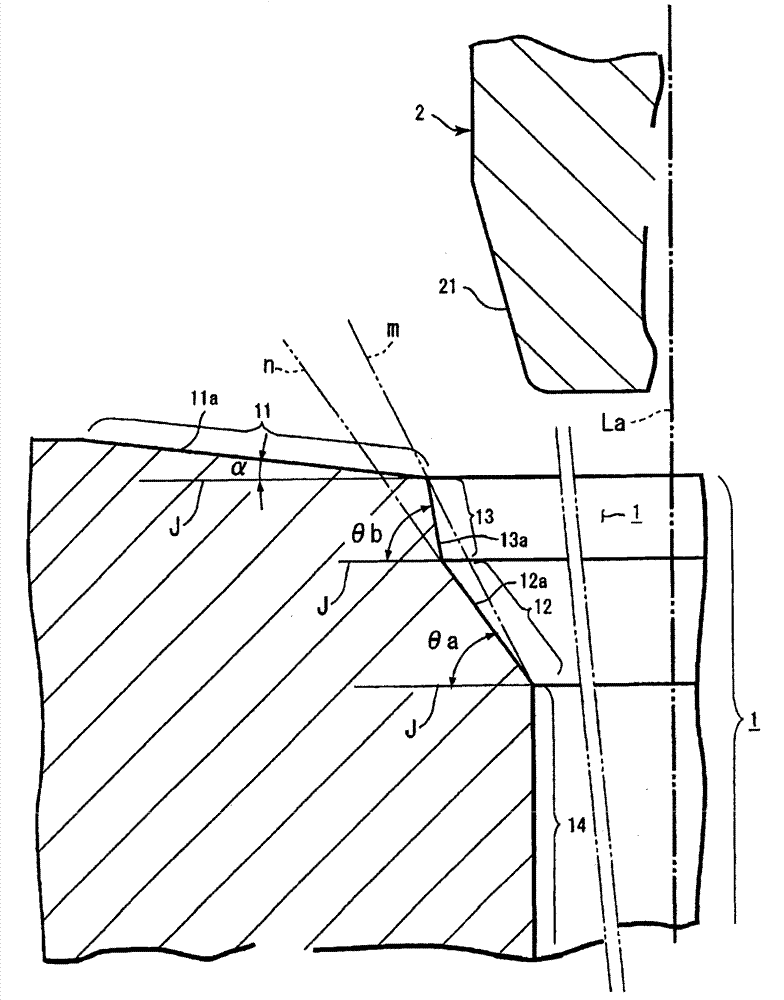

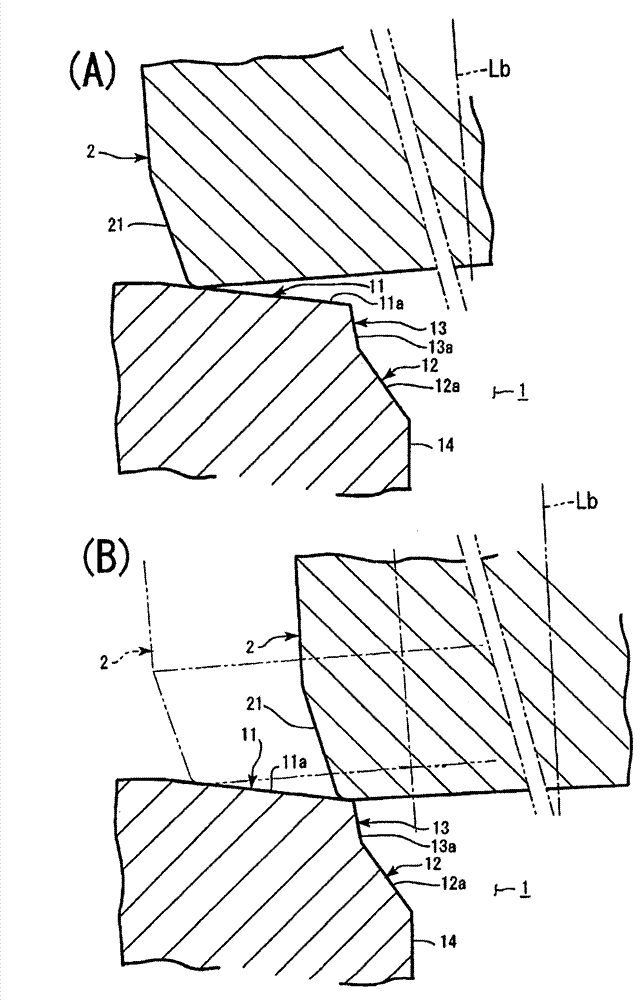

Pressing structure of shaft and shaft hole

ActiveCN101737410BReduce press-fit skewPress in accuratelyShaftsShrinkage connectionsEngineeringMechanical engineering

Owner:YAMADA SEISAKUSHO KK

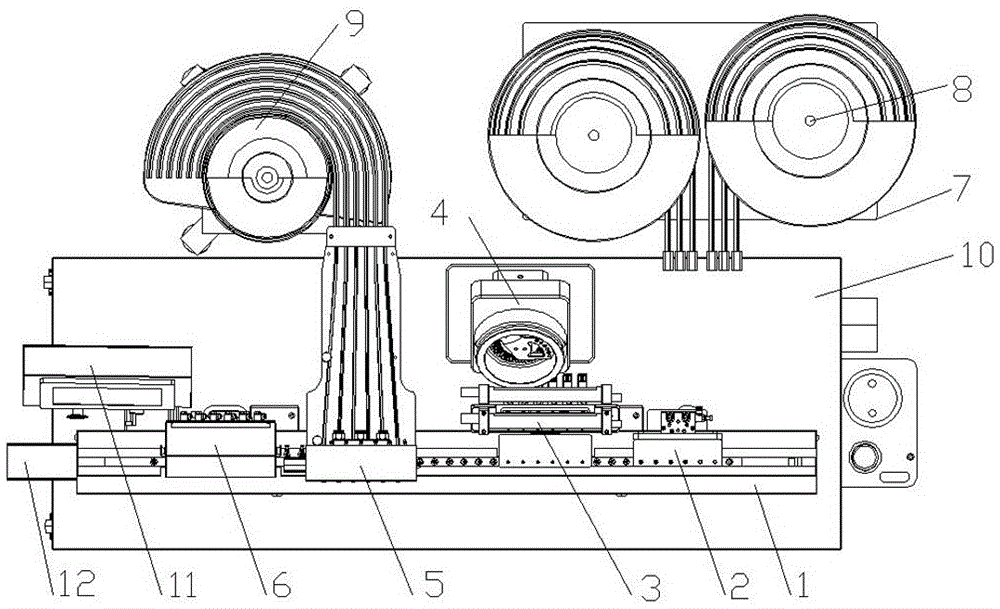

A vacuum electronic counting and filling equipment

ActiveCN105730721BEnsure consistencyNo inversionsSolid materialPackaging automatic controlBiomedical engineeringDelivery system

The invention belongs to the technical field of medicine pill filling, and discloses vacuum electronic multi-particle filling equipment. The vacuum electronic multi-particle filling equipment comprises a conveying system, wherein the conveying system comprises a conveying belt; medicine bottle cups used for containing medicine bottles are arranged on the outer surface of the conveying belt at equal intervals; a medicine filling multi-particle system is arranged above the conveying belt; the medicine filling multi-particle system is provided with a turntable medicine supply system; the medicine filling multi-particle system comprises a medicine filling installing seat and a medicine filling head capable of vertically moving on the medicine filling installing seat; a medicine filling exhaust cap used for locating the medicine bottle is arranged on the medicine filling head; a vacuum generator casing is arranged on the medicine filling installing seat. The vacuum electronic multi-particle filling equipment has the advantages that medicine pills can be precisely sucked out and blown into the medicine bottles through a turntable medicine supply system and the medicine filling multi-particle system; the filling quantity of the medicine pills is controlled through the vacuum generator; the extrusion crushing of the medicine pills is avoided; the precise control on the medicine pill counting is improved; meanwhile, the equipment can be applicable to the filling of the medicine pills with different particle numbers and sizes.

Owner:CHENGDU HEDA AUTOMATION EQUIP

Aluminum alloy door and window sealing strip installation equipment

ActiveCN110962070BAccurately press inEasy accessMetal-working hand toolsEngineeringStructural engineering

The invention relates to the field of door and window processing, in particular to installation equipment for aluminum alloy door and window sealant strips, including a placing platform, above which a moving frame and a drive mechanism for driving the moving frame to reciprocate laterally are arranged, and the moving frame is provided with two The compression wheel is fixedly connected with a correction block, and the correction block is provided with a through groove for the rubber strip to pass through. The cross-sectional shape of the through groove is "concave". The frame is provided with a first air cylinder for driving the pressing wheel to approach or move away from the placing table. This scheme realizes that the rubber strip is automatically installed in the slot hole on the aluminum alloy door and window.

Owner:重庆市金久装饰工程有限责任公司

Automatic assembly equipment for reading valve body components

ActiveCN111185753BImprove work efficiencyReduce assembly failure rateAssembly machinesSortingMechanical engineeringPhysics

The invention relates to an automatic assembly device, in particular to an automatic assembly device for a valve body assembly of a reading valve. It includes a turntable, a first valve body feeding mechanism, a second valve body feeding mechanism, an oiling mechanism for the inner hole and outer ring of the valve body, a first plastic inner ring feeding mechanism, a second plastic inner ring feeding mechanism, a knurled inner ring feeding mechanism, Valve body closing mechanism, O-ring feeding mechanism, O-ring outer ring oiling mechanism and unloading mechanism, the first valve body feeding mechanism, the second valve body feeding mechanism, and the valve body are sequentially arranged around the turntable along the circumferential direction. Hole outer ring oiling mechanism, first plastic inner ring feeding mechanism, second plastic inner ring feeding mechanism, knurled inner ring feeding mechanism, valve body closing mechanism, O-ring feeding mechanism, O-ring outer ring oiling mechanism and Feeding mechanism. The invention can automatically, accurately and reliably complete the assembly work of the valve body assembly of the reading valve by arranging a series of assembly mechanisms around the turntable, thereby improving the work efficiency of assembly.

Owner:弗瑞斯阀门(宁波)有限公司

A Rockwell hardness tester with the function of adjusting the angle of the measuring platform

ActiveCN110411877BHigh measurement accuracyAccurately press inInvestigating material hardnessClassical mechanicsStructural engineering

The invention relates to a Rockwell hardness tester with the function of adjusting the angle, which comprises a body, an indenter installed on the body, a lifting column vertically arranged on the body and directly below the indenter, and a lifting column arranged on the lifting column for The measuring platform where the test block is placed, the middle position of the lower surface of the measuring platform is provided with a connecting piece hinged with the lifting column, and there is an adjustment gap between the measuring platform and the lifting column; Clamping device; the lower surface of the measurement platform and the positions on both sides of the connector are respectively hinged with sleeves, the sleeves are vertically arranged, and the lifting column is provided with a drive that can drive the sleeve to move up and down to adjust the angle of the measurement platform components. The invention has the advantage that the angle of the measurement platform can be adjusted according to the measurement requirements, so as to adapt to different types of blocks to be tested.

Owner:北京精诚恒通工程技术检测有限公司

A sample preparation method and pressing device for raw soil-based materials

ActiveCN105890961BImprove performanceStable compressive strengthPreparing sample for investigationCompressive strengthUltimate tensile strength

The invention discloses a sample preparation method and a compaction device for immature soil base materials. The method comprises the steps that the interior of a mold is coated with a lubricating oil layer, the immature soil base materials are put into the mold layer by layer, the immature soil base material layers in the mold are compacted through a jack every time one layer of immature soil base material is laid, and therefore a sample to be detected is obtained; the compaction speed of the jack is 0.5 mm / s, the compaction pressure of the jack is 18-19 K / N, and the compaction time of the jack is 3-5 min; the compaction device comprises a test bed, the test bed is sequentially provided with a first platform and a second platform in parallel in the horizontal direction from top to bottom, the second platform is coaxially provided with the jack, a gasket, the mold and a pressing column in sequence from bottom to top in the vertical direction, and the top end of the pressing column abuts against the first platform. Compared with a traditional hammer test, a press compaction test and a jack compaction test, the compressive strength of a test piece compacted by the jack is more stable than the compressive strength of a test piece compacted by the other two test methods, test piece overall deformation is good, and the test piece has good ductility when compacted.

Owner:CHANGAN UNIV

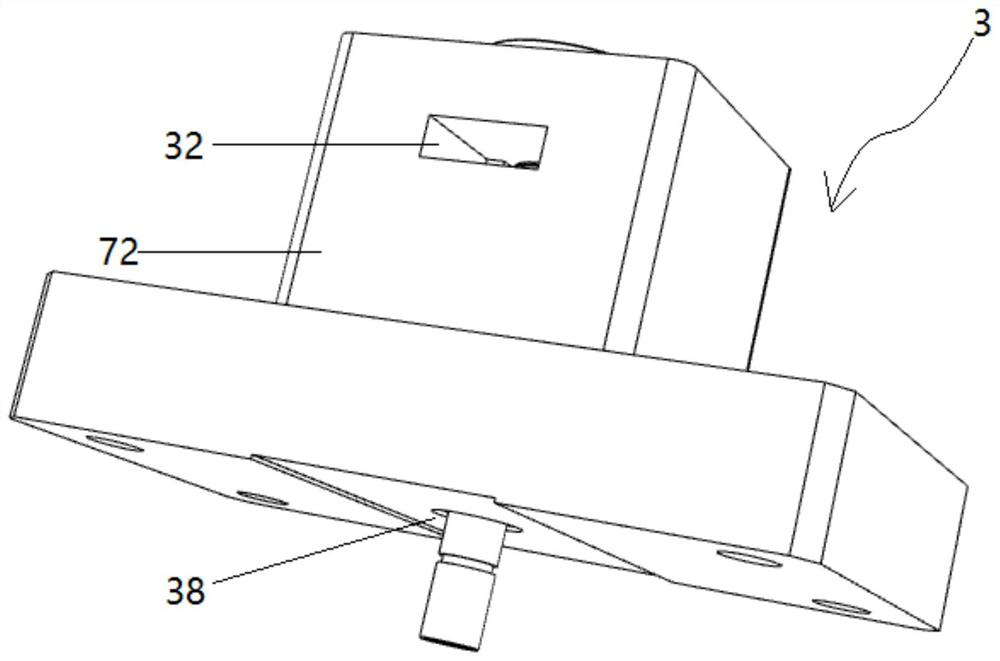

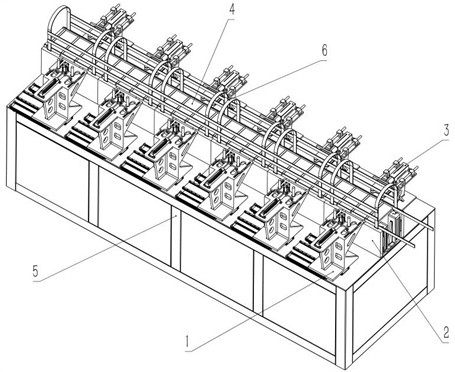

Production equipment for guardrail crawling ladder

ActiveCN112658560AReduce offsetImprove efficiencyWelding/cutting auxillary devicesAuxillary welding devicesMechanical engineeringIndustrial engineering

The invention discloses production equipment for producing a guardrail crawling ladder. The production equipment comprises a base, a rotary welding station, a blocking mechanism, a pressing station and a jig. The base is a mounting platform for the rotary welding station, the blocking mechanism, the pressing station and the jig, the guardrail crawling ladder is fixed to the jig, the main working principle of the rotary welding station is to weld the joint of a guardrail, a pedal rod and a ladder beam, an accurate welding process is completed under the assistance of the blocking mechanism and the pressing station, the problems of low manual operation efficiency and low position precision during current guardrail crawling ladder production are solved, and the requirements of controllability, easiness in operation and datamation of guardrail crawling ladder production are effectively met under the condition of reducing the production cost.

Owner:阜阳市东建市政园林建设有限公司

Liquid heat supply device capable of preventing smoke gas pollution

ActiveCN106813258AAvoid pollutionSimple structureLighting and heating apparatusUsing liquid separation agentEngineeringDust particles

The invention relates to the field of heat supply equipment, in particular to a liquid heat supply device capable of preventing smoke gas pollution. The liquid heat supply device comprises a machine fame, wherein a liquid furnace and a heating device which are mutually matched are arranged on the machine frame; the liquid furnace is connected with a liquid pressing device; a smoke gas treatment device is arranged in an outlet position of a chimney of the liquid furnace and comprises a smoke eliminating water tank and an umbrella-shaped stop block; the smoke eliminating water tank is arranged at the upper part of the chimney in a sleeving way; the umbrella-shaped stop block is arranged right above the chimney outlet; the liquid level of the smoke eliminating water tank is lower than the upper end of the chimney; the area of the umbrella-shaped stop block is 3 to 5 times of the chimney caliber. The invention aims at providing the liquid heat supply device capable of preventing the smoke gas pollution; a simple smoke gas treatment device is arranged at the chimney outlet; water is used as a treatment medium; the smoke gas is blocked into the smoke eliminating water tank through the umbrella-shaped stop block; dust particles and harmful gas in the smoke gas can be cleared through the water; the environment pollution by the smoke gas can be further prevented.

Owner:安徽明亮面业股份有限公司

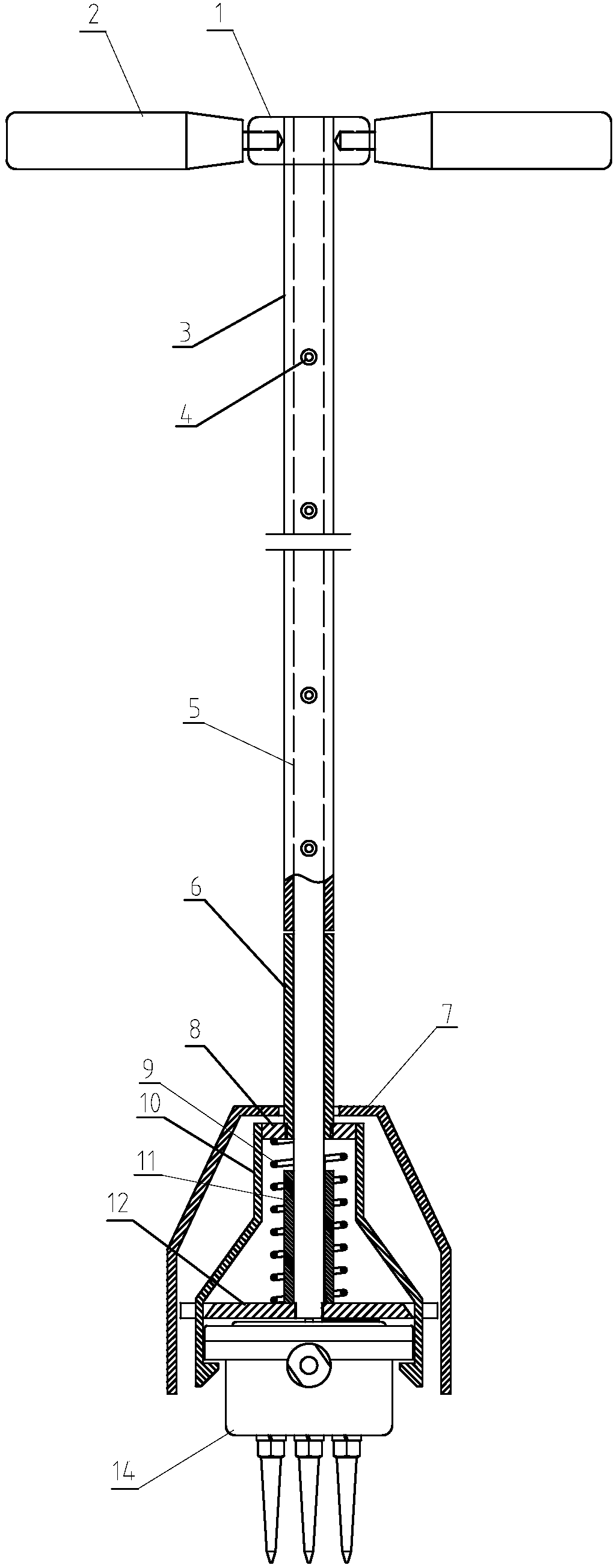

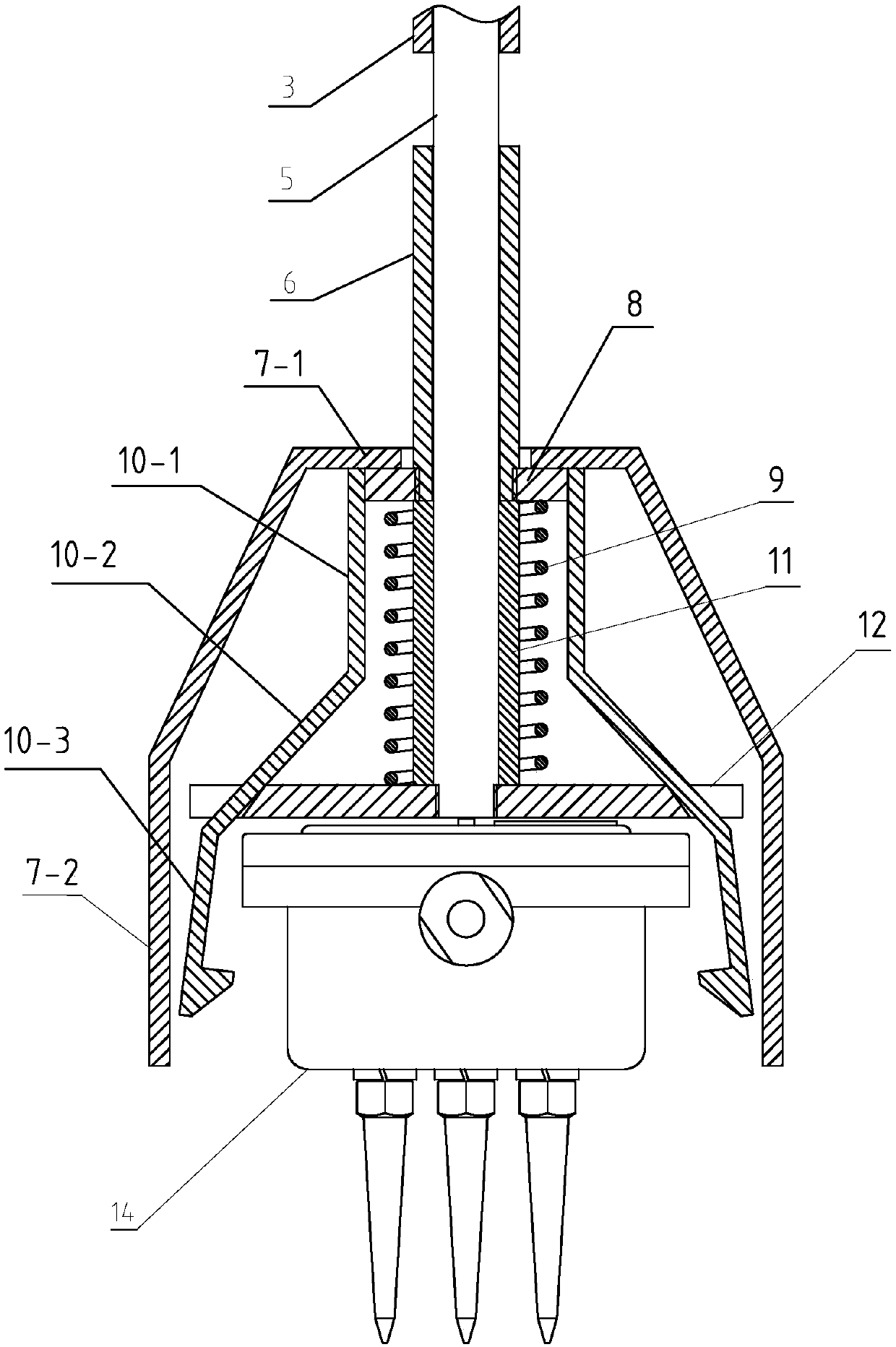

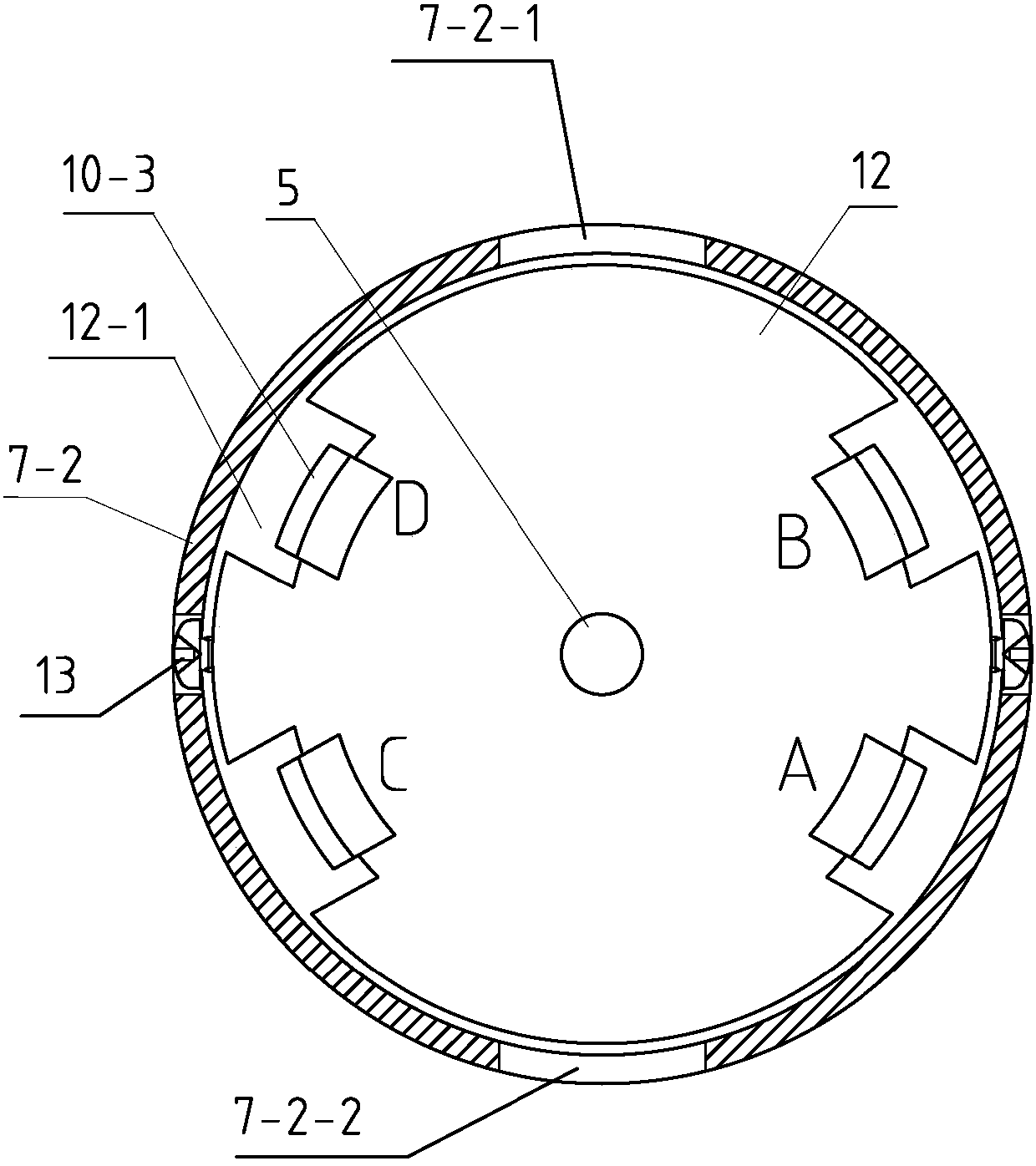

Ground detector arrangement tool

The invention relates to a ground detector arrangement tool. The technical problems of low efficiency, high cost and low operation quality when a three-component geophone is manually arranged in a stratum at present are solved. The tool comprises a connecting body, a handle, an inner long rod, a lower sleeve, a pressing plate, a pressure spring, a claw-shaped chuck, a connecting plate and a limiting shaft sleeve, the handle is connected with the connecting body, the upper end of the inner long rod is connected with the connecting body, and the lower end of the inner long rod is connected withthe pressing plate; the lower sleeve sleeves the inner long rod and is in sliding connection with the inner long rod; the limiting shaft sleeve is connected with the pressing plate, the pressure spring sleeves the limiting shaft sleeve, and the limiting shaft sleeve sleeves the inner long rod; the claw-type chuck is provided with a small-opening end part and a large-opening end part, the connecting plate is connected with the small-opening end part, the large-opening end part is connected with a clamping claw, and the joint of the large-opening end part and the small-opening end part is elastic; the connecting plate is connected with the lower end of the lower sleeve, and the inner long rod penetrates through the connecting plate; a notch is formed in the edge of the pressing plate, and the clamping jaw penetrates through the notch. The method can be applied to the technical field of detectors.

Owner:WEIHAI SUNFULL GEOPHYSICAL EXPLORATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com