Production equipment for guardrail crawling ladder

A technology for production equipment and ladders, which is applied in the field of production equipment for guardrails and ladders, to achieve the effects of accurate position tracking, stable product quality, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

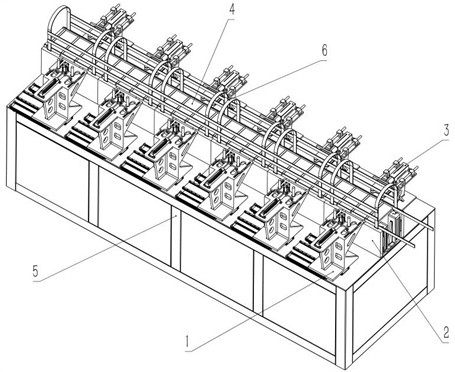

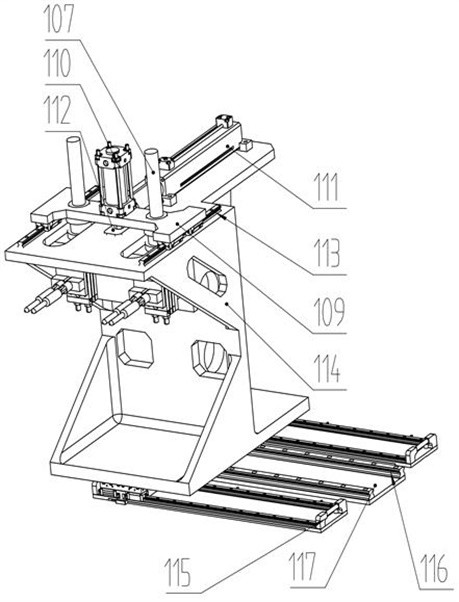

[0022] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 A kind of obstetrics and gynecology transfusion automatic injector shown. The base 4 is the main welding station of the guardrail, and also the installation platform of the rotary welding station 1, the blocking mechanism 2, the pressing mechanism 3, and the jig 5.

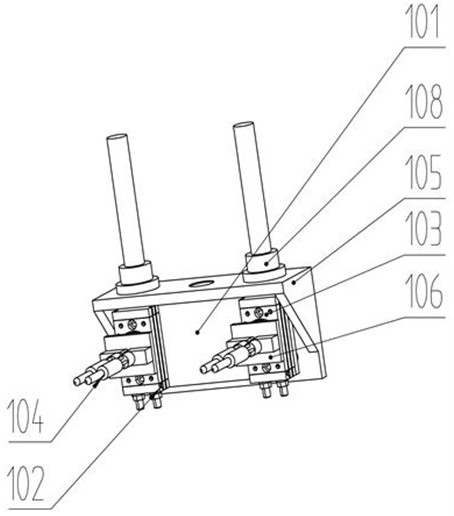

[0023] The concrete structure of blocking mechanism 2 is as Figure 4 As shown, the blocking cylinder 201 is fixedly installed on the surface of the blocking plate 203 to ensure the up and down movement of the blocking plate 203, and the blocking cylinder installation welding frame 202 is fixedly installed on the surface of the base 4 to fix the blocking cylinder 201, and the blocking plate 203 and the blocking chute plate 204 pass through The dovetail grooves are closely matched to ensure the accuracy of the parts when they move with each other, and can withstand certain radial loads. The dovetail chute mounting we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com