Automatic rocker arm assembling device for meter and assembling method

A technology on the meter and the rocker arm, which is applied in the field of meter automatic loading rocker arm device and its assembly, can solve the problems of low adjustment and improvement margin of meter meter performance, difficult to guarantee the batch accuracy of meter, etc., and achieve saving Manpower, high degree of automation, and the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

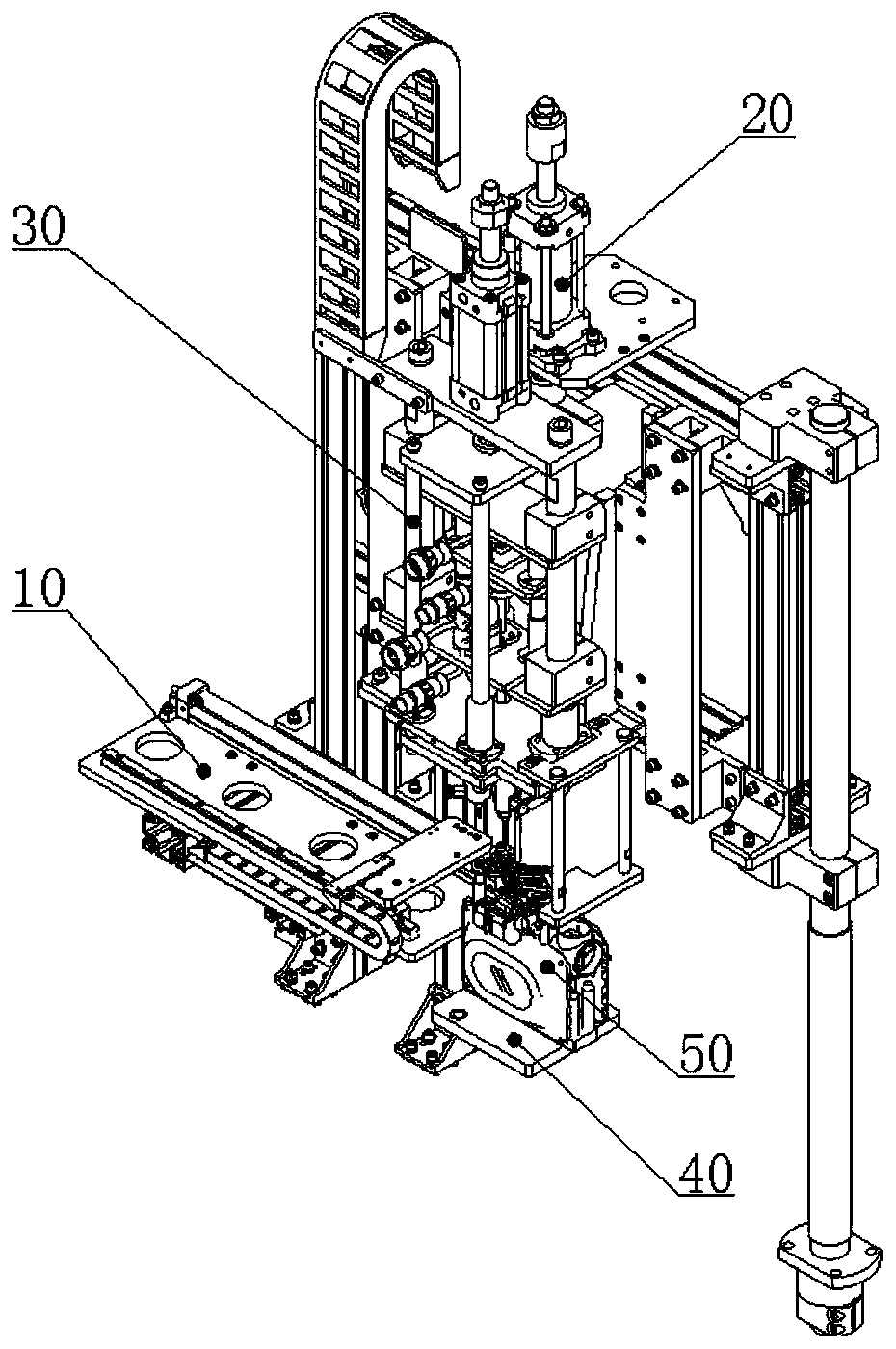

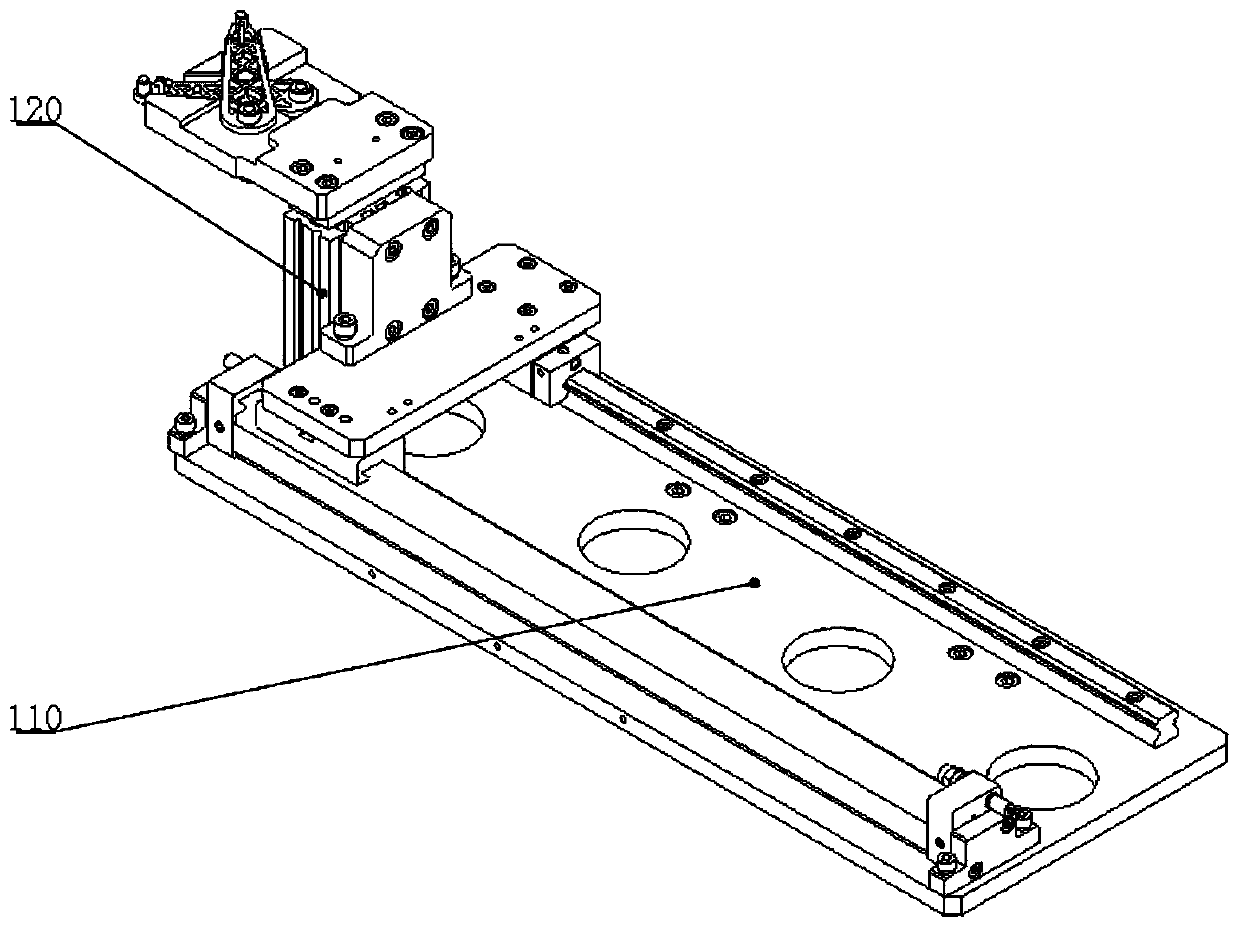

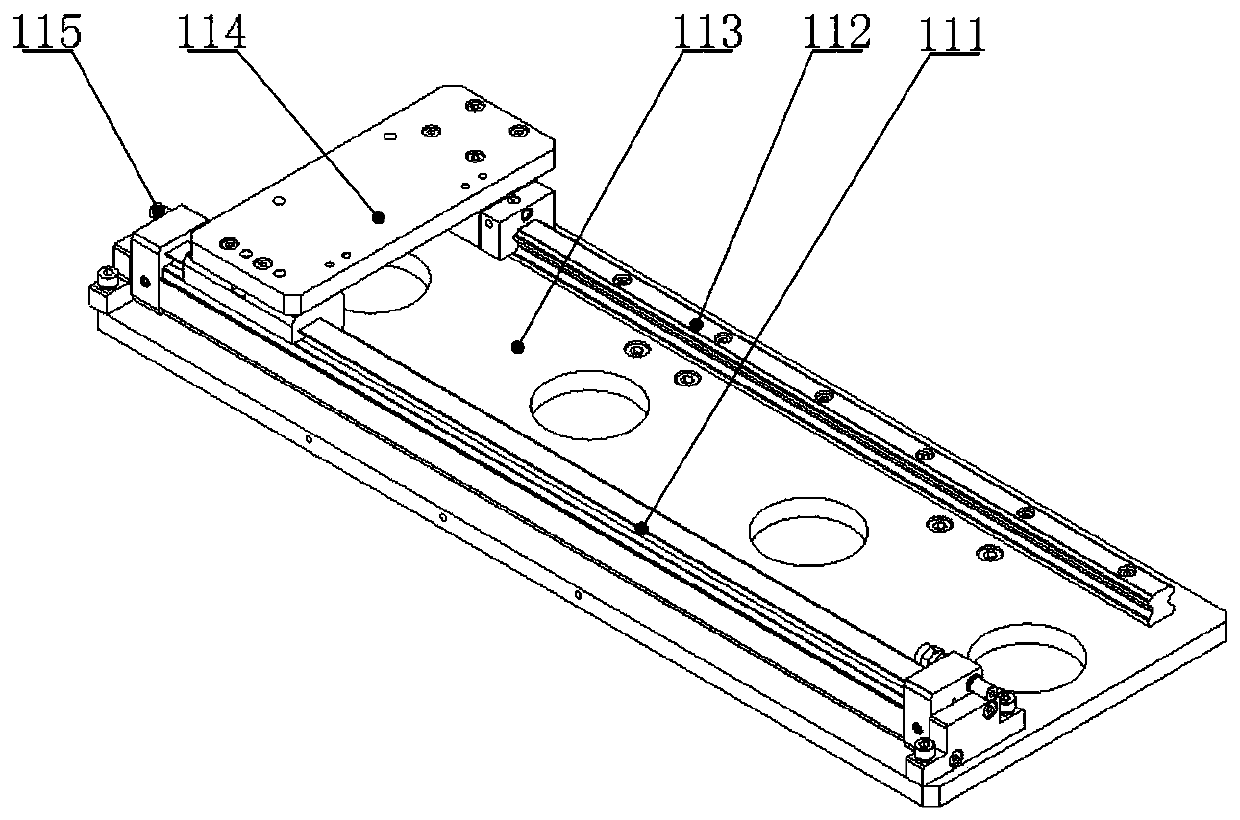

[0055] Such as figure 1 As shown, a kind of measuring meter automatic rocker arm device of the present invention comprises a rocker arm feeding mechanism 10, a rocker arm lifting mechanism 20, a rotary press assembly mechanism 30, a movement assembly tooling 40 and a movement assembly 50, and the rotation press assembly mechanism 30 includes a rocker arm press riveting mechanism 310 and a rotary angle finding mechanism 320 . The rocker arm feeding mechanism 10 moves the rocker arm 503 to be assembled to the target position, the rocker arm pressing mechanism 310 takes the rocker arm 503, and the rocker arm lifting mechanism 20 drives the rotary press-fitting mechanism 30 to move linearly in the vertical direction to the rotary position. The angle mechanism 320 is docked with the vertical shaft 504, the rotating angle finding mechanism 320 driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com