Flexible lifting feeding system based on AGV and feeding control method

A flexible and lifting mechanism technology, applied in the direction of conveyor control devices, manufacturing tools, auxiliary welding equipment, etc., can solve the problems of equipment type and quantity increase, unfavorable cost control, etc., to control production costs, ensure positioning accuracy, and stable The effect of reliable lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0069] In order to clearly and completely describe the technical solution of the present invention and its specific working process, in conjunction with the accompanying drawings, the specific implementation of the present invention is as follows:

[0070] In the present invention, unless otherwise clearly specified and limited, terms such as "installation", "connection", "connection" and "fixation" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection , or integrated; it may be mechanically connected or electrically connected; it may be directly connected or indirectly connected through an intermediary, and it may be the internal communication of two components or the interaction relationship between two components, unless otherwise specified limit. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention according to specific situations.

[0071] In the present i...

Embodiment 1

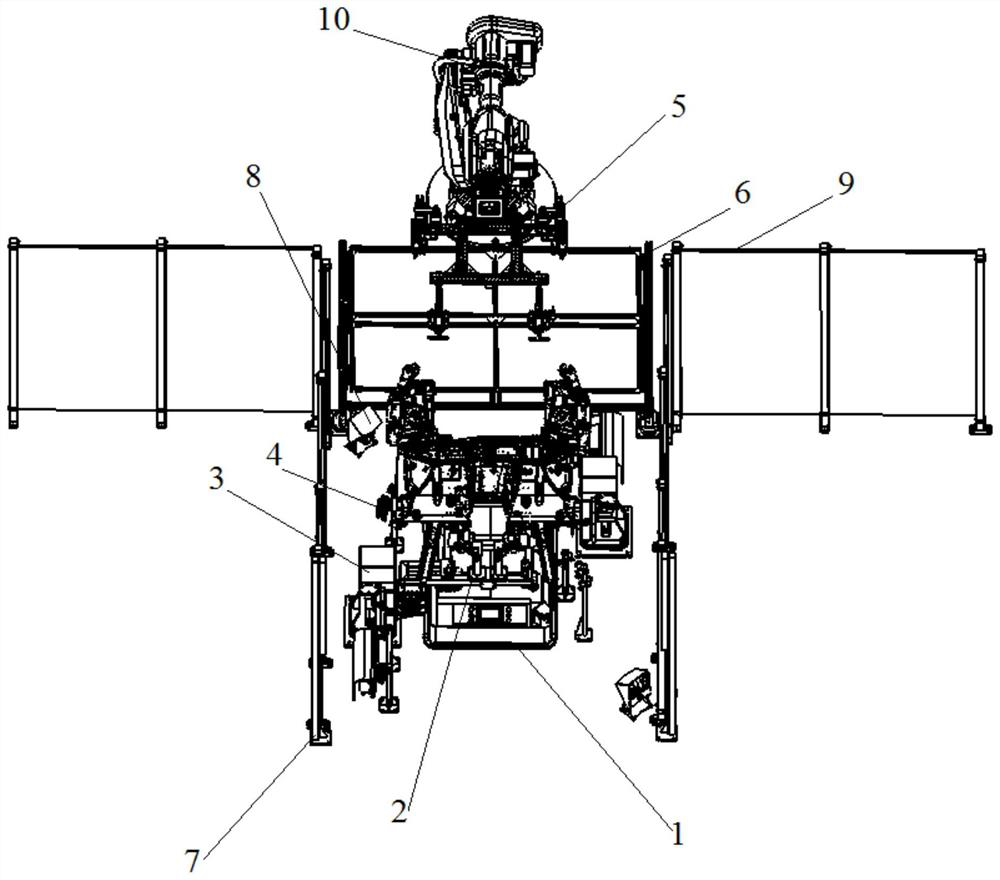

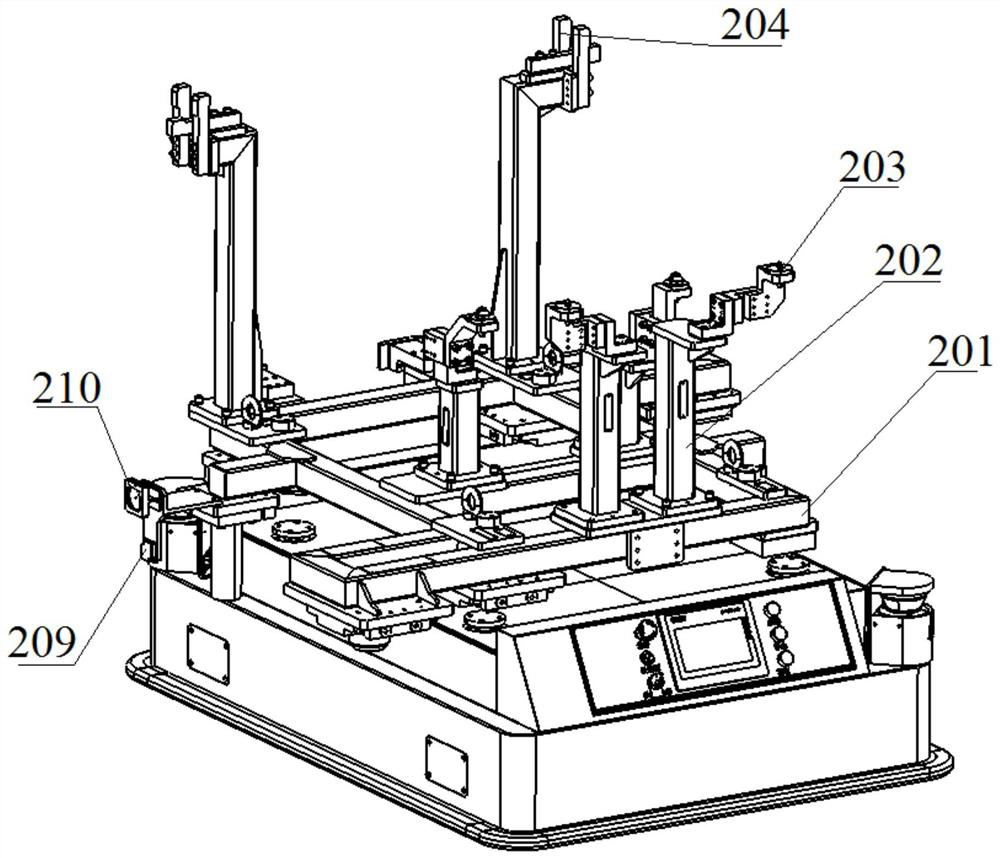

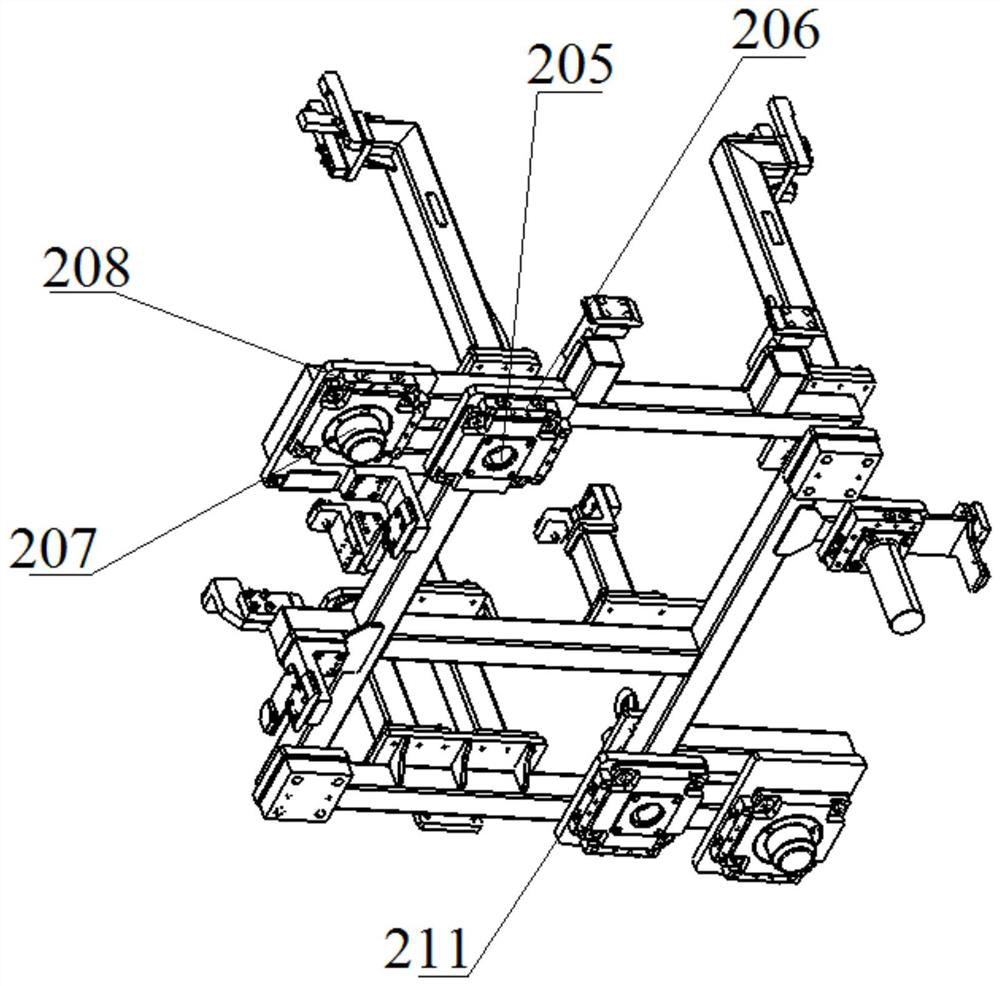

[0075] Such as figure 1 As shown, the first embodiment discloses an AGV-based flexible lifting and feeding system, which includes: AGV logistics vehicle 1, appliance 2, fine positioning lifting mechanism 3, RFID system 4, vision system 5, lifting slide Sliding door 6, grating 7, scanner 8, fence 9, robot 10 and PLC controller.

[0076] The AGV logistics vehicle 1 is used to carry the appliance 2 and move to the position of the feeding port; the appliance 2 is loaded with body-in-white parts products; At the angular position, the precise positioning lifting mechanism 3 is matched with the appliance 2 to lift the appliance 2 loaded with body-in-white parts to the height to be grasped; the RFID system 4 is set on one side of the appliance 2 for identifying the appliance 2 and then identify the type information of the body-in-white parts products loaded on it; the robot 10 is set at the position of the front end of the appliance 2 at the position of the material port to grab the ...

Embodiment 2

[0097] This embodiment 2 discloses the feeding control method of the AGV-based flexible lifting and feeding system described in the previous embodiment 1. The specific process of the feeding control method is as follows:

[0098] First, after the AGV logistics vehicle 1 pulls the device 2 to the loading port station, the precise positioning lifting mechanism 3 lifts the device and positions it to the designated feeding position with high precision;

[0099] Then, the RFID system 4 reads and identifies the vehicle model information of the body-in-white parts product carried by the appliance 2, and sends it to the robot 10. The robot 10 judges whether it matches the current gripper model according to the vehicle model information. If it does not match, the control switches to Matching gripper; at the same time, control the lifting sliding door 6 to open and activate the grating 7 and scanner 8 to start working;

[0100] Finally, the body-in-white parts are photographed and ident...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com