Aluminum alloy door and window sealing strip installation equipment

A technology for aluminum alloy doors and windows and sealing strips, which is applied in the field of door and window processing, and can solve problems such as low efficiency and high operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

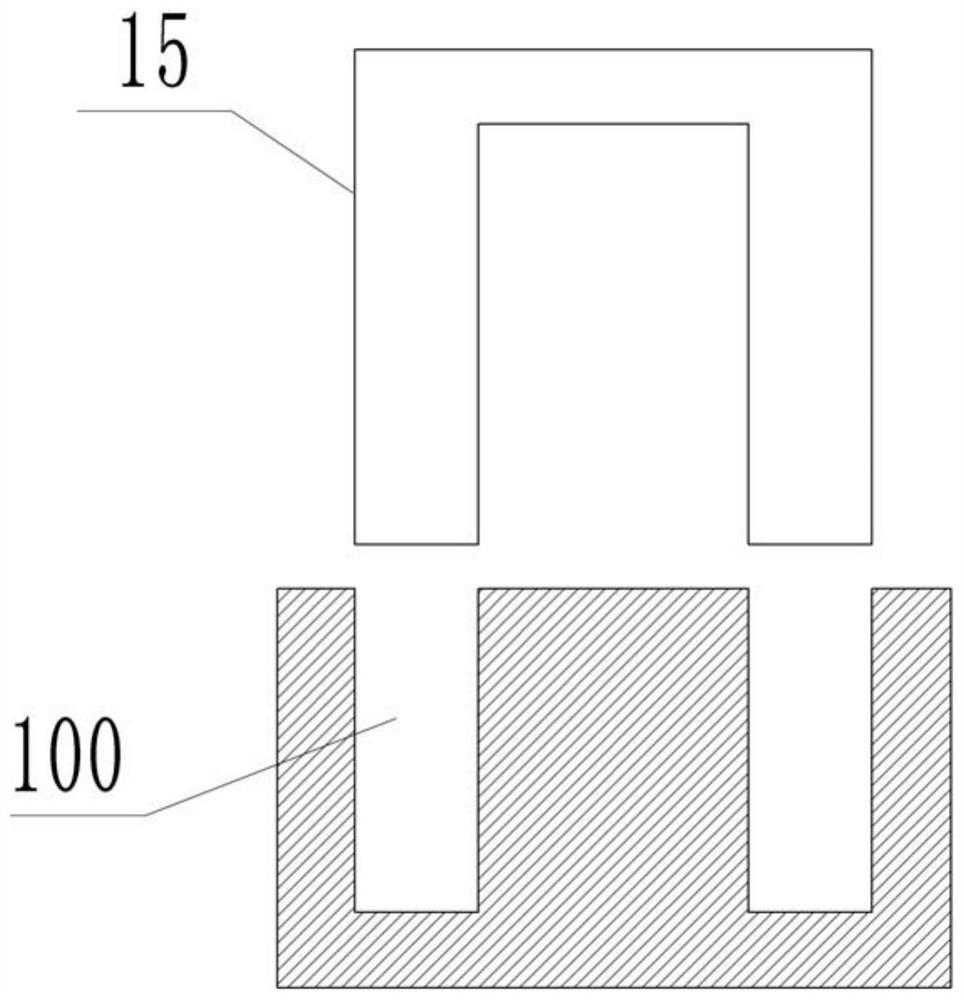

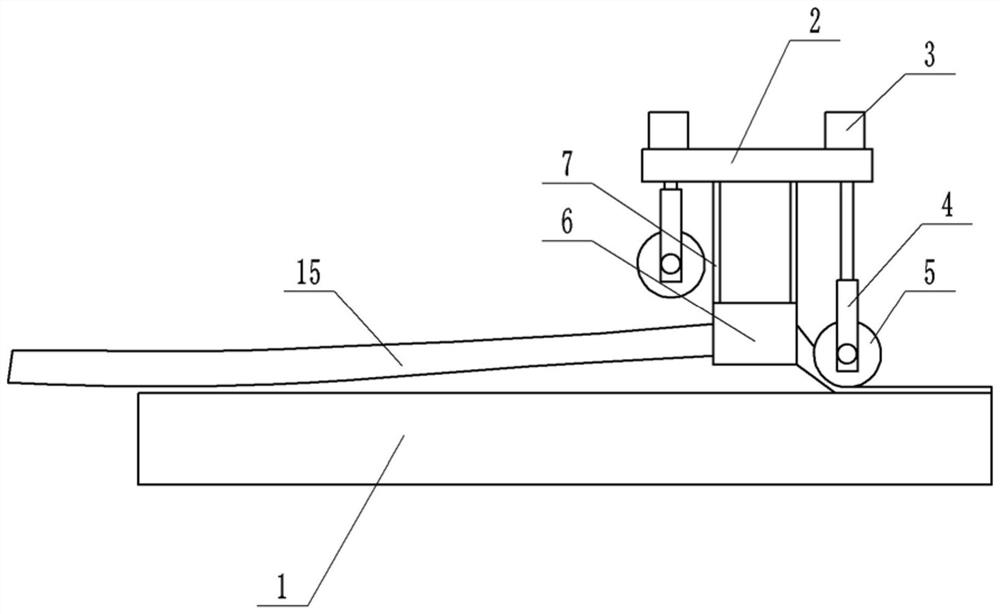

[0030] Basic as attached Figure 2-Figure 3 Shown: installation equipment for aluminum alloy door and window sealant strips, including a frame and a placement table 1, and the placement table 1 is provided with a placement groove for placing aluminum alloy doors and windows. The top of the placement table 1 is provided with a mobile frame 2 and a drive mechanism for driving the mobile frame 2 to move laterally. The mobile frame 2 is horizontally slidably connected to the frame. Guide rail, mobile frame 2 is provided with the chute that cooperates with guide rail. The driving mechanism in this embodiment can be a driving cylinder, which is fixed on the frame by screws, and the cylinder rod of the driving cylinder is welded to the moving frame 2, and the moving frame 2 is driven to reciprocate laterally through the expansion and contraction of the cylinder rod of the driving cylinder.

[0031] The mobile frame 2 is provided with two pressing wheels 5 and is fixedly connected wi...

Embodiment 2

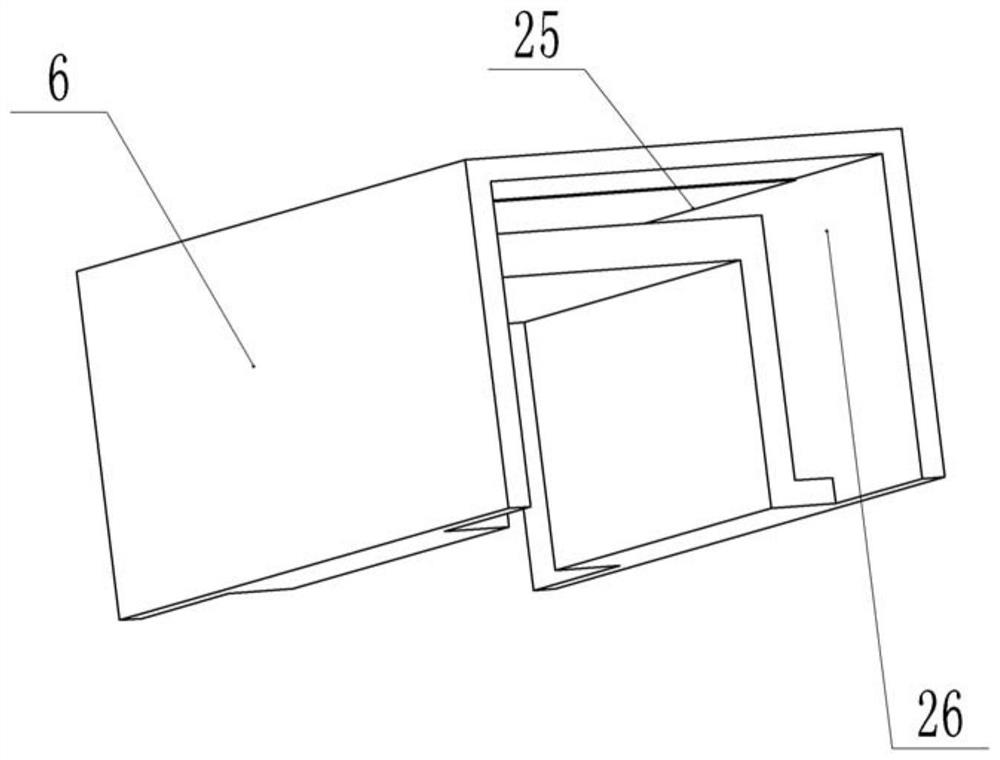

[0036] combine Figure 6-Figure 9 As shown, in the present embodiment, the inner wall of the upper through groove 25 of the correction block 6 is provided with a roller chamber 28, and the roller chamber 28 is rotatably connected with a rotating roller 27. The specific rotation method is: the rotating roller 27 is provided with a shaft The hole, the top and the bottom of the roller cavity 28 are all provided with a shaft cavity, and a vertical shaft tube 101 is welded in the shaft cavity, and the shaft tube 101 is rotatably connected in the shaft hole by a bearing 102 . combine Figure 5 As shown, the mobile frame 2 is provided with a piston cylinder 16 equipped with glue, and the piston cylinder 16 is sealed and slidably connected with a piston. The mobile frame 2 is equipped with a second cylinder 17 by screws, and the end of the cylinder rod of the second cylinder 17 welded to the piston. combine Figure 9 As shown, the inside of the rotating roller 27 in the present emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com