Cylinder sleeve pressing head device

A technology of pressure head and cylinder liner, which is applied in the field of cylinder liner press components, and can solve problems such as uneven pressure, waste, and out-of-round cylinder liner

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content of the present invention, the present invention will be described in detail in conjunction with the accompanying drawings and embodiments.

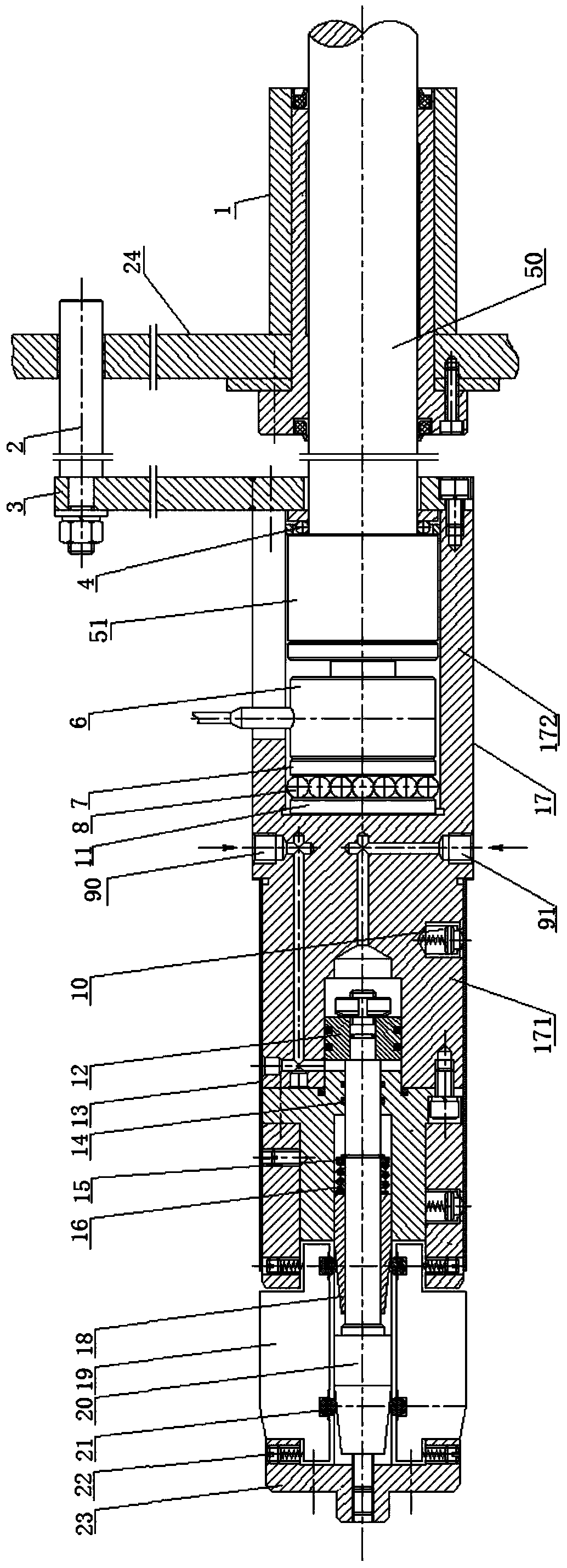

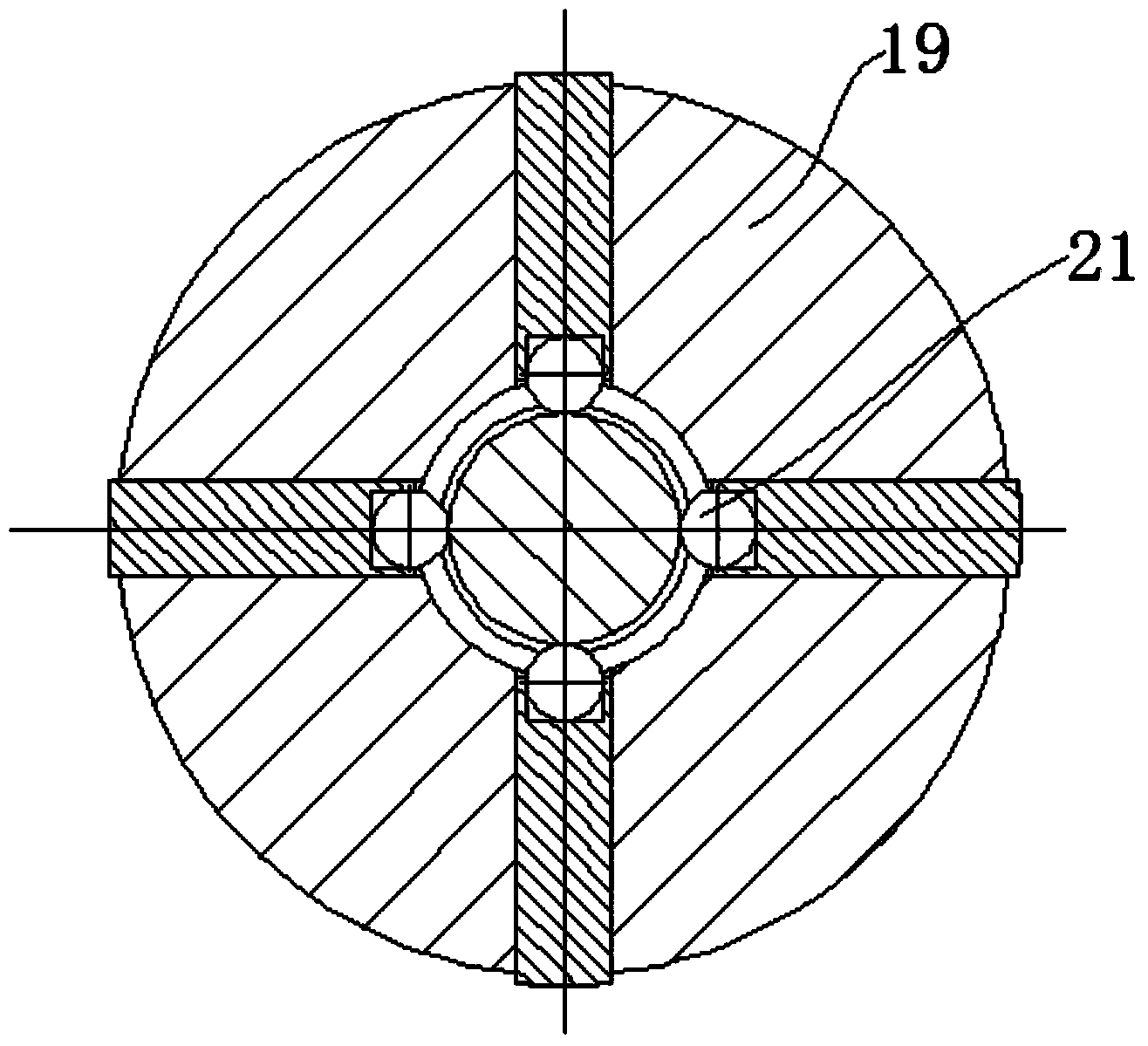

[0027] combine figure 1 , a cylinder liner indenter device of the present invention, comprising a cylinder liner 13, an indenter body 17, a guide sleeve 1, a cylinder piston rod 50, a tapered shaft 20, a guide block 19, a cylinder piston 12, an adjusting screw seat 23, and a positioning cover Plate 3 and guide rod 2, the bottom of taper shaft 20 passes through guide block 19 and links to each other with adjusting screw seat 23; Four, and the return spring 22 acts on the guide block 19, so that the guide block 19 can automatically shrink; in order to play a guiding role, ensure that the device is accurately pressed into the cylinder liner 13, and also in order to achieve the self-centering of the cylinder liner 13 The purpose is to realize the guiding and positioning of the cylinder bore, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com