Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50 results about "Syringe Drive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

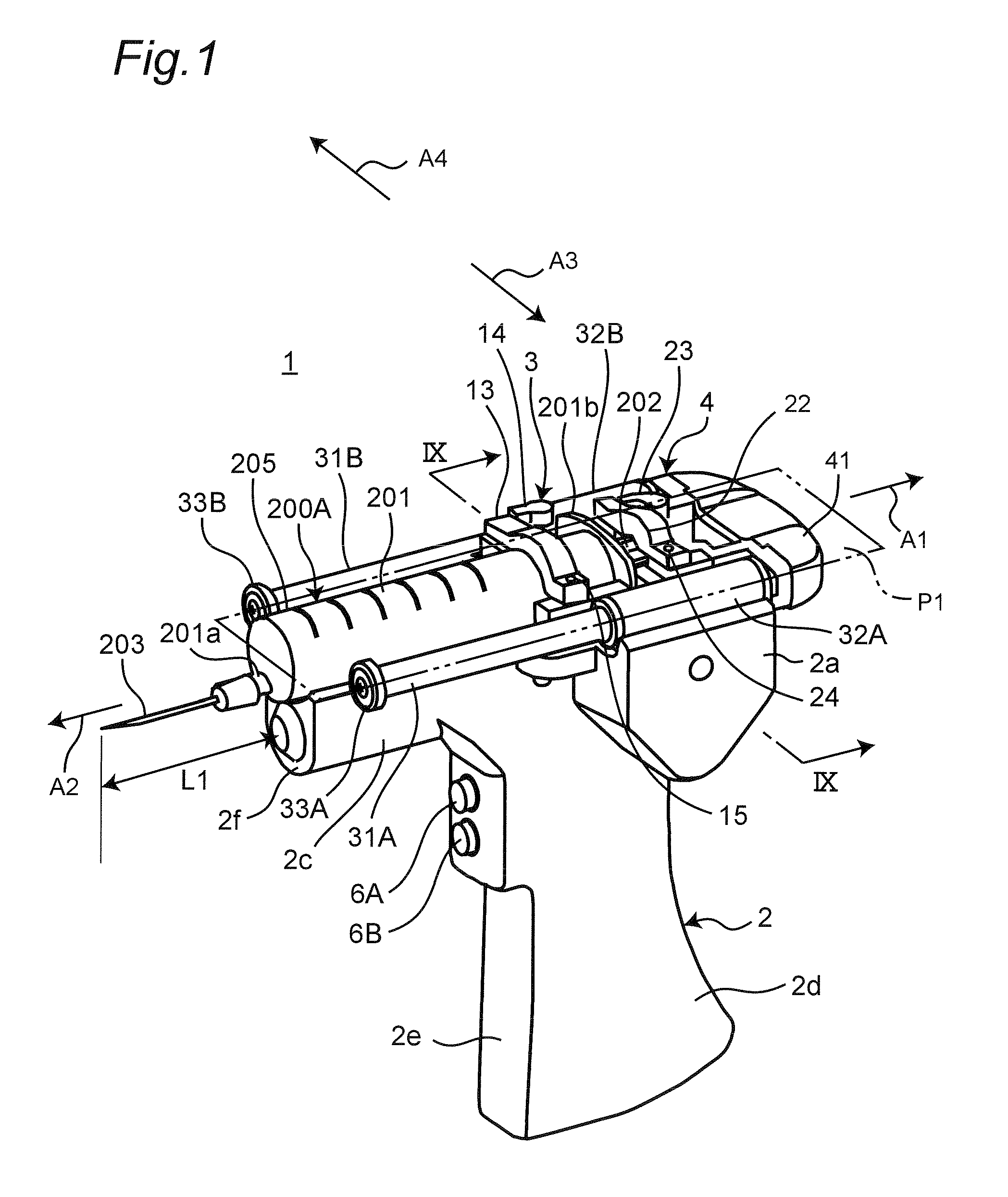

Syringe drive device and medication dispensing device

InactiveUS20120071828A1Readily aspiratedEasy to operateAutomatic syringesPharmaceutical containersInternal pressureEngineering

A syringe drive device 1 includes: a syringe holding section 3; a piston manipulating section 4; and a display section 6. An outer tube 202 of a syringe 201 is detachably held by the syringe holding section 3. A piston 203 of the syringe 201 is detachably engaged with the piston manipulating section 4. The piston manipulating section 4 moves in a direction in response to an operation of operation buttons 8A and 8B, and the piston 203 is thereby moved in a direction where the piston is pushed into or pulled out from the outer tube 202. An internal pressure of a medicinal solution container punctured with an injection needle 204 attached to the outer tube 202 of the syringe 201 is measured and displayed on the display section 6.

Owner:PANASONIC CORP

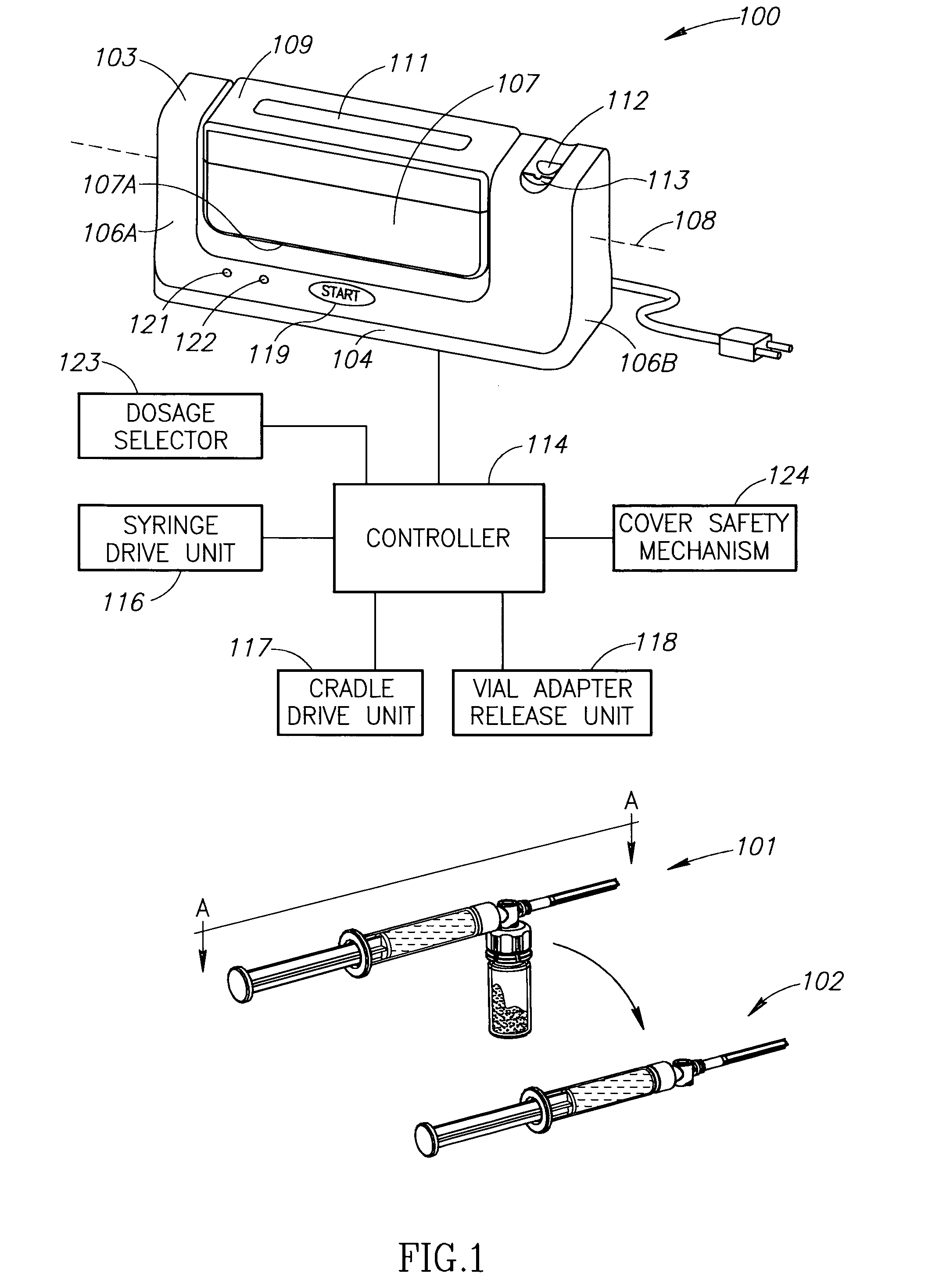

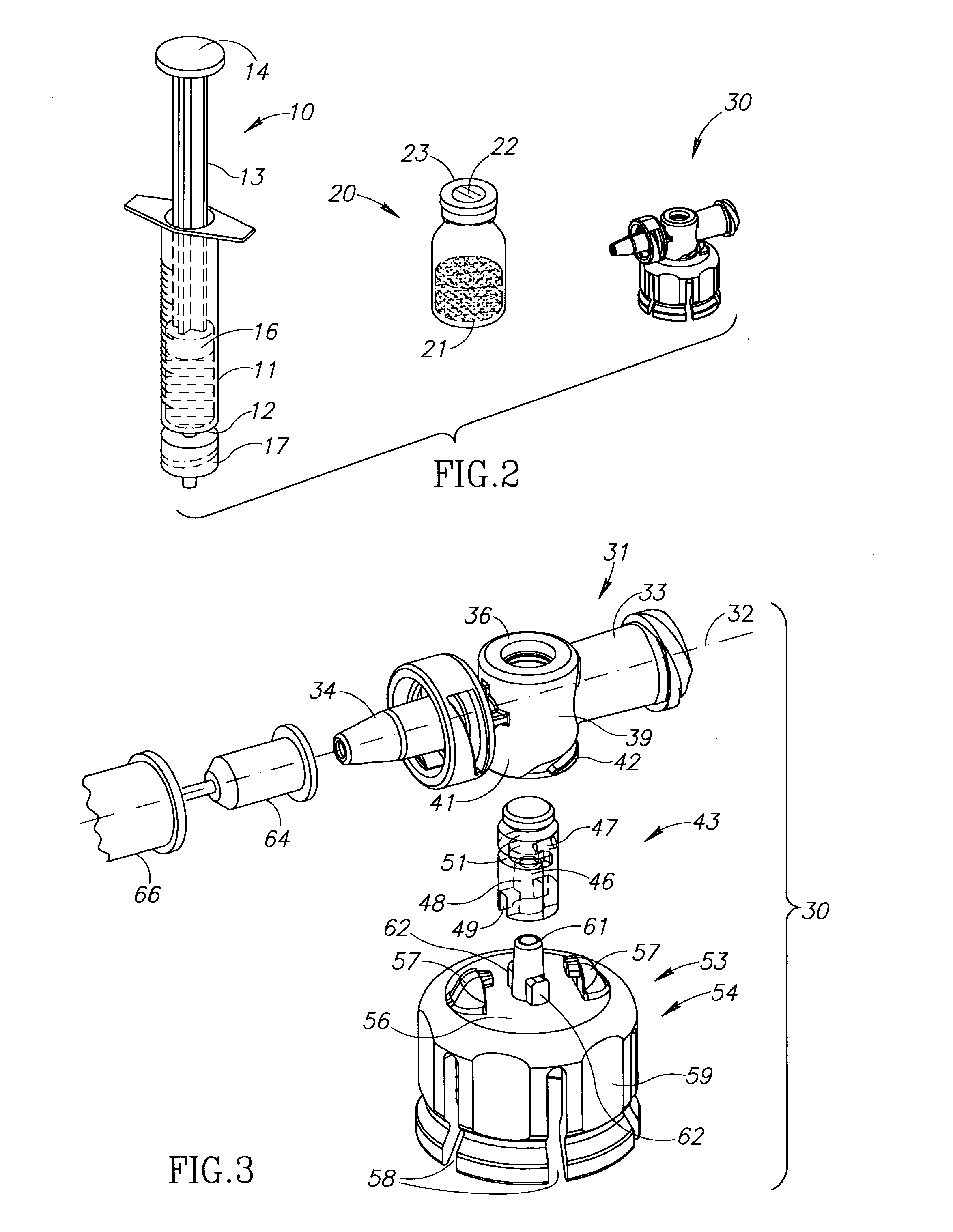

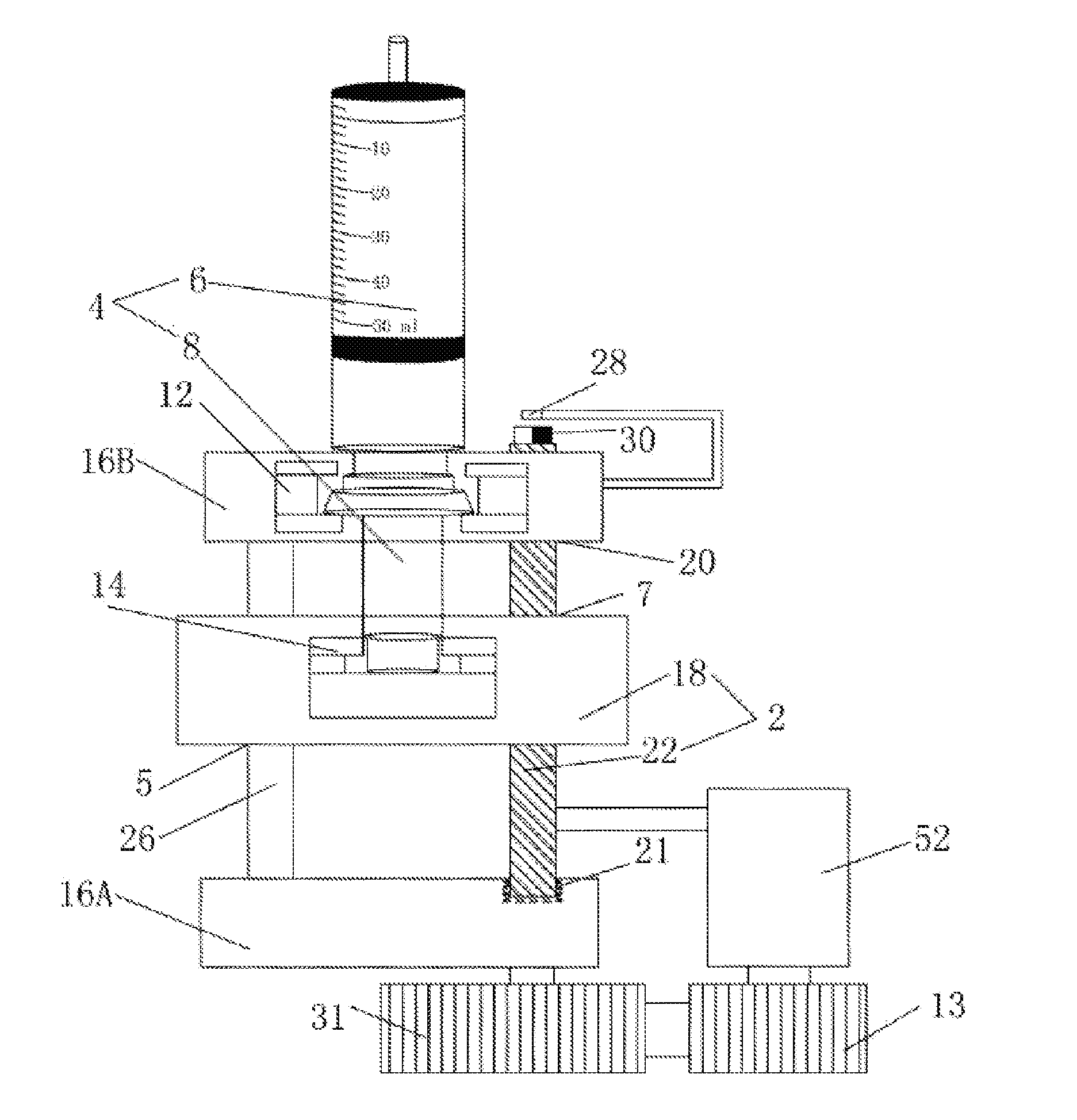

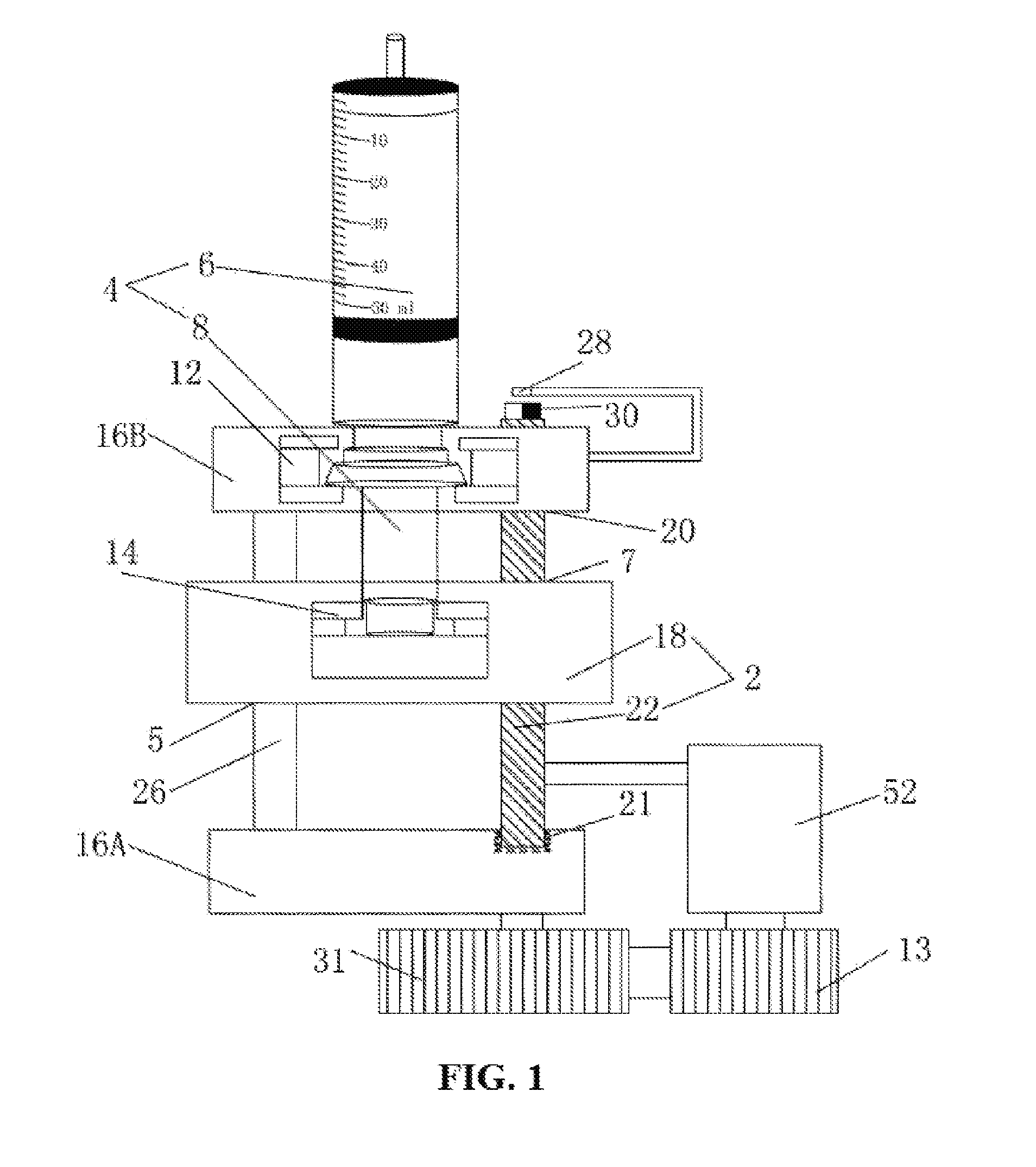

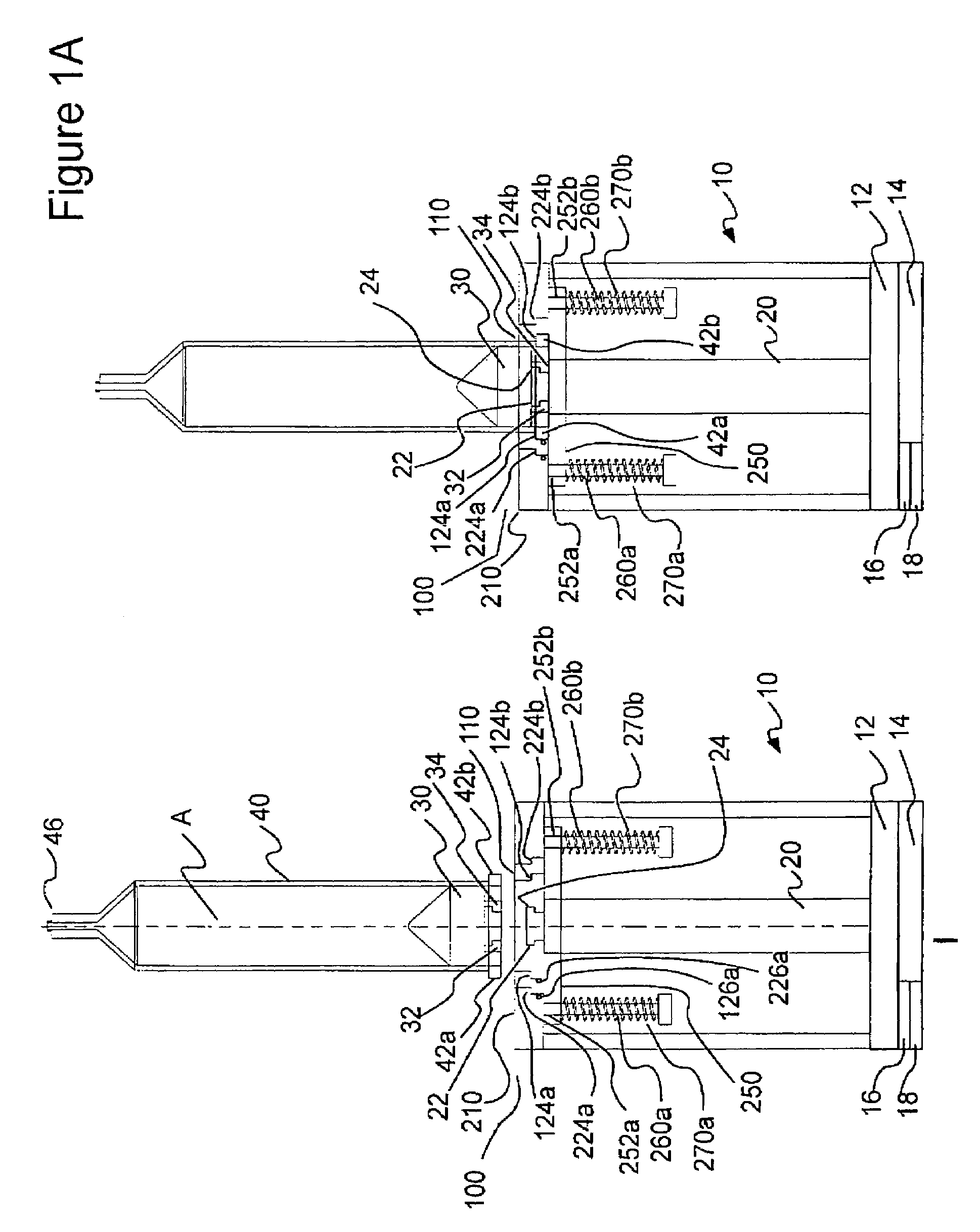

Automatic Liquid Drug Preparation Apparatus for the Preparation of a Predetermined Dosage of Liquid Drug

Automatic liquid drug preparation apparatus for preparing a liquid drug assemblage with a predetermined dosage of liquid drug. The liquid drug assemblage is prepared from a preparatory assemblage including a fluid control device having a body member with a syringe port, a vial adapter, and an administration port, a vial pre-filled with powder or liquid medicament, and a syringe pre-filled with diluent for mixing with the medicament. The automatic liquid drug preparation apparatus includes a housing, a cradle for receiving the preparatory assemblage, and a controller for controlling a motorized syringe drive unit for selectively transferring liquid contents between the syringe and the vial, a motorized cradle drive unit for selectively rotating the cradle relative to the housing, and a motorized vial adapter release unit for selectively detaching the vial adapter with its attached spent vial from the body member to form the liquid drug assemblage.

Owner:MEDIMOP MEDICAL PROJECTS

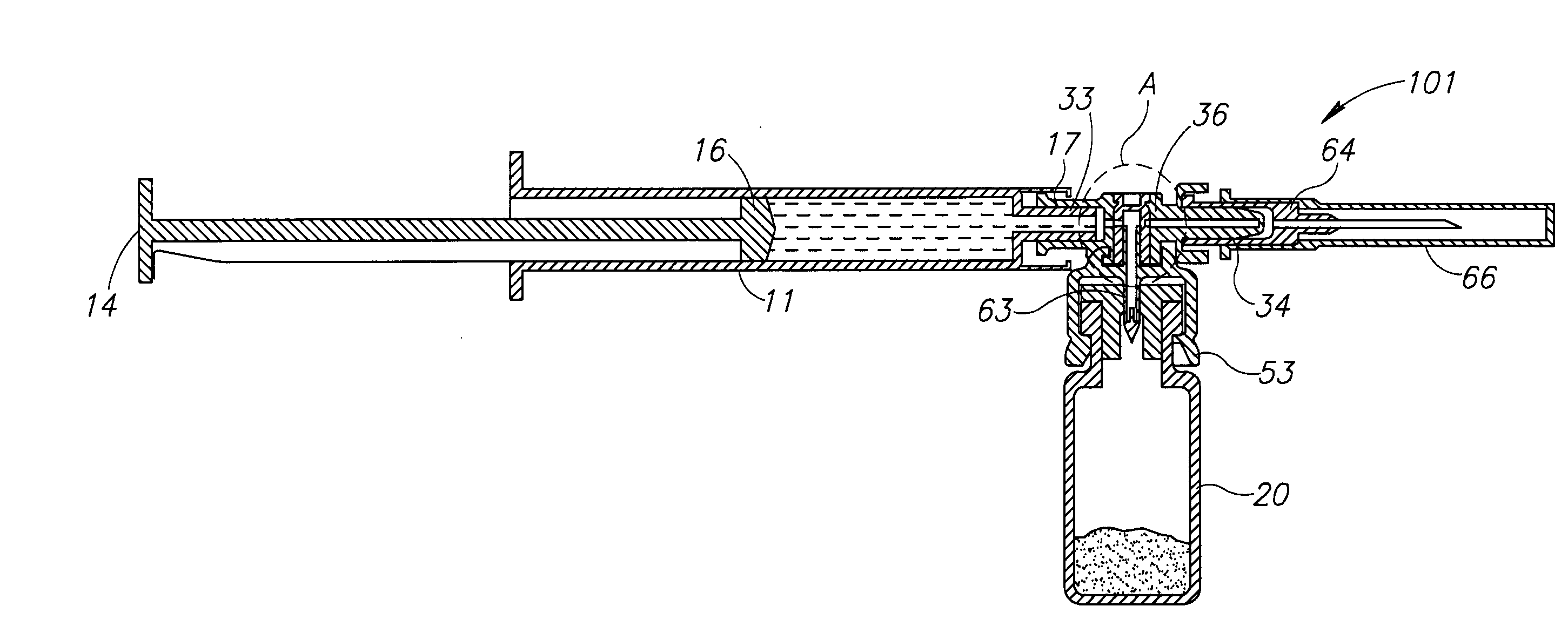

Syringe drive device and syringe drive method

InactiveUS20120299737A1Operational securityHigh precisionMedical devicesIntravenous devicesInternal pressurePush and pull

A syringe drive device 11 includes a fixing section 15 fixing an outer tube 14, a movable holder 16 holding a plunger 13, and a drive section 42 driving the holder 16 along an axis of the plunger to push and pull the plunger with respect to the outer tube 14. An internal pressure detector 18 has a positive pressure detection switch 63 detecting an internal pressure of a syringe 12. A determination section 41 determines issue of an alert when the holder 16 is stopped and the positive pressure detection switch 63 is ON. A display section 19 is lit to indicate the alert when the determination section 41 determines issue of the alert.

Owner:PANASONIC CORP

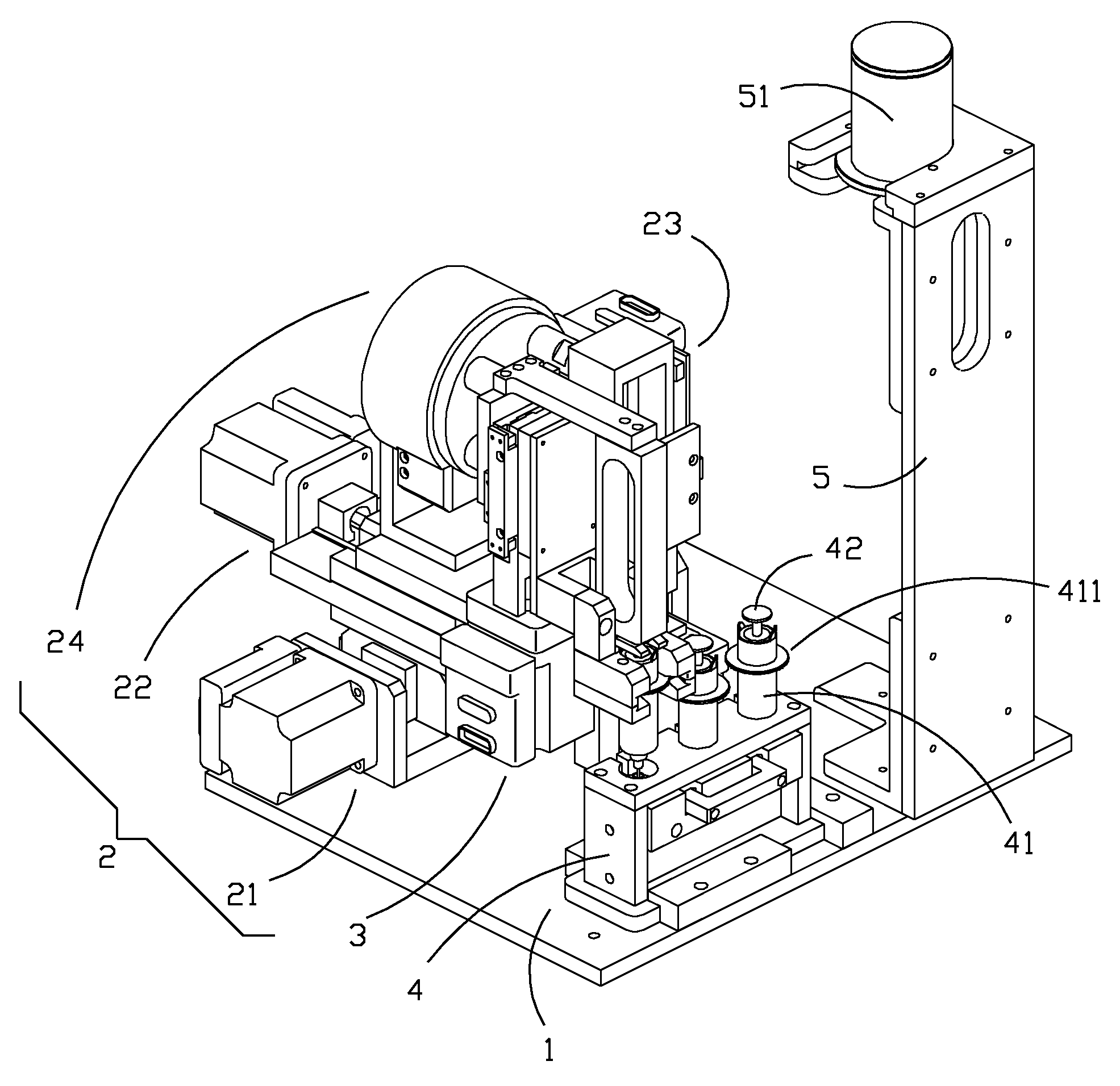

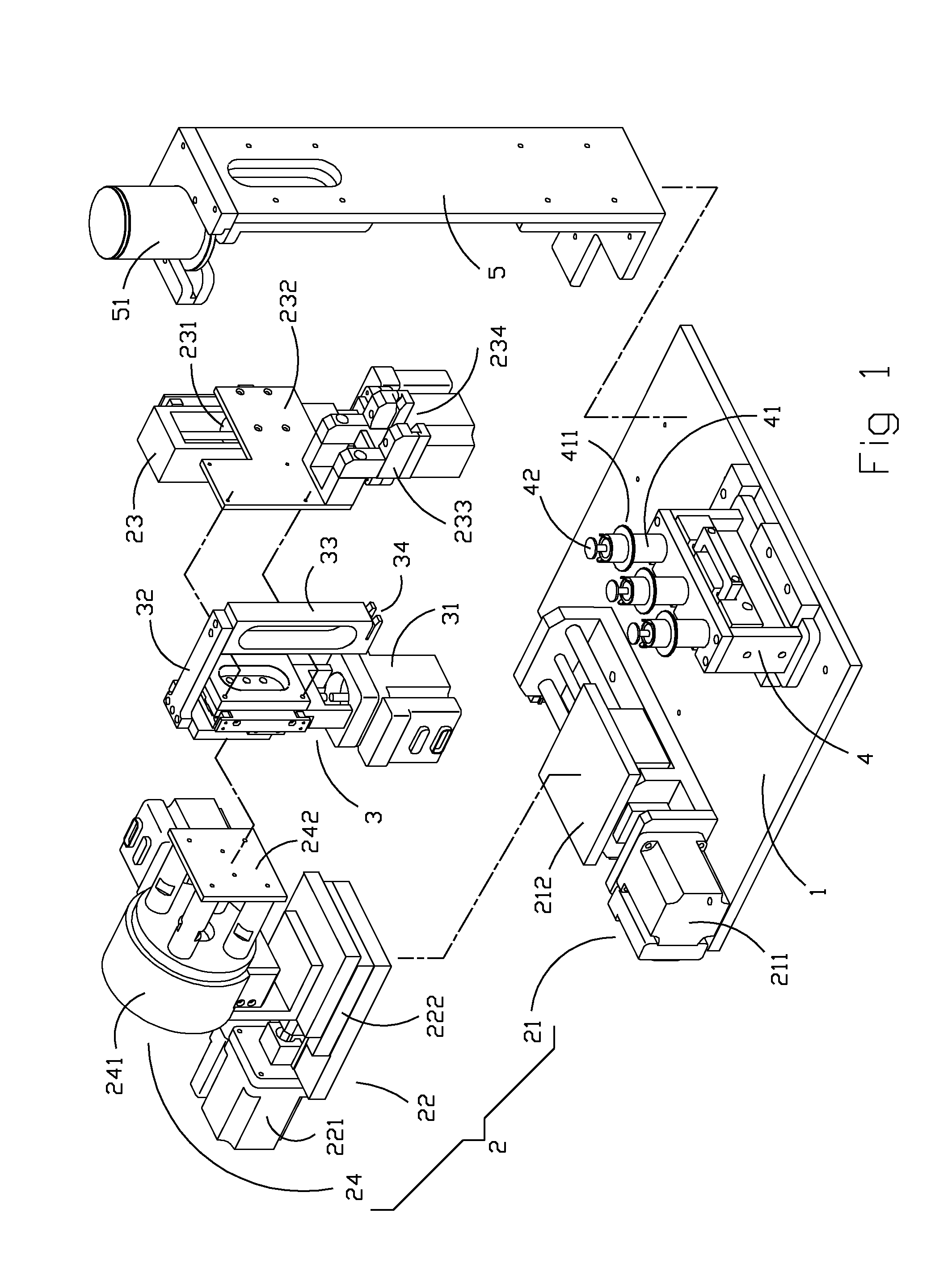

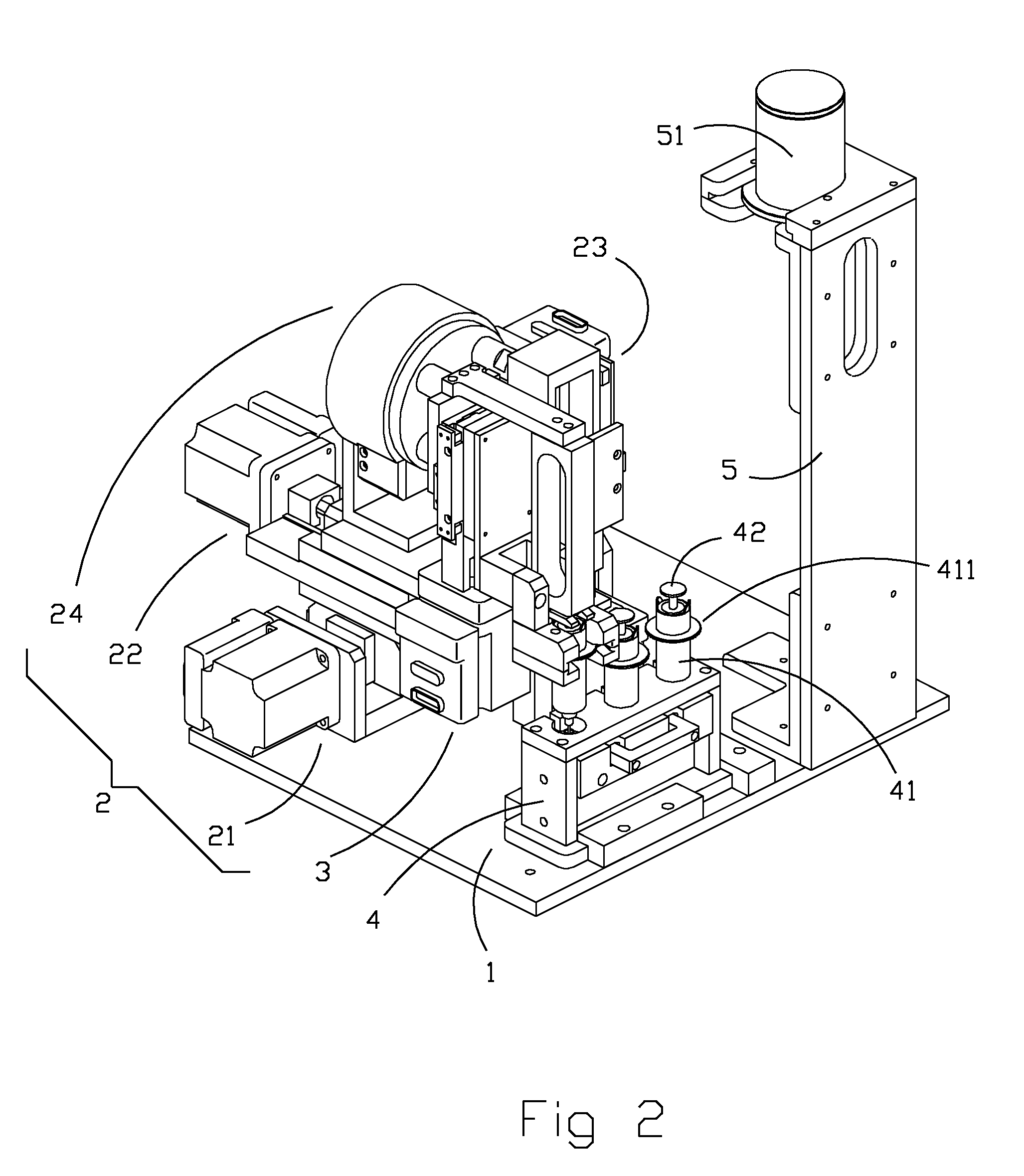

Automated Dispenser for Radiopharmaceuticals

ActiveUS20090108018A1Reduce direct exposureIsotope delivery systemsRegistering devicesBottleSyringe needle

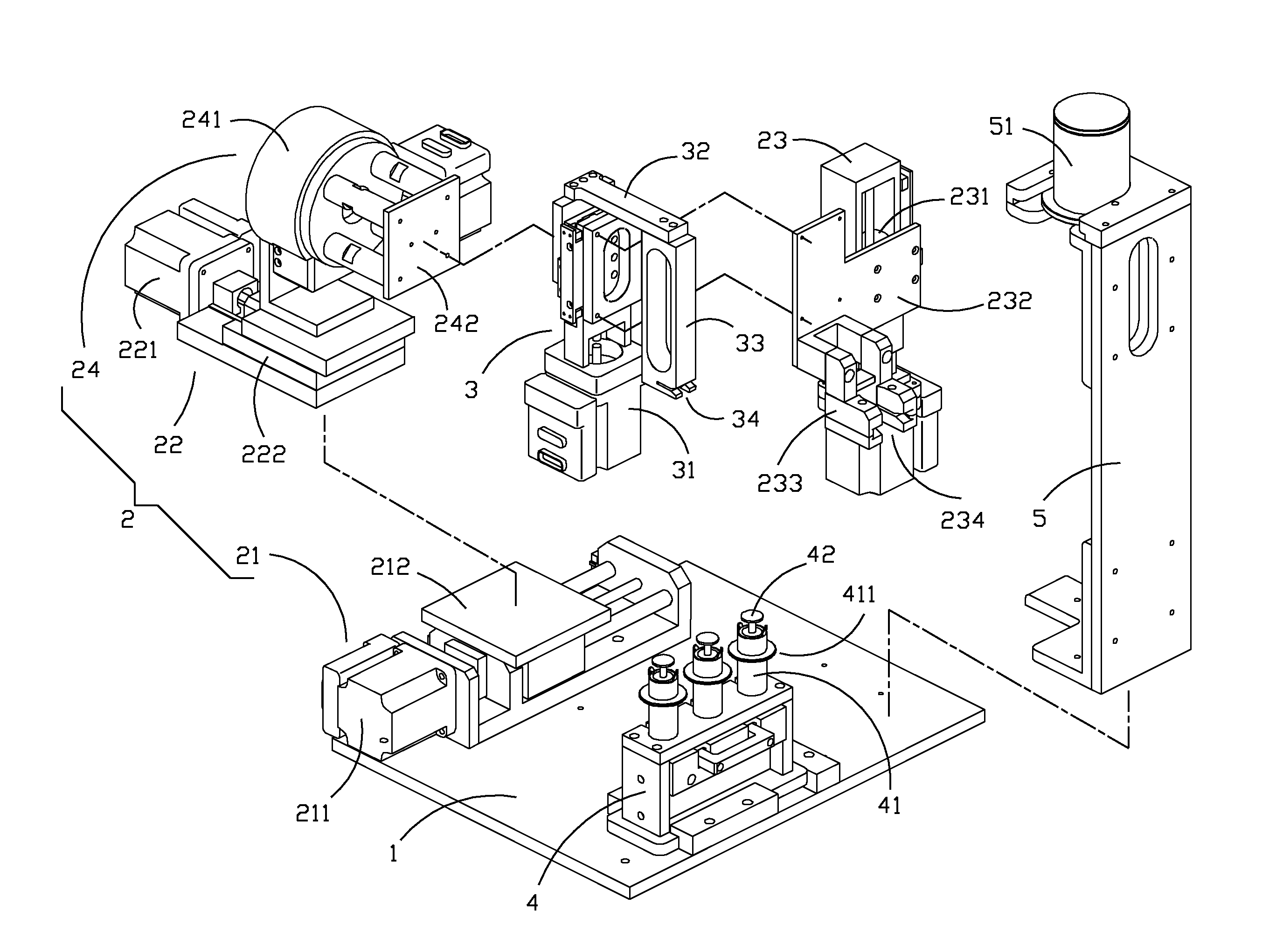

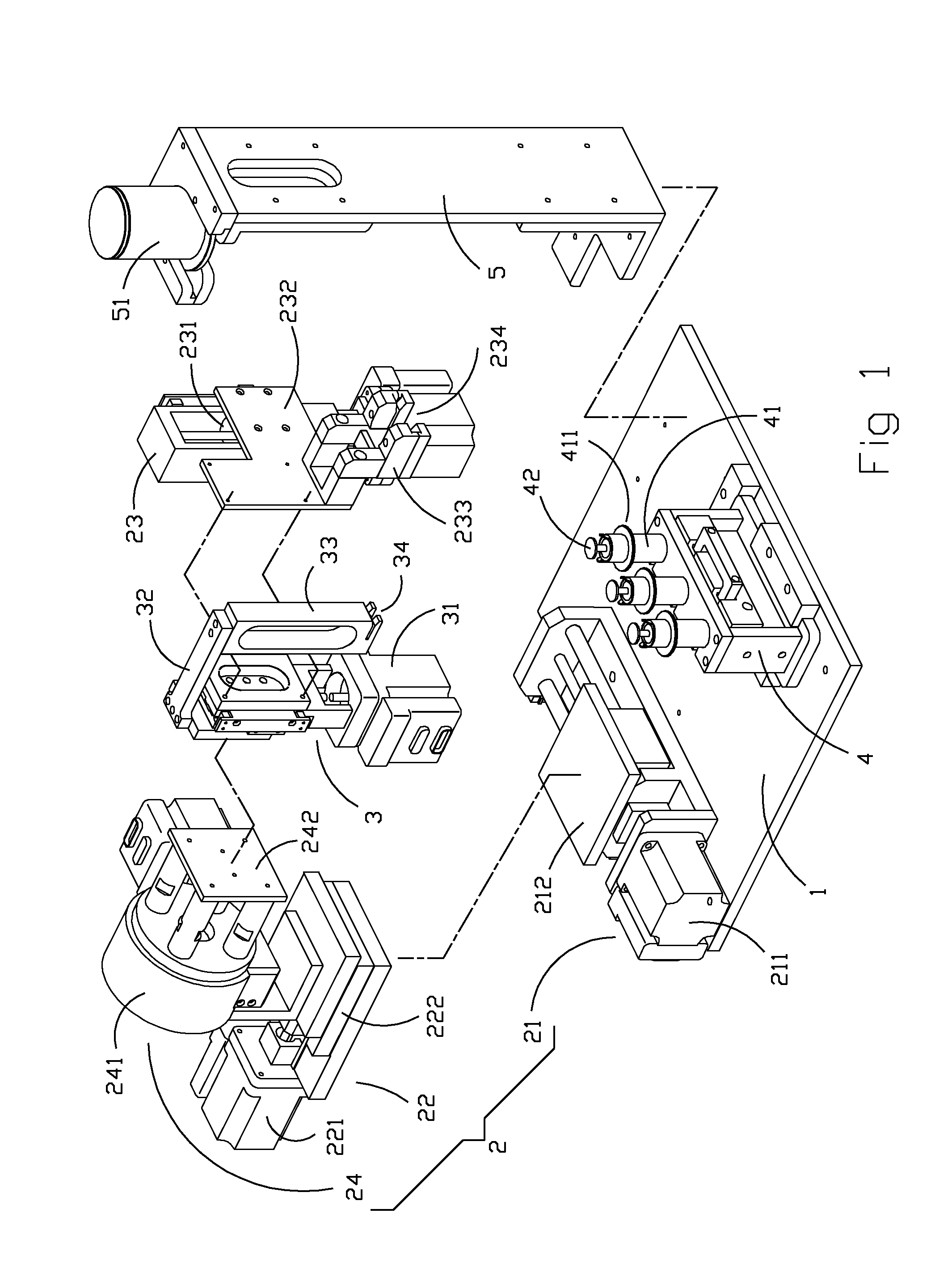

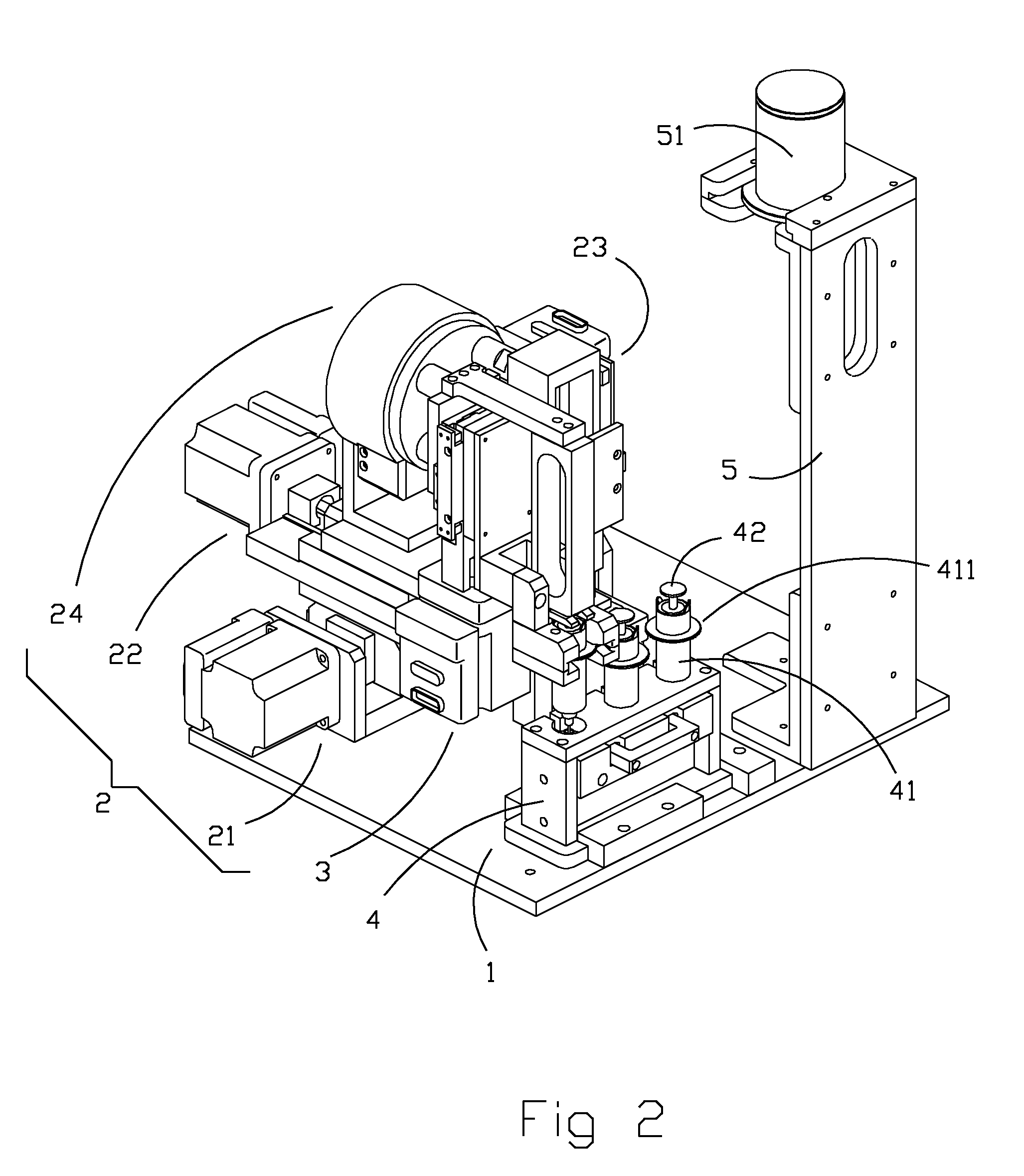

An automated dispenser for radiopharmaceuticals is mainly for a platform to have a moving mechanism being able to move three-dimensionally back and forth, a syringe holder and a bottle holder. The syringe holder is for holding a plural number of syringes. The bottle holder has a reverse drug bottle. The moving mechanism has a syringe clamp rotatable around a horizontal axis and a syringe driving mechanism. The syringe clamp is activated to hold a syringe and move it to where the syringe needle is inserted to the drug bottle. The syringe driving mechanism and the syringe clamp are simultaneously associated with the syringe for drug-withdrawing action.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Assembly machine for disposable syringe-driven filter

ActiveUS20130255051A1Increase productionRealize automated productionAssembly machinesLoose filtering material filtersEngineeringAssembly machine

An assembly machine for disposable syringe-driven filter, which comprises a rack and an automatic controller arranged on the rack, the automatic controller is electrically connected with a rotating table, a first automatic loading mechanism, an automatic filter disc-sucking mechanism, a second automatic loading mechanism, and an automatic unloading mechanism. By means of the first automatic loading mechanism, the automatic filter disc-sucking mechanism, the second automatic loading mechanism and the automatic unloading mechanism, as well as the automatic controller adapted thereto, the present invention can realize the automatic loading of the upper cover of disposable syringe-driven filter, the automatic placing of filter disc, the automatic loading and assembling of the lower cover of filter and the automatic unloading of the disposable syringe-driven filter, so that the automatic production of the disposable syringe-driven filter can be realized. The present invention is applicable to automatic production of the disposable syringe-driven filter.

Owner:GUANGZHOU JET BIOFILTRATION CO LTD

needle grinder

ActiveCN102267086ASolve efficiency problemsSolve for uniformityLapping machinesEngineeringGrinding wheel

The invention discloses a syringe-driven grinding machine which comprises a frame body, a knife-shaped rear pressing plate, a main plate, two cylinders, a tooling fixture angle turnover mechanism, a syringe needle fixture mechanism and an abrasion wheel grinding device, wherein the knife-shaped rear pressing plate, the main plate, the two cylinders, the tooling fixture angle turnover mechanism, the syringe needle fixture mechanism and the abrasion wheel grinding device are arranged on the frame body; the two cylinders fixed on the main plate are connected with a clamping shaft of the syringe needle fixture mechanism by an expansion link passing through a through hole on the main plate, and the clamping shaft is fixed on the rear pressing plate; the syringe needle fixture mechanism is arranged between the rear pressing plate and the main plate; and the main plate and the rear pressing plate are also connected with the tooling fixture angle turnover mechanism by which the main plate andthe rear pressing plate can be performed turnover inclining. By using the grinding machine disclosed by the invention, the effect of relatively increasing the number of the syringe needle clamped each time in a syringe needle grinding process and the purpose of automation can be achieved, and the defects that the grinding machine is low in production efficiency and the syringe needle is grinded unevenly are overcome.

Owner:温州奥昌米萨瓦医疗科技有限公司

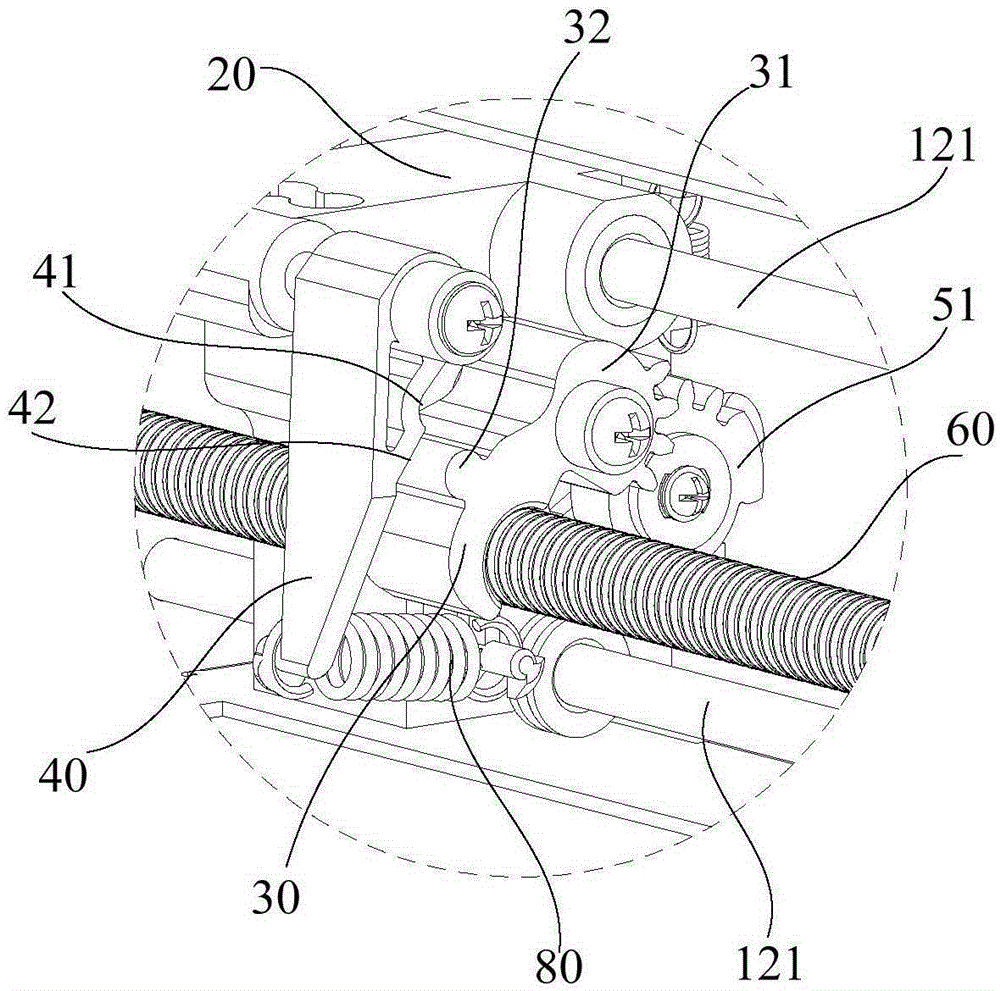

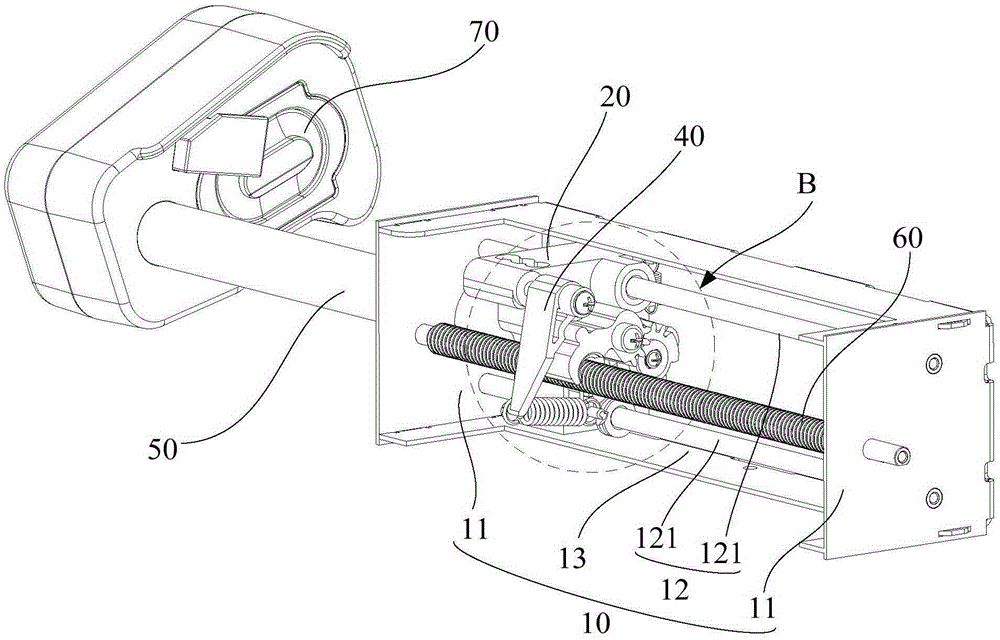

Syringe driving mechanism and injection pump

ActiveCN105288794AGuaranteed disengagementAvoid teeth grindingAutomatic syringesEngineeringInjection pump

The invention discloses a syringe driving mechanism and an injection pump, wherein the syringe driving mechanism comprises a stand, a sliding base, a split nut, a press block, a push rod and a screw rod which is arranged in a mode of being parallel with the push rod; the stand comprises two end plates and a guide component; the split nut is meshed with the screw rod; a driven piece and a limiting part are arranged on the peripheral wall of the split nut; the driven piece is connected to the sliding base in a rotatable mode; a rotating shaft of the driven piece is parallel with the screw rod; the press block is connected to and arranged on the sliding base; the press block is elastically propped against the limiting part; a clamping part, which is clamped and matched with the limiting part, is arranged on the press block; the sliding base is movably sleeved on the push rod, and the push rod is capable of undergoing a spinning motion relative to the sliding base; a driving piece, which is transmitted and matched with the driven piece, is arranged on the push rod, and the driven piece is rotated by the driving piece when the push rod is rotated; and the split nut is completely separated from the screw rod when the limiting part is clamped into the clamping part. Through the technical scheme of the invention, a phenomenon that the split nut and the screw rod are ground in an operation of adjusting the position of a push head, so that the safety of the injection pump is guaranteed.

Owner:深圳莫微医疗技术有限公司

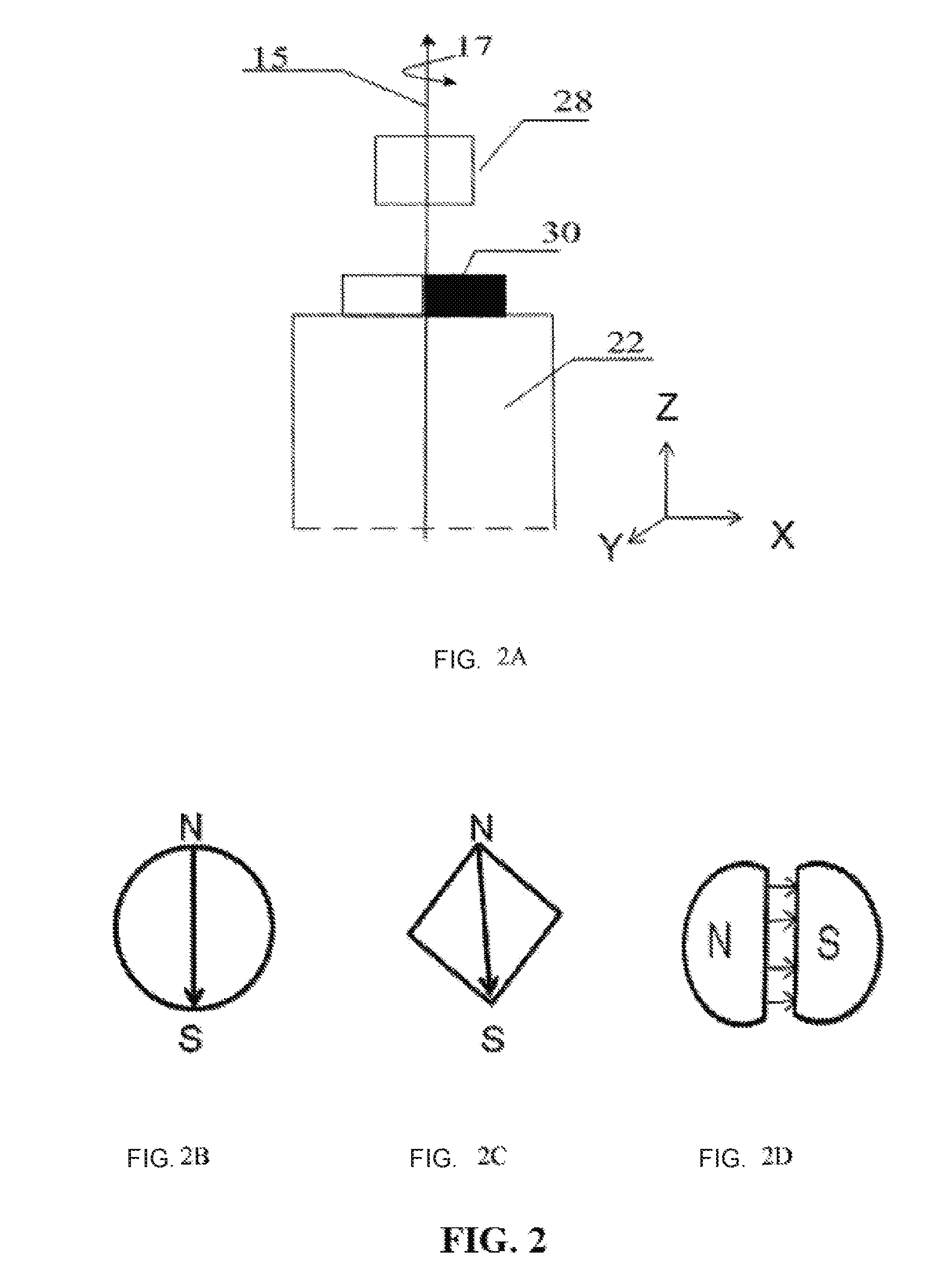

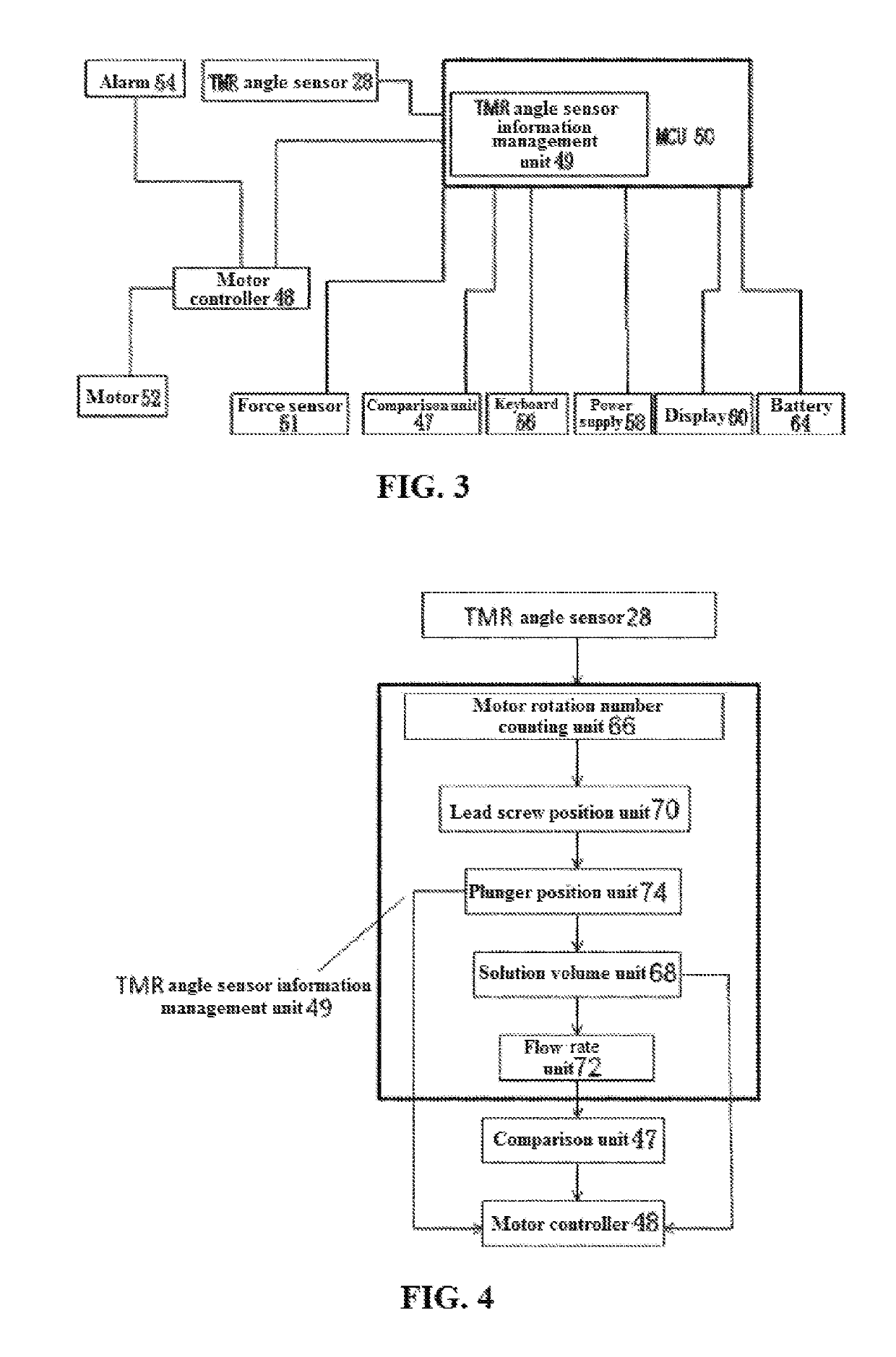

Precision syringe pump and manufacturing method thereof

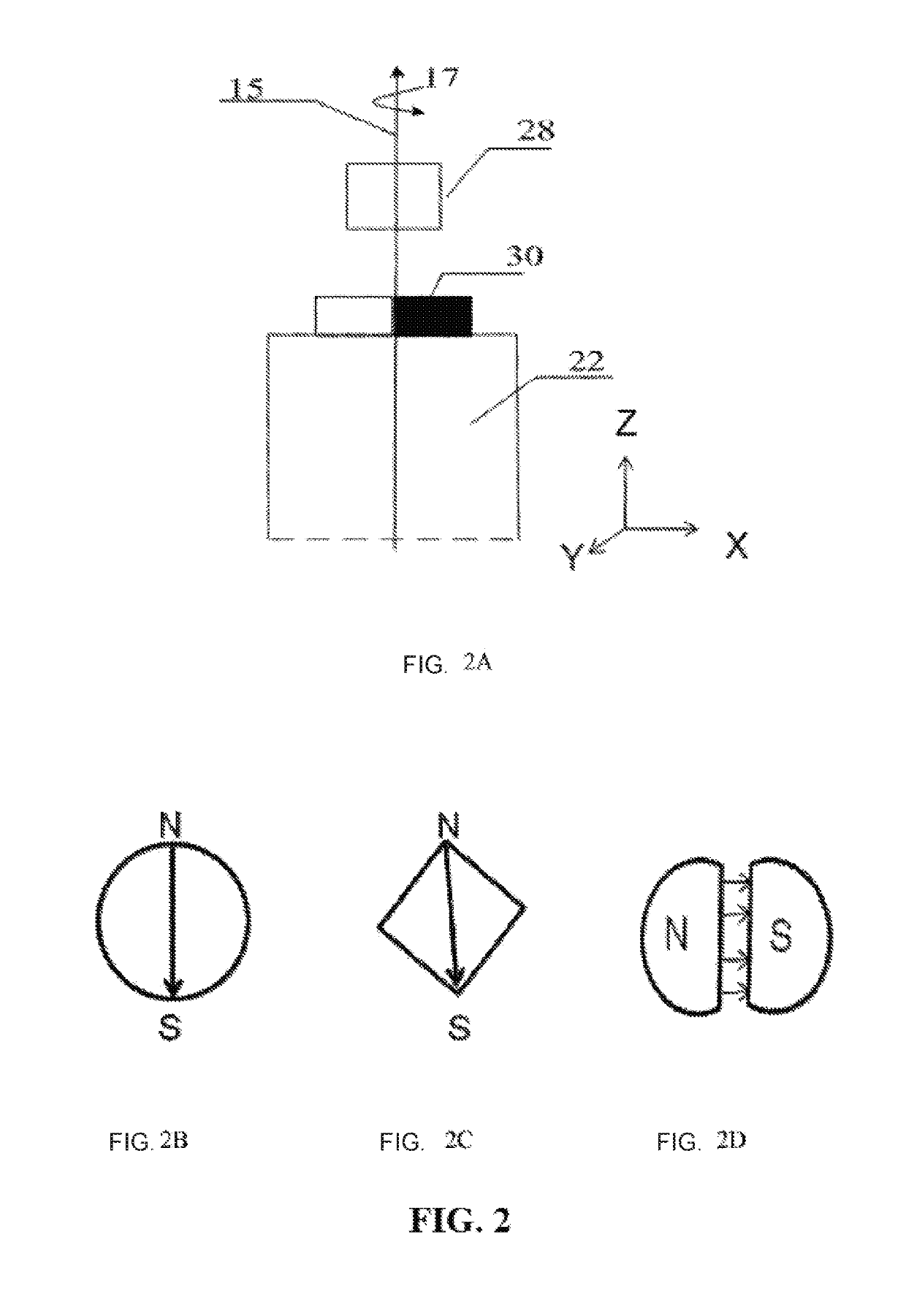

ActiveUS20170056581A1Improve precisionImprove reliabilityMedical devicesPressure infusionMotor driveEngineering

A precision syringe pump employing a syringe comprises a motor, a lead screw and a syringe driving head connected to the lead screw. The syringe comprises a cylinder and a plunger. The motor drives the lead screw to rotate clockwise or counterclockwise to drive the syringe driving head and push the plunger to move within the cylinder. The syringe pump further comprises: a magnetoresistive sensor, at least one permanent magnet and an MCU, the at least one permanent magnet being located on the lead screw and rotating therewith; the magnetoresistive sensor can sense the magnetic field generated by the at least one permanent magnet; the input end of the MCU is connected to the magnetoresistive sensor, and the output end of the MCU is connected to the motor; the MCU receives signals from the magnetoresistive sensor and controls, according to the signal feedback, the direction and velocity of the lead screw rotated by the motor. The precision syringe pump of the present invention is characterized by high sensitivity, high reliability, low power consumption and low cost, and is convenient to use.

Owner:MULTIDIMENSION TECH CO LTD

Automated dispenser for radiopharmaceuticals

ActiveUS8181677B2Reduce direct exposureIsotope delivery systemsRegistering devicesHorizontal axisBottle

An automated dispenser for radiopharmaceuticals is mainly for a platform to have a moving mechanism being able to move three-dimensionally back and forth, a syringe holder and a bottle holder. The syringe holder is for holding a plural number of syringes. The bottle holder has a reverse drug bottle. The moving mechanism has a syringe clamp rotatable around a horizontal axis and a syringe driving mechanism. The syringe clamp is activated to hold a syringe and move it to where the syringe needle is inserted to the drug bottle. The syringe driving mechanism and the syringe clamp are simultaneously associated with the syringe for drug-withdrawing action.

Owner:INST NUCLEAR ENERGY RES ROCAEC

Non-contact dispensing of liquid droplets

InactiveUS20090218412A1Maintain integrityMinimal amountLiquid surface applicatorsWatering devicesFree fallingEngineering

Apparatus and method for dispensing droplets of a liquid includes structure providing a passage along which the liquid may be delivered to form a droplet at an orifice. The structure is configured to propagate a shockwave to impact the droplet and thereby to displace it from the orifice, whereby the droplet is dispensed. The structure may provide an elongate passage to longitudinally receive a syringe needle positionable with its tip, and the orifice at the tip, at or adjacent on open end of the passage, one or more needle guides to locate the needle in the passage, which is of greater cross-section than the needle at the open end, and a seal arrangement to substantially seal the passage about the needle at a position displaced from the open end of the passage whereby to define a chamber between the position and the open end. A syringe drive device may have a head adapted to be coupled to a syringe and means to operate the syringe to dispense droplets by free-fall from the syringe tip orifice, and structure adapted to be selectively coupled to the head and / or to a syringe carried thereby.

Owner:SGE ANALYTICAL SCIENCE

Precision syringe pump and manufacturing method thereof

ActiveUS10238793B2Improve precisionImprove reliabilityMedical devicesPressure infusionMotor driveClockwise

Owner:MULTIDIMENSION TECH CO LTD

Syringe drive device

InactiveUS20120078180A1Improve workabilityReduce workloadAmpoule syringesAutomatic syringesEngineeringPiston

Owner:PANASONIC CORP

Syringe drive device

A syringe drive device drives a syringe including a cylindrical cylinder and a piston. The cylinder includes a solution supply port at one end, and an opening at the other end. The piston is inserted into the cylinder through the opening. The syringe drive device includes a cylinder holder to rotatably hold the cylinder of the syringe, and a piston driver to drive the piston in its axial direction with respect to the cylinder held in the cylinder holder.

Owner:PANASONIC CORP

Device used for replacing experimental tools and guaranteeing positioning accuracy for stereotaxic apparatus conveniently and rapidly and application method of device

The invention provides a device used for replacing experimental tools and guaranteeing the positioning accuracy for a stereotaxic apparatus conveniently and rapidly and an application method of the device. The device used for replacing the experimental tools and guaranteeing the positioning accuracy conveniently and rapidly comprises a stand column, a first driving shaft, a first driving sliding block, a connecting plate, a spindle head, a micro-syringe driving device and a guider, the first driving shaft and the guider are arranged at the two ends of the same side of the stand column respectively, the spindle head and the micro-syringe driving device are both fixedly arranged on the connecting plate, the connecting plate is fixedly connected with the first driving sliding block, and the first driving sliding block is arranged on the first driving shaft to slide. Through the spindle head adjustable in clamping range, clamping of the experimental tools of different types and different models is achieved. In addition, the guider, the spindle head and the micro-syringe driving device are used in a matched mode to guarantee the positioning accuracy of the experimental tools. The device solves the problem that in the traditional technology, a plurality of experimental clamping tools are needed, simplifies design of the clamping tools, and saves the troubles brought by the clamping tools, and meanwhile, the device is convenient to use, simple to operate and obvious in effect.

Owner:SHANDONG UNIV

Syringe drive device and medication dispensing device

InactiveCN102413807AEasy to operateStable supportAutomatic syringesPharmaceutical containersEngineeringSyringe needle

A syringe drive device (1) is provided with a syringe holding section (3), a piston operation section (4), and a display section (6). The outer tube (202) of a syringe (201) is removably held by the syringe holding section (3). The piston (203) of the syringe (201) is removably engaged with the piston operation section (4). The piston operation section (4) is moved in the direction corresponding to the operation of operation buttons (8A, 8B), and this causes the piston (203) to move in the direction in which the piston is pushed into or pulled out of the outer tube (202). The pressure within a medication solution container into which a syringe needle (204) mounted to the outer tube (202) of the syringe (201) is inserted is measured and displayed on the display section (6).

Owner:PANASONIC CORP

Syringe quick disconnect apparatus and related method

InactiveUS20150292495A1Flexible member pumpsPharmaceutical containersBiomedical engineeringSyringe Drive

A fluid metering system having a syringe assembly attachable to a syringe dock is provided. The fluid metering system also comprises a plunger assembly with the syringe assembly that has a plunger configured to aspirate a fluid into the syringe assembly and / or dispense a fluid contained in the syringe assembly. A driving portion of a syringe drive with the fluid metering system is attachable to the plunger assembly, wherein the driving portion is configured to actuate dispensing and / or aspirating of the fluid. A slot with the syringe dock is configured to accept the syringe assembly, and an end cap with the syringe assembly slidingly engages the slot.

Owner:NORGREN KLOEHN

Automatic liquid drug preparation apparatus for the preparation of a predetermined dosage of liquid drug

InactiveUS8316898B2Guaranteed mixInfusion syringesPharmaceutical containersFluid controlDrugs preparations

Owner:MEDIMOP MEDICAL PROJECTS

Syringe drive device

InactiveUS20120016303A1Easy to useImprove air purification effectAutomatic syringesInfusion devicesEngineeringPiston

A syringe drive device drives a syringe including a cylindrical cylinder and a piston. The cylinder includes a solution supply port at one end, and an opening at the other end. The piston is inserted into the cylinder through the opening. The syringe drive device includes a cylinder holder to rotatably hold the cylinder of the syringe, and a piston driver to drive the piston in its axial direction with respect to the cylinder held in the cylinder holder.

Owner:PANASONIC CORP

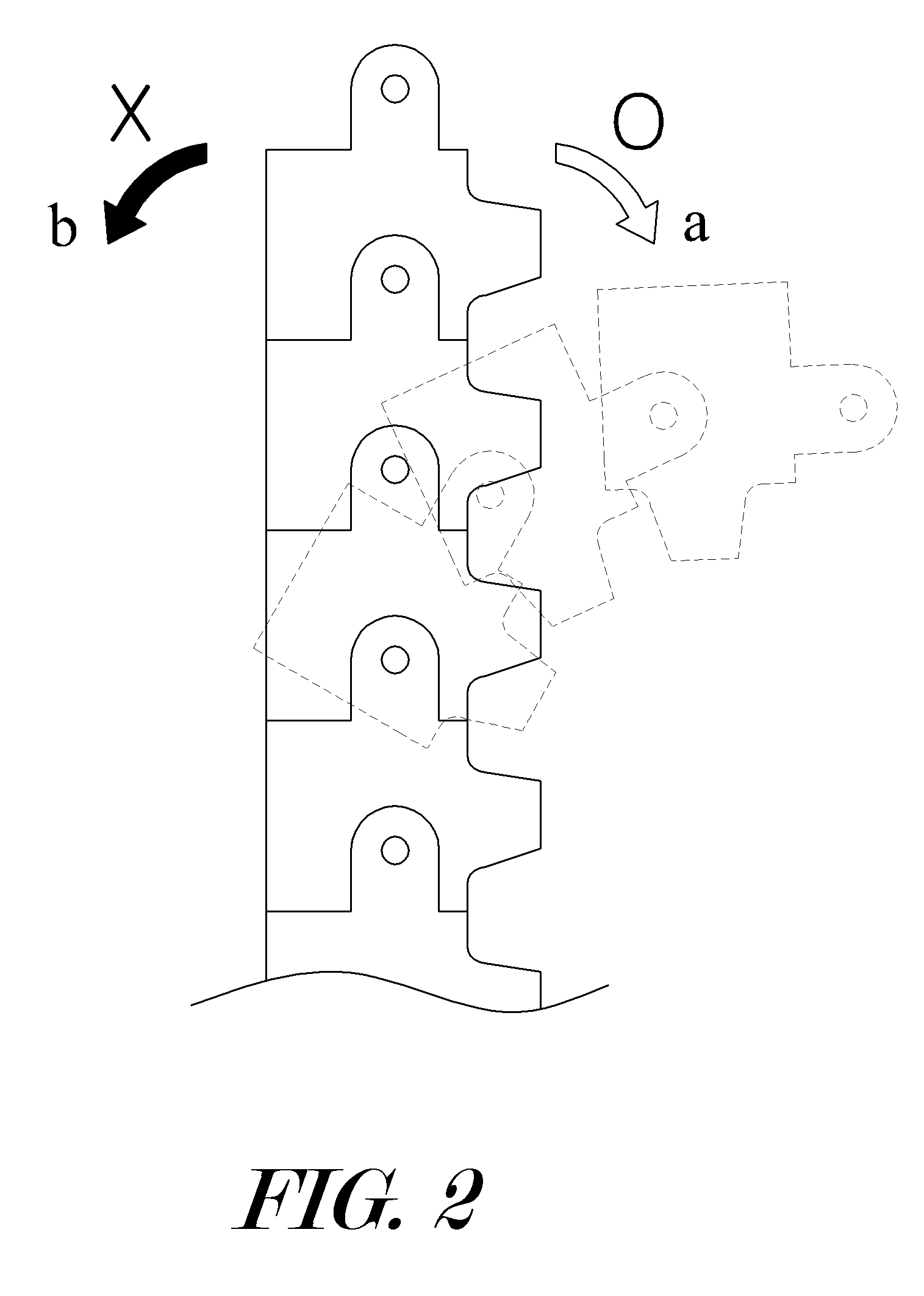

Injectors and syringe interfaces for syringes of variable size

A syringe interface for attaching syringes to a drive mechanism which includes a drive member to impart motion to a syringe plunger includes a plurality of syringe mount apertures having different dimensions to attach each of a plurality of syringes to the syringe interface. Each of the syringes for attachment to the syringe interface includes at least one mounting flange, and each of the plurality of syringes has a different mounting flange dimension. Each of the plurality of syringe mount apertures is in general alignment with an axis of the drive member. A syringe drive mechanism includes a syringe interface as described above. The syringe drive mechanism can further include a sensing system to sense which size of the plurality of syringes is mounted on the syringe interface. The syringe drive mechanism can also include a processor and a memory which are in operative communication with the drive member. The memory includes a control program stored therein. The processor is in communication with the sensing system so that the control program controls the drive member according to the syringe sensed to be attached to the syringe interface. A powered injector includes a drive member and a drive to deliver power to the drive member. A processor of the powered injector is in communication with the drive and with a memory in which at least one control program is stored. The control program includes instructions for control of the drive. The powered injector further includes a syringe interface as described above for attaching syringes to the powered injector so that the drive member can impart motion to a plunger slidably positioned within each of the syringes. The powered injector further includes a sensing system to detect which of the syringes is attached to the syringe interface. The sensing system is in communication with the processor so that the control program controls the drive in a manner determined by the syringe detected to be attached to the syringe interface.

Owner:BAYER HEALTHCARE LLC

Syringe drive device

InactiveUS20120330237A1Good adhesionEasy detachmentMedical devicesPressure infusionEngineeringFlange

A syringe drive device 15 according to the present invention includes: an outer tube fixing portion 31 that detachably fixes an outer tube 22 of a syringe 16; a plunger holder 21 that holds a plunger 17 of the syringe 16; and a drive portion that moves the plunger holder 21 along an axis of the syringe. The outer tube fixing portion 31 includes: a flange catcher 33 facing a rear end of a flange 22a of the outer tube 22, the rear end being located far from the plunger 17 to be pushed; slide portions 34 and 35 that are located in front of a front end of the flange 22a to hold the flange 22a between the flange catcher 33 and the slide portions, the front end being located close to the plunger 17 to be pushed; slide guides 36 and 37 that support the slide portions 34 and 35 so as to be slidable along the axis of the syringe; and a slide portion operation mechanism that is switchable between a first state where the slide portions 34 and 35 slide along the axis of the syringe, and a second state where the slide portions 34 and 35 are held at positions to hold the flange 22a between the flange catcher 33 and the slide portions.

Owner:PANASONIC CORP

Instrument and method for nucleic acid isolation

InactiveUS20090099350A1Avoid distractionAvoid stickingIon-exchange process apparatusSugar derivativesFluid levelInstrumentation

According to this invention, an instrument and a method for nucleic acid isolation is realized, whereby it is possible to prevent, for example, adherence of a discharged solution upon dispersion of such solution to the vicinity of a nucleic acid isolation column outlet.A light source unit and a light-receiving unit that receives totally reflected light of the photosensor 41 for detecting the fluid level are placed on a site on the side surface of the nucleic acid isolation column 35, where the photosensor can detect the fluid level corresponding to a remaining liquid volume of approximately 10 ul. In addition, the light source unit of the photosensor 41 is positioned in a manner such that incident light is totally reflected from the interface between the nucleic acid isolation column 35 and air in the nucleic acid isolation column 35 and light is allowed to be incident in the solution when reaching the interface between the nucleic acid isolation column 35 and the solution in the nucleic acid isolation column 35. The light-receiving unit of the photosensor 41 is positioned in a manner such that it receives the totally reflected light and is fixed on the upper part of the nucleic-acid-adsorptive solid phase 24. The fluid level detection sensor is in communication with a syringe-driving motor 34 via a control unit 40 such that a syringe 31 is driven upward when the fluid level reaches a predetermined level, provided that a certain volume of the liquid remains in the nucleic acid isolation column 35. Accordingly, dispersion of the dispersed liquid is prevented.

Owner:HITACHI HIGH-TECH CORP

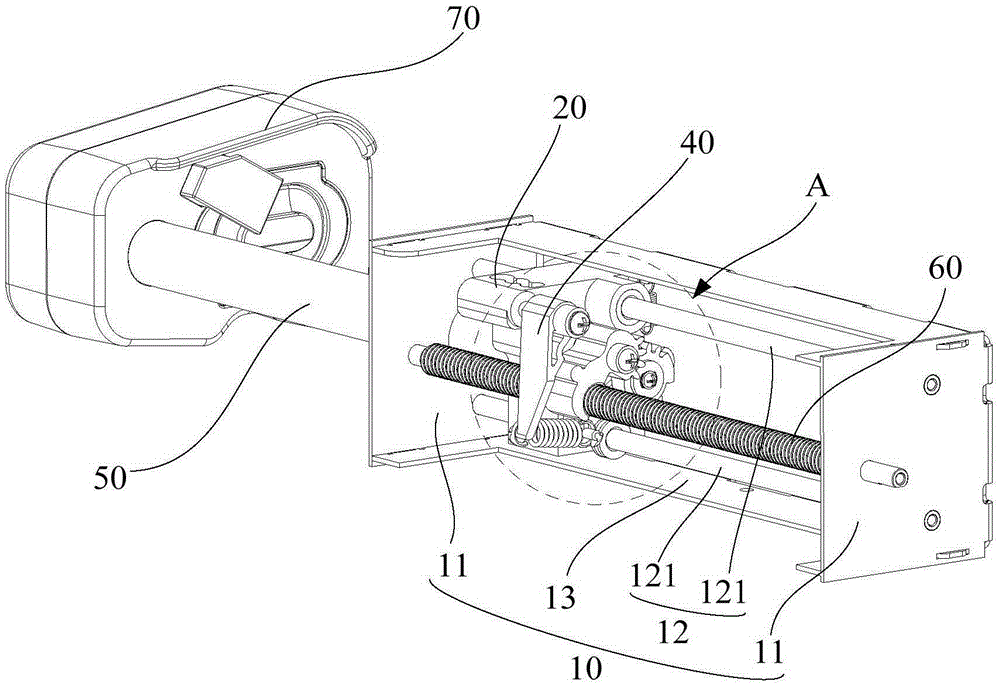

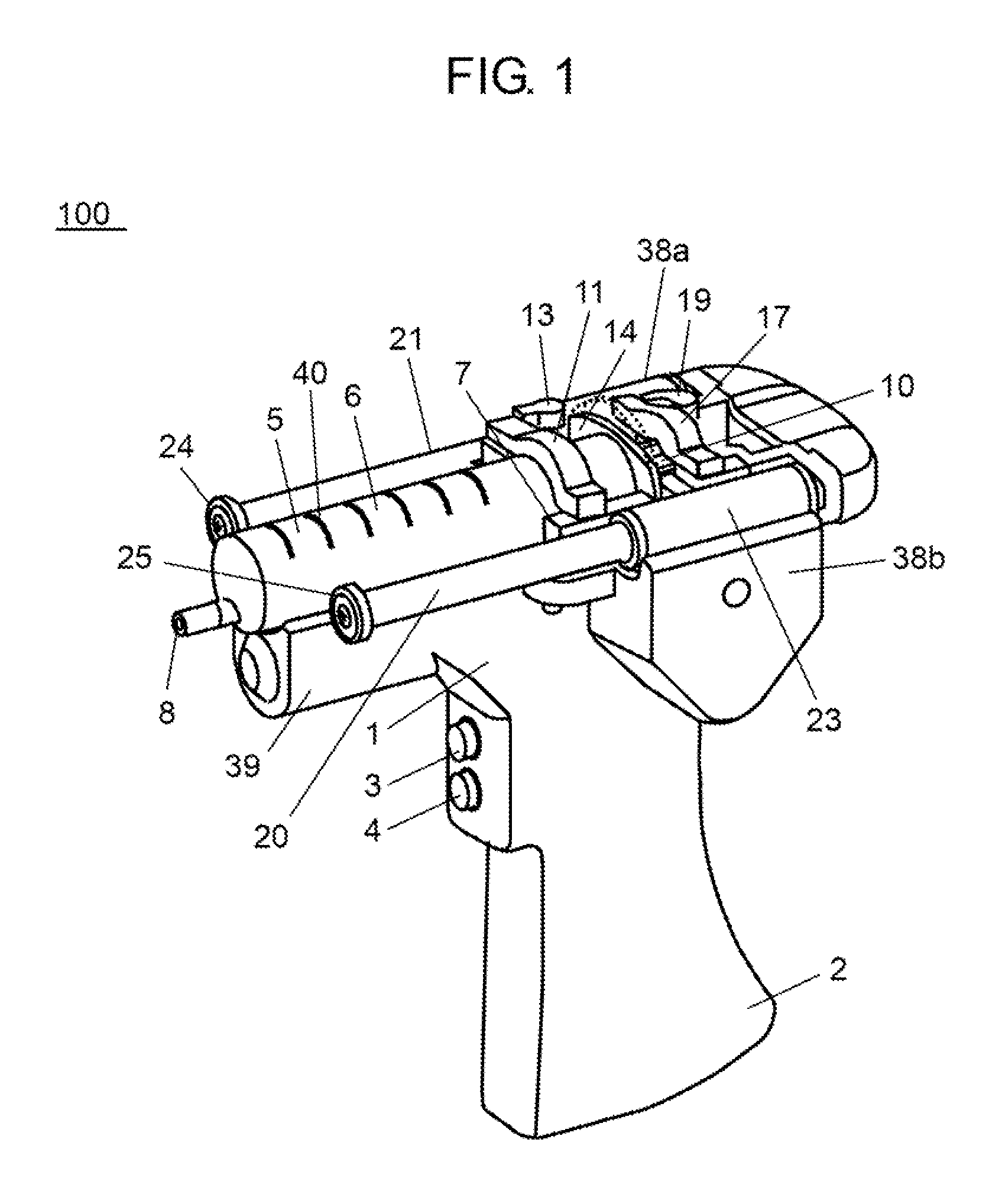

Length-reducing syringe driving device

InactiveUS20170049968A1Easy to carryShorten the lengthAutomatic syringesInfusion devicesRisk strokeBiomedical engineering

Disclosed herein is a length-reducing syringe driving device, the length-reducing syringe driving device wherein a drive for syringe device is installed at a syringe device (10), and pushes and drives a piston (12) equipped at an injection cartridge (11) which has a discharging outlet (13) at one dead end thereof.The length-reducing syringe driving device (100) comprises: a rotation driving part (110) installed at one or more places at an outer sidewall surface at the other dead end of the injection cartridge (11); and a one-way bending member (120) provided to be contacted to the piston (12) at one dead end thereof, configured to be bended exclusively to one direction, and having a sidewall surface of a bending direction driven by the rotation driving part (110) and pushing the piston (12).In the present invention, main elements of the invention are disposed at an outer sidewall surface of an injection cartridge and the entire length (L) of a driving device is remarkably reduced when having the same stroke. Therefore, it is to provide a syringe device which is convenient to be carried and to make syringe devices having many different embodiments possible.

Syringe drive device and medication dispensing apparatus

InactiveUS8529509B2Readily aspiratedEasy to operateAutomatic syringesPharmaceutical containersInternal pressureBiomedical engineering

A syringe drive device 1 includes: a syringe holding section 3; a piston manipulating section 4; and a display section 6. An outer tube 202 of a syringe 201 is detachably held by the syringe holding section 3. A piston 203 of the syringe 201 is detachably engaged with the piston manipulating section 4. The piston manipulating section 4 moves in a direction in response to an operation of operation buttons 8A and 8B, and the piston 203 is thereby moved in a direction where the piston is pushed into or pulled out from the outer tube 202. An internal pressure of a medicinal solution container punctured with an injection needle 204 attached to the outer tube 202 of the syringe 201 is measured and displayed on the display section 6.

Owner:PANASONIC CORP

Liquid mixing device for automatic dispensing

InactiveCN104997633BSimple structureCompact layoutPharmaceutical containersMedical packagingDrug productBiomedical engineering

The invention relates to a liquid mixing device for automatic dispensing, comprising a storage mechanism for a dispensing syringe, used for placing the dispensing syringe and transporting the dispensing syringe to a set extraction station; and an extraction mechanism for the dispensing syringe , for extracting the syringe for dispensing from the storage mechanism from the extraction station and transferring it to the clamping station; and the clamping mechanism for the syringe for dispensing, the clamping mechanism for the syringe for dispensing is installed on the The conveying mechanism of the syringe is used to position and clamp the syringe for dispensing at the clamping station; and the conveying mechanism of the syringe for dispensing is used to transport the clamping mechanism of the syringe for dispensing to the clamping station, Or the ampoule station, or the mother solution station and the vial station, drive the syringe for dispensing through the clamping mechanism of the syringe for dispensing to mix the drug in the ampoule or / and vial with the mother solution, and prepare the required medicinal solution . It reduces the work intensity of dispensing staff and improves work efficiency.

Owner:THE SECOND AFFILIATED HOSPITAL ARMY MEDICAL UNIV

Syringe driving apparatus

ActiveCN108379698AReduce cleaningReduced maintenance needsAutomatic syringesMedical devicesGeneral surgerySyringe Drive

A syringe driving apparatus includes a housing, a driving member disposed in the housing and a resilient member connected between the housing and the driving member. The housing is configured to attach a syringe thereon. The driving member is movable relative to the housing between the front end and the back end. Movement of the driving member towards the back end resiliently deforms the resilientmember to store resilient potential energy, and upon release of the resilient potential energy, the resilient member moves the driving member towards the front end of the housing to press a plunger to expel medicine out of the syringe.

Owner:EPIC MEDICAL PTE LTD

Micro atomizer

A micro atomizer to produce stable aerosol concentrations having an aerosol mass median aerodynamic diameter (MMAD) of less than 10 microns with liquid flow rates in the microliter per minute range is provided. The micro atomizer includes a liquid channel in the shape of a thick-wall tube and a cap having an aerosol outlet orifice whereby a liquid-gas contact space is formed by the internal surface of the cap and the substantially flat end of the liquid channel. Pressurized carrier gas and the liquid to be aerosolized are allowed to come into contact within a precisely formed liquid-gas contact space. The desired aerosol characteristics are accurately established, stable, and reproducible. In an exemplary embodiment, the micro atomizer is used with a syringe and syringe drive to provide a continuous liquid source for aerosol generation.

Owner:UNITED STATES OF AMERICA

Syringe drive device

InactiveUS8690828B2Improve workabilityReduce workloadAmpoule syringesAutomatic syringesEngineeringPiston

A syringe drive device 1 includes a cylinder holding section 3 configured to detachably hold a cylinder 201, a piston manipulating section 4 detachably coupled with a piston, and a piston drive section 5 including racks 31A and 31B coupled with the piston manipulating section 4 and configured to move the piston manipulating section 4 so that a piston 202 is moved in a push-in direction or a pull-out direction. A cylinder 200A having a given capacity (for example, 50 cc) is directly loaded in the syringe drive device 1 with no adapter therebetween. A syringe 200C having a different capacity (for example, 20 cc) is loaded in the syringe drive device 1 by means of a cylinder adapter 81 and a piston adapter 82.

Owner:PANASONIC CORP

A flow cytometer fluid system and flow cytometry detection method

ActiveCN104127192BPush sample flow is smoothExtended service lifeDiagnostic recording/measuringSensorsBlood collectionDrive motor

Owner:SHENZHEN DYMIND BIOTECH

Syringe Drive Mechanism and Syringe Pump

ActiveCN105288794BGuaranteed disengagementAvoid teeth grindingAutomatic syringesInjection pumpSyringe Drive

The invention discloses a syringe driving mechanism and an injection pump, wherein the syringe driving mechanism comprises a stand, a sliding base, a split nut, a press block, a push rod and a screw rod which is arranged in a mode of being parallel with the push rod; the stand comprises two end plates and a guide component; the split nut is meshed with the screw rod; a driven piece and a limiting part are arranged on the peripheral wall of the split nut; the driven piece is connected to the sliding base in a rotatable mode; a rotating shaft of the driven piece is parallel with the screw rod; the press block is connected to and arranged on the sliding base; the press block is elastically propped against the limiting part; a clamping part, which is clamped and matched with the limiting part, is arranged on the press block; the sliding base is movably sleeved on the push rod, and the push rod is capable of undergoing a spinning motion relative to the sliding base; a driving piece, which is transmitted and matched with the driven piece, is arranged on the push rod, and the driven piece is rotated by the driving piece when the push rod is rotated; and the split nut is completely separated from the screw rod when the limiting part is clamped into the clamping part. Through the technical scheme of the invention, a phenomenon that the split nut and the screw rod are ground in an operation of adjusting the position of a push head, so that the safety of the injection pump is guaranteed.

Owner:深圳莫微医疗技术有限公司

High-pressure syringe driving device with flexible shaft connection

PendingCN107126598ALarge thrustIncrease powerAutomatic syringesMedical devicesGear wheelElectric machine

The invention discloses a high-pressure syringe driving device with flexible shaft connection. The high-pressure syringe driving device comprises a shielding case, a motor, a flexible shaft, a flexible shaft fixing screw sleeve, a bent tube assembly, a driving gear, a transmission gear and a pair of lead screws, wherein the shielding case is made of a metallic material through enclosing, the motor is arranged in the shielding case and is shielded, one end of the flexible shaft is correspondingly connected with an output shaft of the direct-current motor, the flexible shaft fixing screw sleeve is used for correspondingly fixing the flexible shaft to the output shaft of the motor, the bent tube assembly sleeves the outer side of the flexible shaft and at least comprises one bend, the driving gear is in fit with the other end of the flexible shaft, the transmission gear is engaged with the driving gear, and the lead screws are in fit with the center of the transmission gear. According to the high-pressure syringe driving device, the motor can be used in an MRI nuclear magnetic environment and can meet the requirements of a thrusting rod on relatively high thrust during needle cylinder thrusting, the power and torque are relatively high, and the reliability is high.

Owner:NANJING JUSHA DISPLAY TECH +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com