Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52 results about "Joint spacer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Knee Joint Spacer (UniSpacer™) The UniSpacer™ is a small, minimally invasive device made of cobalt chrome that fits between the natural bone structures of the knee and stays in place without bone cement or screws. It is geometrically designed to center itself and follow the normal motion of each individual’s knee.

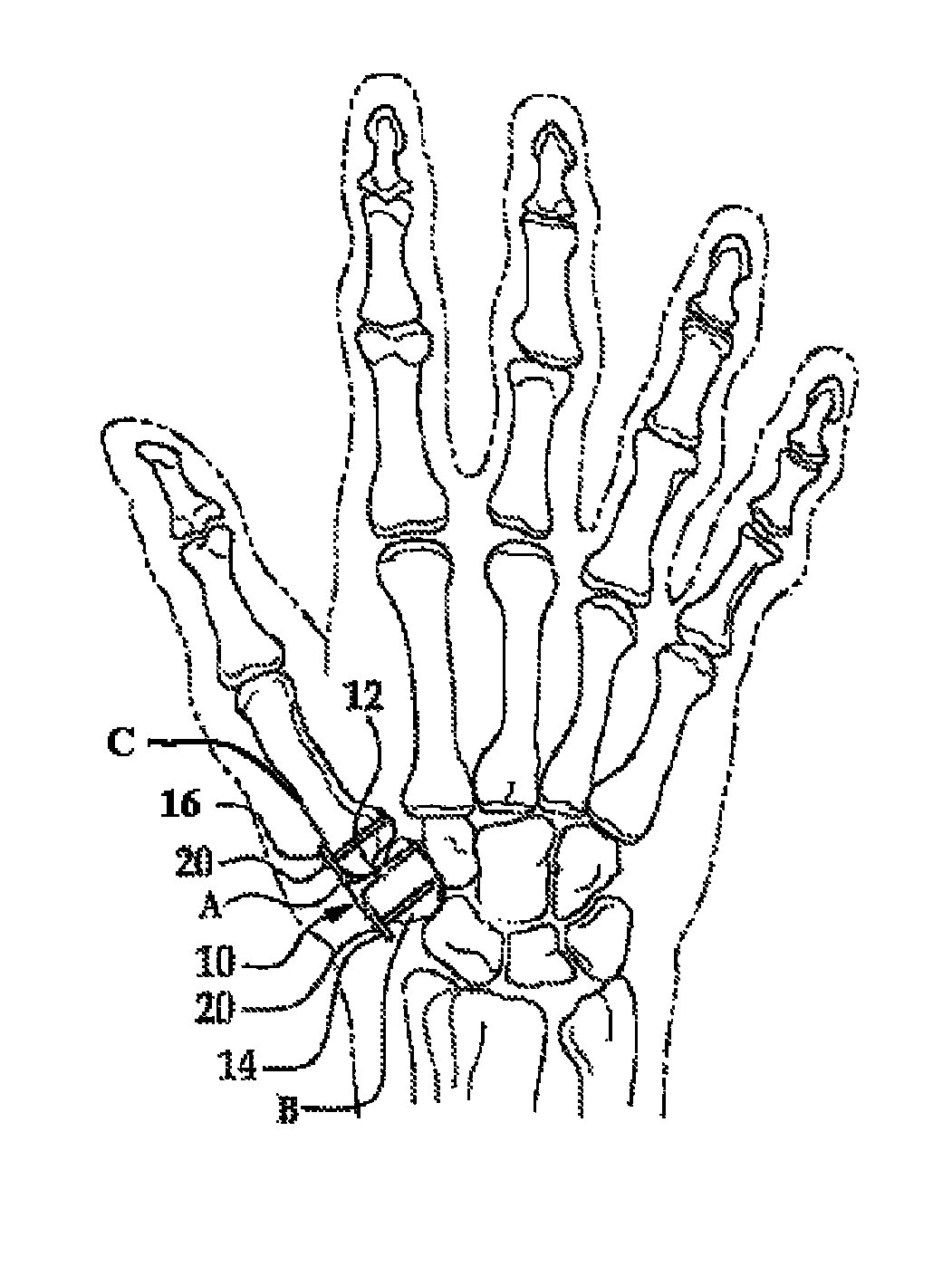

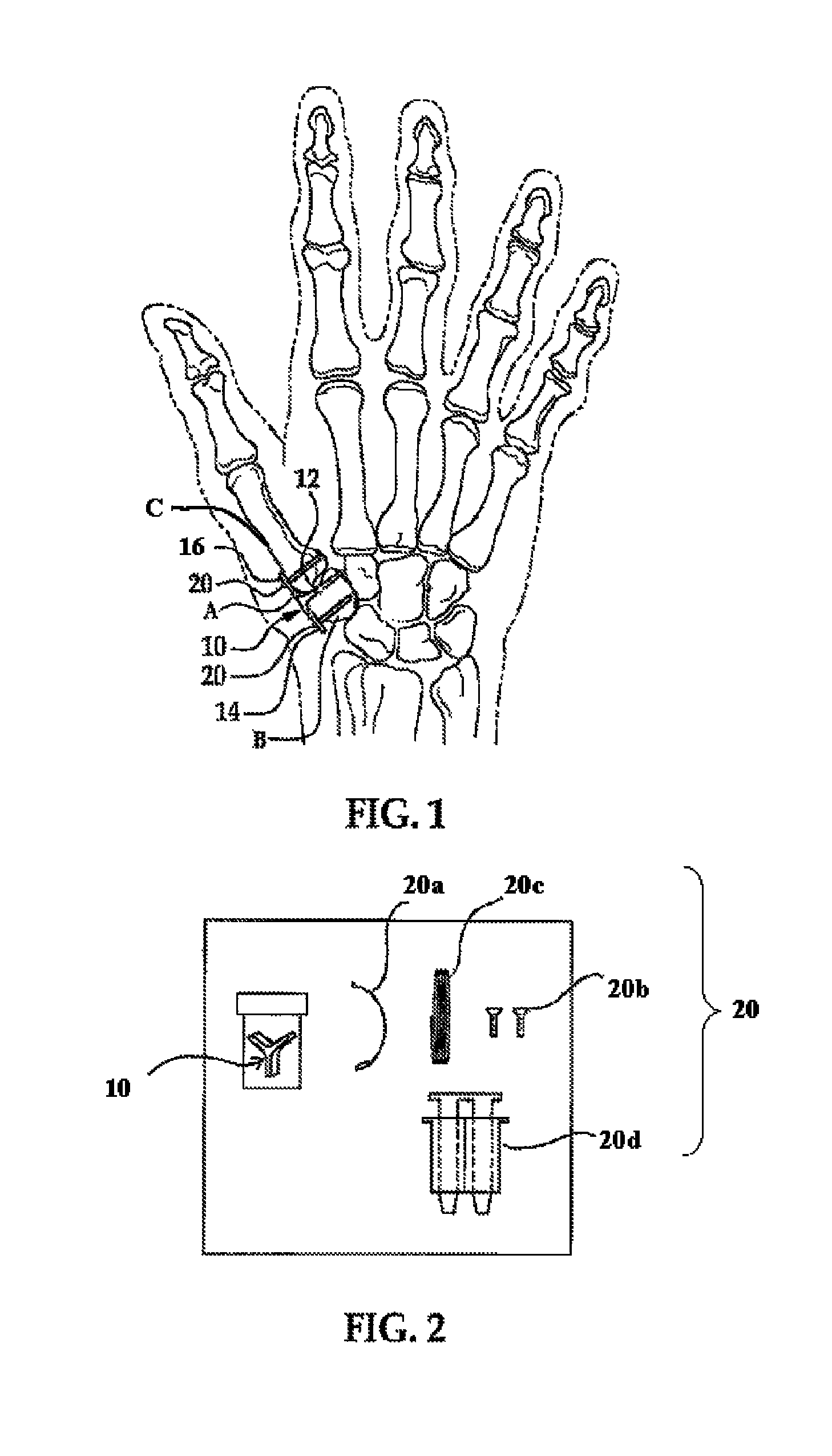

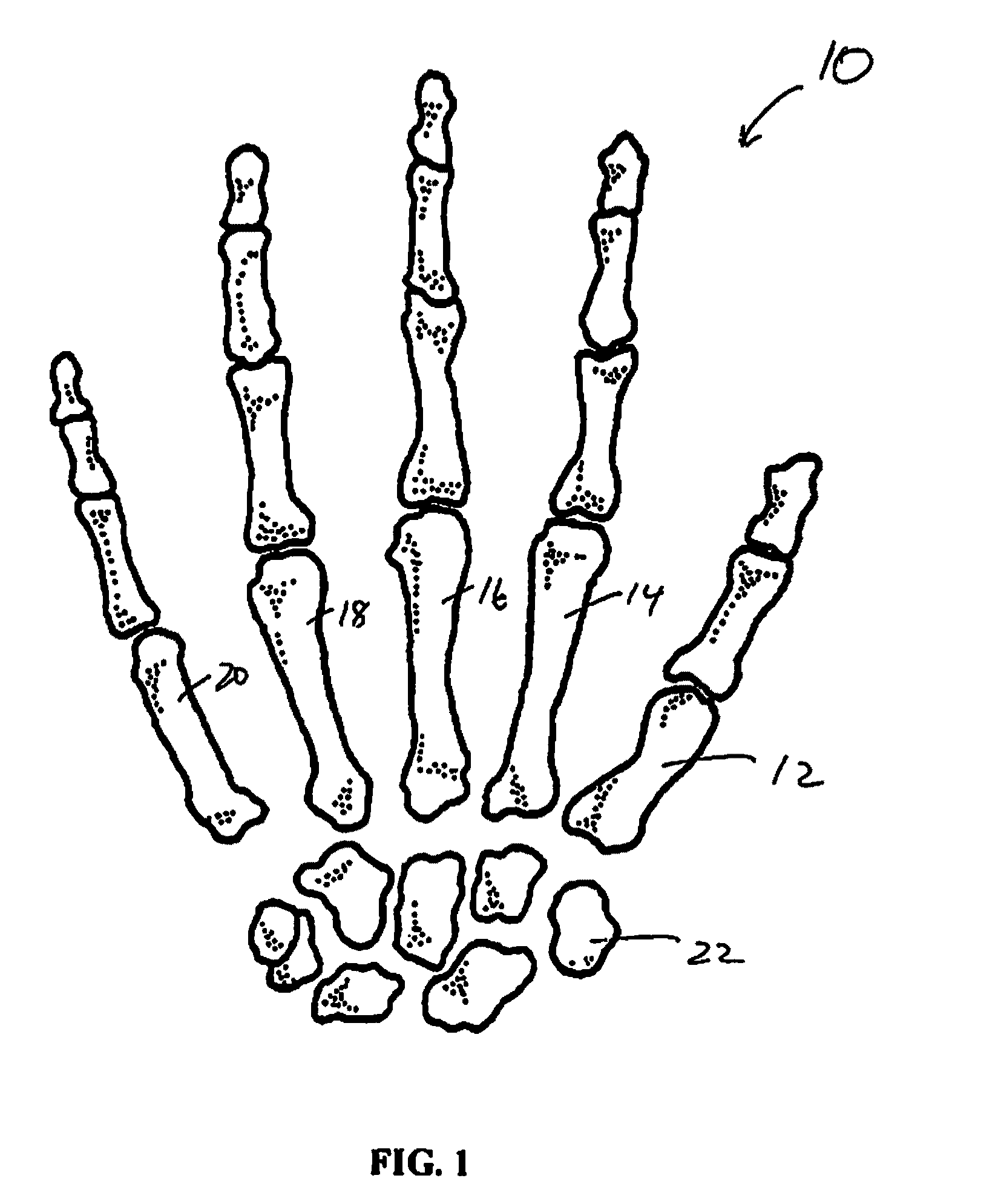

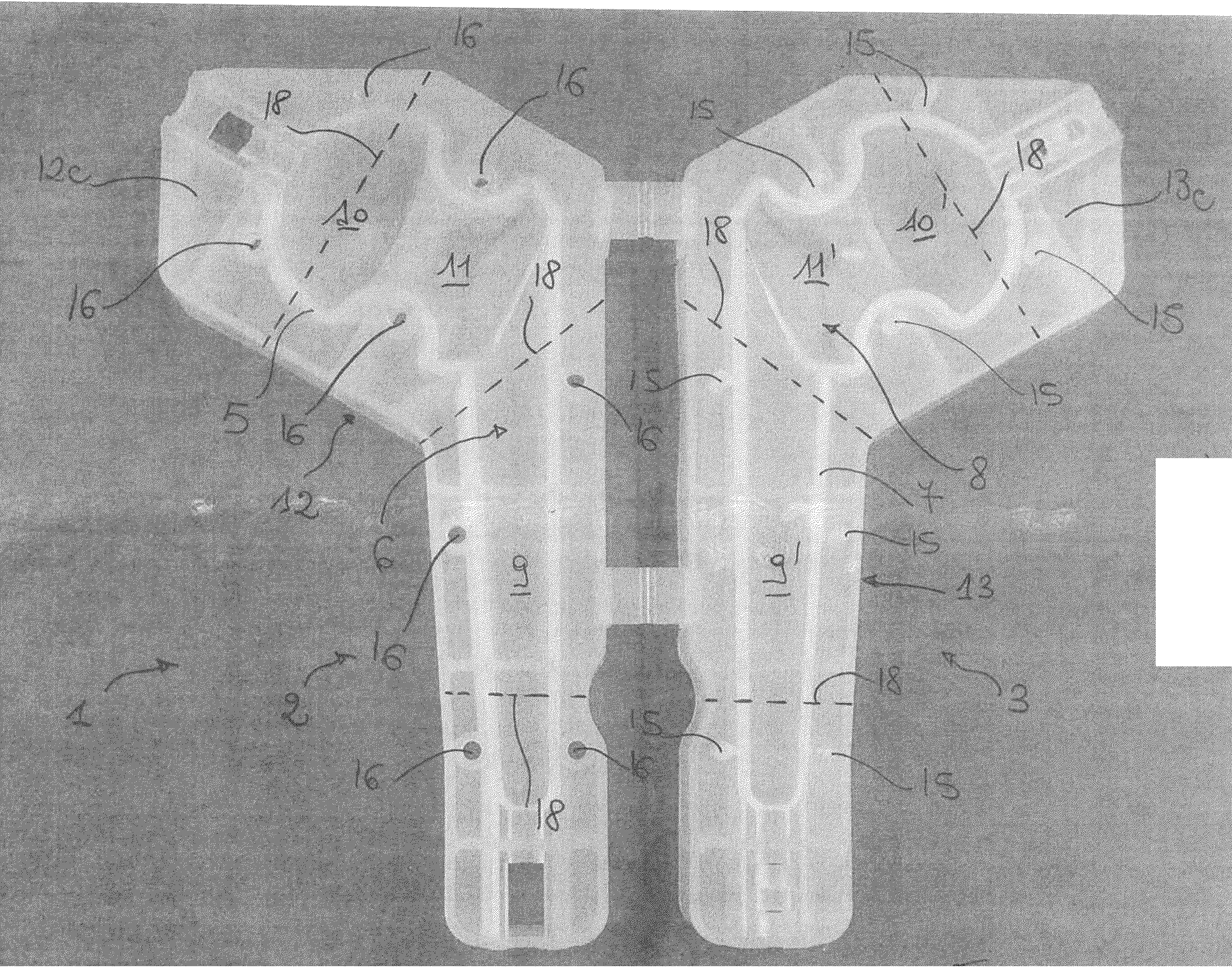

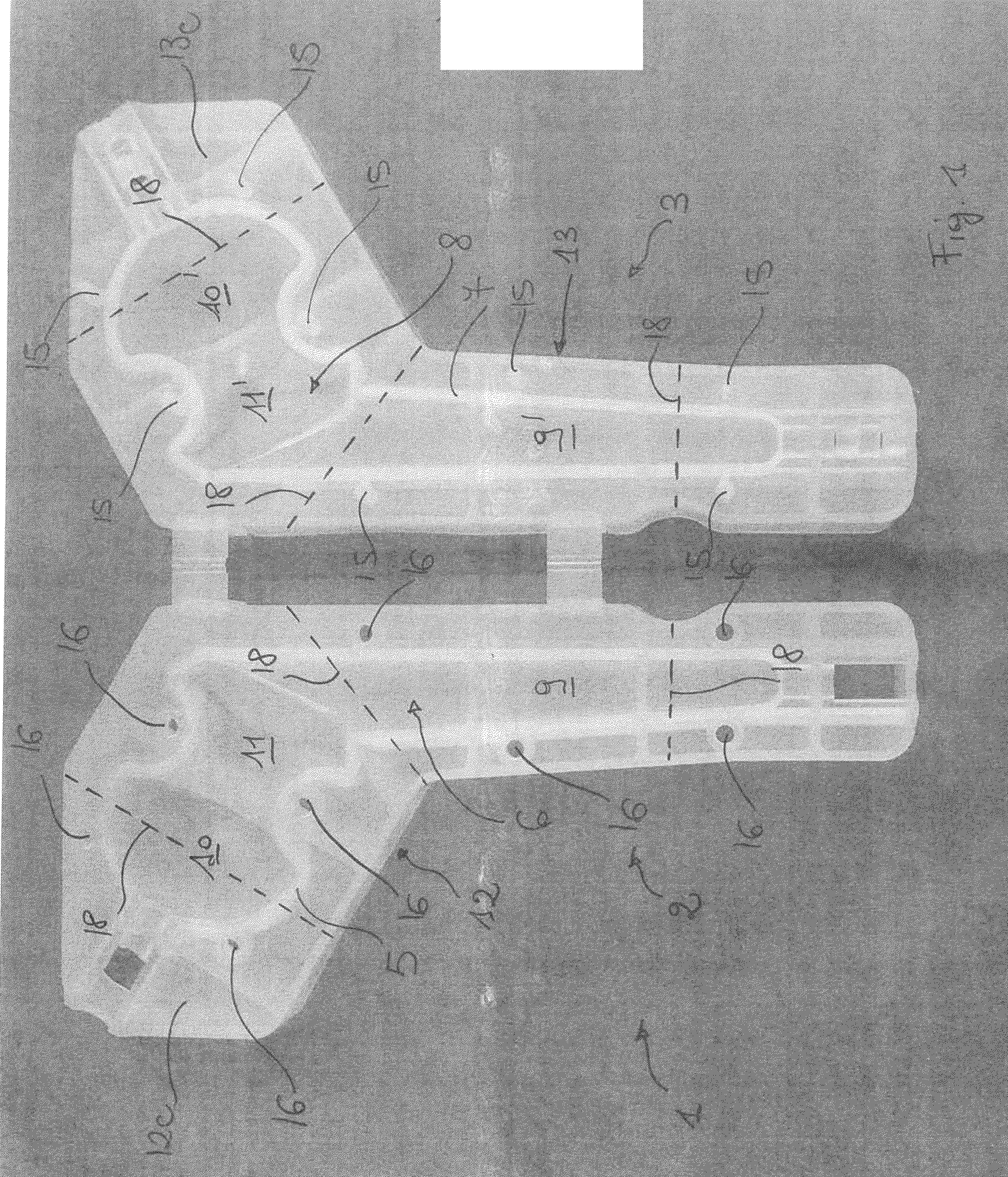

Surgical technique using a contoured allograft cartilage as a spacer of the carpo-metacarpal joint of the thumb or tarso-metatarsal joint of the toe

A spacer for implantation into a subject is provided that includes a sterilized piece of cartilaginous allograft tissue. The piece forms a Y-shape with a base adapted to insert within a first carpo-metacarpal joint or carpo-metatarsal joint of the subject, and has a first arm adapted to secure to a trapezium bone adjoining the joint, and a second arm adapted to secure to a proximal metacarpal or metatarsal bone adjoining the joint. A procedure for implanting the spacer includes exposing a target joint and abrading a bone surface interior to the joint to induce surface bleeding. The spacer base is then inserted into the joint. The spacer first arm is adhered to the first bone of the joint and the spacer second arm is adhered to the second bone of the joint. A kit is also provided for surgical implantation of the spacer.

Owner:SHAPIRO PAUL S

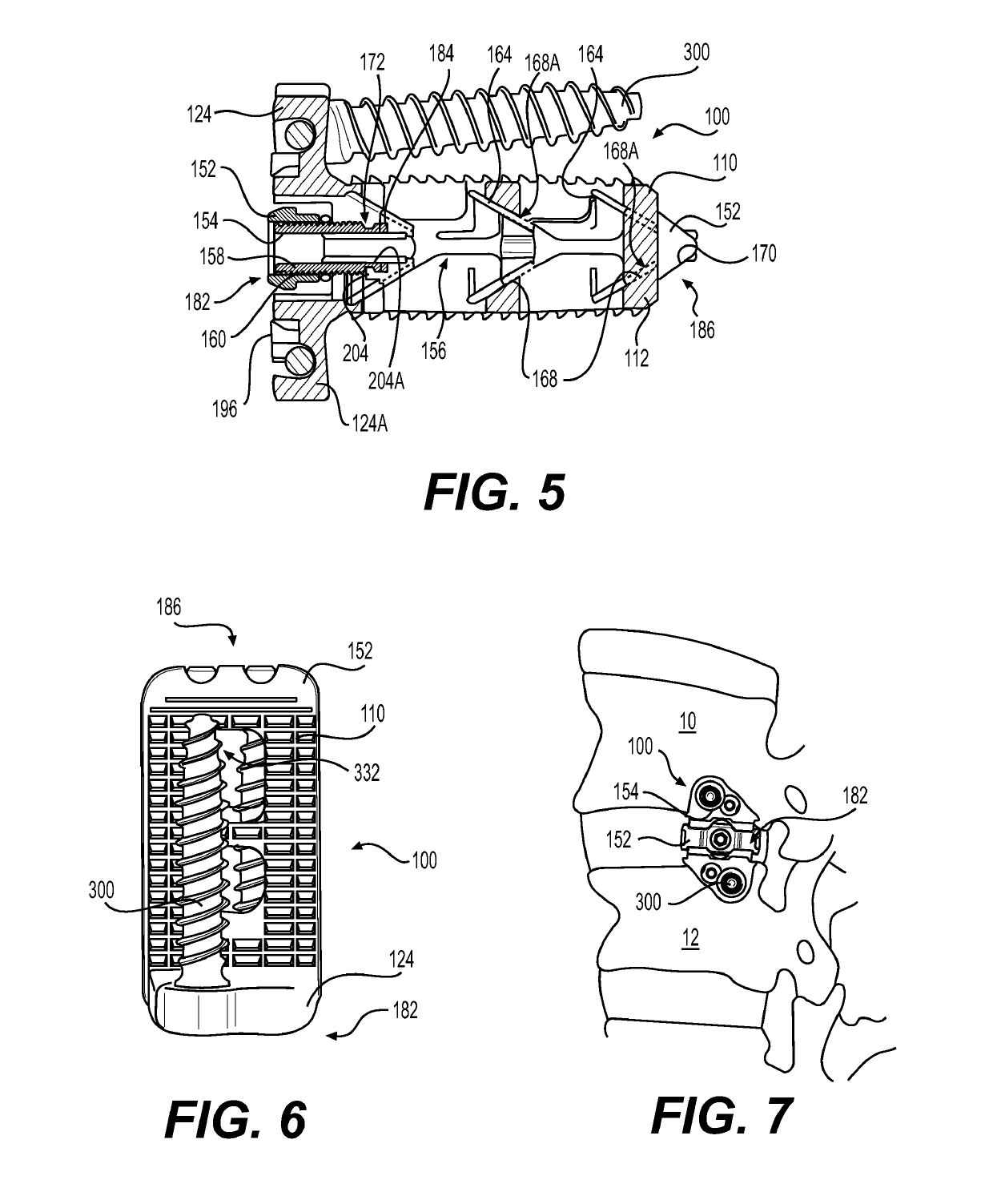

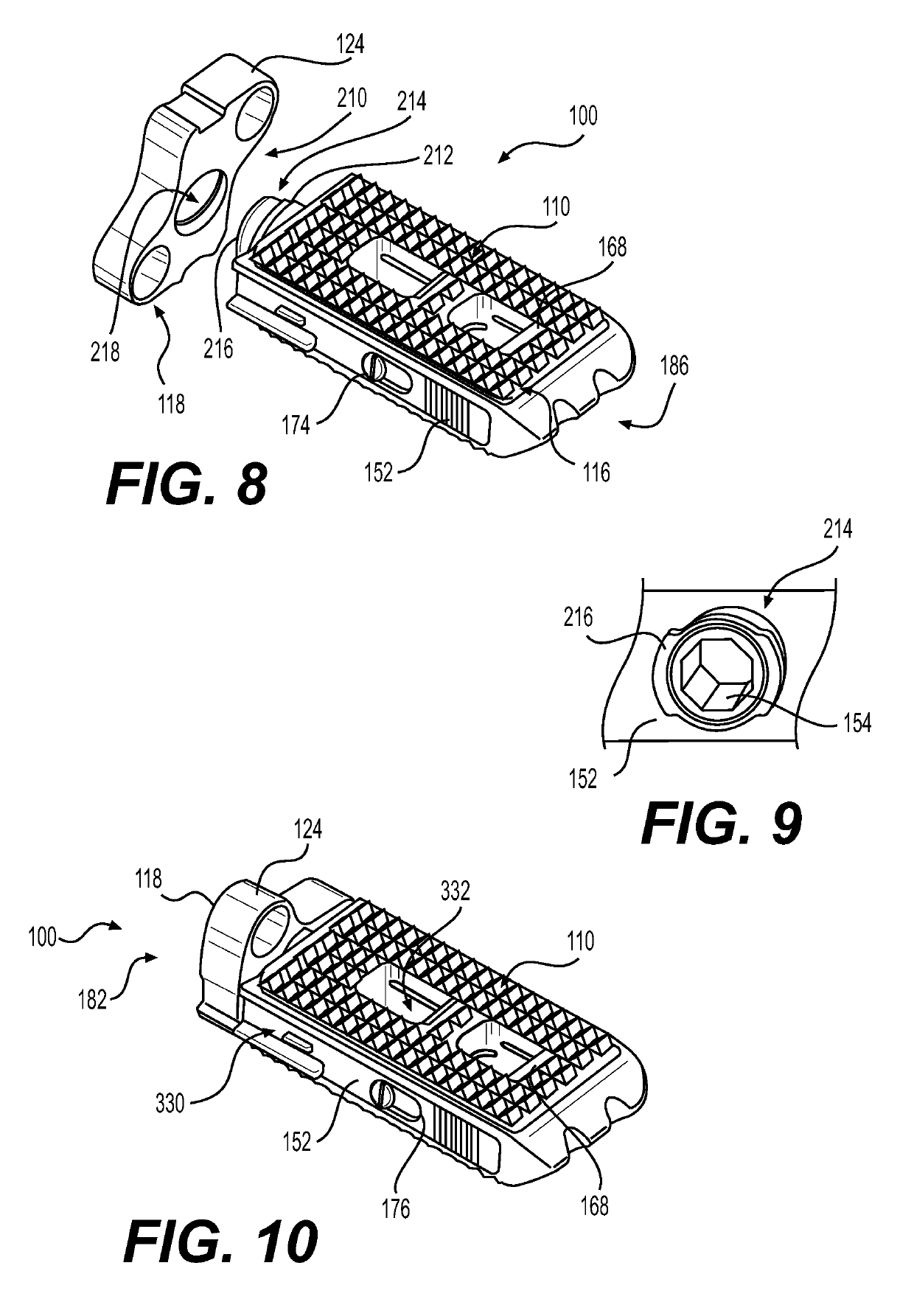

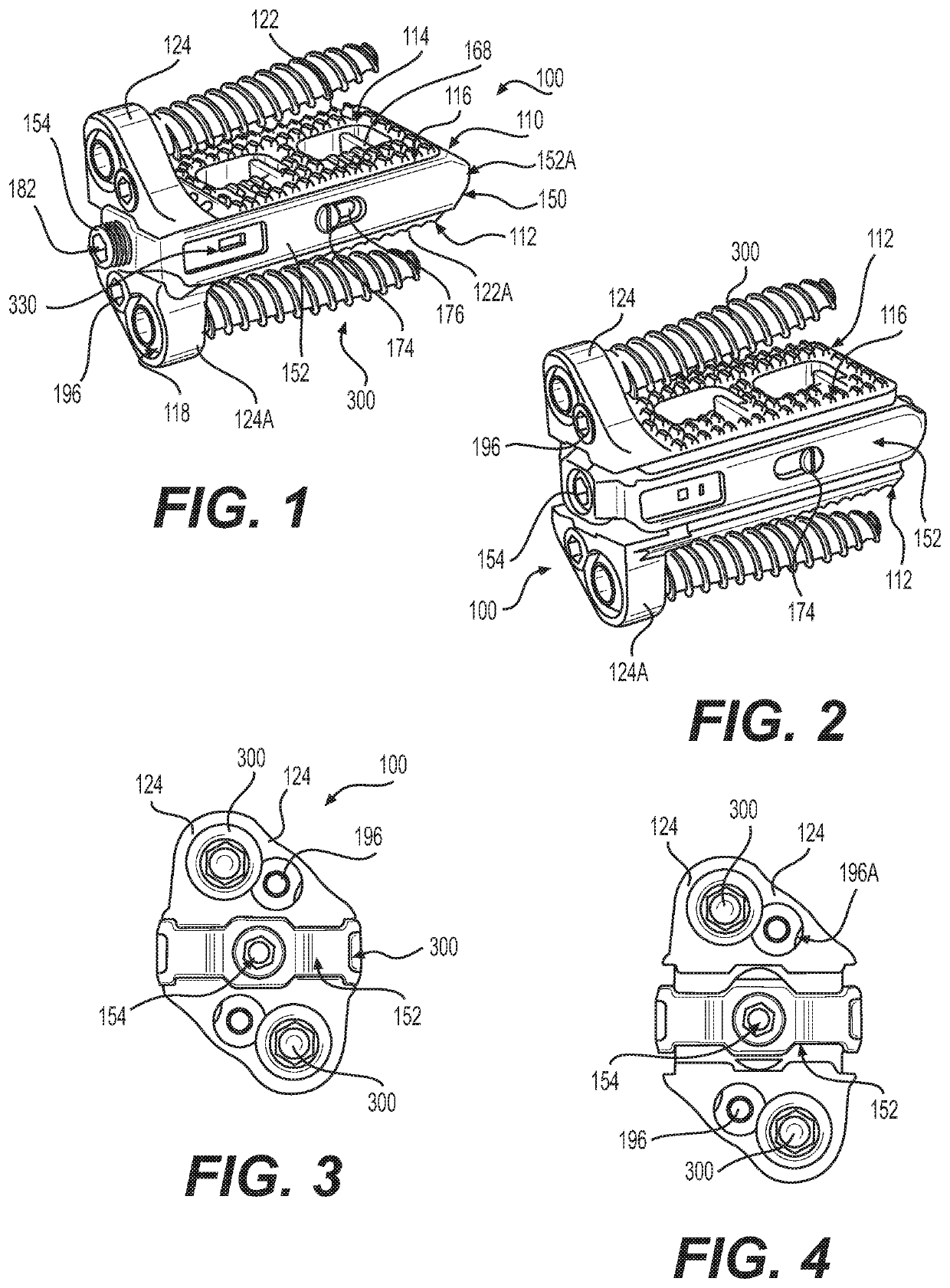

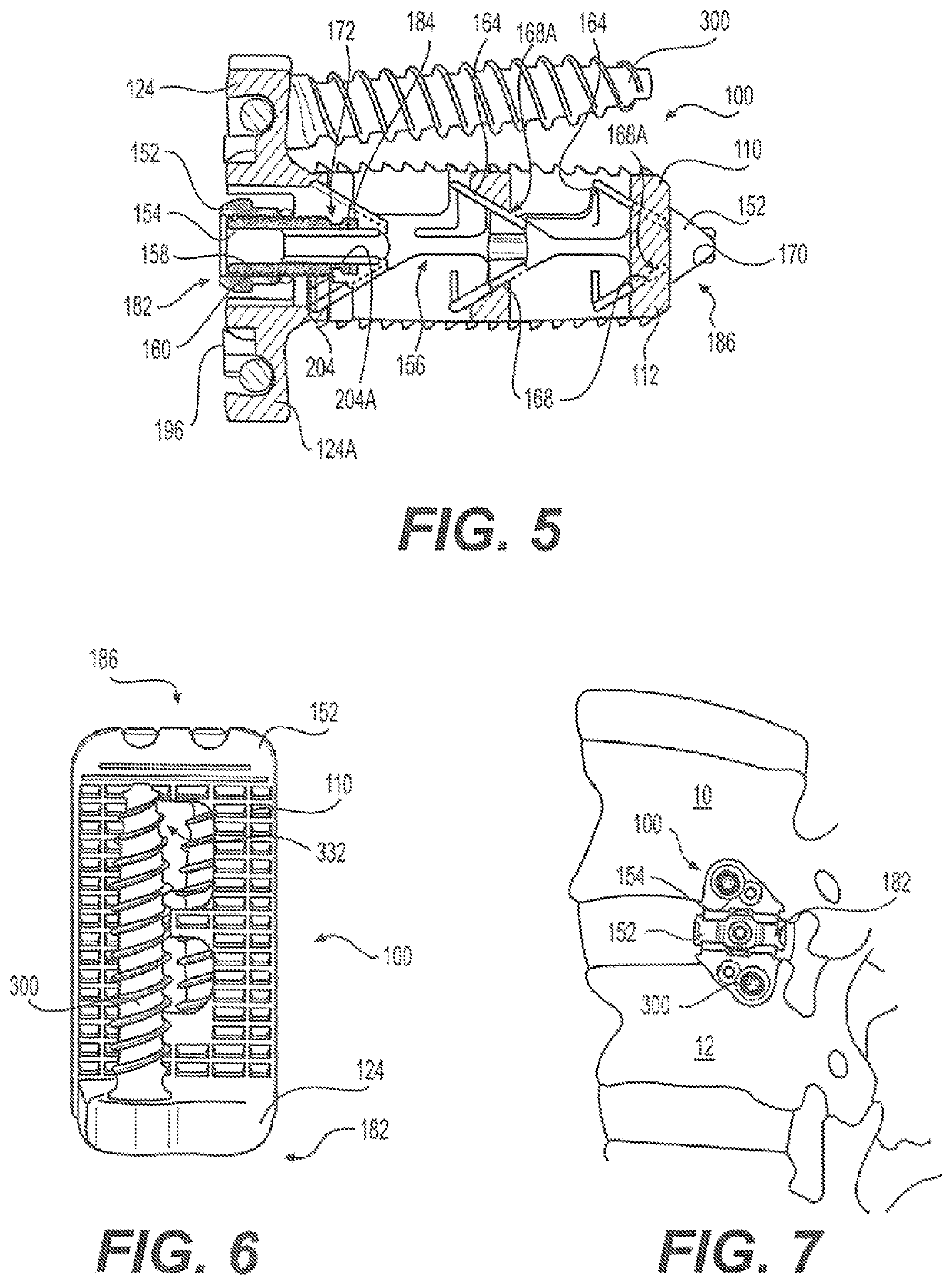

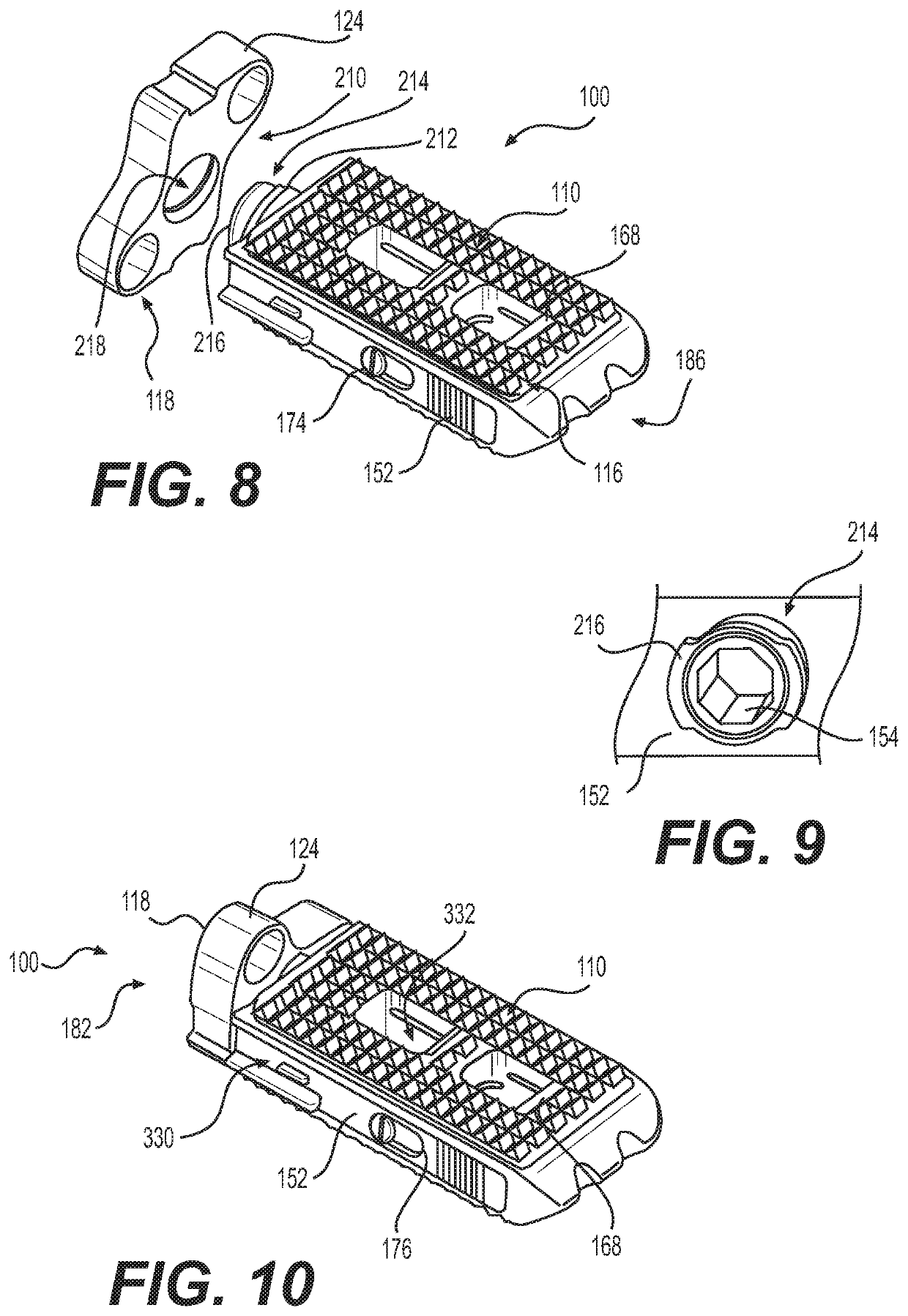

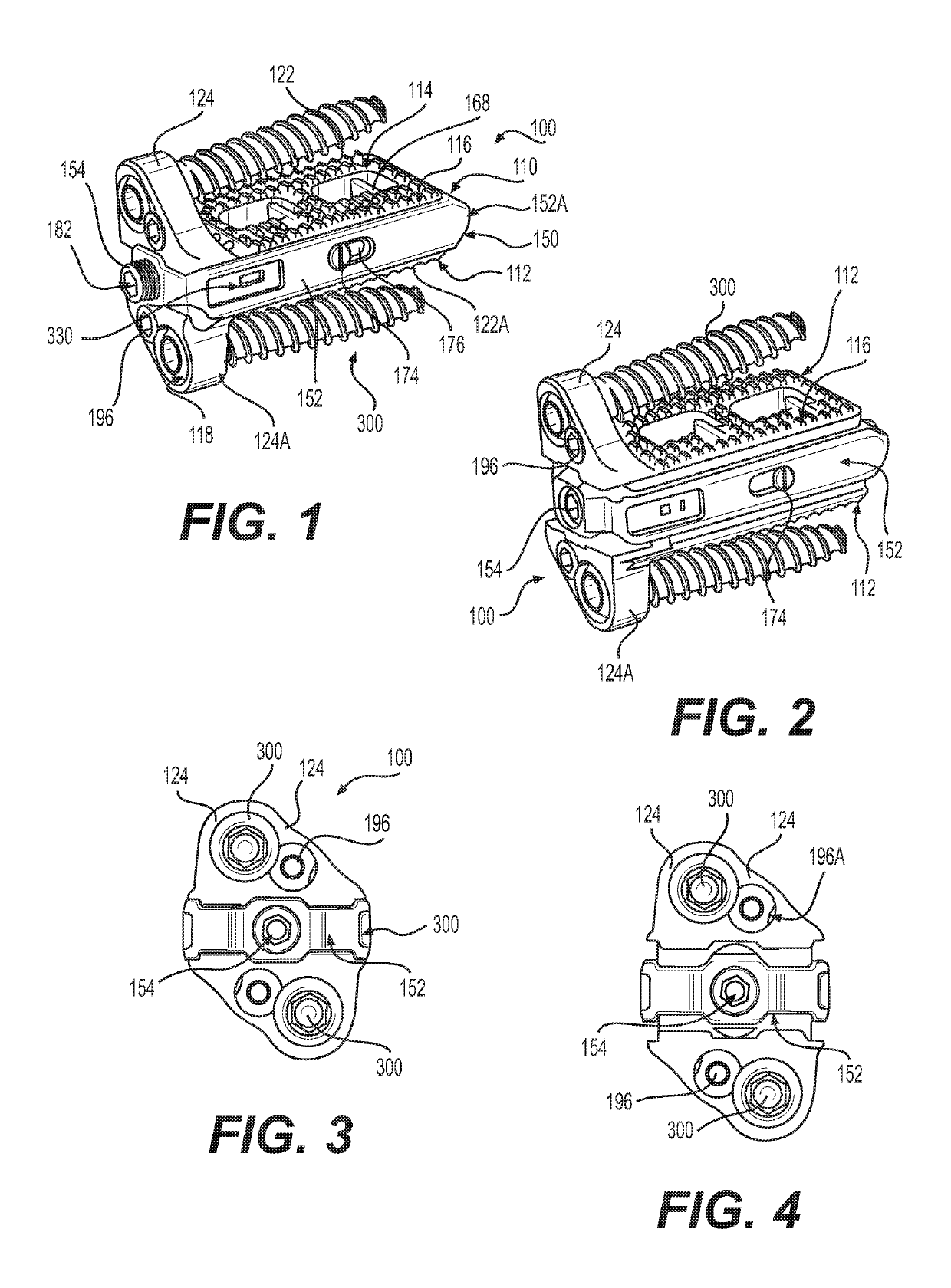

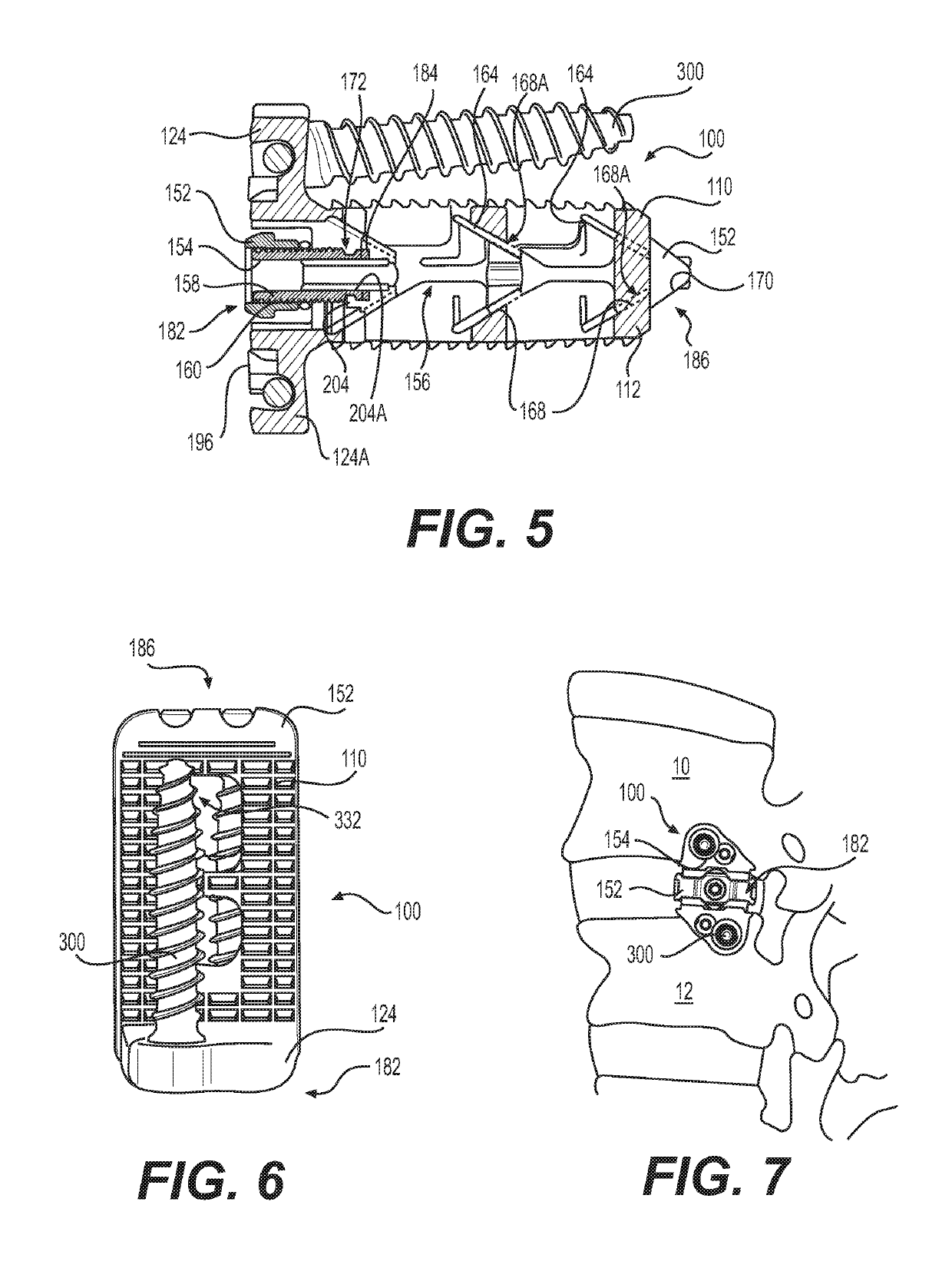

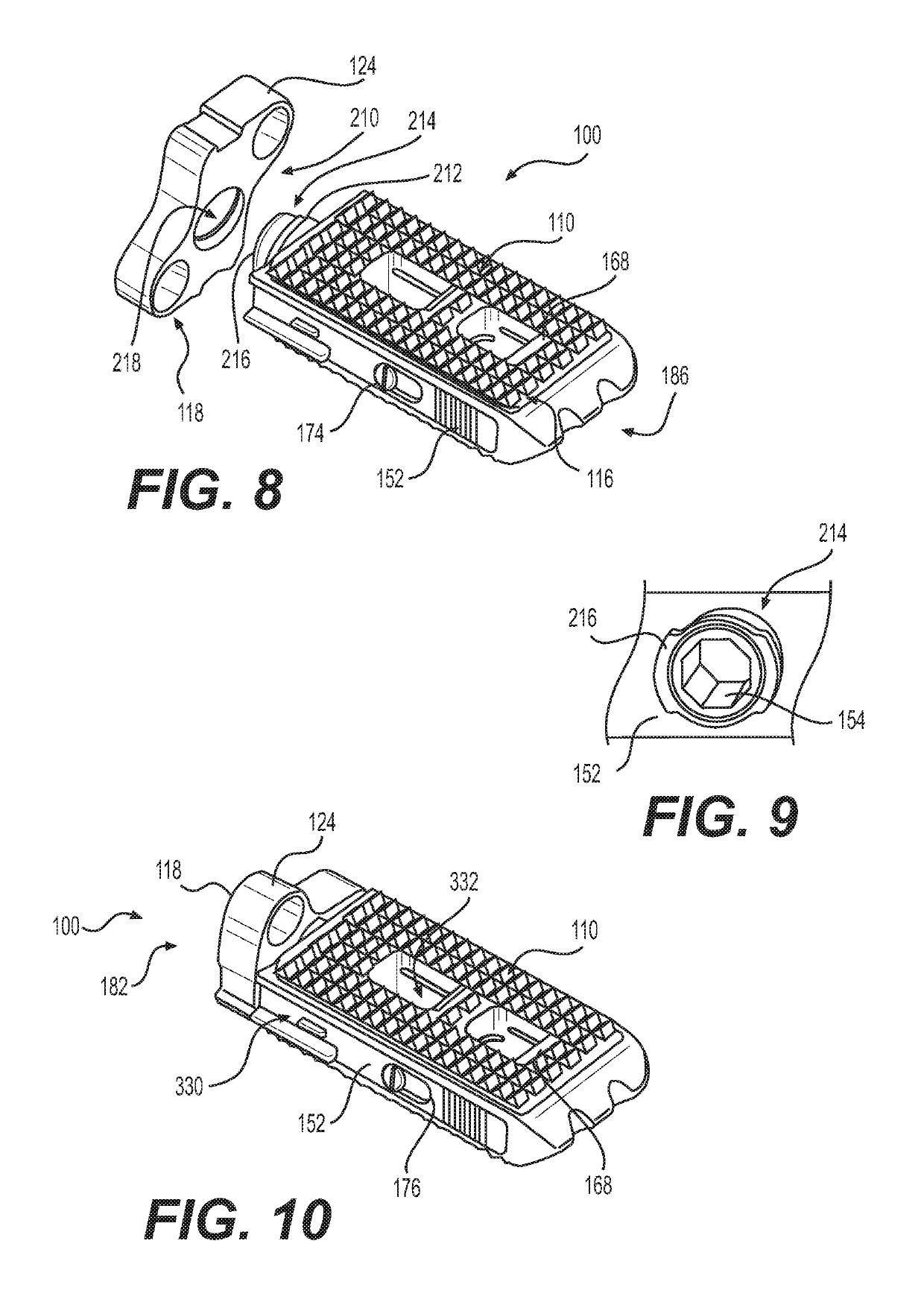

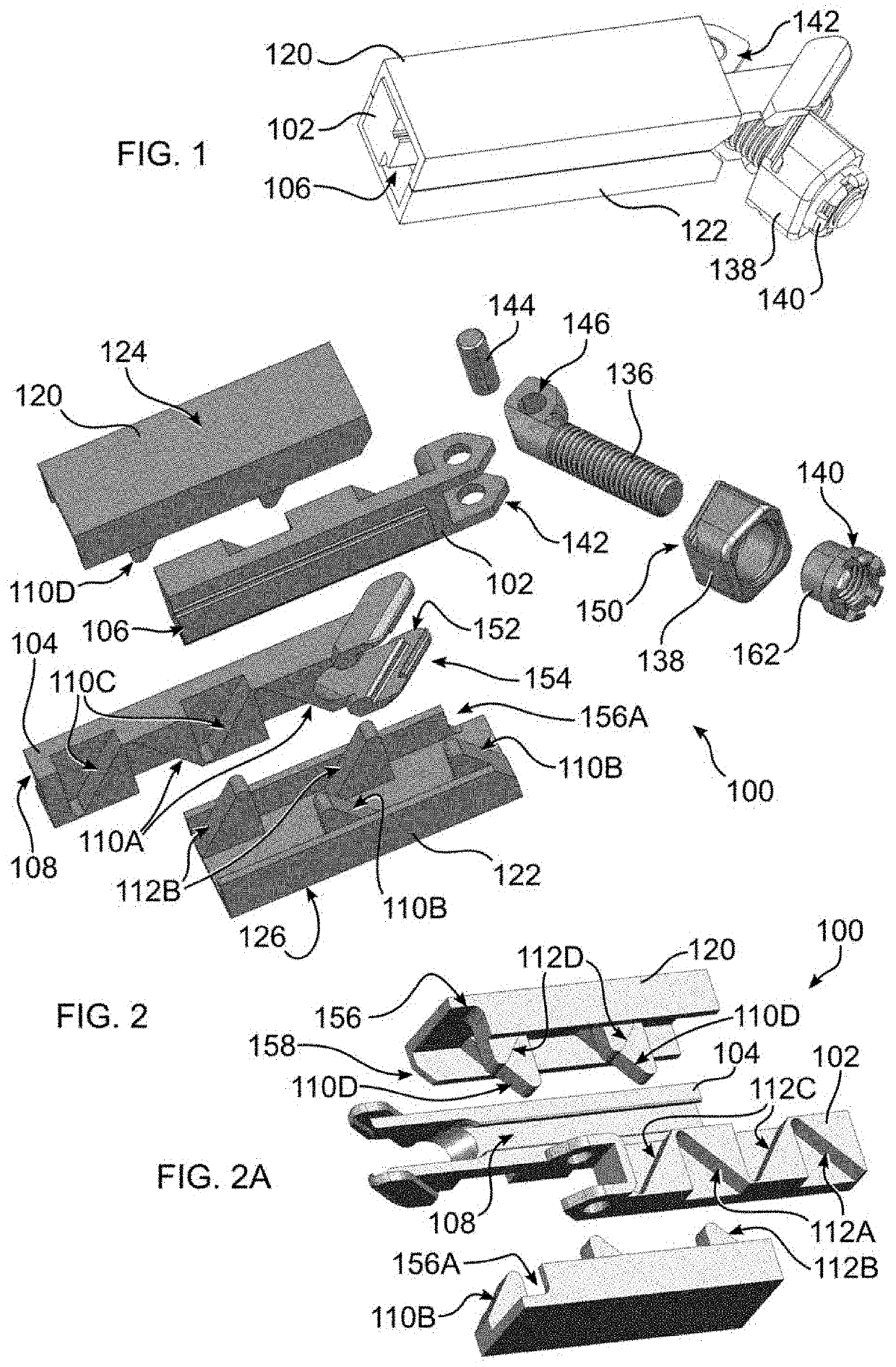

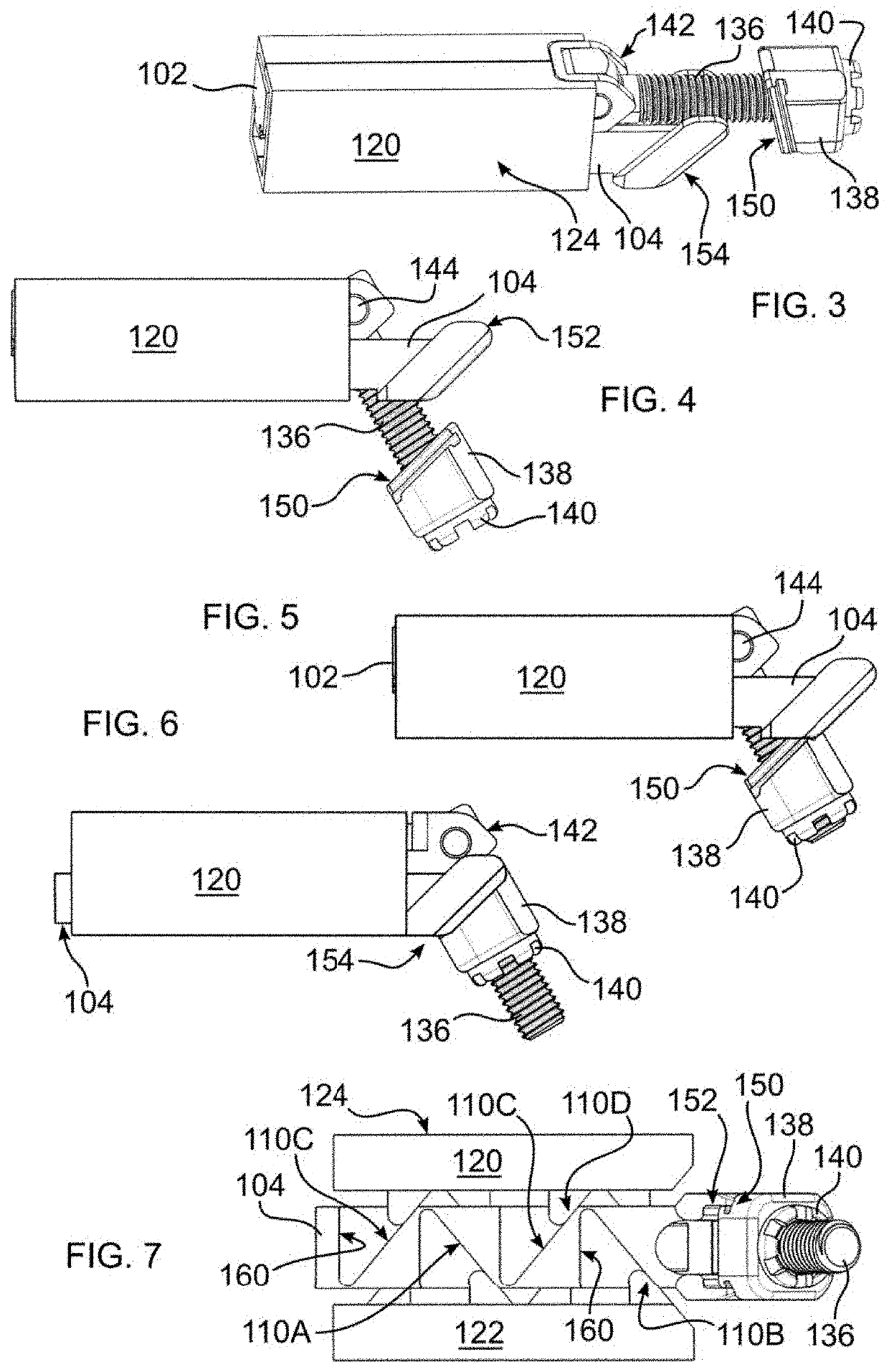

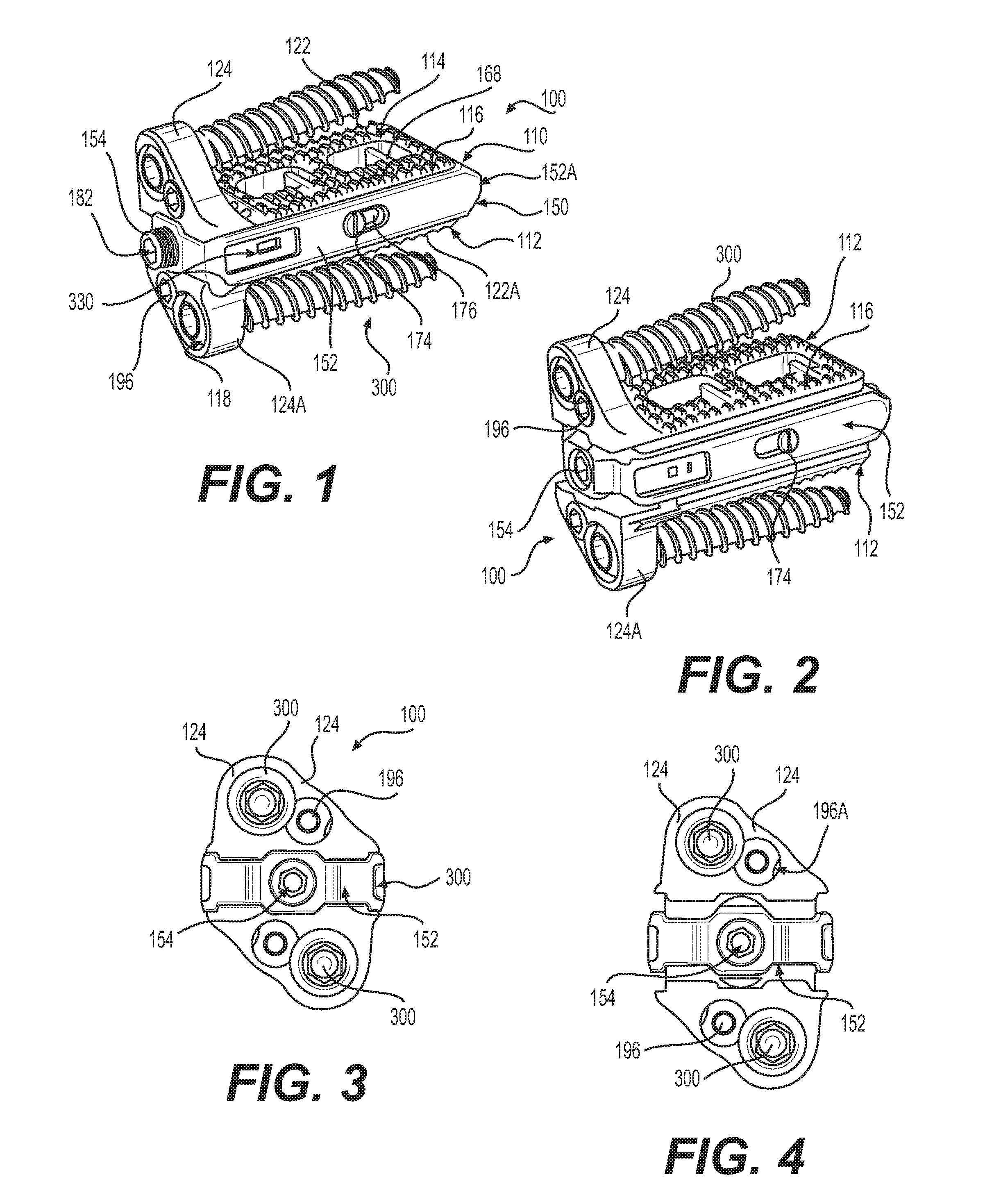

Expandable Vertebral Implant

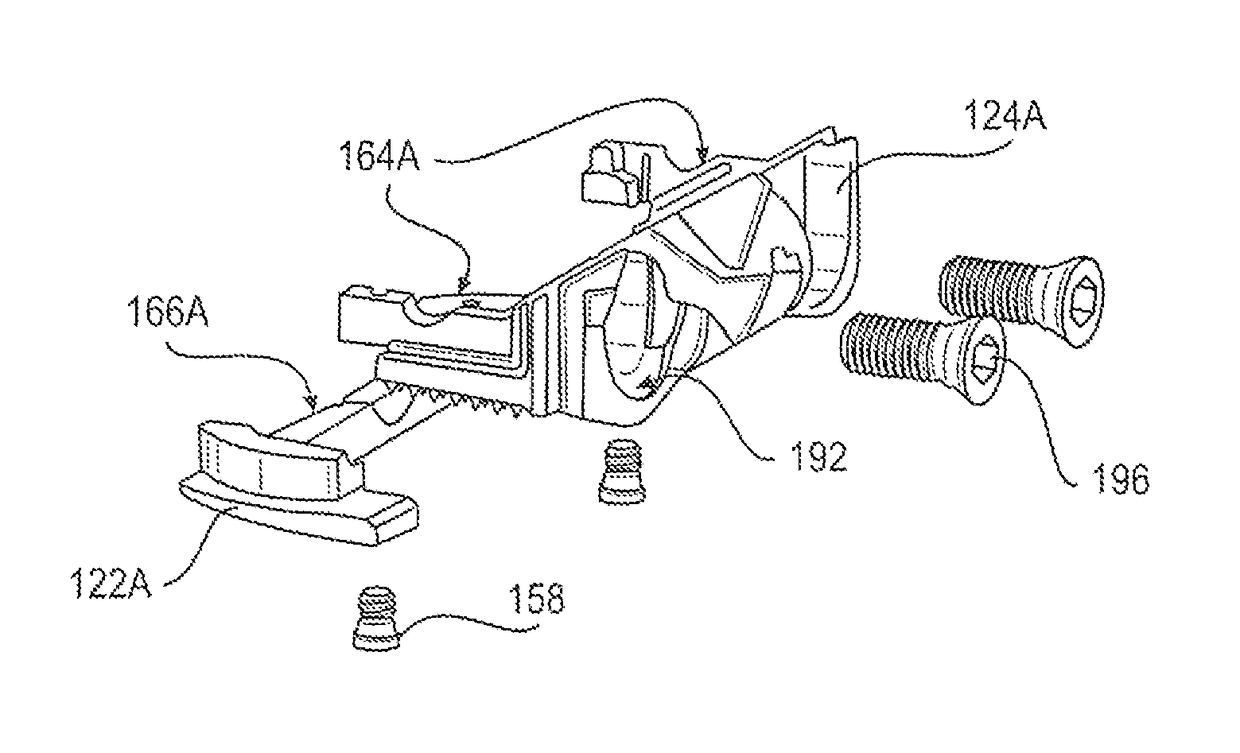

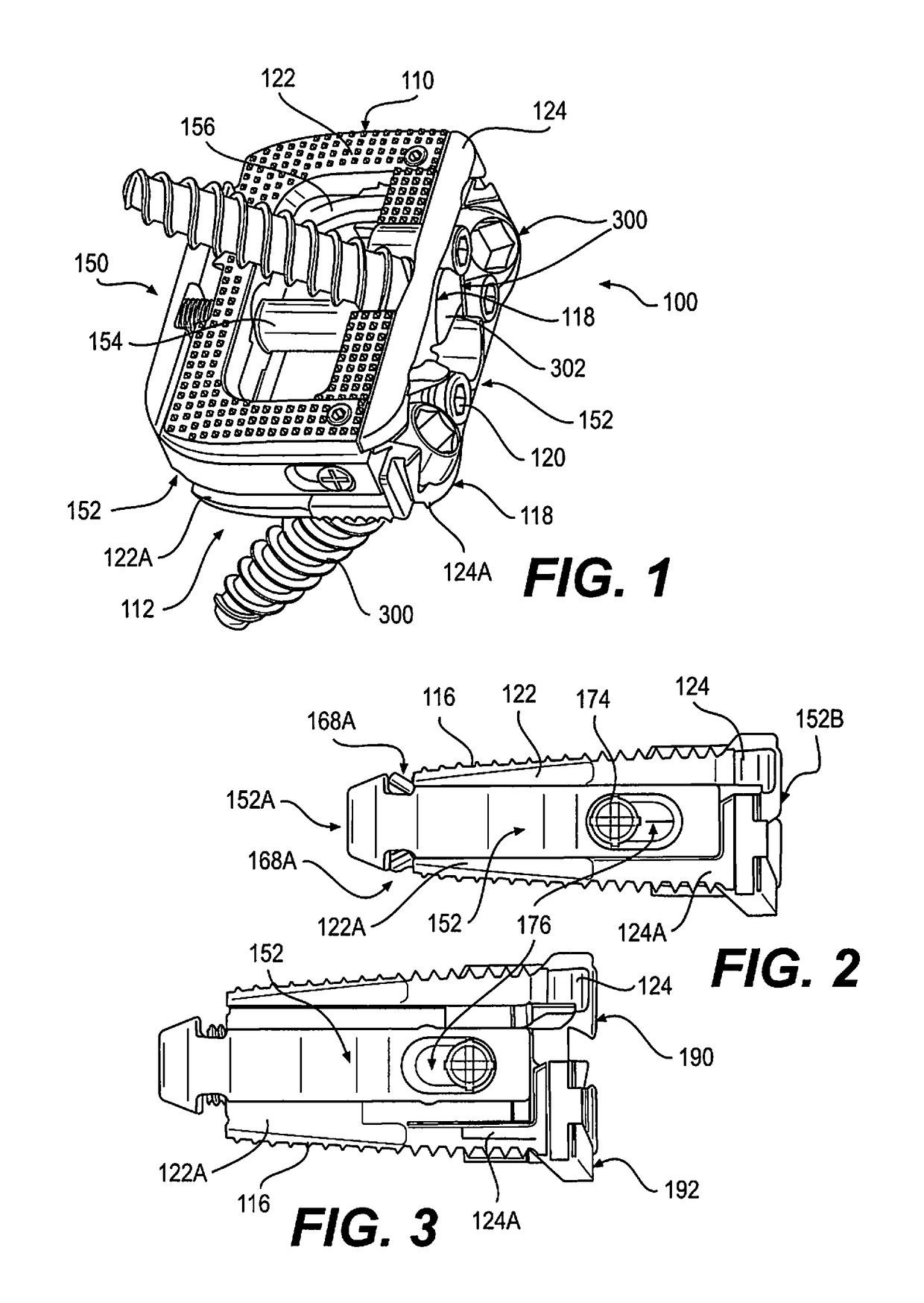

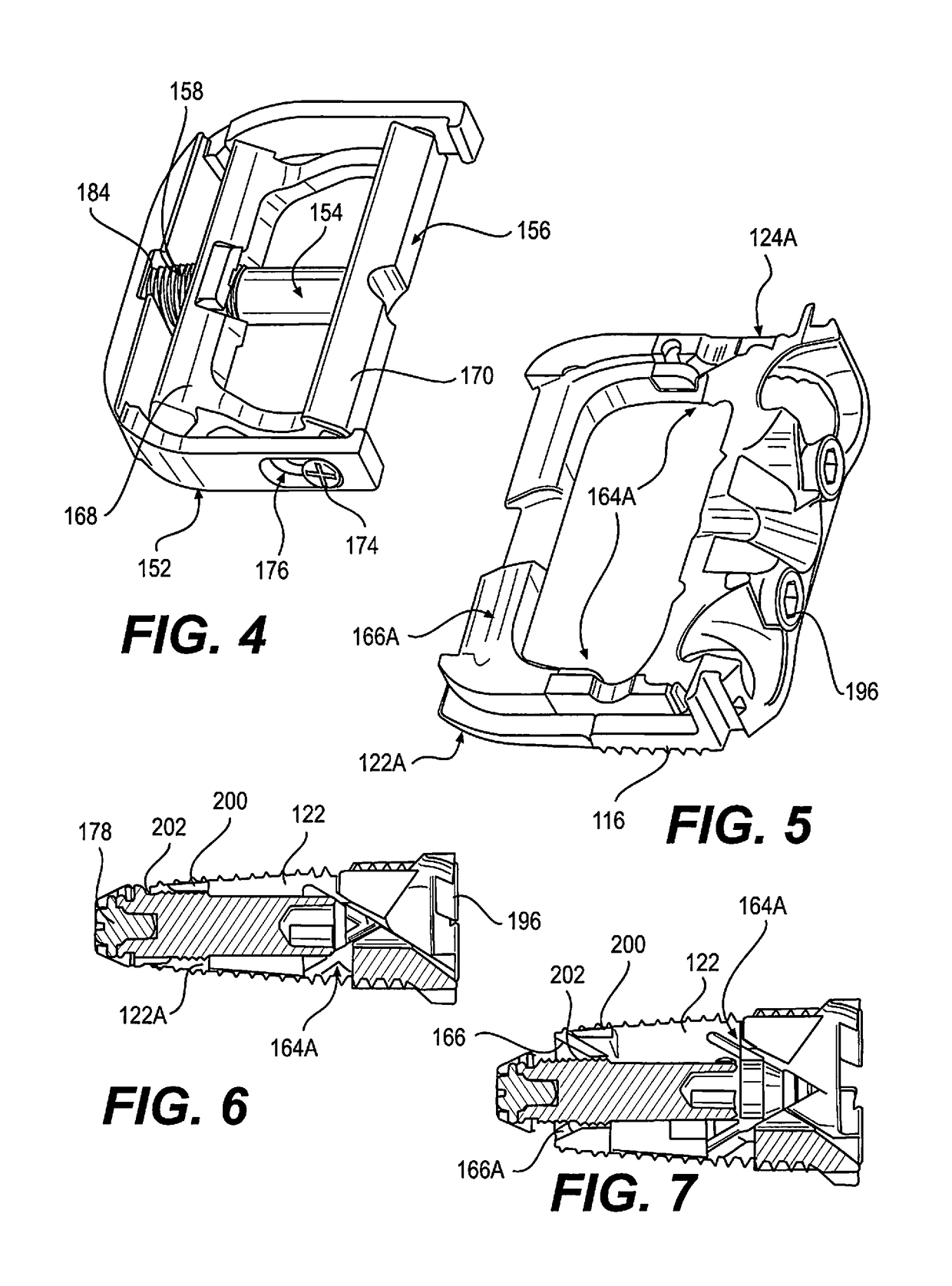

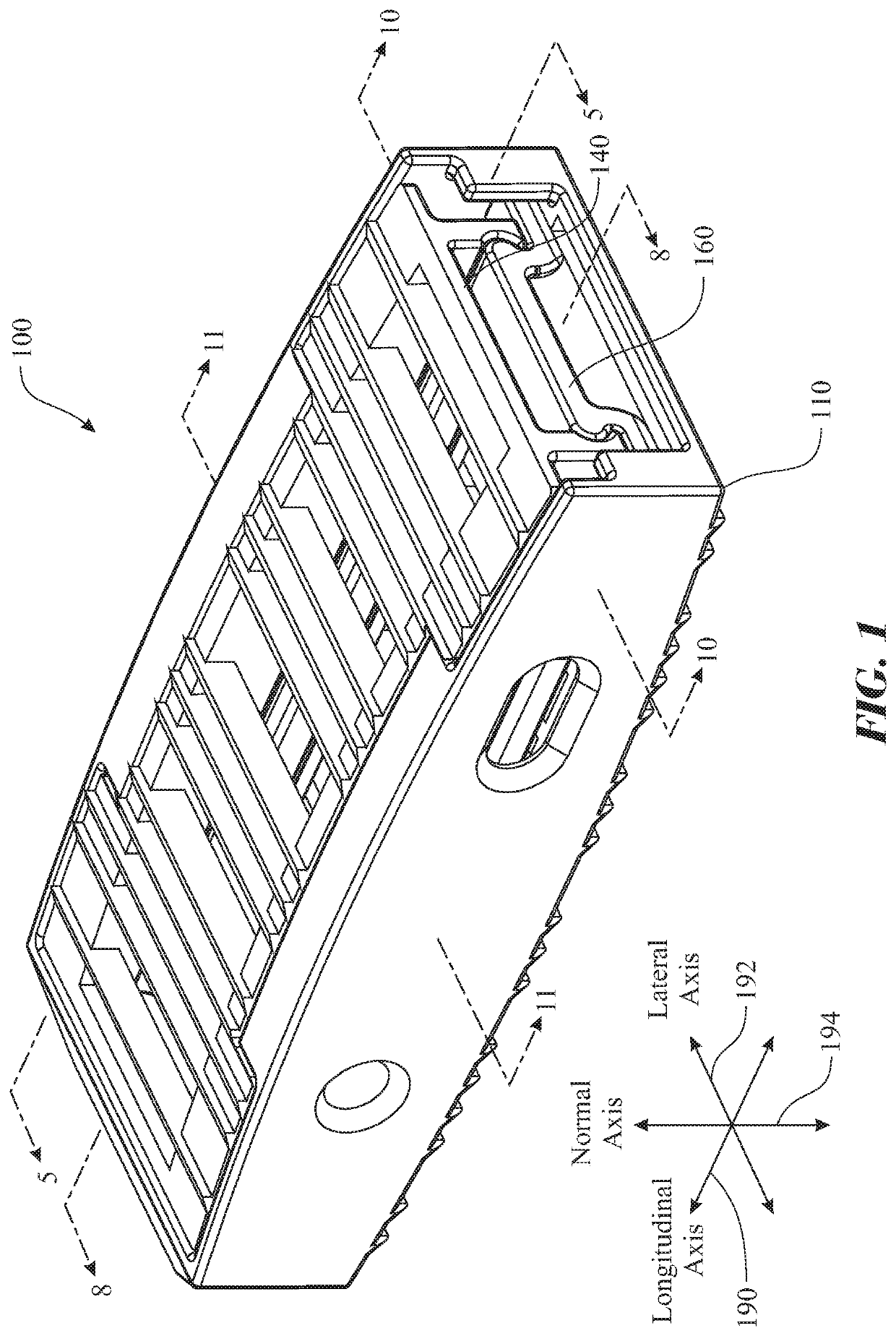

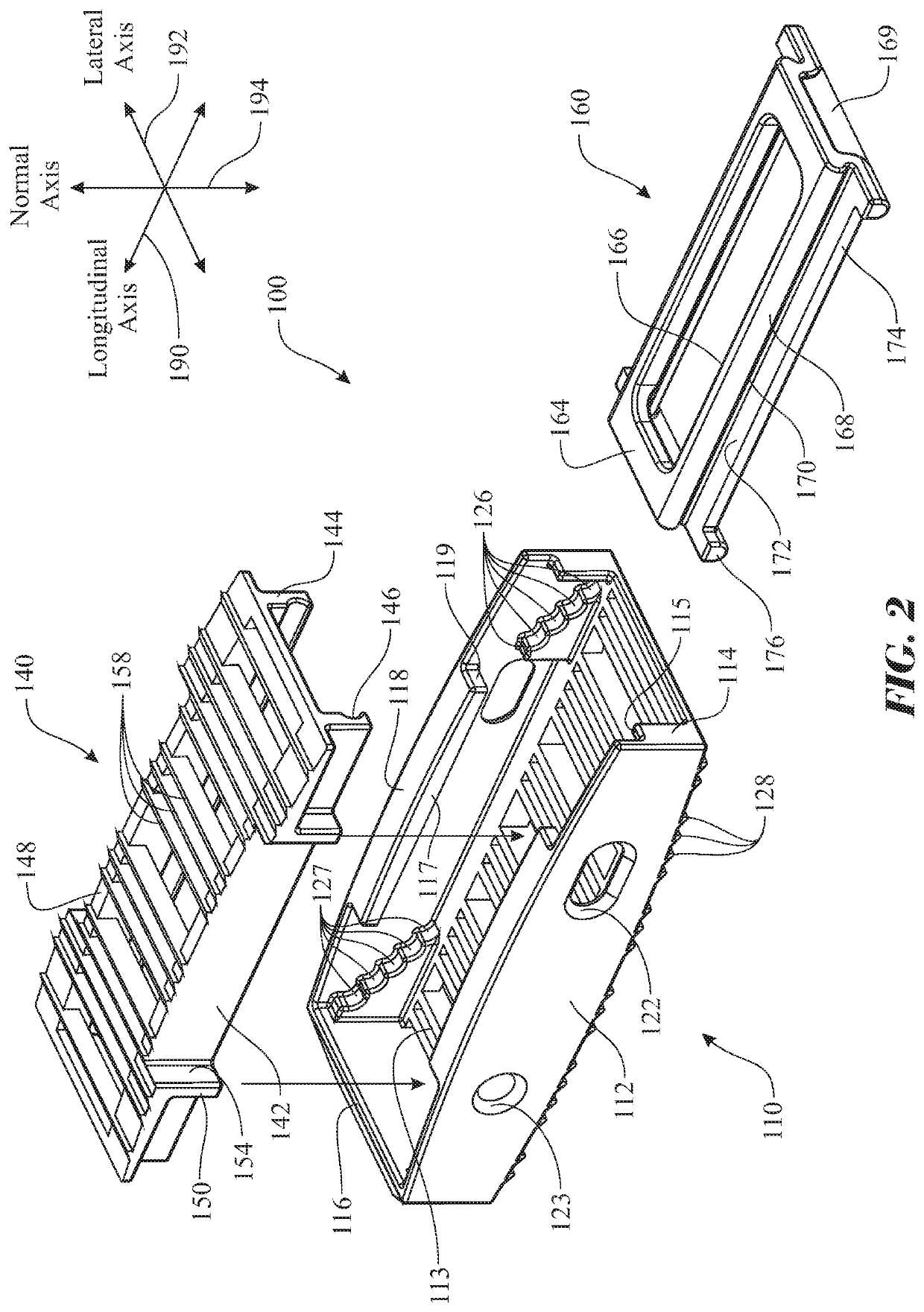

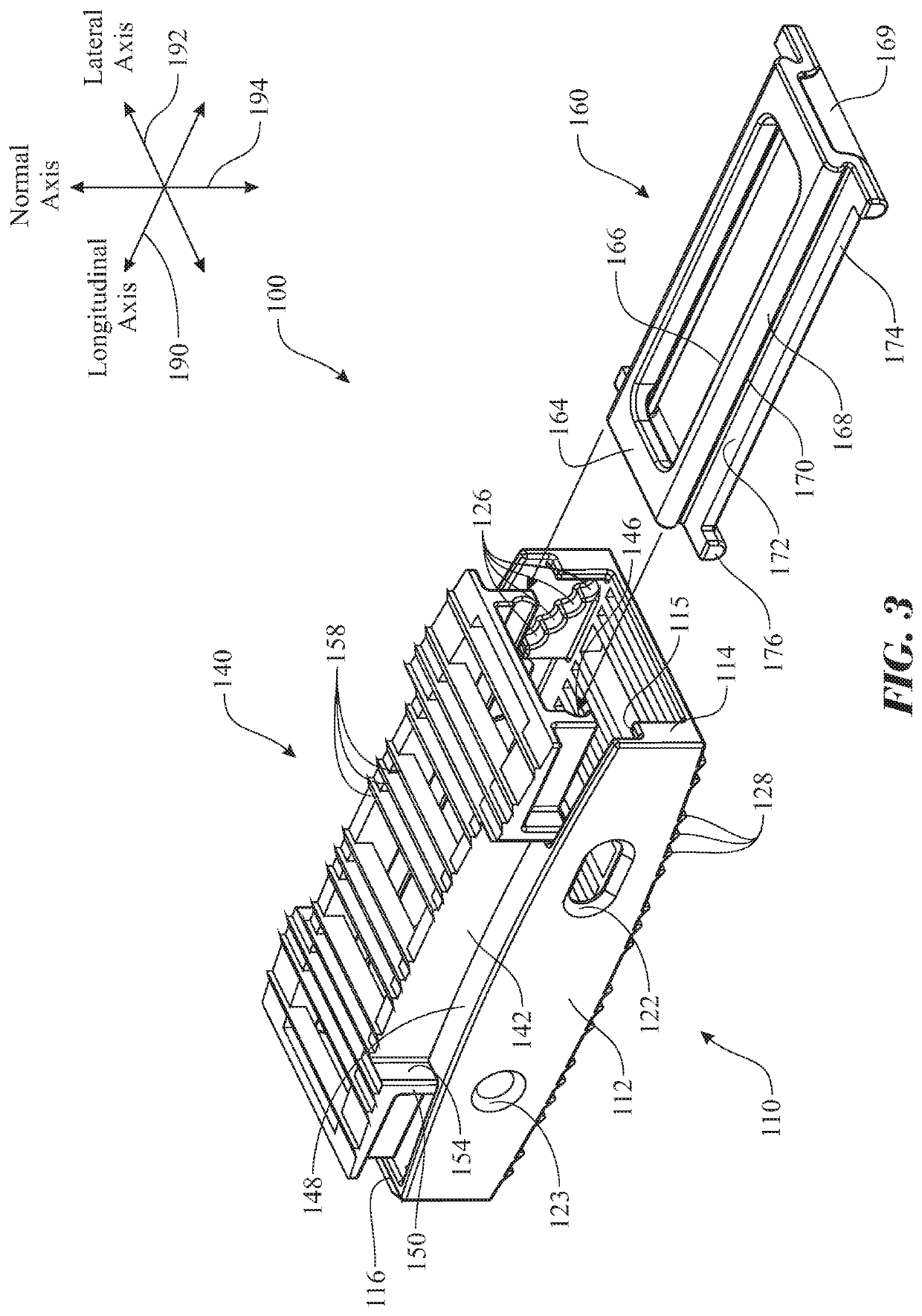

InactiveUS20140163682A1Increase heightMaintain separationSpinal implantsBone platesJoint spacerEngineering

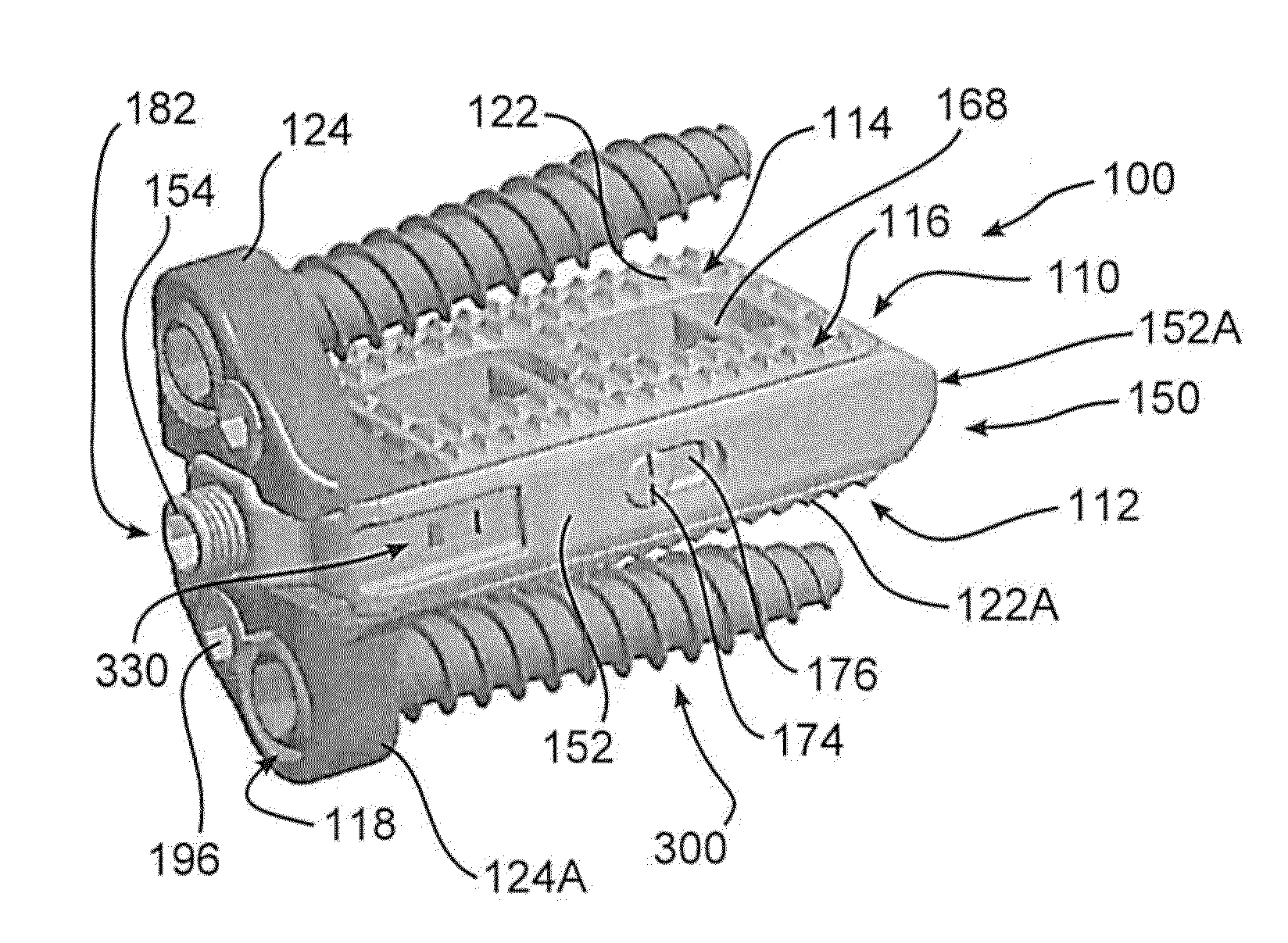

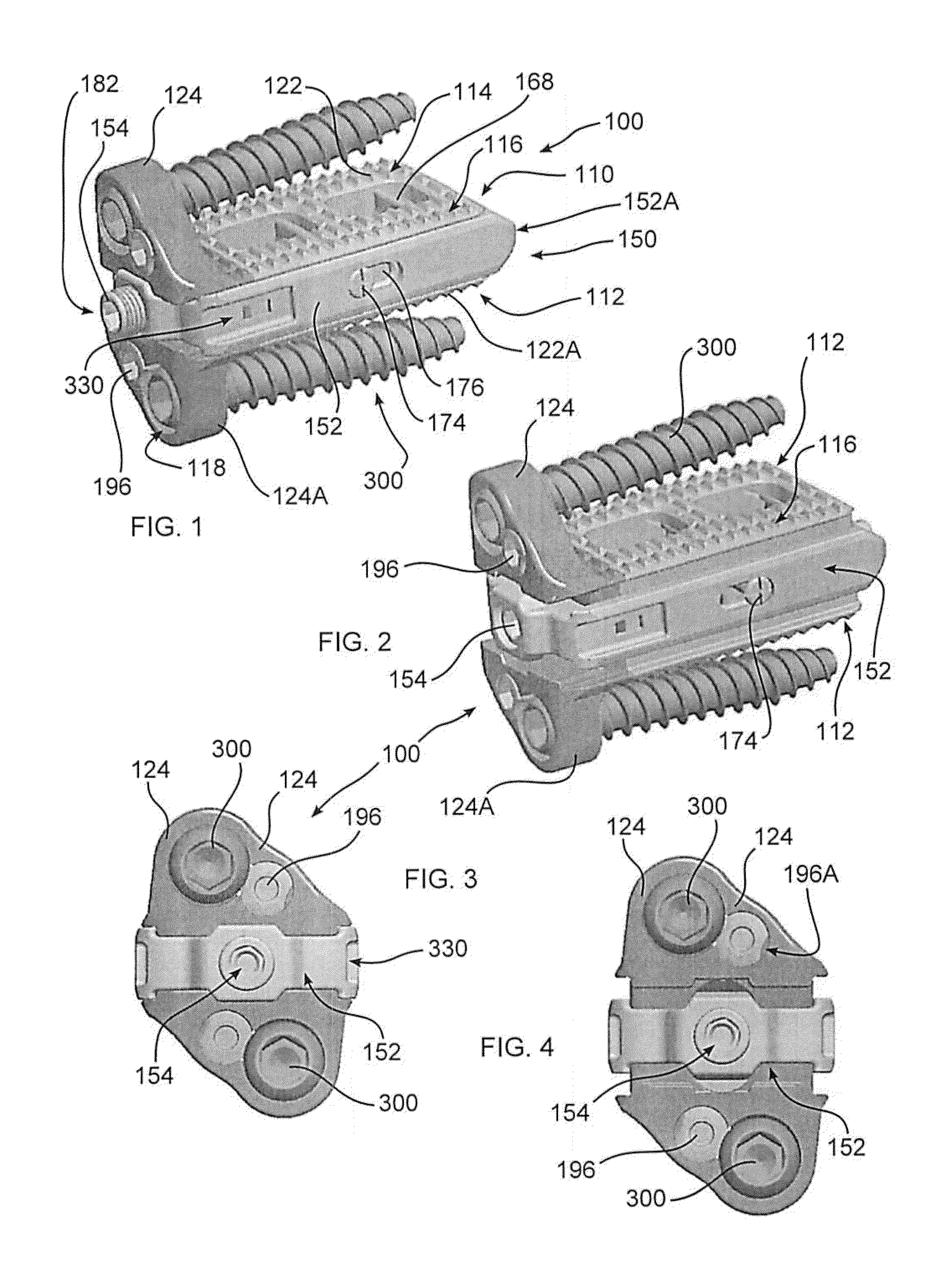

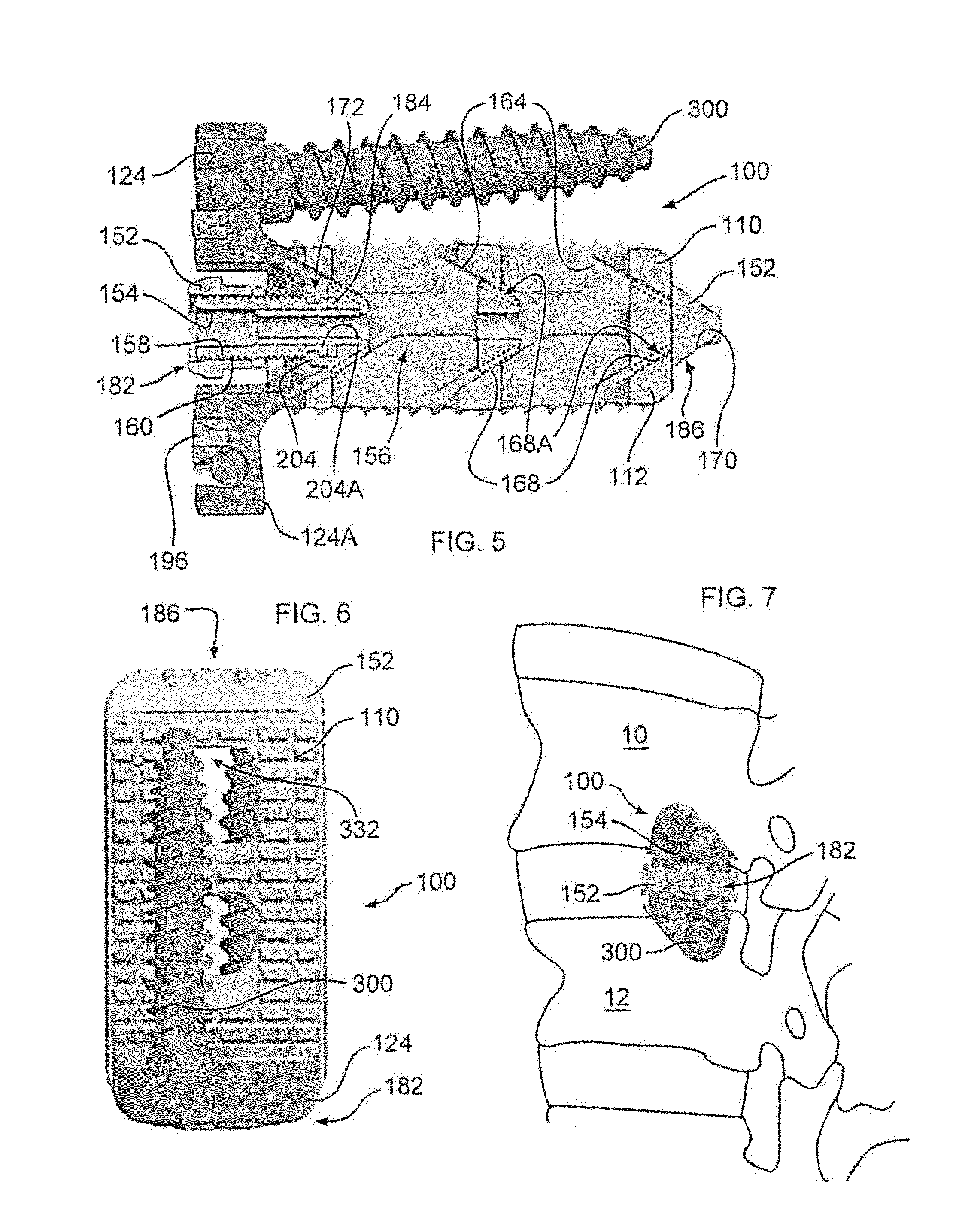

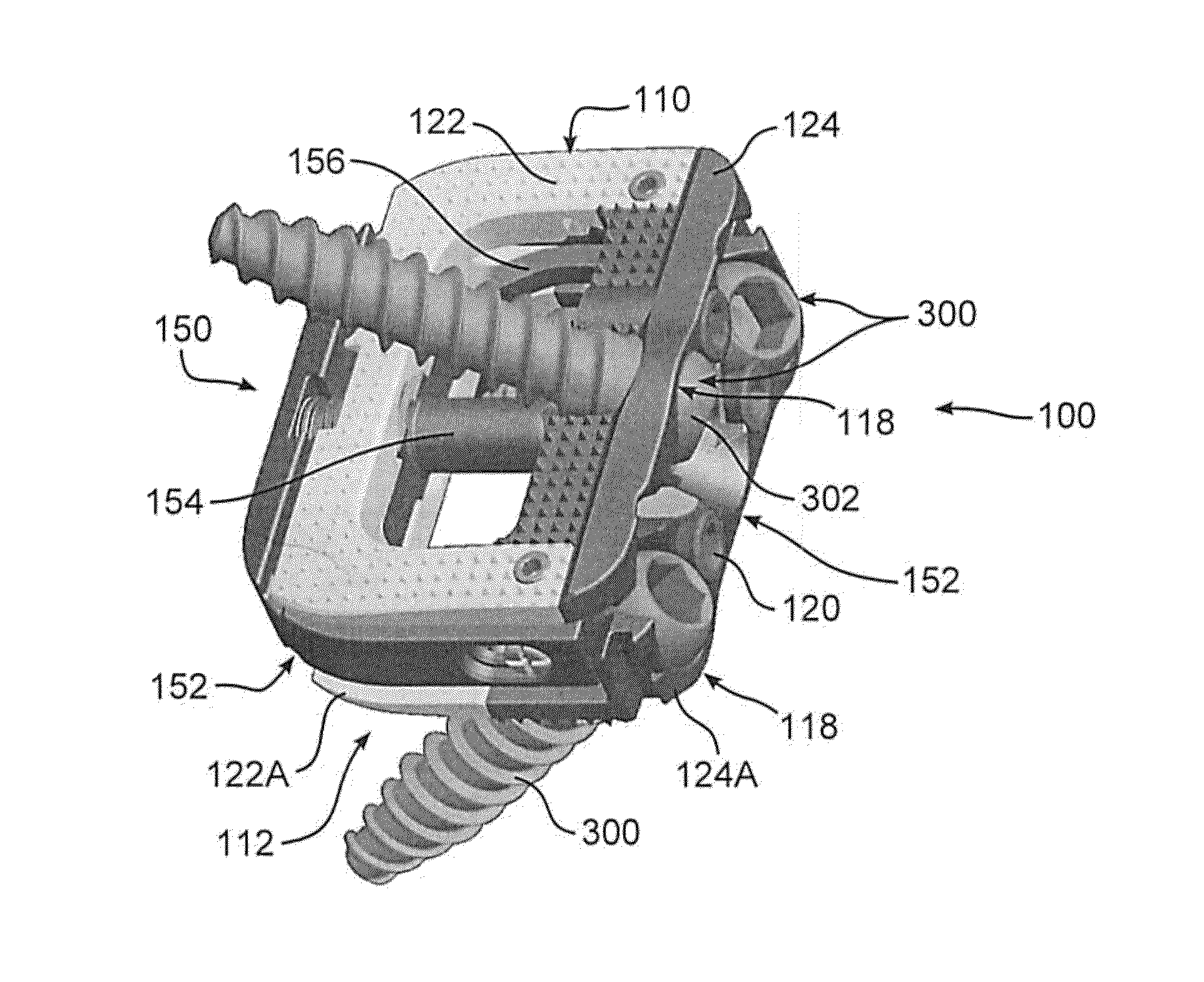

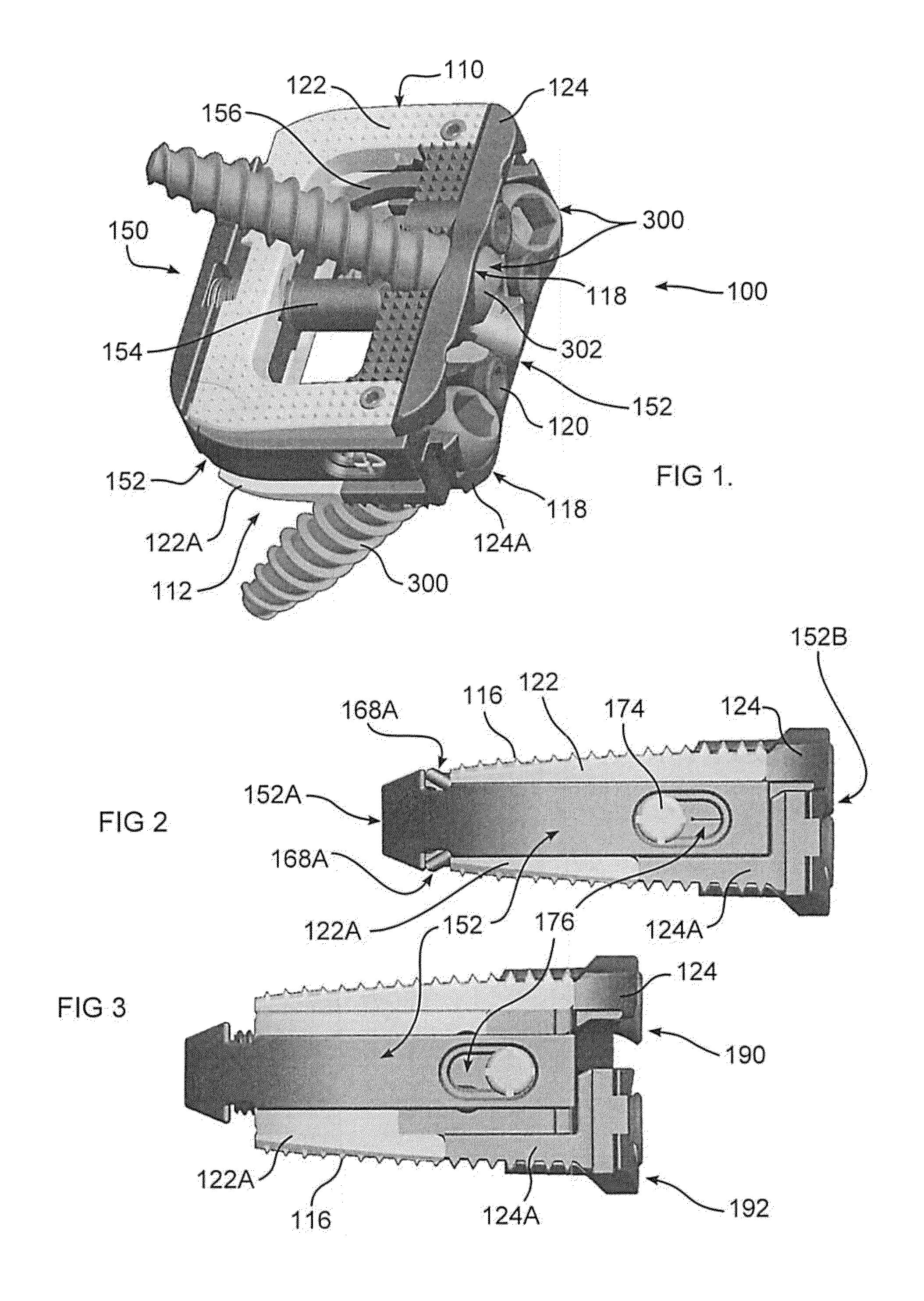

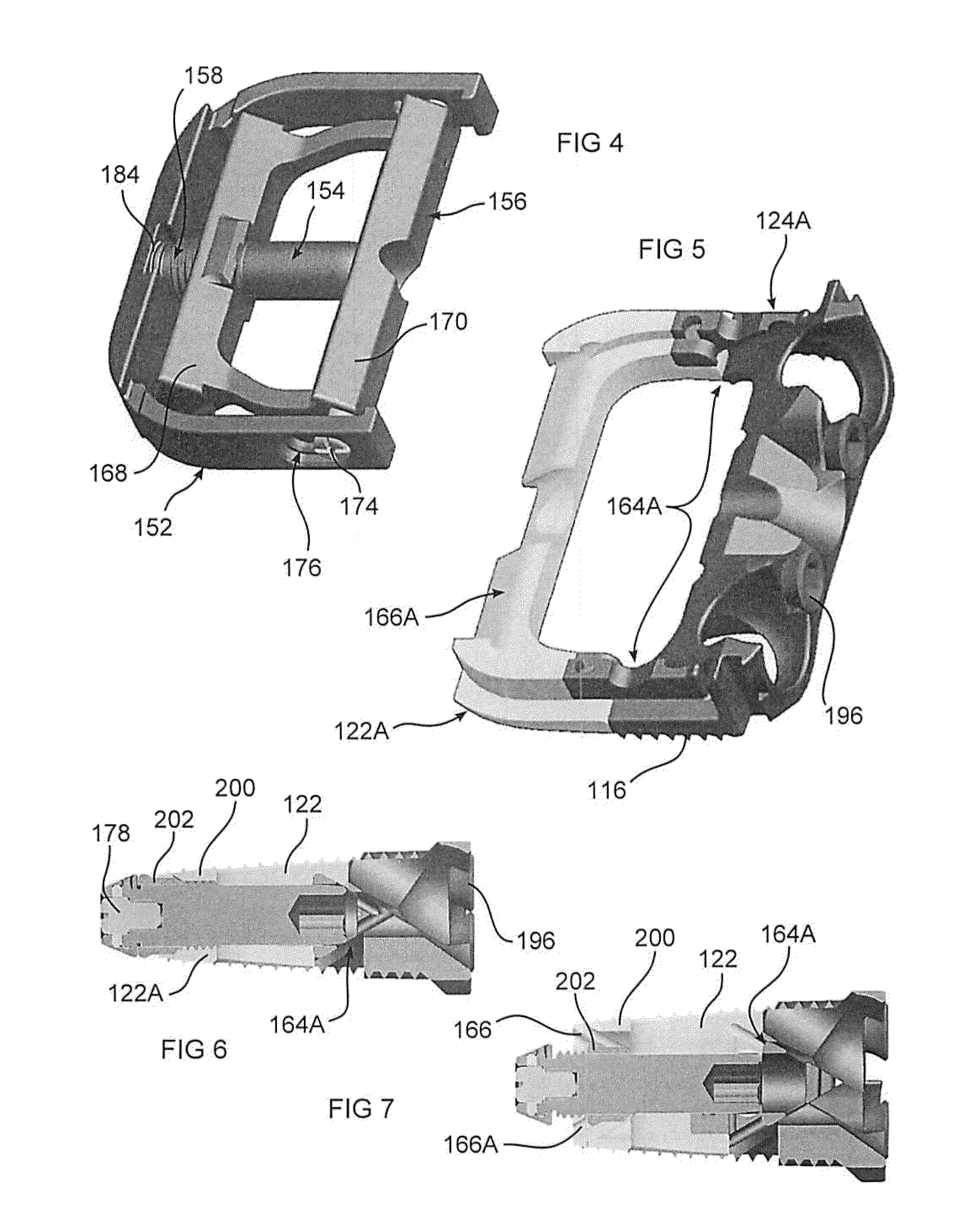

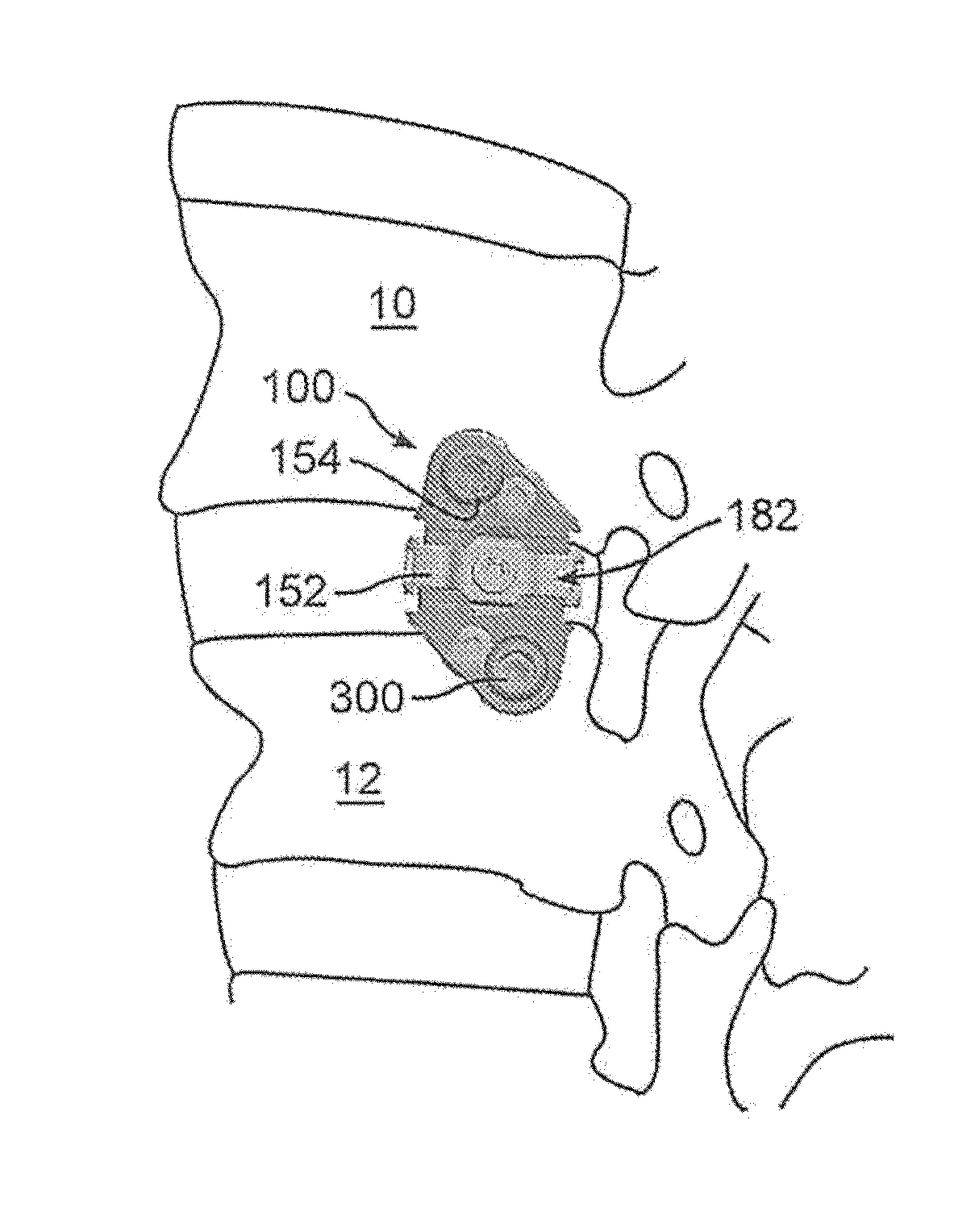

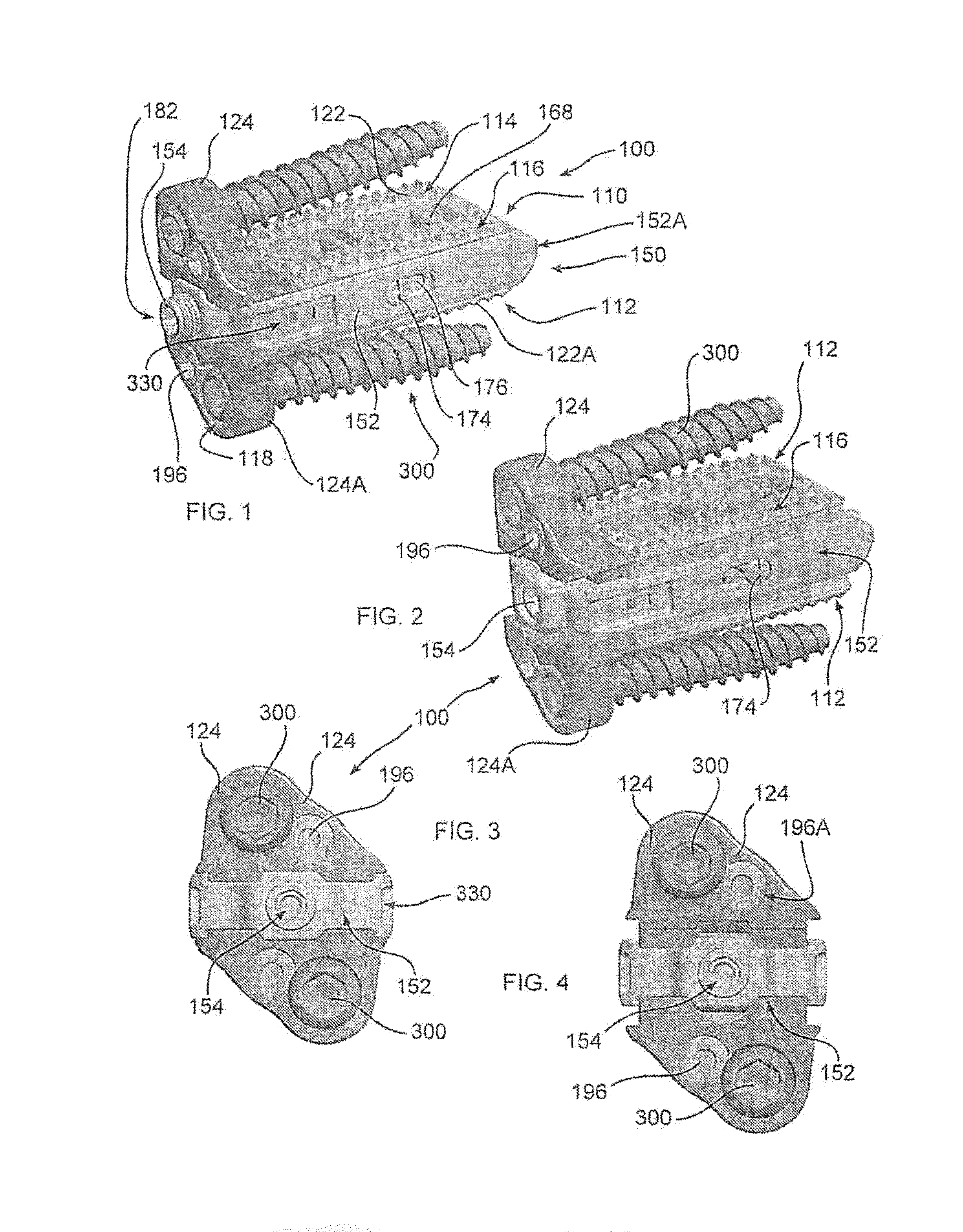

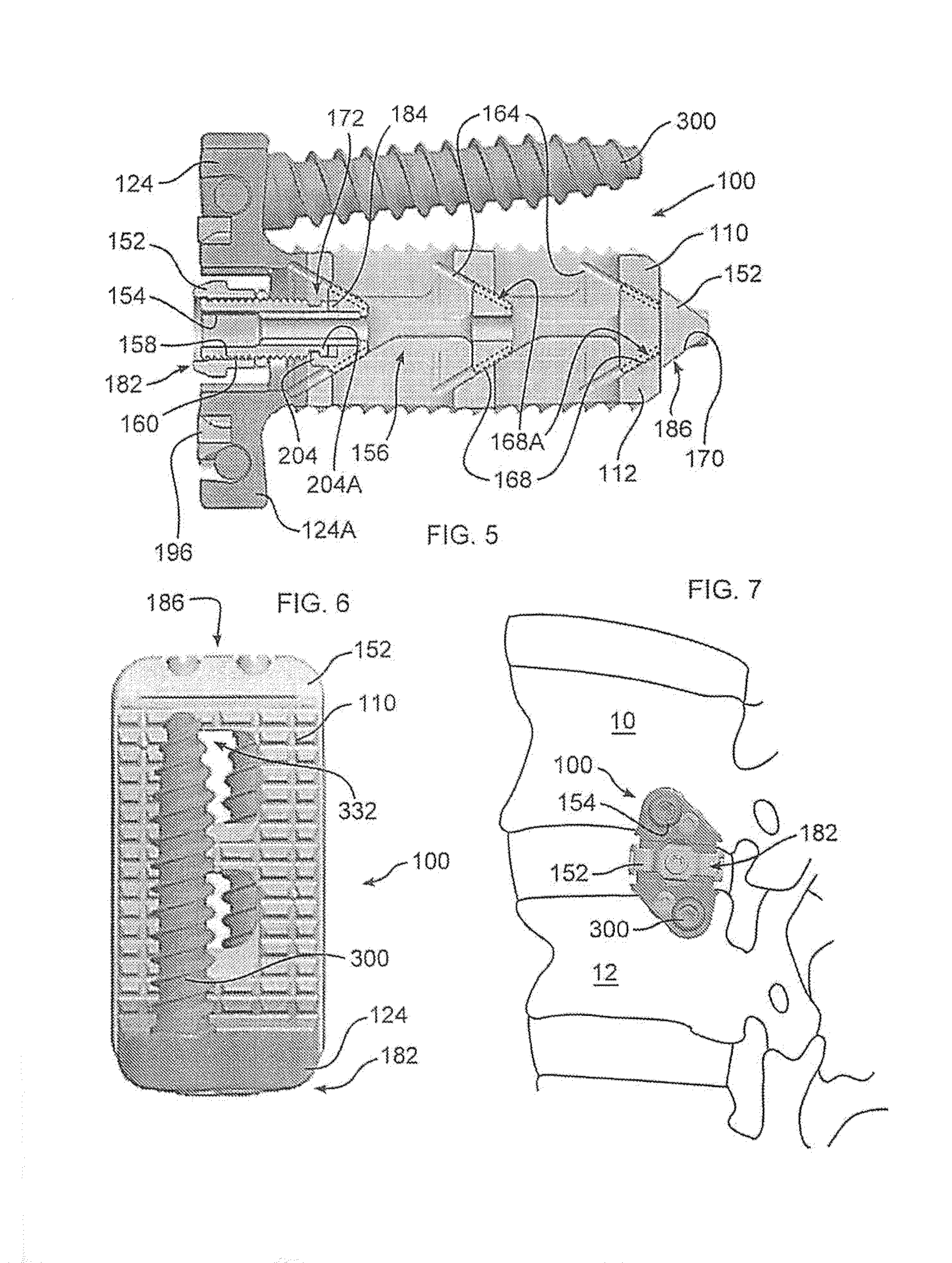

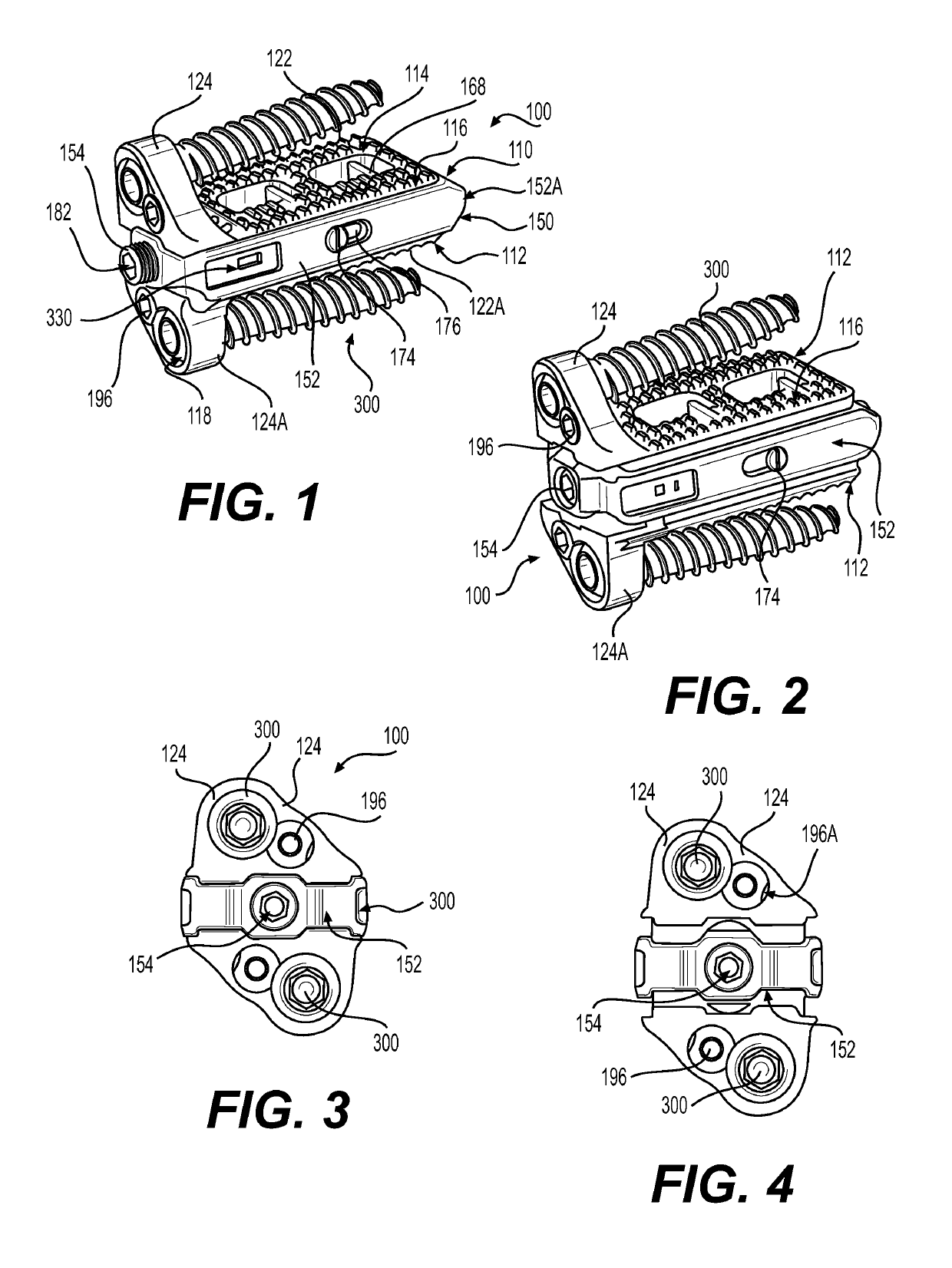

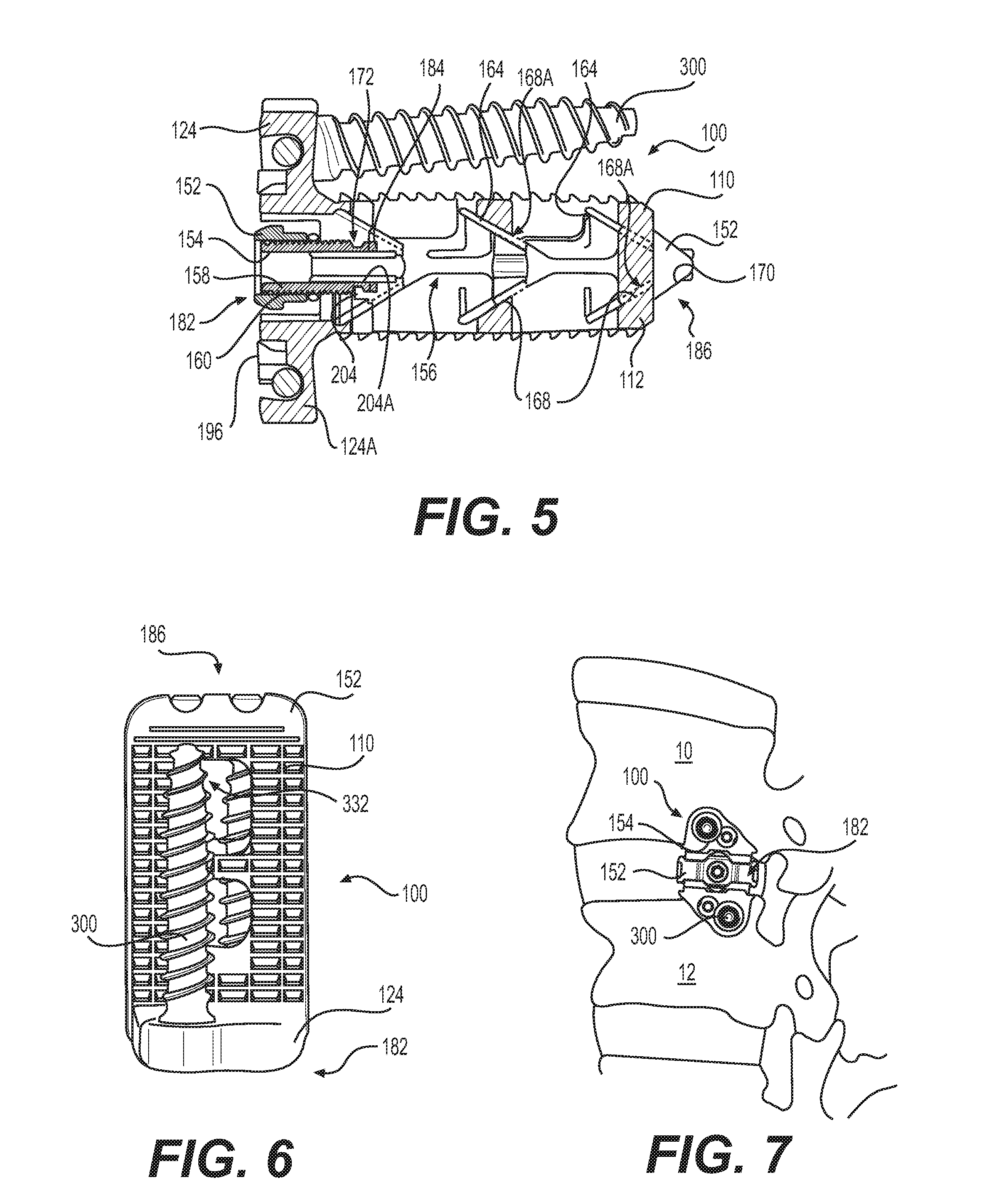

A joint spacer therapeutically maintains separation of bones of a joint. A carriage is slideably retained within the frame and has at least one ramped surface. An actuator screw is threadably engaged with the frame, and rotatably connected to the carriage, to cause the carriage to slideably move within the frame when the actuator screw is rotated. First and second endplates engage the bones of the joint, and each has at least one ramped surface that is mateable with the ramped surface of the carriage, whereby when the carriage is slideably moved by rotation of the actuator screw, the endplates ramped surface slides against the carriage ramped surface to cause the endplates to move along an axis transverse to the longitudinal axis of the frame, to increase the height of the spacer. Piercing elements are connected to the carriage to pierce bone of the joint when the carriage is moved.

Owner:GLOBUS MEDICAL INC

Expandable Intervertebral Implant

A joint spacer for therapeutically maintains separation of bones of a joint. A frame defines a longitudinal axis extending between distal and proximal ends. A carriage is slideably retained within the frame and has at least one ramped surface and a threaded portion. An actuator screw is threadably engaged with the threaded portion, and bears against said frame to cause the carriage to slideably move within the frame when the actuator screw is rotated. A first endplate engages a bone of the joint, and has at least one ramped surface that is mateable with the ramped surface of the carriage.

Owner:GLOBUS MEDICAL INC

Expandable vertebral implant

ActiveUS20160242927A1Increase heightMaintain separationBone implantSpinal implantsJoint spacerEngineering

A joint spacer therapeutically maintains separation of bones of a joint. A carriage is slideably retained within the frame and has at least one ramped surface. An actuator screw is threadably engaged with the frame, and rotatably connected to the carriage, to cause the carriage to slideably move within the frame when the actuator screw is rotated. First and second endplates engage the bones of the joint, and each has at least one ramped surface that is mateable with the ramped surface of the carriage, whereby when the carriage is slideably moved by rotation of the actuator screw, the endplates ramped surface slides against the carriage ramped surface to cause the endplates to move along an axis transverse to the longitudinal axis of the frame, to increase the height of the spacer. Piercing elements are connected to the carriage to pierce bone of the joint when the carriage is moved.

Owner:GLOBUS MEDICAL INC

Expandable vertebral implant

A joint spacer therapeutically maintains separation of bones of a joint. A carriage is slideably retained within the frame and has at least one ramped surface. An actuator screw is threadably engaged with the frame, and rotatably connected to the carriage, to cause the carriage to slideably move within the frame when the actuator screw is rotated. First and second endplates engage the bones of the joint, and each has at least one ramped surface that is mateable with the ramped surface of the carriage, whereby when the carriage is slideably moved by rotation of the actuator screw, the endplates ramped surface slides against the carriage ramped surface to cause the endplates to move along an axis transverse to the longitudinal axis of the frame, to increase the height of the spacer. Piercing elements are connected to the carriage to pierce bone of the joint when the carriage is moved.

Owner:GLOBUS MEDICAL INC

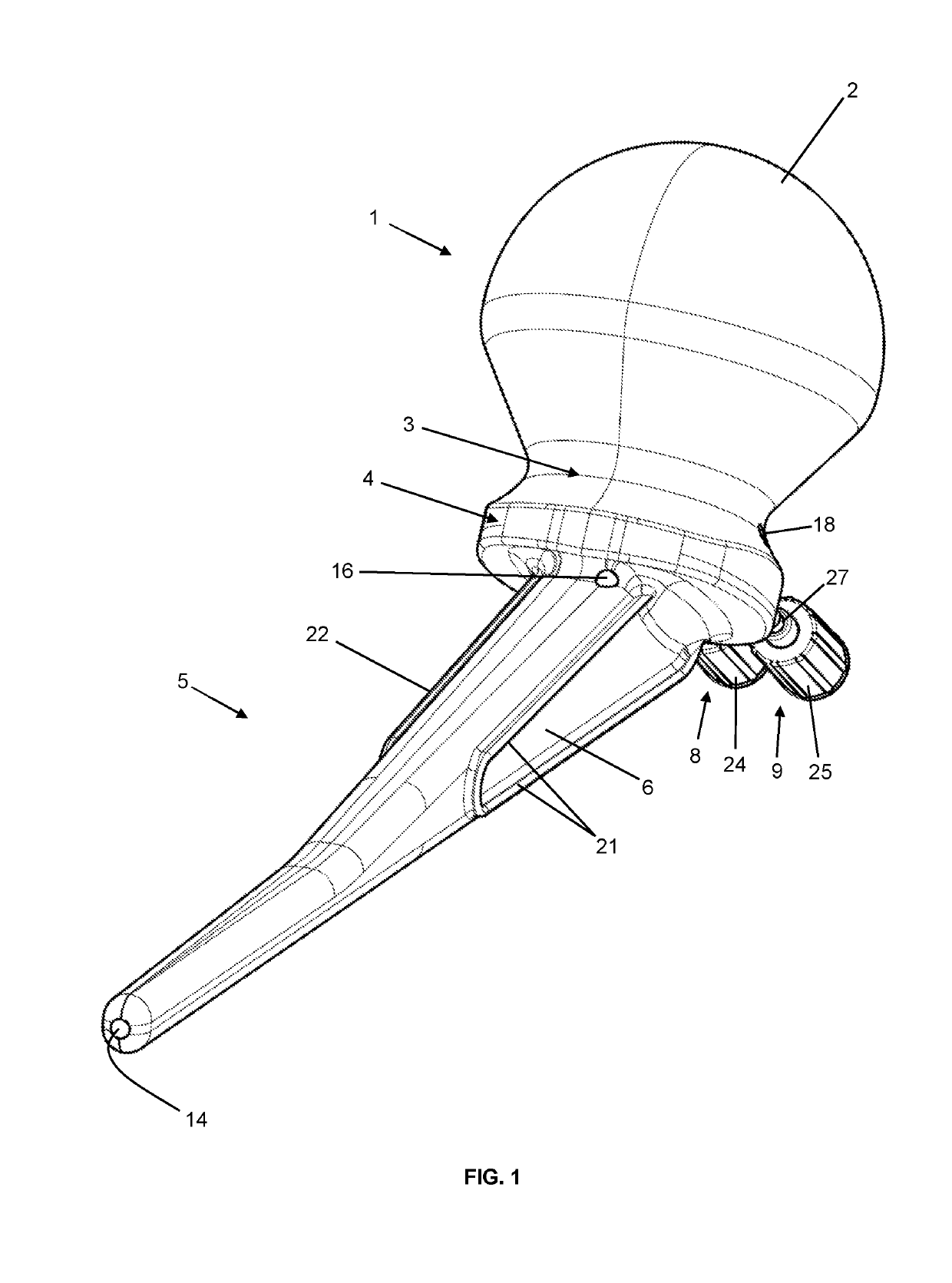

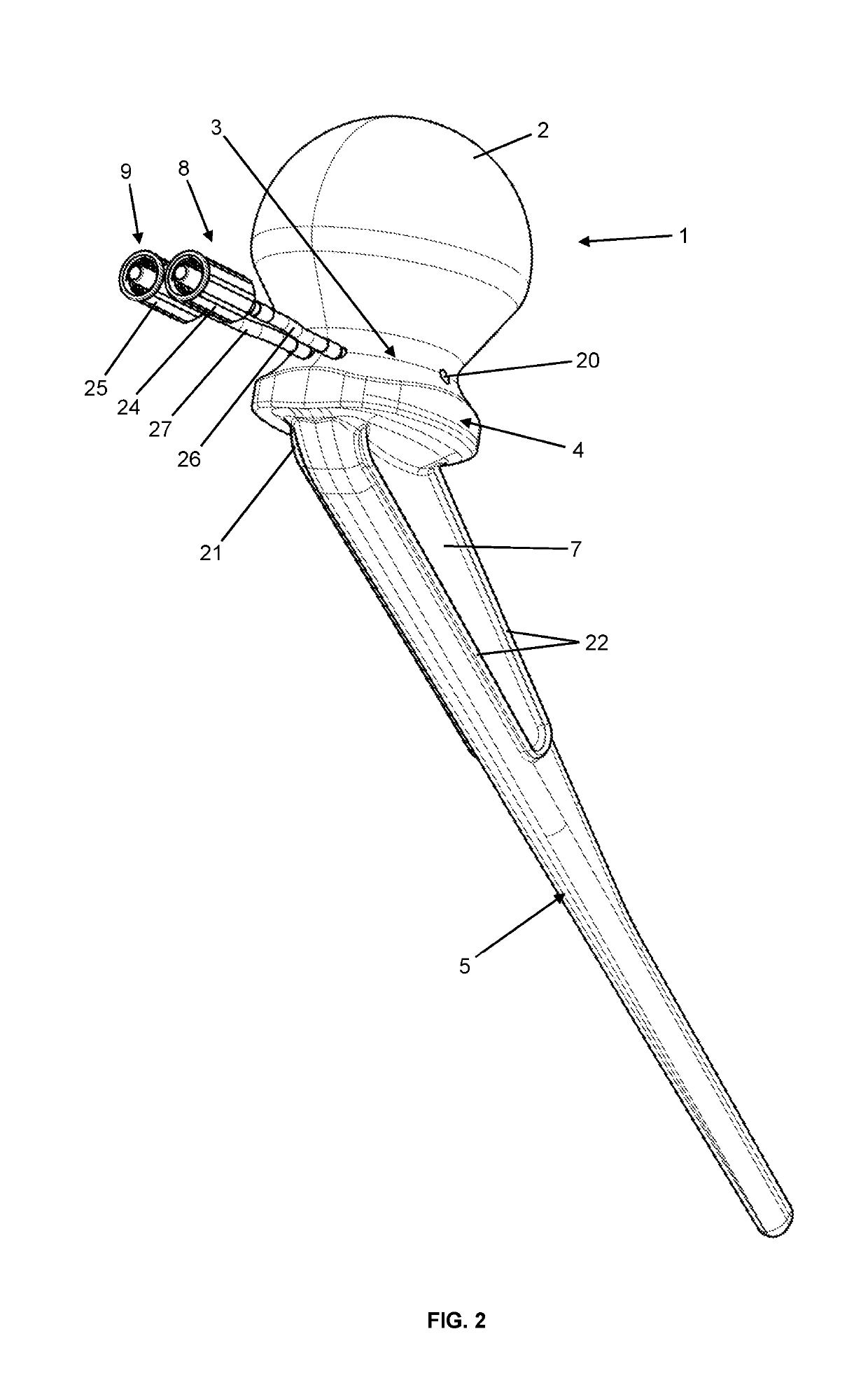

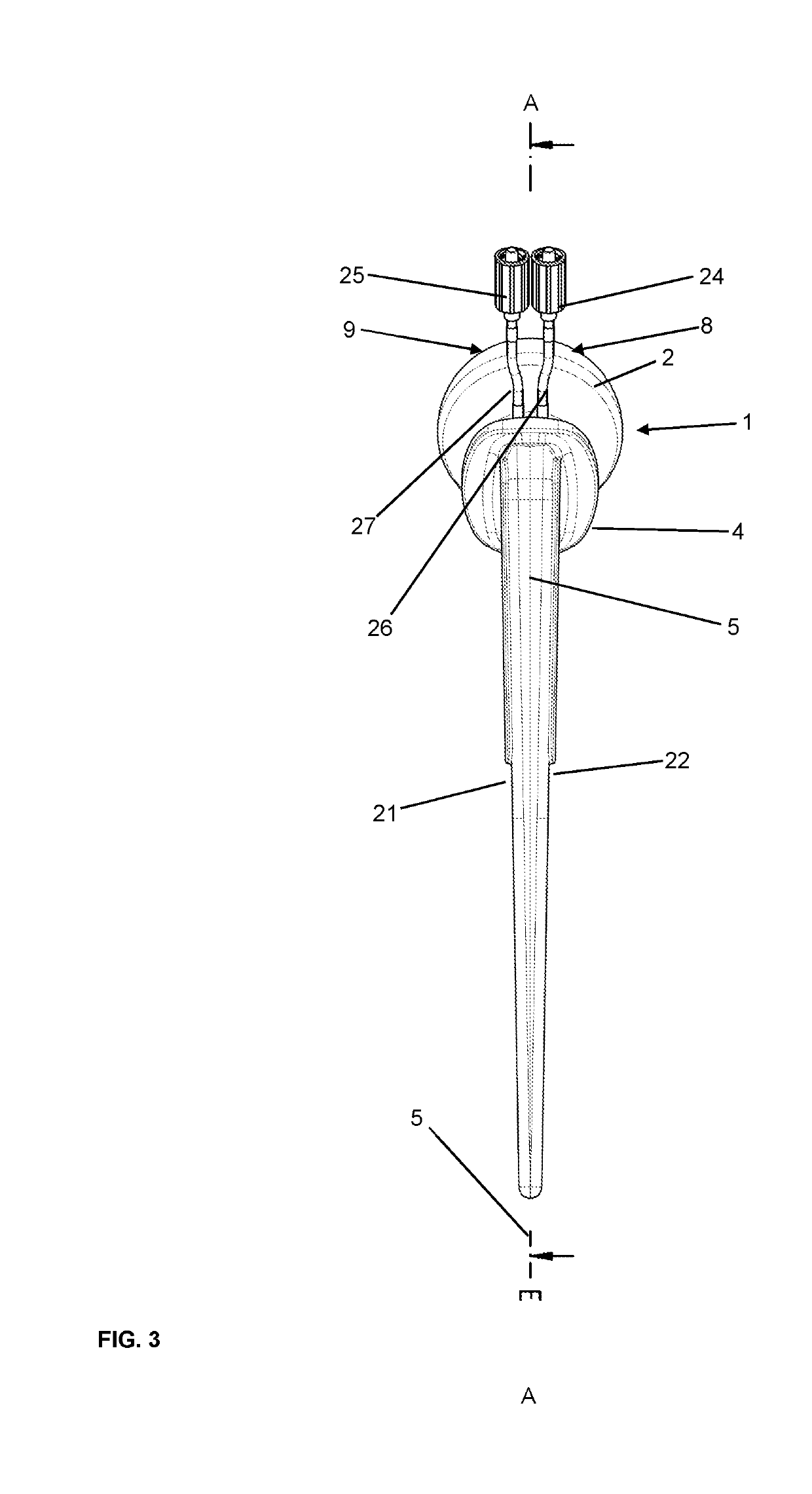

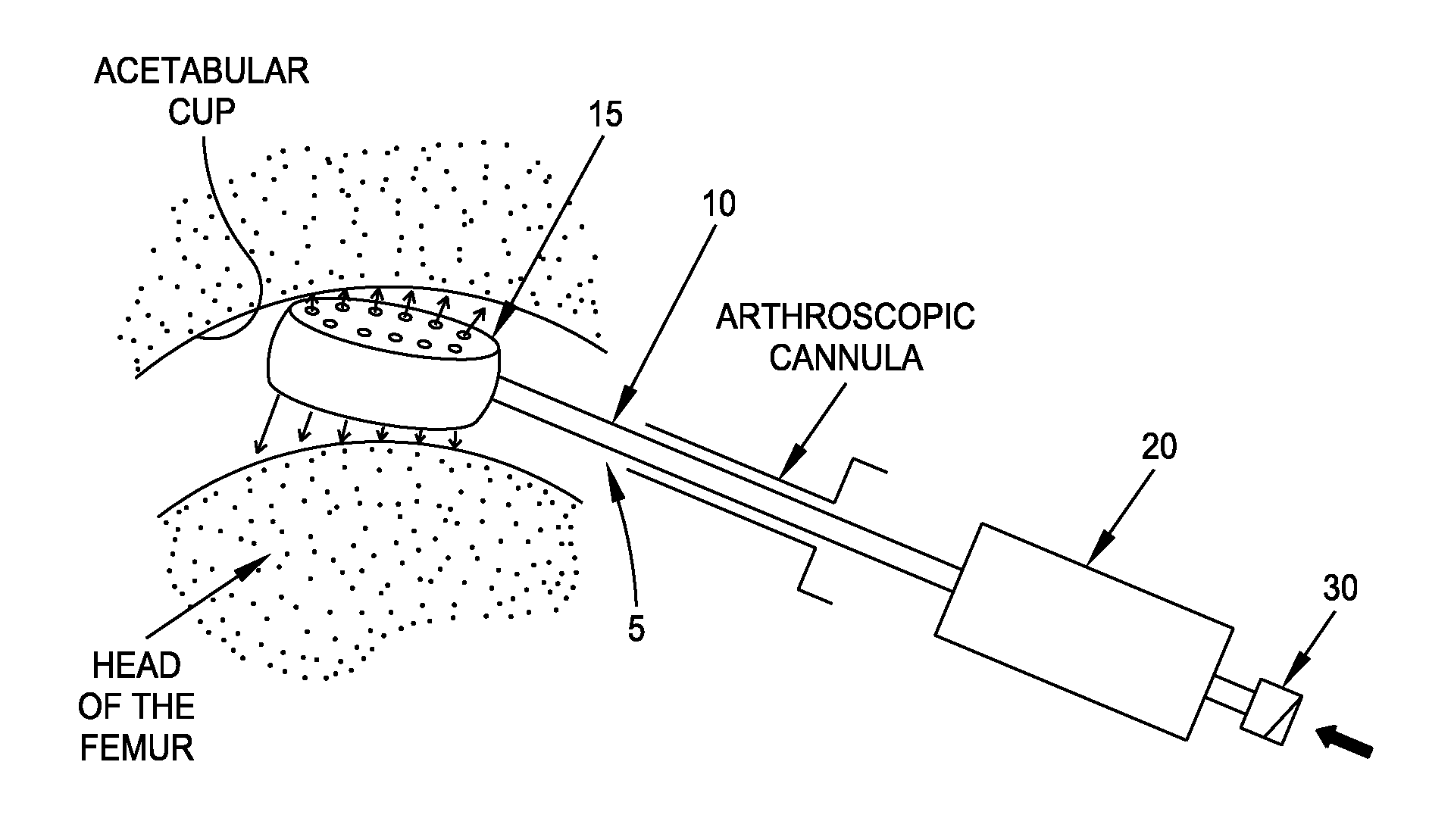

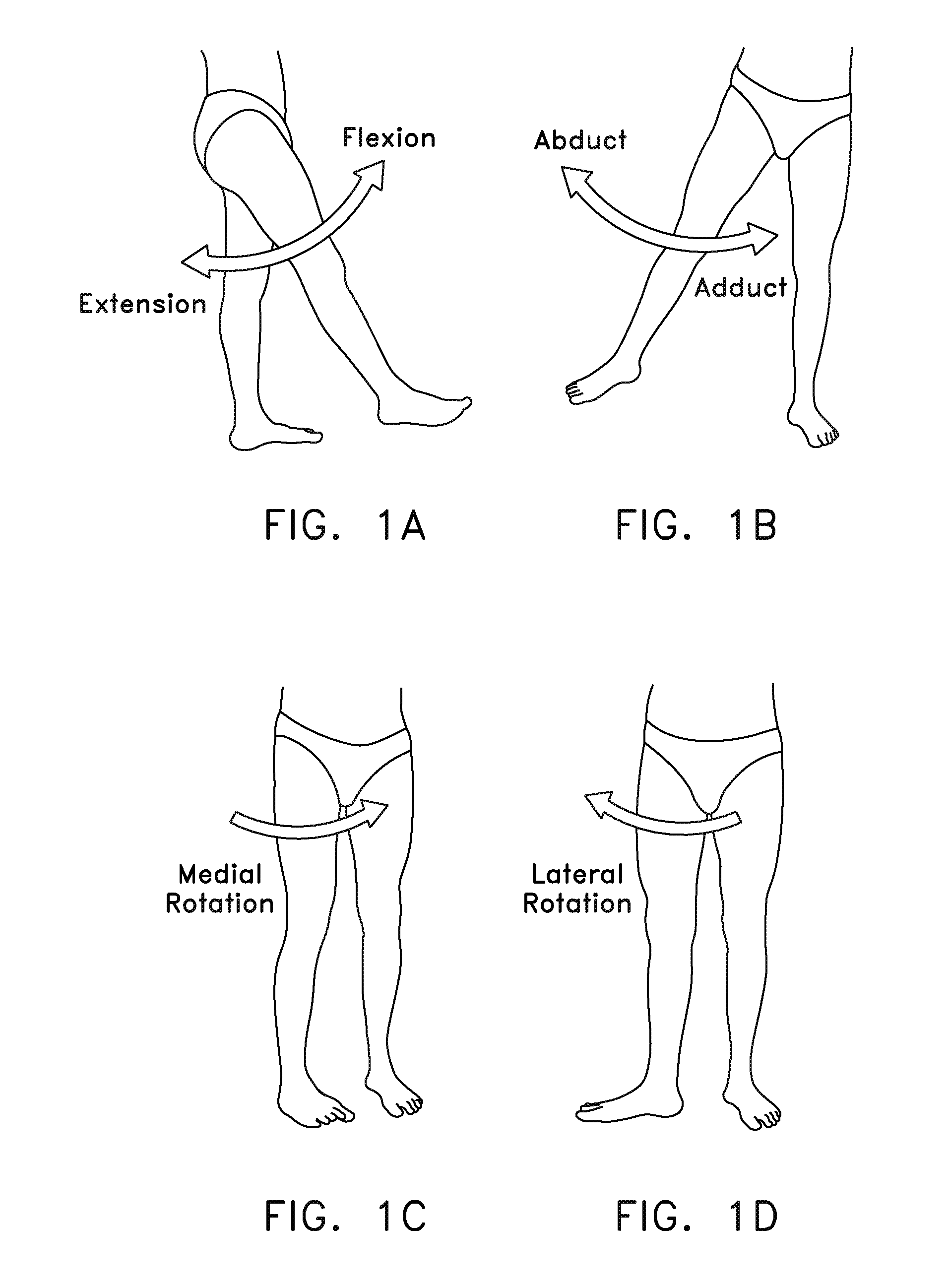

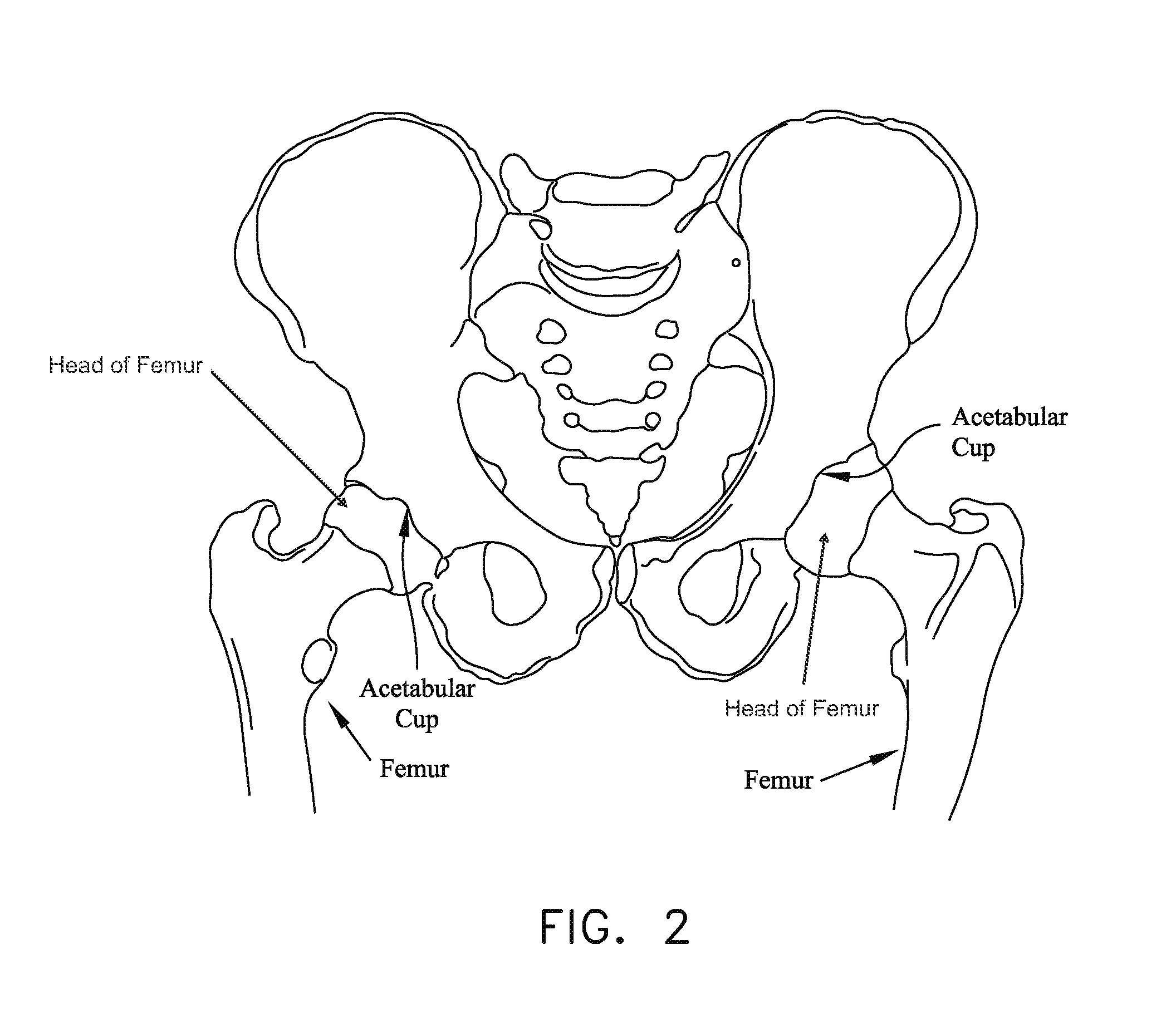

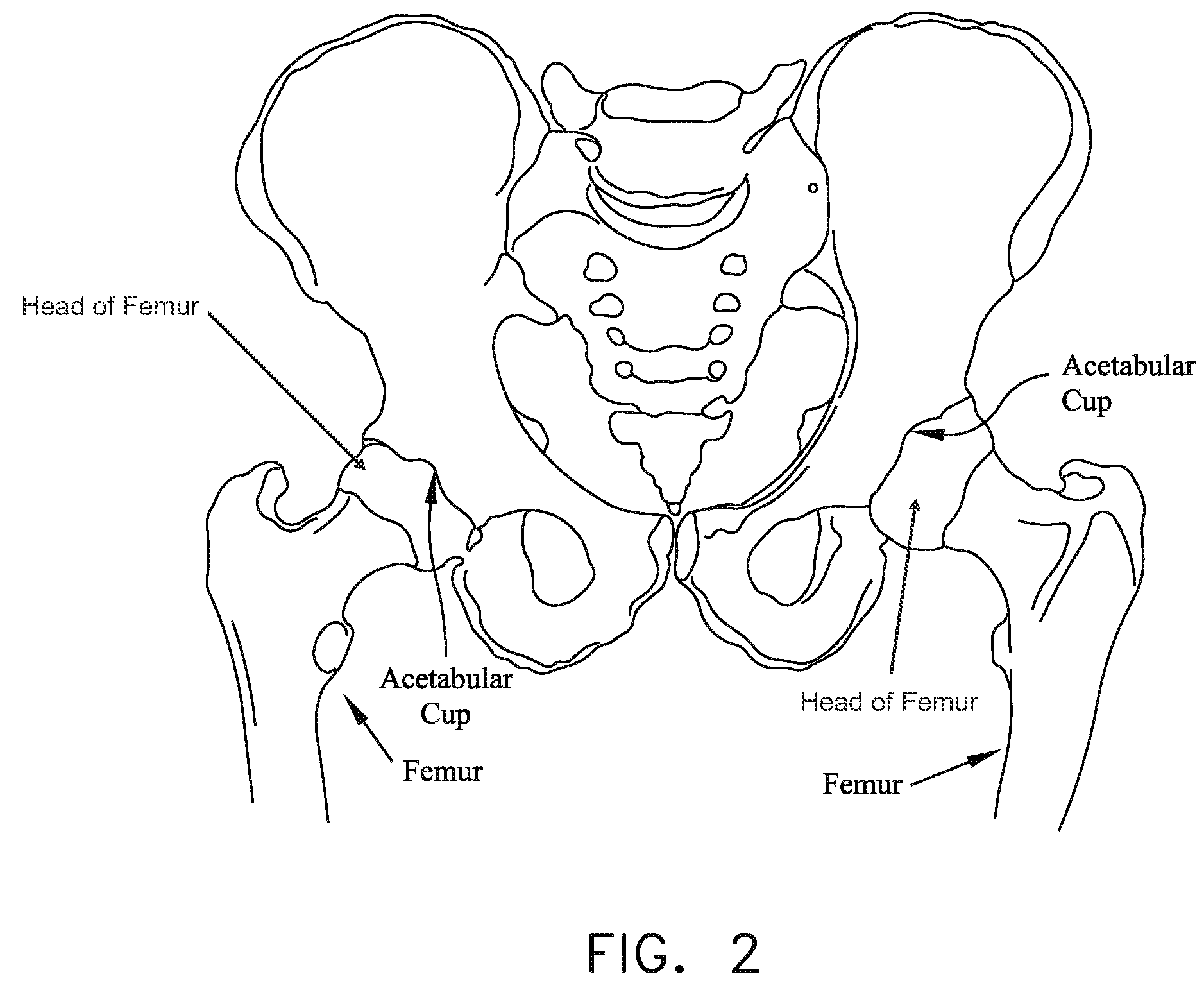

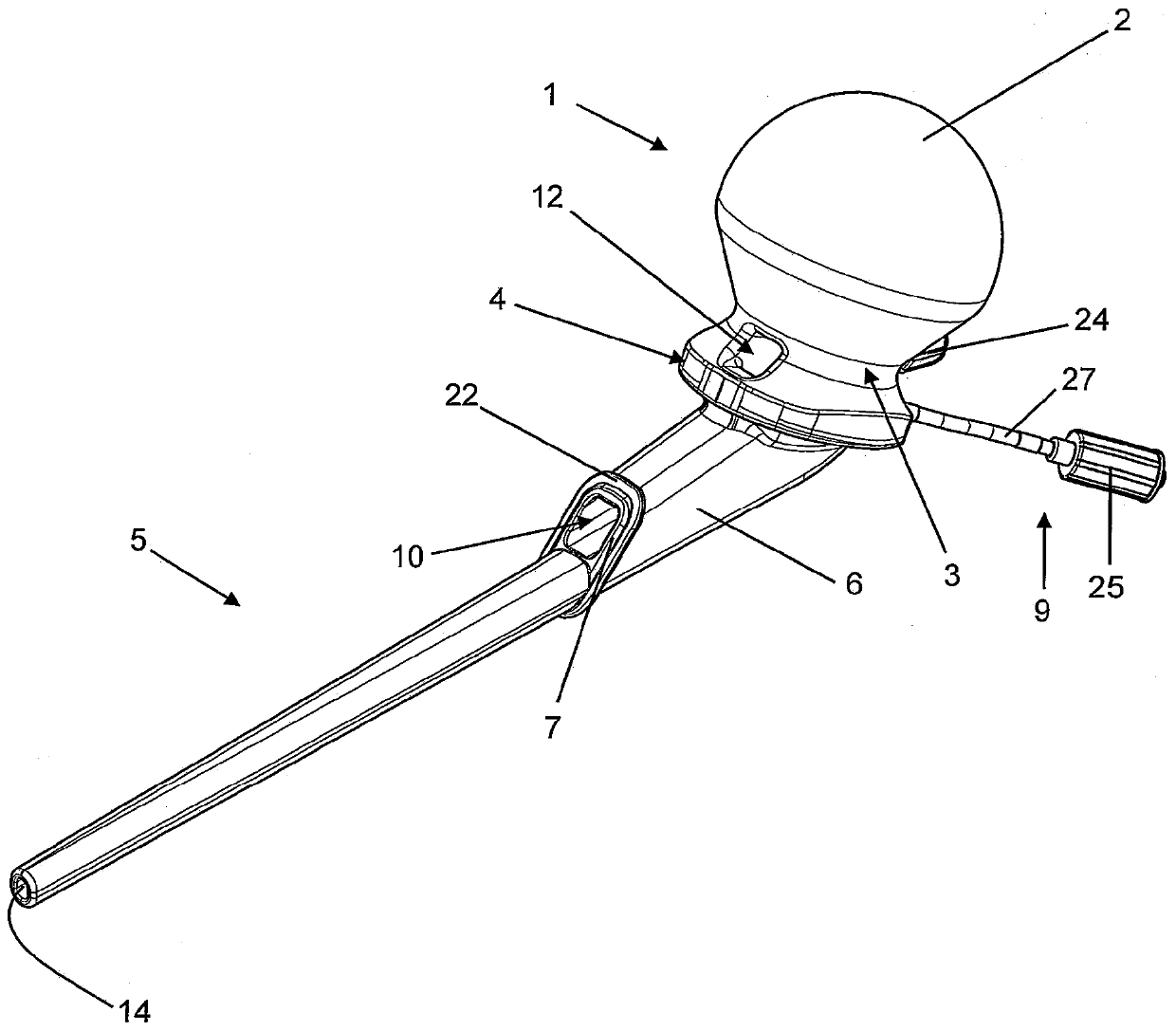

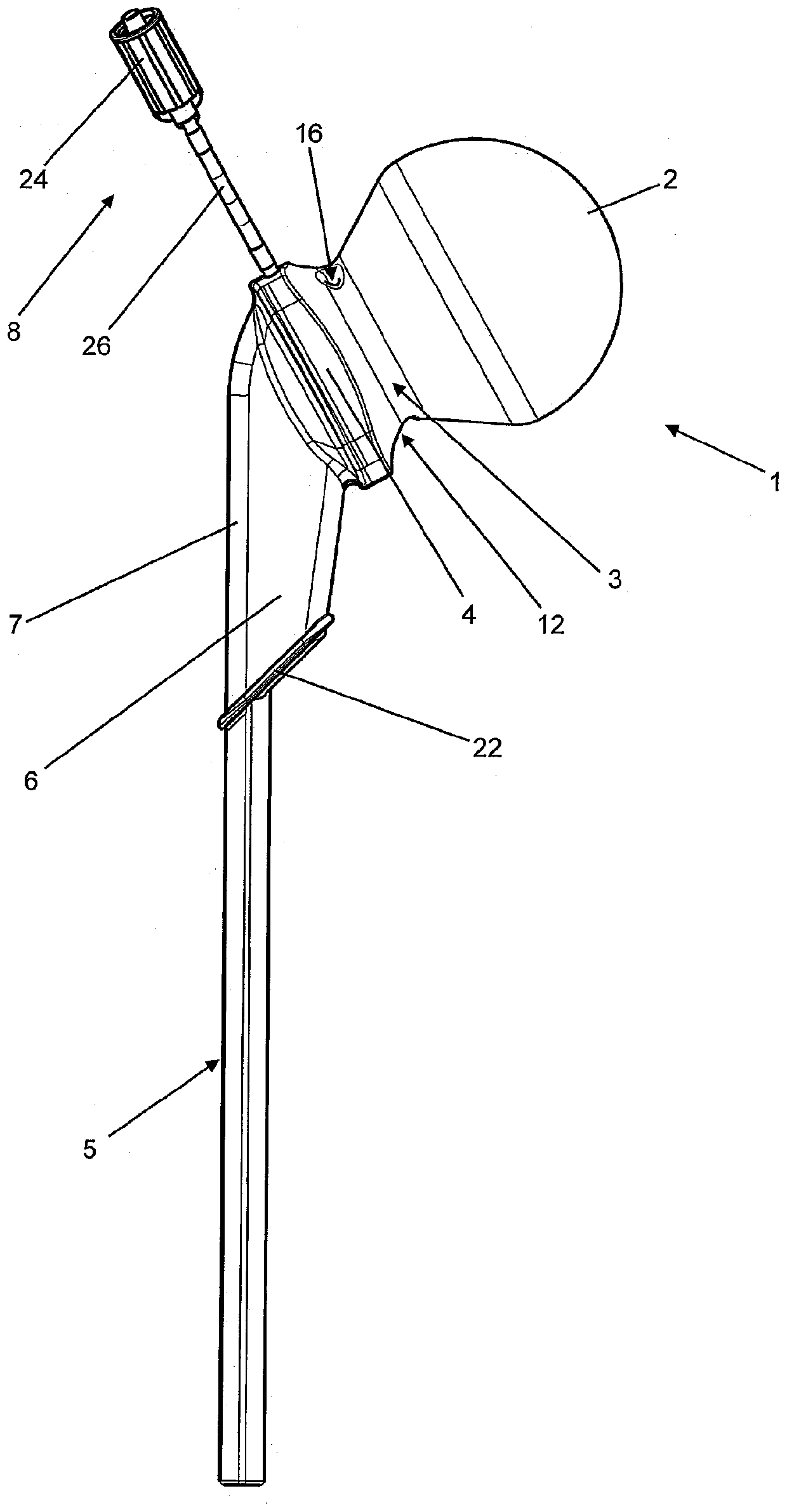

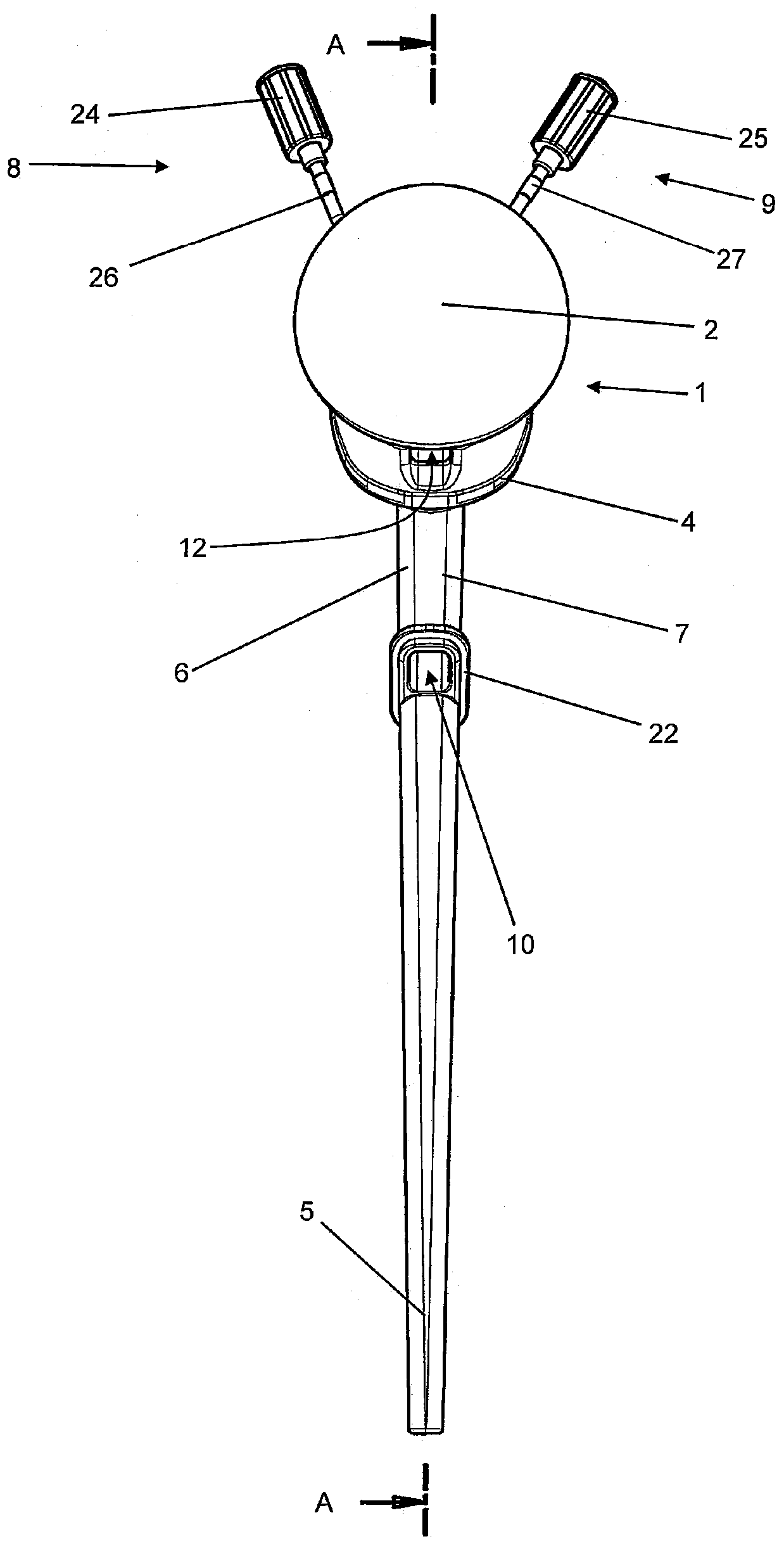

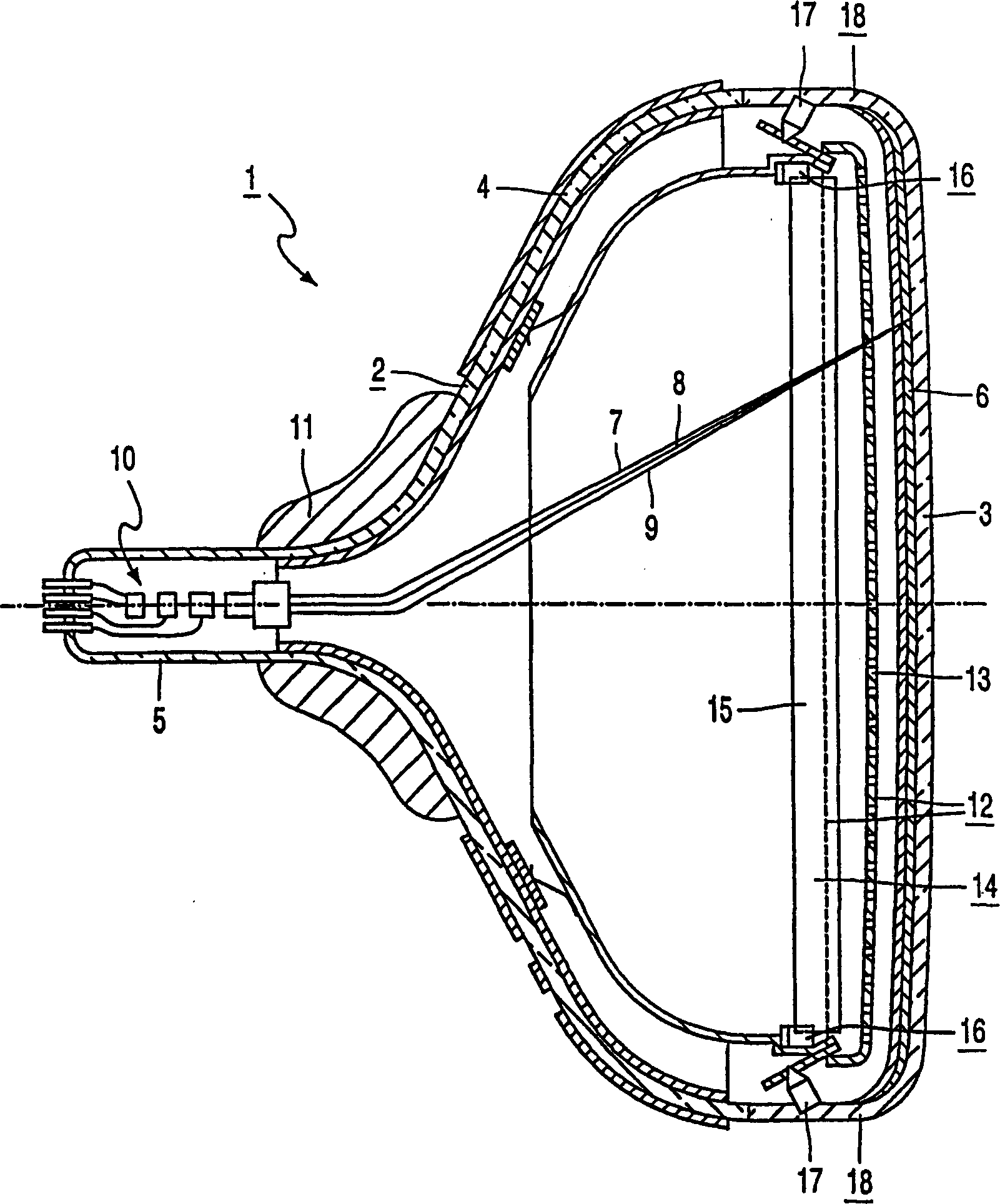

Femoral hip joint spacer with irrigation device

ActiveUS20190290833A1Shorten recovery timeEasy to adjustCannulasEnemata/irrigatorsJoint spacerProsthesis

A femoral hip joint spacer including a prosthesis body having a ball head with a sliding surface, a neck, a collar and a stem. A fastening area is arranged on the stem. The femoral hip joint spacer further has a first connector for feeding a medical irrigation liquid into the body, a second connector for draining the irrigation liquid from the body, and an irrigation liquid inlet opening. The first connector is connected in a liquid-conveying manner to the irrigation liquid inlet opening and an irrigation liquid outlet opening. The second connector is connected in a liquid-conveying manner to the irrigation liquid outlet opening, an irrigation liquid discharge opening and an irrigation liquid intake opening. The irrigation liquid discharge opening is connected inside the body to the irrigation liquid inlet opening and the irrigation liquid intake opening is connected inside the body to the irrigation liquid outlet opening.

Owner:HERAEUS MEDICAL

Expandable vertebral implant

ActiveUS10709571B2Increase heightReduce rotationJoint implantsSpinal implantsJoint spacerIliac screw

A joint spacer therapeutically maintains separation of bones of a joint. A carriage is slideably retained within the frame and has at least one ramped surface. An actuator screw is threadably engaged with the frame, and rotatably connected to the carriage, to cause the carriage to slideably move within the frame when the actuator screw is rotated. First and second endplates engage the bones of the joint, and each has at least one ramped surface that is mateable with the ramped surface of the carriage, whereby when the carriage is slideably moved by rotation of the actuator screw, the endplates ramped surface slides against the carriage ramped surface to cause the endplates to move along an axis transverse to the longitudinal axis of the frame, to increase the height of the spacer. Piercing elements are connected to the carriage to pierce bone of the joint when the carriage is moved.

Owner:GLOBUS MEDICAL INC

Expandable intervertebral implant

ActiveUS10117754B2Increase heightReduce rotationJoint implantsSpinal implantsJoint spacerEngineering

A joint spacer for therapeutically maintains separation of bones of a joint. A frame defines a longitudinal axis extending between distal and proximal ends. A carriage is slideably retained within the frame and has at least one ramped surface and a threaded portion. An actuator screw is threadably engaged with the threaded portion, and bears against said frame to cause the carriage to slideably move within the frame when the actuator screw is rotated. A first endplate engages a bone of the joint, and has at least one ramped surface that is mateable with the ramped surface of the carriage.

Owner:GLOBUS MEDICAL INC

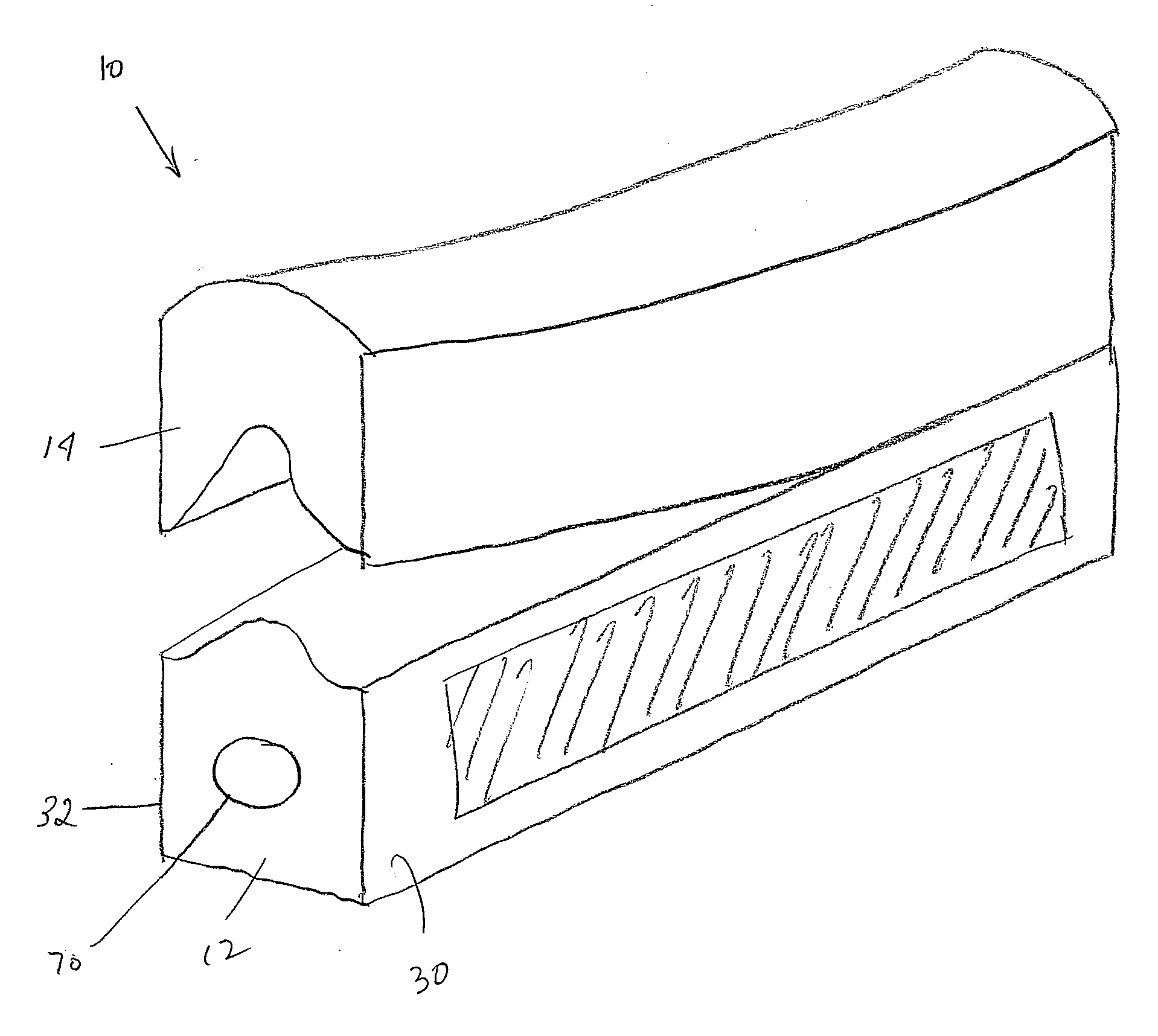

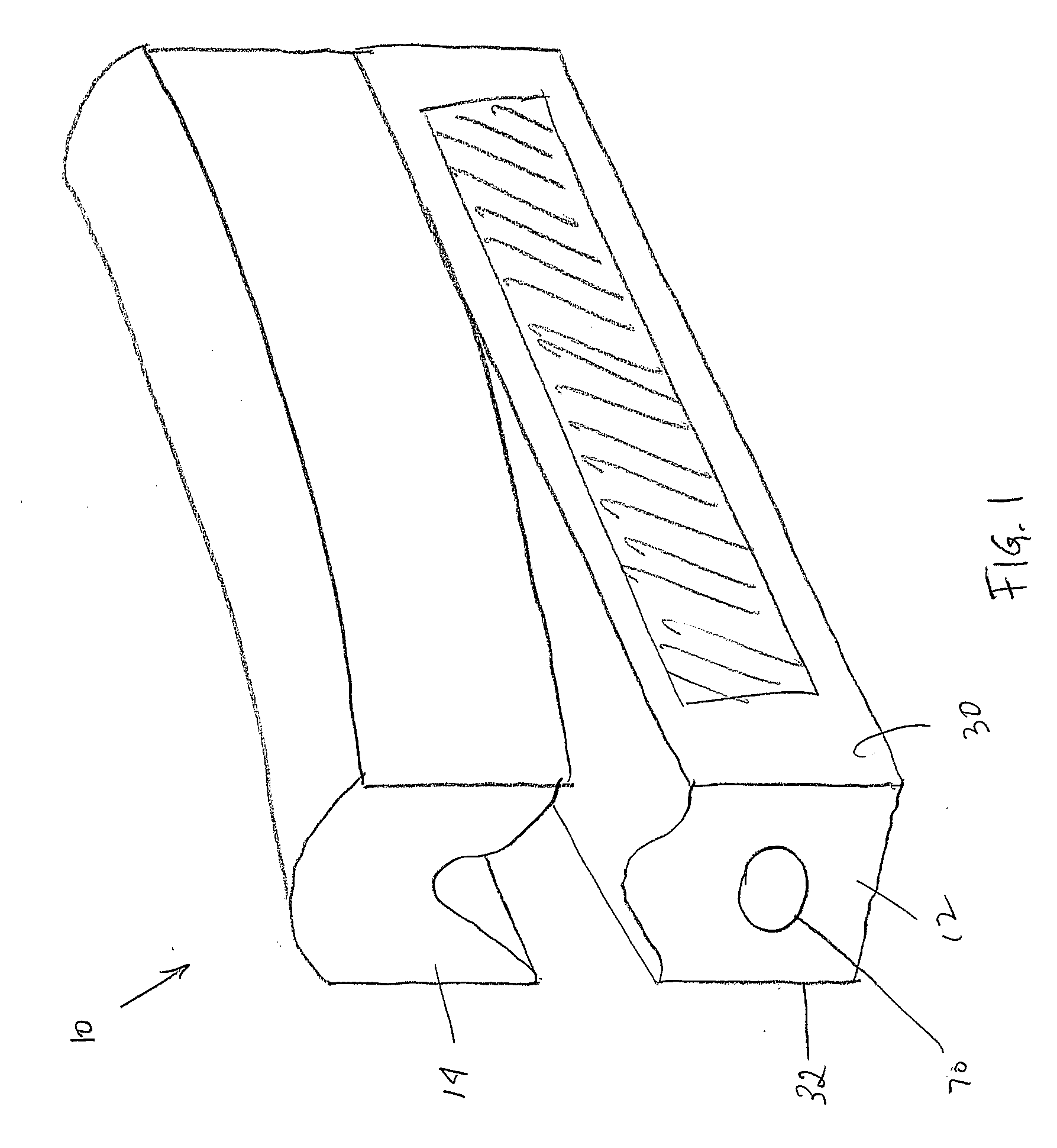

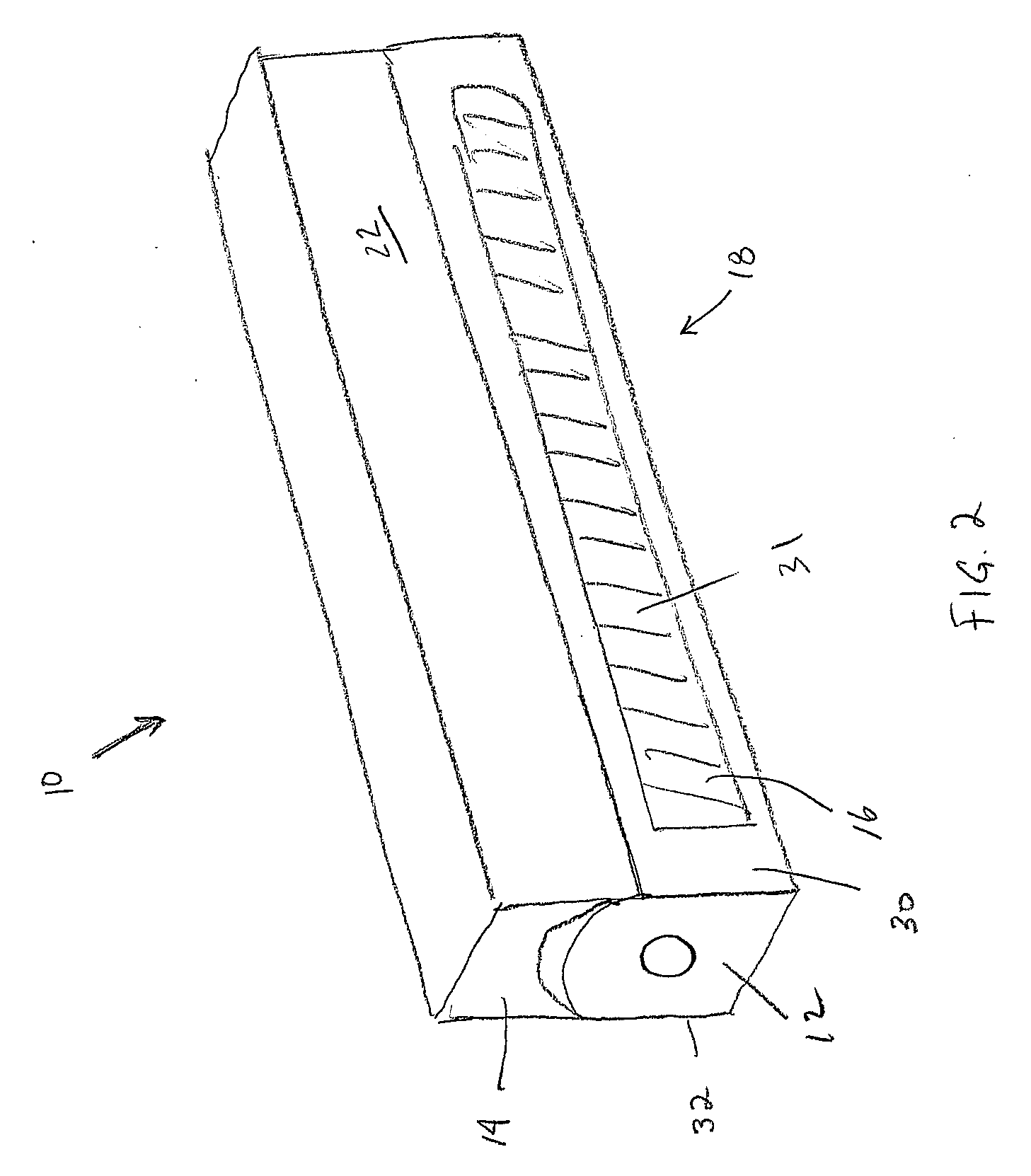

Carpometacarpal joint spacer

InactiveUS20100324693A1Stable positionRestore separationFinger jointsAnkle jointsJoint spacerPositive pressure

A swellable, resilient, flexible carpometacarpal (CMC) joint spacer is provided that is made of a swellable fluid absorbing polymeric medium, the spacer being dimensioned and configured to fit into the space between a natural or replacement trapezium and adjacent metacarpal bones and restore separation therebetween. In embodiments, the spacer has a cylindrical shape. In embodiments, the polymeric medium is a hydrogel. In embodiments, the spacer contains an internal reinforcement member. In embodiments, the spacer is delivered to a target site in at least a partially dehydrated state, whereupon it hydrates and expands to create positive pressure against opposing surfaces, thereby causing separation of the joint.

Owner:HARDENBROOK FREDERICK H

Expandable vertebral implant

A joint spacer therapeutically maintains separation of bones of a joint. A carriage is slideably retained within the frame and has at least one ramped surface. An actuator screw is threadably engaged with the frame, and rotatably connected to the carriage, to cause the carriage to slideably move within the frame when the actuator screw is rotated. First and second endplates engage the bones of the joint, and each has at least one ramped surface that is mateable with the ramped surface of the carriage, whereby when the carriage is slideably moved by rotation of the actuator screw, the endplates ramped surface slides against the carriage ramped surface to cause the endplates to move along an axis transverse to the longitudinal axis of the frame, to increase the height of the spacer. Piercing elements are connected to the carriage to pierce bone of the joint when the carriage is moved.

Owner:GLOBUS MEDICAL INC

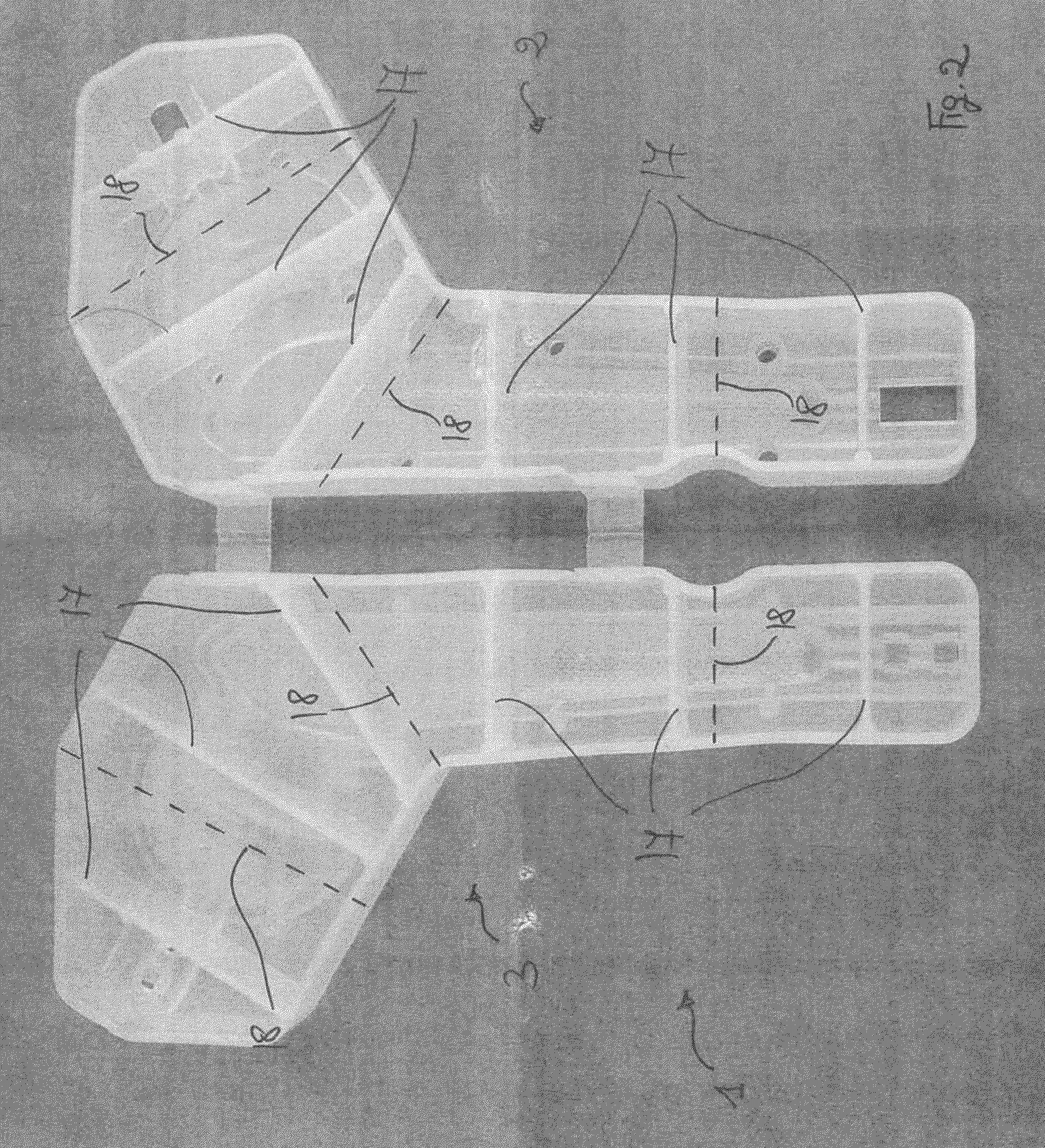

Mold for forming a joint spacer device or a part thereof

ActiveUS20160129610A1Good conditionSimple processJoint implantsCeramic shaping apparatusJoint spacerSpacer device

A mold for forming a joint spacer device or a part thereof includes a rigid container body having a first perimeter profile delimiting a first molding surface configured to shape a first portion of the joint spacer or a part thereof; and a rigid cover provided with a second perimeter profile delimiting a second molding surface configured to shape a second portion of the joint spacer or a part thereof. The rigid container body and the rigid cover are removably engageable to each other, at the first and the second perimeter profile, so as to delimit a cavity corresponding to the external configuration of the joint spacer or the part thereof. The mold includes a weakening system on the rigid container body and on the rigid cover so that they are separable into parts to allow the extraction of a spacer device or a part thereof, molded therebetween.

Owner:COSSINGTON LTD

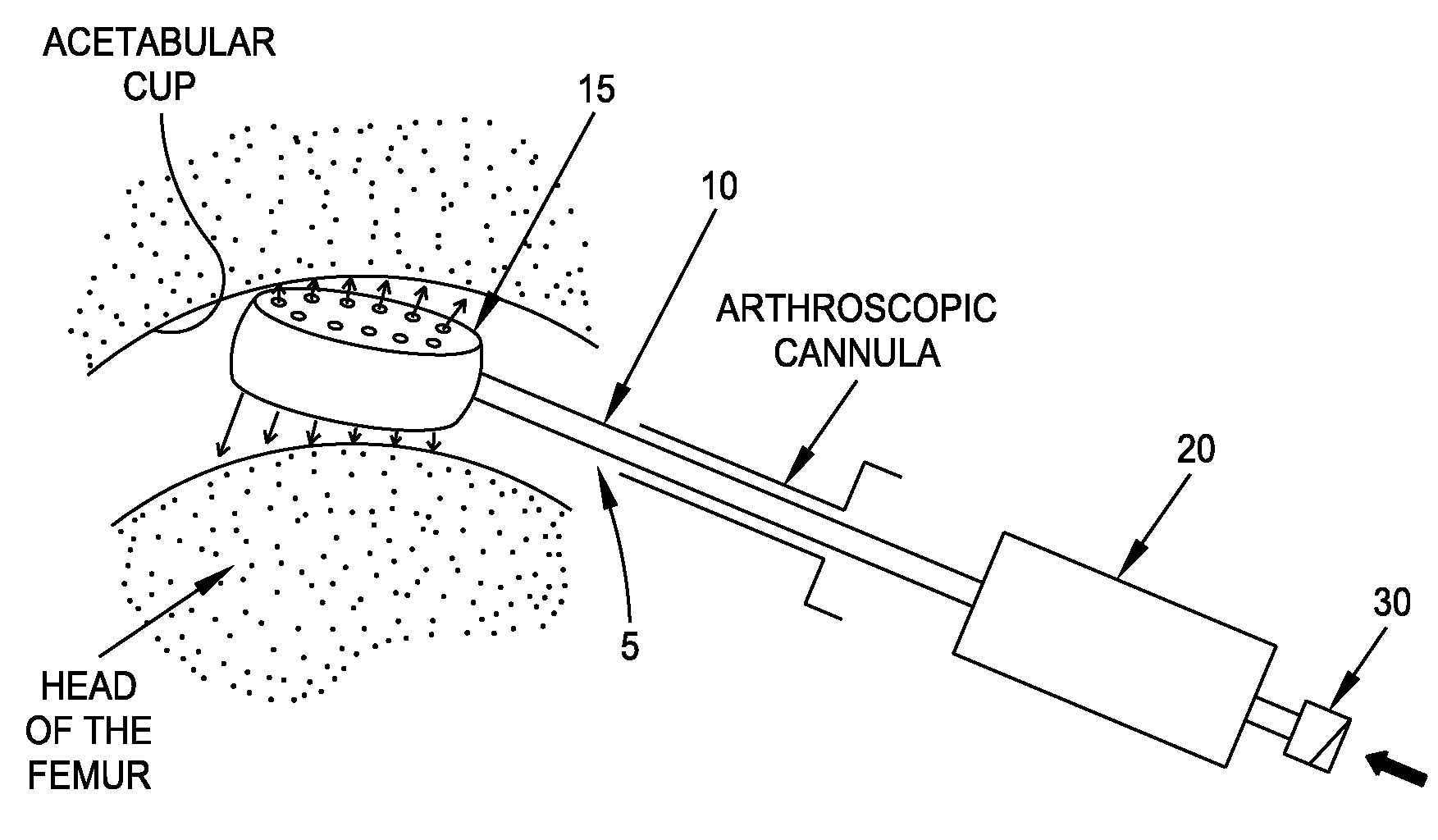

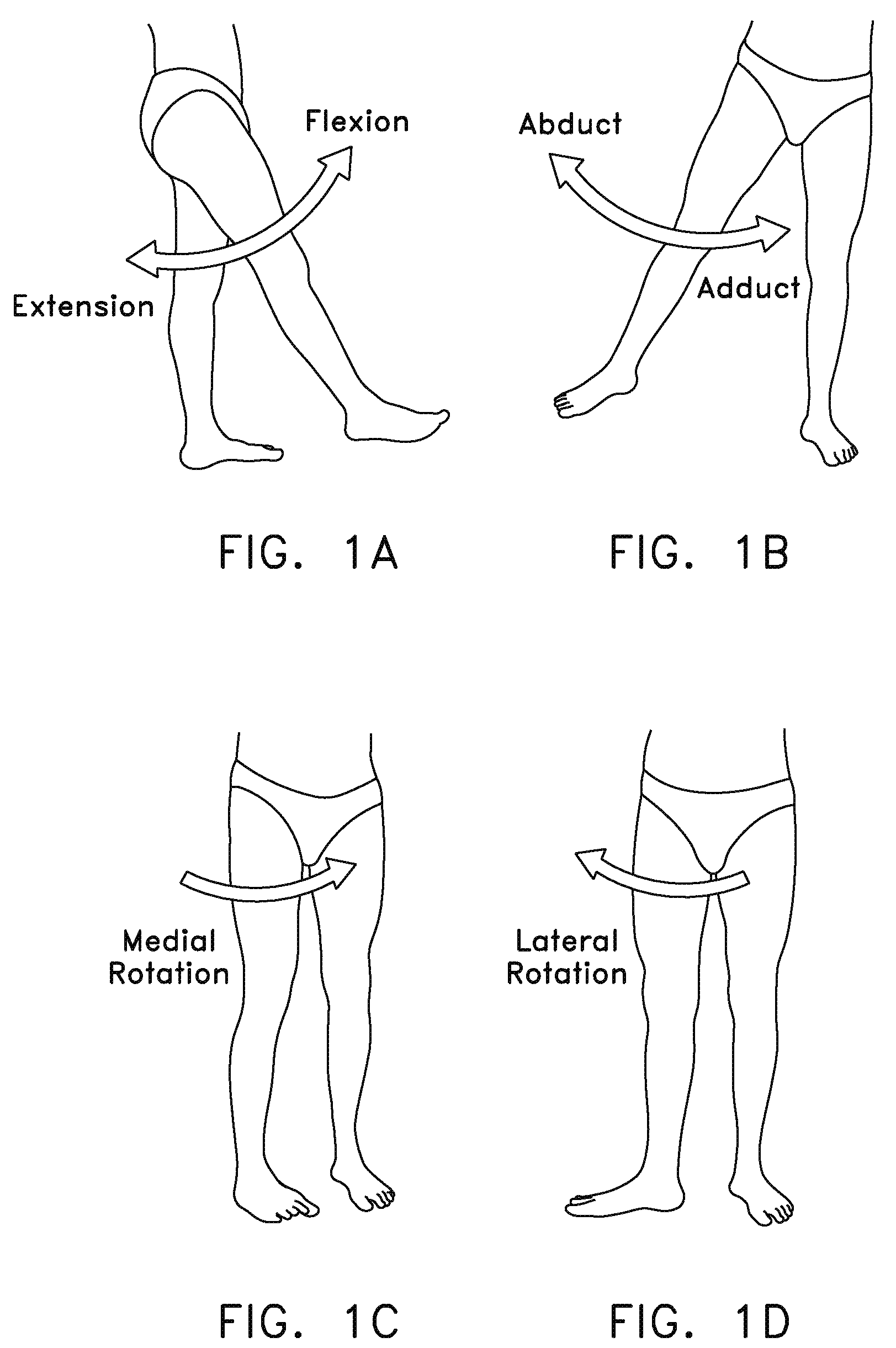

Method and apparatus for distracting a joint, including the provision and use of a novel fluid joint spacer

InactiveUS20110196378A1Maintain distractionMinimizing damageProsthesisOsteosynthesis devicesJoint spacerEngineering

A fluid joint spacer comprising a body having means for receiving a pressurized fluid from an external source and applying that pressurized fluid against a joint element so as to create a flowing fluid bearing within the joint.

Owner:STRYKER CORP

Expanding intervertebral implants

A joint spacer has first and second endplates, with each having a bone engaging surface, and at least two cams with an inclined cam surface positioned on an opposite side. First and second slides, each having ramps with an inclined surface are engaged with the cams of the endplate. The first slide has an angled portion at an end, and the second slide has a hinge portion. A threaded shaft has a hinge portion connected to the slide hinge portion, connecting the shaft to the slide, enabling the shaft to pivot. A nut is threaded to the shaft, and can contact and interfere with the angled portion of the first slide to drive the first slide with respect to the second slide. This results in engagement of the cams and ramps to drive the endplates apart to increase the spacer height.

Owner:GLOBUS MEDICAL INC

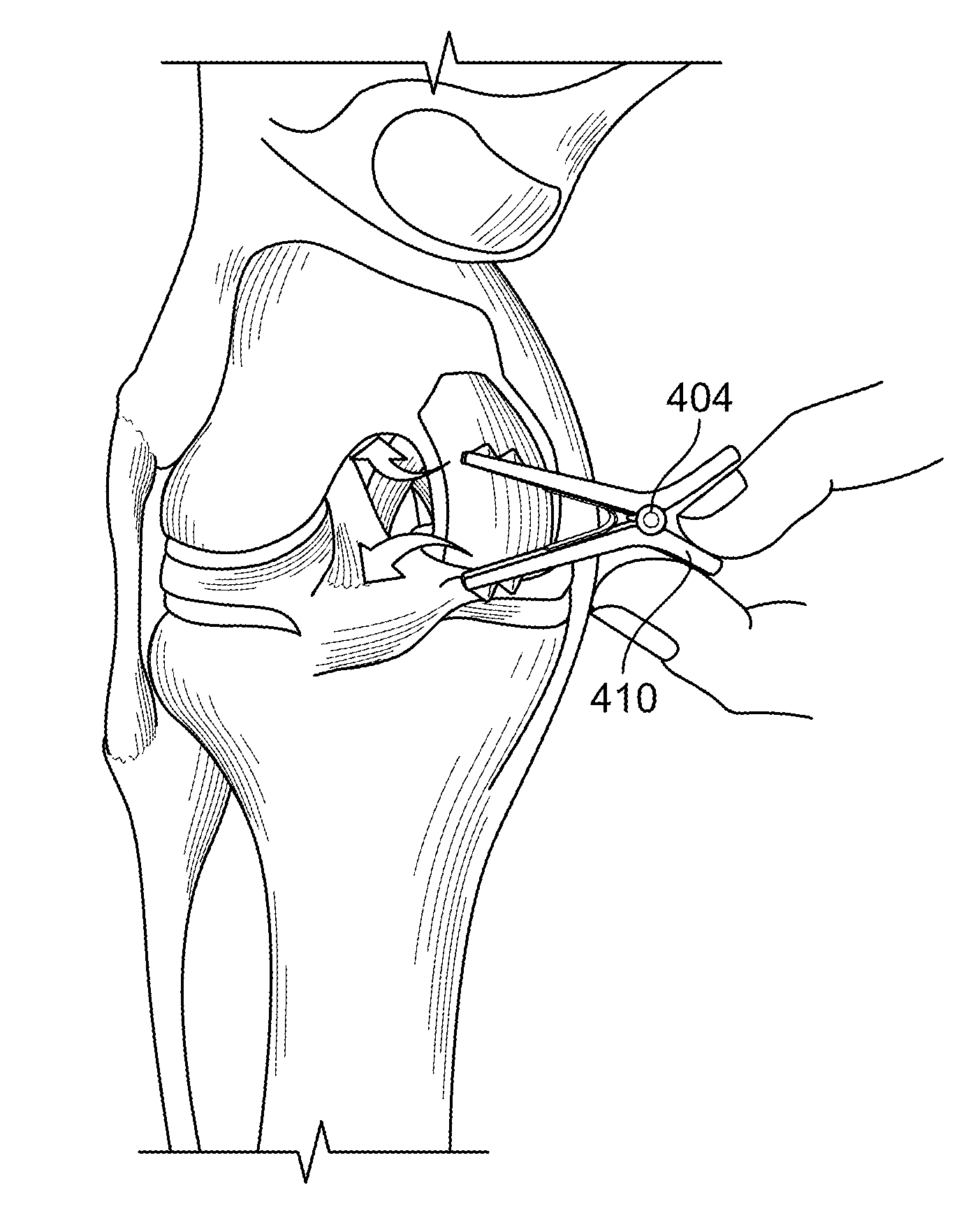

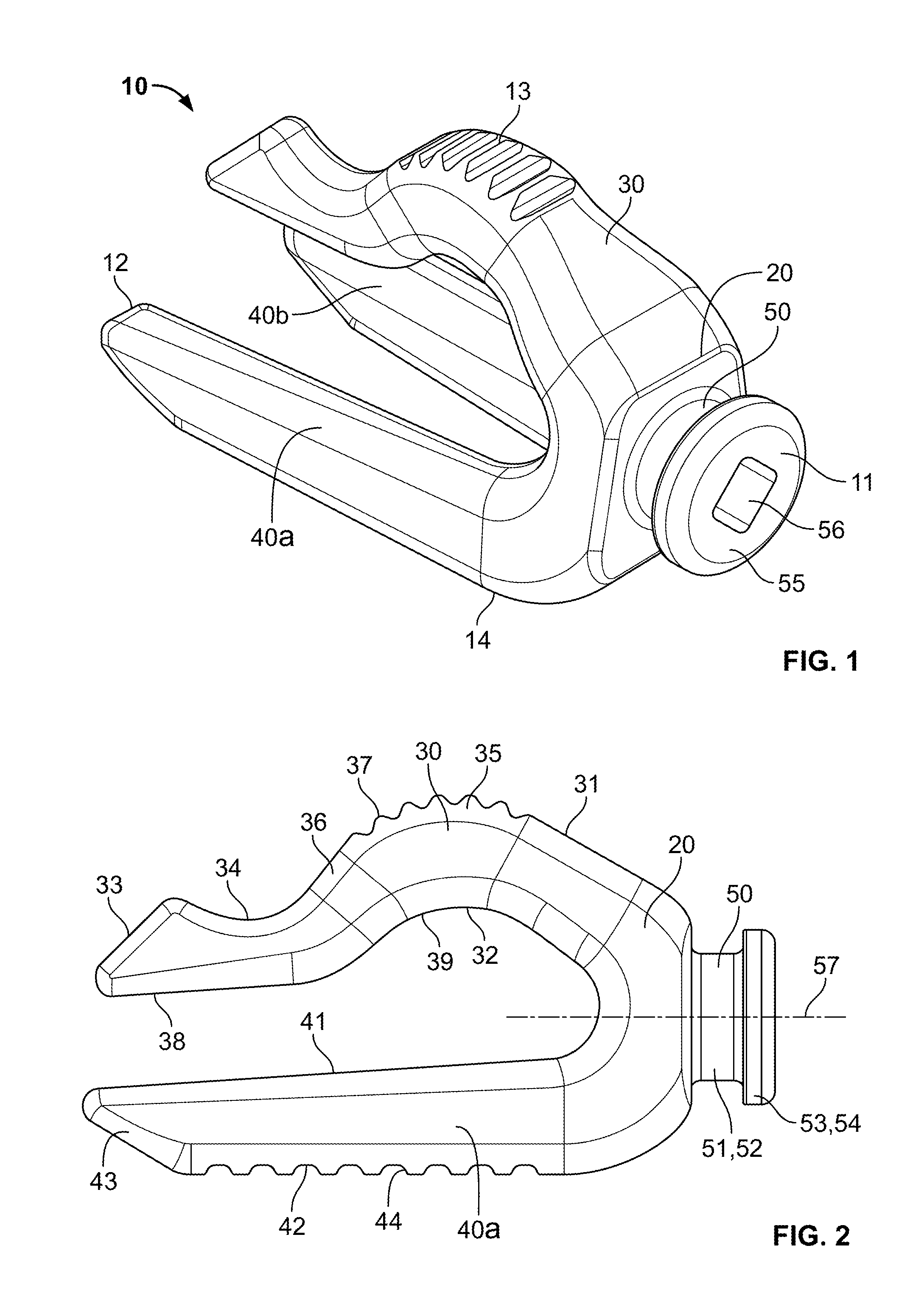

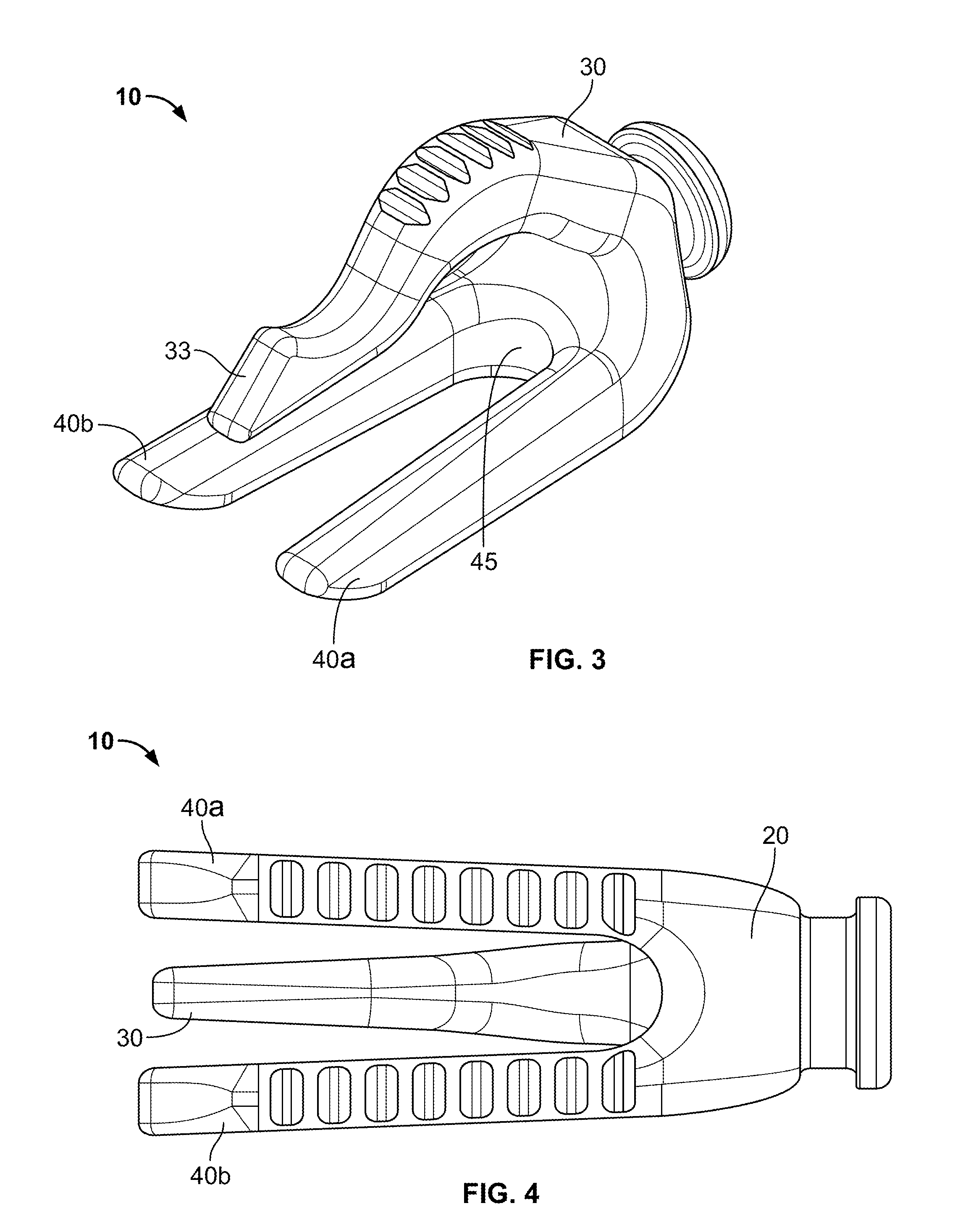

Joint stabilizing instrument and method of use

InactiveUS20140012270A1Prevent insertionPrevent over insertionProsthesisSurgical forcepsJoint spacerEngineering

A joint spacer having a body and a series of extensions projecting therefrom is disclosed. A first of the series of extensions may include a curved section for housing a portion of a joint therein (e.g., the intercondylar notch of a knee), and a second and third of the extensions may be configured to abut an opposing portion of the joint. Once inserted, the joint spacer may maintain the spacing between, and the stabilization of, the joint during surgery. A fourth extension may be included with the spacer in which the extension may interact with an insertion-removal instrument. The insertion-removal instrument may include one end having an insertion geometry for use in inserting the spacer into the joint, and an opposing end having a removal geometry for removing the spacer. Related methods for inserting the joint spacer and various alternate joint distraction devices are also disclosed.

Owner:STRYKER CORP

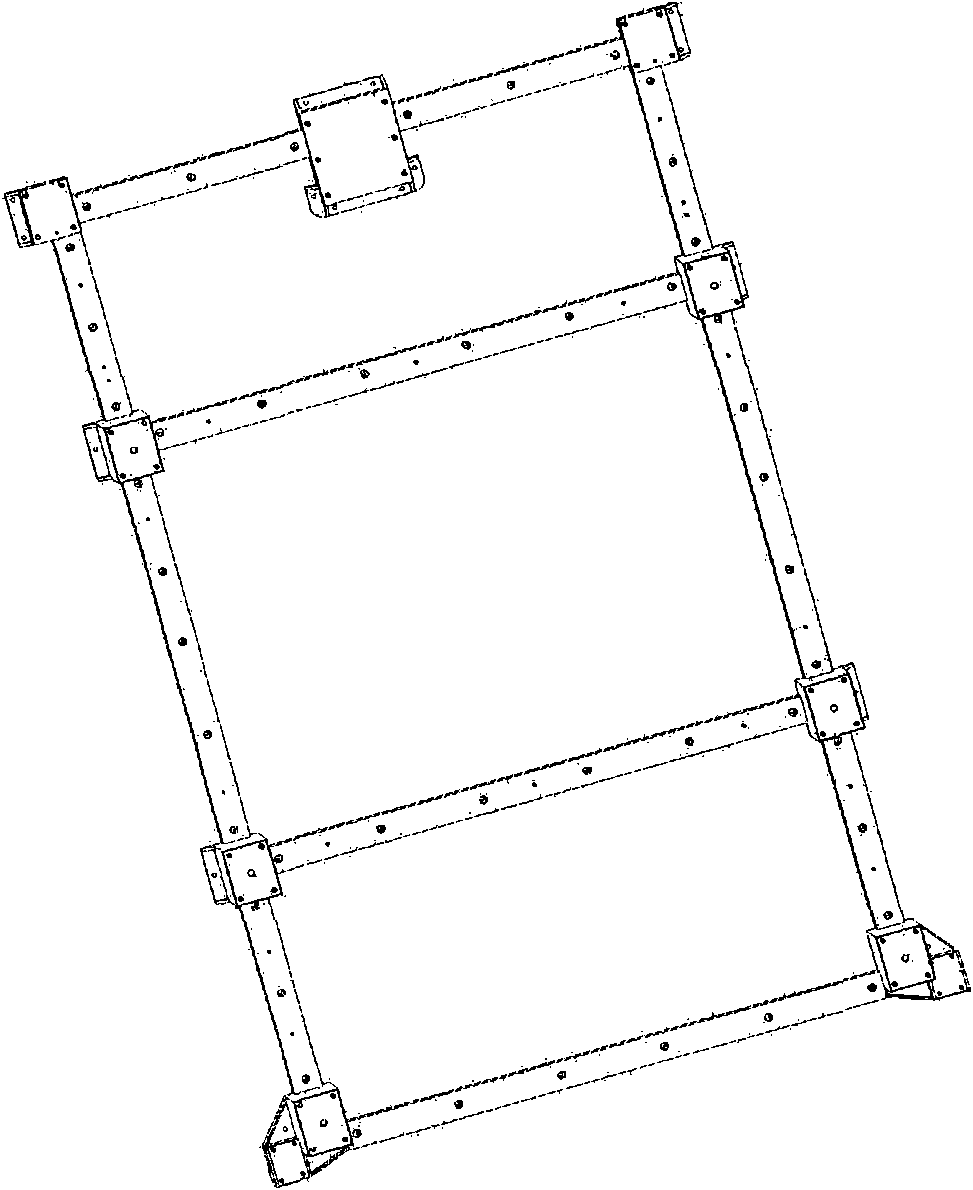

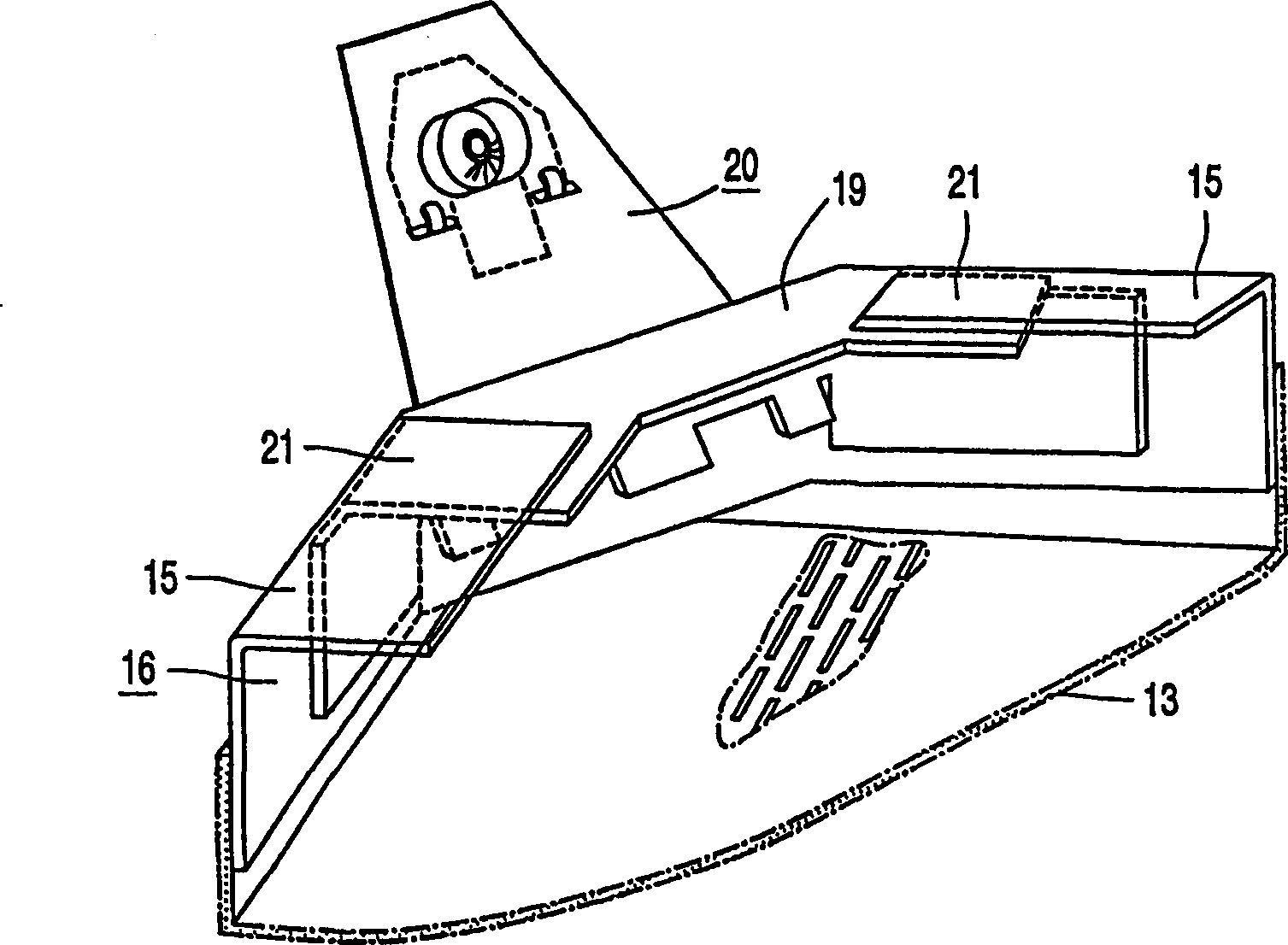

Method for realizing light-weight high-accuracy composite material frame

ActiveCN102145752AReduce structural weightSmall thermal deformationCosmonautic vehiclesCosmonautic partsJoint spacerMaterials science

Owner:SHANGHAI SATELLITE ENG INST

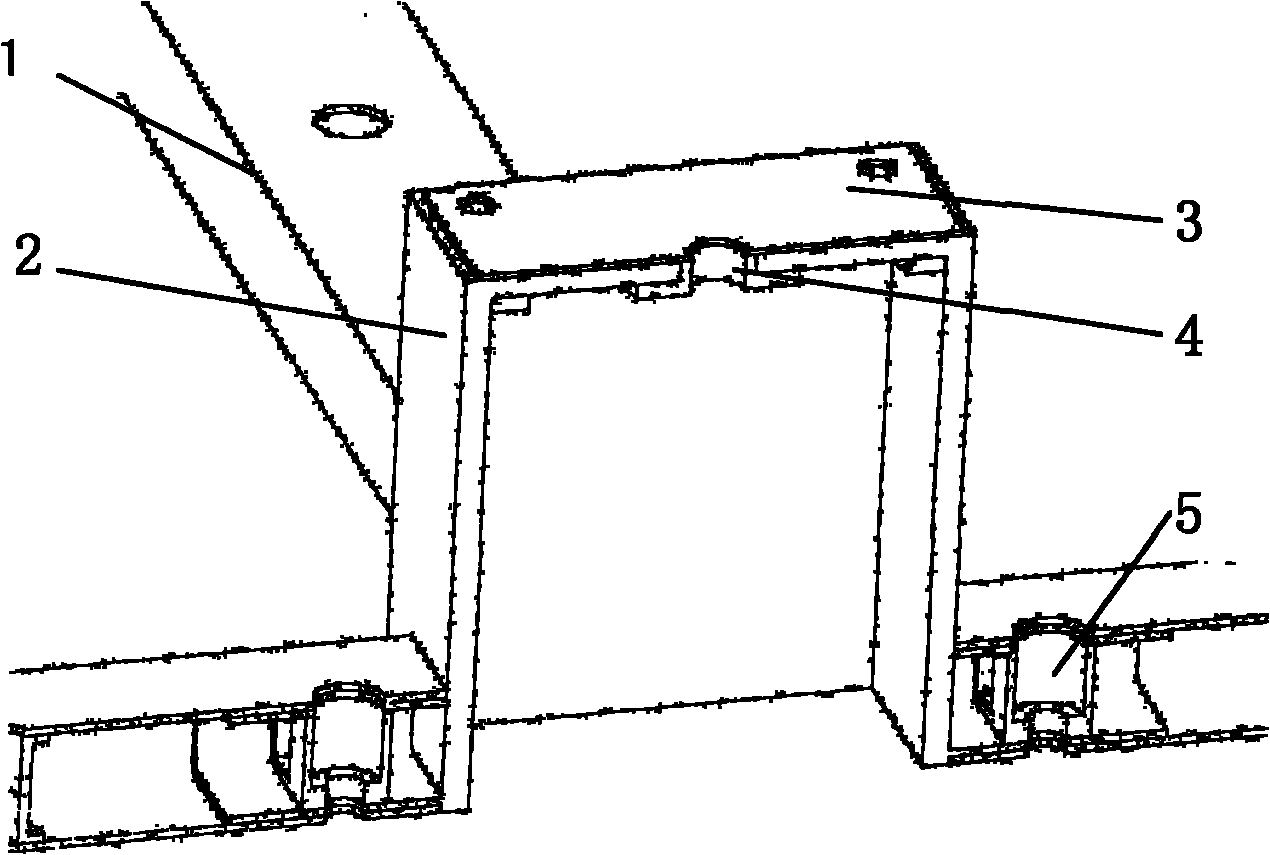

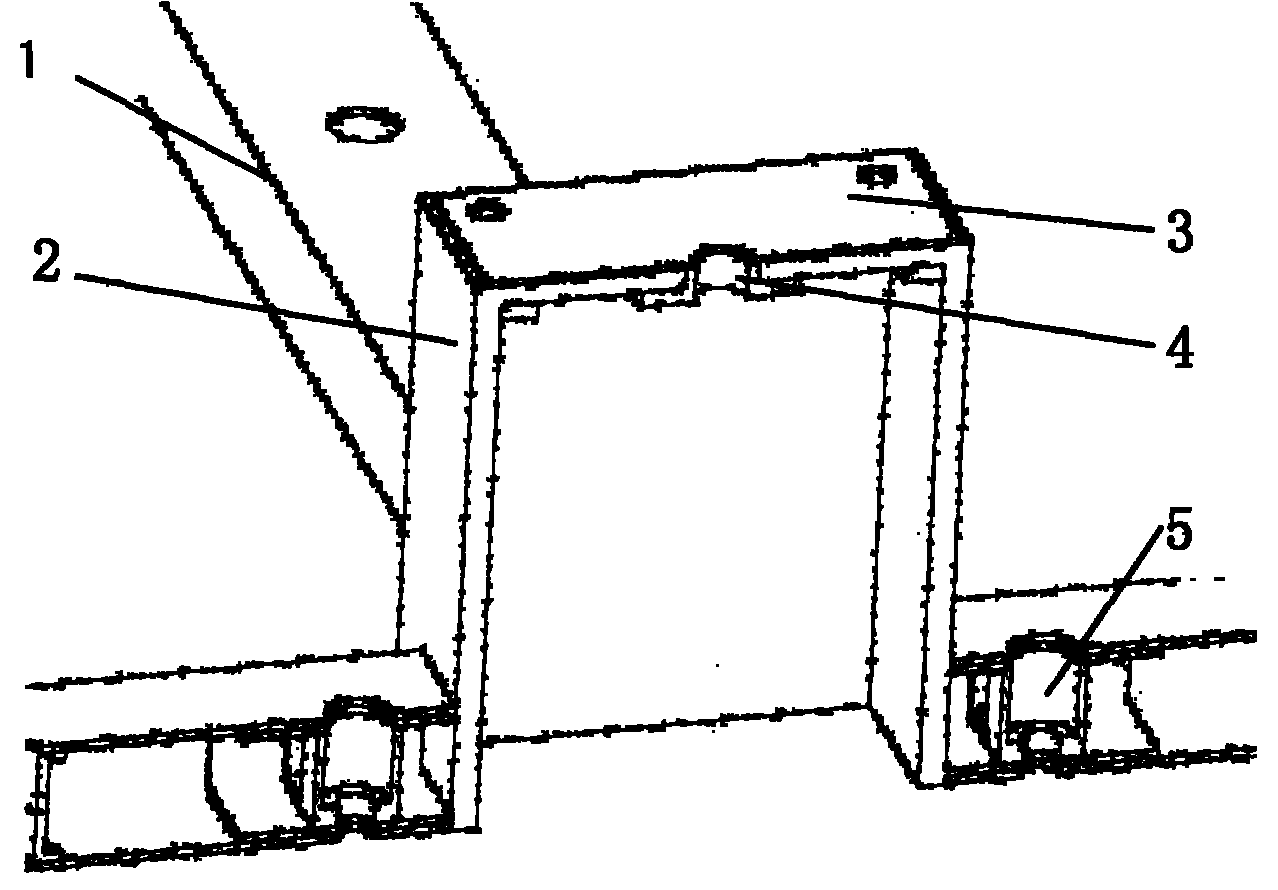

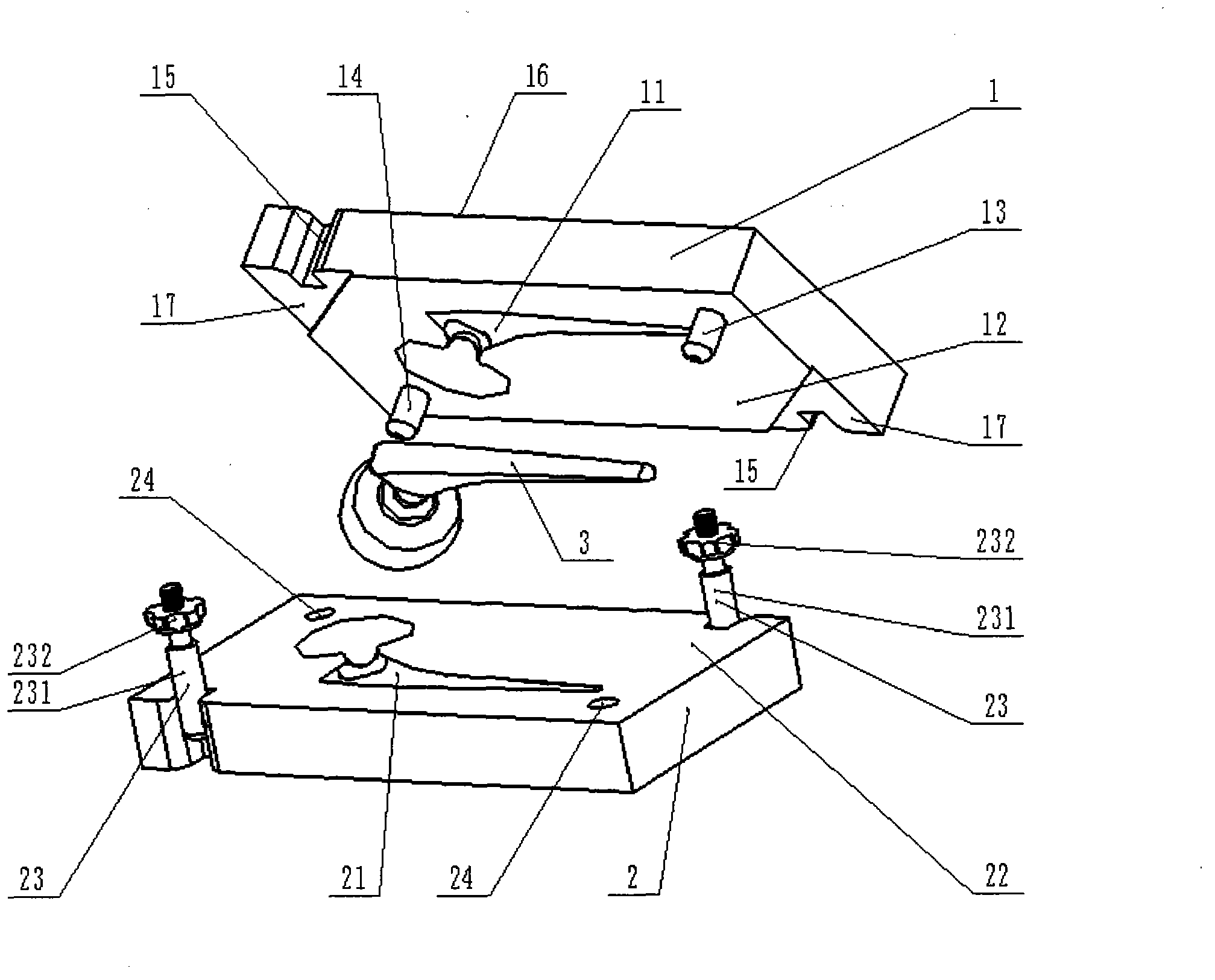

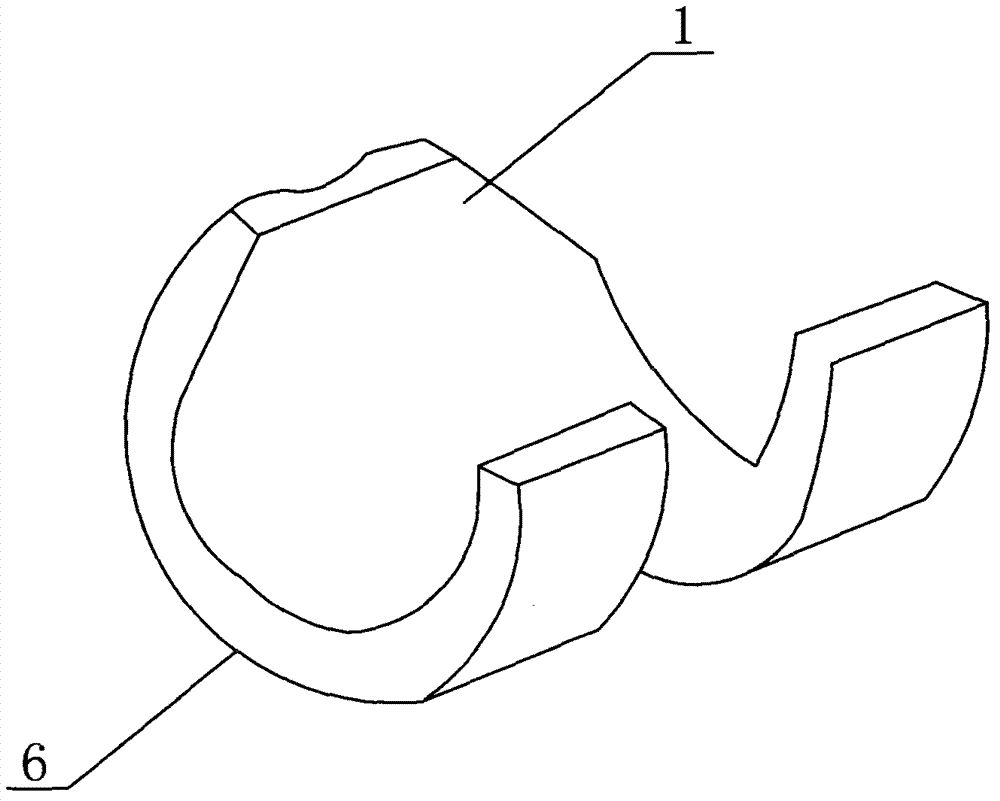

Hip joint spacer mold

The invention discloses a hip joint spacer mold comprising an upper mold component and a lower mold component, wherein the upper mold component and the lower mold component are fastened to form a sealed cavity in a form of a semi-hip prosthesis, and the cavity is used for forming a hip joint cement spacer; the lower mold component comprises a base and a fastening system, wherein the fastening system can rotate along an axle department, thus facilitating release of fastening; the upper mold component comprises a mold cavity, a location pin and a groove; through the location pin, the upper mold and the lower mold are rightly combined, and the groove is convenient for opening of the mold. The hip joint spacer mold has the beneficial effects that the upper mold component and the lower mold component can be conveniently combined due to the location pin, so that combination precision is high and surface quality of the spacer is not affected by misplacement of the mold. The hip joint spacer mold, because of the fastening device, does not require a doctor to press the upper and lower molds through hands, and the spacer mold can continuously provide a squeezing capacity and guarantee manufacturing quality of the spacer; the fastening device can rotate along the axle and can easily release fastening, and the design of the groove in the upper mold facilitate the doctor to open the mold and take out the spacer, thus saving operation time.

Owner:BEIJING AKEC MEDICAL

Joint Materials and Configurations

A method and apparatus for forming a sealed joint between first and second construction surfaces comprises a joint spacer having a first state and a second state. In the first state, the joint spacer has a unitary structure which includes a first component and a second component, wherein in the first state the second component is engaged to the first component. In the second state the second component is disengaged from the first component. The joint spacer also has an adhesive disposed on at least a portion of only the first component, the adhesive configured to adhere to the first construction surface.

Owner:TROUT JOHN T

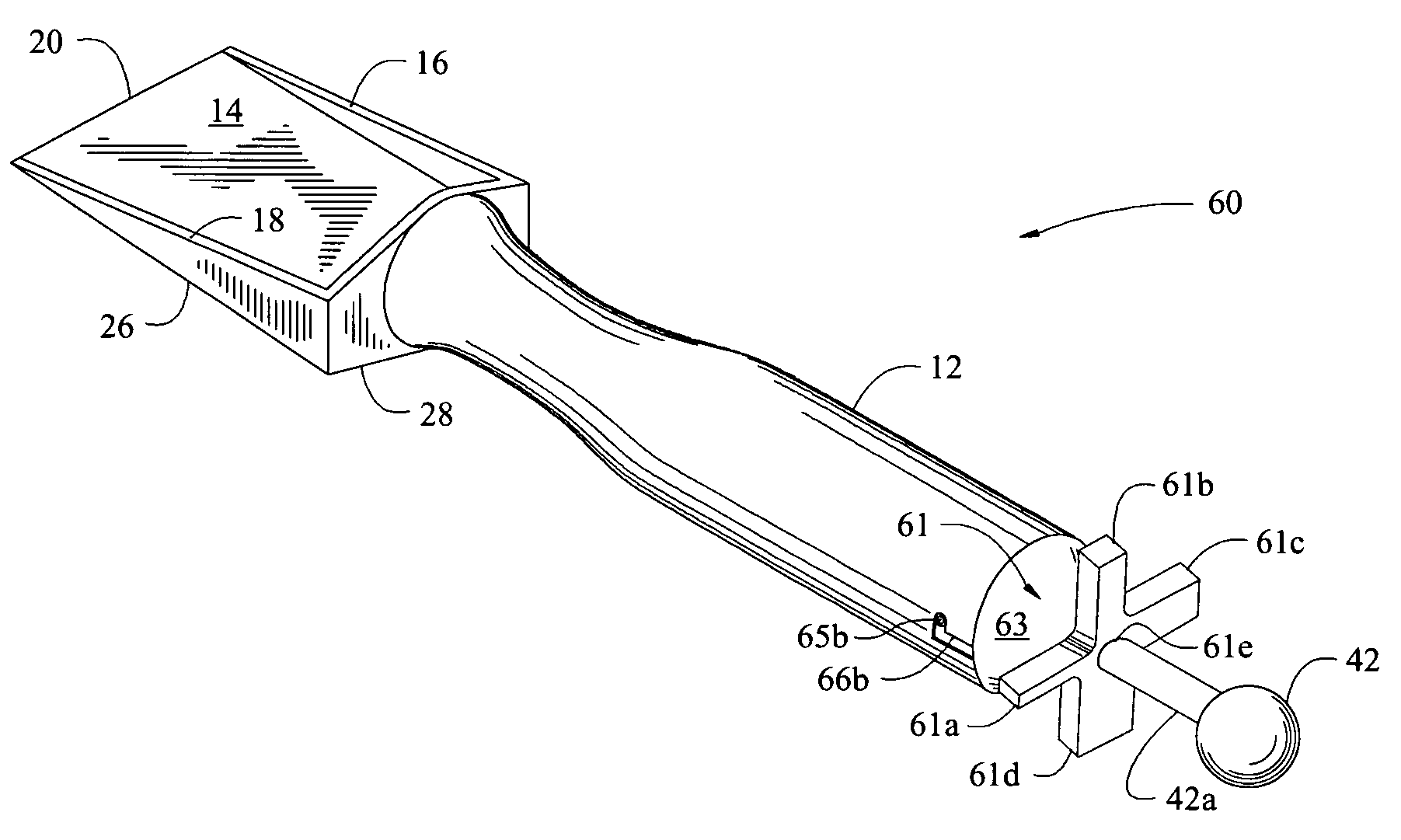

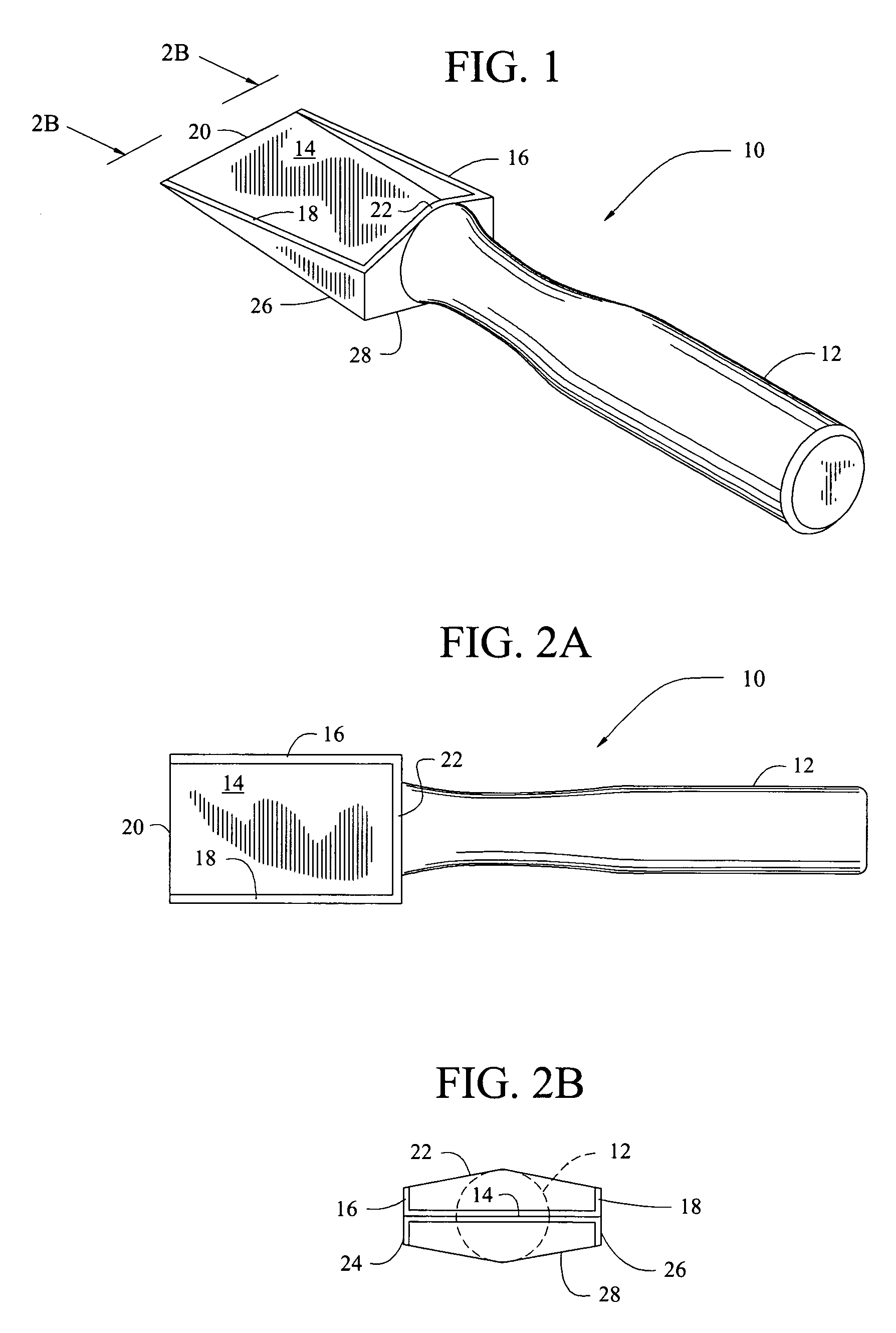

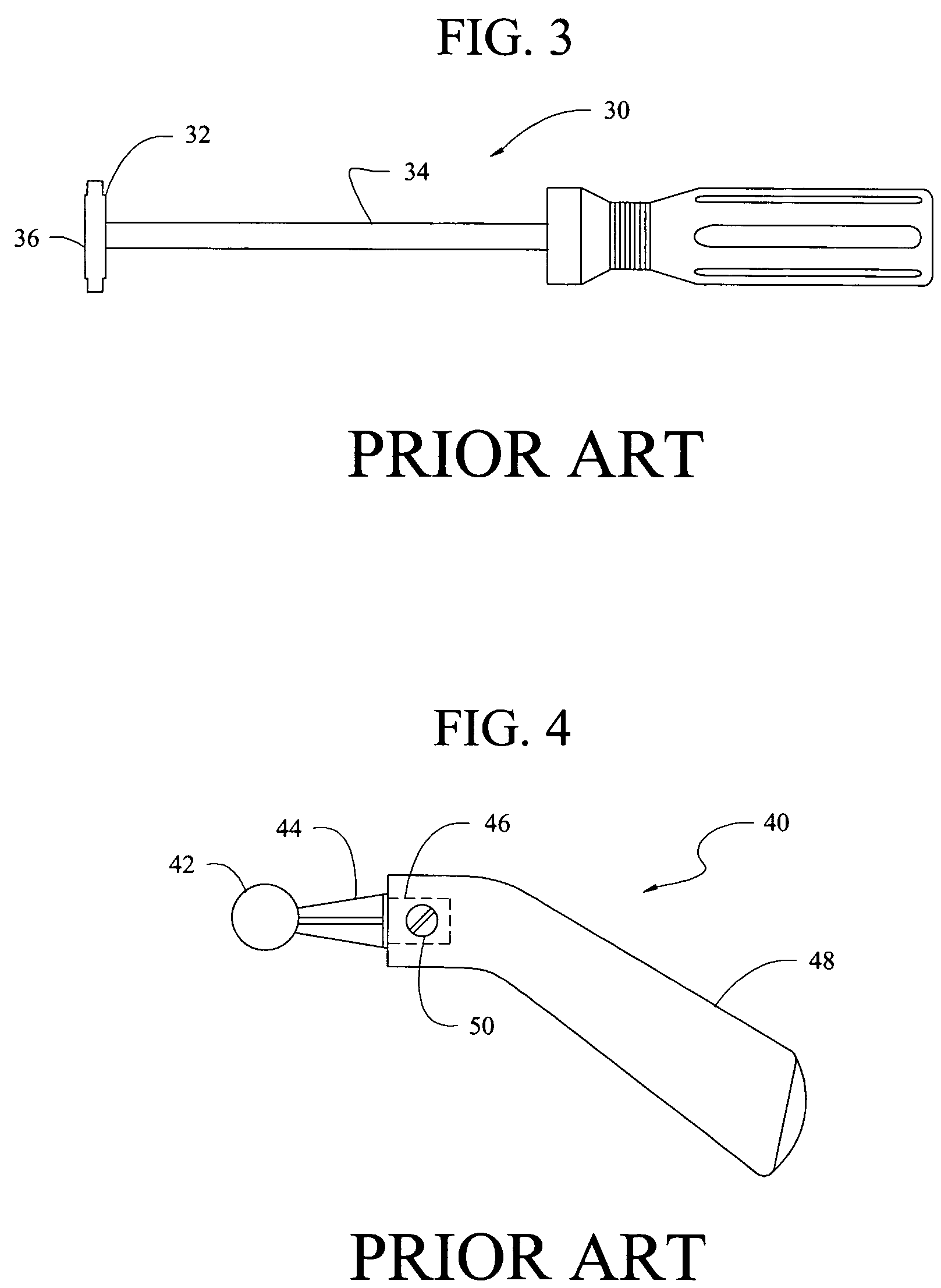

Excess grout and cement remover, packer, profiler and spacer

InactiveUS7793378B1Avoid small quantitiesEasy retrievalLiquid surface applicatorsKitchenware cleanersJoint spacerKnife blades

A combination tool having utility in tile installation procedures includes a wide blade adapted to remove excess grout and caulk in relatively large quantities, a four-armed cement remover and grout joint spacer, a spherical grout packer and a “V”-shaped grout and caulk profiler adapted to be secured to a hollow handle in varying combinations. In a first embodiment, the wide blade is attached to a first end of the handle and the four-armed cement remover-grout joint spacer and the spherical packer are releasably secured to a second end of the handle. A second embodiment includes the blade at the first end and the “V”-shaped profiler at the second end in lieu of the cement remover and packer. The hollow handle provides a storage compartment for additional packers. The tool may be made of material that floats in water. The handle may also have a non-hollow web construction.

Owner:KIRBY MARK E

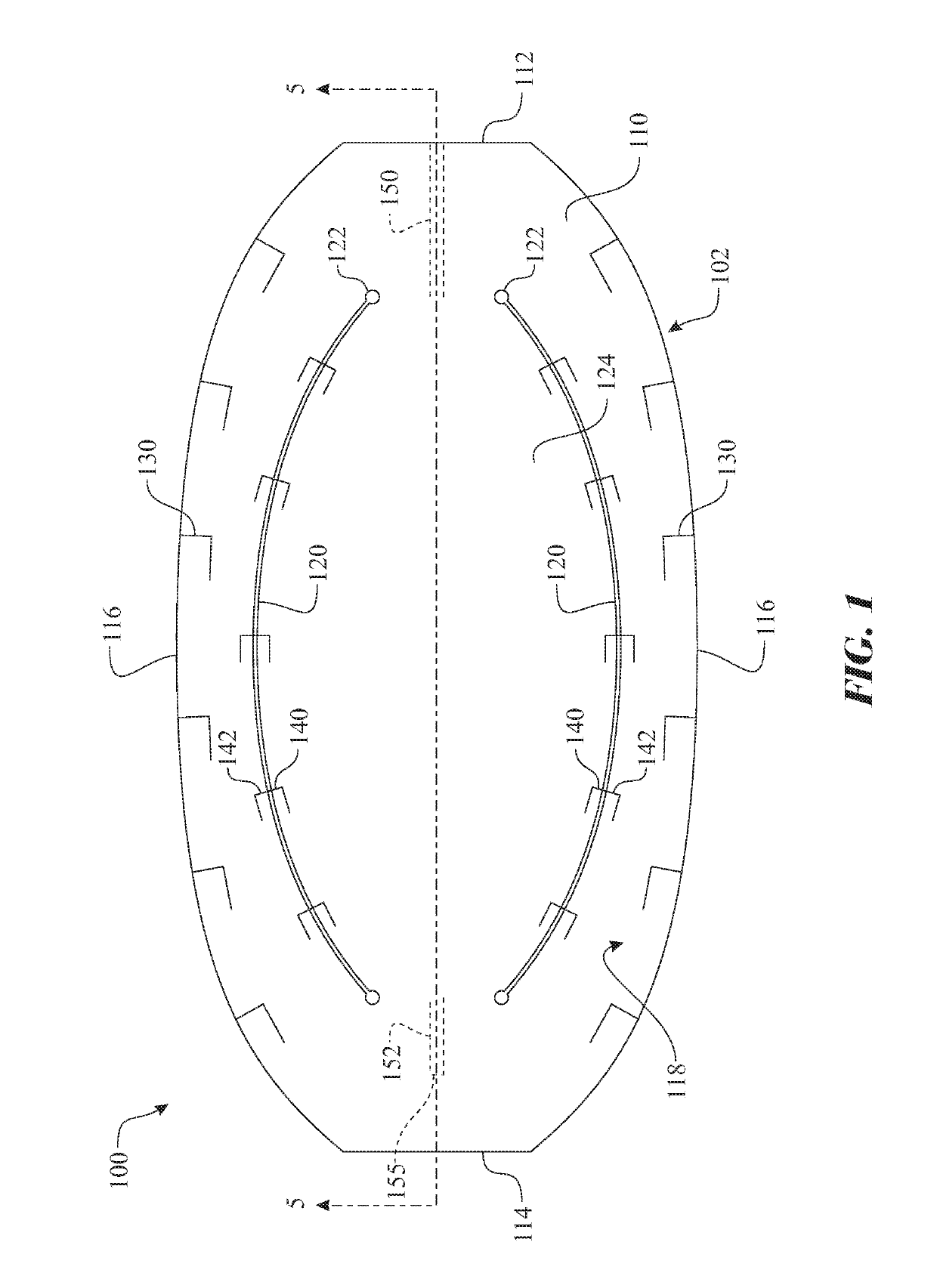

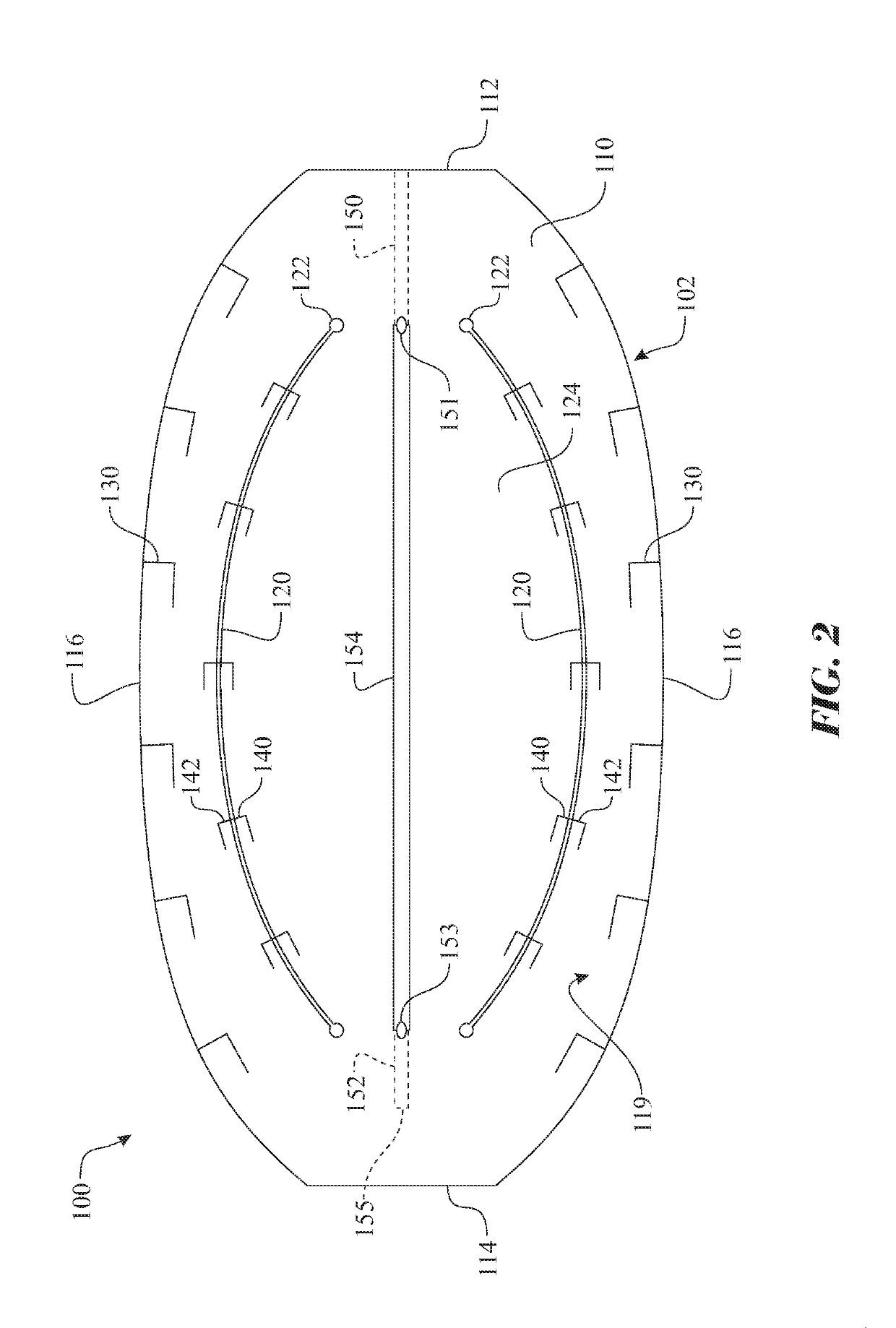

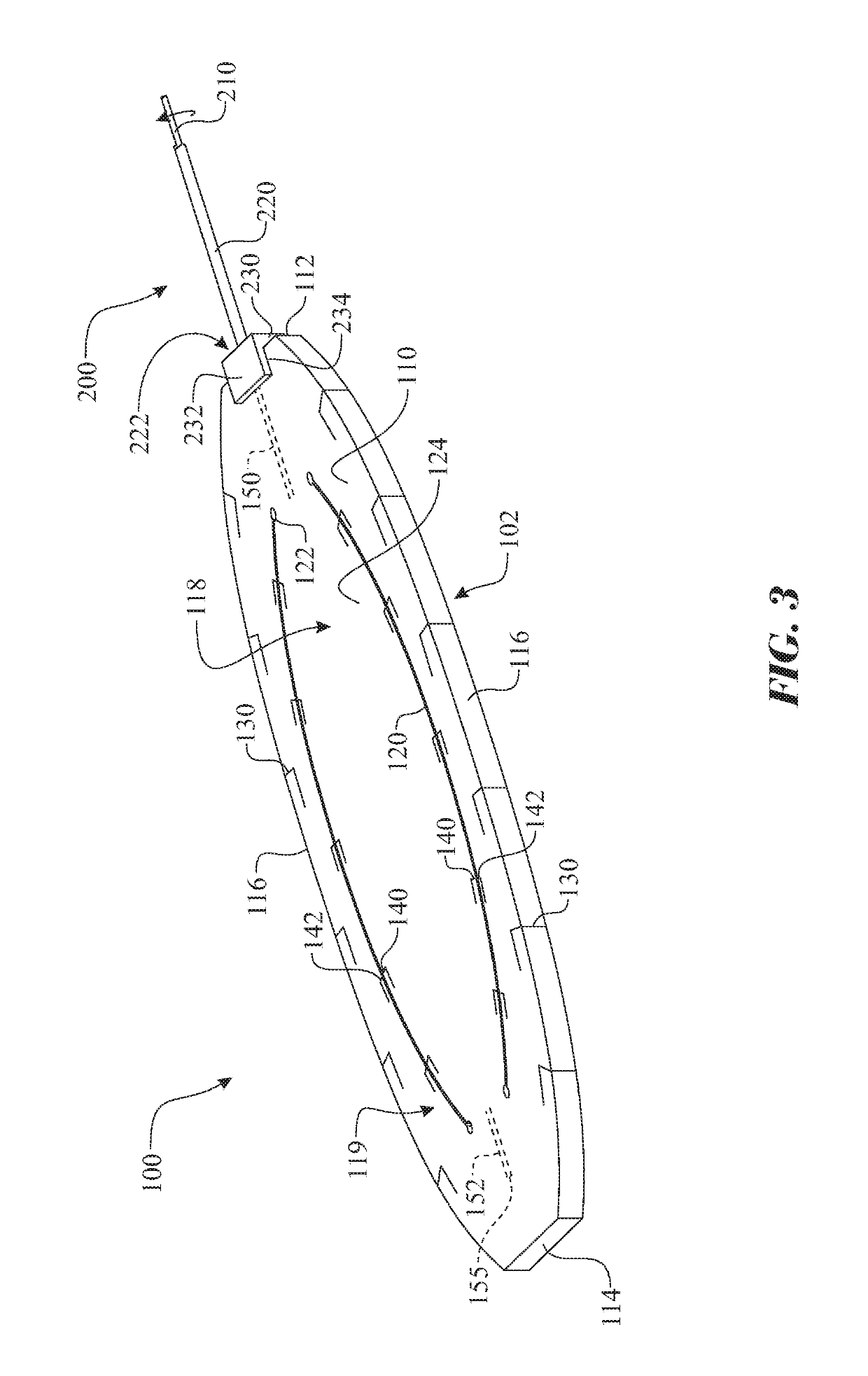

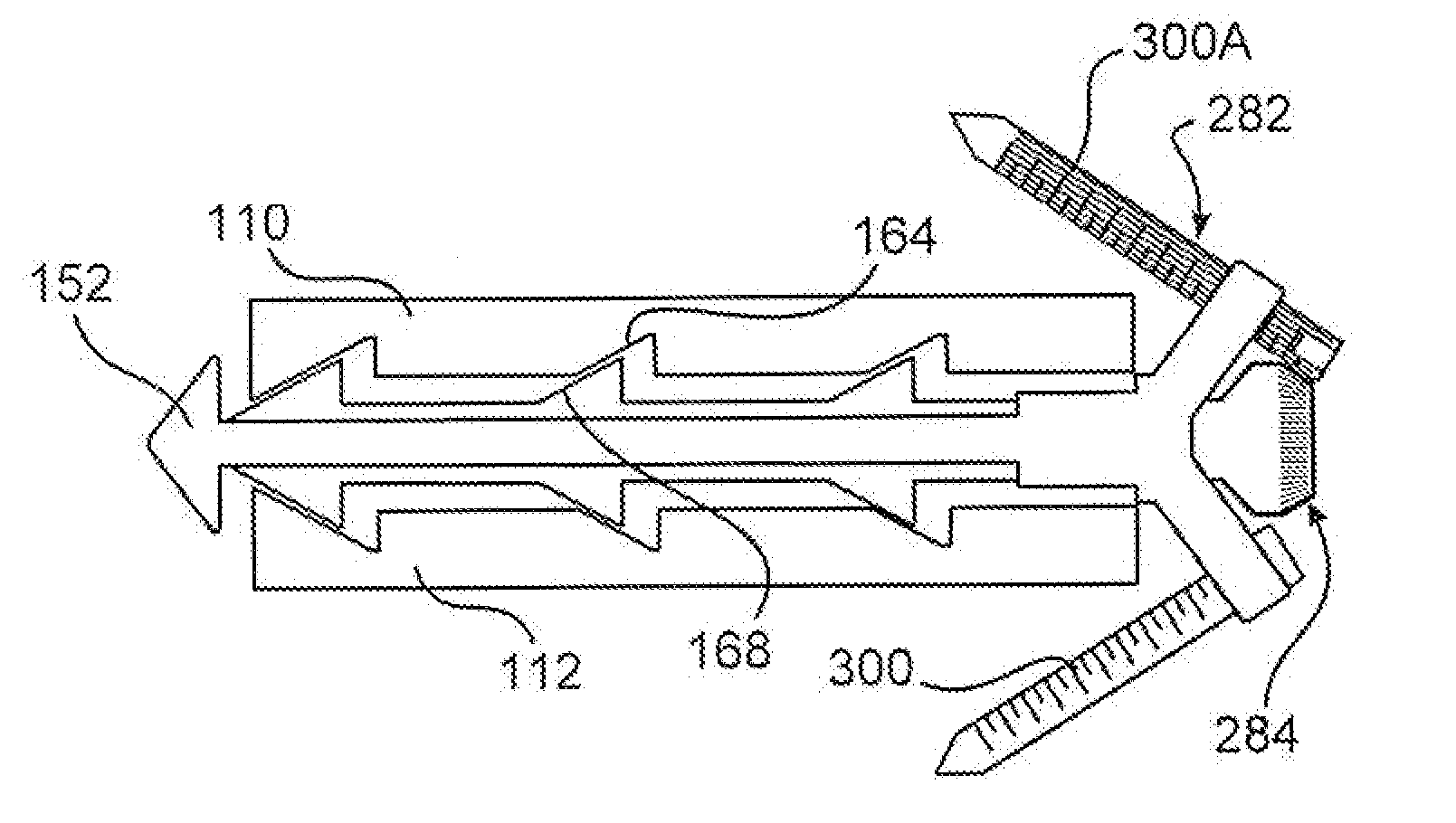

Surgically implantable joint spacer

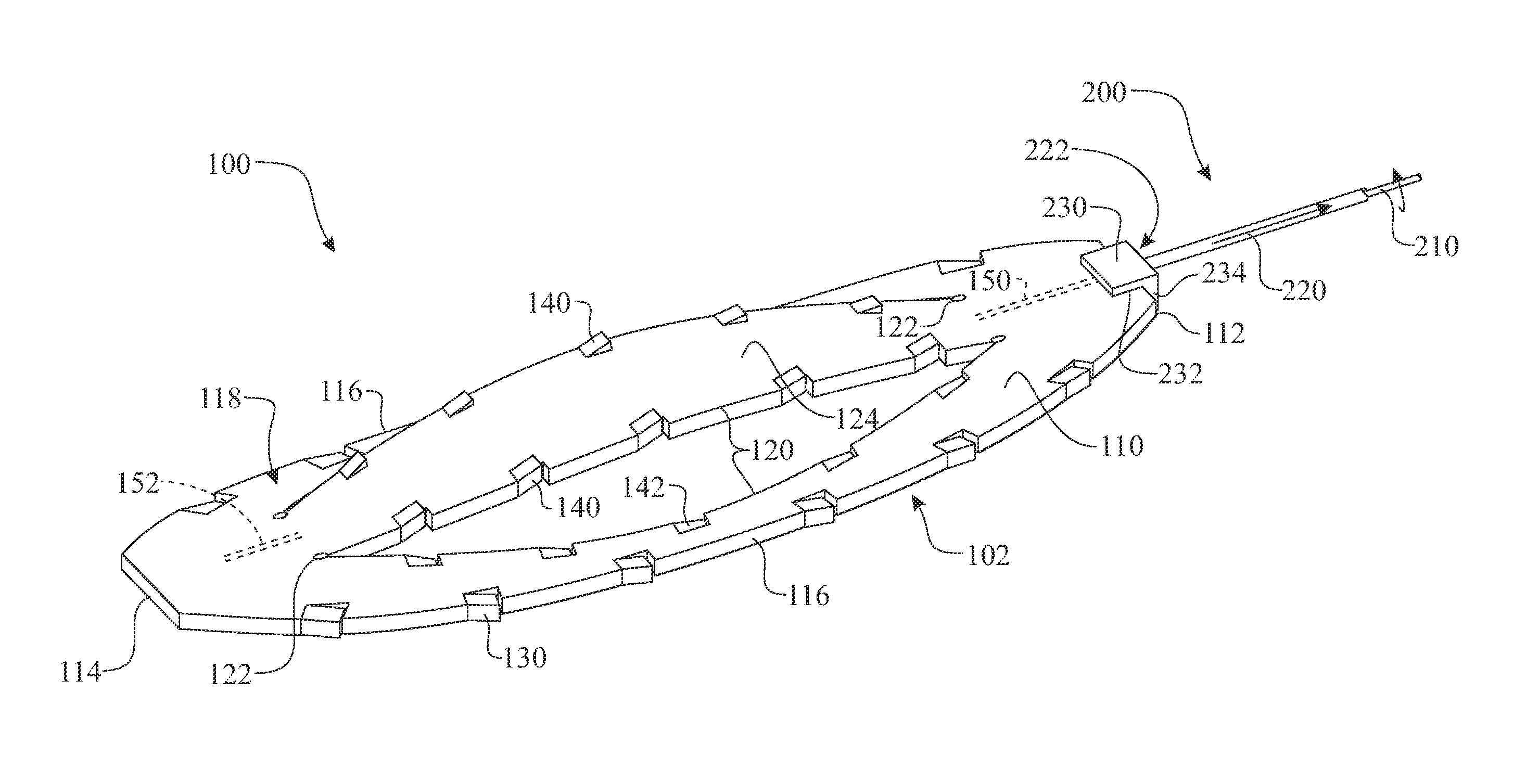

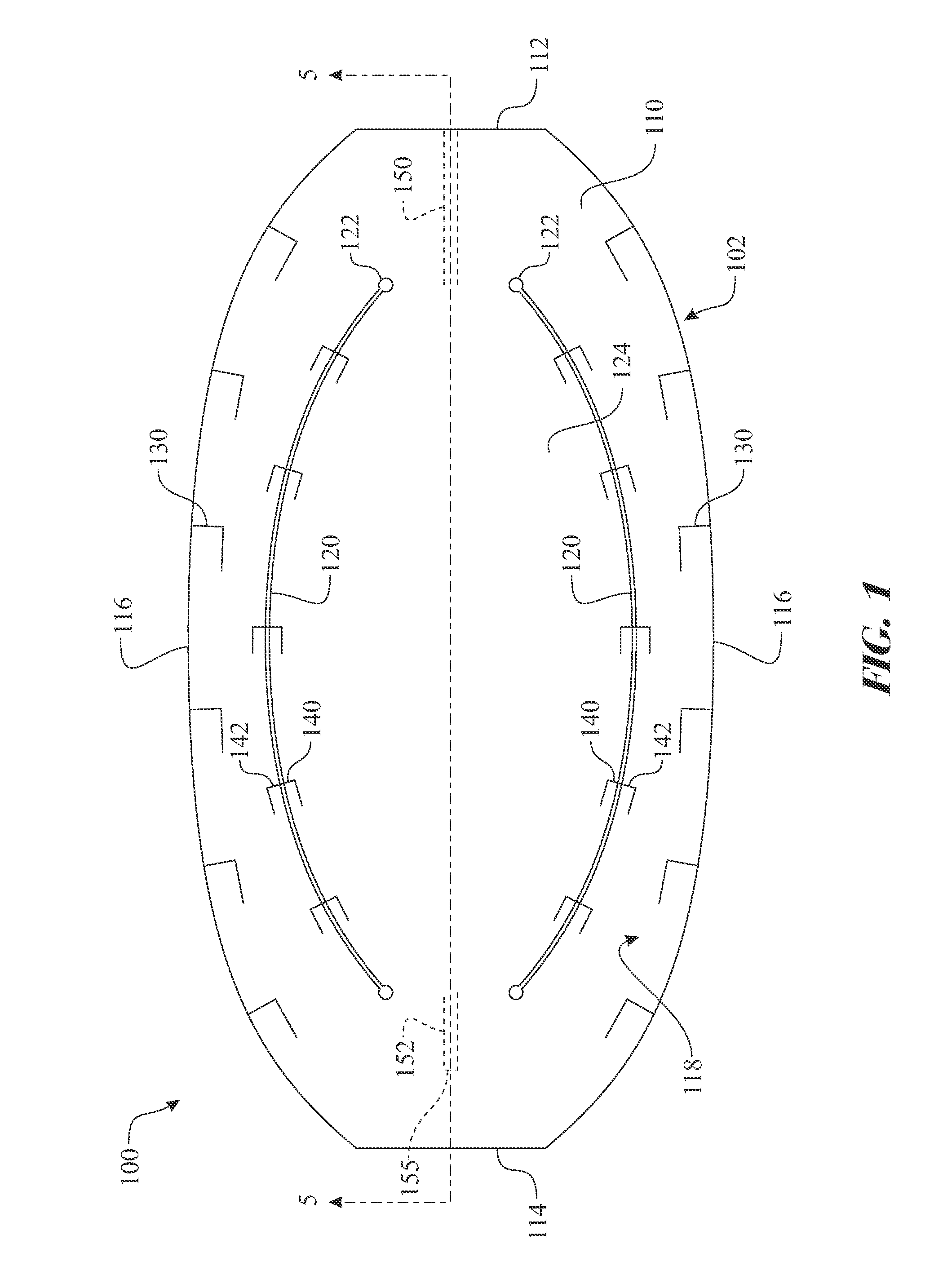

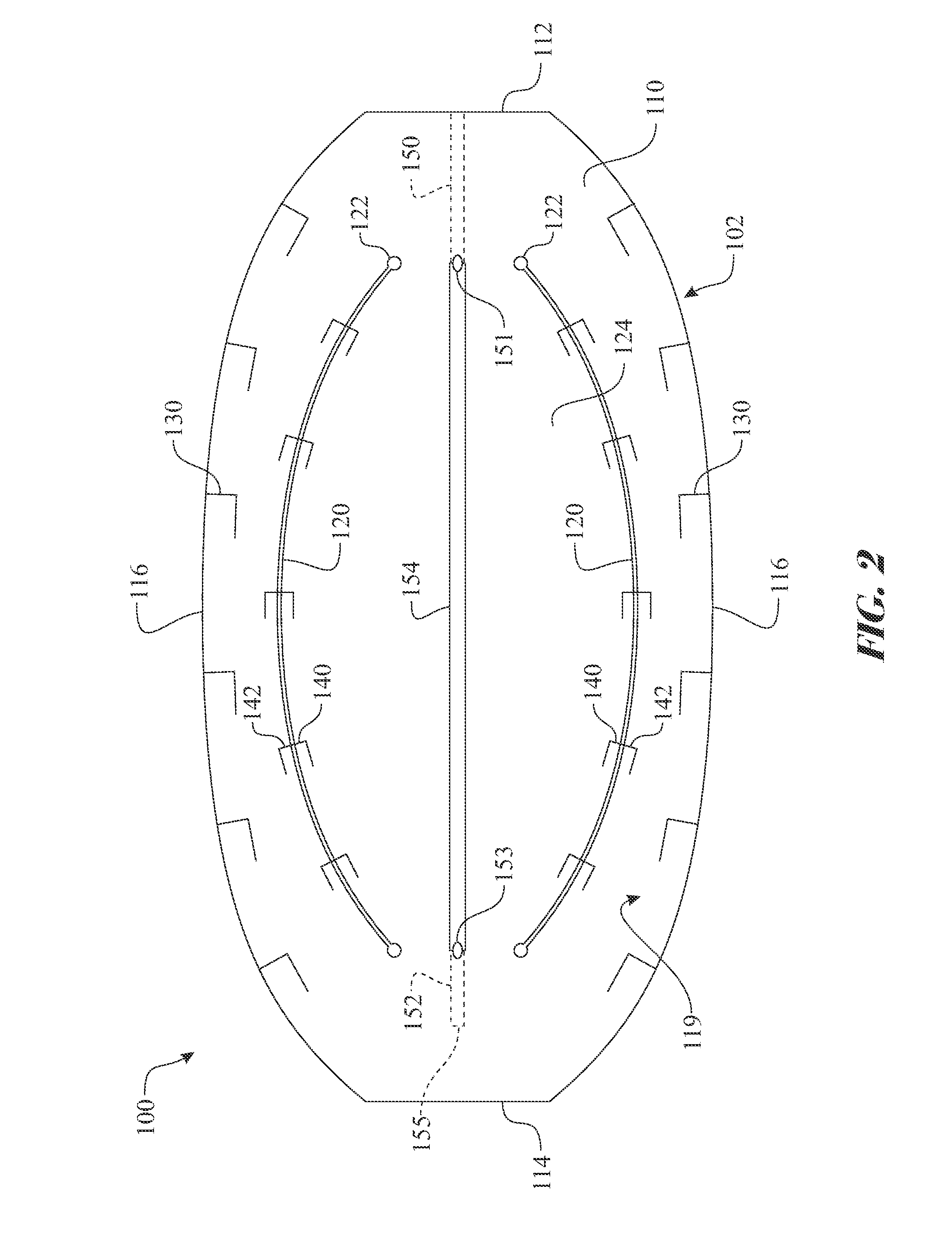

A spacer formed of an intermetallic compound, such as nitinol. The spacer includes at least two segments shaped in opposing arches. The unique properties of the intermetallic compound enable the material to be deformed into a planar, insertable shape when the material is cooled below a transition temperature and returns to the undeformed shape when the material returns to an ambient, operational temperature. An expansion mechanism assembly engages with the spacer to apply an expansion force, extending the spacer longitudinally drawing the spacer into the planar configuration. The expansion mechanism assembly can be used to guide the spacer into the desired position within the patient. The spacer control mechanism assembly is subsequently removed, relieving the expansion force, returning the spacer to the natural un-deformed, arched shape as it returns to body temperature. Retention features can be integrated in the spacer to aid in retaining the spacer in location.

Owner:RODRIGUEZ CARLOS ANDRES +1

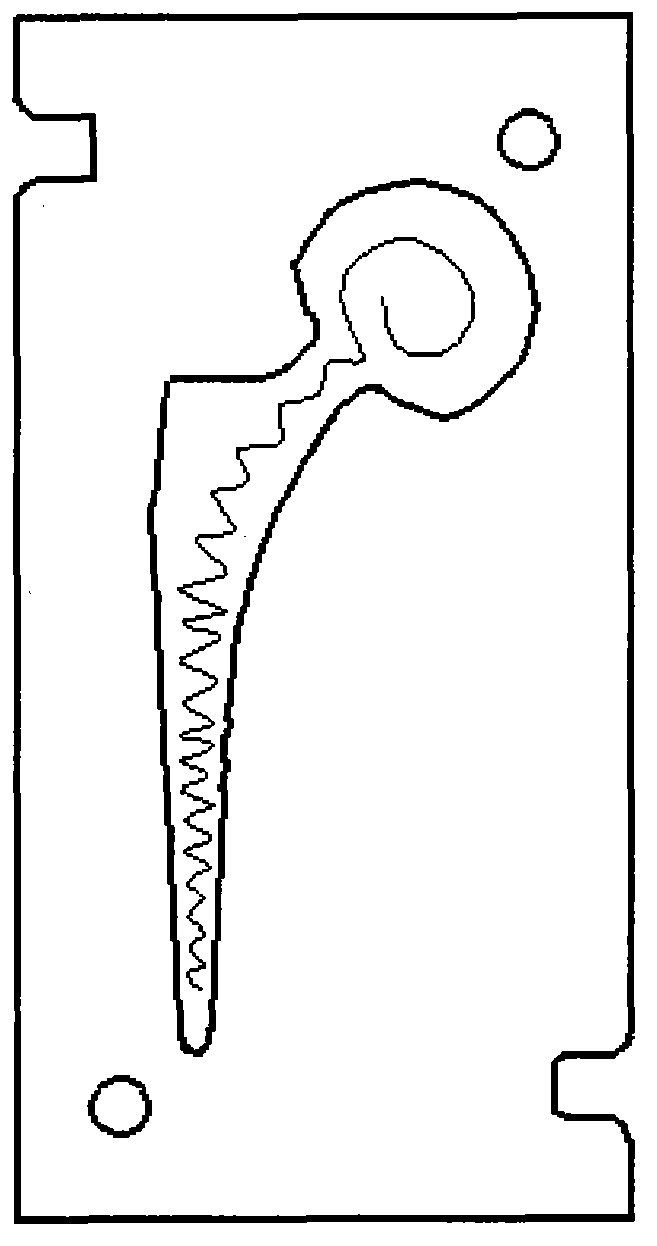

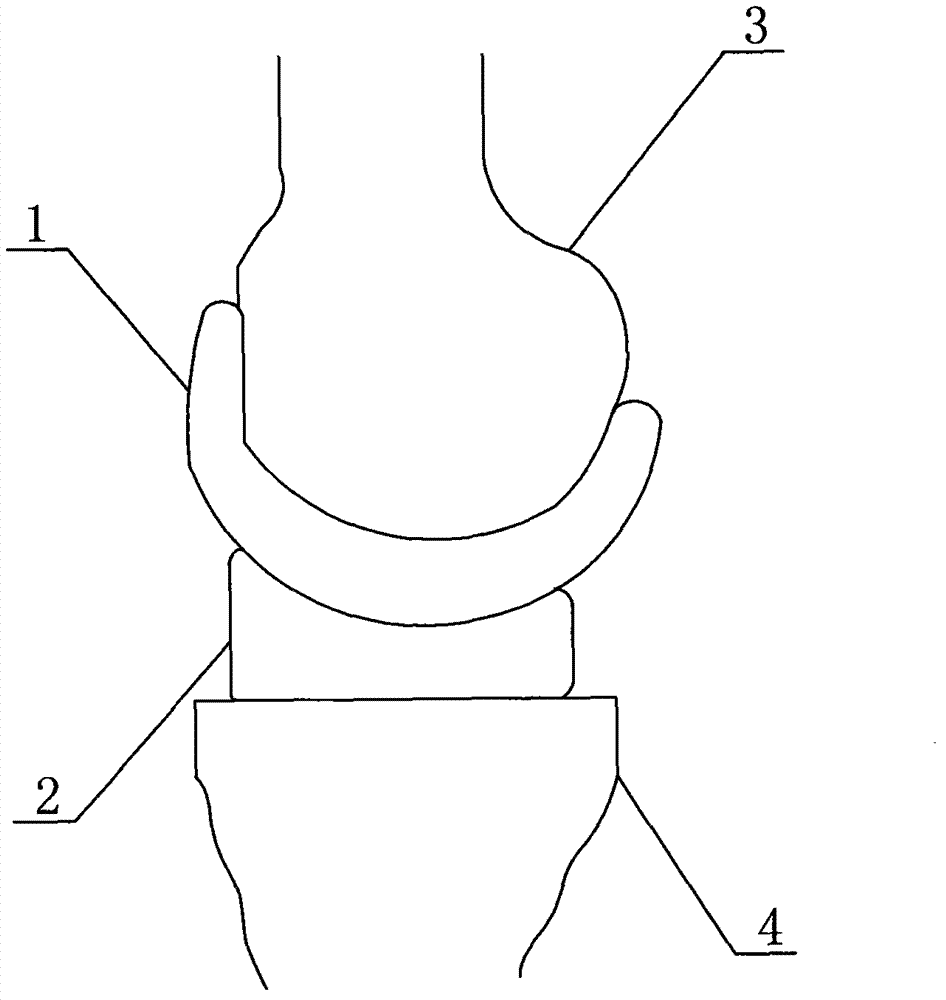

Movable joint spacer for infection after total knee replacement

InactiveCN102860887ABiomechanicalProtect knee functionJoint implantsKnee jointsPhysical medicine and rehabilitationJoint spacer

The invention discloses a movable joint spacer for infection after total knee replacement. The movable joint spacer for the infection after the total knee replacement is characterized by comprising a thighbone element and a shin bone substrate, wherein the thighbone element and the shin bone substrate are mutually connected in the manner of joint. The thighbone element and the shin bone substrate are respectively made of bone cement. A good amount of antibiotic is added when the thighbone element and the shin bone substrate are manufactured. The invention provides the movable joint spacer for the infection after the total knee replacement, which can be directly implanted into a knee joint by a surgeon because of reasons of septicopyemia or disinfection failure and can enable the knee joint to be movable and be high in strength.

Owner:青岛城阳古镇正骨医院

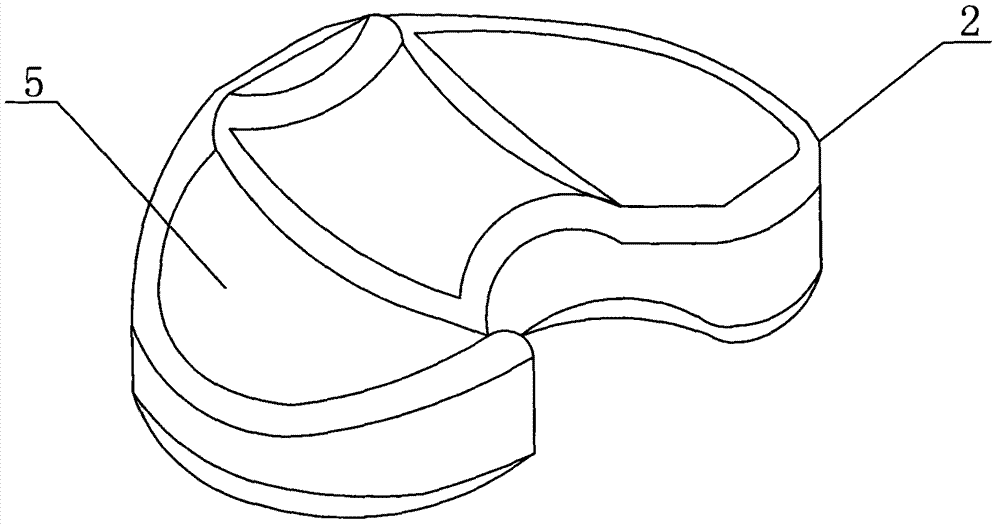

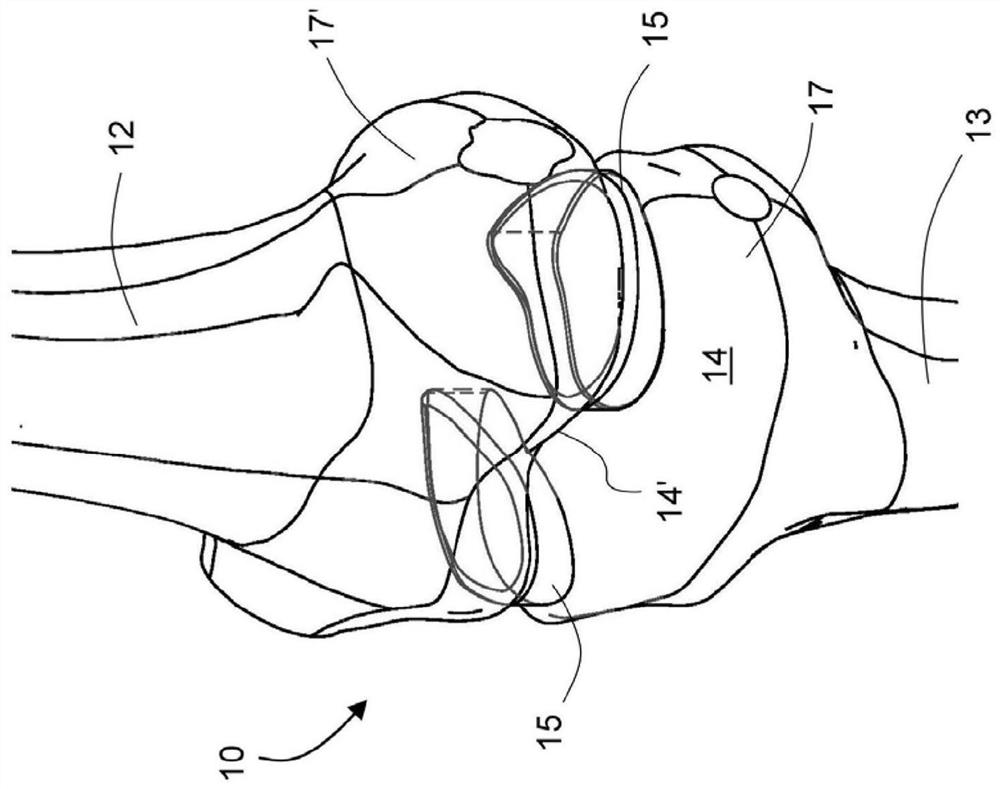

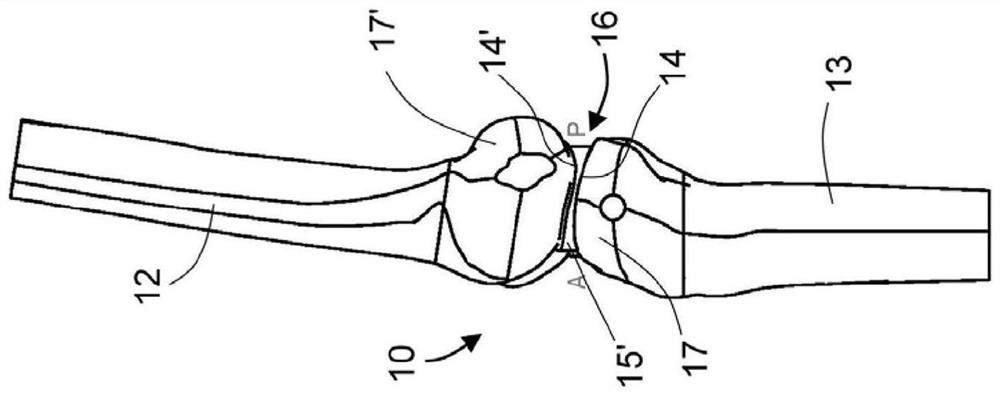

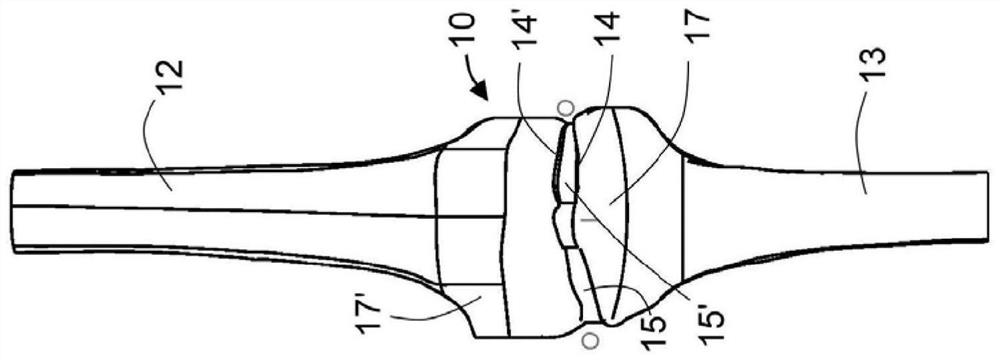

Two-part articulating joint spacer and method for producing said joint spacer

The invention relates to an articulating joint spacer for temporary replacement of a joint, whereby the joint spacer comprises two spacer parts which each comprise one sliding surface on which the spacer parts, in the patient-inserted state, touch against each other in mobile manner and roll off on each other, and the remaining spacer parts are made, at least in part, of a second bone cement that contains at least one water-soluble antibiotic. The invention also relates to a method for producing a two-part articulating joint spacer, in which a sliding surface is formed in both spacer parts from a low-abrasion first bone cement and at least the surfaces of the remaining spacer parts, at least 50% thereof, are formed with a second bone cement that contains at least one water-soluble antibiotic.

Owner:HERAEUS MEDICAL

Expandable vertebral implant

ActiveUS20170035577A1Increase heightReduce rotationSpinal implantsBone platesJoint spacerEngineering

A joint spacer therapeutically maintains separation of bones of a joint. A carriage is slideably retained within the frame and has at least one ramped surface. An actuator screw is threadably engaged with the frame, and rotatably connected to the carriage, to cause the carriage to slideably move within the frame when the actuator screw is rotated. First and second endplates engage the bones of the joint, and each has at least one ramped surface that is mateable with the ramped surface of the carriage, whereby when the carriage is slideably moved by rotation of the actuator screw, the endplates ramped surface slides against the carriage ramped surface to cause the endplates to move along an axis transverse to the longitudinal axis of the frame, to increase the height of the spacer. Piercing elements are connected to the carriage to pierce bone of the joint when the carriage is moved.

Owner:GLOBUS MEDICAL INC

Surgically implantable joint spacer

ActiveUS9320611B2Simple processChange shapeJoint implantsSpinal implantsJoint spacerSacroiliac joint

A spacer formed of an intermetallic compound, such as nitinol. The spacer includes two segments shaped in opposing arches. The unique properties of the intermetallic compound enable the material to be deformed into a planar, insertable shape when the material is cooled below a transition temperature and returns to the undeformed shape when the material returns to an ambient, operational temperature. An expansion mechanism assembly can engage with the spacer to apply an expansion force. The expansion force extends the spacer longitudinally drawing the spacer into the planar configuration. The expansion mechanism assembly can be used to guide the spacer into the desired position within the patient. The spacer control mechanism assembly is subsequently removed, relieving the expansion force. The spacer returns to the natural undeformed shape as it returns to body temperature. Retention features can be integrated in the spacer to aid in retaining the spacer in location.

Owner:RODRIGUEZ CARLOS ANDRES +1

Method and apparatus for distracting a joint, including the provision and use of a novel fluid joint spacer

A fluid joint spacer comprising a body having means for receiving a pressurized fluid from an external source and applying that pressurized fluid against a joint element so as to create a flowing fluid bearing within the joint.

Owner:STRYKER CORP

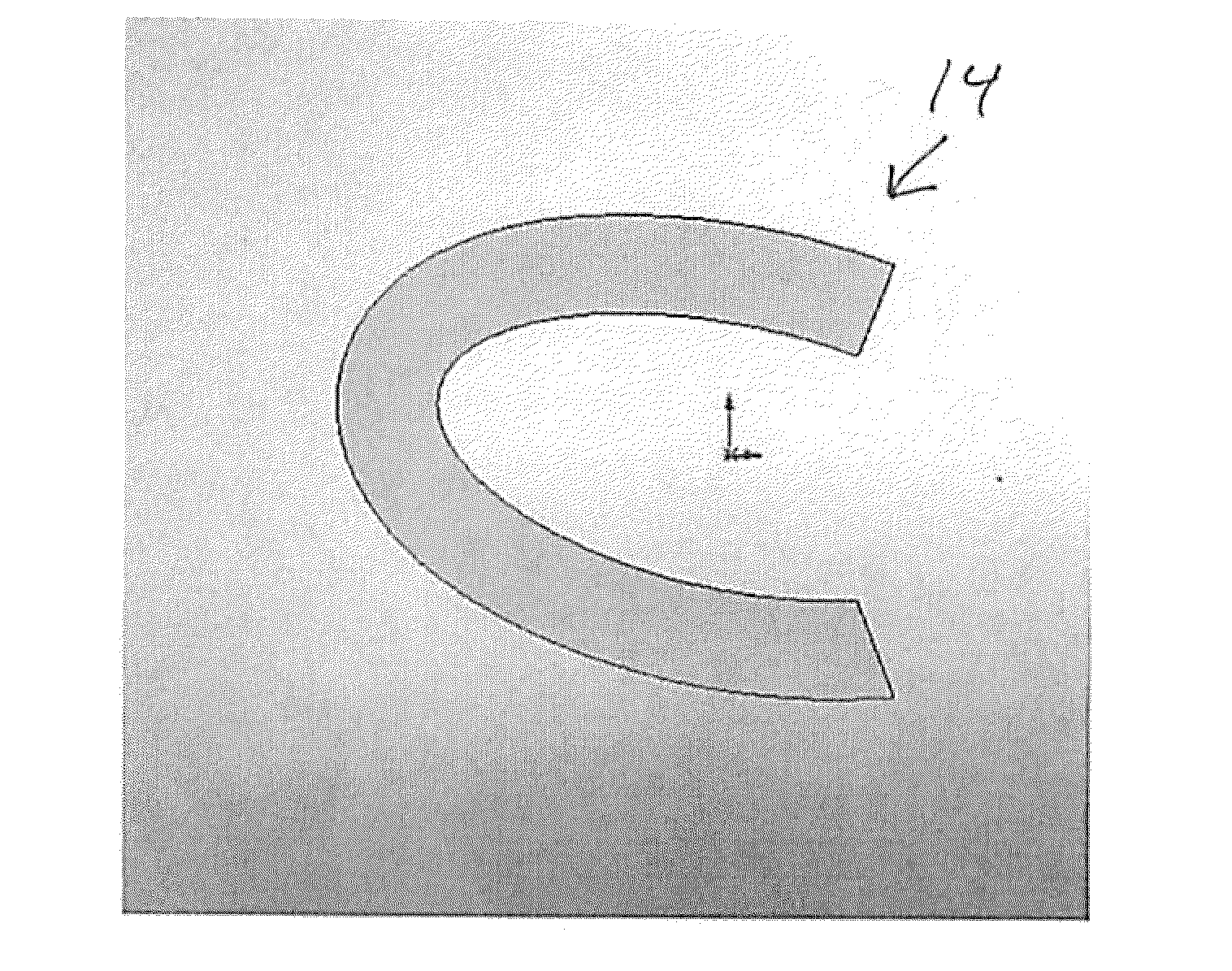

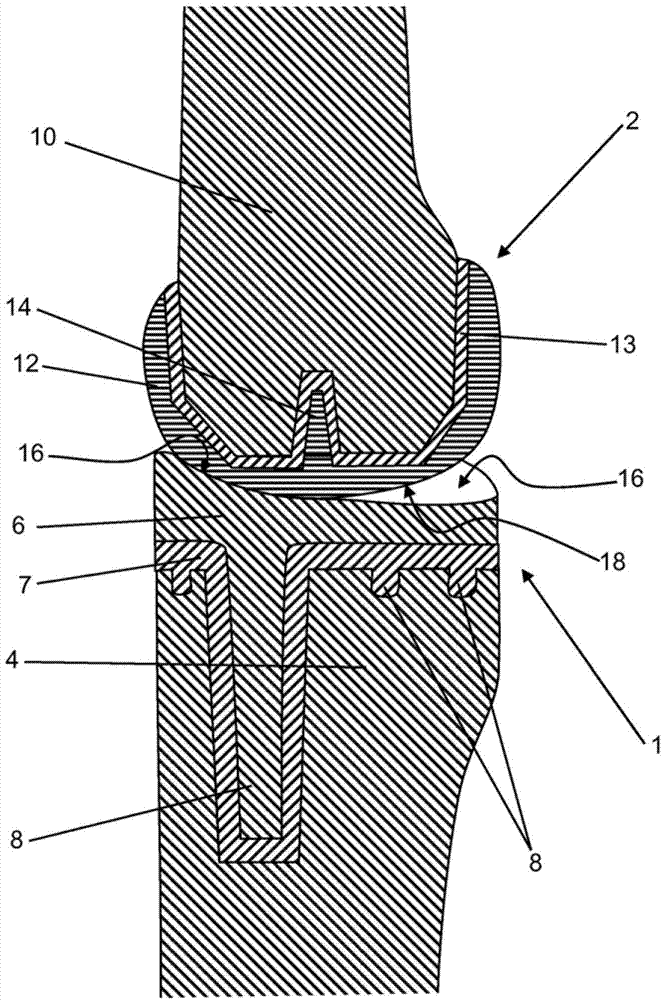

Femoral hip joint spacer with irrigation device

The invention relates to a femoral hip joint spacer having a prosthesis body with a ball head (1), a neck (3), a stem (5) and an anchoring sleeve (7) which encloses the stem (5) on a proximal side ofthe stem (5) with a circumferential fastening area (6), an irrigation liquid inlet opening and an irrigation liquid outlet opening in a surface of the prothesis body, at least one irrigation liquid discharge opening (14) on a distal side of the stem (5) and at least one irrigation liquid intake opening on the ball head (1) or on the neck (3), wherein the at least one irrigation liquid discharge opening (14) inside the prosthesis body is connected in a liquid-permeable manner to the irrigation liquid inlet opening and is not connected in a liquid-permeable manner to the irrigation liquid outletopening and the at least one irrigation liquid intake opening is connected inside the prothesis body in a liquid-permeable manner to the irrigation liquid outlet opening and is not connected in a liquid-permeable manner to the irrigation liquid inlet opening, and wherein a cavity (28) which is open on two sides is formed inside the anchoring sleeve (7), which cavity connects a proximal side of the anchoring sleeve (7) to a distal side of the anchoring sleeve (7) in a liquid-permeable manner.

Owner:HERAEUS MEDICAL

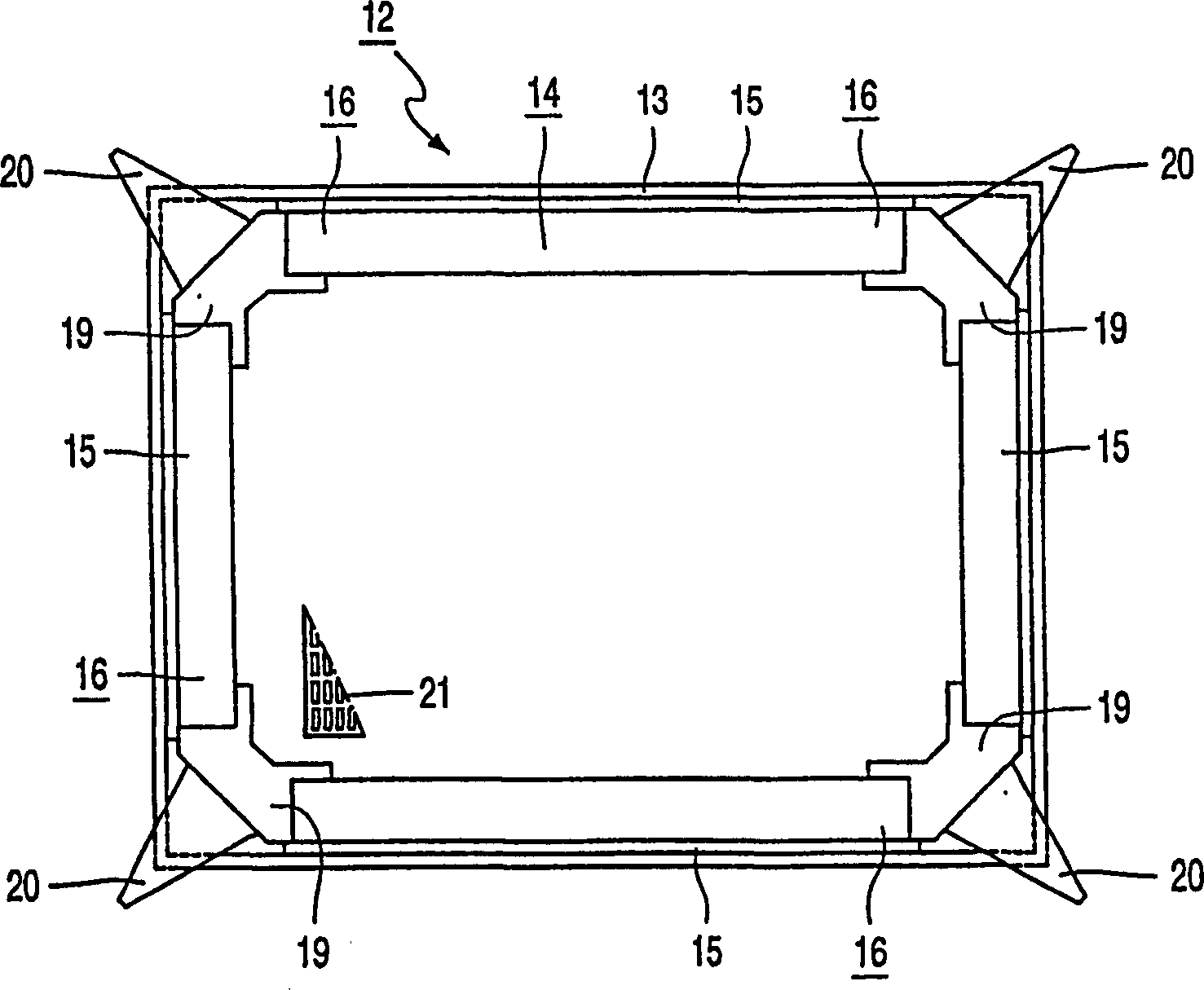

Colour display tube provided with colour selection electrode

InactiveCN1383574AGood dimensional stabilityAvoid stressCathode ray tubes/electron beam tubesTreatment resultsJoint spacer

In the manufacturing process of the color picture tube (1), the display window (3) and the cone portion (4) are assembled together through heat treatment in a furnace. Since the color picture tube (1) has an invar shadow mask, the partition (15) is also made of invar, and the corner part (16) is made of iron in order to have sufficient hardness, so the heat treatment causes deformation of the color selection electrode (12). Invar and iron have different coefficients of thermal expansion, causing the solder joints (22) connecting the partition plate (15) and the corner piece (16) to break. In order to overcome this shortcoming, the present invention proposes to provide slots (23) or indentations (24) on the separator (15), so that no stress is generated between the solder joints (22) when the color selection electrode (12) is heated.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Joint spacer

PendingCN111991124AImprove tear resistanceJoint implantsSpinal implantsPhysical medicine and rehabilitationJoint spacer

The invention concerns a joint spacer, in particular a knee spacer and a hip spacer. In order to produce a long-lasting joint spacer which is sufficiently cushioned and abrasion-resistant and which can also support locally very high loads, the invention proposes a joint spacer having a Shore-A hardness of between 20 and 77 and tensile stress values at unit strain of between 20 % and 60 %, preferably 50 %, of greater than 3.8 N / mm2, preferably of greater than 4.6 N / mm2 and particularly preferably of greater than 6 N / mm2, and / or compressive stress values at linear compression of between 20 % and60 %, preferably 50 %, of greater than 7.8 N / mm2, preferably of greater than 9 N / mm2, and particularly preferably of greater than 10.5 N / mm2, and / or a Shore-A hardness of up to 85 and tensile stressvalues at unit strain of between 20 % and 60 %, preferably 50 %, of greater than 6 N / mm2, preferably of greater than 7 N / mm2, and particularly preferably of greater than 8 N / mm2, and / or compressive stress values at linear compression of between 20 % and 60 %, preferably 50 %, of greater than 10.5 N / mm2, preferably of greater than 12 N / mm2, and particularly preferably of greater than 14 N / mm2.

Owner:REVOMOTION

Surgically implantable joint spacer

ActiveUS11129728B1Reduce weightClearance can be providedJoint implantsSpinal implantsJoint spacerReoperative surgery

Owner:MOLINA GUILLERMO

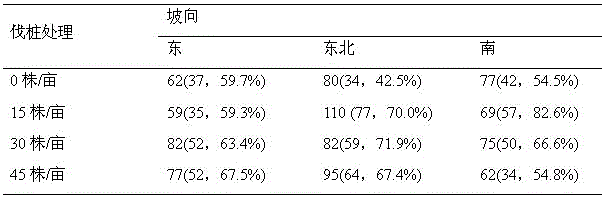

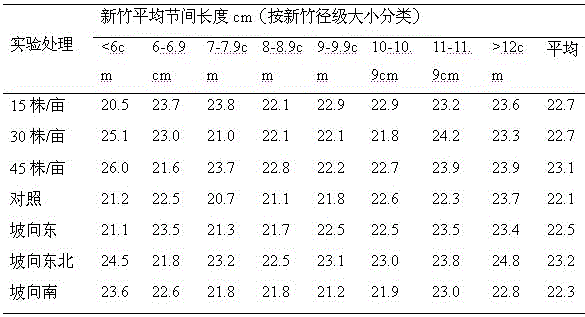

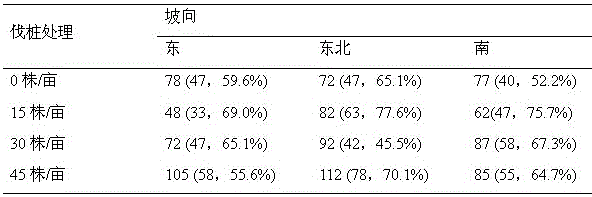

Water-saving phyllostachys edulis irrigation method

ActiveCN106106051ASustainable water supplyProductivity impactWatering devicesCultivating equipmentsWater storageWater saving

The invention discloses a water-saving phyllostachys edulis irrigation method. The water-saving phyllostachys edulis irrigation method comprises the following steps that 1, phyllostachys edulis forest land is selected, and horizontal ditches are dug; 2, PVC pipes with the diameter of 6-8 cm are sawed open from the middles and are respectively divided into two parts to establish horizontal water collecting ditches; 3, fixing columns are evenly distributed and arranged on two sides of each horizontal water collecting ditch in the length direction; 4, water collecting containers are arranged at the lower ends of the horizontal water collecting ditches and are covered with plastic films; 5, old phyllostachys edulis different in ground diameter are selected and are felled at the end of February, stump joints spacers are made through, stumps are fully filled with water every 15-30 days according to the weather condition, and water-saving irrigation is conducted on the phyllostachys edulis. The water-saving phyllostachys edulis irrigation method applies a field runoff field rainwater collecting method to establish an efficient and economical anti-drought technology of a water storage system using phyllostachys edulis stumps as cores, and provides sustainable water supply for phyllostachys edulis water-starved for a long time in middle-slope, upper-slope and remote regions so as to reduce the influence on phyllostachys edulis productivity of extreme or continuous drought.

Owner:RES INST OF SUBTROPICAL FORESTRY CHINESE ACAD OF FORESTRY

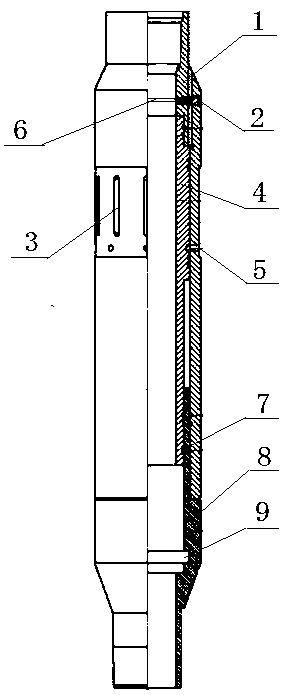

A blasting start sliding sleeve

ActiveCN105089598BEliminate perforatingImprove construction efficiencyFluid removalSystems designJoint spacer

The invention belongs to the technical field of fracturing transformation of oil and gas wells, in particular to a blasting start-up sliding sleeve designed for multi-layer fracturing transformation of oil and gas wells, comprising an upper joint and a lower joint connected by threads, and the pipe wall of the upper joint is evenly spaced along the circumferential direction. There are multiple vertical strip-shaped fracturing ports, a piston is installed inside the upper joint, and the piston blocks the fracturing port; a bursting disc holder is installed on the upper pipe wall of the upper joint, and the bursting disc holder passes through On the pipe wall of the upper joint, the end of the bursting disc holder located inside the upper joint is equipped with a bursting disc. The bursting disc is in the shape of a disc with the same inner diameter as the upper joint, forming a spacer in the upper joint to block the upper joint. The bursting disc is located on the upper part of the piston. This kind of blasting starting sliding sleeve can realize the starting sliding sleeve of the first stage of fracturing during the multi-layer and multi-stage fracturing construction of the casing sliding sleeve, eliminating the perforation operation, improving the construction efficiency and saving construction. Reduce costs and reduce construction difficulties and risks.

Owner:PETROCHINA CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com